A kind of complexed ferrous activated persulfate oxidation water treatment method

A technology for activating persulfate and a treatment method, applied in the field of complex ferrous activated persulfate oxidizing water treatment, can solve the problems of low equipment requirements, low energy consumption, low mineralization rate of pollutants, etc. The effect of acid cost, treatment cost reduction, and removal efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A complexed ferrous activated persulfate oxidation water treatment method, the specific steps are as follows:

[0031] (1). Take the printing and dyeing wastewater and measure the COD of the wastewater cr It is 296mg / L, and the pH is 4.0. Take two oxidation tanks, add 500mL of waste water to each of the two oxidation tanks, add 16.7 mg of sodium oxalate to one oxidation tank and stir thoroughly, and add no complexing agent to the other.

[0032] (2). Add 172 mg of ferrous sulfate heptahydrate to each of the above two oxidation tanks and stir fully.

[0033] (3). Add 148 mg of sodium persulfate to each of the two oxidation tanks in step (2), stir well, and react for 1 hour.

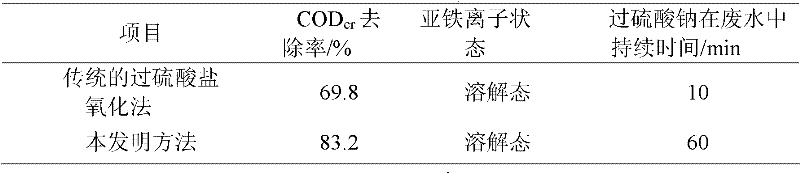

[0034] The results are shown in Table 1, and the results in Table 1 show that the complexed ferrous activated persulfate oxidation water treatment technology established by the present invention ensures the persistence and high efficiency of the persulfate oxidation method.

[0035] Table 1 Degra...

Embodiment 2

[0038] A complexed ferrous activated persulfate oxidation water treatment method, the specific steps are as follows:

[0039] (1) Take the printing and dyeing wastewater and measure the COD of the wastewater cr It is 348mg / L, and the pH is 6.8. Take two oxidation tanks, add 500mL waste water to each of the two oxidation tanks, add 43.0 mg of trisodium citrate dihydrate to one oxidation tank and stir thoroughly, and add no complexing agent to the other one.

[0040] (2). Add 203 mg of ferrous sulfate heptahydrate to each of the above two oxidation tanks and stir fully.

[0041] (3). Add 174 mg of sodium persulfate to each of the two oxidation tanks in step (2), stir well, and react for 4 hours.

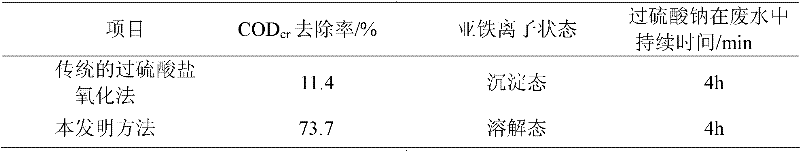

[0042] Its result is as shown in table 2, and the result of table 2 shows that the complexed ferrous activated persulfate oxidation water treatment technology that the present invention establishes guarantees that persulfate oxidation method can be applicable to the waste water under...

Embodiment 3

[0046] A complexed ferrous activated persulfate oxidation water treatment method, the specific steps are as follows:

[0047] (1). Take the printing and dyeing wastewater and measure the COD of the wastewater crIt is 268mg / L, and the pH is 9.2. Take two oxidation tanks, add 500mL waste water to each of the two oxidation tanks, add 24.0 mg of sodium D-gluconate to one oxidation tank and stir thoroughly, and add no complexing agent to the other.

[0048] (2). Add 157 mg of ferrous sulfate heptahydrate to each of the above two oxidation tanks and stir fully.

[0049] (3). Add 134 mg of sodium persulfate to each of the two oxidation tanks in step (2), stir well, and react for 4 hours.

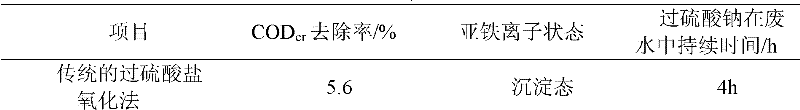

[0050] Its result is as shown in table 3, and the result of table 3 shows that the complexed ferrous activated persulfate oxidation water treatment technology that the present invention establishes guarantees that persulfate oxidation method can be applicable to the waste water under alkaline neu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com