High-precision eutectic welding equipment capable of maintaining constant pressing force

A eutectic welding, high-precision technology, applied in the direction of welding equipment, metal processing equipment, auxiliary devices, etc., can solve the problems that affect the welding quality, cannot guarantee the stability and badness of the two components to be welded, and achieve the improvement of eutectic welding Effect of precision and welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

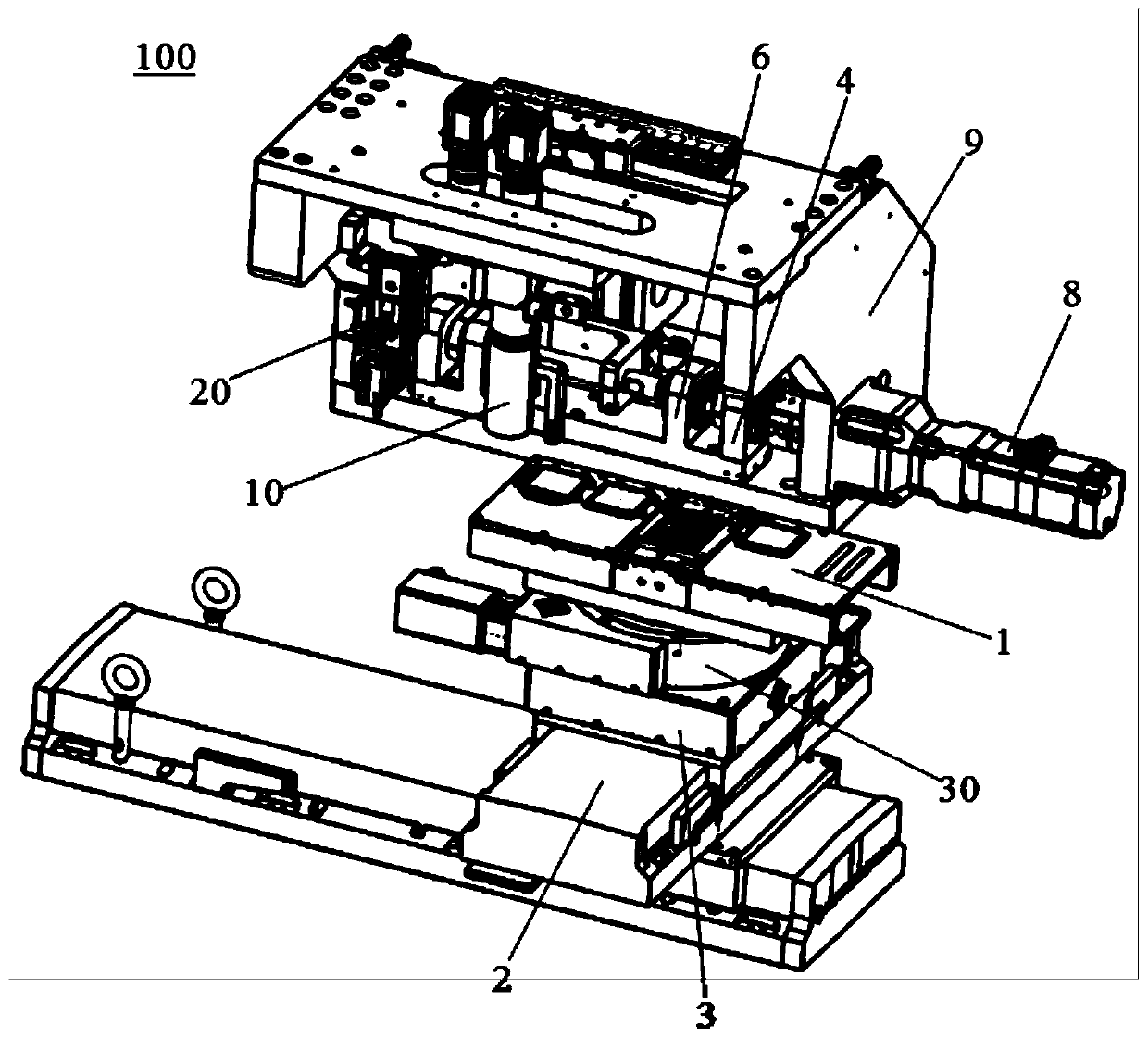

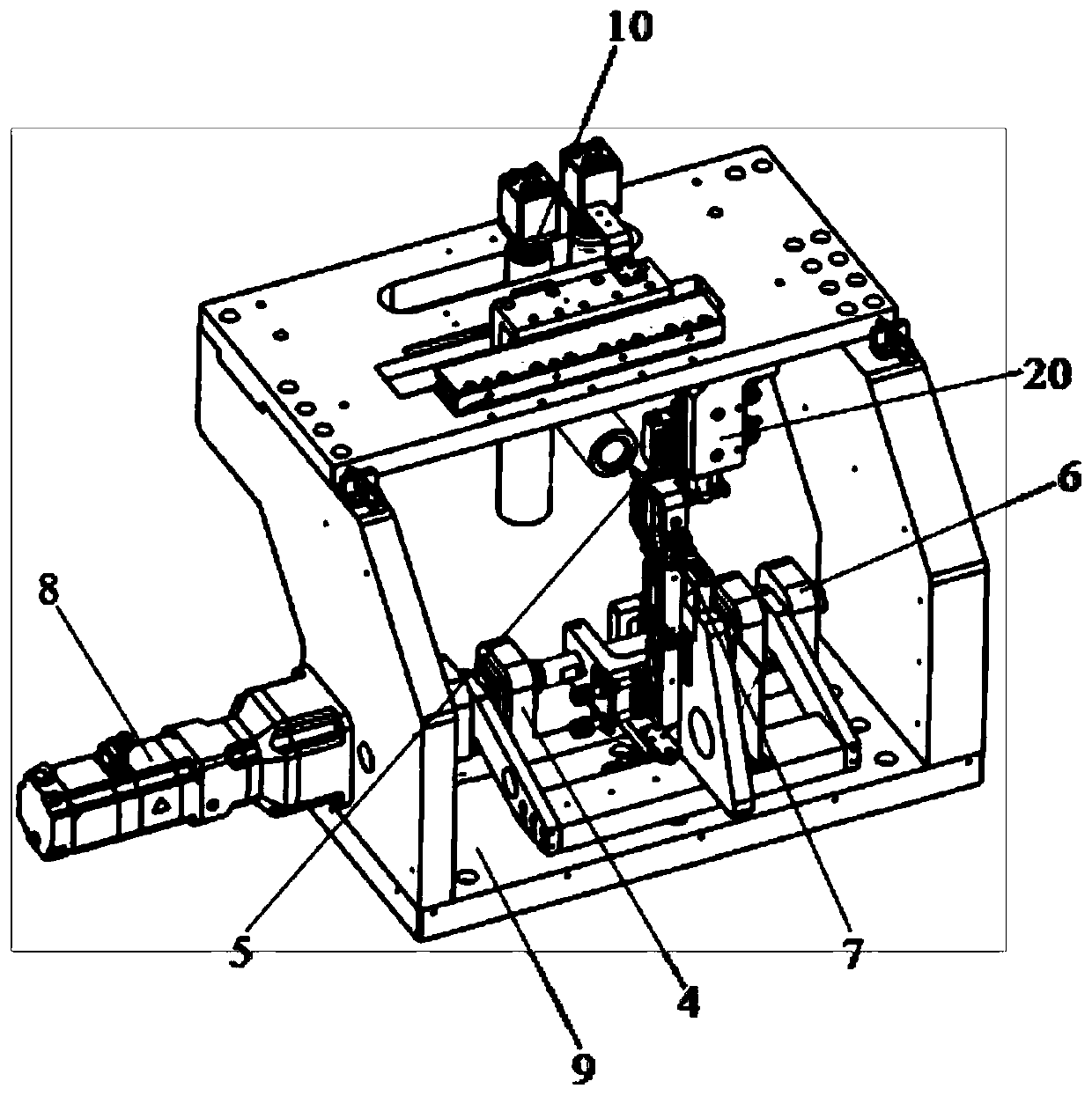

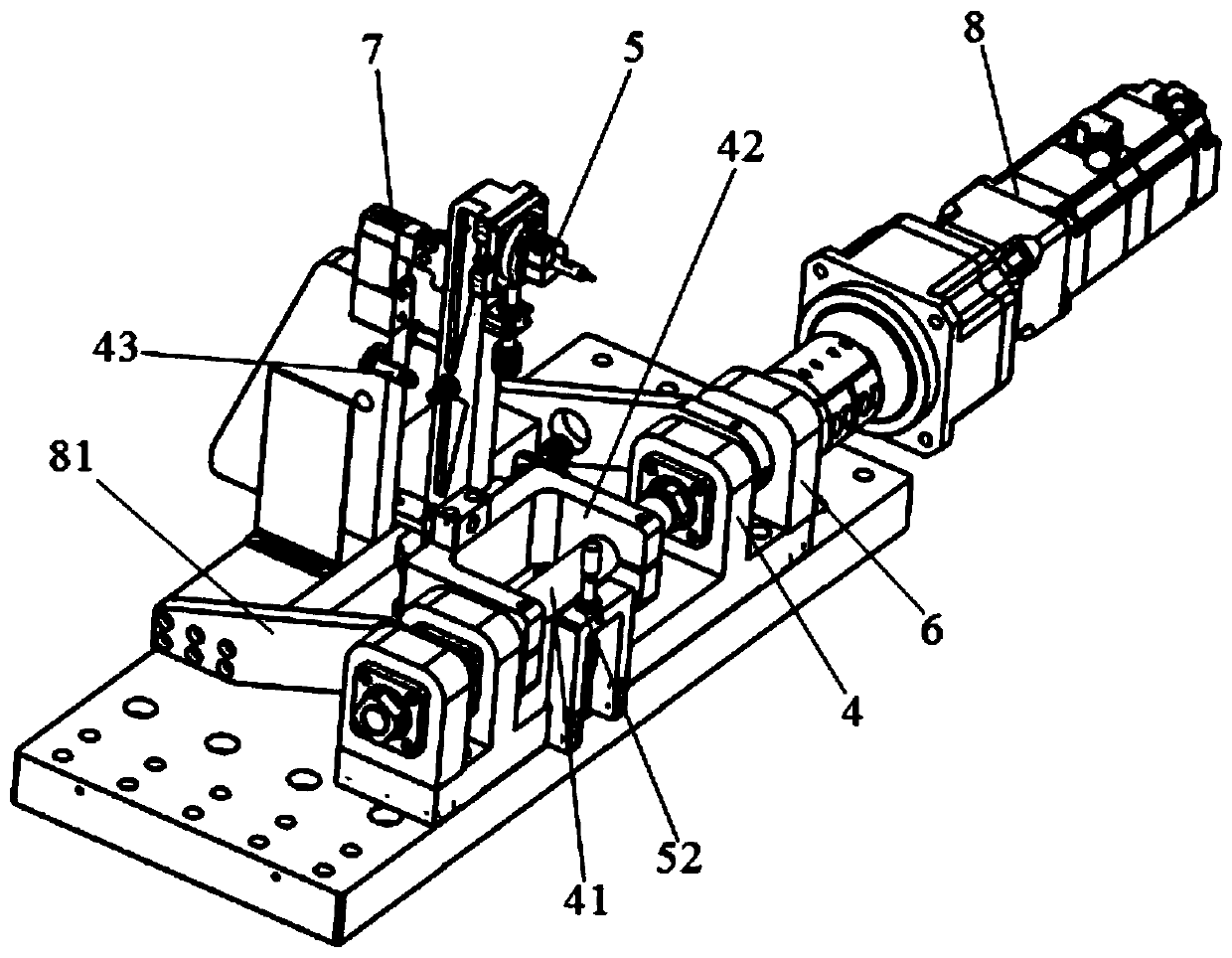

[0044] Please refer to Figure 1-Figure 12 , the present embodiment is a high-precision eutectic welding equipment 100 capable of maintaining a constant pressing force, which includes a eutectic soldering table 1 that supports and fixes a workpiece A, and an XY-axis drive unit that drives the eutectic soldering table 1 to move in a horizontal plane 2. Drive the eutectic soldering station 1 to fine-tune the Z-axis driving unit 3 on the Z-axis, the rotatable pressing head assembly 5 that is set on the first support 4 and presses the workpiece B, and the rotatable setting on the second The pressure sensor assembly 7 on the two bearings 6 and exerting pressure on the compression head assembly 5, and the servo driver 8 that drives the pressure sensor assembly 7 to rotate, the pressure sensor assembly 7 and the Z-axis drive unit 3 are in a closed loop control, when the pressure data of the pressure sensor assembly 7 is less than the set value, the Z-axis drive unit 3 drives the eute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com