Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Stimulate latent activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chlorine-free powdery cement grinding aid and preparation method thereof

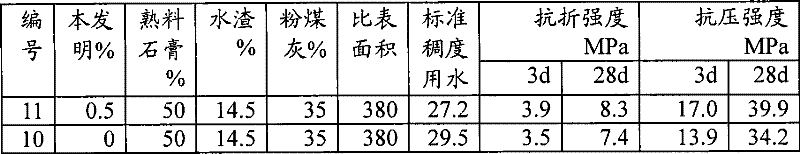

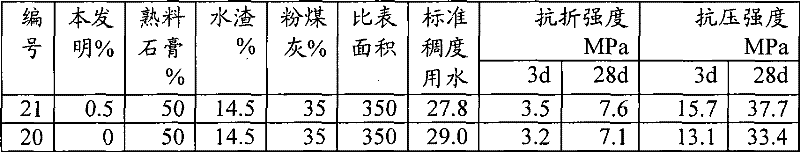

InactiveCN101665338AHigh strengthStrong compound synergistic effectCement productionSulfateLignosulfonates

The invention discloses a chlorine-free powdery cement grinding aid suitable for fly ash, which comprises the following components in parts by weight: 0-5 parts of alkanolamine, 2-5 parts of polylol,15-75 parts of sulfate, 5-20 parts of acetate, 0-5 parts of lignosulphonate, 2-6 parts of carbohydrate organic matter, 5-25 parts of miltonite, 0-25 parts of carbamide and 5-50 parts of inorganic carrier material. The invention also discloses a preparation method of the chlorine-free powdery cement grinding aid suitable for the fly ash. A compound grinding aid can lower the cement cost and uses the fly ash for replacing partial clinker to save the clinker dosage by 10-15 percent on the premise of keeping the cement strength unchanged, and uses extra 10-15 parts of fly ash without increasing the required water amount of cement standard consistency; the cost of the cement per ton is lowered by more than 10 Yuan.

Owner:NANJING ZHUJI ENERGY SAVING TECH

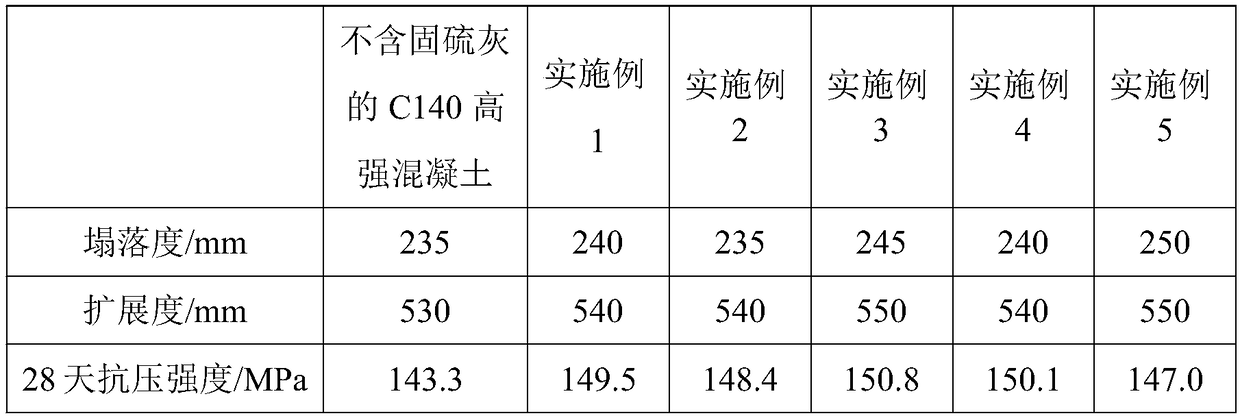

C140 high-strength concrete and preparation method thereof

The invention belongs to the field of concrete, and particularly discloses C140 high-strength concrete and a preparation method thereof. The concrete is prepared from the following materials in partsby weight: 490-570 parts of cement, 45-65 parts of coal ash, 100-120 parts of mineral powder, 65-85 parts of desulphurization ash, 20-40 parts of silica fume, 750-950 parts of coarse aggregate, 400-600 parts of fine aggregate, 5.5-7.5 parts of a water reducer, 10-20 parts of a corrosion inhibitor, 60-100 parts of fibers and 145-160 parts of water. The invention provides the C140 high-strength concrete; the concrete has a good slump, good extended degree, good compressive strength, and excellent comprehensive performance, and meanwhile, the problems of resource shortage of traditional cement admixtures of the mineral powder, the coal ash, the silica fume and the like, and limited resourced approaches and a low utilization rate of the desulphurization ash are solved.

Owner:成都宏基建材股份有限公司

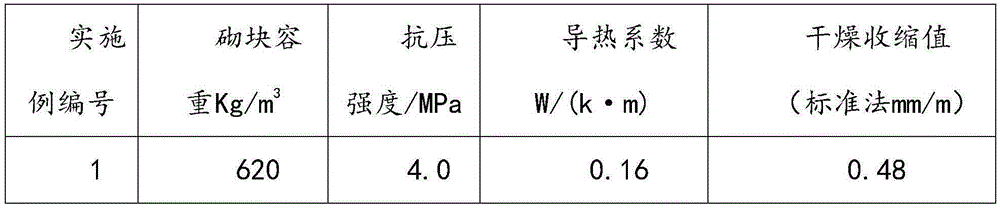

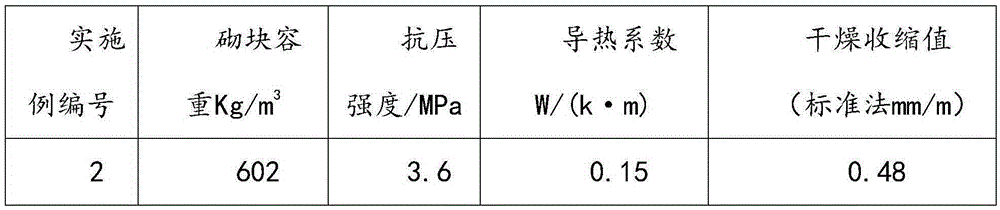

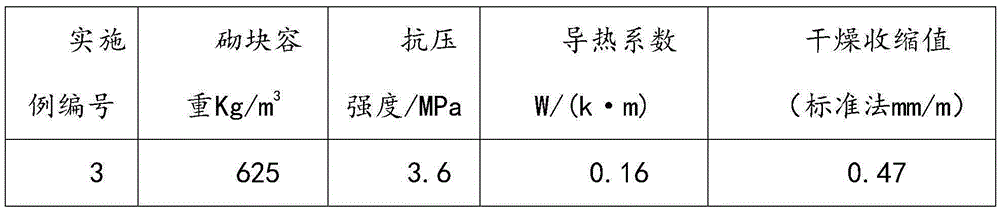

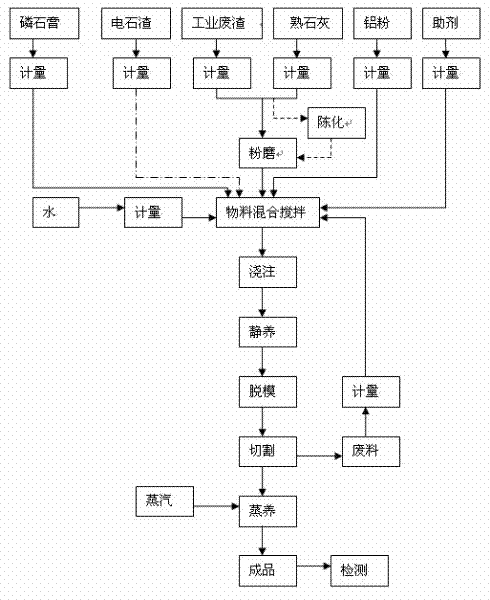

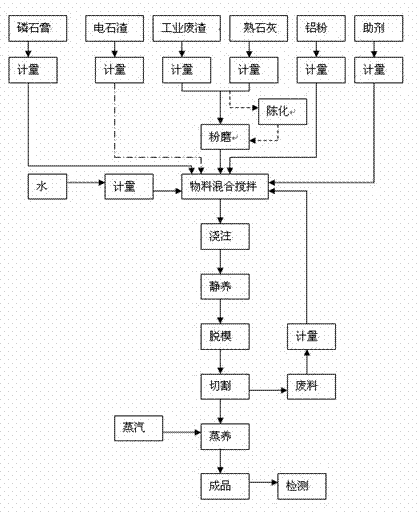

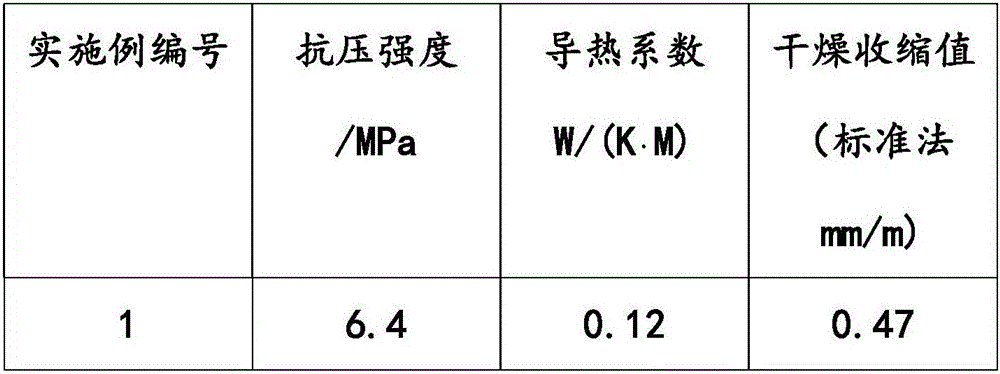

Light-weight block prepared by taking 'phosphorus solid waste' as raw material and preparation method of light-weight block

The invention relates to a light-weight block prepared by taking 'phosphorus solid waste' as a raw material and a preparation method of the light-weight block. The light-weight block and the method solve the problems of complicated technology, high energy consumption, long production period, low production cost and low waste utilization rate of the existing light-weight block preparation. The light-weight block is prepared by taking 55-65 parts of phosphorus tailing, 10-15 parts of carbide slag, 10-20 parts of salic active mineral admixture, 2-3 parts of phosphogypsum, 6-8 parts of cement and 3-5 parts of additive as raw materials, and carrying out crushing, wet ball milling, stirring, forming, gas forming, trimming, and steam pressing. The block is simple to construct, has a high waste utilization rate, can effectively stimulate potential activity of phosphorus tailings, saves energy, reduces consumption, and is environmentally friendly, low in production cost, low in cost, and outstanding in performance, and the raw materials are not required to be pre-dried, and are easy to obtain.

Owner:HUBEI UNIV OF TECH

Method for producing aerated building block with phosphogypsum as main raw material

The invention discloses a method for producing an aerated building block with phosphogypsum as a main raw material. The method comprises the steps of: adding phosphogypsum, industrial waste residues, mineral activator main components and aluminum powder or aluminum paste to a stirrer with adjust rotation speed, adding water, stirring, slowly stirring for 3min, then rapidly stirring for 2min, then adding mineral activator auxiliary components and auxiliary agents, rapidly stirring for 3min, pouring the obtained slurry to a mold, foaming for 30-40min, then standing and maintaining at 50-55 DEG C for 4h, demolding, cutting, and carrying out normal-pressure steam maintaining for 16-24h to obtain the aerated block. Compared with the prior art, the method has the advantages that the obtained aerated building block has stable physical performance and good heat insulation property, the utilization rate of phosphogypsum is high, the process is simple, the cost is low, natural resources are saved, and the like. The obtained product can be widely applied to non-bearing partitions of urban high-rising buildings, low-temperature heat insulation of industrial equipment and the heat-insulation block of refrigeration warehouses.

Owner:KUNMING UNIV OF SCI & TECH

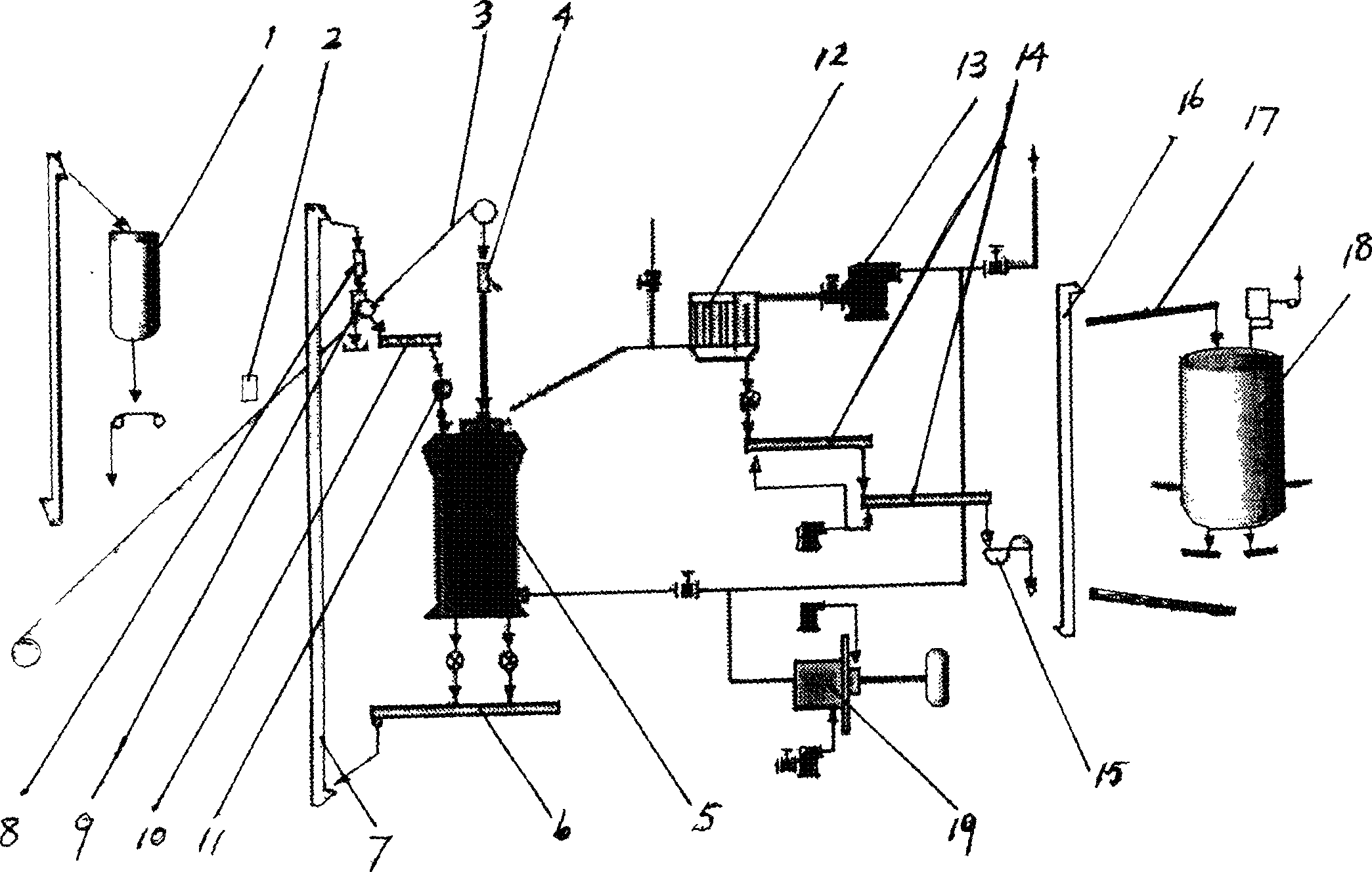

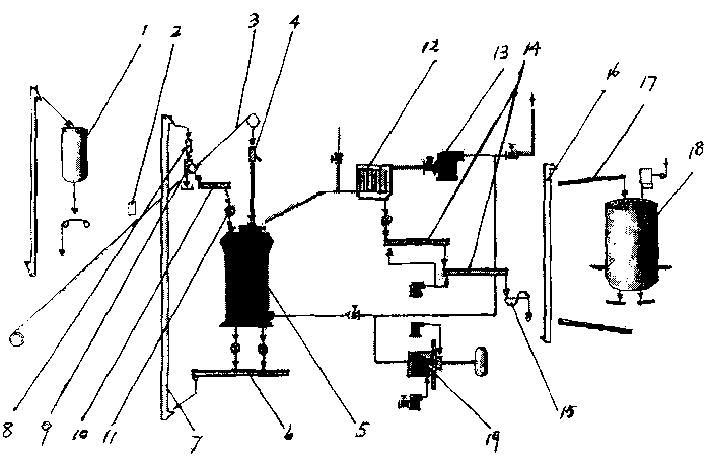

Instantly grinding scoria micro powder and process for manufacturing the same

InactiveCN1482090AIncrease productivityReduce energy consumptionSolid waste managementChemical compositionMetallurgy

The vertically ground mineral residue fine powder has the chemical composition of CaO 39.0-40.0 wt%, Al2O3 13.0-16.0 wt%, SiO2 32.0-35.0 wt%, MgO 2-10 wt%, and small amount of MnO, TiO2, T-Fe, T-S, P2O5, Na2O, K2O, L.O.I and I.R. It is crushed fully, has specific surface area greater than 400 sq m / kg, and over 90 % of it has grain size less than 30 microns. The production process includes material conveyance, once iron elimination, grinding and storing. The vertically ground mineral residue fine powder can raise the comprehensive performance of concrete with it, and the vertical grinding process has high production efficiency, low power consumption and low production cost.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

Method for preparing cement mixture from waste phosphorus dregs through wet-milling method

The invention relates to a method for preparing a cement mixture from waste phosphorus dregs through a wet-milling method. The method comprises the steps of crushing the waste phosphorus dregs, salic industrial wastes and industrial by-product gypsums with an excitation function in a crushing machine to 2 to 20mm, and powder milling in a ball mill through a wet method; feeding 0.5 to 0.6 percent of water and doping 0.1 to 0.2 percent of water reducing agent into a mixing tank, stirring through an electric stirrer, then adding 40 to 65 parts of phosphorus slags and 32 to 50 parts of salic industrial wastes for stirring, finally adding the industrial by-product gypsums with the excitation function for continuously stirring, and obtaining a liquid slurry; and pumping into the vertical ball mill, wet-milling to below 10 mum, and preparing the slurry cement mixture. According to the method for preparing the cement mixture from the waste phosphorus dregs through the wet-milling method provided by the invention, the phosphorus dregs, the salic materials and the industrial wastes are adopted as raw materials, and the water reducing agent is added for wet-milling, so that the materials are activated without doping an exciting agent; and the method is simple in operation process, has no need to dry solid wastes, and is energy-saving and environmental-friendly, and good in economic efficiency.

Owner:HUBEI UNIV OF TECH

Controllable clay and cement seepage-proof reinforcement paste

The invention discloses controllable clay and cement seepage-proof reinforcement paste. The controllable clay and cement seepage-proof reinforcement paste is mainly prepared from clay raw stock, cement and water, wherein the clay raw stock is mainly obtained by stirring clay and water. A modifier is added in the controllable clay and cement seepage-proof reinforcement paste; the doping amount of the modifier is 1 to 3 percent; the modifier mainly comprises mineral additives, sulfate and bentonite in a mass ratio of a:b:c; and a:b:c is 5:(5-0):(0-5). The product has the advantages of high stability and water flow dilution resistance, controllable setting time, adjustable strength, high antiseepage performance, low cost, environment friendliness and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

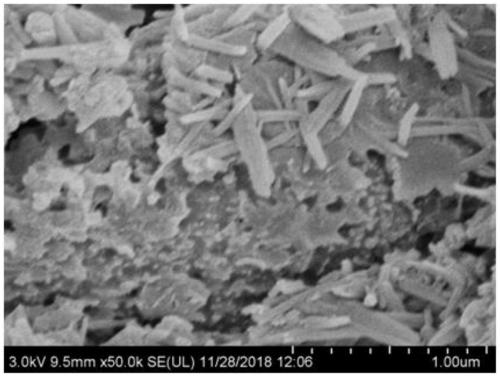

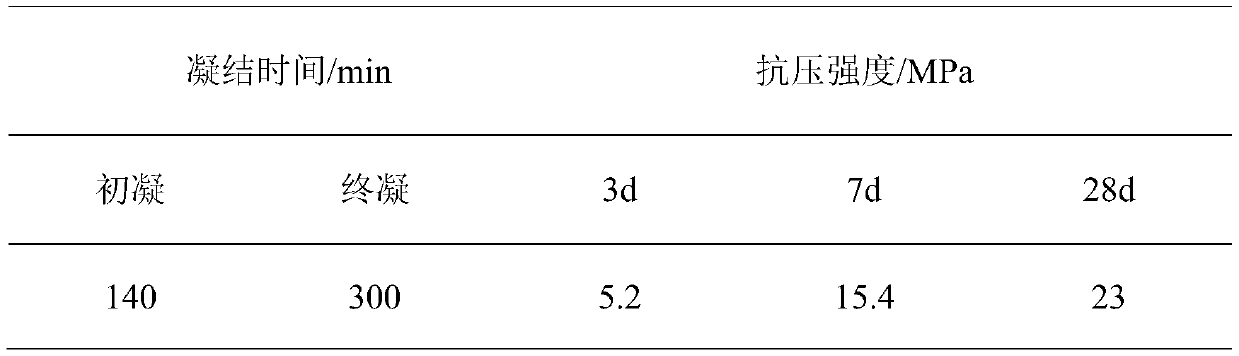

Construction connector grouting material prepared by wet grinding

The invention discloses a construction connector grouting material prepared by wet grinding. The preparation method comprises following steps: adding water into mineral slag and steel slag in a wet grinding machine, carrying out wet grinding to obtain a mixed slurry material; grinding calcium carbide residues, desulfurized gypsum, and silica fume in a dry grinding machine to obtain a mixed powderymaterial; mixing the mixed slurry material and the mixed powdery material to obtain a mixture; adding SAP, tailing sand, cement, a water reducer, an early strength agent, and water into the mixture,stirring the mixture for 2 minutes in a blending machine at a low speed at first, then stopping the blending machine for 15 seconds, and stirring the mixture for 2 minutes at a high speed then to obtain the grouting material. A large amount of wastes such as mineral slag, steel slag, calcium carbide residues, desulfurized gypsum, silica fume, and the like, is added, and the wastes are converted into valuable resources. A wet grinding technology is adopted, solid wastes namely mineral slag and steel slag are fully wet-grinded and completely activated; the grouting material is used to connect steel bar sleeves; and the water absorbing material (SAP) can fully absorb water that enters the sleeves and fix the heavy metal ions to prevent the steel bars from being corroded.

Owner:HUBEI UNIV OF TECH

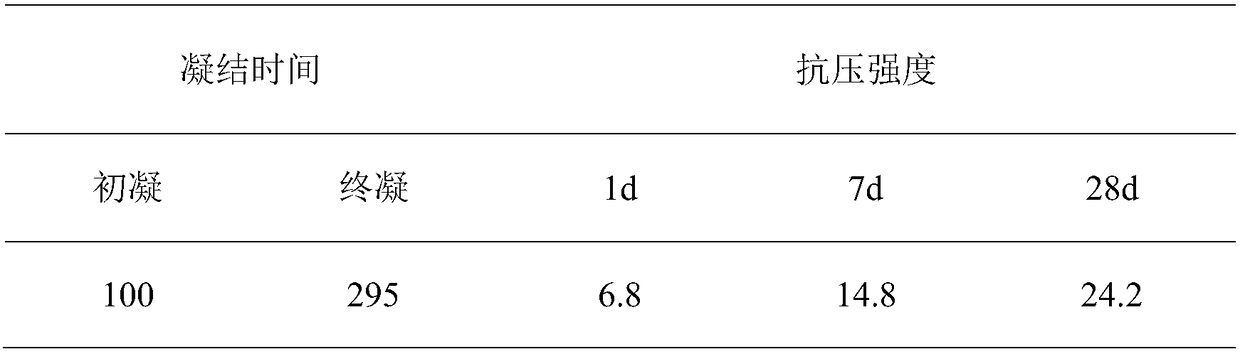

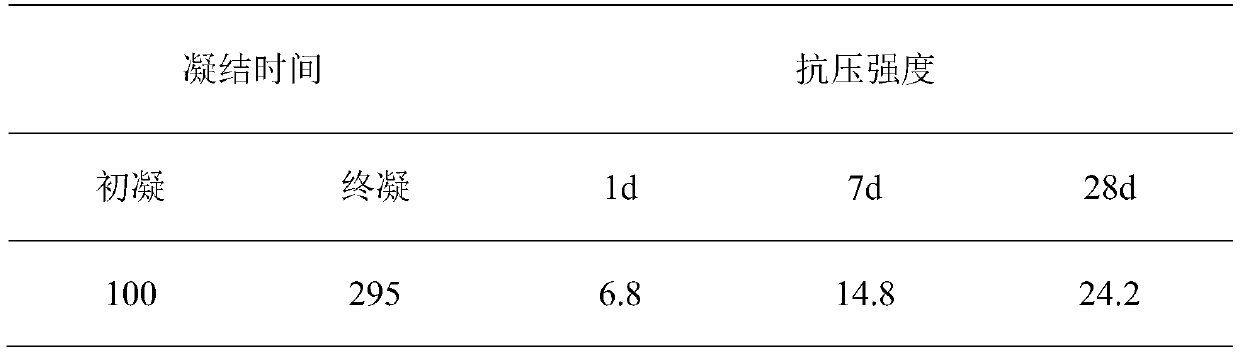

Method for preparing grouting material by using water-containing red mud synergistic blast furnace slag

The invention provides a novel red mud-based grouting material and preparation method thereof. The grouting material is prepared from the following components by weight percent: 70-80% of red mud liquid, 15-25% of blast furnace slag powder, 5-10% of compound alkali-activator, 2-10% of water reducing agent and 1-2% of early strength agent. The novel red mud-based grouting material prepared from redmud and the blast furnace slag powder is good in fluidity, high in early strength and short in time of coagulation, and does not shrink. The preparation method provided by the invention reasonably utilizes industrial waste, can reduce the influence of the waste on the environment, and is easy in preparation; the method is simple in steps, convenient to operate and high in practicability.

Owner:SHANDONG UNIV

Liquid high-efficiency cement grinding aid reinforcing agent and producing method thereof

InactiveCN101209908AReduce coagulationEliminate hazardsSolid waste managementCement productionAluminium sulfatePolyol

The invention relates to a liquid cement grinding-assisting reinforcing agent and a production method thereof, particularly to a high-efficient liquid compound non-chlorinated and low alkali cement grinding-assisting reinforcing agent of a defoaming mechanism and cement stability performance and a production method thereof. Pulp waste liquid is used as main material which is in complexation with triethanolamine and polyol and added with small amount of stabilizers of phosphogypsum and aluminum sulfate, etc., to eliminate the harm of free state CaO, and ethal etc. is added to play a role of defoaming, thereby the stability and density of the cement is enhanced and the intensity of the cement is further enhanced. The production method is to separate grinding-assisting reinforcing ingredient and additive ingredient respectively and averagely which are then stirred and mixed. In addition to simple technique and low price, the product is easy for storage and transportation, which occupies little cement mixed weight, obviously enhances the early and later period intensity of the cement and is extremely applicable to wide application in cement industry.

Owner:DALIAN UNIV OF TECH

Mineral admixture concrete and preparation method thereof

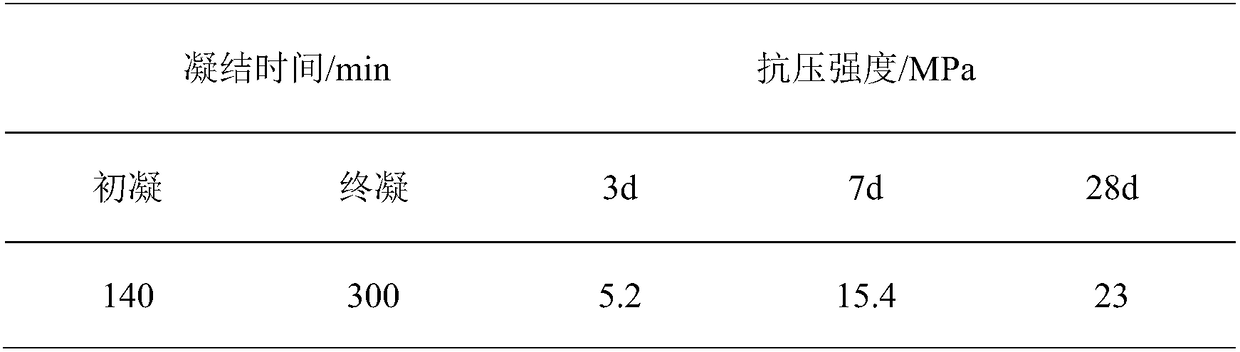

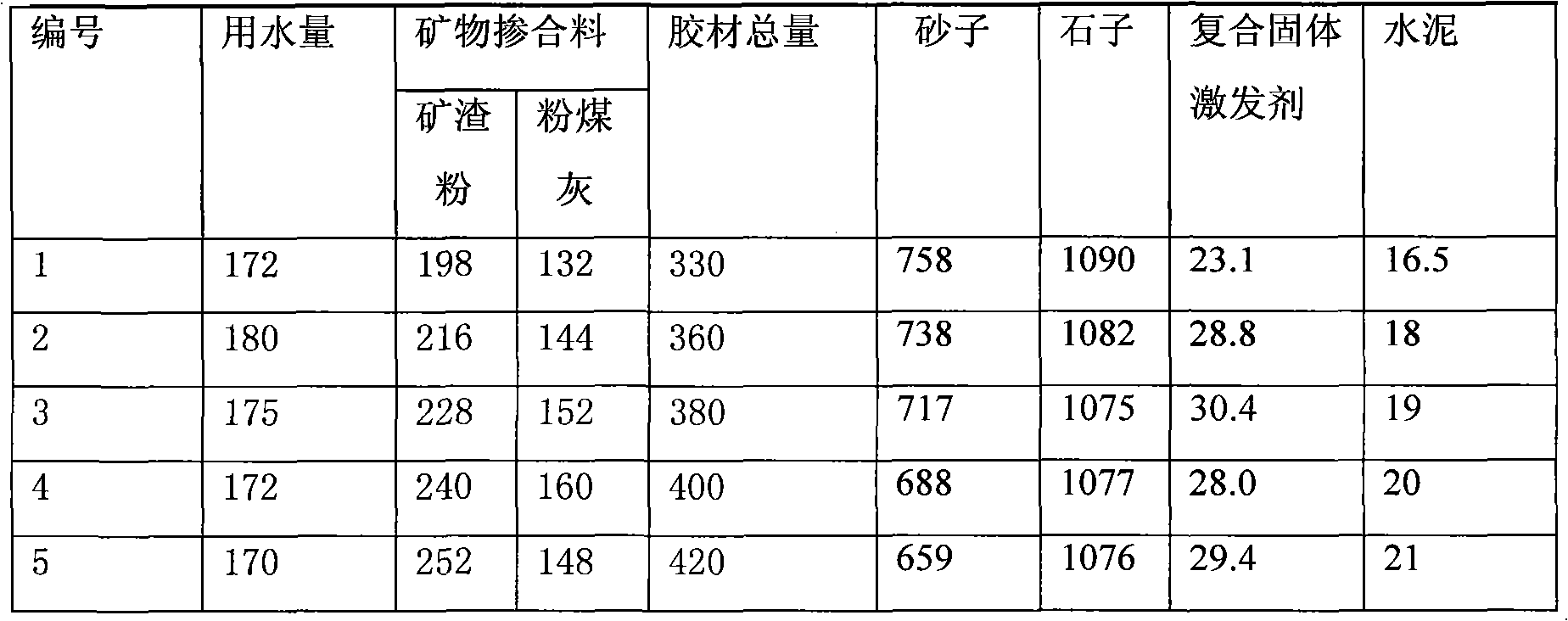

The invention relates to mineral admixture concrete and a preparation method thereof and belongs to the field of building materials. The preparation method is characterized in that a composite solid exciting agent is utilized to excite potential activity of a mineral admixture and produces a synergistic effect with common cement so that the mineral admixture concrete having strength of C30-C70 and excellent durability such as anti-permeability and frost-resistance and allowing normal setting time is obtained. The composite solid exciting agent can greatly improve the strength and the durability of the mineral admixture concrete. Through replacement of 90 to 95% of cement with a large amount of an industrial waste residue-slag powder-fly ash admixture, a production cost is reduced obviously. The mineral admixture of a cementing agent, a sand aggregate and the composite solid exciting agent is pre-stirred and then is added with mixing water so that the composite solid exciting agent is dispersed uniformly and after addition of the mixing water, the mineral admixture can be fully excited. In construction, the mineral admixture concrete has good workability and no ropiness, can be operated easily, has high strength after setting and hardening, good durability and a low cost, and can be used in various engineering construction and concrete products.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Liquid grinding aid for steel slag cement and preparation method of liquid grinding aid

The invention discloses a liquid grinding aid for steel slag cement. The liquid grinding aid comprises raw materials in percentage by mass as follows: 40%-55% of polymeric polyol, 5%-10% of sodium thiosulfate, 5%-10% of sodium silicate, 1%-5% of sodium carbonate and the balance of water, and the sum is 100%. According to the liquid grinding aid, polymeric polyol is adopted to replace more expensive triethanolamine, the material liquidity can be remarkably improved, the grinding efficiency of a grinder is improved, and the output of the grinders per hour is increased; sodium thiosulfate contained in the liquid grinding aid can have good inhibition effect on volume expansion of hardened paste of the steel slag cement; sodium silicate contained in the liquid grinding aid can stimulate the potential activity of steel slag, and 3-day strength and 28-day strength are increased on year-on-year basis; with the adoption of sodium carbonate, the steel slag cement setting time can be adjusted.

Owner:NANJING YONGNENG MATERIALS

Fly ash activator

The invention discloses a fly ash activator, relates to the technical field of materials for improving fly ash activity, and specifically relates to a fly ash activator. The fly ash activator is prepared by homogenizing and stirring the following raw materials in parts by weight: 10 to 30 parts of alum stone, 10 to 20 parts of anhydrous sodium sulphate, 10 to 20 parts of calcium chloride, 10 to 20 parts of sodium hydroxide, and the balance being fly ash or stone flour. The fly ash activator can effectively activate the potential activity of fly ash, increases the addition amount of fly ash, and reduces the amount of cement in concrete. The cost of the activator is maximally reduced at the same time. The fly ash activator can increase the economic profits and social profits of the industry of concrete and products thereof on the basis that the technical effect is not affected, and can realize the energy saving and emission reduction at the same time.

Owner:哈尔滨强石新材料技术开发股份有限公司

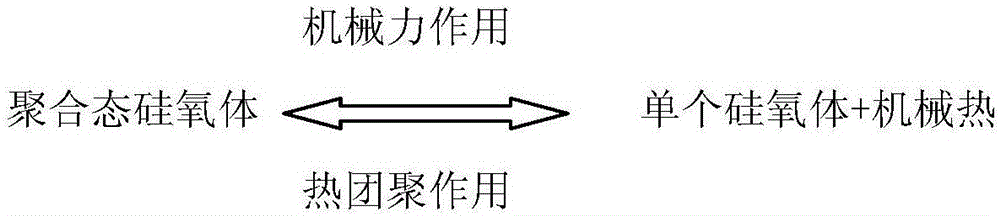

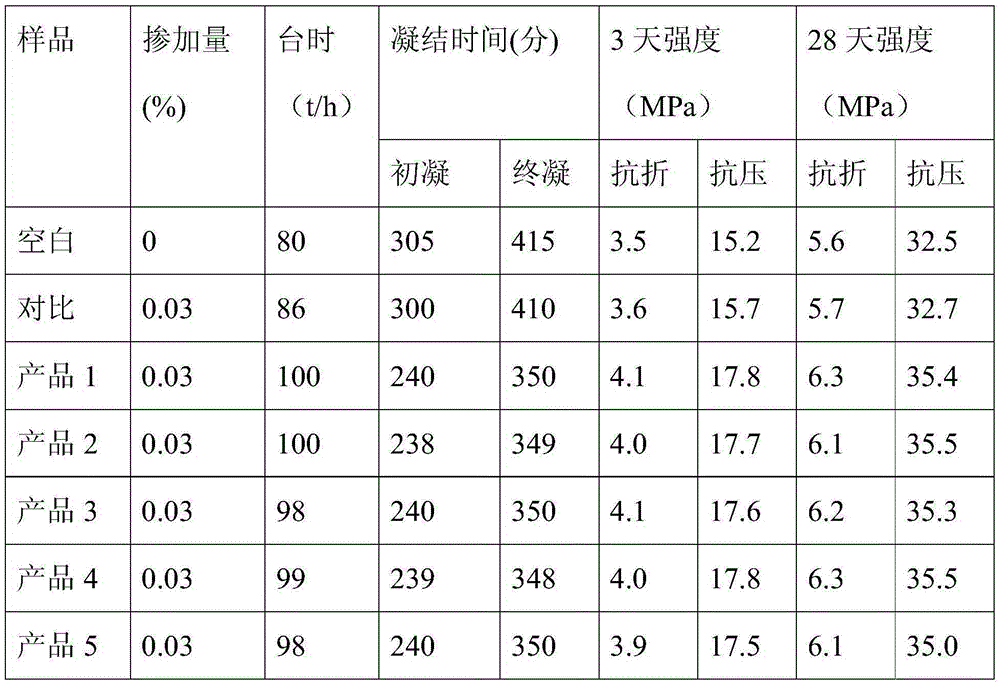

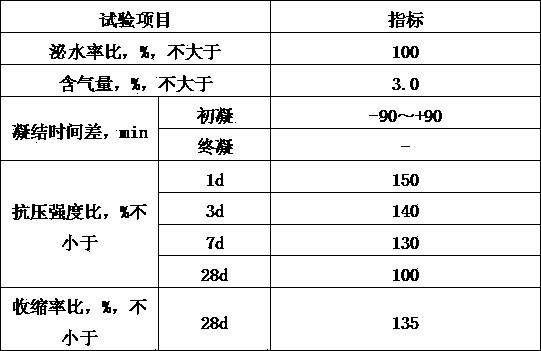

Powdery compound cement grinding aid and preparation method thereof

InactiveCN101708971AQuality assuranceReduce clinkerSolid waste managementSodium acetateSodium nitrite

The invention relates to a cement admixture, in particular to a powdery compound cement grinding aid and a preparation method thereof. The invention solves the problems of bottleneck effect in the reactions among various cement components in the prior cement grinding aid, poor effect of enhancing cement properties in various aspects, and the like. The powdery compound cement grinding aid is prepared from a liquid part and a powder part, wherein the liquid part is prepared from triethanolamine, cocoanut oil diethan olamide, potassium dichromate, sodium nitrite, sodium hexametaphosphate, an SM naphthalene water-reducing agent and the like; and the powder part is prepared from alunite powder, sodium acetate, iron vitriol, sodium thiosulfate, limestone powder and the like. The powdery compound cement grinding aid can provide an intermediate platform for the reactions among various cement components, so that the components in the cement produce mutual compound cooperation and superimposition effects, thereby effectively exciting the lateral reactivities of the components, enabling the components to perform the respective grind aiding functions in the powder grinding process, effectively eliminating the phenomena of ball paste and heavy grinding, increasing the specific area of the cement and the production output per hour of the cement grinder and greatly enhancing the rupture strength and the compression strength of the cement.

Owner:YANGCHENG JIXIN BUILDING MATERIAL

Ecotype full-regeneration rapid repair concrete

ActiveCN102807341AAchieve full utilizationEcological and environmental protection effect is obviousSolid waste managementAcid waterReducer

The invention discloses an ecotype full-regeneration rapid repair concrete which is characterized in that the concrete is prepared by the following components in parts by weight: 310-400 parts of cement, 20-60 parts of metakaolin, 40-90 parts of regeneration powder, 40-80 parts of rapid repairing agent, 1050-1200 parts of regeneration coarse aggregate, 520-600 parts of regeneration fine aggregate, 5-10 parts of polycarboxylic acid water reducer and 170-220 parts of water. The ecotype full-regeneration rapid repair concrete has the advantages that waste materials are sufficiently used, energy reduction and environmental protection are achieved, the traffic is opened as soon as possible, and the cost is low.

Owner:汇绿园林建设发展有限公司

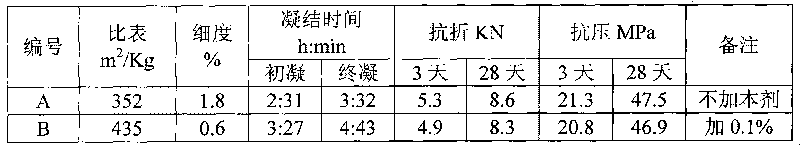

Liquid composite cement grinding aid and preparation method thereof

The invention relates to a cement additive, in particular to liquid composite cement grinding aid and a preparation method thereof, which solve the problems of bottleneck effect occurring in reactions among various components in cement caused by conventional cement grinding aid, poor effect in improving performance of each aspect of the cement and the like. The grinding aid is prepared from coconut oil diethan olamide, water, acetic acid, melamine, sodium nitrite, sodium acetate, sodium thiosulfate, molasses, sodium hexametaphosphate, calcium lignosulfonate and soap, can provide an intermediate platform for reactions among the components in the cement to ensure that the components in the cement can generate compound synergy and additive effects with one another, and more effectively excites potential activity of raw material components, thereby receiving sufficient reactions to play respective grinding aid effect in a powder grinding process, effectively eliminating ball stick and over grinding phenomena, improving the specific surface area of the cement, and simultaneously improving the machine-hour output of a cement mill; and the product which is added with 0.1 weight percent of cement can improve the 3-day strength of the cement by 4 to 7MPa, and improve the 28-day strength of the cement by 3 to 6MPa.

Owner:YANGCHENG JIXIN BUILDING MATERIAL

Concrete reinforcing agent

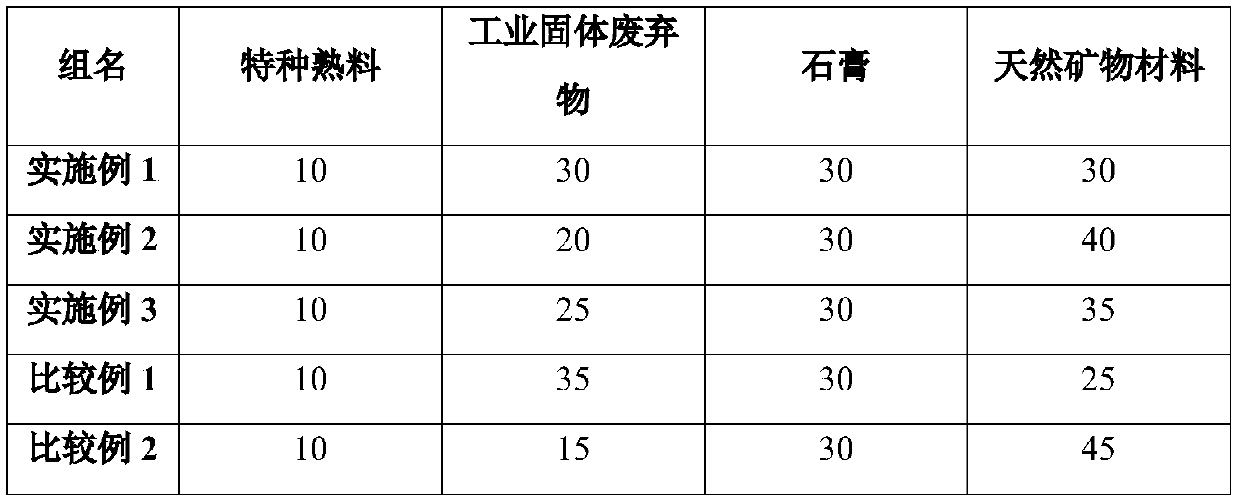

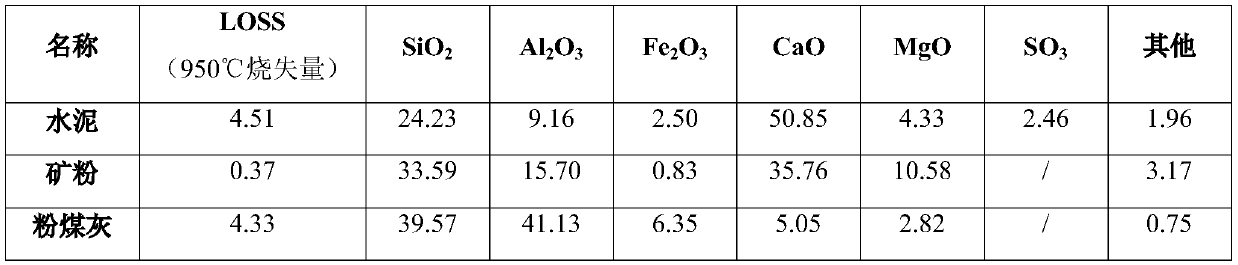

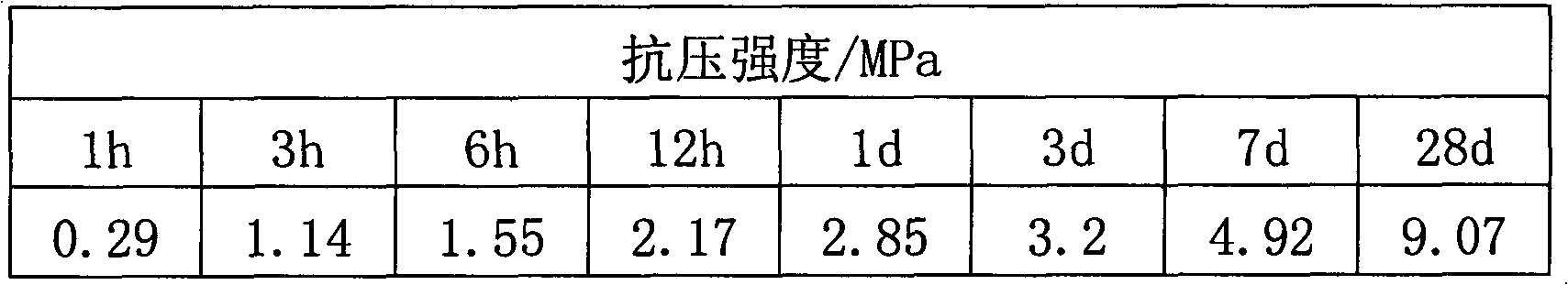

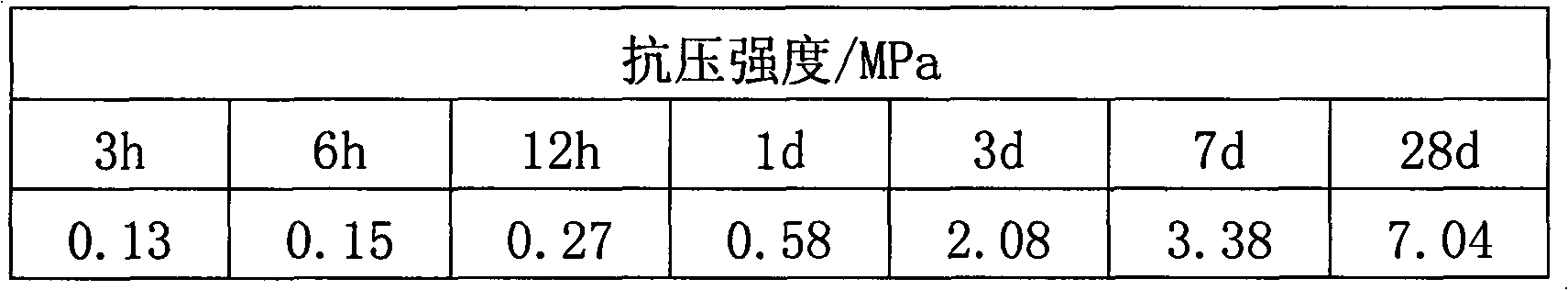

The invention discloses a concrete reinforcing agent which comprises, by weight, 10 parts of special clinkers, 20-30 parts of industrious solid rubbish, 30 parts of gypsum, 30-40 parts of natural mineral materials and internal maintenance continuous activators, and the internal maintenance continuous activator account for 5% of the total weight of the concrete reinforcing agent. A preparation method of the special clinkers includes the steps: grinding phosphogypsum, furnace clinkers granulated furnace phosphorus slag, granulated furnace phosphorus slag and limestone; mixing grinded materials;adding water and granulating mixture; drying the granulated materials; calcining the materials; cooling the materials; rapidly cooling and crushing the materials to obtain the special clinkers. Steelslag and granulated furnace phosphorus slag are mixed to form the industrious solid rubbish, solid sulfur ash is sufficiently soaked into acrylamide solution, mixture is extracted and filtered at negative pressure and then treated until a saturated surface dry state is achieved to obtain the internal maintenance continuous activators, and the natural mineral materials are alum stone powder. The reinforcing agent can replace 10-15% of cement amount, cost is reduced, compressive strength, penetration resistance and the like are optimized, and reuse of various solid rubbishes is promoted.

Owner:武汉源锦建材科技有限公司

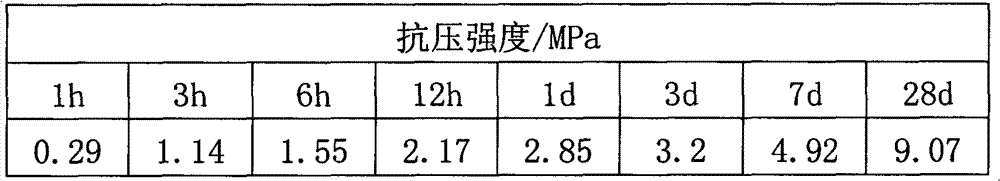

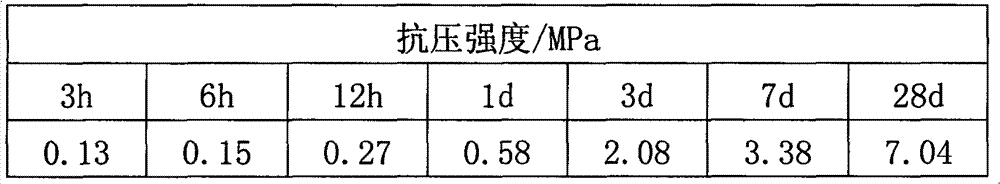

Double-fluid rapid hardening slurry for roadway grouting and mollisol compaction grouting

InactiveCN101974319AGuaranteed durabilityImprove grouting processDrilling compositionSodium silicateCoal

The invention discloses double-fluid rapid hardening slurry for roadway grouting and mollisol compaction grouting, remedying the defects that a cement-sodium silicate slurry concrement body has poor durability, and the grouting process is complicated. The slurry contains fluids A and B; the fluids A and B are injected at equal volume, and the on-site operation is simple. The fluid A contains 50 percent of portland cement, 0.5-0.75 percent of inorganic sodium salt, 0.025-0.05 percent of organic alcohol early strength agent and the balance of water; and the fluid B contains 43.6-48.8 percent of coal ash, 13.9-20.05 percent of sodium silicate and the balance of water. The performances of the slurry are shown as follows: the gelation time is adjustable within the range of 36s-124s, the concrement rate is 100 percent and the early compression strength is high; moreover, the concrement body has good durability and does not crack or pulverize. Compared with the original cement-sodium silicate slurry, the grouting process is simple, the durability of the slurry concrement body is obviously improved, the sodium silicate consumption is saved and the grouting cost is greatly reduced.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Silicate cement prepared from solid wastes and preparation method of silicate cement

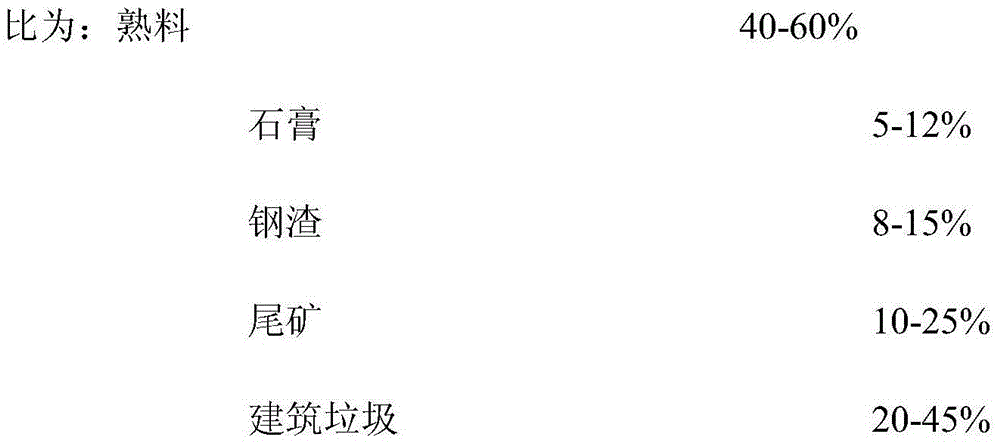

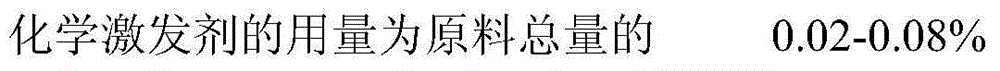

The invention discloses silicate cement prepared from solid wastes and a preparation method of the silicate cement and belongs to the technical field of building materials. The silicate cement is prepared from the raw materials: clinkers, gypsum, slag, tailings and building wastes by adding a chemical excitant. The silicate cement is prepared from the following raw materials in percentage by weight: 40-60% of clinkers, 5-12% of gypsum, 8-15% of slag, 10-25% of tailings and 20-45% of building wastes, wherein the use level of the chemical excitant is 0.02-0.08% of the total weight of the raw materials; the slag is slag without metallic iron; the tailings are wastes left by exploiting a mine; the building wastes are building waste bricks or concrete plate blocks without metals or other impurities. The silicate cement disclosed by the invention is widely applied to concrete and cement products, relieves increasingly deficient clinker firing resources and reduces discharge of carbon dioxide of cement, thereby facilitating reduction of severe haze in atmosphere. primary resources are saved and replaced, so that the circular economy development is promoted and the pollution is reduced to protect the ecological environment. In the production process, further pollution on the environment is not generated.

Owner:XUZHOU YUXIN ENVIRONMENTAL PROTECTION BUILDING MATERIALS CO LTD +1

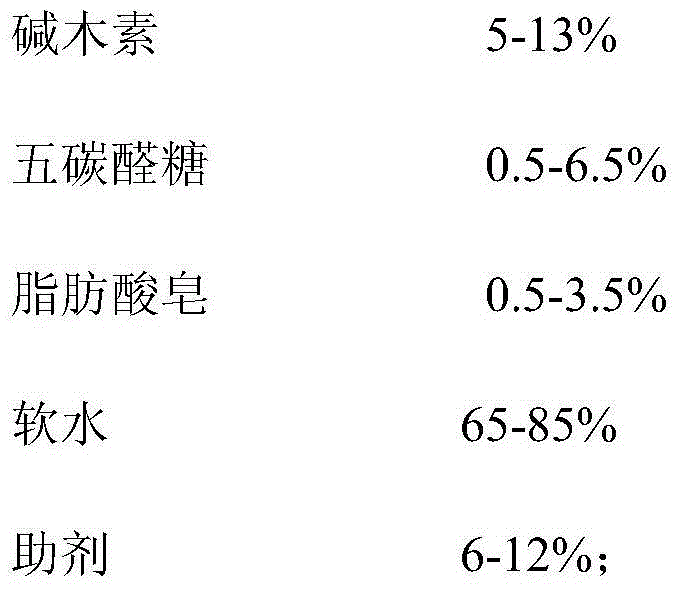

C80 high-strength concrete and preparation method thereof

InactiveCN109020403AReduce water demandReduce Microstructural DefectsHigh strength concreteWater reducer

The invention belongs to the field of concrete, and particularly discloses C80 high-strength concrete and a preparation method thereof. The concrete is prepared from the following materials in parts by weight: 400-450 parts of cement, 75-95 parts of mineral powder, 30-40 parts of coal ash, 45-65 parts of desulphurization ash, 950-1100 parts of coarse aggregate, 650-750 parts of fine aggregate, 3-5parts of a water reducer, 5-15 parts of a corrosion inhibitor and 130-145 parts of water. The invention provides the C80 high-strength concrete; the concrete has a good slump, good extended degree, good compressive strength, and excellent comprehensive performance, and meanwhile, the problems of resource shortage of traditional cement admixtures of the mineral powder, the coal ash and the like, and limited resourced approaches and a low utilization rate of desulphurization ash are solved.

Owner:成都宏基建材股份有限公司

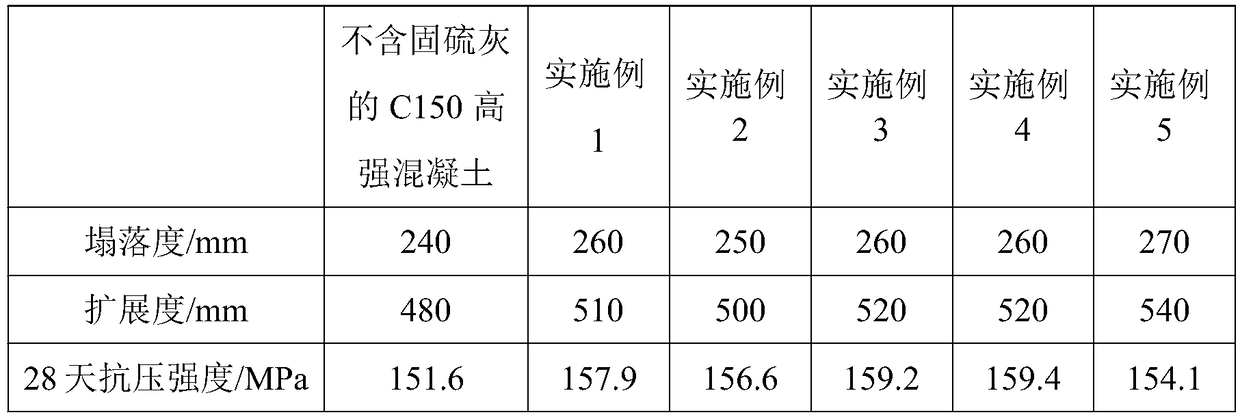

C150 high-strength concrete and preparation method thereof

The invention belongs to the field of concrete and particularly discloses C150 high-strength concrete and a preparation method thereof. The concrete consists of the following materials in parts by weight: 500 to 580 parts of cement, 45 to 65 parts of coal ash, 110 to 130 parts of ore powder, 65 to 85 parts of solid sulfur ash, 20 to 40 parts of silicon ash, 750 to 950 parts of crude aggregate, 400to 600 parts of fine aggregate, 5.5 to 7.5 parts of water reducer, 10 to 20 parts of corrosion inhibitor, 100 to 150 parts of fiber and 145 to 165 parts of water. The C150 high-strength concrete provided by the invention has good slump degree, expansion degree and compressive strength, has excellent comprehensive property, and overcomes the problems of shortage of the traditional cement admixtureresources such as the ore powder, the coal ash and the silicon ash, limited recycling route of the solid sulfur ash and low utilization rate of the solid sulfur ash.

Owner:成都宏基建材股份有限公司

Building block made of river sand as raw material and preparation method of building block

The invention discloses a building block made of quartz sand as a raw material and a preparation method of the building block, and solves problems of low reactivity of quartz sand, difficulty in grinding, high energy consumption and the like in the conventional building blocks. The building block provided by the invention is prepared from the following raw materials in parts by weight: 55-65 parts of quartz sand, 10-15 parts of carbide slag, 10-20 parts of silicon-aluminum active admixture, 6-8 parts of lime, 2-3 parts of cement, 3-7 parts of additive and 8-10 parts of acid solution with concentration of 5%. The preparation method comprises the following steps: firstly mixing and grinding quartz sand with the acid solution; then, adding the other components to be grinded to obtain slurry; placing the slurry in a stirring machine; adding cement and additive to be stirred and formed; then, performing gas release, blank repairing and steam pressing to obtain a sand aerated building block. The building block provided by the invention is simple in process, low in production cost, high in reactivity, excellent in performance, low in energy consumption and friendly to the environment.

Owner:HUBEI UNIV OF TECH

Method for preparing grouting material by using water-containing red mud and blast furnace slag

Owner:SHANDONG UNIV

Coal gangue activity exciting agent and high-fluidity and high-solid-content cemented filling slurry

The invention discloses a coal gangue active activator and high-fluidity high-solid-content cemented filling slurry, and the coal gangue active activator is composed of the following components: 2.5-15 parts by weight of calcined dolomite or calcined limestone, 3-9 parts by weight of silicate, 35-80 parts by weight of caustic soda, 3-22 parts by weight of gypsum and 0.025-1.4 parts by weight of a water reducing agent. The high-fluidity and high-solid-content cemented filling slurry is composed of water and a cemented filling material. The cemented filling material is composed of 65-95 parts by weight of coal gangue and 5-35 parts by weight of a coal gangue activity exciting agent; the mass fraction of water in the high-fluidity and high-solid-content cemented filling slurry is 7.2-9.8 wt%. The coal gangue can be hydrated and hardened to generate enough strength without using cementitious materials such as cement, and the cemented filling slurry is low in water content and good in fluidity, does not shrink after being hardened, and can be well topped due to micro-expansion.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

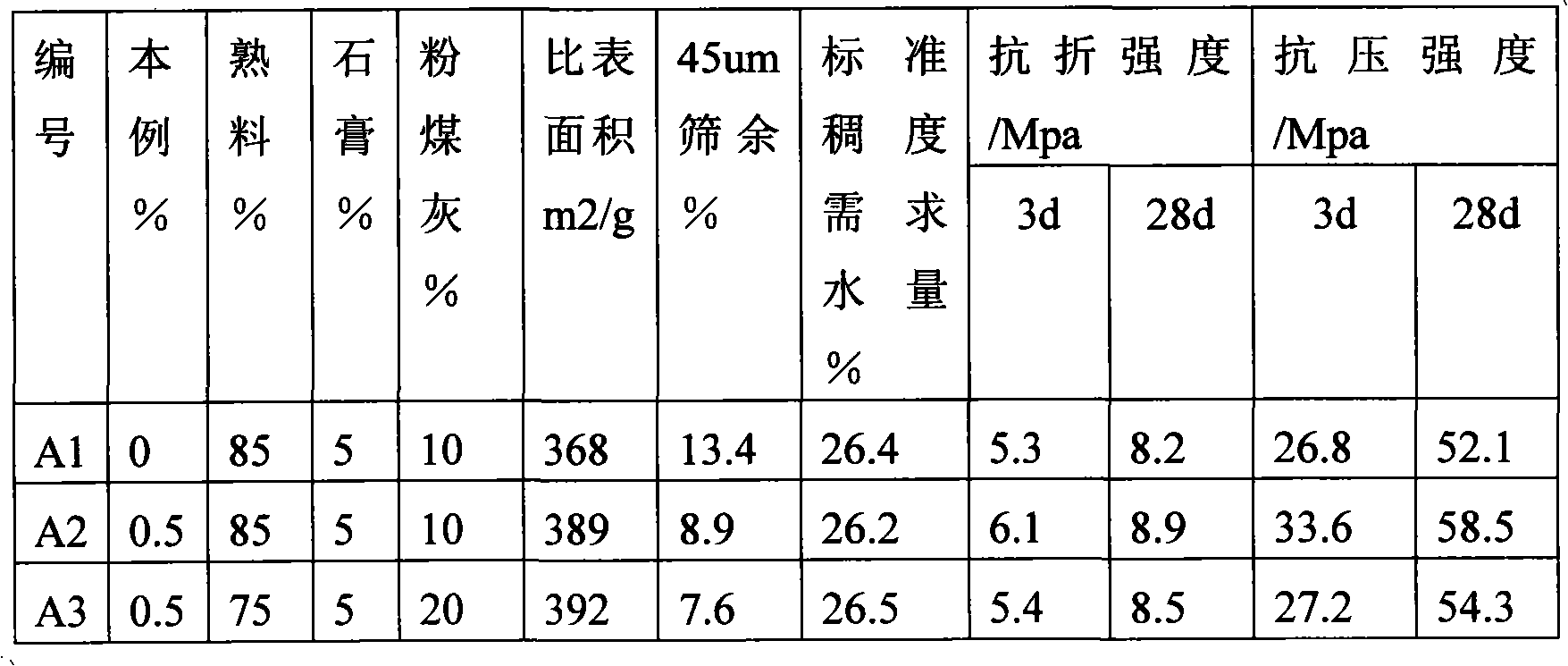

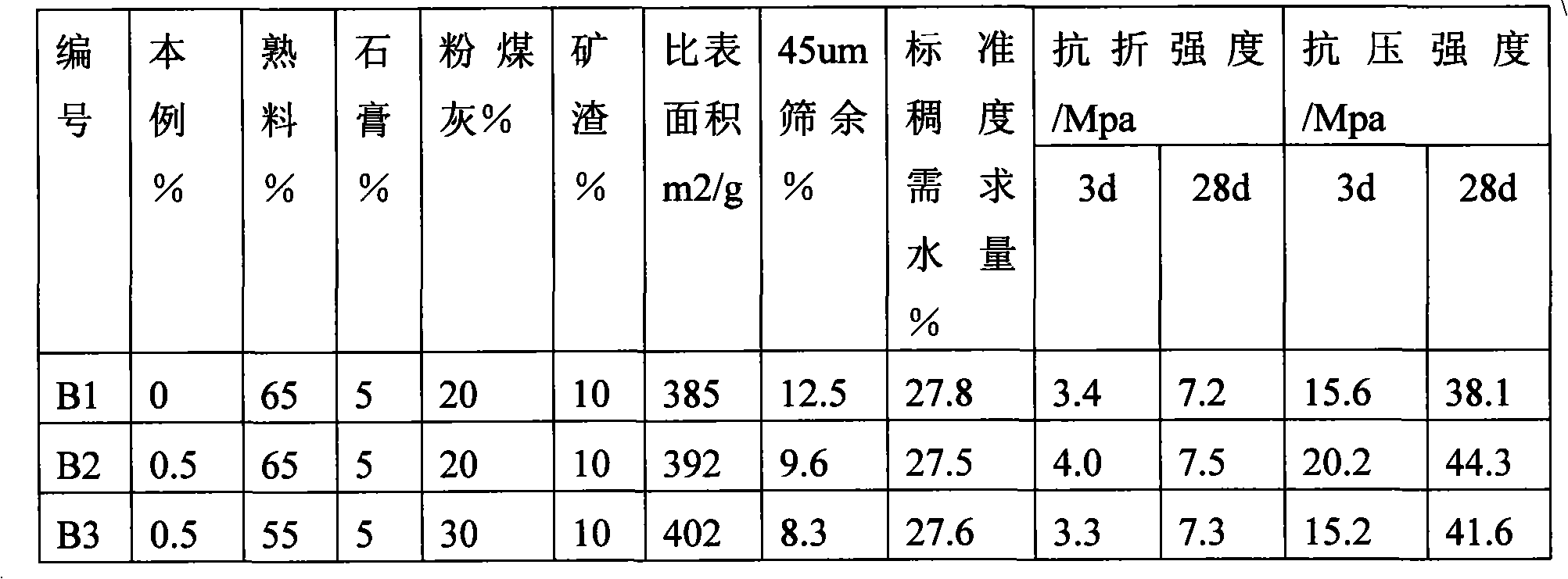

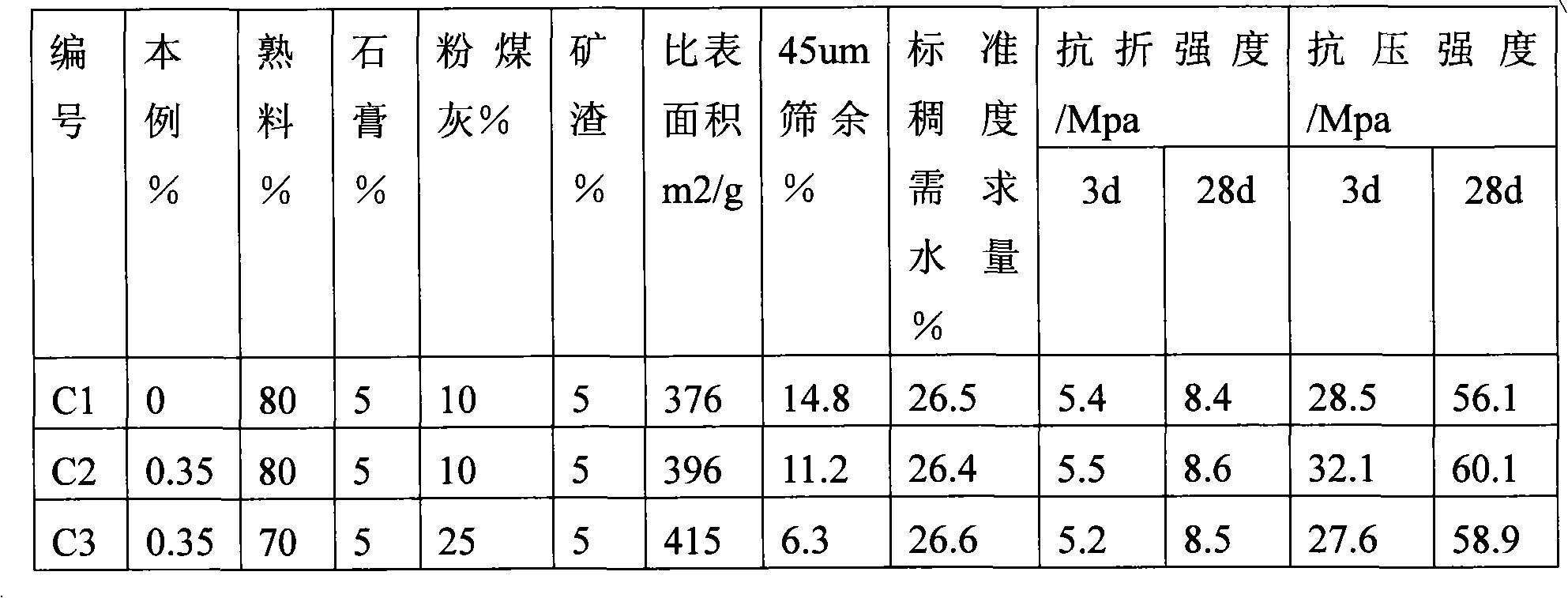

Composite grinding aid, production method and uses thereof

InactiveCN101428985BImprove compound synergyHigh strengthSolid waste managementCement productionSlagElectric consumption

The invention relates to a composite grinding aid for cement production and a preparation method and application thereof. The grinding aid contains 1 to 10 percent weight of organic aid and 90 to 99 percent weight of inorganic matrix material. The organic aid comprises at least one of polycarboxylic acid and lignosulphonate, C2-C5 polyfatty alcohols, C2-C5 polyfatty alcohol amines and gluconate, and the inorganic matrix material comprises at least one of sodium silicate and sodium carbonate, sulfate, calcined gypsum and calcium oxide. The invention also discloses the preparation method and the application for the composite grinding aid. The product can remarkably improve early and later strengths of cement, reduce the electric consumption of the grinding, and reduce the using amount of clinker. The compressive strength of the cement is obviously improved, the grinding efficiency is improved by between 10 and 20 percent, and the water consumption of the standard consistency of the cement is kept unchanged basically when 10 to 15 percent of the using amount of the clinker is reduced. The composite grinding aid is particularly suitable for a cement production technology which uses pulverized fuel ash and furnace bottom slag of coal-fired power plants as a composite material.

Owner:魔水科技(北京)有限公司

C70 high-strength concrete and preparation method thereof

InactiveCN109020400AStimulate latent activityElicitor can stimulate latent activityHigh strength concreteWater reducer

The invention belongs to the field of concrete, and particularly discloses C70 high-strength concrete and a preparation method thereof. The concrete is prepared from the following materials in parts by weight: 365-415 parts of cement, 70-90 parts of mineral powder, 25-35 parts of coal ash, 40-60 parts of desulphurization ash, 950-1100 parts of coarse aggregate, 650-800 parts of fine aggregate, 3-4.5 parts of a water reducer, 5-12 parts of a corrosion inhibitor and 125-145 parts of water. The invention provides the C70 high-strength concrete; the concrete has a good slump, good extended degree,good compressive strength, and excellent comprehensive performance, and meanwhile, the problems of resource shortage of traditional cement admixtures of the mineral powder, the coal ash and the like,and limited resourced approaches and a low utilization rate of the desulphurization ash are solved.

Owner:成都宏基建材股份有限公司

Double-fluid rapid hardening slurry for roadway grouting and mollisol compaction grouting

The invention discloses double-fluid rapid hardening slurry for roadway grouting and mollisol compaction grouting, remedying the defects that a cement-sodium silicate slurry concrement body has poor durability, and the grouting process is complicated. The slurry contains fluids A and B; the fluids A and B are injected at equal volume, and the on-site operation is simple. The fluid A contains 50 percent of portland cement, 0.5-0.75 percent of inorganic sodium salt, 0.025-0.05 percent of organic alcohol early strength agent and the balance of water; and the fluid B contains 43.6-48.8 percent ofcoal ash, 13.9-20.05 percent of sodium silicate and the balance of water. The performances of the slurry are shown as follows: the gelation time is adjustable within the range of 36s-124s, the concrement rate is 100 percent and the early compression strength is high; moreover, the concrement body has good durability and does not crack or pulverize. Compared with the original cement-sodium silicate slurry, the grouting process is simple, the durability of the slurry concrement body is obviously improved, the sodium silicate consumption is saved and the grouting cost is greatly reduced.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Method for preparing flyash excitant based on palm leaves

The invention relates to a method for preparing a flyash excitant based on palm leaves, belongs to the technical field of flyash excitants and provides a method for preparing a flyash excitant based on palm leaves. The method comprises the steps of extracting organic acid substances and an organic salt from the palm leaves by using ultrasonic oscillation and gas explosion; adding sodium hydroxide and the organic acid substances for reaction to increase the content of the organic salt; modifying an extract by adopting vanadium pentoxide as a catalyst and using dimercaprol dimercaptopropanol to increase the bonding capacity of the extract and a metal; and finally adopting the activated and modified carbide as a carrier for adsorbing beneficial components in the modified extract to prepare the flyash excitant. According to the prepared flyash excitant, the potential activity of flyash can be effectively excited, the dose of the flyash in concrete is increased, the peaceability of the concrete can be improved, cement is greatly saved under the condition of not affecting the strength of the concrete, the cost of the concrete and a concrete product is reduced, and the method has significant economical benefits and social benefits.

Owner:CHANGZHOU AMANTE CHEM CO LTD

Flyash cement auxiliary material and its use

InactiveCN1491912AIncrease productionLow costSolid waste managementCement productionMetallurgical slagPortland cement

The auxiliary material for cement consists of metallurgical slag 10-35 wt%, flyash 30-50 wt%, lime or limestone 25-40 wt%, gypsum 5-10 wt%, sodium silicate or sodium borate 0-3 wt% and alkali 0-2 wt%. The preparation process includes crushing material, mixing and stacking for 1-2 days. The auxiliary material is mixed with Portland cement clinker in the weight ratio of 1 to 2-3 to produce cement product.

Owner:赖兆平 +1

Controllable clay and cement seepage-proof reinforcement paste

The invention discloses controllable clay and cement seepage-proof reinforcement paste. The controllable clay and cement seepage-proof reinforcement paste is mainly prepared from clay raw stock, cement and water, wherein the clay raw stock is mainly obtained by stirring clay and water. A modifier is added in the controllable clay and cement seepage-proof reinforcement paste; the doping amount of the modifier is 1 to 3 percent; the modifier mainly comprises mineral additives, sulfate and bentonite in a mass ratio of a:b:c; and a:b:c is 5:(5-0):(0-5). The product has the advantages of high stability and water flow dilution resistance, controllable setting time, adjustable strength, high antiseepage performance, low cost, environment friendliness and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com