Controllable clay and cement seepage-proof reinforcement paste

A technology for reinforcing paste and clay, which is applied in the field of cement paste and paste anti-seepage reinforcement materials, can solve the problems of difficult to control reaction time accurately, toxicity of chemical grouting materials, poor durability, etc. The effect of good irrigation and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

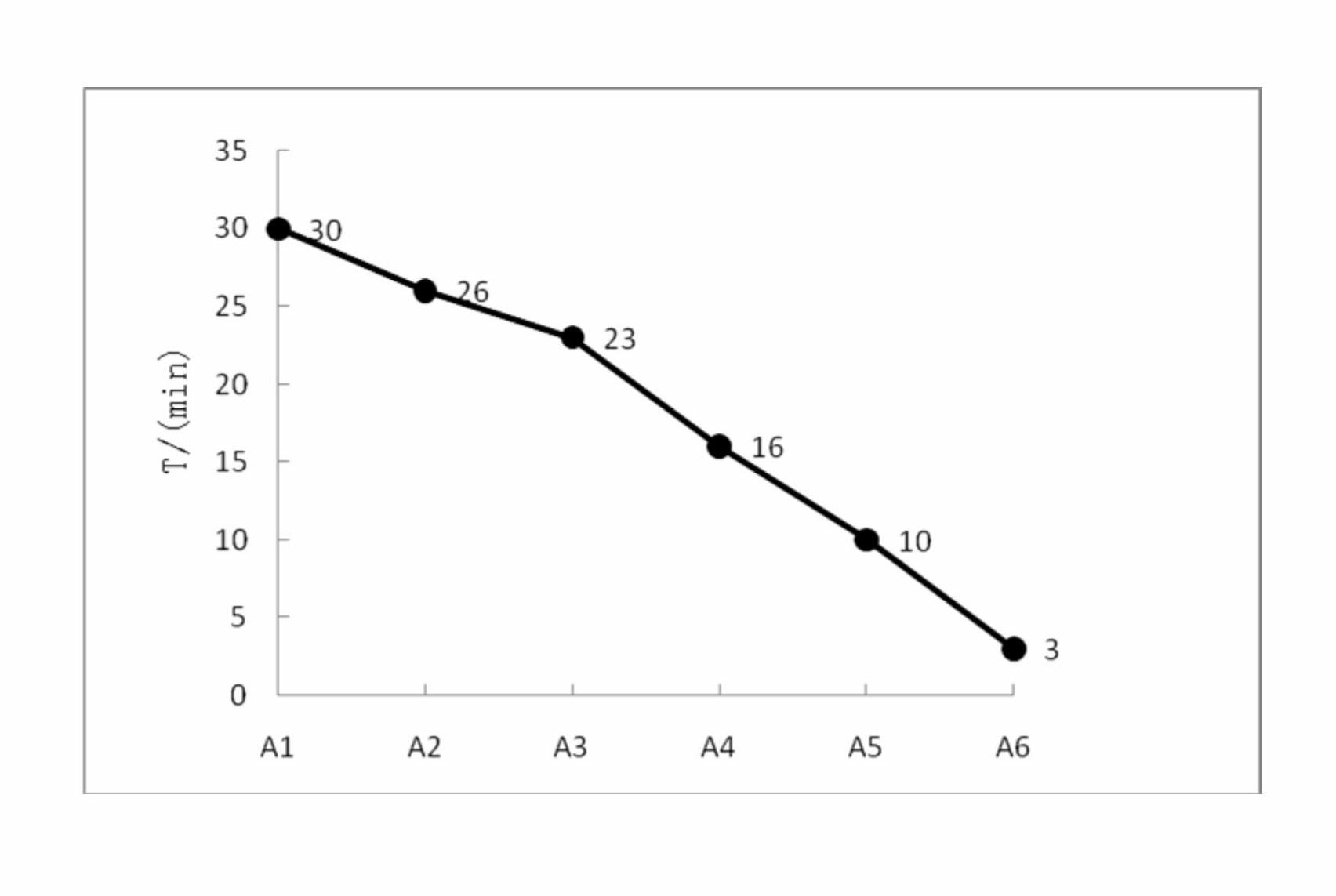

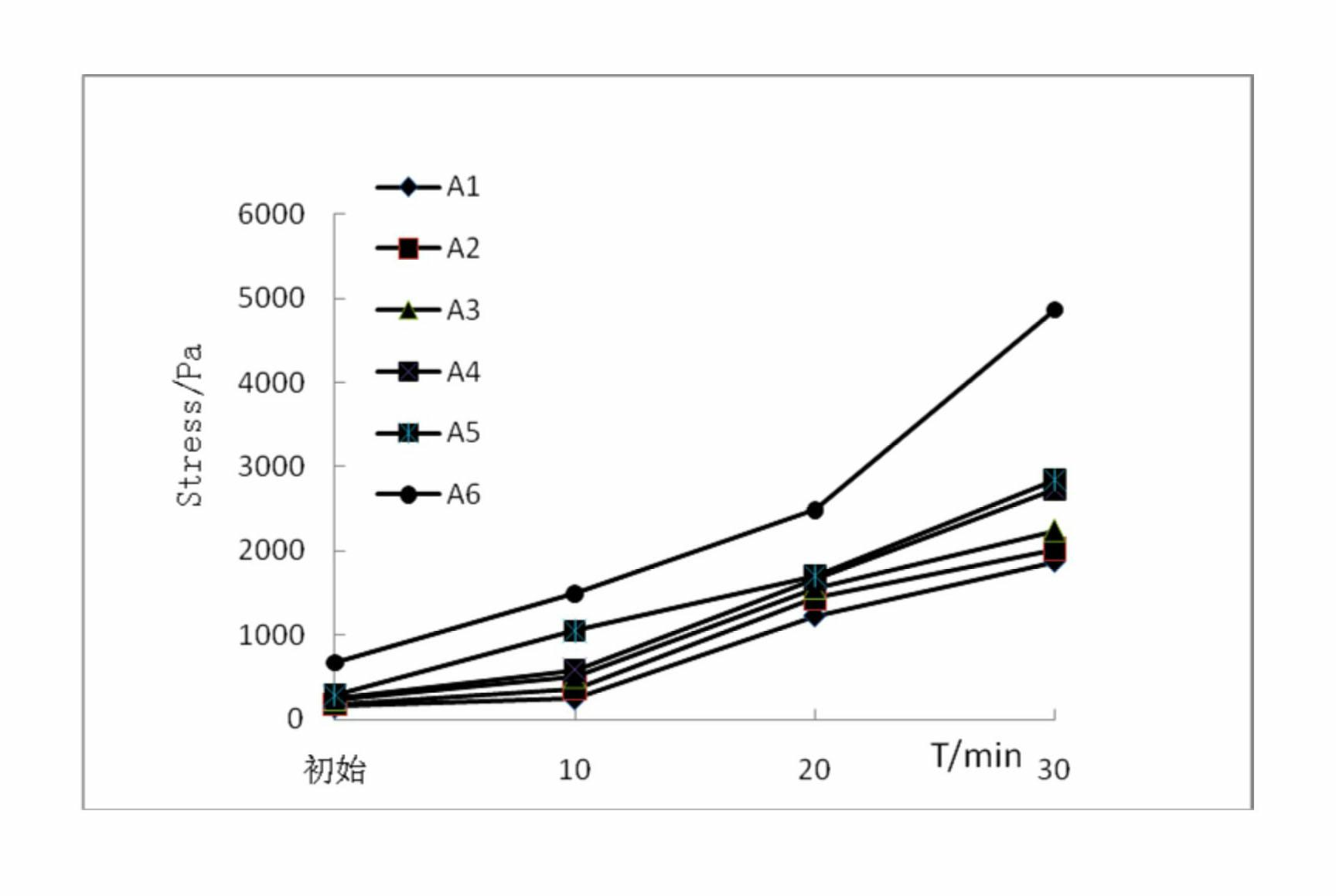

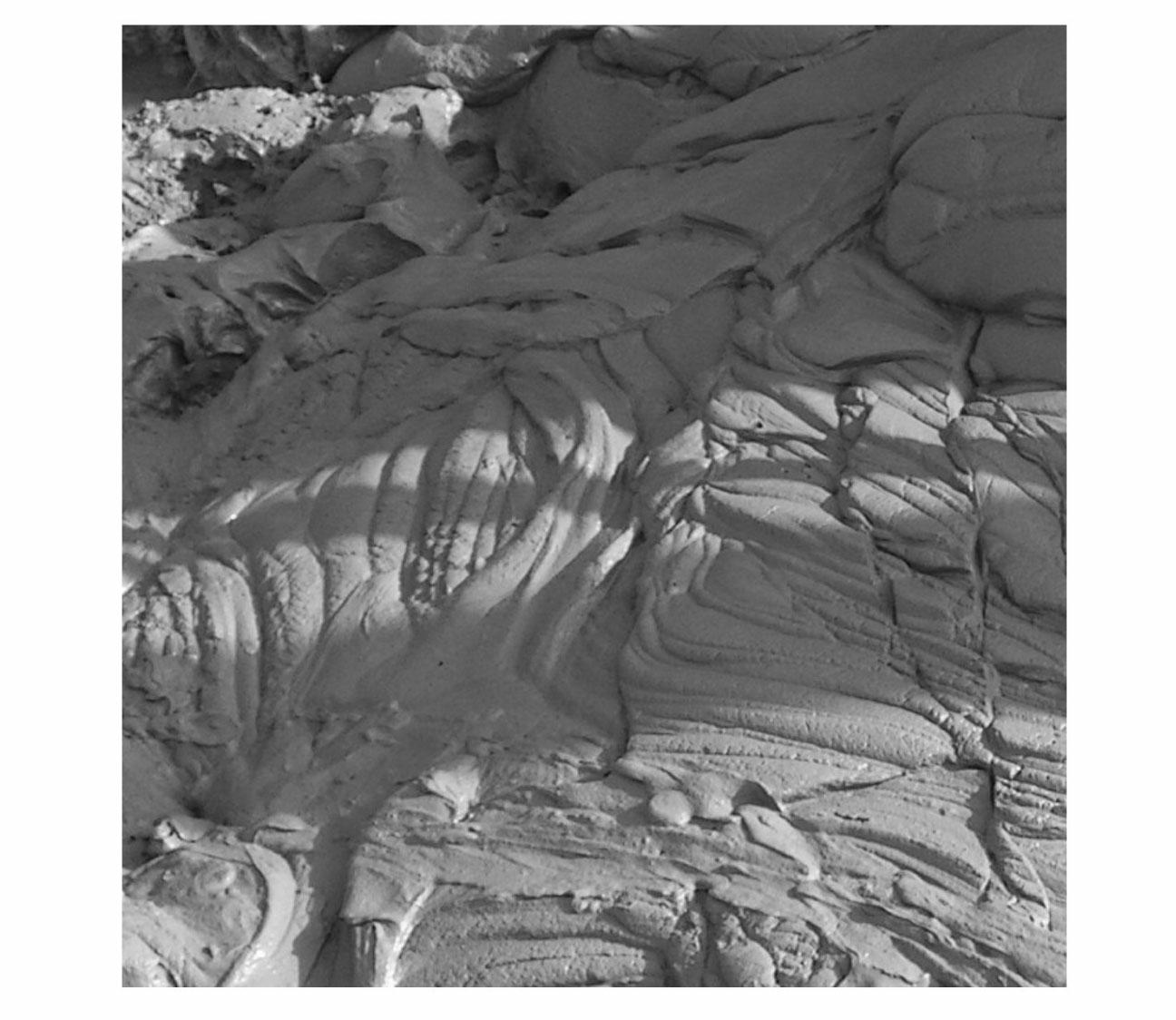

[0021] a kind of like image 3 The controllable clay cement anti-seepage reinforcement paste of the present invention is mainly prepared from clay puree, cement (P42.5 ordinary Portland cement is enough) and water, and the clay puree is mainly composed of high-quality clay (High-quality clay with low sand content) mixed with water. The controllable clay cement anti-seepage reinforcement slurry is added with modifier, and the amount of modifier (the amount of modifier is the mass of modifier accounts for The proportion of cement mass) is 2%, and the modifier is mainly composed of mineral additives (sodium metaaluminate), calcium sulfate and calcium-based bentonite with a mass ratio of a:b:c, a:b:c is selected from the following table Six groups of mass ratios in 1.

[0022] Table 1: The main material mass ratio of controllable clay cement anti-seepage reinforcement paste in Example 1

[0023] serial number a:b:c (mineral additives: sulfate: bentonite) Clay pulp s...

Embodiment 2

[0028] A controllable clay cement anti-seepage reinforcement paste of the present invention, which is mainly prepared from clay stock, cement (P42.5 ordinary Portland cement is enough) and water, and the clay stock is mainly composed of high-quality clay ( High-quality clay with low sand content) mixed with water, the controllable clay cement anti-seepage reinforcement paste is added with a modifier, the amount of the modifier is 1% to 3%, the modifier is mainly composed of mass The ratio is a:b:c mineral additives (sodium metaaluminate), calcium sulfate and calcium-based bentonite, and a:b:c = 5:(5~0):(0~5).

[0029] The specific gravity of clay protoplasm in this embodiment is 1.2~1.4 g / cm 3 The original slurry (can be adjusted according to actual engineering needs), the water-solid ratio of the controllable clay cement anti-seepage reinforcement slurry is (0.56-1.43): 1, and the water-cement ratio of the controllable clay cement anti-seepage reinforcement slurry Less than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel time | aaaaa | aaaaa |

| cone penetration | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com