Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Reduce the amount of clinker" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

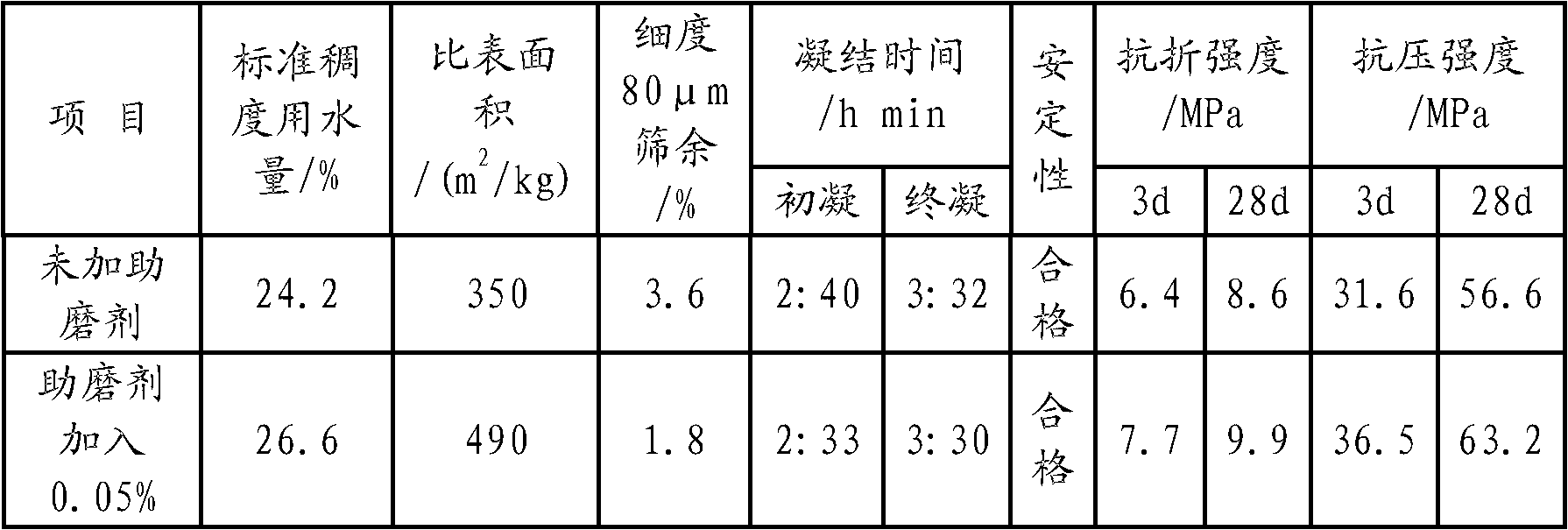

Chlorine-free powdery cement grinding aid and preparation method thereof

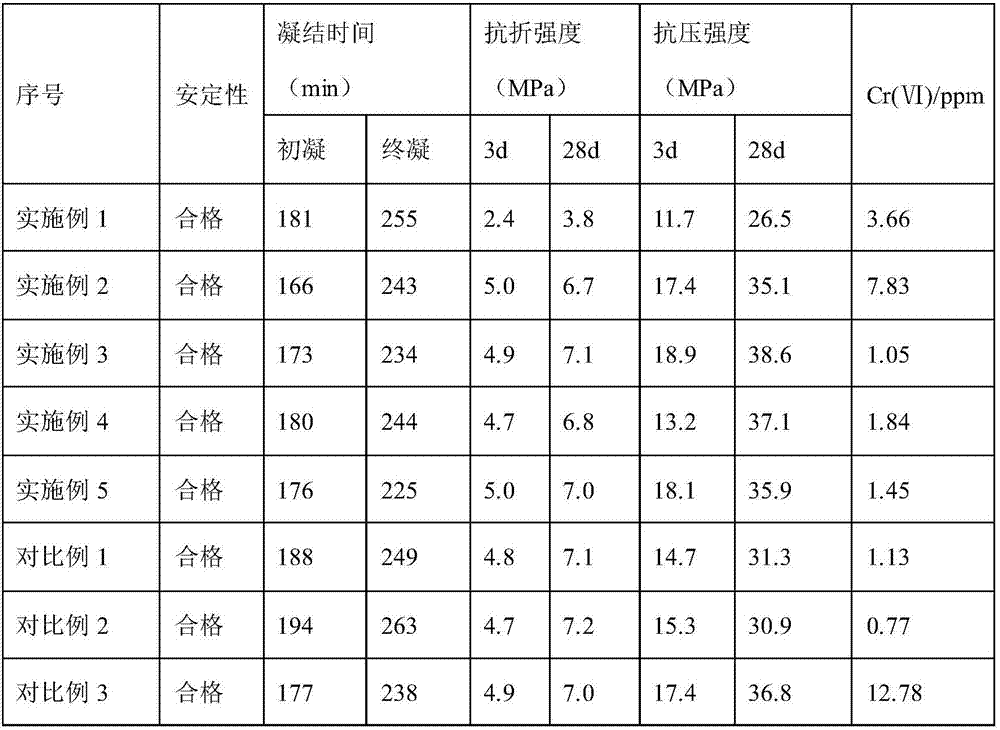

InactiveCN101665338AHigh strengthStrong compound synergistic effectCement productionSulfateLignosulfonates

The invention discloses a chlorine-free powdery cement grinding aid suitable for fly ash, which comprises the following components in parts by weight: 0-5 parts of alkanolamine, 2-5 parts of polylol,15-75 parts of sulfate, 5-20 parts of acetate, 0-5 parts of lignosulphonate, 2-6 parts of carbohydrate organic matter, 5-25 parts of miltonite, 0-25 parts of carbamide and 5-50 parts of inorganic carrier material. The invention also discloses a preparation method of the chlorine-free powdery cement grinding aid suitable for the fly ash. A compound grinding aid can lower the cement cost and uses the fly ash for replacing partial clinker to save the clinker dosage by 10-15 percent on the premise of keeping the cement strength unchanged, and uses extra 10-15 parts of fly ash without increasing the required water amount of cement standard consistency; the cost of the cement per ton is lowered by more than 10 Yuan.

Owner:NANJING ZHUJI ENERGY SAVING TECH

Composite cement grinding aid and preparation method thereof

The invention discloses a composite cement grinding aid and its preparation method. According to a formula, the composite cement grinding aid comprises: a grinding agent, a reinforcing agent, a surfactant, molasses, N, N-bis(2-hydroxyethyl)isopropanolamine and water. The composite cement grinding aid can enhance the fluidity of materials during grinding, effectively reduce overgrinding phenomenon of a mill, improve adhesion of the materials to a grinding body, a lining board, and a bin partition board as well as the self agglomeration phenomenon of the materials, thus increasing the machine-hour yield of the cement grinding mill by l0%-20%, enhancing the cement specific surface area to 20-40m<2> / Kg, reducing the sieve residue, optimizing cement particle gradation, promoting cement clinker hydration, and improving the cement mixture activity. The 3-day compressive strength is increased by 3-5MPa, and the 28-day compressive strength is increased by 4-8MPa. The clinker consumption is reduced by 6-10%. The cement production cost is effectively reduced, the cement security is improved, and the adaptability of cement and concrete admixtures are improved.

Owner:ZHEJIANG HUAJUN BUILDING MATERIAL

Liquid cement grinding additive

InactiveCN101696096AImprove early and late strengthReduce the amount of clinkerEthylenediamineDiethylenetriamine

The invention provides a liquid cement grinding additive, which comprises the following components in percentage by weight: 10 to 20 percent of tetrahydroxyethyl-ethylenediamine, 10 to 20 percent of ethoxyl-diethylenetriamine, 10 to 15 percent of diethylene glycol, 5 to 10 percent of polyethylene glycol, 2 to 5 percent of sodium tripolyphosphate, 3 to 5 percent of calcium lignosulphonate, 0 to 10 percent of tri-isopropanolamine, 0 to 8 percent of sodium gluconate, and the balance of water, wherein the molecular weight of the polyethylene glycol is between 200 and 400. As a preferred scheme of the invention, the content of the tri-isopropanolamine is between 5 and 10 percent, and the content of the sodium gluconate is between 5 and 8 percent. A cement and concrete admixture using the liquid cement grinding additive has good adaptability, can significantly improve the grinding efficiency of a grinding machine and improve the strengths of the cement in an early period and a later period by 2 to 4 MPa, or can reduce the clinker dosage by 4 to 8 percent and increase the adding volume of a mixed material by 4 to 8 percent in the cement under a condition of keeping the same cement strength grade.

Owner:NANJING YONGNENG MATERIALS

High efficiency cement composite grinding additive and preparation method thereof

InactiveCN101618955AIncrease incorporationIncrease productionSolid waste managementAluminiteSodium metasilicate

The invention discloses a high efficiency cement composite grinding additive, comprising the following raw materials by weight percent: 10-25% of calcined gypsum, 10-30% of calcined aluminite, 20-40% of sodium metasilicate, 2-4% of triethanolamine, 0.5-2% of polyacrylate, 0.5-3% of dispersant and 20-30% of zeolite powder. The preparation method of the high efficiency cement composite grinding additive comprises the following steps: first selecting raw materials, then dripping liquid raw materials-triethanolamine and polyacrylate TH-1100 with a liquid pump in zeolite powder, then preparing reinforced grinding component with a dry powder mixer, finally adding the reinforced grinding component, calcined gypsum, calcined aluminite, sodium metasilicate and dispersant in a kneader to mix for 20-30min and obtaining the product. The product has prominent grinding aid, and can increase the hourly output of mills by 10-15%, reduce the consumption of electricity, and increase the cement 3-day compression strength and the cement 7-day compression strength by more than 20% and the cement 28-day compression strength by 10-15%.

Owner:葫芦岛市辽西混凝土外加剂有限公司

Composite cement grinding aid

The invention discloses a composite cement grinding aid, which is characterized by being prepared from the following components in percentage by weight: 5-15 percent of triethanolamine, 20-30 percent of diisopropanolamine, 15-20 percent of polymeric alkylol amine, 5-10 percent of sodium polyphosphate, 10-20 percent of lignosulfonate, 5-10 percent of syrup and the balance of water. By adopting the composite cement grinding aid, the grinding assisting effect of the conventional grinding aid is kept, the fluidity and dispersity of a material in a grinder can be enhanced remarkably, the bonding property of the material is reduced, the graduation of particles in the grinder is changed, the activity of the material is excited, the grinding efficiency is increased by 3-8 percent, the using amount of cement clinker is reduced by 4-10 percent, the hourly output of a cement grinding table is increased by 8-15 percent, the tensile strength of cement is enhanced by 4.1-5MPa within three days, the tensile strength of cement is enhanced by 6.7-7.9MPa within two days, the adaptability of an additive is enhanced, the cement production cost is reduced effectively, and a good energy-saving effect is achieved.

Owner:惠州市富力新技术有限公司

Copper smelting typical waste slag coordinated curing/stabilizing treatment method

ActiveCN108273830AAchieving processing powerAchieve stabilizationSolid waste disposalSlagEconomic benefits

The invention discloses a copper smelting typical waste slag coordinated curing / stabilizing treatment method. According to the method, copper smelting industry typical waste slag (flotation slag, neutralization slag and gypsum slag) serves as the raw material, and a small number of exciting agents are adopted for assisting. A finished product is prepared through the technologies of flotation slagmodification pretreatment, crushing, ball grinding, burdening, injection molding, forming, curing and the like. By means of the method, the waste resource in the copper smelting industry is sufficiently utilized. The problem about curing / stabilizing of typical waste slag containing arsenic and other toxic metals in the copper smelting industry is solved; and meanwhile waste can be reutilized, andthe environment and economic benefits are obvious.

Owner:CENT SOUTH UNIV

Cement grinding aid and using method thereof

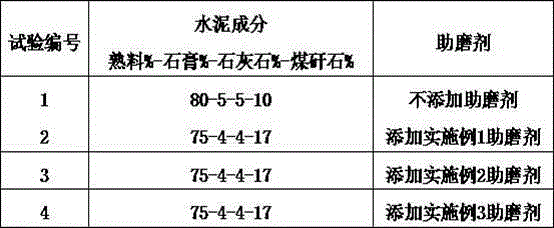

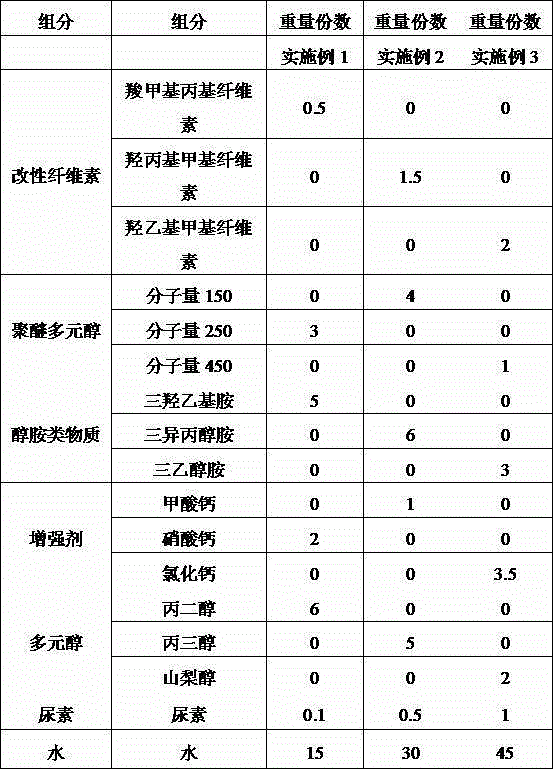

The invention belongs to a cement auxiliary and particularly relates to a cement grinding aid and a using method thereof. The cement grinding aid is prepared from the following components in parts by weight: 0.5-5 parts of modified cellulose, 1-5 parts of polyether polyol, 2-10 parts of hydramine substances, 1-9 parts of an enhancer, 2-10 parts of polyhydric alcohol, 0.1-1 part of urea and 14-45 parts of water. The grinding aid for a cement processing process provided by the invention plays a role of adjusting the particle sizes of cement, enhances the cement strength and reduces the energy consumption in the cement production process.

Owner:仇鹏

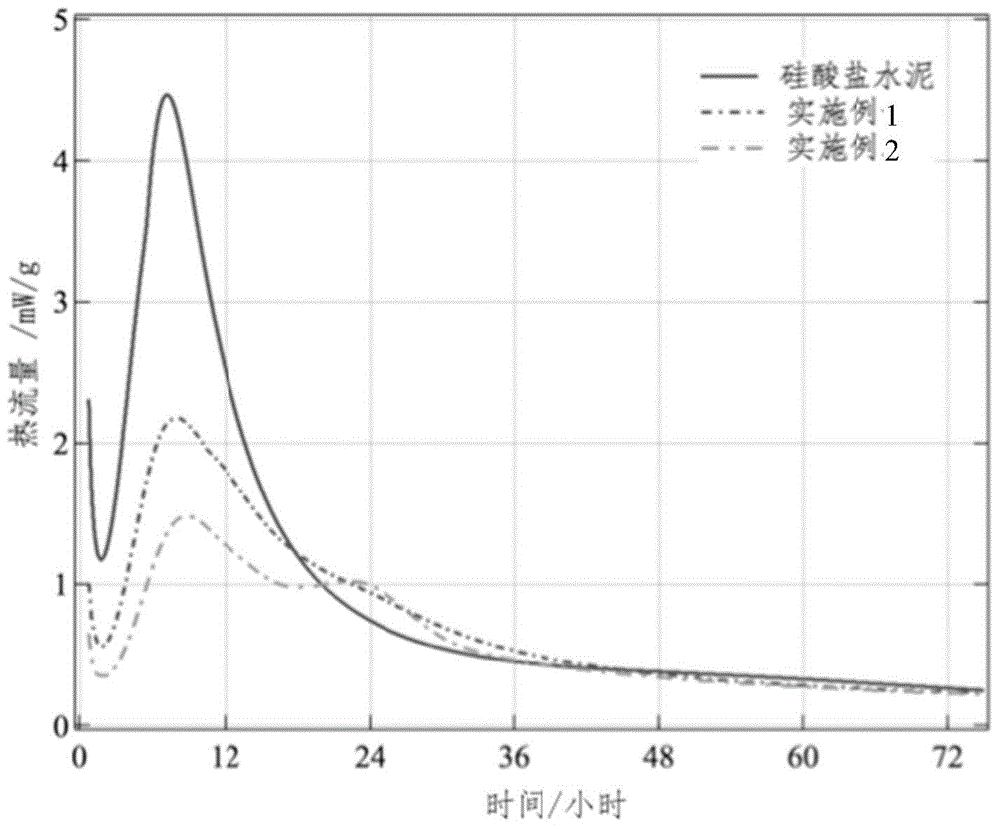

Low-heat micro-expansion composite cement and preparation method thereof

ActiveCN104529319AReduce heat of hydrationReduce autogenous shrinkageSolid waste managementGypsumIndustrial waste

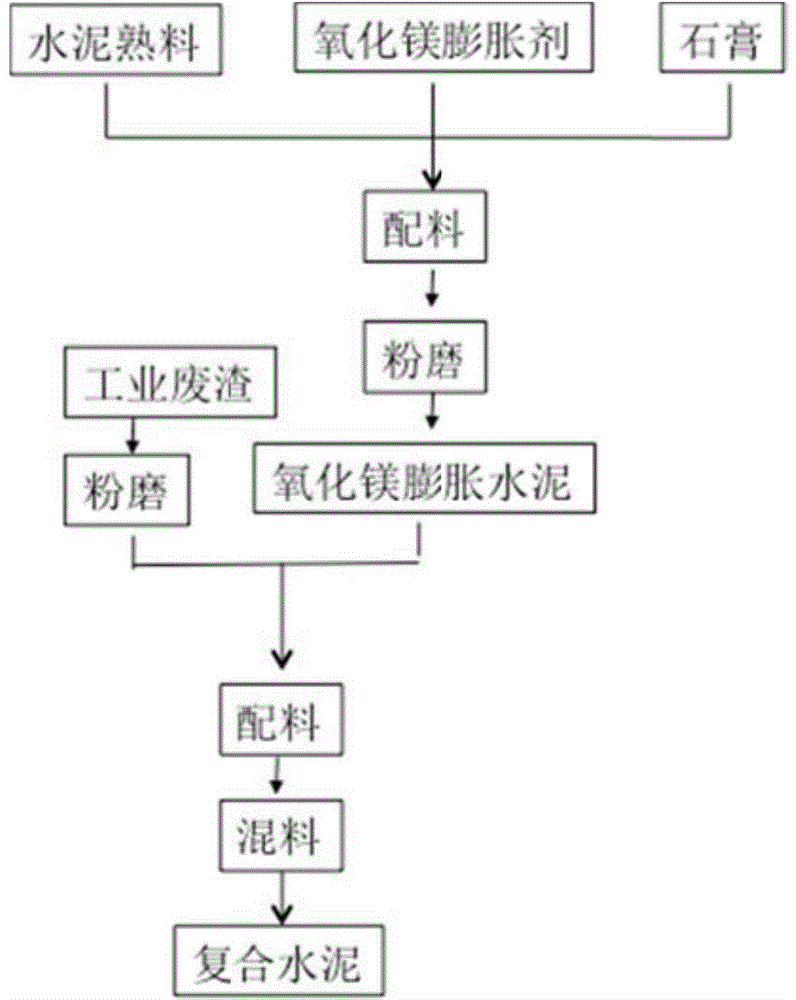

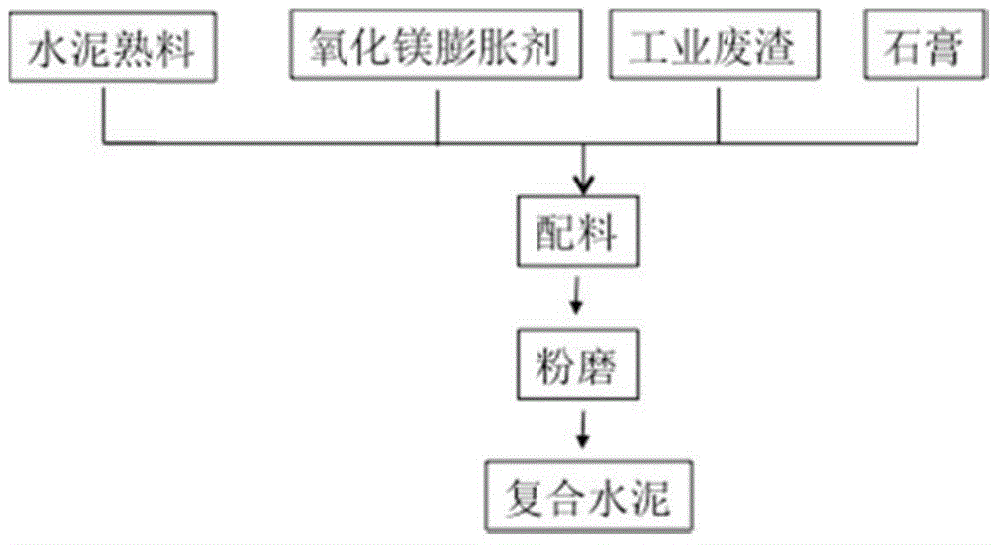

The invention relates to a low-heat micro-expansion composite cement and a preparation method thereof. The composite cement comprises the following components: 1-8 parts of a magnesium oxide expanding agent, 25-70 parts of industrial waste residue, 25-70 parts of portland cement clinker, and 1-4 parts of gypsum. The preparation method includes: mixing and grinding the magnesium oxide expanding agent, the portland cement clinker and the gypsum to prepare magnesium oxide expansive cement with a specific surface area of not lower than 300m<2> / kg, then mixing the magnesium oxide expansive cement with the industrial waste residue evenly according to the ratio to prepare composite cement; or burdening and mixing the magnesium oxide expanding agent, the cement clinker, the gypsum and the industrial waste residue in proportion, and carrying out grinding together to obtain composite cement. The composite cement prepared by the method has fineness of 80-micrometer square hole screen residue of less than 10%, and a specific surface area of not less than 300m<2> / kg. The composite cement provided by the invention can generate expansion in the early stage, also can generate expansion in the middle and late stage, simultaneously satisfies compensation of concrete shrinkage in the early stage and the middle and late stage, and prevents shrinkage crack of concrete.

Owner:NANJING UNIV OF TECH

Anti-cracking reinforced ecological cement

InactiveCN101134645AProlong initial setting timeReduce early thermal cracksSolid waste managementGypsumFiber

The anticracking high strength ecological cement is produced with Portland clinker 35-80 wt%, fly ash 5-30 wt%, ferroalloy slag 1.0-30 wt%, boiler slag 5-40 wt%, gangue 10-40 wt%, grinding aid 0.1-2.0 wt%, gypsum 0.5-10 wt%, reinforcing fibrous inorganic mineral material 1-20 wt% and polymer fiber 0.01-10 wt%, and through grinding and mixing. Compared with available technology, the anticracking high strength ecological cement of the present invention has the advantages of low hydration heat, low shrinkage, low water demand, high early strength, etc.

Owner:JIANGXI GANFENG CEMENT

Calcium-poor and silicon-rich ecological cement and application thereof

ActiveCN105502973ALow costAchieving processing powerCement productionPortland cementUltimate tensile strength

The invention discloses a calcium-poor and silicon-rich ecological cement and application thereof. The cement is prepared from a silicon-rich body and a calcium-rich body in a mixing mode. The silicon-rich body is obtained by adding a small amount of alkali metal salt into a wide-source silicon-aluminum material and then carrying out low-temperature calcination, and the calcium-rich body is composed of a raw material releasing Ca(OH)2 when hydrated and a raw material containing CaSO4. Compared with portland cement, the calcium-poor and silicon-rich ecological cement is good in early strength property, and the long-term strength can meet most use requirements; the raw materials of the calcium-poor and silicon-rich ecological cement are easy to obtain, and carbon emission, energy consumption, pollution and the like are substantially reduced; furthermore, a large quantity of solid industrial residues can be consumed, and the calcium-poor and silicon-rich ecological cement has important economic and social value.

Owner:HUNAN UNIV OF SCI & TECH

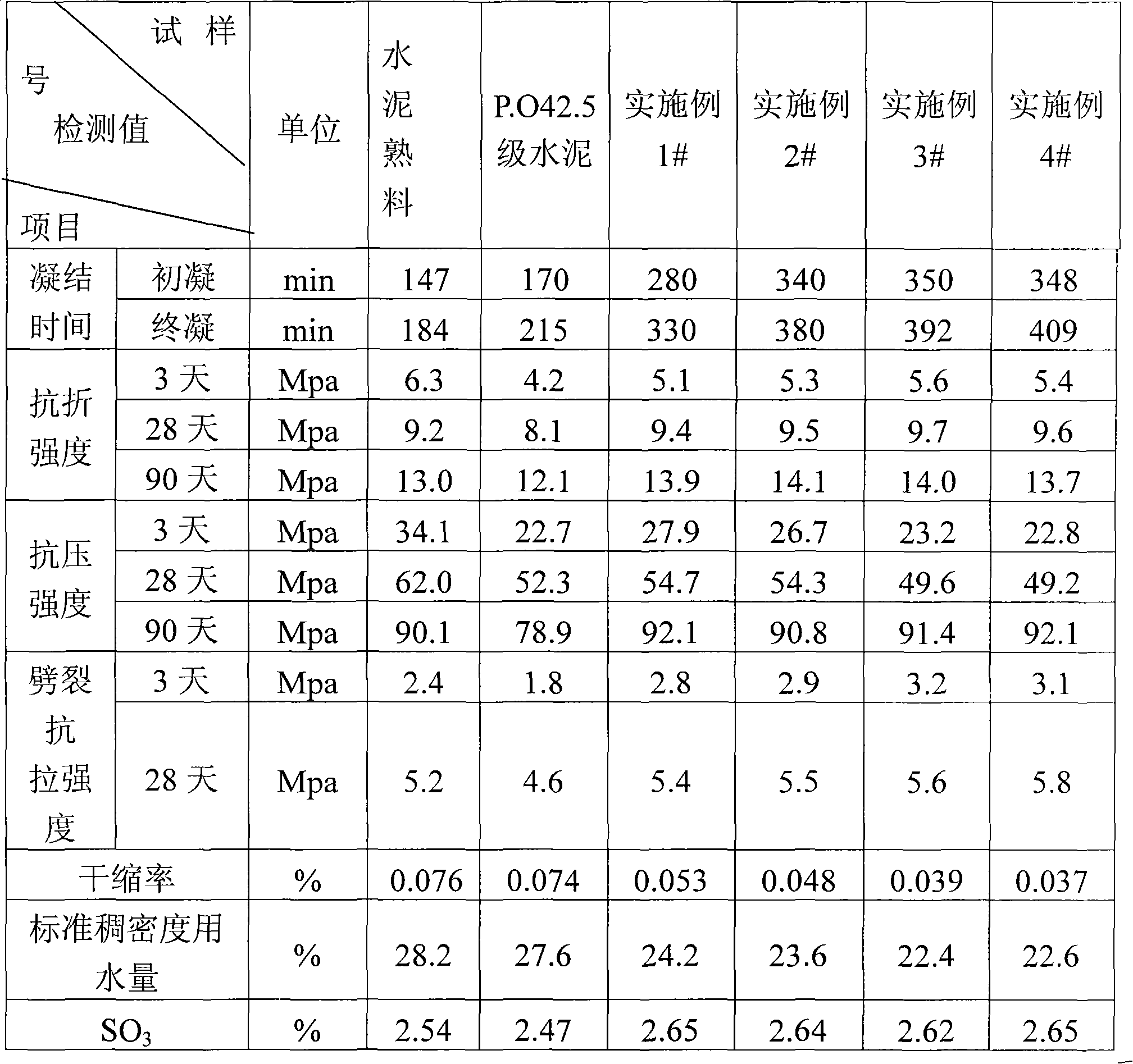

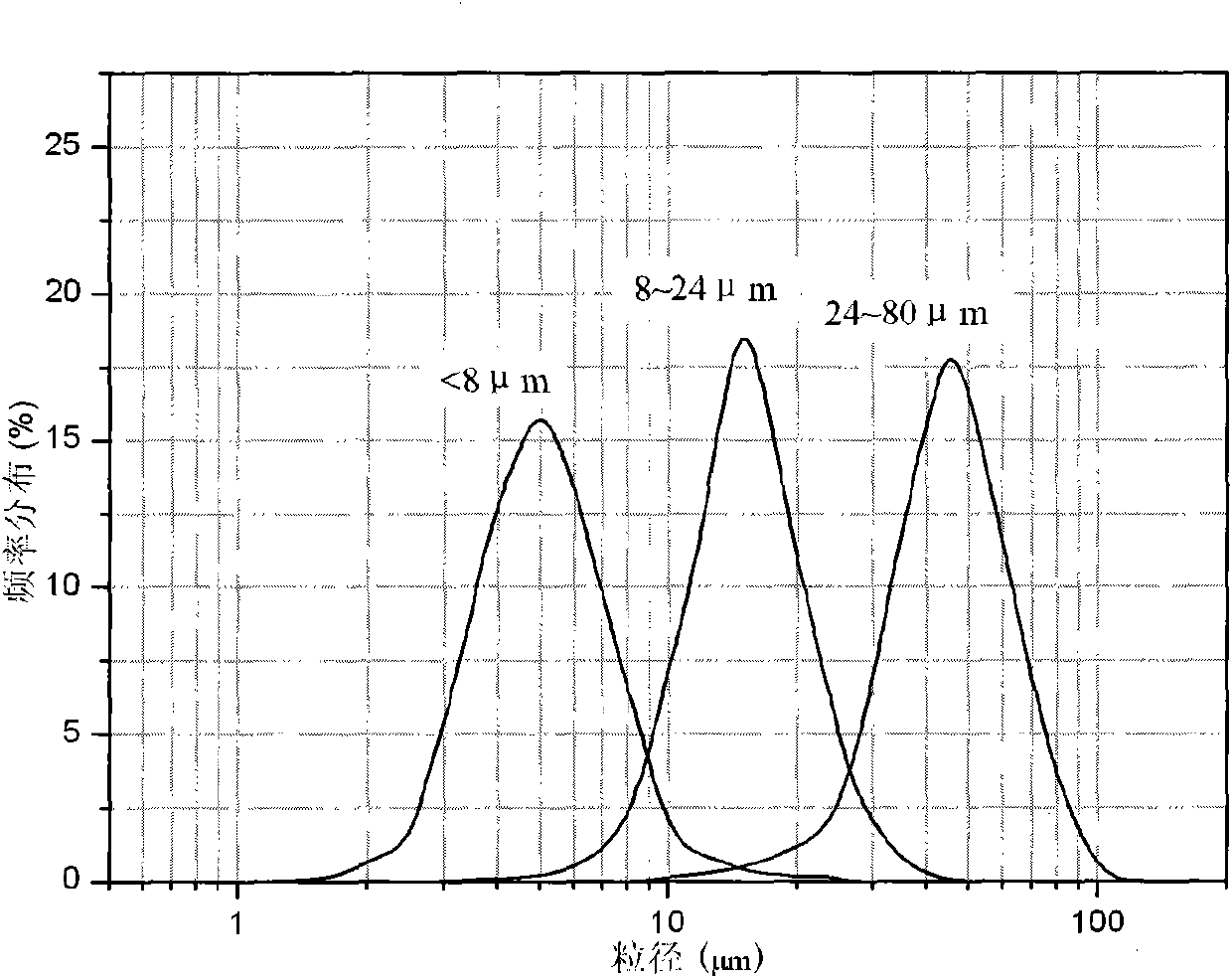

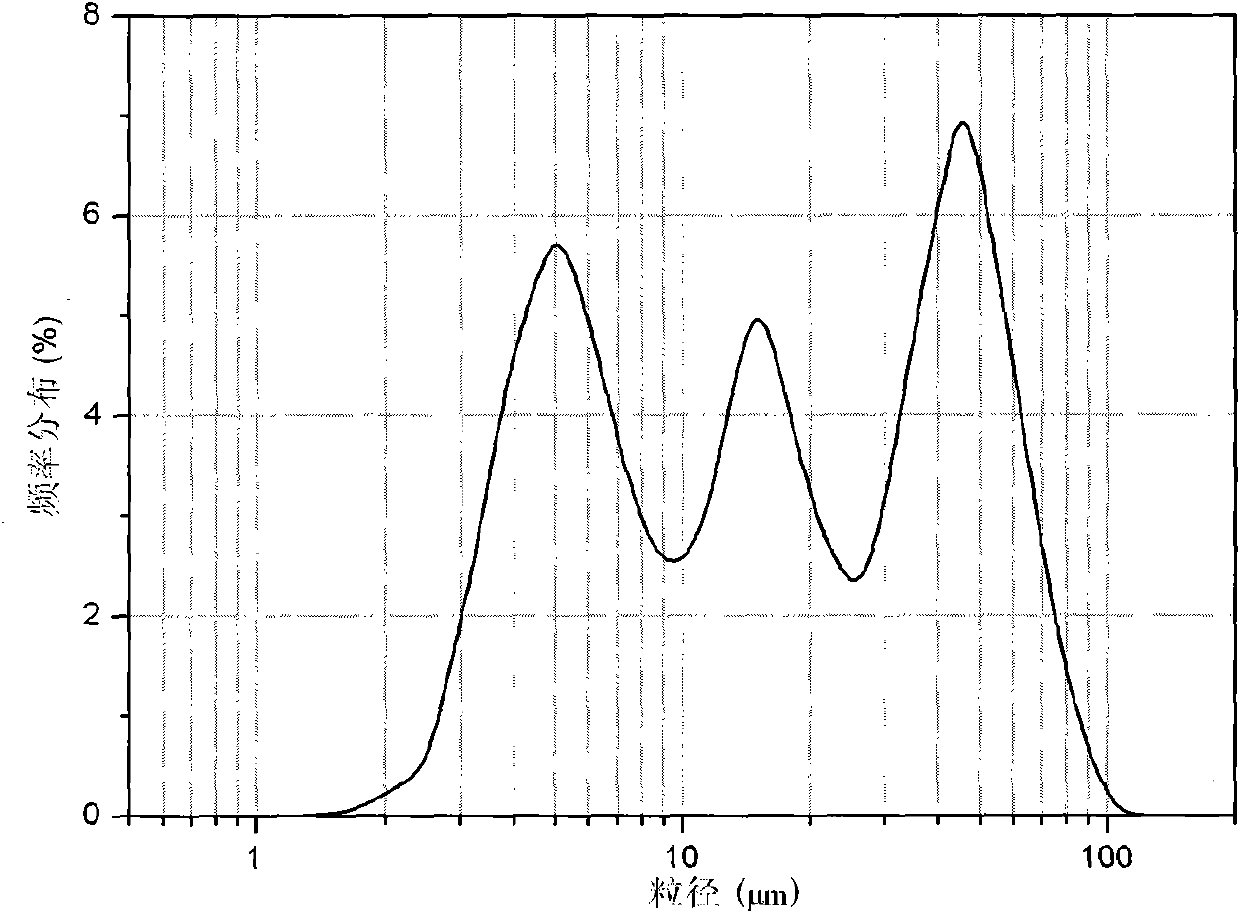

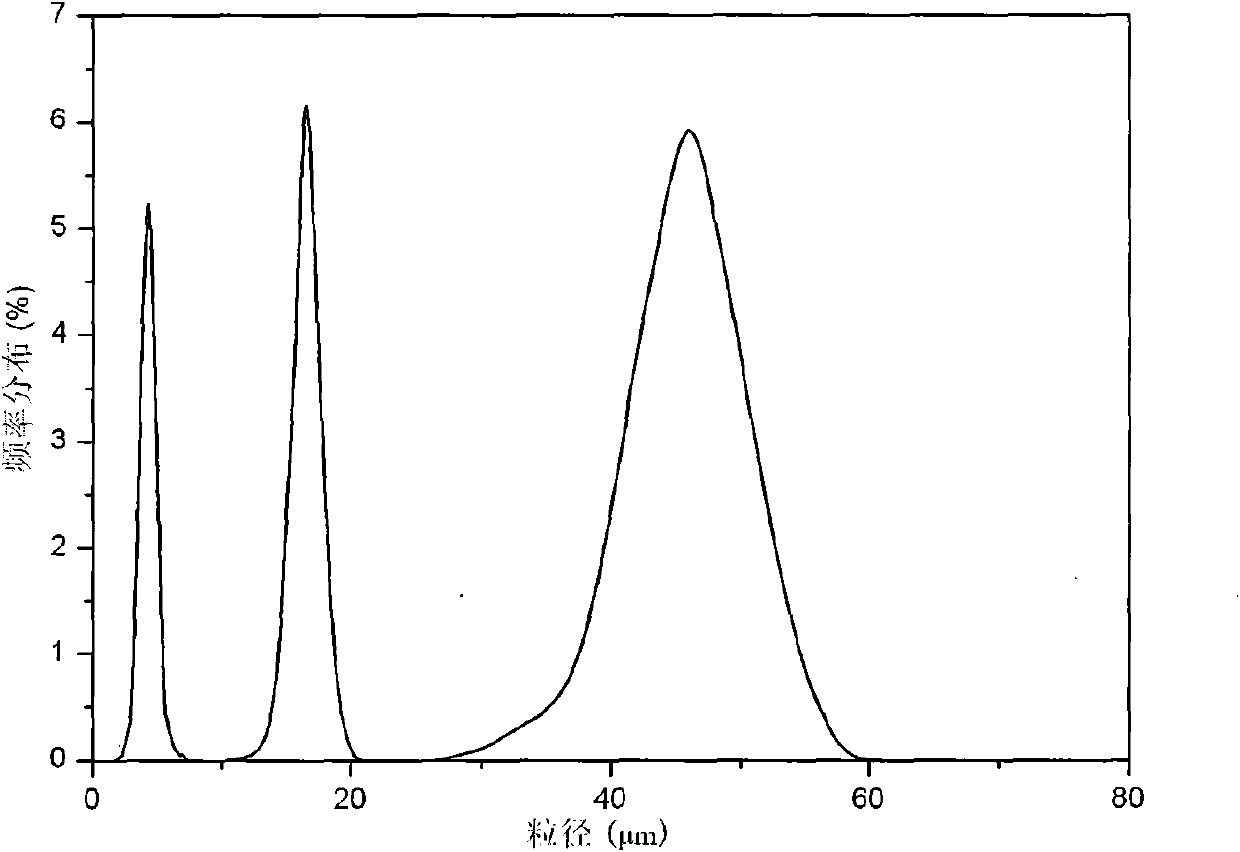

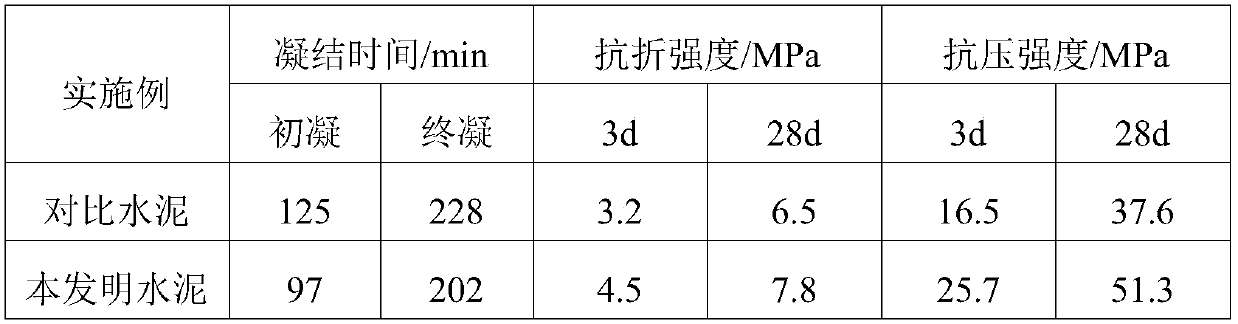

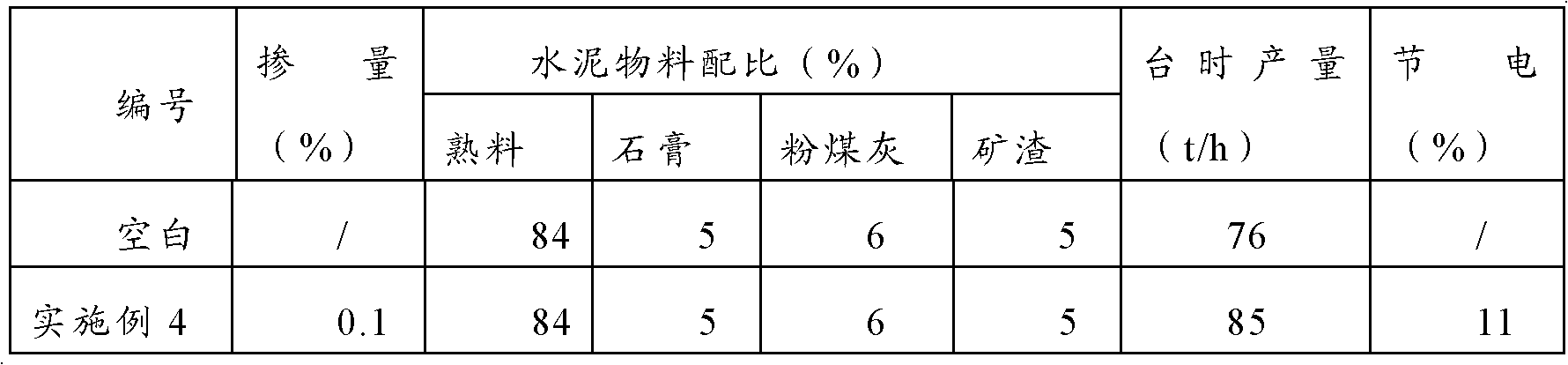

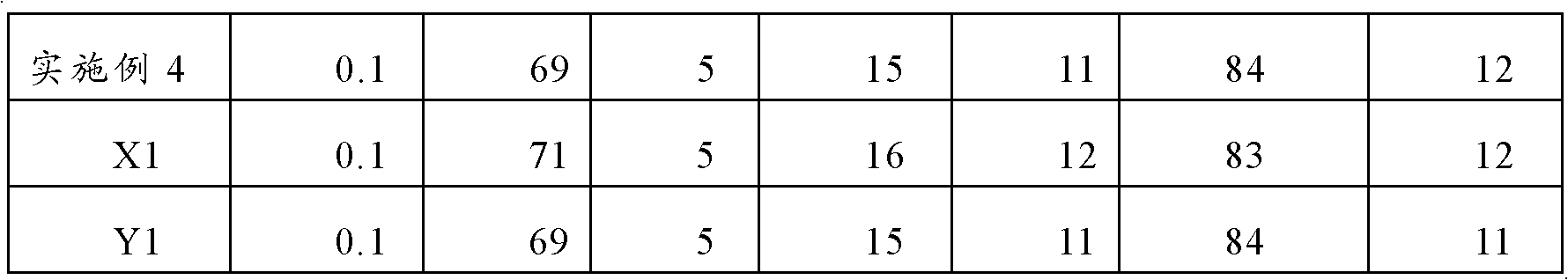

Preparation method of composite cement with low clinker dosage and high flexural compression ratio

The invention discloses a preparation method of composite cement with low clinker dosage and high flexural compression ratio. The preparation method is to mix three size ranges of powder particles and obtain the composite cement. The three size ranges of powder particles are as follows: 1) the grain size of particles is less than 8mu m, the particles are composed of high-activity supplementary cementing material with the grain size; 2) the grain size of particles is 8-24mu m, the particles are composed of cement clinker particles with the grain size; and 3) the grain size of particles is 24-80mu m, and the particles are composed of low-activity supplementary cementing material or inert filler. The volume percentages of the three size ranges of powder particles are 25-40%, 25-30% and 30-45% respectively. The clinker volume percentage of the composite cement is 25-30%, the 28-day compressive strength is up to 35-50MPa, the flexural strength is up to 10-12Mpa, the flexural compression ratio is 1 / 3-1 / 4; and the composite cement has low hydration heat and good anti-cracking capability and can be used in the civil construction / engineering with the demand on the anti-cracking capability.

Owner:SOUTH CHINA UNIV OF TECH

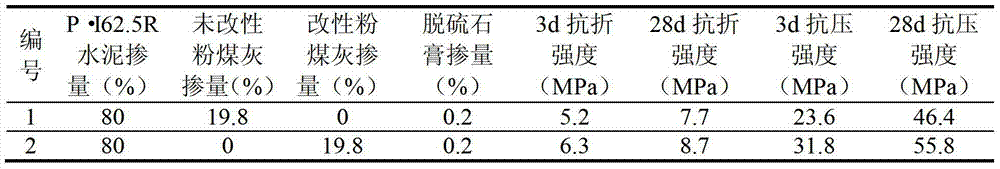

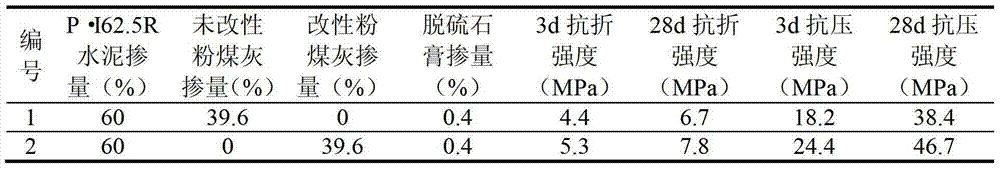

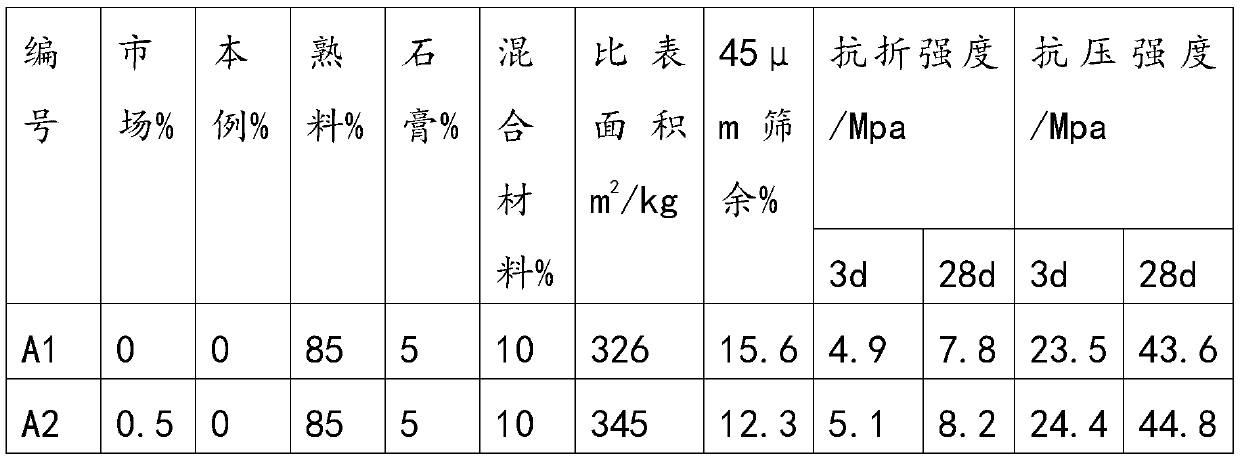

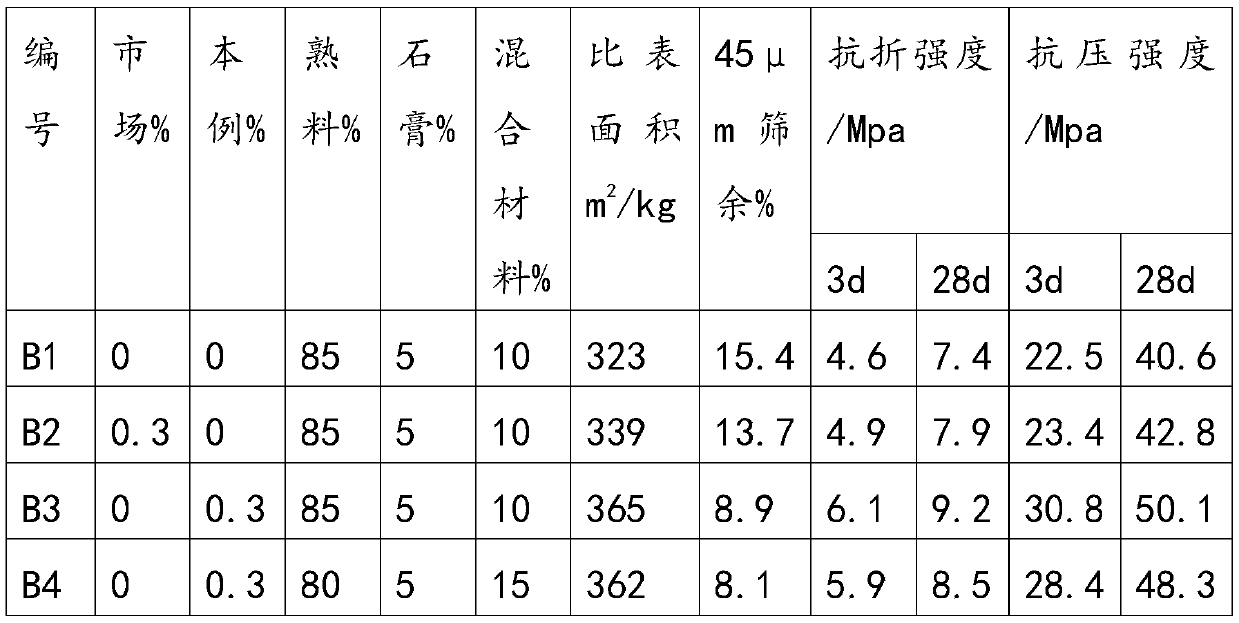

Portland fly-ash cement and preparation method thereof

InactiveCN107793052AIncrease dosageReduce the amount of clinkerCement productionPortland cementSulfate

The invention relates to a Portland fly-ash cement and a preparation method thereof. In the method, an intermediate mineral--calcium sulfosilicate formed during the traditional firing process of sulphoaluminate cement clinker is used as a fly ash activity stimulator, and the Portland fly-ash cement is prepared from the following raw materials in percentage by weight: 40 to 68% of Portland cement clinker, 25 to 40% of fly ash, 2 to 6% of gypsum, and 5 to 14% of calcium sulfosilicate. The above-mentioned component materials are prepared in proportion, evenly mixed by a ball mill, and ground to such a fineness that sieving residue is less than or equal to 10% after passing a 200-mesh sieve, thereby obtaining the Portland fly-ash cement. The Portland fly-ash cement provided by the invention has the advantages that under the condition that a large amount of fly ash replaces the silicate cement clinker, the strength of cement is ensured and improved, the production cost of cement is reduced,and the pollution of the fly ash to the environment is reduced; meanwhile, silicate waste residues with high calcium sulfate content can be consumed in the preparation of calcium sulfosilicate mineral, the energy is saved, the consumption is reduced, the process is simple, the implementation is convenient and the like.

Owner:YANGZHOU UNIV

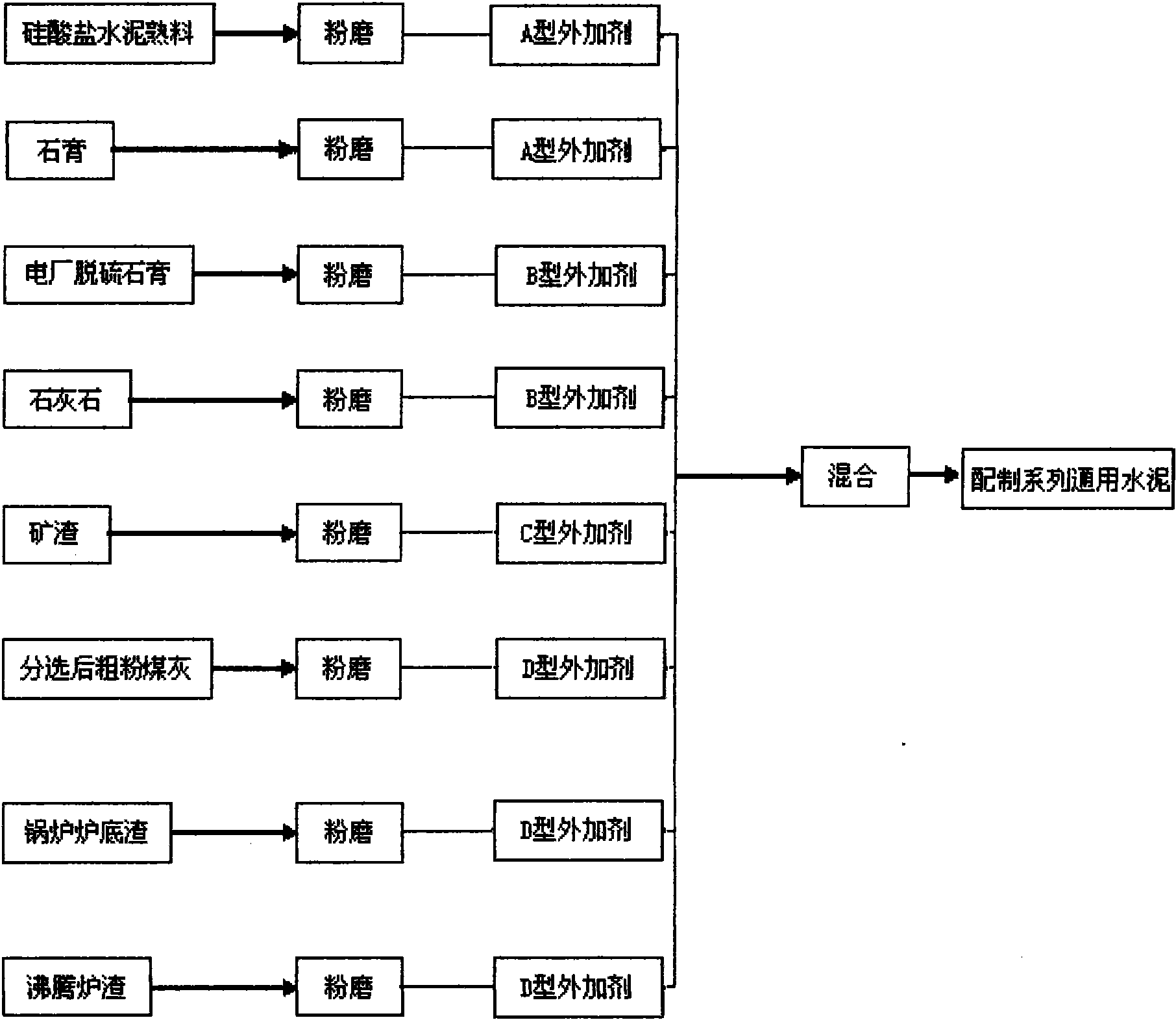

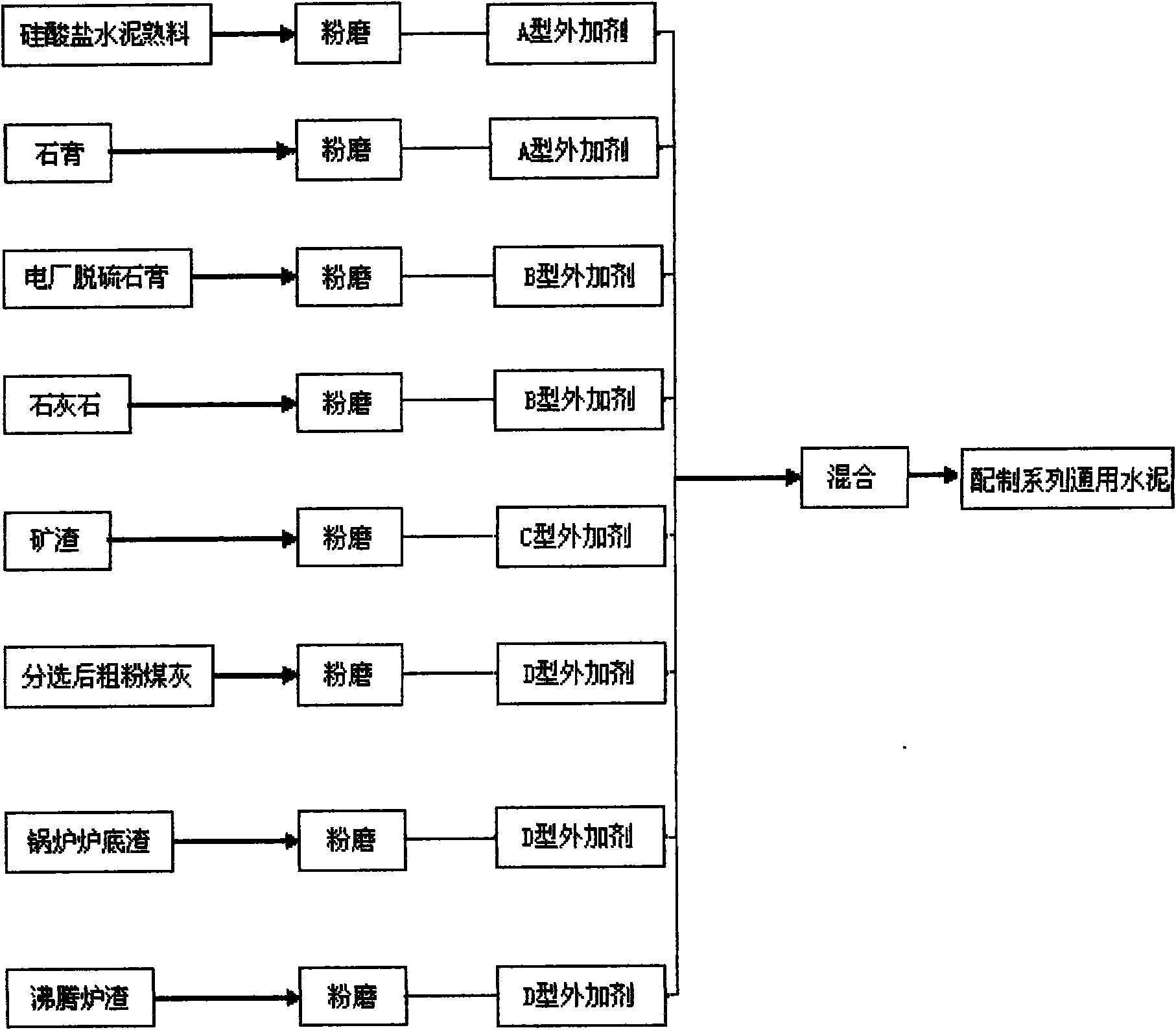

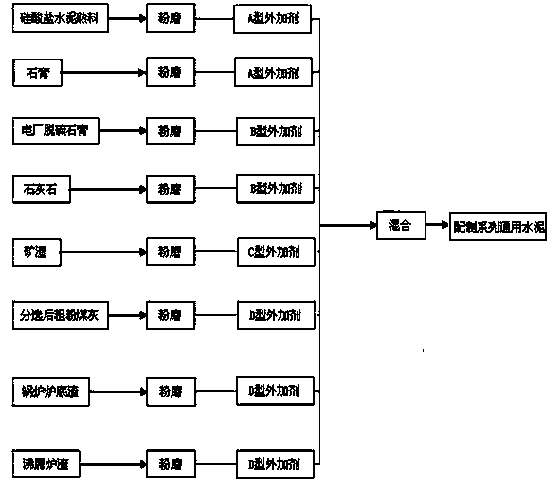

Cement composition and preparation method thereof

InactiveCN101870576AReduce heat of hydrationResolve chemical activitySolid waste managementGypsumSlag

The invention relates to a cement composition and a preparation method thereof. The various raw materials for producing cement and semi-finished products have different grindability, the raw materials are introduced into the cement composition according to different dispersions, and the physical and chemical functions of the raw materials vary greatly. The cement composition and the preparation method of the invention can use limestone, slag and separated crude coal ash to the largest extent, so the production cost of the cement composition can be reduced and the comprehensive property of the cement composition can be improved. The cement composition comprises portland cement clinker, gypsum, desulfurized gypsum from power plants, the limestone, the slag, the separated crude coal ash, the bottom slag of boilers, the slag of fluidized bed furnaces and the like.

Owner:山西建和节能环保技术有限公司

Green and environment-friendly cement

The invention belongs to the technical field of energy conservation and emission reduction and discloses green and environment-friendly cement. The green and environment-friendly cement is composed of the following raw materials in parts by weight: 5-20 parts of clinker, 3-8 parts of gypsum, 10-20 parts of sorted municipal solid waste incineration bottom ash, 10-20 parts of aluminum profile waste residues, 30-60 parts of smelting slag, 0.1-0.5 part of a reinforcing agent, 0.02-0.05 part of a grinding aid and 0.01-0.1 part of a hexavalent chromium ion reducing agent. According to the green and environment-friendly cement disclosed by the invention, the municipal solid waste incineration bottom ash and the aluminum profile waste residues can be effectively utilized, and the environmental pollution is reduced.

Owner:来凤县金凤建材工业有限责任公司

Cement grinding aid and preparing method thereof

InactiveCN102491672AGood wear resistance and compression resistanceImprove grinding effectCement grindingPolymer chemistry

The invention provides a modified lignin, which is prepared by methanal, alcamines compound and lignin. Mass ratio of the lignin, the alcamines compound and the methanal which form a repetitive unit and are in the modified lignin is (10-15):(10-15):(24-30). A cement grinding aid comprising the modified lignin is further provided. The cement grinding aid comprising the modified lignin is low in preparing cost, small in adding amount and excellent in grinding aiding performance. A preparing method for the modified lignin and a preparing method for the cement grinding aid comprising the modifiedlignin are further provided.

Owner:GUIZHOU CHUZHI BUILDING MATERIAL SCI & TECH

Cement composition

ActiveCN103833248AReduce heat of hydrationResolve chemical activityCement productionDispersityChemical effects

The invention relates to a cement composition and its preparation method. The raw materials and semi-finished products for cement production are different in grindability, are introduced into the cement composition in terms of different dispersity, and also have significantly different physical and chemical effects. The cement composition and its preparation method provided by the invention can maximumly give play to limestone, slag, and sorted coarse fly ash, is in favor of lowering the production cost of the cement composition and improving the comprehensive performance of the cement composition. The cement composition comprises portland cement clinker, gypsum, power plant desulfurization gypsum, limestone, slag, sorted coarse fly ash, boiler bottom slag and fluidized bed furnace slag, etc..

Owner:GUANGZHOU FORM BUILDING MATERIAL CO LTD

Preparation process of polyglycerol cement grinding aid

InactiveCN103011653AImprove performanceGood effectEther preparation by compound dehydrationElectrostatic adsorptionCement particle

The invention relates to the technical field of cement production, and particularly relates to a preparation process of a polyglycerol cement grinding aid. The polyglycerol cement grinding aid is prepared by mixing 90-95% of polyglycerol and 5-10% of inorganic reinforcer. The polymerization process of the polyglycerol comprises the following steps: adding 15-30% of recovered glycerol, 1-3% of NaOH and 69-84% of kerosene into a reactor, heating to 120-180 DEG C under the condition of introducing N2 for protection, and reacting for 4-8 hours while keeping the temperature, wherein the average polymerization degree n is calculated by determining the refractive index of the reactant, and the average polymerization degree n of the polyglycerol is controlled to be 3-5. According to the invention, the prepared cement grinding aid can change the dispersity of a material in a mill, effectively eliminate electrostatic adsorption and mill bonding phenomena of fine cement particles and optimize the gradation of the cement particles under the condition of not changing the status of the cement grinding mill. The original yield of the grinding mill is kept unchanged, the cement grinding rate and specific area are increased, the 3d strength of the cement is increased by 15%, and the 28d strength is increased by more than 8%. Alternatively, the existing cement grinding rate and specific area are kept, and the yield of the cement grinding mill can be increased by more than 10%.

Owner:安徽珍珠水泥集团股份有限公司 +1

Highly effective cement grinding aid

An efficient cement grinding aid relates to a cement grinding aid. The main purpose of the invention is to resolve the existing problems in cement production that the clinker consumption is large, energy consumption is large and production cost is high as well as the product cement has weak compressive strength etc. The raw material ratio of the invention is that aluminum silicate or aluminum sulfate is 950-1,050 kg, anhydrous sodium sulfate is 900-1,000 kg, triethanolamine is 6-10 kg, and calcium oxide is 40-45 kg; the aluminum silicate or the aluminum sulfate, the anhydrous sodium sulfate and the calcium oxide are grinded and mixed together, and during mixing, the triethanolamine is sprayed. The invention has the advantages that the application in cement production can not only reduce the clinker consumption by about 15%, save energy, lower the production cost; but also can improve waste utilization rate, the production, cement stability, decrease free lime in cement, improve the compressive strength of the cement that achieving 17-19 MPa within 3 days and 39-42 MPa within 28 days.

Owner:张括嘉

Environment-friendly cement technological additive

The invention belongs to the technical field of environmental protection and specifically relates to an environment-friendly cement technological additive. The additive is prepared from the following raw materials: 10%-20% of grinding aid, 10%-20% of reinforcing component, 10%-20% of hexavalent chromium reducing component, 2%-5% of cosolvent and the balance of water. The environment-friendly cement technological additive has a good grinding-aiding effect; the output of the grinding machine can be increased by above 10%; the power consumption for grinding the cement is saved; the reinforcing effect is good; after the cement technological additive is added, the 3d strength of the cement is increased by above 4MPa and 28d strength is increased by above 6MPa; under the condition of unchanged cement performance, above 12% of the clinker dosage can be reduced; above 12% of the industrial residue is additionally used, so that the resource is saved and the environment is protected; a chromium removing effect is excellent; and more than 90% of water-soluble hexavalent chromium in the cement can be reduced.

Owner:志成信(天津)科技有限公司

Method for producing slag portland cement by basalt in ingredients of cement

The invention discloses a method for producing slag portland cement by basalt in ingredients of cement, and aims to solve the problems of low early strength, low admixing amount of mixed material in cement and high dosage of clinker in the conventional portland cement. The method comprises the following steps: A, grinding portland cement clinker, gypsum and basalt to produce clinker powder by a large roll squeezer and a ball grinder; B, grinding and pelletizing blast furnace slag and gypsum to produce fine slag powder by a slag vertical grinding machine; C, mixing and agitating the clinker powder of which the weight percentage is 35% and the fine slag powder of which the weight percentage is 65% to obtain the slag portland cement through a mixing homogenizer, wherein the weight percentage of each material in the slag portland cement is 5-7% of basalt, 26-28% of portland cement clinker powder, 6% of gypsum and 61% of pelletized blast furnace slag. According to the method disclosed by the invention, the early strength of the slag portland cement is improved; the admixing amount of mixed material in the cement is increased and the dosage of the clinker is reduced.

Owner:嘉峪关祁连山水泥有限公司

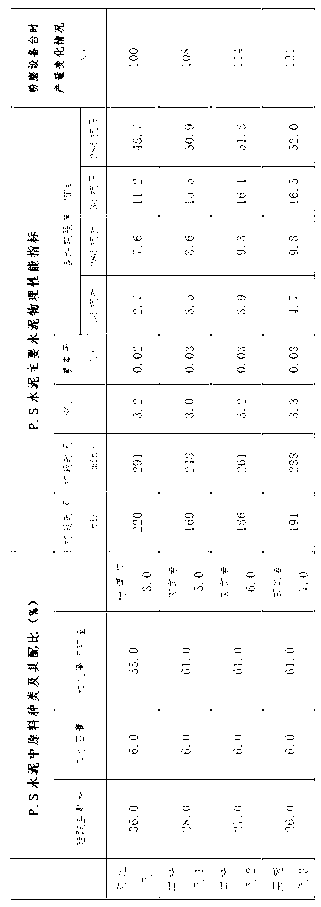

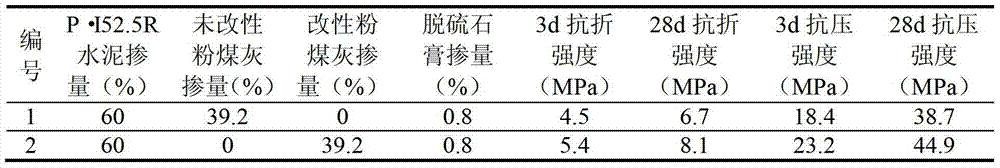

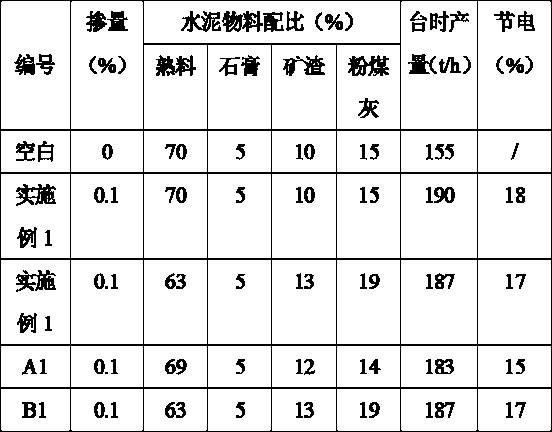

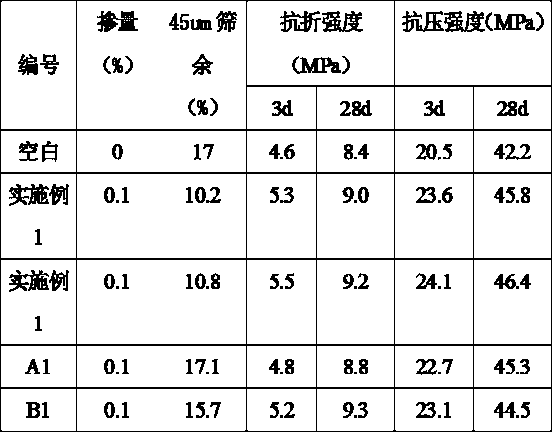

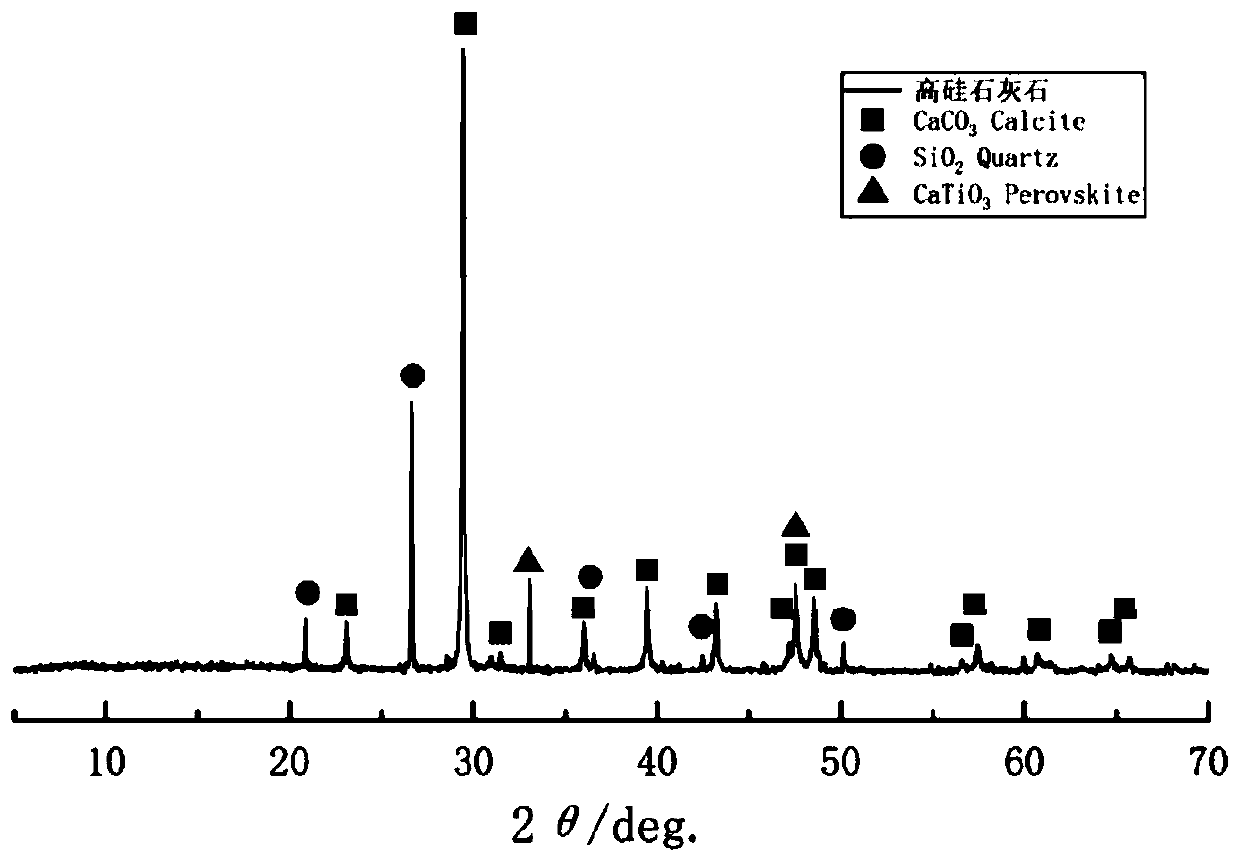

Method for preparing cement by modified compound coal ash

The invention discloses a method for preparing cement by modified compound coal ash. The method comprises the following steps of: grinding the coal ashes until the specific surface areas of the coal ashes reaches 350 m<2> / kg-600m<2> / kg; selecting the coal ashes with the specific surface areas of 350 m<2> / kg-400 m<2> / kg, 450 m<2> / kg-500 m<2> / kg and 550 m<2> / kg-600 m<2> / kg; compounding the coal ashes in a proportion of (15%-25%):(25%-40%):(40%-60%) to obtain the modified compound coal ash; adding the modified compound coal to cement clinker in a proportion of 20%-40%, and adding desulfurization gypsum which is 0.5%-2.5% of the weight of the compound coal ash for mixing and grinding. The method for preparing cement by modified compound coal ash can be used for optimizing the grain size distribution by improving the fineness of the coal ash, so that the activity of the coal ash is improved, and therefore, and energy conservation and emission reduction can be realized by largely utilizing industrial waste residues.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD +1

High-mill-temperature cement grinding aid and preparation method thereof

The invention relates to the field of cement grinding aids and in particular relates to a high-mill-temperature cement grinding aid and a preparation method thereof. The high-mill-temperature cement grinding aid is characterized by being prepared from the following components in parts by mass: 30 to 60 parts of a mixed solution of aliphatic sodium sulfonate and aluminum sulfate, 1 to 10 parts of triethanolamine, 5 to 10 parts of alcamines, 1 to 10 parts of sodium tripolyphosphate, 1 to 10 parts of sodium gluconate, 0.1 to 5 parts of a dispersant and 10 to 30 parts of water. By adopting the high-mill-temperature cement grinding aid provided by the invention, the surface energy of a material can be reduced and an aggregation effect generated by molecular attraction is weakened; accelerated expansion of particle cracks are facilitated when an external force acts, so that the grinding efficiency is improved and the aims of high quality, energy saving and high yield of a ball mill are realized; the fineness of cement can be reduced and the output per machine hour of the ball mill can be improved.

Owner:NINGXIA PAGODA CHEM CENT LAB CO LTD

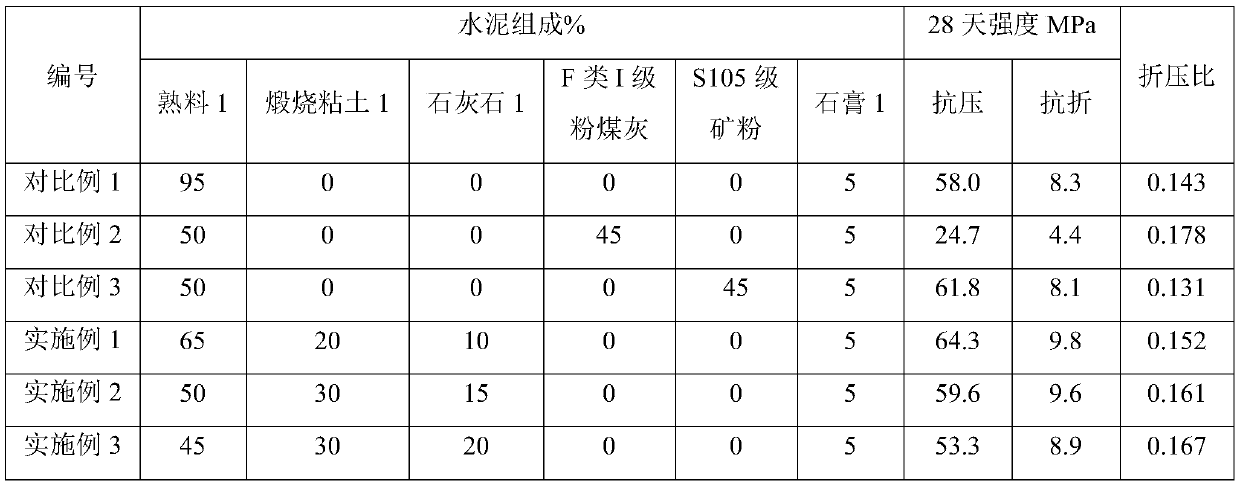

High flexural strength composite Portland cement and preparation method thereof

ActiveCN110436801AHigh flexural strengthImprove the structural strength in all directionsGypsumBuilding material

The invention belongs to the field of building materials, and especially relates to a high flexural strength composite Portland cement and a preparation method thereof. The high flexural strength composite Portland cement is prepared from, by weight, 35-65 parts of a Portland cement clinker, 17.5-40 parts of calcined clay, 10-22.5 parts of limestone and 1.5-5 parts of gypsum. The high flexural strength composite Portland cement mainly prepared from the ordinary Portland cement clinker, calcined clay and low-grade limestone concrete is prepared by starting from the concrete core raw material cement and improving the ratio of bending-compressive strength and the flexural strength of cement on the premise of ensuring a high compressive strength, and the preparation method has the characteristics of simple process, and suitableness for industrial production.

Owner:SINOMA INT ENG +1

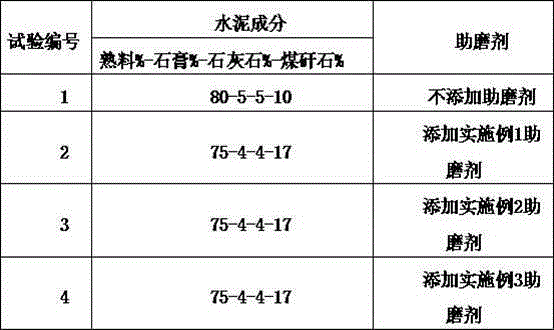

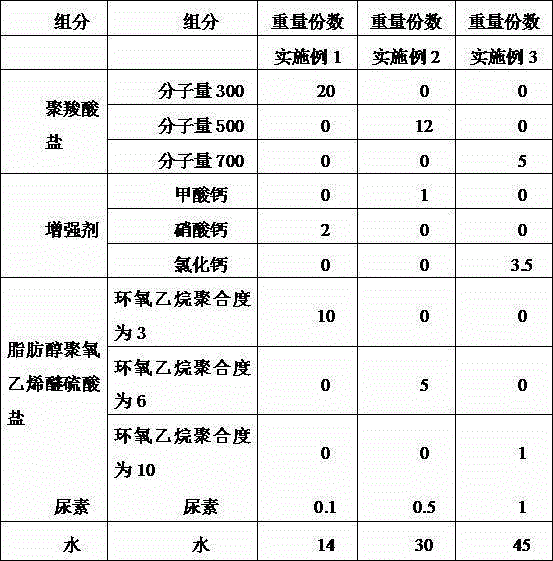

Compound cement grinding agent and method for applying same

The invention belongs to cement auxiliaries, and particularly relates to a compound cement grinding agent and a method for applying the same. The compound cement grinding agent comprises, by weight, 5-20 parts of polycarboxylate, 1-9 parts of reinforcing agents, 1-10 parts of fatty alcohol polyoxyethylene ether sulfate, 0.1-1 part of urea and 14-45 parts of water. The compound cement grinding agent and the method have the advantages that the grinding agent is used in cement processing procedures, accordingly, cement particle diameter adjusting effects can be realized, the strength of cement can be improved, and energy consumption can be reduced in cement production procedures.

Owner:仇鹏

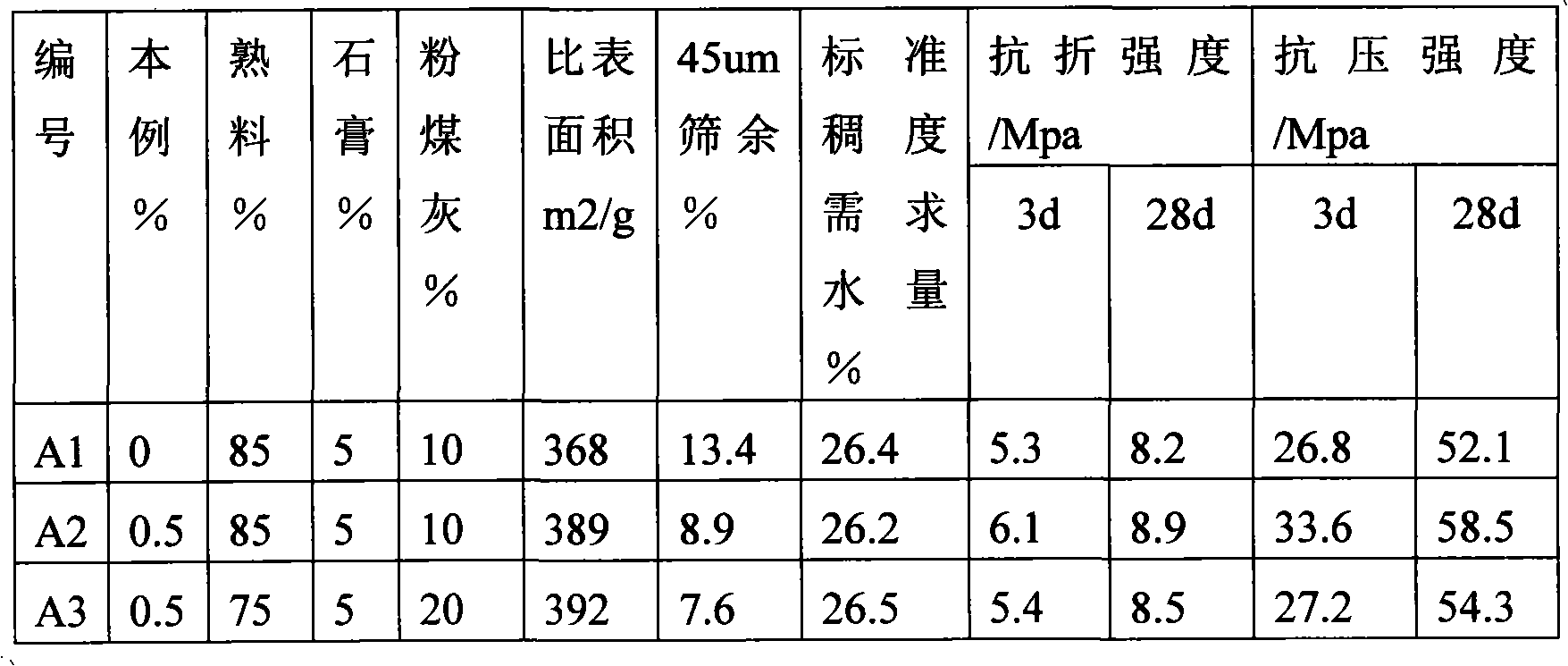

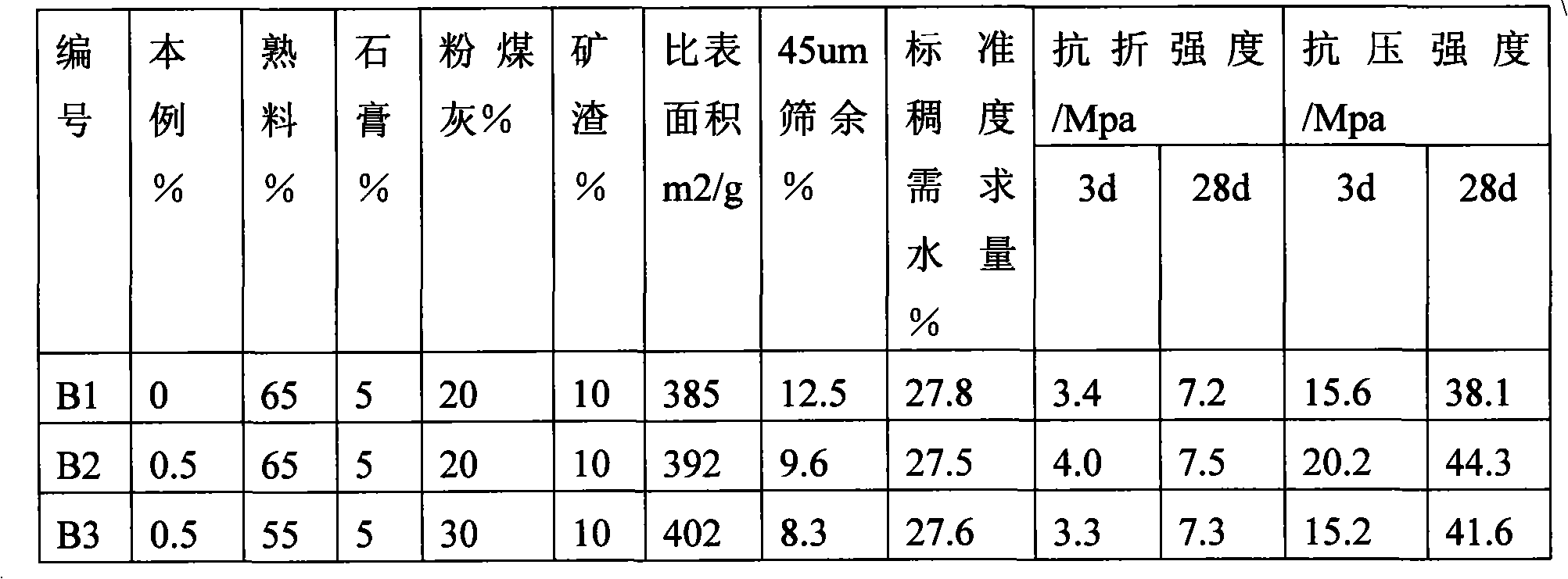

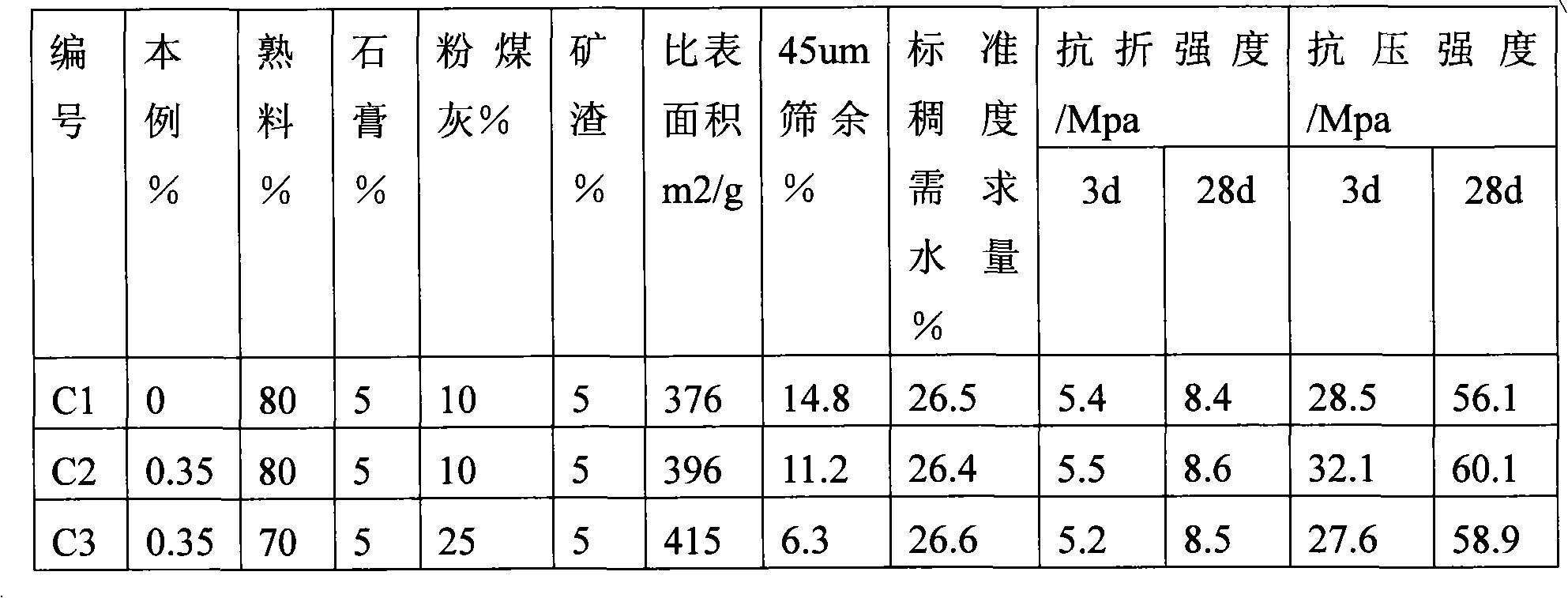

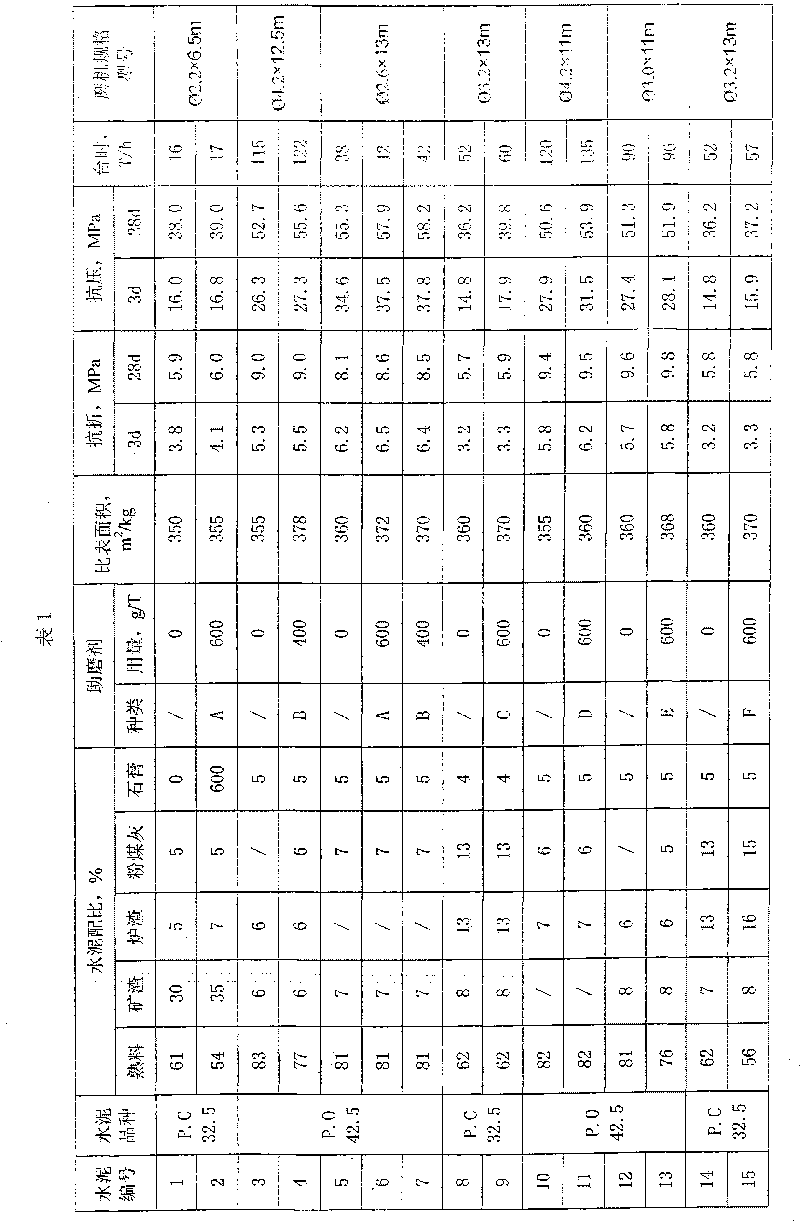

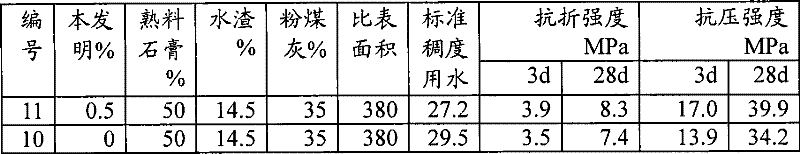

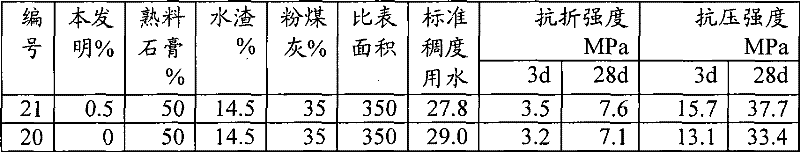

Composite grinding aid, production method and uses thereof

InactiveCN101428985BImprove compound synergyHigh strengthSolid waste managementCement productionSlagElectric consumption

The invention relates to a composite grinding aid for cement production and a preparation method and application thereof. The grinding aid contains 1 to 10 percent weight of organic aid and 90 to 99 percent weight of inorganic matrix material. The organic aid comprises at least one of polycarboxylic acid and lignosulphonate, C2-C5 polyfatty alcohols, C2-C5 polyfatty alcohol amines and gluconate, and the inorganic matrix material comprises at least one of sodium silicate and sodium carbonate, sulfate, calcined gypsum and calcium oxide. The invention also discloses the preparation method and the application for the composite grinding aid. The product can remarkably improve early and later strengths of cement, reduce the electric consumption of the grinding, and reduce the using amount of clinker. The compressive strength of the cement is obviously improved, the grinding efficiency is improved by between 10 and 20 percent, and the water consumption of the standard consistency of the cement is kept unchanged basically when 10 to 15 percent of the using amount of the clinker is reduced. The composite grinding aid is particularly suitable for a cement production technology which uses pulverized fuel ash and furnace bottom slag of coal-fired power plants as a composite material.

Owner:魔水科技(北京)有限公司

Method for preparing cement grinding aid by utilizing landfill leachate

The invention provides a method for preparing a cement grinding aid by utilizing landfill leachate. The method comprises the following steps: firstly adding calcium hydroxide and / or sodium hydroxide according to a test situation, removing a peculiar smell, regulating pH (Potential of Hydrogen) value of the landfill leachate to be 11 to 13, then standing the landfill leachate for reacting, and thencarrying out filtration treatment on the landfill leachate after reaction, thus obtaining filter residue and filtrate; sequentially adding basic salt, the filtrate, a viscosity regulating agent, a coupling agent, polyol, molasses and a stabilizing agent into water, and stirring and dissolving until enabling the solution to be uniform, thus obtaining a finished product-the cement grinding aid. Under the situation that the adding amount of the cement grinding aid is 0.05 to 0.08 weight percent and under the situation that the yield is enabled to be essentially unchanged when a machine is groundby a cement component, the 3-day compression strength of cement can be increased to 3 to 7 MPa, and the 28-day compression strength of the cement can be increased to 5 to 10 MPa; not only the production cost of the cement grinding aid is reduced, but also resource utilization of the landfill leachate can be realized.

Owner:SHANDONG ZHONGSEN TECH

Additives for a hydraulic binder based on a belite-calcium-sulphoaluminate-ferrite clinker

InactiveCN102482148ALong-term high mechanical strengthReduce the amount of clinkerSolid waste managementCement productionCarboxylic acidMaterials science

The subject of the present invention is a composition comprising at least, in % expressed by weight relative to the total weight of composition, from 0.01 to 3% of polycarboxylic acid or one of the salts of said polycarboxylic acid comprising from 2 to 4 carboxyl groups per molecule; and from 97 to 99.99% of a Belite-Calcium-Sulphoaluminate-Ferrite clinker (BCSAF clinker).

Owner:LAFARGE SA

Novel powdery cement grinding aid and preparation method thereof

The invention discloses a novel powdery cement grinding aid, and relates to the field of building materials. The novel powdery cement grinding aid comprise, by weight, 40-60 parts of fly ash, 14-23 parts of sulphoaluminate cement, 25-35 parts of anhydrous sodium sulfate and 1-2 parts of a synergistic solution, wherein the synergistic solution is prepared by a simple chemical reaction of diethanolmonoisopropanolamine, hydrochloric acid, a foaming agent and water. The invention also discloses a preparation method of the novel powdery cement grinding aid. The novel powdery cement grinding aid can effectively improve the particle fineness of the powder, increase the output per machine-hour of a grinding machine, increase the strength of the cement and reduce the use amount of cement clinker,and has the advantages of good grinding dispersibility, good grinding aiding effect, simplicity in processing and preparation, low cost and stable performances.

Owner:湖南格林朗科技有限公司

Cement reinforcing modifier

The invention provides a cement reinforcing modifier. The mixing amount of cement is 0.1% to 0.5% by weight of the cement. The cement reinforcing modifier is prepared from the following components inpercentage by weight: 1% to 15% of liquid diethanol monoisopropanolamine or liquid triethanolamine, 1% to 10% of sodium gluconate or white sugar or brown sugar, 0.7% to 10% of sodium thiosulfate or sodium sulfate, 0. 3% to 5% of acetic acid, and 60% to 95% of carrier. The cement reinforcing modifier provided by the invention is added into the cement from a cement production ball mill or a verticalgrinding tail. The cement reinforcing modifier provided by the invention has the advantages of improving the strength of the cement, reducing the amount of clinker by 2% to 4%, reducing the cement producing cost, and reducing the water demand of standard consistency of cement by 2 to 4 ml. The cement reinforcing modifier provided by the invention is mixed with a concrete water reducing agent without the formation of precipitates, which can reduce the gradual loss; the ash and sand flying can be controlled by the cement reinforcing modifier when the floor is produced by the cement, and the surface hardness of the cement is improved.

Owner:吴正旺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com