Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

976 results about "Cement grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

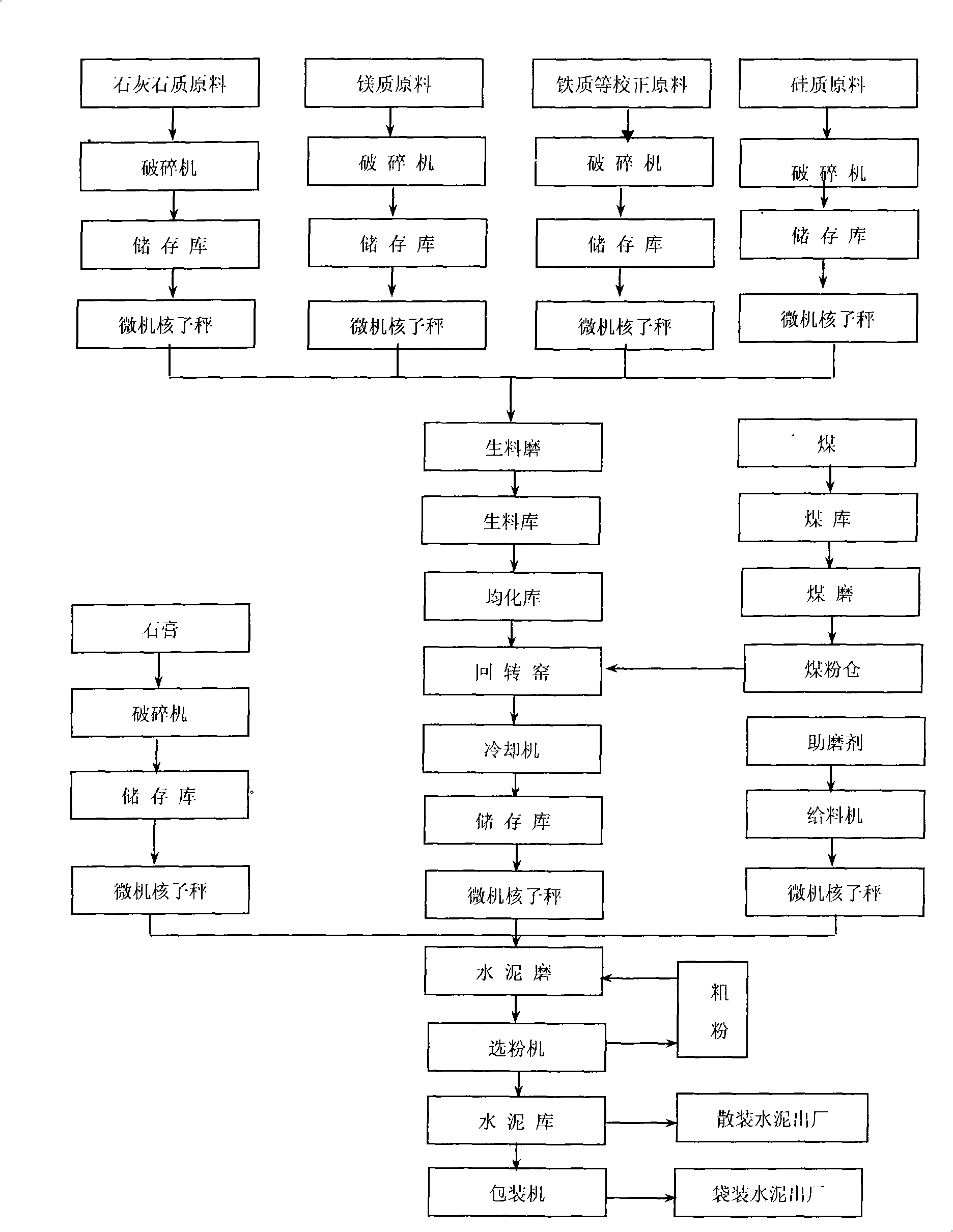

The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine grinding. Some of the main ingredients used to make cement include limestone, clay, shale, iron, and sand.

System and method for treating dust contained in extracted cement kiln combustion gas

ActiveUS7749311B2Effectively remove dustLow facility requirementsCombination devicesLiquid degasificationCycloneEngineering

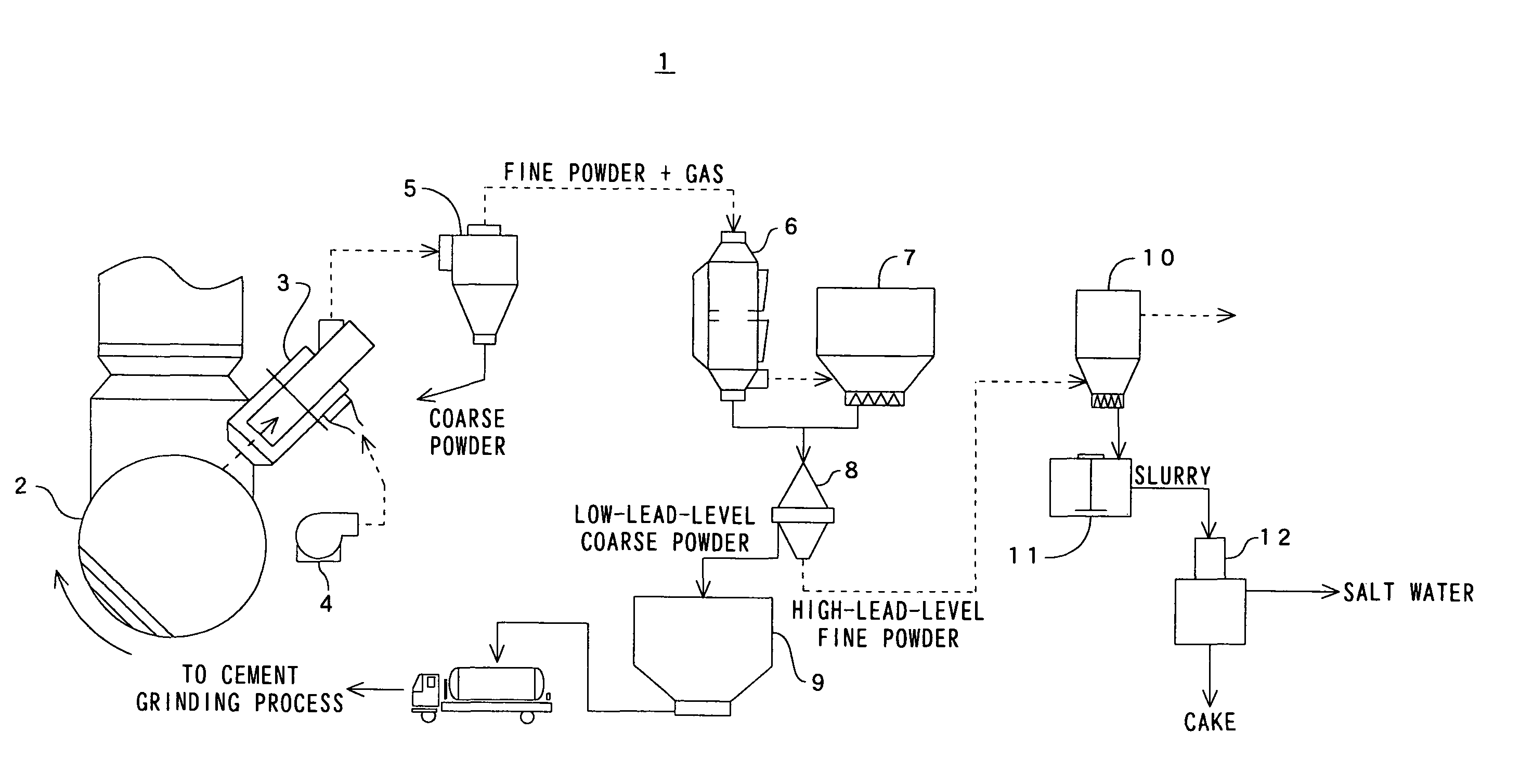

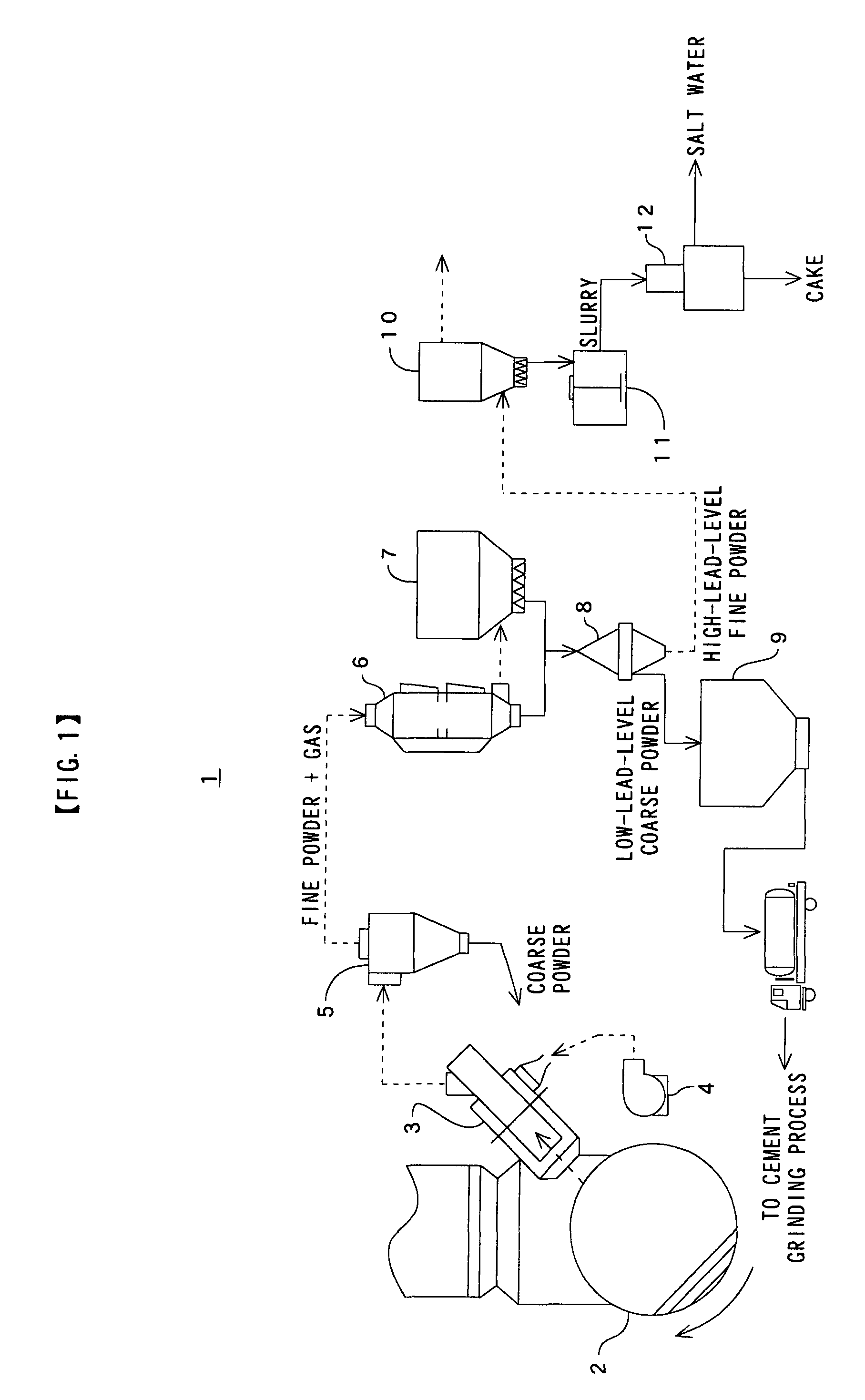

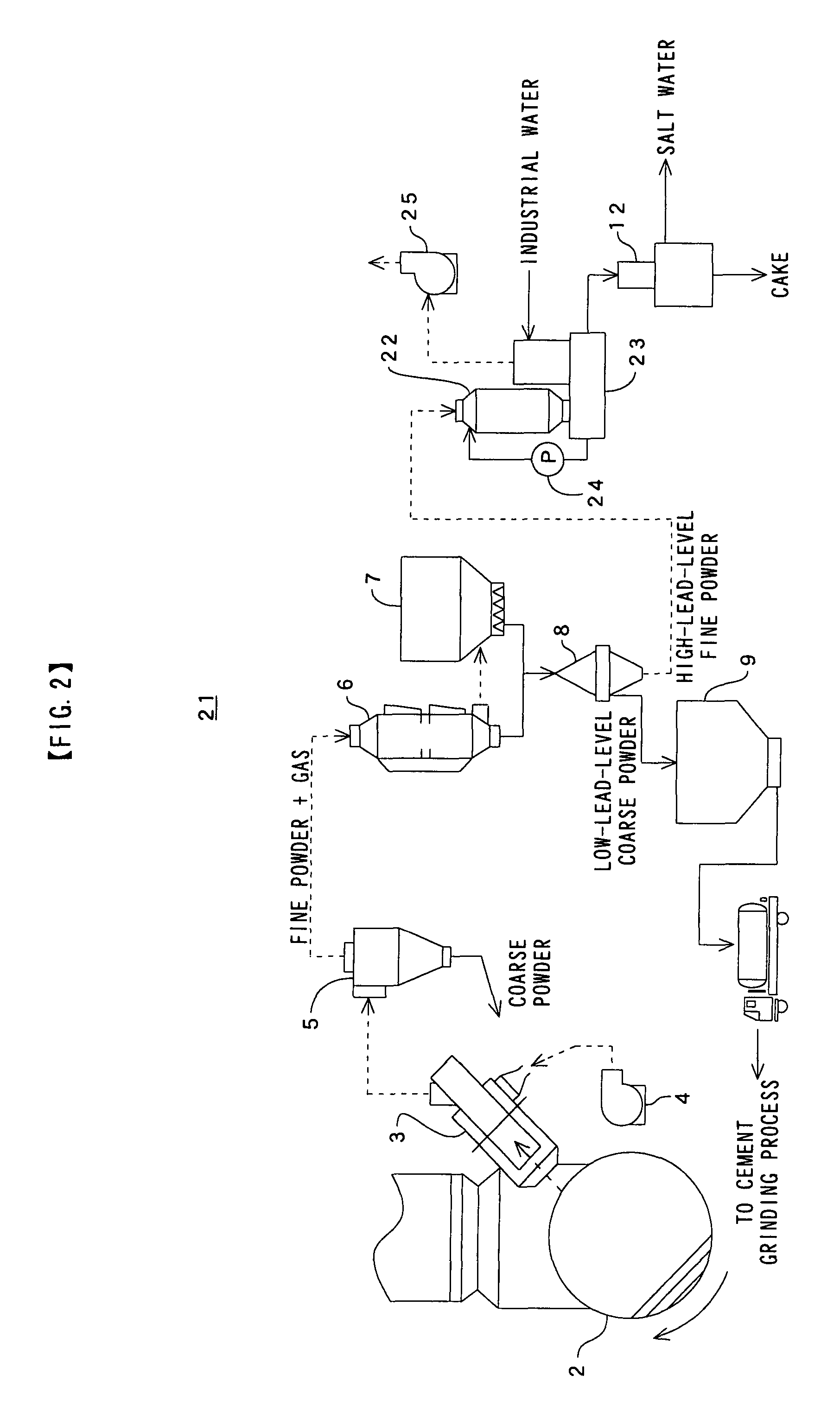

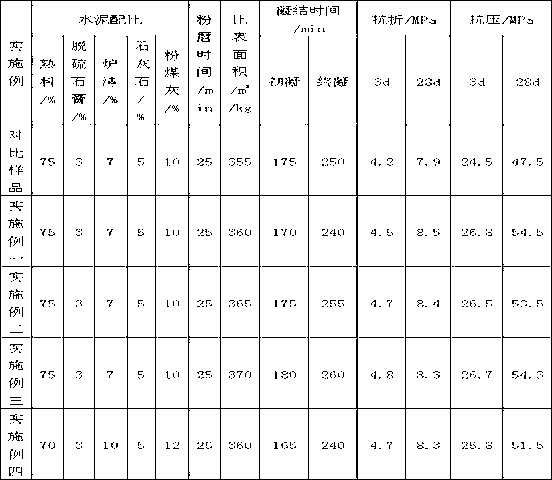

A treatment system to efficiently remove lead from dust contained in extracted cement kiln combustion gas while reducing facility and running costs. A treatment system 1 comprising a probe 3 for extracting a part of combustion gas, while cooling it, from a kiln exhaust gas passage, which runs from an inlet end of a cement kiln to a bottom cyclone; a first classifier 5 for separating coarse powder from dust contained in the combustion gas extracted; a dust collector 7 for collecting dust from the extracted gas containing fine powder discharged from the first classifier 5; and a second classifier 8 for dividing dust discharged from the dust collector 7 into fine powder and coarse powder, and others. Since more lead is distributed on the fine powder side classified by the second classifier 8, lead can efficiently be removed without using chemicals and the like. The fine powder classified by the classifier 8 may be desalted by washing; high-lead-level cake obtained after the washing can be recycled; or salt water can be added to a cement mill. The coarse powder may be added to a cement grinding process or returned to cement material grinding process after the desaltation through washing.

Owner:TAIHEIYO CEMENT CORP

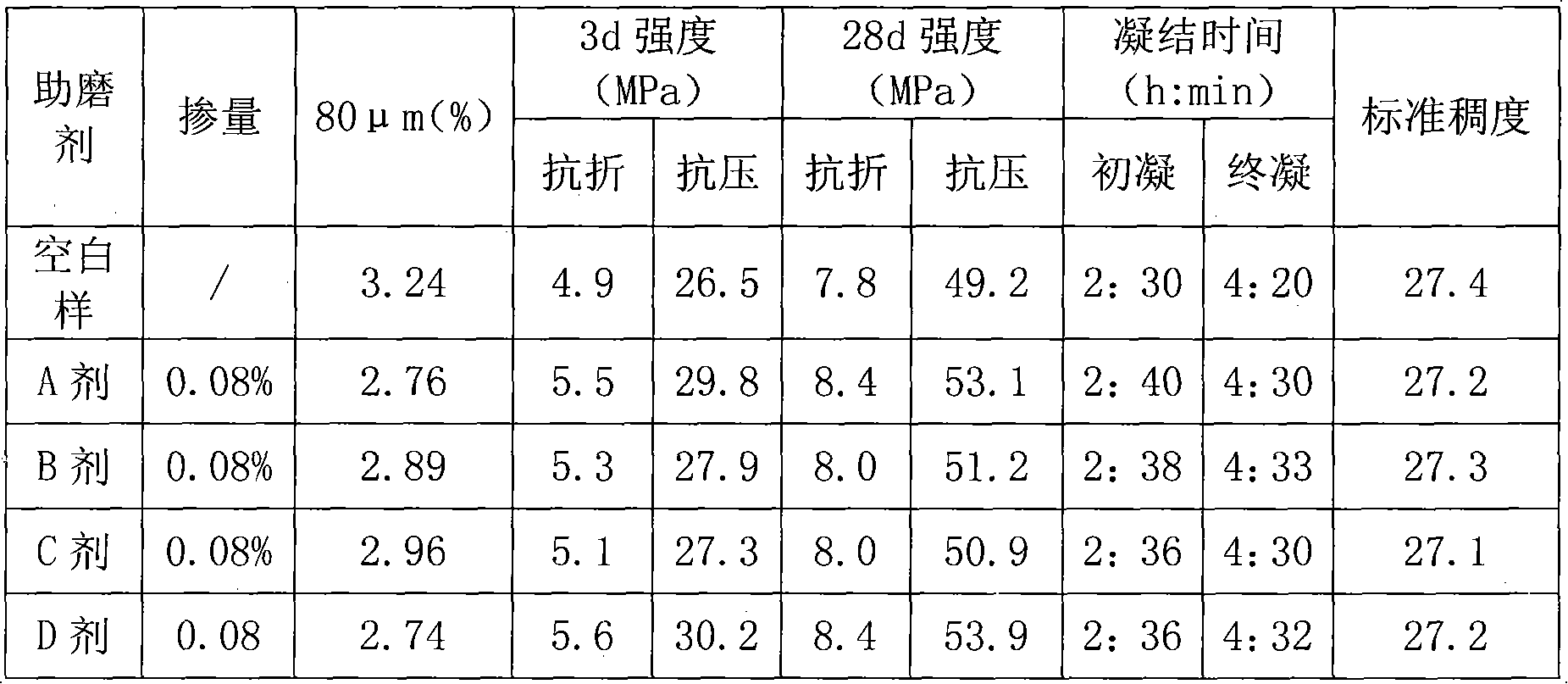

Liquid compound reinforced type cement grinding aid and preparation method thereof

The invention discloses a liquid compound reinforced type cement grinding aid. The liquid compound reinforced type cement grinding aid is prepared by the following ingredients in part by weight: 5 to 15 parts of reinforced compounds, 20 to 40 parts of grinding aiding compound, 0.1 to 1 part of silicon-contained compound, 10 to 50 parts of stable compounds, and the balance of water. The invention also discloses a preparation method of the liquid compound reinforced type cement grinding aid. The preparation method comprises the following steps: 1, adding water to a reacting kettle, and heating to reach 50 to 60 DEG C; 2, sequentially adding the reinforced component and the silicon-contained compound, and stirring for 30 minutes; 3, adding the stabile component and the grinding aiding component, and stirring for 10 minutes; and 4, adjusting the pH (Potential Of Hydrogen) of the solution to 8 to 9, and stirring for 10 minutes. The cement grinding aid disclosed by the invention can improve the physical and mechanical performances, and is low in dosage and free from harmful ingredients such as chlorine salt; and the preparation method of the cement grinding aid is simple in technological preparation and low in cost.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

Chlorine-free powdery cement grinding aid and preparation method thereof

InactiveCN101665338AHigh strengthStrong compound synergistic effectCement productionSulfateLignosulfonates

The invention discloses a chlorine-free powdery cement grinding aid suitable for fly ash, which comprises the following components in parts by weight: 0-5 parts of alkanolamine, 2-5 parts of polylol,15-75 parts of sulfate, 5-20 parts of acetate, 0-5 parts of lignosulphonate, 2-6 parts of carbohydrate organic matter, 5-25 parts of miltonite, 0-25 parts of carbamide and 5-50 parts of inorganic carrier material. The invention also discloses a preparation method of the chlorine-free powdery cement grinding aid suitable for the fly ash. A compound grinding aid can lower the cement cost and uses the fly ash for replacing partial clinker to save the clinker dosage by 10-15 percent on the premise of keeping the cement strength unchanged, and uses extra 10-15 parts of fly ash without increasing the required water amount of cement standard consistency; the cost of the cement per ton is lowered by more than 10 Yuan.

Owner:NANJING ZHUJI ENERGY SAVING TECH

Liquid cement grinding aid

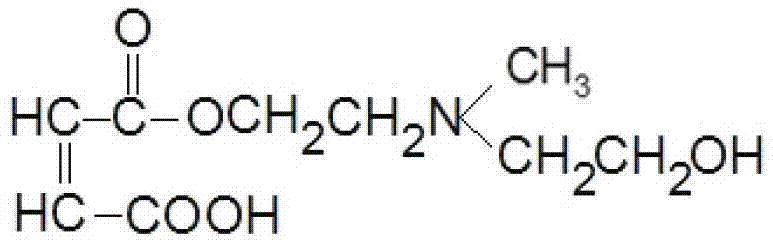

The invention discloses a liquid cement grinding aid. The liquid cement grinding aid comprises the following components by weight percent: 10-24% of triethanolamine, 10-16% of polymeric polyol, 10-13% of molasses, 1-3% of calcium formate, 3-5% of sodium acetate, 5-10% of sodium thiosulfate and the balance water. Compared with the prior art, the liquid cement grinding aid has the advantages that the grain composition of a cement material is changed, the strength of cement is improved, enhancing effect of the cement mixed with a large quantity of limestone is improved obviously; the cost is lower as the using amount of triethanolamine is reduced; the cement output in the unit time is increased effectively, and the power consumption of per unit output is reduced as the mixing amount in the cement finishing process is low; the liquid cement grinding aid is green and environmental-friendly and cannot hurt people, or cannot damage buildings and the like as chloridion content is not contained.

Owner:柳州宝能建材科技有限公司

Liquid cement grinding aid

InactiveCN101318792AEasy to measureChange the production processSodium phosphatesTriterpenoid saponin

The invention relates to a liquid cement grinding aid which can obviously reduce the dosage of trolamine and does not contain urea. The grinding aid comprises the following compositions in weight percentage: 1 to 10 percent of trolamine, 5 to 10 percent of diglycol, 1 to 10 percent of trimeric sodium phosphate, 10 to 30 percent of molasses, 0 to 20 percent of sodium thiosulfate, 0 to 10 percent of air entraining component and the balance being water, wherein the air entraining compositions are triterpenoid saponin air entraining agent, sodium lignin sulfonate or a mixture of the triterpenoid saponin air entraining agent and the sodium lignin sulfonate at any proportion. The invention obviously reduces the dosage of the trolamine, does not contain the urea, lowers product cost and simultaneously facilitates the environmental protection. The sodium thiosulfate has the function of exciting mixed materials of cement and can improve the initial strength and the later strength of the cement, thereby effectively improving the service performance of the cement grinding aid. The triterpenoid saponin air entraining agent and the sodium lignin sulfonate have the action of the auxiliary aided grinding and simultaneously properly entrain air to reduce the water consumption of the cement standard consistence.

Owner:NANJING YONGNENG MATERIALS

Cement grinding aid and preparation method thereof

The invention relates to a cement grinding aid, in particular to a cement grinding aid and a preparation method thereof. The cement grinding aid is prepared from, by weight, 13-18 parts of polymeric polylol, 8-12 parts of tri-isopropanolamine, 12-15 parts of polyol ether, 15-20 parts of ethanediol, 25-30 parts of triethanolamine, 15-18 parts of molasses, 13-15 parts of lignin, 0.03-0.06 part of sodium chloride, 0.5-1 part of silane coupling agents and 40-45 parts of water. By means of the obtained cement grinding aid, in the cement production process, the phenomena of clinker fine particle aggregation and ball pasting can be effectively improved, mobility of clinker particles is enhanced, thereby the pulverization effect of grinding media in a grinding machine for materials is enhanced, grinding efficiency can be improved by 15-20%, the cement machine-hour yield is increased, electricity consumption is greatly lowered, production cost is lowered, in addition, strength of cement at different ages can be remarkably improved, and flowability of the cement is improved.

Owner:内蒙古同佳技术发展有限公司

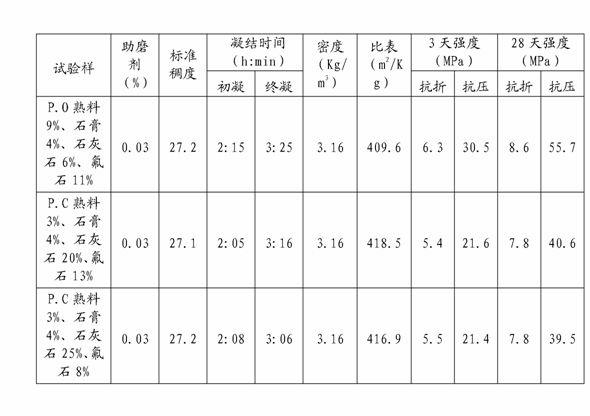

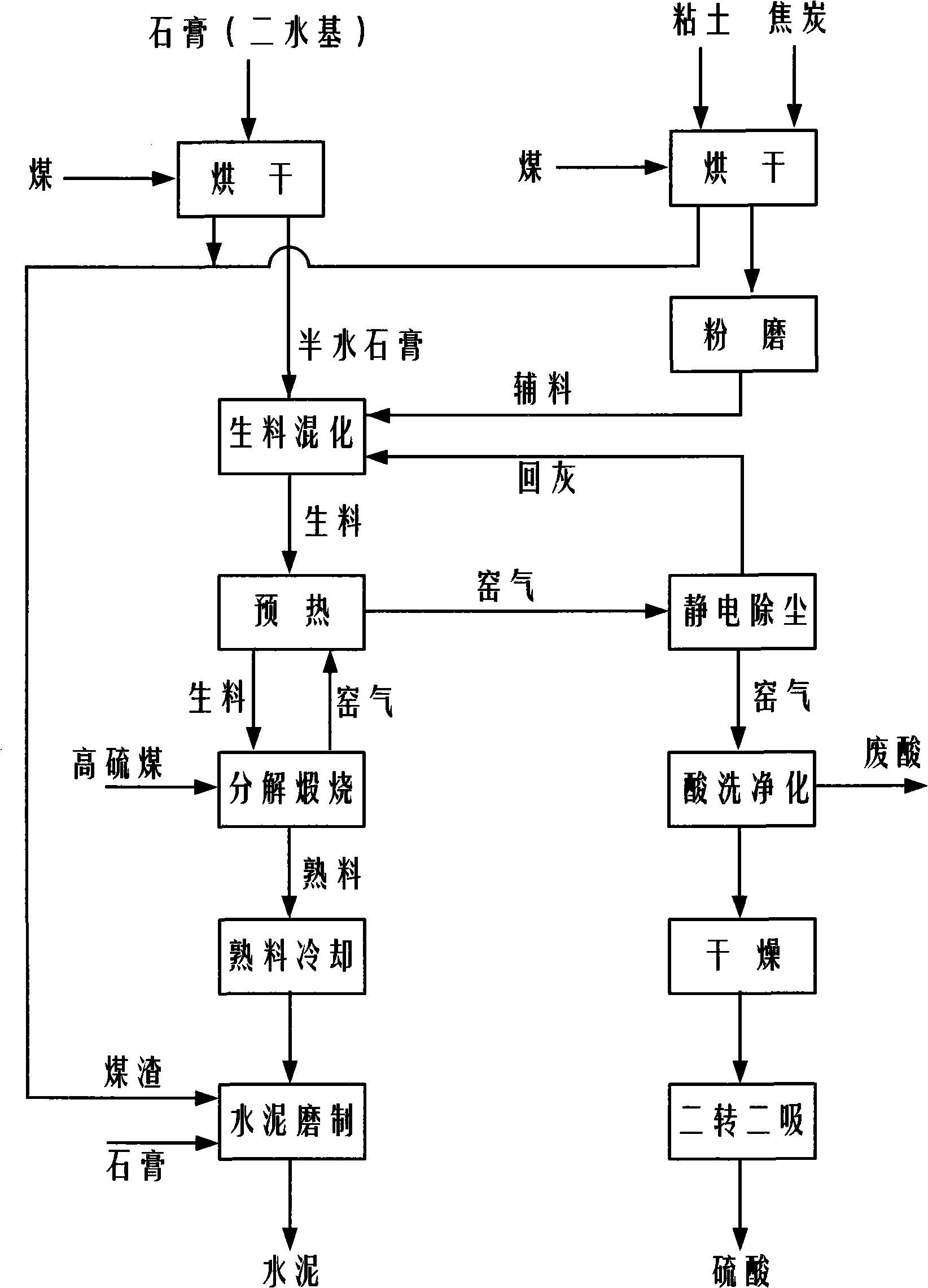

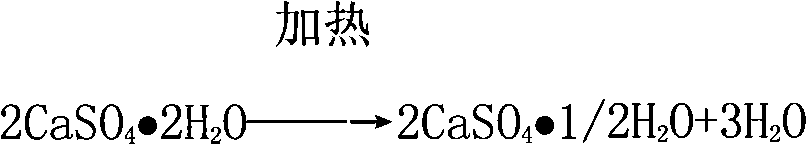

Improved preparation technique for preparing sulphuric acid and cement with gypsum

ActiveCN101343047AEliminate pollutionAlleviate supply shortagesCement productionSulfur-trioxide/sulfuric-acidSource materialAcid washing

The invention provides an improved production process of utilizing gypsum to produce sulfuric acid and cement, which relates to the sulfuric acid and cement industry production technology, and the resource comprehensive utilization and environmental protection governing field of the industrial byproduct gypsum. The improved production process is characterized in that natural gypsum with the CaSO4*2H2O as the main composition or the industrial byproduct gypsum is adopted as the main source material; clay, coke and fly ash clinker are used as supplementary materials; the half-water drying gypsum flow, the single stage powder grinding, raw material mixing melting, suspension preheater kiln decomposing calcination, closing diluted acid washing and purification, two-turning and two-suction processes are adopted; the sulfuric acid and cement products are prepared through six steps of source material homogenizing, drying and dehydration, raw material preparation, clinker burning, kiln gas acid production and cement grinding; the improved production process has the advantages of wide range source material, solving the land occupation and environmental pollution problems of the gypsum waste residue, realizing the circulation utilization of sulfur resource, adopting a plurality of new processes and devices, realizing the large scale production easily, advanced technology, mature process, easy operation in production control, low energy consumption, high benefit, no waste water and waste residues exhaust.

Owner:SHANDONG LUBEI ENTERPRISE GROUP

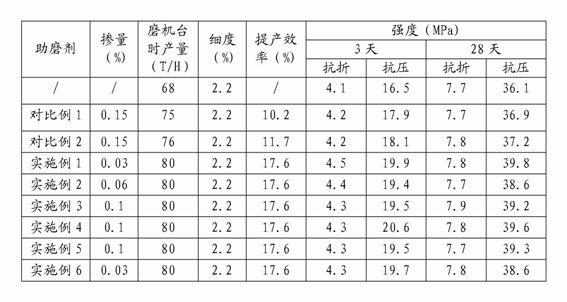

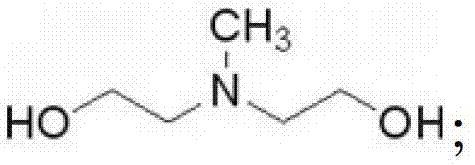

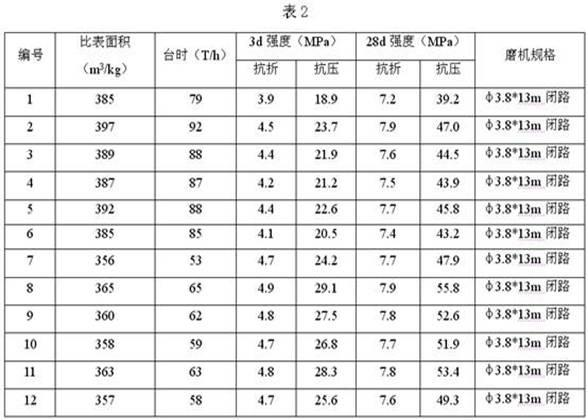

Composite cement grinding aid and preparation method thereof

The invention discloses a composite cement grinding aid and its preparation method. According to a formula, the composite cement grinding aid comprises: a grinding agent, a reinforcing agent, a surfactant, molasses, N, N-bis(2-hydroxyethyl)isopropanolamine and water. The composite cement grinding aid can enhance the fluidity of materials during grinding, effectively reduce overgrinding phenomenon of a mill, improve adhesion of the materials to a grinding body, a lining board, and a bin partition board as well as the self agglomeration phenomenon of the materials, thus increasing the machine-hour yield of the cement grinding mill by l0%-20%, enhancing the cement specific surface area to 20-40m<2> / Kg, reducing the sieve residue, optimizing cement particle gradation, promoting cement clinker hydration, and improving the cement mixture activity. The 3-day compressive strength is increased by 3-5MPa, and the 28-day compressive strength is increased by 4-8MPa. The clinker consumption is reduced by 6-10%. The cement production cost is effectively reduced, the cement security is improved, and the adaptability of cement and concrete admixtures are improved.

Owner:ZHEJIANG HUAJUN BUILDING MATERIAL

High-hardness, wearable, self-protecting metal cored surfacing welding wire

InactiveCN1621193ALow boiling pointPrevent intrusionWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The high hardness high wear resistance self-protecting metal core built-up welding filament used in material processing engineering features the metal core comprising chromium carbide 64-77 wt%, 75# ferrosilicon 4-8 wt%, metal Mg 5-10 wt%, Al-Mg alloy 1-3 wt%, ferroborium 2-5 wt%, ferrotitanium 2-6 wt%, ferrocolumbium 1-5 wt% and ferrovanadium 1-8 wt%. Using the filament in welding needs no added protecting gas and produces no welding slag, and this makes it possible to perform continuous welding. Programming the automatic welding machine can perform automatic welding operation in high built-up welding quality. The present invention is used mainly in built-up welding for repairing coal grinding roller, cement grinding disc, chute, etc.

Owner:BEIJING UNIV OF TECH

Cement grinding aid and preparation method thereof

InactiveCN101125742AImprove grinding efficiencyReduce grinding power consumptionCement grindingTriisopropanolamine

The invention discloses a cement grinding aid and a preparation method thereof. Raw materials of the cement grinding aid consists of 10-30 percent of triethanolamine, 12-30 percent of tirisopropanolamine, 5-20 percent of ethylene glycol, 3-10 percent of propanediol, 15-40 percent of water, 1-5 percent of sodium dodecyl benzene sulfonate, 3-10 percent of lignin and 2-5 percent of anhydrous sodium sulfate; water is poured into a reactor and heated to 40-50 DEG C to be reserved; the sodium dodecyl benzene sulfonate is added to be stirred for 15min; the anhydrous sodium sulfate is added and stirred for 10min, then the lignin is added and stirred for 30min; materials in the reactor are filtered by a 150 mesh screen; the ethylene glycol and the propanediol are added and stirred for 20min; the triethanolamine and the tirisopropanolamine are added and stirred for 30min and the grinding aid products are obtained. The cement grinding aid can improve grinding efficiency and early and later strength of cement and reduce cement cost.

Owner:洛阳万顺建材有限公司

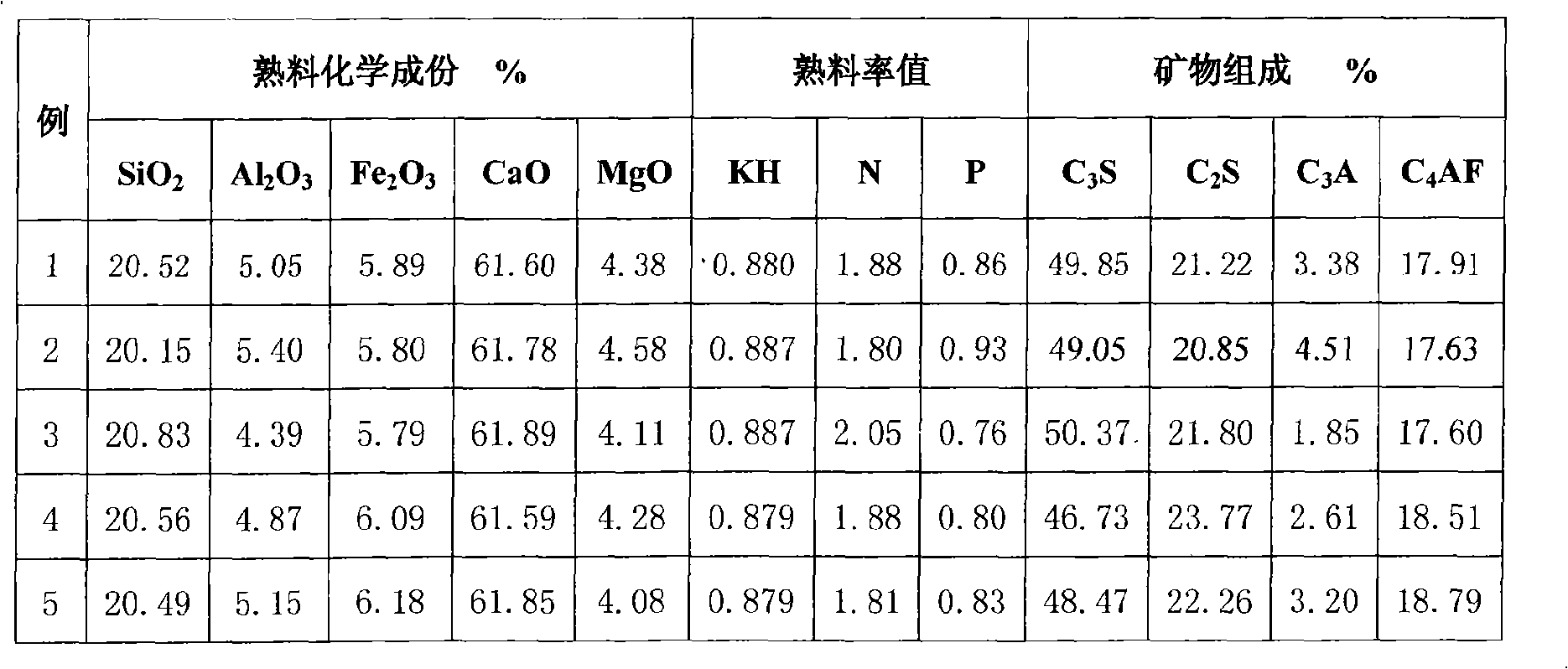

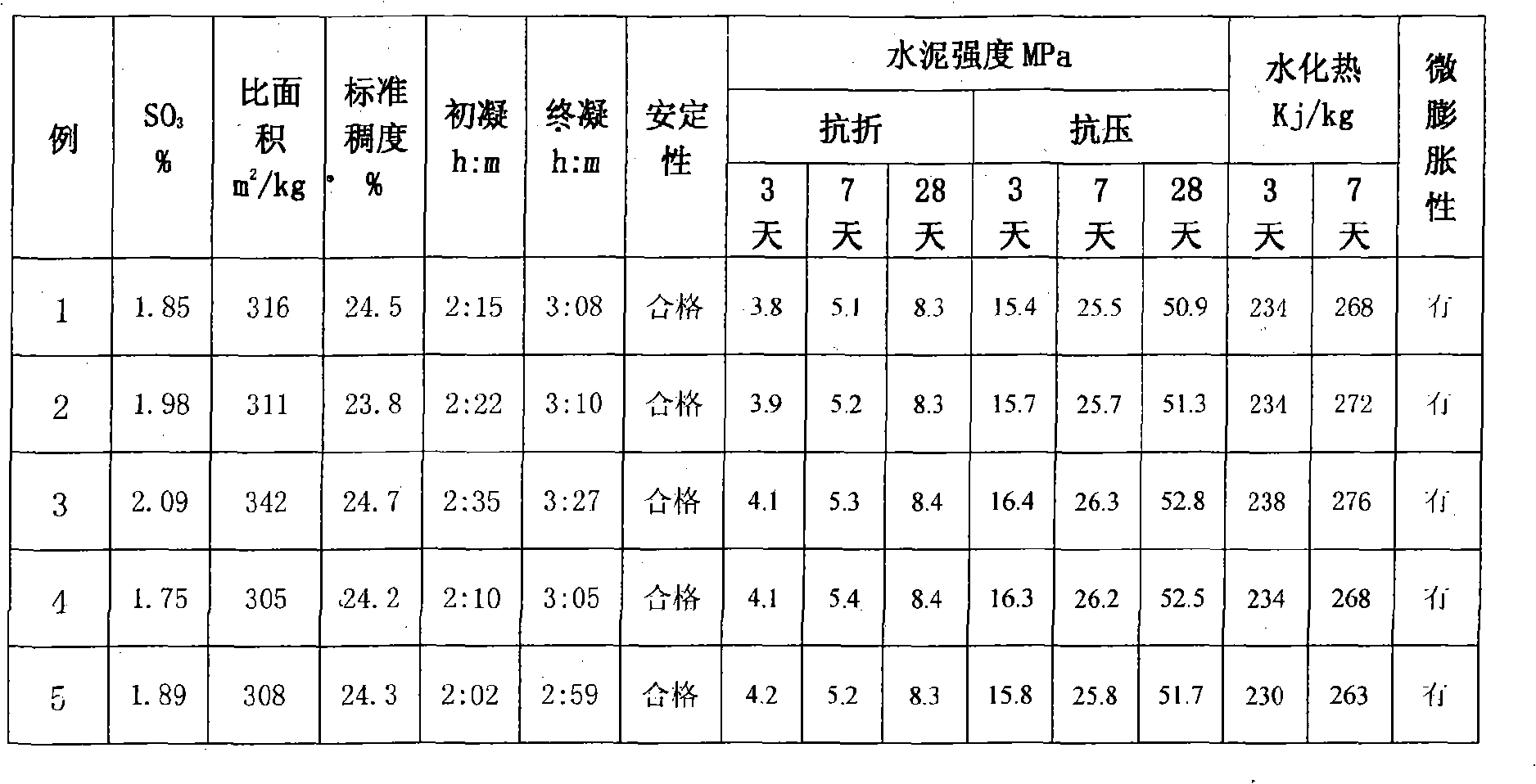

High-magnesium moderate-heat portland cement and production method thereof

InactiveCN101353231AReduce water demandThe micro-expansion property hasClinker productionHigh magnesiumPortland cement

The invention relates to a high-magnesium moderate heat portland cement, which is characterized in that (1) the contents of MgO and SO3 in the cement are 3.0-6.5% and 1.4-2.2% respectively; (2) the weight percentages of the mineral composition for grinding cement clinker are 35-55% of C3S, 15-35% of C2S, 1-6% of C3A and 10-25% of C4AF; and the content of MgO in the cement clinker is 3.0-6.5%; (3) in the raw materials for calcining the clinker, the contents of MgO, CaO and Fe2O3 are respectively controlled at a certain value within the ranges of 2.5-3.8%, 38.0-42.0% and 3.5-4.5%, and the variation ranges thereof are respectively controlled within plus or minus 0.10%, plus or minus 0.20% and plus or minus 0.15%. The production method of the cement mainly comprises three procedures of raw material milling, clinker calcining and cement grinding, namely, 'two grinding and one calcining'. The concrete made from the cement is characterized by good fluidity, low water requirement, moderate cement heat, high later strength, good durability, microdilatancy performance, and the like; compared with the conventional portland cement and moderate heat portland cement, the high-magnesium moderate heat portland cement is more favorable for realizing high performance of the concrete.

Owner:湖南石门特种水泥有限公司

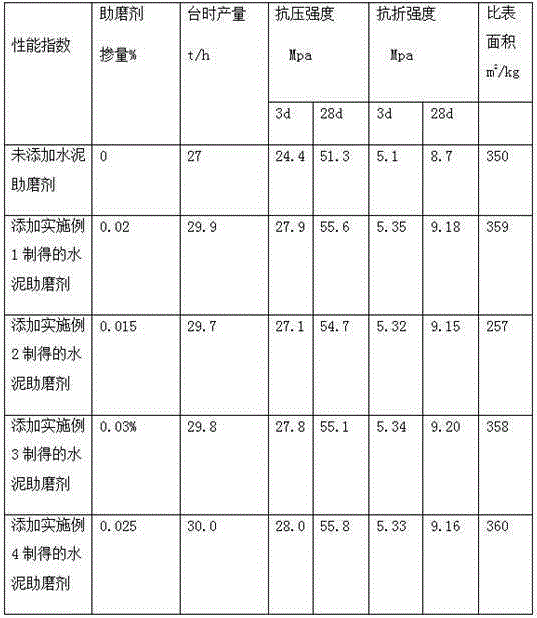

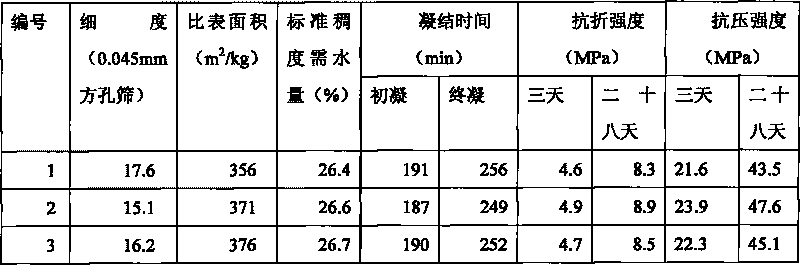

Industrial waste slag-doped composite silicate cement and production method thereof

InactiveCN102101757ABlending amount increasedImprove early strengthCement productionMetallurgical slagAlloy

The invention discloses industrial waste slag-doped composite silicate cement and a production method thereof. The industrial waste slag-doped composite silicate cement comprises the following material components: 45-58 percent of silicate cement clinker, 3-5 percent of desulfurization gypsum, 1.5-4 percent of lime stone, 0.2-0.3 percent of cement grinding additive, 10-29 percent of granulated blast furnace slag, 2-10 percent of coal slag, 4-10 percent of pulverized fuel ash, 2-10 percent of ferroalloy slag, 2-10 percent of zinc metallurgical slag and 0.2-0.25 percent of waste slag grinding aid active excitant. The production method comprises the following steps of: taking and mixing the first four materials according to the proportion and grinding into 300-350m<2> / kg of powder; taking and mixing the rest six materials according to the proportion and grinding into 420-450m<2> / kg of superfine powder; and then combining the two kinds of powder, stirring and homogenizing. By adopting respective grinding of clinker and waste slag, the waste slag fineness reaches an optical value for stimulating the activity, the hydration progress and the cement clinker reach synchronization, and the doping amount and doping category of waste slag are also improved.

Owner:王明贵

Composite high-efficient liquid cement grinding aid

InactiveCN101693605AImprove durabilityReduce dosageCement productionCement grindingTriisopropanolamine

The invention belongs to the technical field of cement technology admixtures, and relates to a composite high-efficient liquid cement grinding aid which contains water solution with the following materials by weight percent: 10 to 20 percent of triethanolamine, 5 to 10 percent of glycol, 5 to 10 percent of tri-isopropanolamine, 5 to 10 percent of calcium lignosulphonate, 5 to 10 percent of molasses, and 5 to 10 percent of sodium silicate; and the water solution is subjected to magnetization treatment. The composite high-efficient liquid cement grinding aid has the following advantages: by the magnetization treatment, solid / liquid stable suspension durability is good, no separation or sediment phenomenon occurs after long-term storage, dosing amount is low, application range is wide, hourly output of a cement grinding mill can be improved by 15 to 20 percent, cement strength can be improved by 1 to 2MPa, 5 to 8 percent of clinker can be saved, and 5 to 8 percent of industrial residue can be additionally dosed.

Owner:山东天汇科技有限公司

Enhanced liquid cement grinding aid

InactiveCN102115316AIncrease late strengthImprove grinding efficiencySodium acetateSodium lignosulfonate

The invention relates to an enhanced liquid cement grinding aid capable of improving the grinding efficiency of a cement grinding mill and enhancing the strength of cement. The liquid cement grinding aid comprises the components with the weight percentages as follows: 10 to 20 percent of triethanolmine, 5 to 10 percent of triisopropanolamine, 3 to 5 percent of diethylene glycol, 2 to 5 percent of sodium formate, 2 to 5 percent of sodium acetate, 1 to 3 percent of sodium lignosulfonate, 10 to 20 percent of desugarized molasses, 5 to 10 percent of glycerin, and water.

Owner:山东国元新材料有限公司

Cement grinding aid

InactiveCN101898878AIncrease productionReduce power consumptionCement productionCalcium formateGlycerol

The invention discloses a cement grinding aid, comprising calcium formate solution, compound glycerol distilled residue solution, triethanolamine, diols and molasses. While the product reutilizes the industrial wastes, the components of the product synergistically act to optimize the efficacy of the grinding process and the product modifies the cement particles, thus improving the quality and performance of the cement while improving the cement yield and saving electricity, and the product does not only have grinding function.

Owner:宜兴市宏伟科技有限公司

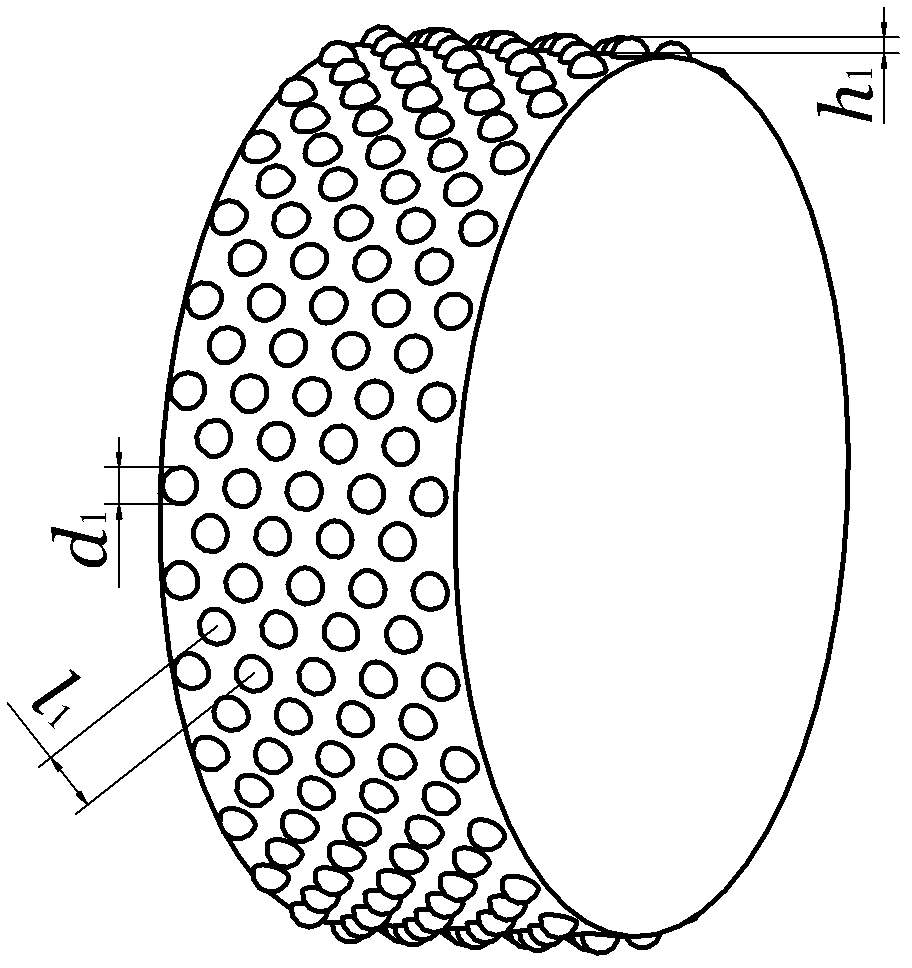

Nonmetal grinding medium for cement grinding, and application thereof

InactiveCN104845584AReduce mill power consumptionReduce power consumptionOther chemical processesCement grindingCompressive strength

Owner:朱晖 +1

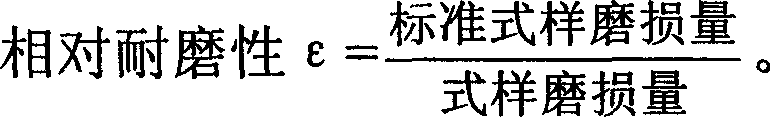

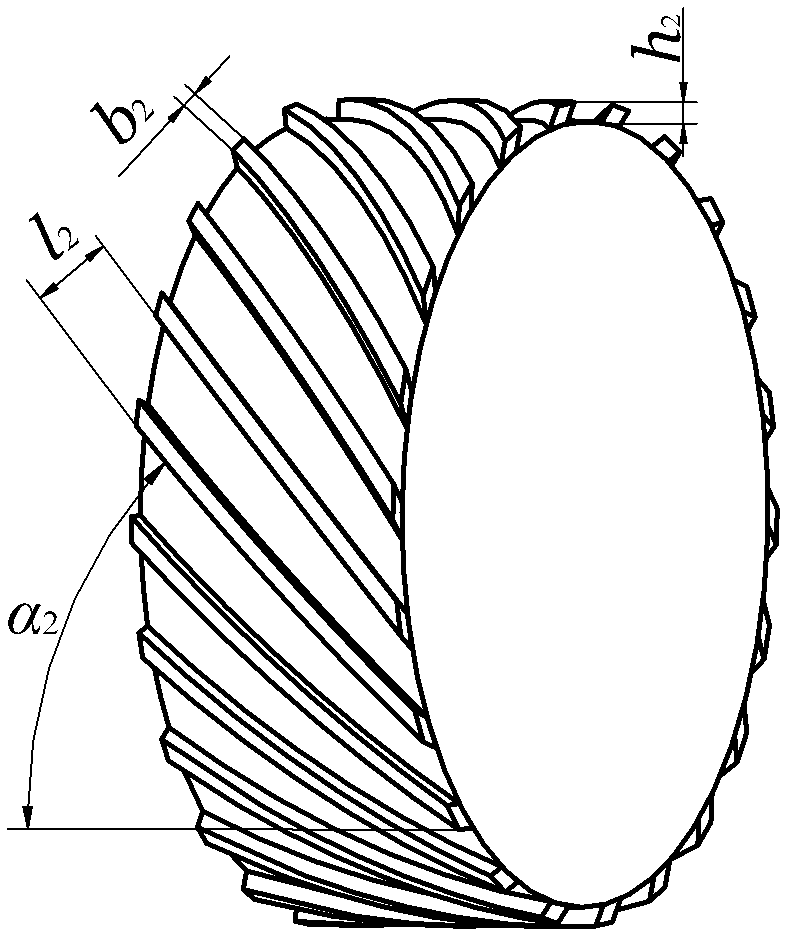

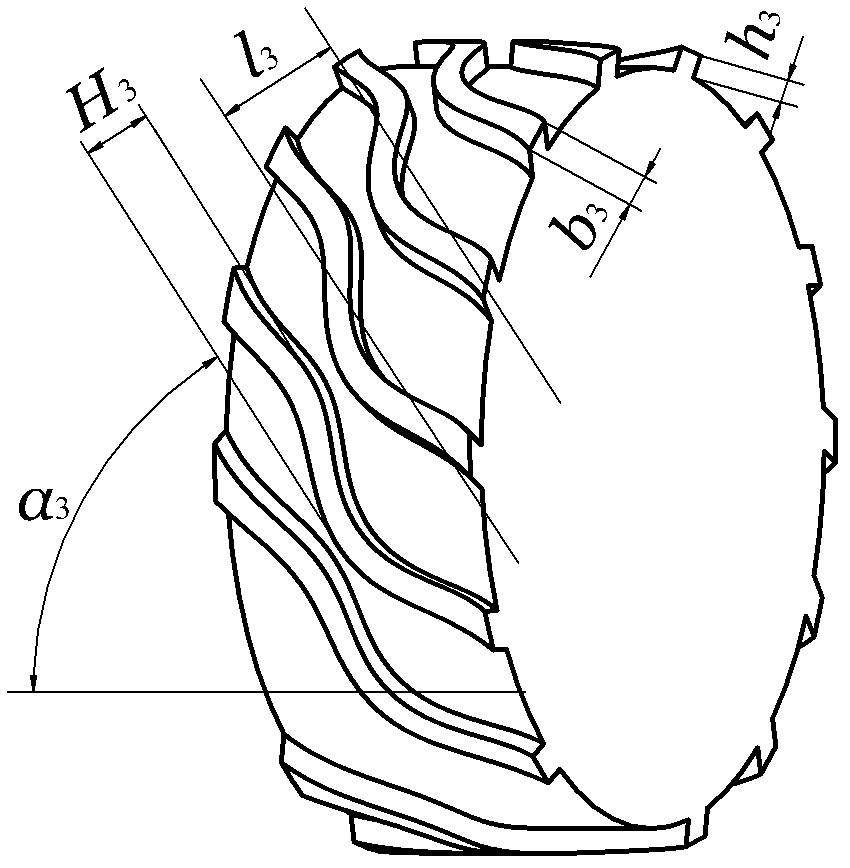

Cement grinding roller with bionic coupling wear-resistant surface layer and preparation method thereof

InactiveCN102302964AImprove wear resistanceImprove grinding effectGrain treatmentsSurface layerCoupling

The invention relates to a grinding roller for cement powder grinding, in particular to a cement grinding roller with a bionic coupling wear-resistant surface layer and a preparation method thereof. Simulating a natural biological coupling wear-resistant principle, the bionic coupling wear-resistant surface layer consists of a bionic coupling strengthening layer, a wear-resistant layer arranged at the lower part of the strengthening layer and a transition layer, wherein the bionic coupling strengthening layer is formed by a cooperative combination of a millimeter-level convex hull, stripe, ripple, grid or squama-shape non-smooth form with an embedded-type structure. The preparation method comprises the following steps of: firstly preparing the transition layer on a parent substance surface of a core part material by using a flux-cored wire electric-arc surfacing method, wherein the thickness of the transition layer is 10-25 millimeters; then changing welding materials and further surfacing the wear-resistant layer on the surface of the transition layer, wherein the thickness of the wear-resistant layer is 5-15 millimeters; and finally preparing the bionic coupling strengthening layer. According to the cement grinding roller and the preparation method provided by the invention, the coupling among the grinding roller surface form, the structure, the soft-hard alternated organization and the materials is realized; the surface wear resistance and grinding effect are significantly increased; and compared with a smooth surface grinding roller with the same substrate material, the service life of the bionic coupling grinding roller is increased by 1.5-3 times.

Owner:JILIN UNIV

Cement grinding aid strengthening agent

The invention relates to a cement grinding-aid intensifier. The weight percent is that alkylol amine: polyalcohol: amide: initiator is equal to 1:1.2-1.6:0.1-0.5:0.01-0.04. The alkylol amine and the polyalcohol are mixed in a reaction tank evenly, the reaction acidity is controlled under stirring at 100-110 DEG C; the reaction time is 2-6 hours; the alkylol amine and the initiator are added, the pH value is adjusted to 7-7.5, then stirring is carried out for reaction for 3-5 hours; alkali is used for neutralization, the pH value is 8-10, and the finished product is obtained. The cement grinding-aid intensifier has the advantages that static electricity produced during powder grinding can be eliminated, thus facilitating the materials not to bond each other and penetrate into the cracks of grains and improving powder grinding efficiency; catalysis is acted during cement hydration, the diffluent complexing ions are produced, and the intensity of the testing body is improved; separation of cement powder grains in super thin grinding powder milling is restrained, thus avoiding the phenomenon of sticky balls, wall built-up and static electricity absorption; powder grinding ability of millers is improved, the specific surface of the thin powder is increased, and early strength, fast coagulation and hydration are fast; product cost is lowered, effect for aiding grinding is outstanding, the working environment is improved, performance of cement is improved obviously, production process is simple, and the products can be stored for a long period.

Owner:淄博宜龙实业有限公司

Liquid cement grinding additive

InactiveCN101696096AImprove early and late strengthReduce the amount of clinkerEthylenediamineDiethylenetriamine

The invention provides a liquid cement grinding additive, which comprises the following components in percentage by weight: 10 to 20 percent of tetrahydroxyethyl-ethylenediamine, 10 to 20 percent of ethoxyl-diethylenetriamine, 10 to 15 percent of diethylene glycol, 5 to 10 percent of polyethylene glycol, 2 to 5 percent of sodium tripolyphosphate, 3 to 5 percent of calcium lignosulphonate, 0 to 10 percent of tri-isopropanolamine, 0 to 8 percent of sodium gluconate, and the balance of water, wherein the molecular weight of the polyethylene glycol is between 200 and 400. As a preferred scheme of the invention, the content of the tri-isopropanolamine is between 5 and 10 percent, and the content of the sodium gluconate is between 5 and 8 percent. A cement and concrete admixture using the liquid cement grinding additive has good adaptability, can significantly improve the grinding efficiency of a grinding machine and improve the strengths of the cement in an early period and a later period by 2 to 4 MPa, or can reduce the clinker dosage by 4 to 8 percent and increase the adding volume of a mixed material by 4 to 8 percent in the cement under a condition of keeping the same cement strength grade.

Owner:NANJING YONGNENG MATERIALS

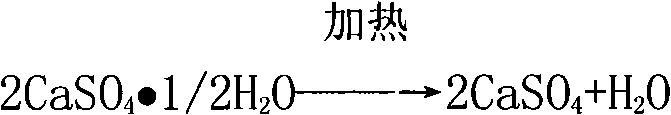

Preparation method of special low-density grinding ball for cement grinding mill

The invention relates to a preparation method of a special low-density grinding ball for a cement grinding mill. The preparation method comprises the steps of with bauxite, alumina powder and the like as main raw materials and chromium oxide, zirconium oxide, calcium oxide, magnesium oxide, ferric oxide, manganese oxide, titanium oxide, silicon dioxide and the like as modified raw materials, adding alumina sol, silica sol and metal salt into slurry at a grinding stage; molding by rolling, isostatic pressing or machine pressing to obtain a green body; and calcining after drying the green body to obtain the low-density grinding ball. By virtue of scientific proportion design, strict process control and unique calcining system, the special low-density grinding ball disclosed by the invention is low in cost, excellent in wear resistance, lower in power load as comparison with a high-density metal grinding body, suitable for substituting a metal grinding body in cement grinding, iron ore grinding and gold ore grinding and capable of reducing the electric consumption for grinding by 30-50%.

Owner:UNIV OF JINAN

Preparation method of high efficiency controllable polycarboxylic acids series cement grinding aid

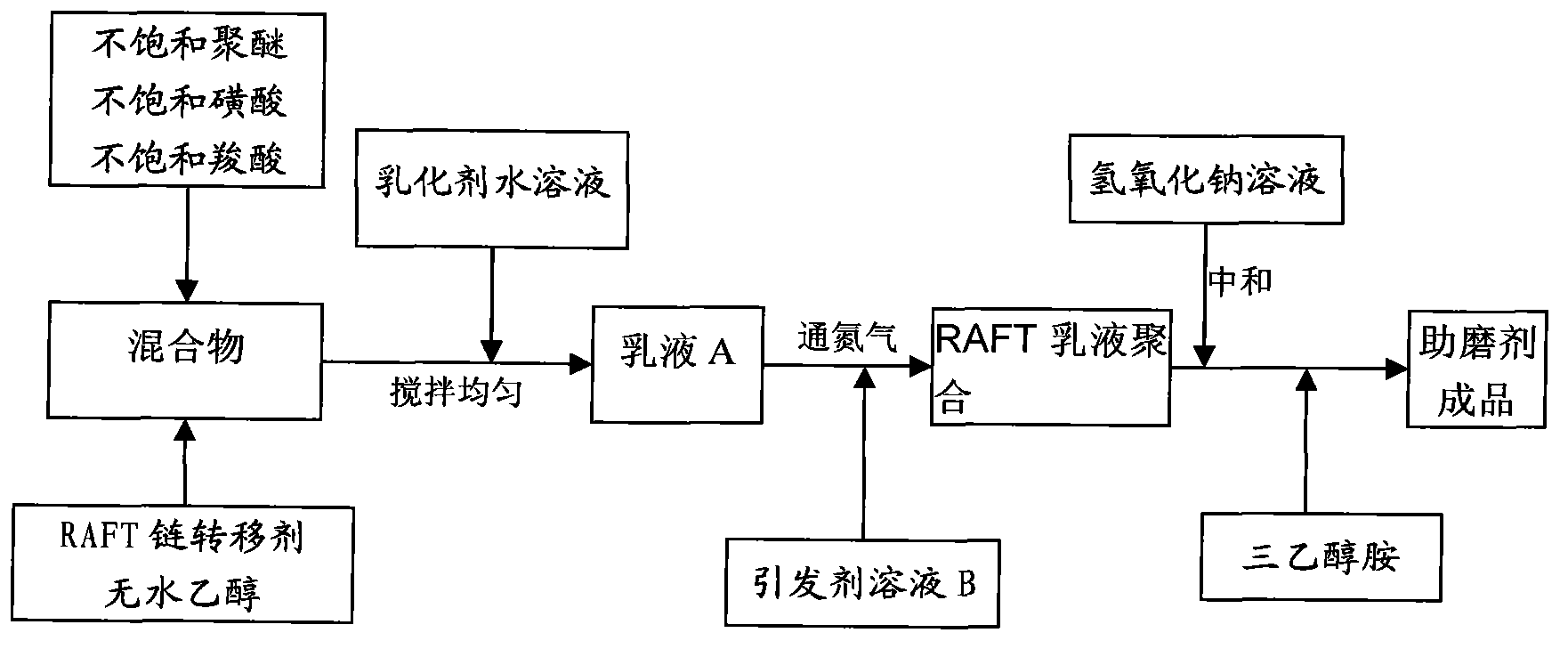

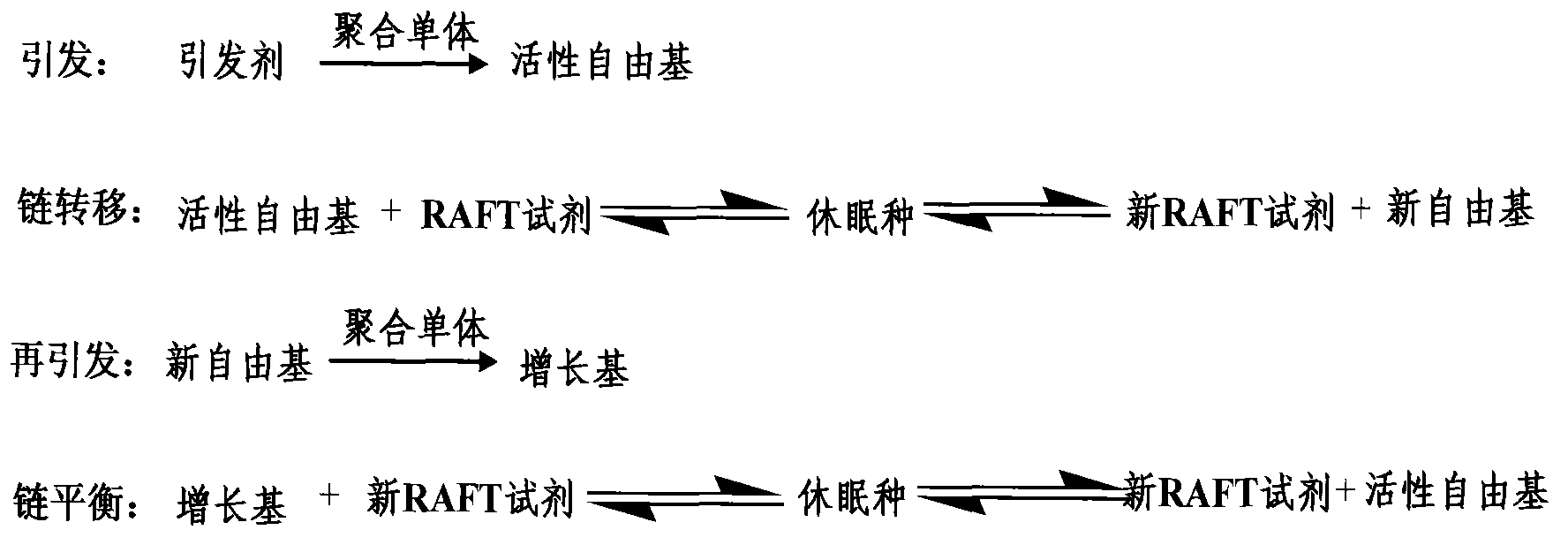

The invention relates to a preparation method of a high efficiency controllable polycarboxylic acids series cement grinding aid, which comprises the following steps: mixing nonsaturated polyether, nonsaturated sulfonic acid, unsaturated carboxylic acid, a RAFT chain transferring agent and absolute ethanol, adding an emulsifier aqueous solution, uniformly stirring and mixing to prepare an emulsion A; blending an initiator and water to obtain a solution B; under the condition that nitrogen is introduced in the emulsion A, heating to certain temperature and adding the solution B drop by drop, adjusting a flowmeter by finishing dropping after 1.0-2.5 hours, continuously reacting for 10-15 hours; after the reaction is finished, adding a sodium hydroxide solution with mass fraction of 30% and neutralizing to obtain the pH value between 6.5 and 7.5, adding triethanolamine which accounts for 3-7% of total mass of a reaction system in the solution drop by drop, and uniformly stirring to obtain the polycarboxylic acids series grinding aid product. The preparation principle is RAFT controllable / active free radical emulsion polymerization. The polycarboxylic acids series cement grinding aid has the advantages of low effective mixing amount and stable applicability, and has substantial effects for improving and enhancing the cement grinding aiding and cement physical properties.

Owner:LIAOCHENG TIANCHENG CEMENT TECH RES DEV

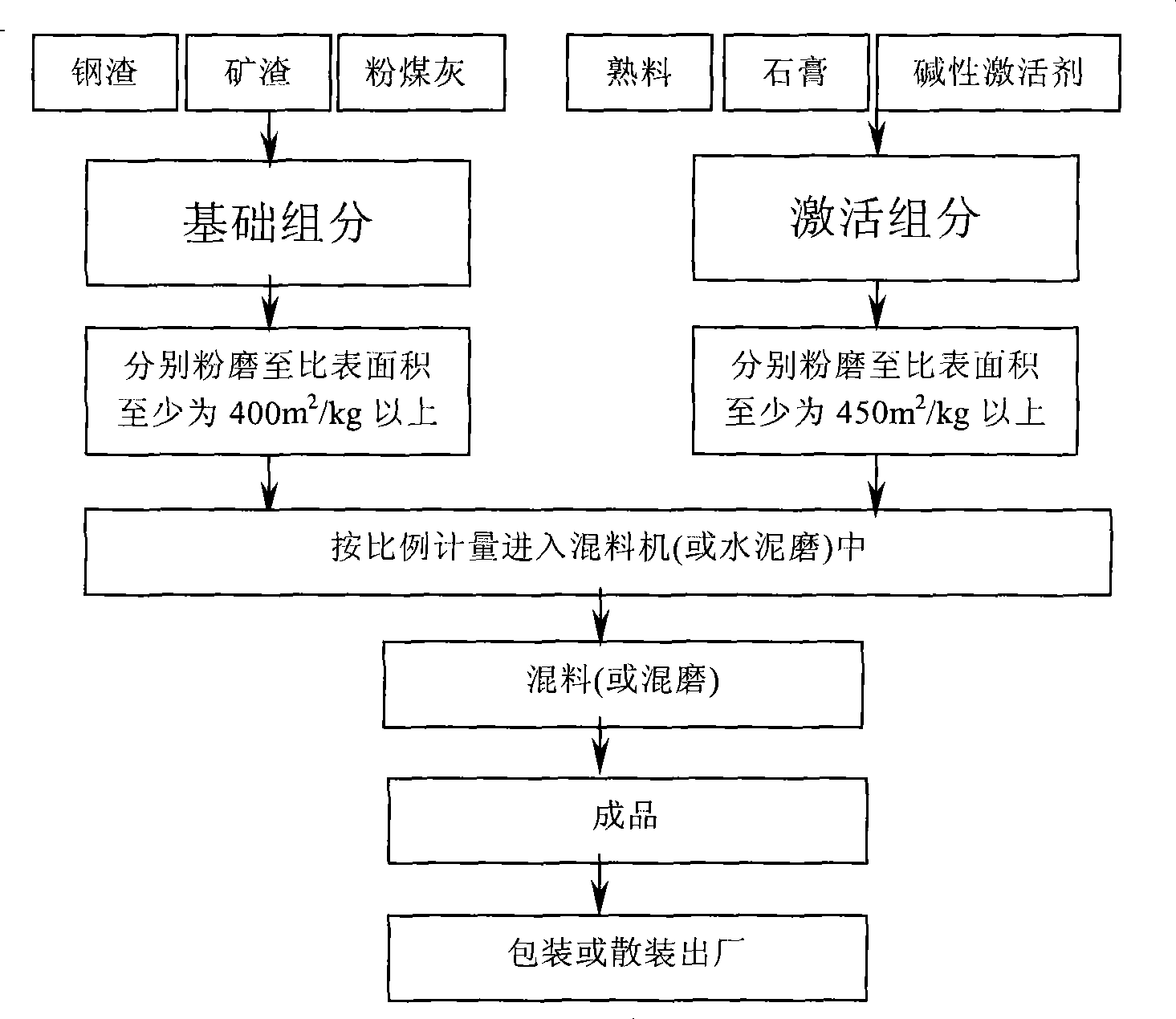

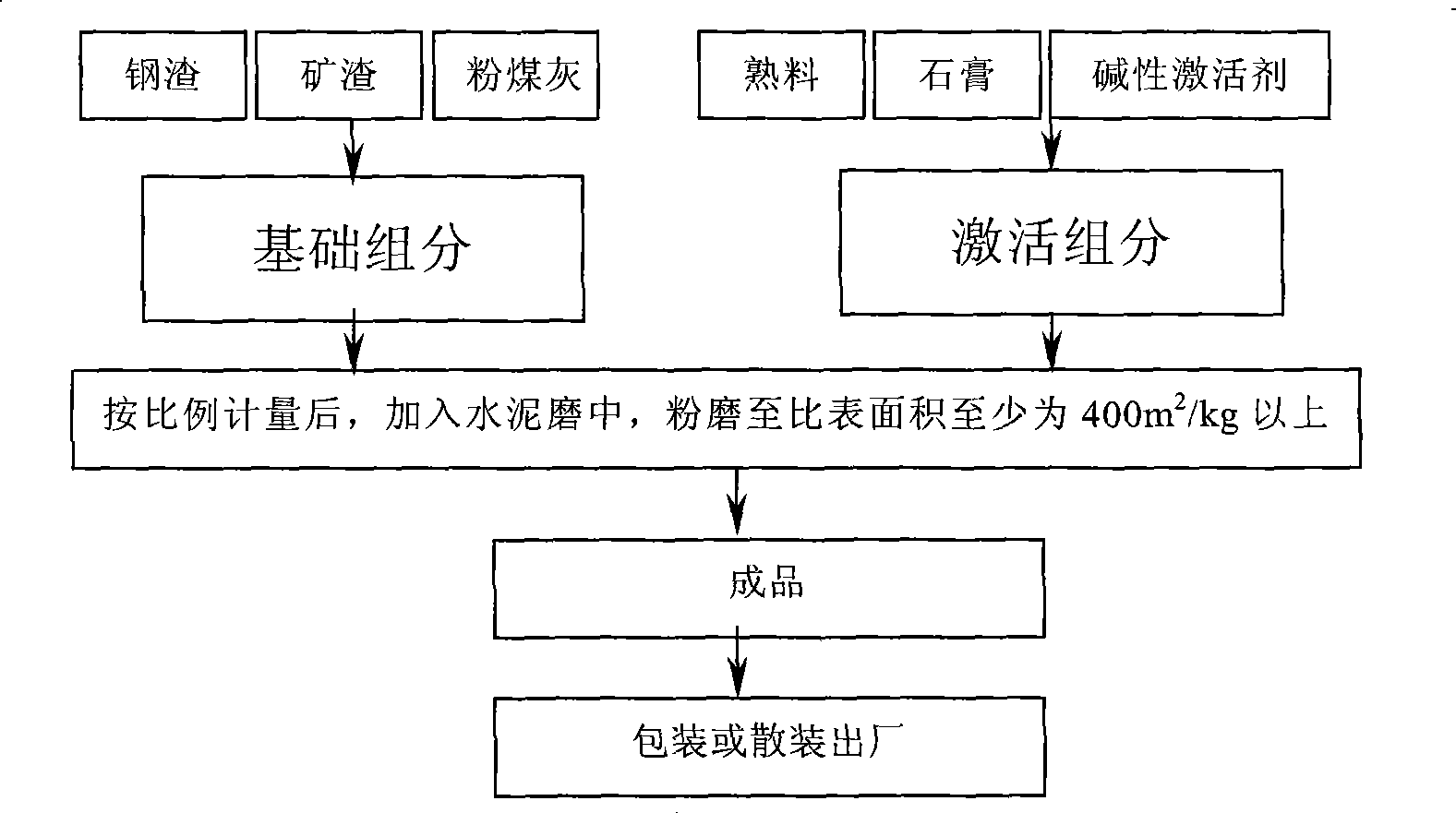

Steel slag ultra-sulphate cement and preparation method thereof

The invention relates to steel slag super-sulphate cement, which comprises the following components in weight percentage: 20 to 80 percent of steel slag, 5 to 65 percent of slag and / or fly ash, 5 to 25 percent of sulfate activator, 1 to 10 percent of cement clinker or calcium hydroxide, and 0.05 to 3 percent of alkaline activator. A method for preparing the steel slag super-sulphate cement comprises the following steps: grinding the steel slag, the slag and / or the fly ash, and further grinding the cement clinker, the sulfate activator and / or the alkaline activator separately; and adopting a mixed grinding method or a mixed material method to prepare the cement after the measurement according to a formulation, wherein when the mixed grinding method is adopted, each raw material is added into a cement grinding mill until the grinding is even after the measurement according to the formulation; and when the mixed material method is adopted, each raw material is added into a compulsory mixer after the measurement according to the formulation until the mixture is mixed sufficiently; or each raw material is directly added into the cement grinding mill to perform grinding after the measurement according to the formulation. The method can change wastes of the steel slag, the slag, and the fly ash which are difficult to be used into valuable, thereby contributing to preventing environment, saving piling ground, and reducing cost with simple and practical preparation process.

Owner:WUHAN UNIV OF TECH

Enhanced cement grinding aid and preparation method thereof

The invention relates to an enhanced cement grinding aid and a preparation method thereof. The enhanced cement grinding aid comprises the following raw materials by mass percent: 5 to 20% of triethanolamine, 5 to 20% of diethanolamine single isopropyl alcohol amine, 20 to 50% of diisopropyl monoethanolamine, 5 to 8% of propylene glycol, 2 to 8% of lignosulfonate, 3 to 10% of sodium lauryl sulfate, 3 to 10% of sodium humate and 10 to 30% of water. The invention further comprises the preparation method of the enhanced cement grinding aid. The prepared enhanced cement grinding aid has the advantages that the strength of cement is improved, the production efficiency is improved, and the cost is lowered.

Owner:史才军

Multifunctional cement grinding aid

A multifunctional grinding aid for cement is prepared from powdered coal ash, sodium chloride, triethanolamine, sodium silicate, zinc ore powder, benzyl trisodium, gypsum, and biethanediol. It can speed up grinding, and improving the strength and anti-radiation, antistatic, anticorrosion, antifreezing and antirust functions of cement.

Owner:SHENYANG LIGONG UNIV

Modified triethanolamine, preparation method and application thereof

InactiveCN101337788AReduce consumptionImprove early strengthCement productionPolymer scienceChemical reaction

The invention discloses modified triethanolamine, a preparation method thereof and various grinding aids produced by using the modified triethanolamine. The modified triethanolamine is a cross mixed ester product produced through the chemical reaction of triethanolamine, inorganic mixed acid and catalyzer at a temperature. Grinding aid intensifier in powdered form, aqueous liquid form and nonaqueous liquid form is prepared by effectively compounding the product with other components. The triethanolamine is converted into the cross mixed ester having large molecular weight, thus reducing the cost by about 30 percent; the modified triethanolamine is applicable for powder grinding process at high temperature. The cement grinding aid intensifier prepared by compounding triethanolamine with other materials has better grinding aid effect compared with such conventional grinding aids which are used separately as triethanolamine and so on, improves the early strength of cement and reduces the consumption of wrought material; the materials used are cheap, and are stored and transported easily. The multiform products (powdered and in liquid state) are widely applicable in the cement industry.

Owner:SHANDONG SHANSHUI CEMENT GRP CO LTD

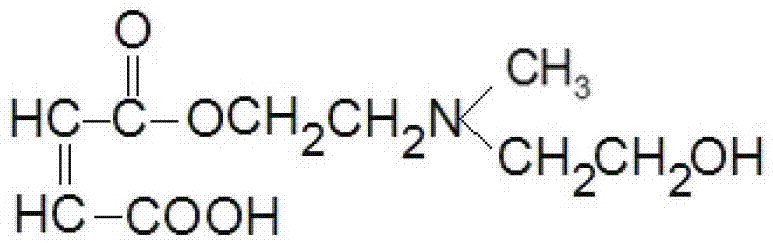

Alcohol amine-carboxylic acid polymer as well as preparation method and application thereof

The invention discloses an alcohol amine-carboxylic acid polymer. The molecular structural formula of the principal component of the alcohol amine-carboxylic acid polymer is as follows: a,b=2-20, and n=20-60. The invention also provides a method for preparing the alcohol amine-carboxylic acid polymer and an application thereof as a cement grinding aid. The alcohol amine-carboxylic acid polymer disclosed by the invention can improve the consistency of cement and a water-reducing agent as the cement grinding aid and has the advantages of outstanding grind aiding effect, excellent general effect, stability in property, low cost, small effective mixing amount and wide application prospect.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Cement grinding aid and preparation method thereof

ActiveCN102126843AImprove performanceNo adverse side effectsSolid waste managementCelluloseCarbamate

The invention discloses a cement grinding aid. The cement grinding aid comprises the following components in percentage by weight: 8 to 20 percent of triethanolamine, 0 to 10 percent of triisopropanolamine, 8 to 20 percent of diol byproduct, 0 to 10 percent of synthetic glycerine, 0 to 25 percent of molasses, 0 to 5 percent of calcium lignosulfonate, 0 to 15 percent of polyurethane, 0 to 10 percent of cystine, 3 to 5 percent of sorbitol, 5 to 10 percent of sodium carboxymethylcellulose, 0 to 5 percent of citric acid, 0 to 5 percent of silica powder, 0 to 5 percent of fly ash and the balance of water. The invention also discloses a preparation method of the cement grinding aid. The grinding aid can effectively improve the equipment-hour yield of a cement grinding mill, reduce energy consumption and remarkably improve cement performance, does not have adverse side effects on cement, reduces the using amount of cement clinkers by 4 to 10 percent, improves the equipment-hour yield of cement production by 6 to 10 percent, and has a good effect. The method has a unique process, a part of raw materials are treated by ultrasound, and the prepared grinding aid has high performance.

Owner:CHINA UNITED CEMENT LUNAN

Preparation method of functionalized adjustable amphiprotic polycarboxylates cement grinding aid

ActiveCN102134300AImprove grinding efficiencyReduce grinding power consumptionNitrogenCarboxylic acid

The invention discloses a preparation method of a functionalized adjustable amphiprotic polycarboxylates cement grinding aid. The method comprises the following steps: according to a certain ratio, adding unsaturated polyether, unsaturated sulfoacid and water in a kettle; preparing unsaturated acid, a catalyst, a ligand and water into an aqueous solution A, and preparing an initiator and water into an aqueous solution B; heating the kettle to 75-95DEG C under the protection of nitrogen, and dropwise adding the aqueous solutions A and B at the same time for 3-5 hours; after the dropwise addition is finished, reacting under heat insulation condition for 1 hour; and after the reaction is finished, adding a certain part of sodium hydroxide for neutralization, and adding water for dilution until the concentration is 40% to obtain a finished product. In the invention, an active / controllable free radical polymerization and macromolecule design theory is adopted to research and develop the functionalized adjustable amphiprotic polycarboxylates cement grinding aid aiming at the effect required by the cement grinding aid, so as to prepare the product of the functionalized adjustable cement grinding aid.

Owner:KZJ NEW MATERIALS GROUP CO LTD +2

Blast furnace slag liquid grinding aid and preparation method thereof

InactiveCN101597655AEasy to measure and addImprove grinding efficiencyRecycling and recovery technologiesSlagCement grinding

The invention discloses a blast furnace slag liquid grinding aid, which comprises the following components by mass percentage: 10%-20% of diglycol, 10%-15% of cane sugar slag waste liquid, 10%-20% of sorbitol, 10%-20% of glycerin, 1-5% of sodium tripolyphosophate, 1-10% of sodium carbonate, and the remainder being water. The grinding aid prepared by the invention has the advantages of remarkably improving slag grinding output, enhancing slag micro powder strength, easily purchasing raw materials with low cost and the like. The further optimized scheme for the invention is as follows: 1-5% of glycol and 1-5% of sodium dodecyl benzene sulfonate by mass percentage are added into the grinding aid, which can further enhance the effect of slag grinding efficiency. At the same time, the invention also discloses a preparation method of the liquid cement grinding aid.

Owner:NANJING YONGNENG MATERIALS

Reinforced cement grinding aid

The invention discloses a reinforced cement grinding aid which comprises the following ingredients in parts by weight: 10-15 parts of diethanolisopropanolamine, 3-5 parts of triethanolamine, 4-6 parts of sodium acetate, 6-10 parts of sodium thiosulfate, 10-12 parts of sodium chloride, 4-6 parts of sodium carboxymethylcellulose and 15-18 parts of papermaking black liquid. The reinforced cement grinding aid is low in mixing amount, good in reinforcement effect and low in cost.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com