Chlorine-free powdery cement grinding aid and preparation method thereof

A technology of cement grinding aid and fly ash, which is applied in the direction of cement production, etc. It can solve the problems of affecting the service life and durability of concrete, hindering the development, popularization and application, and corrosion of concrete steel bars, so as to reduce the water required for standard consistency, The effect of reducing the power consumption of grinding and reducing the cost of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

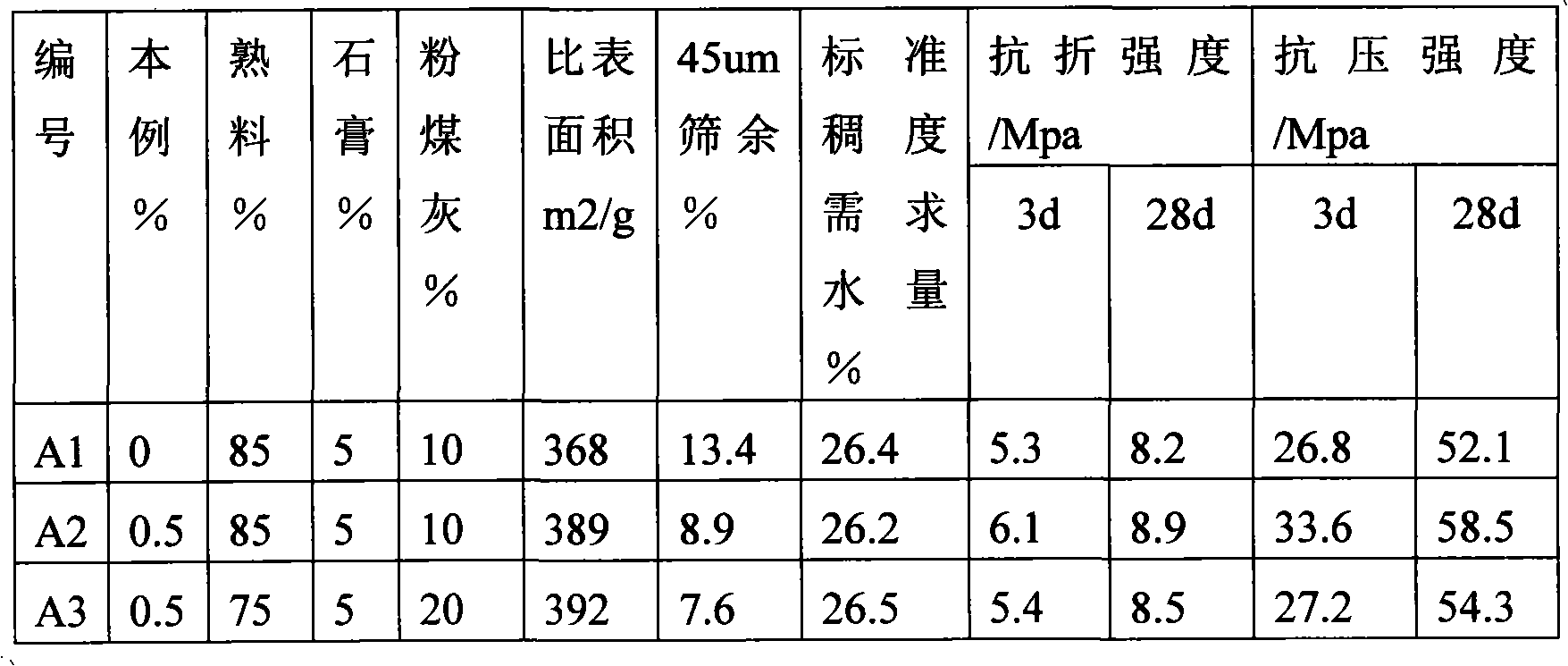

Examples

Embodiment 1

[0031] A chlorine-free powder cement grinding aid suitable for fly ash, including:

[0032] 3 parts of glycerol, 2 parts of dipropylene glycol, 45 parts of anhydrous sodium sulfate, 15 parts of sodium acetate, 1 part of sodium lignosulfonate, 3 parts of molasses, 1 part of corn syrup, 15 parts of calcined gypsum (particle size ≤ 2mm), 10 parts of urea, 15 parts of stone powder.

[0033] Preparation Process:

[0034] Weigh 3 parts of glycerol, 2 parts of dipropylene glycol, 3 parts of molasses, and 1 part of corn syrup in order to stir in the reaction kettle. When the temperature rises to 75°C, keep stirring for 30 minutes to prepare a uniform mixed solution for later use.

[0035] Then weigh 45 parts of anhydrous sodium sulfate, 15 parts of sodium acetate, 1 part of sodium lignosulfonate, 15 parts of calcined gypsum, 10 parts of urea, and 15 parts of stone powder and put them into the mixer in order to stir, and at the same time, spray the mixed solution prepared above evenly...

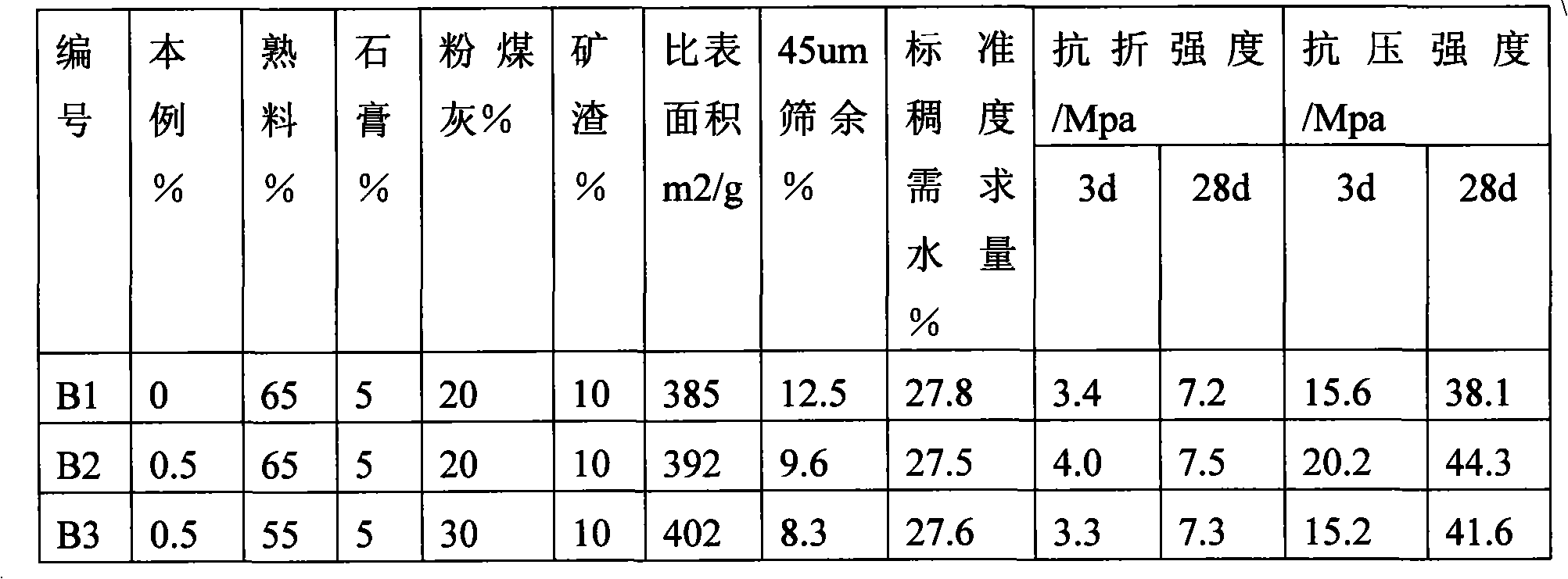

Embodiment 2

[0040] A chlorine-free powder cement grinding aid suitable for fly ash, including:

[0041] 1 part of triethanolamine, 1 part of triisopropanolamine, 3 parts of glycerin, 35 parts of anhydrous sodium sulfate, 15 parts of aluminum sulfate, 10 parts of sodium acetate, 0.5 parts of sodium gluconate, 4.5 parts of molasses, 15 parts of calcined gypsum (Particle size ≤ 2mm), stone powder 15 parts.

[0042] Preparation Process:

[0043] Weigh 1 part of triethanolamine, 1 part of triisopropanolamine, 3 parts of glycerol, 0.5 parts of sodium gluconate, and 4.5 parts of molasses, put them into the reaction kettle and stir in turn, and keep stirring for 60 minutes when the temperature rises to 80°C. Make a uniform mixed solution for later use.

[0044]Then take 35 parts of anhydrous sodium sulfate, 15 parts of aluminum sulfate, 10 parts of sodium acetate, 15 parts of calcined gypsum, and 15 parts of stone powder, and put them into the mixer in turn to stir, and at the same time, spray ...

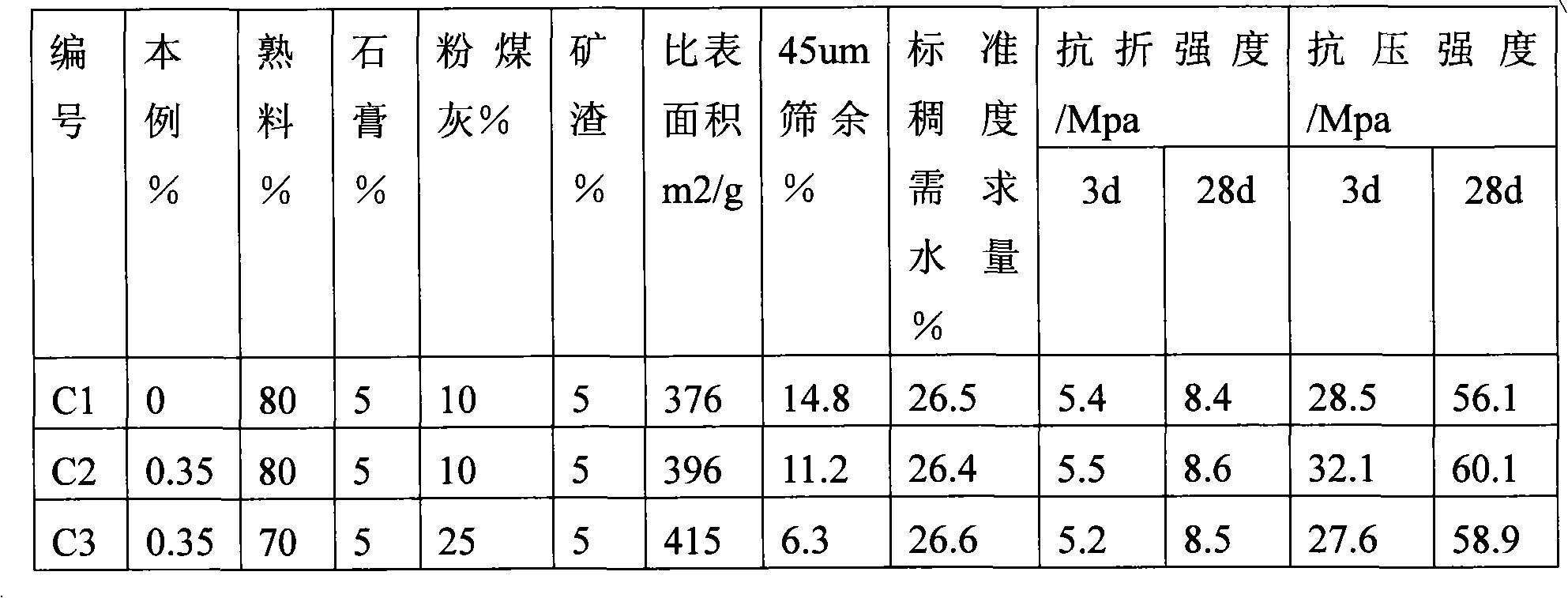

Embodiment 3

[0049] A chlorine-free powder cement grinding aid suitable for fly ash, including:

[0050] 1.5 parts of N-methyldiethanolamine, 2 parts of glycerol, 1.5 parts of dipropylene glycol, 30 parts of anhydrous sodium sulfate, 10 parts of aluminum sulfate, 15 parts of sodium acetate, 5 parts of calcium acetate, 2.5 parts of sodium lignosulfonate 2.5 parts of molasses, 20 parts of calcined gypsum (particle size ≤ 2mm), 5 parts of urea, and 5 parts of stone powder.

[0051] Preparation Process:

[0052] Weigh 1.5 parts of N-methyldiethanolamine, 2 parts of glycerol, and 2.5 parts of molasses, and put them into the reaction kettle in order to stir. When the temperature rises to 80°C, keep stirring for 60 minutes to prepare a uniform mixed solution for later use.

[0053] Then weigh 30 parts of anhydrous sodium sulfate, 10 parts of aluminum sulfate, 15 parts of sodium acetate, 5 parts of calcium acetate, 2.5 parts of sodium lignosulfonate, 20 parts of calcined gypsum, 5 parts of urea, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com