Upper swinging type lens grinding machine

A grinding machine and grinding mechanism technology, applied in grinding machine tools, grinding devices, grinding tools, etc., can solve the problems of easy occurrence of scrapped products, low work efficiency, difficult grinding process operation, etc., so as to improve work efficiency and grinding efficiency. , Improve the effect of grinding uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

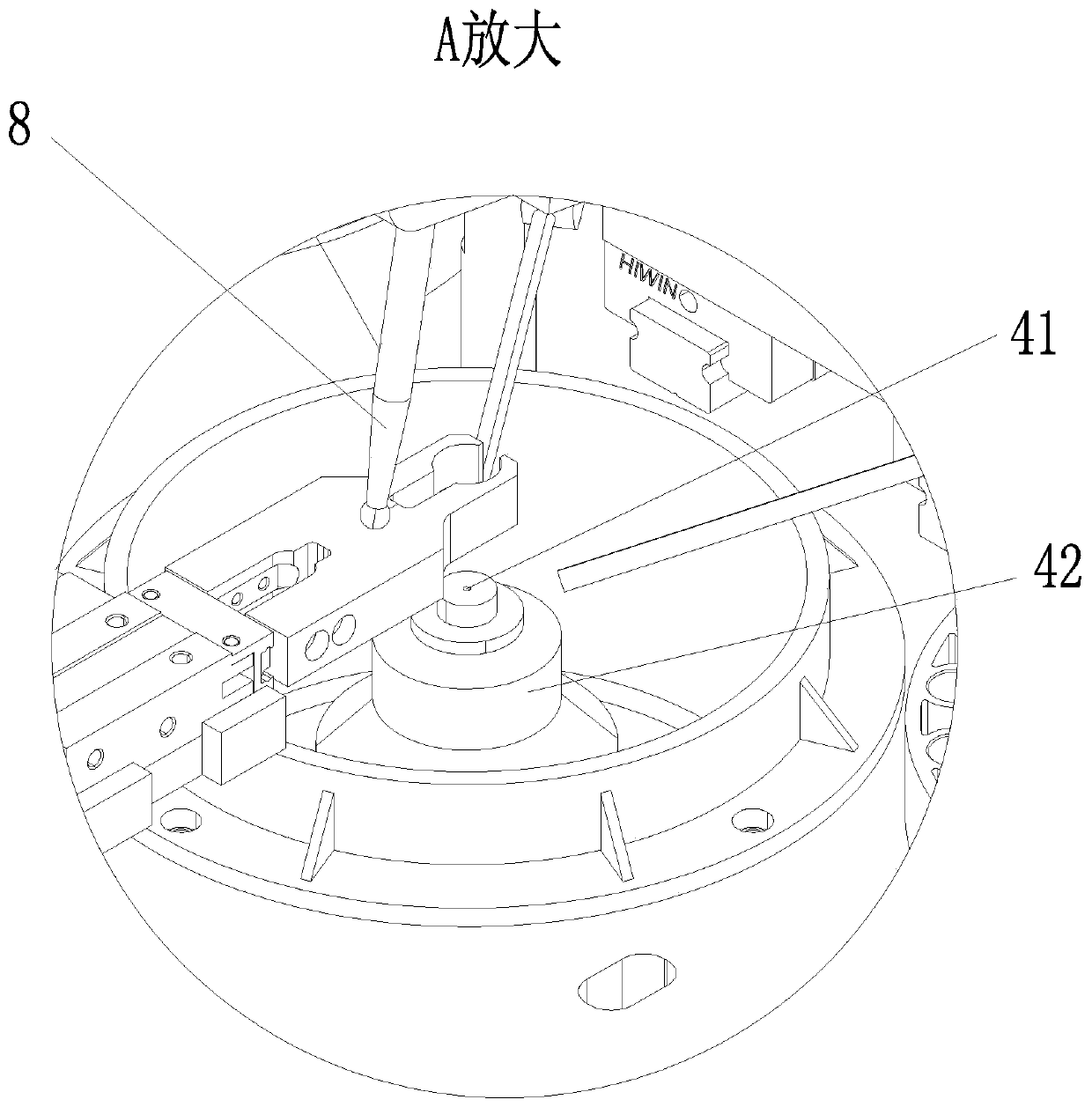

[0063] Such as Figure 1-17As shown, a kind of upper pendulum lens grinding machine of the present invention is characterized in that: comprise more than one group of complete grinding machine 1, each group of grinding complete machine 1 comprises frame 2, is respectively installed on the frame 2 and is used for processing The grinding mechanism 4 for grinding the material 3, the material storage mechanism 5 arranged on one lateral side of the grinding mechanism 4 for placing the material 3 to be processed, and the material storage mechanism 5 arranged on the other lateral side of the grinding mechanism 4 for storing finished materials 3, the finished product storage mechanism 6, the frame 2 is also provided with a material for transferring the material 3 to be processed on the material storage mechanism 5 to the grinding mechanism 4 and transferring the finished material 3 on the grinding mechanism 4 to the finished product The material transfer mechanism 7 on the storage mec...

Embodiment 2

[0089] Such as Figure 18 As shown, the difference between the present embodiment and the first embodiment is that the complete grinding machine 1 is set up sequentially according to the sequence of the spherical lens processing process, and the combined design of multiple processes can realize multiple processes such as roughing, polishing, and fine grinding at the same time. conduct.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com