Positive electrode material and preparation method and application thereof

A cathode material and substrate technology, applied in the field of electrochemistry, can solve the problems of aggravated side reactions between cathode active materials and electrolyte, and deterioration of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The second aspect of the present invention provides the preparation method of the positive electrode material provided by the first aspect of the present invention, comprising:

[0030] Provide the substrate;

[0031] A cladding layer is formed on the surface of the substrate.

[0032] The preparation method of the positive electrode material provided by the present invention may include: providing a substrate. The method for providing the base material should be known to those skilled in the art, for example, it may include: mixing and sintering the raw materials of the base material to provide the base material. Those skilled in the art can select appropriate raw materials and proportions of the substrate according to the elemental composition of the substrate. For example, the raw materials of the substrate may include ternary material precursors of nickel, cobalt, manganese and / or aluminum, sources of lithium, sources of M, sources of Me, sources of A, etc., and t...

Embodiment 1

[0062] In the preparation of the above (1) positive electrode material, the specific process is:

[0063] 1) Prepare substrate precursor:

[0064] Nickel sulfate, manganese sulfate, and cobalt sulfate are configured into a solution with a concentration of 1mol / L in a molar ratio of 8:1:1, and a lithium-nickel transition metal oxide A with a larger particle size is prepared by using hydroxide co-precipitation technology. Precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 . In the process of preparing the precursor, the particle size can be controlled by controlling the reaction time, pH value and ammonia concentration during co-precipitation;

[0065] 2) Lithium nickel transition metal oxide A (polycrystalline LiNi 0.8 co 0.1 mn 0.1 o 2 ) preparation method:

[0066] The large-grain nickel-cobalt-manganese ternary material precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 , Li-containing compound LiOH·H 2 O is placed in a mixing device for mixing, and then placed in an atmosphere furnace...

Embodiment 2~14

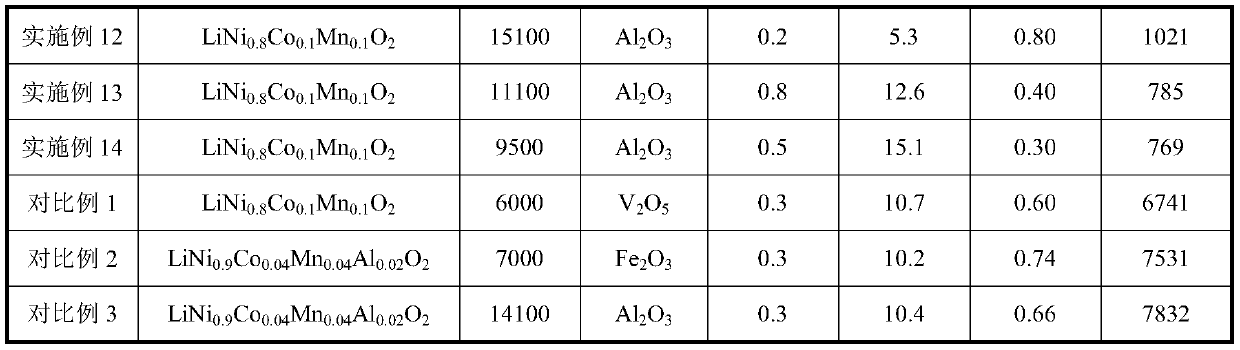

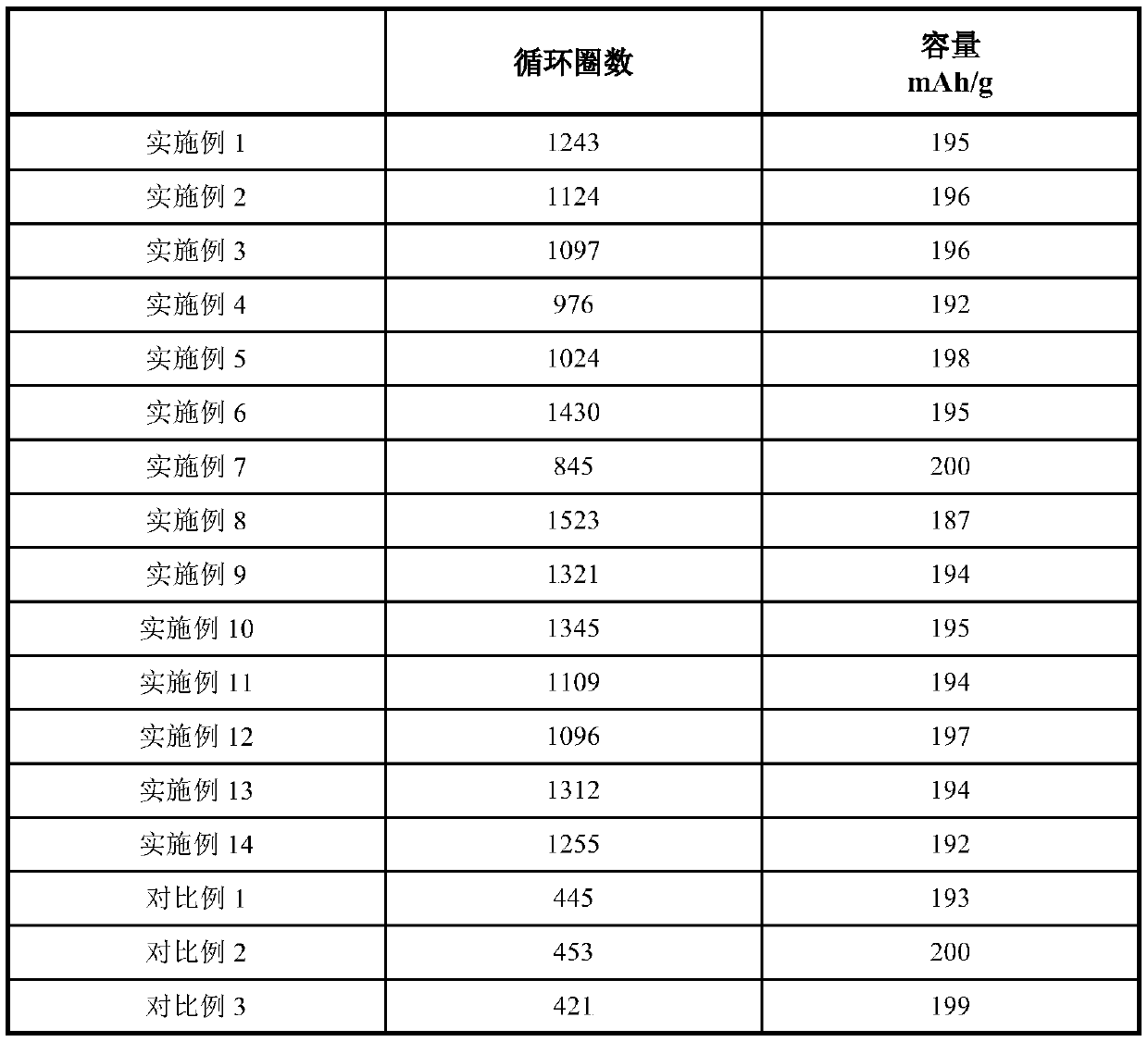

[0068] The preparation method of the positive electrode material of Example 1 is basically the same, the difference is that: the relative content of Ni, Co, Mn, and Al elements in the precursor is different, and substrates with different components are prepared; when adjusting the reaction time and co-precipitation pH value, ammonia concentration, change the size of the primary particle and secondary particle; at the same time, change the material type, coating amount and heat treatment temperature of the coating layer, the specific characteristics of the positive electrode material in the above examples are shown in Table 1, and finally implemented The positive electrode materials in Examples 2-14.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com