Composite high-efficient liquid cement grinding aid

A cement grinding aid and liquid technology, which is applied in the field of cement process admixtures, can solve the problems of poor solid-liquid stable suspension persistence, poor grinding aid effect, and high cost of use, and achieve good grinding aid effect, wide application range, and low cost of use. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

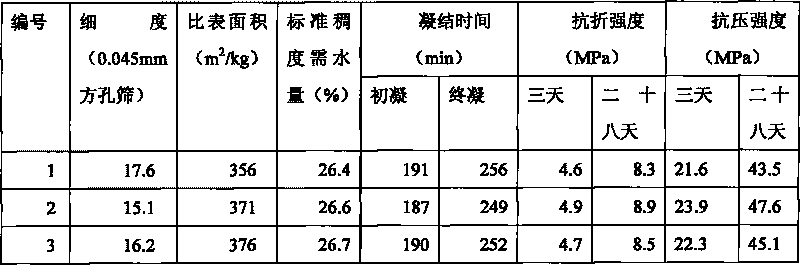

example 1

[0021] First add 460Kg of water to the reaction tank, heat it to 45°C, add 60Kg of calcium lignosulfonate, and turn on the stirring blade at the same time, add while stirring, after the calcium lignosulfonate is completely dissolved, add 60Kg of ethylene glycol and 80Kg of silicic acid Sodium, stir for about 30 minutes; then add 200Kg triethanolamine and 60Kg triisopropanolamine while stirring, and stir for 30 minutes; finally add 80Kg molasses while stirring; The magnetic field of 7000 Gauss is used for magnetization treatment, stirring for 3 hours while magnetizing, filtering to remove the precipitate, and the clear liquid is filtered with a 325-mesh sieve to obtain the finished product.

[0022] The above-mentioned finished product was placed for 2 years without any precipitation.

example 2

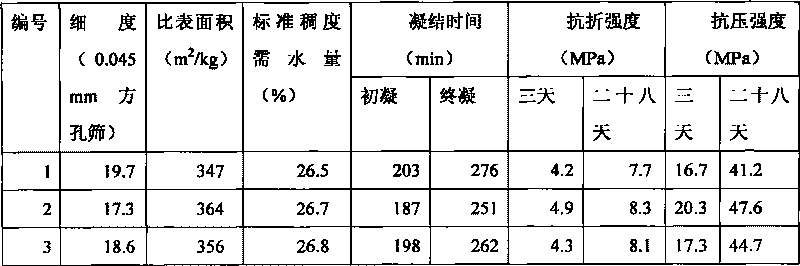

[0024] First add 520Kg of water to the reaction tank, heat it to 45°C, add 80Kg of calcium lignosulfonate, and turn on the stirring blade at the same time, add while stirring, after the calcium lignosulfonate is completely dissolved, add 80Kg of ethylene glycol and 60Kg of silicic acid Sodium, stir for about 30 minutes; then add 120Kg triethanolamine and 80Kg triisopropanolamine while stirring, and stir for 30 minutes; finally add 60Kg molasses while stirring; The magnetic field of 6000 gauss is used for magnetization treatment, stirring for 3 hours while magnetizing, filtering to remove the precipitate, and the clear liquid is filtered with a 325-mesh sieve to obtain the finished product.

[0025] The above-mentioned finished product was placed for 2 years without any precipitation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com