Liquid cement grinding aid

A cement grinding aid and liquid technology, applied in the field of cement manufacturing, can solve the problems of insignificant cement strengthening effect, high amount of triethanolamine, toxic components, etc., and achieve the effect of increasing cement output, low cost and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

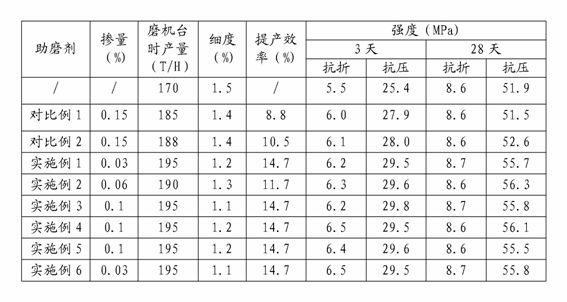

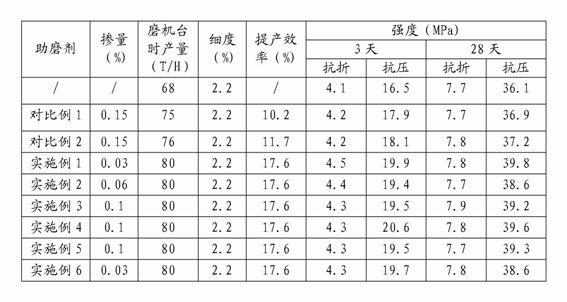

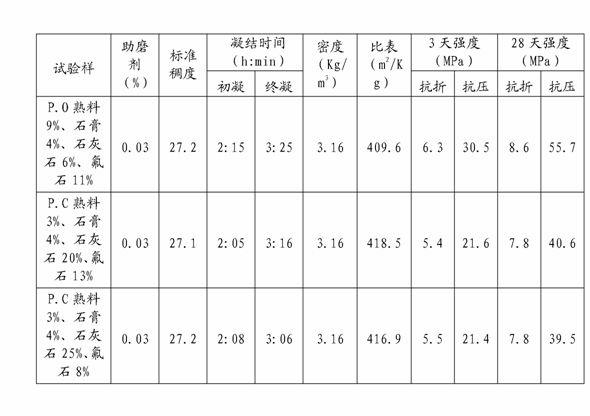

Examples

Embodiment 1

[0017] The liquid cement grinding aid (1 ton) in this example includes raw materials with the following weight contents: 240 kg of triethanolamine, 160 kg of polyether polyol, 100 kg of molasses, 30 kg of calcium formate, 50 kg of sodium acetate, sulfide 50 kilograms of sodium sulfate, the configuration method is to weigh calcium formate, sodium acetate and sodium thiosulfate according to the above weight and add them to the reactor, add water and stir for 30 minutes, so that the raw materials are fully dissolved in water, and then add them to the reactor according to the amount Molasses, the temperature is controlled at 60°C, stirred at constant temperature for 15 minutes, then triethanolamine and polyether polyol are added into the reaction kettle according to the amount, and stirred continuously for 30 minutes, and finally a uniform mixed liquid is formed, which is the liquid cement described in the present invention Grinding aid.

Embodiment 2

[0019] The liquid cement grinding aid (1 ton) in this example includes raw materials with the following weight contents: 200 kg of triethanolamine, 120 kg of polyester polyol, 130 kg of molasses, 20 kg of calcium formate, 40 kg of sodium acetate, sulfide Sodium sulfate is 80 kg, and its configuration method is to weigh calcium formate, sodium acetate and sodium thiosulfate according to the above weight and add them to the reactor, add water and stir for 30 minutes, so that the raw materials are fully dissolved in water, and then add them to the reactor according to the amount Molasses, control the temperature at 60°C, stir at constant temperature for 15 minutes, then add triethanolamine and polyester polyol into the reaction kettle according to the amount, continue stirring for 30 minutes, and finally form a uniform mixed liquid, which is the liquid cement of the present invention Grinding aid.

Embodiment 3

[0021] The liquid cement grinding aid (1 ton) in the present embodiment includes the following raw materials by weight: 100 kilograms of triethanolamine, 100 kilograms of polyether polyol, 60 kilograms of tripropylene glycol, 120 kilograms of molasses, 30 kilograms of calcium formate, 30 kilograms of sodium acetate and 50 kilograms of sodium thiosulfate, the configuration method is to weigh calcium formate, sodium acetate and sodium thiosulfate according to the above weight and add them to the reaction kettle, add water and stir for 30 minutes, so that the raw materials are fully dissolved in water, and then Add molasses to the reaction kettle according to the amount, control the temperature at 60°C, stir at constant temperature for 15 minutes, then add triethanolamine, polyether polyol and triglyceride into the reaction kettle according to the amount, continue stirring for 30 minutes, and finally form a uniform The mixed liquid is the liquid cement grinding aid described in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com