Method for preparing grouting material by using water-containing red mud synergistic blast furnace slag

A technology of grouting material and blast furnace slag, which is applied in the field of red mud-based new grouting material and its preparation, can solve the problems of high cost, high heat consumption, and large energy consumption, and achieve high early strength, fast coagulation speed, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Get 8.3g of NaOH, water glass (its mode is 2.8, Baume degree is 35) 8.3g, portland cement clinker 8.3g and mix the three to prepare a composite alkaline activator;

[0033] 2) Take the specific surface area as 380m 2 / Kg~420m 2 / Kg blast furnace slag powder 125g, take polycarboxylate superplasticizer SP-409 10g, calcium chloride 5g;

[0034] 3) Take red mud soup (water content is 62%, specific surface area is 250m 2 / Kg, pH value is 11-13) 335g, pour blast furnace slag and alkaline activator into red mud soup, stir for ten minutes, and grouting operation can be carried out after stirring evenly.

[0035] 4) Strength test method: The laboratory is designed according to the water-cement ratio of 0.8:1, and the sample is poured using a 70.7×70.7×70.7mm test mold. The curing temperature is 20°C and the humidity is 90%.

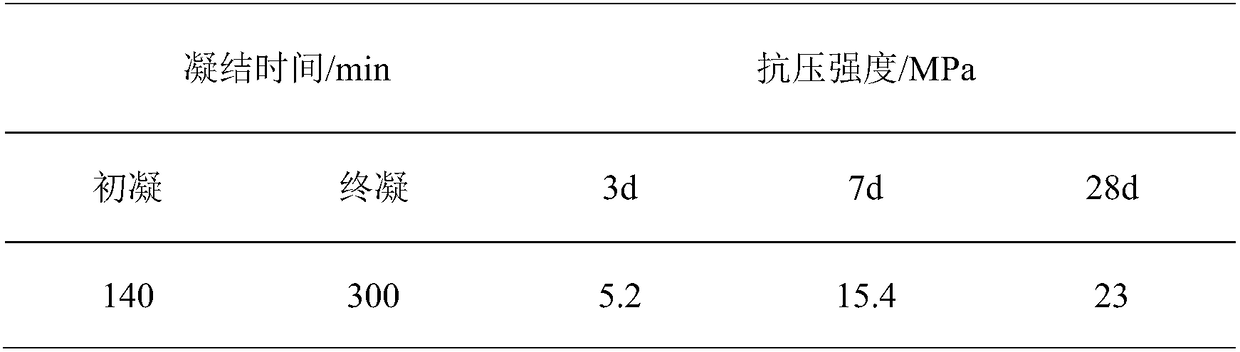

[0036]

Embodiment 2

[0038] 1) Take NaOH 10g, water glass (its mode is 2.8, Baume degree is 35) 8.3g, portland cement clinker 6.6g and mix the three to prepare a composite alkaline activator;

[0039] 2) Take the specific surface area as 380m 2 / Kg~420m 2 / Kg blast furnace slag powder 100g, take polycarboxylate superplasticizer SP-409 10g, calcium chloride 5g;

[0040] 3) Take red mud soup (water content is 62%, specific surface area is 250m 2 / Kg, pH value is 11-13) 350g, pour blast furnace slag and alkaline activator into red mud soup, stir for five minutes, and grouting operation can be carried out after stirring evenly.

[0041] 4) Strength test method: The laboratory is designed according to the water-cement ratio of 0.8:1, and the sample is poured using a 70.7×70.7×70.7mm test mold. The curing temperature is 20°C and the humidity is 90%.

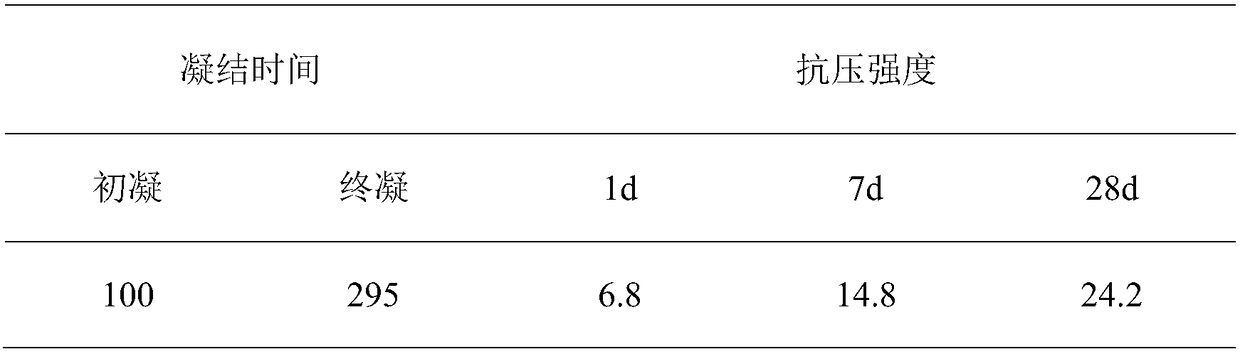

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com