Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "High flexural strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

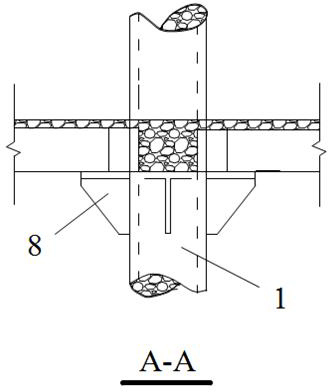

Concrete and preparation method thereof

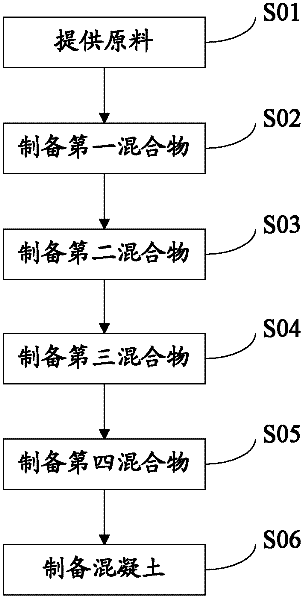

The invention is applicable to the technical field of building materials, and provides a concrete and a preparation method of the concrete. The concrete comprises a cementing material, river sands, a super plasticizer, water, steel fibers and polypropylene fibers. The concrete of the invention has a gradation synergetic effect by utilizing mixed graded steel fibers, so as to greatly improve compressive strength and bending strength, crack resistance and impact resistance of concrete; and the concrete overcomes early-stage microcrack problem of concrete via fine polypropylene fibers, and mainly improves toughness of concrete via coarse polypropylene fibers, so as to realize the advantages of concrete such as high compressive strength and bending strength, high crack resistance, and good durability. The concrete preparation method is easy in operation and low in cost, and is very suitable for industrial production.

Owner:黄贺明

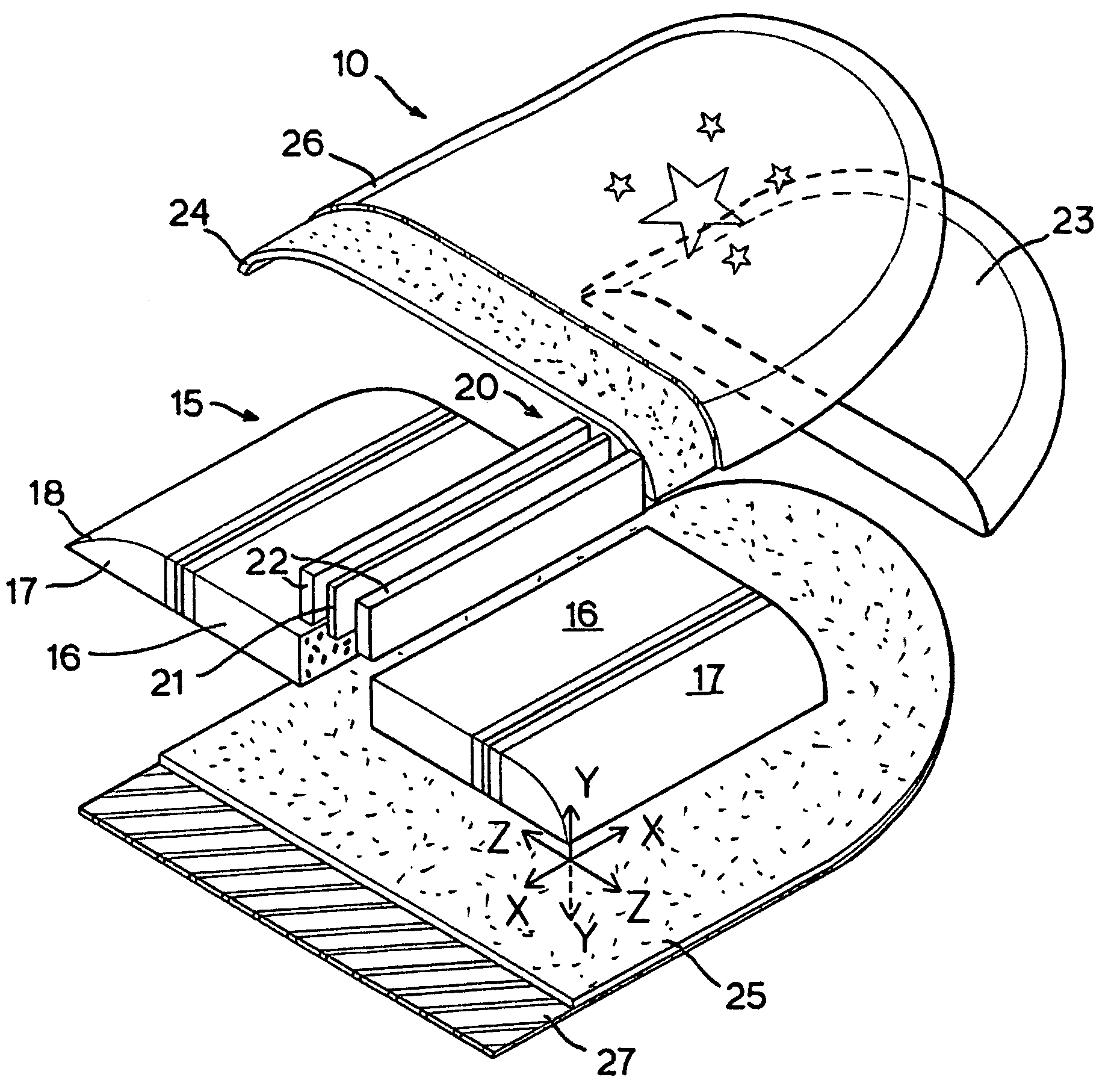

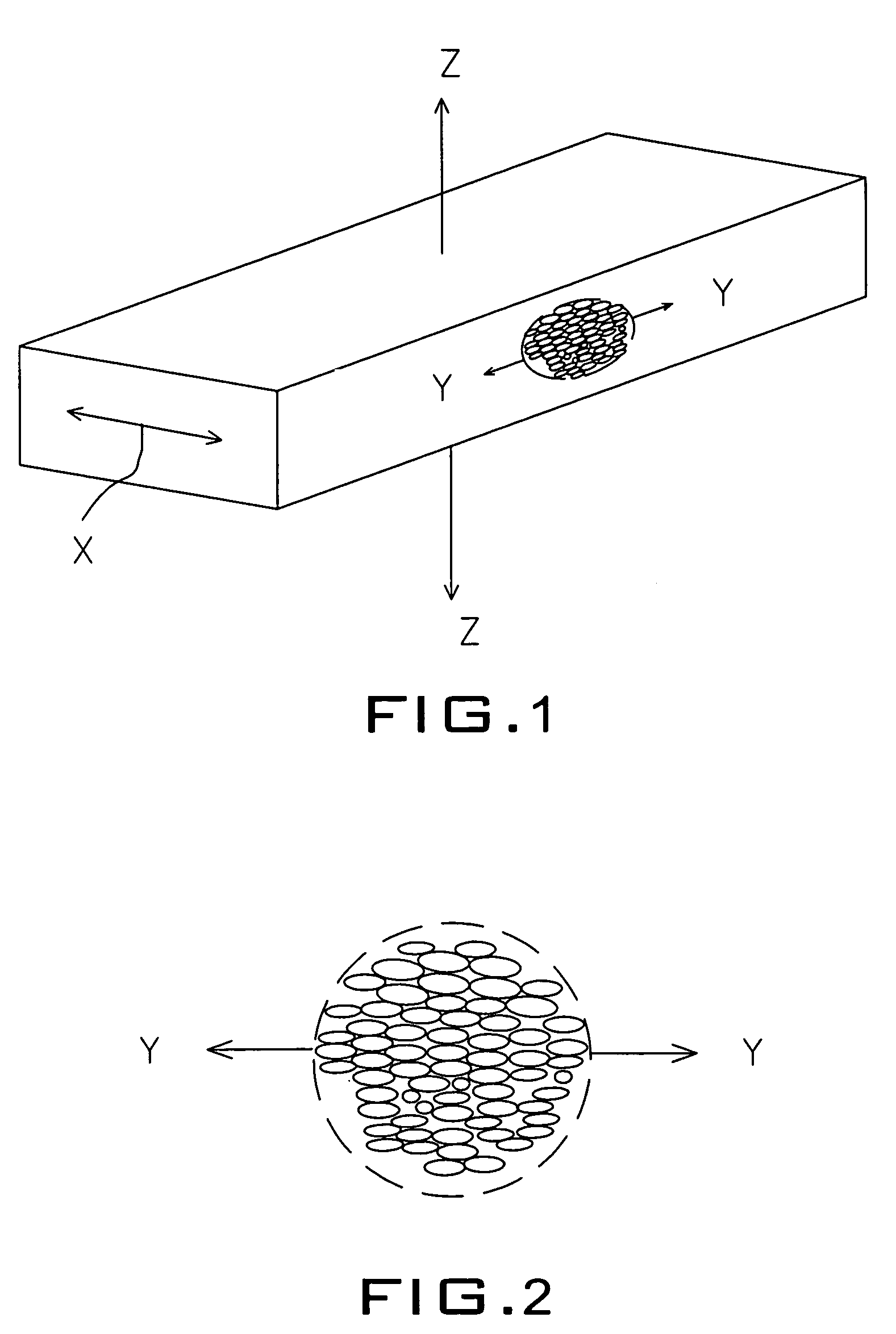

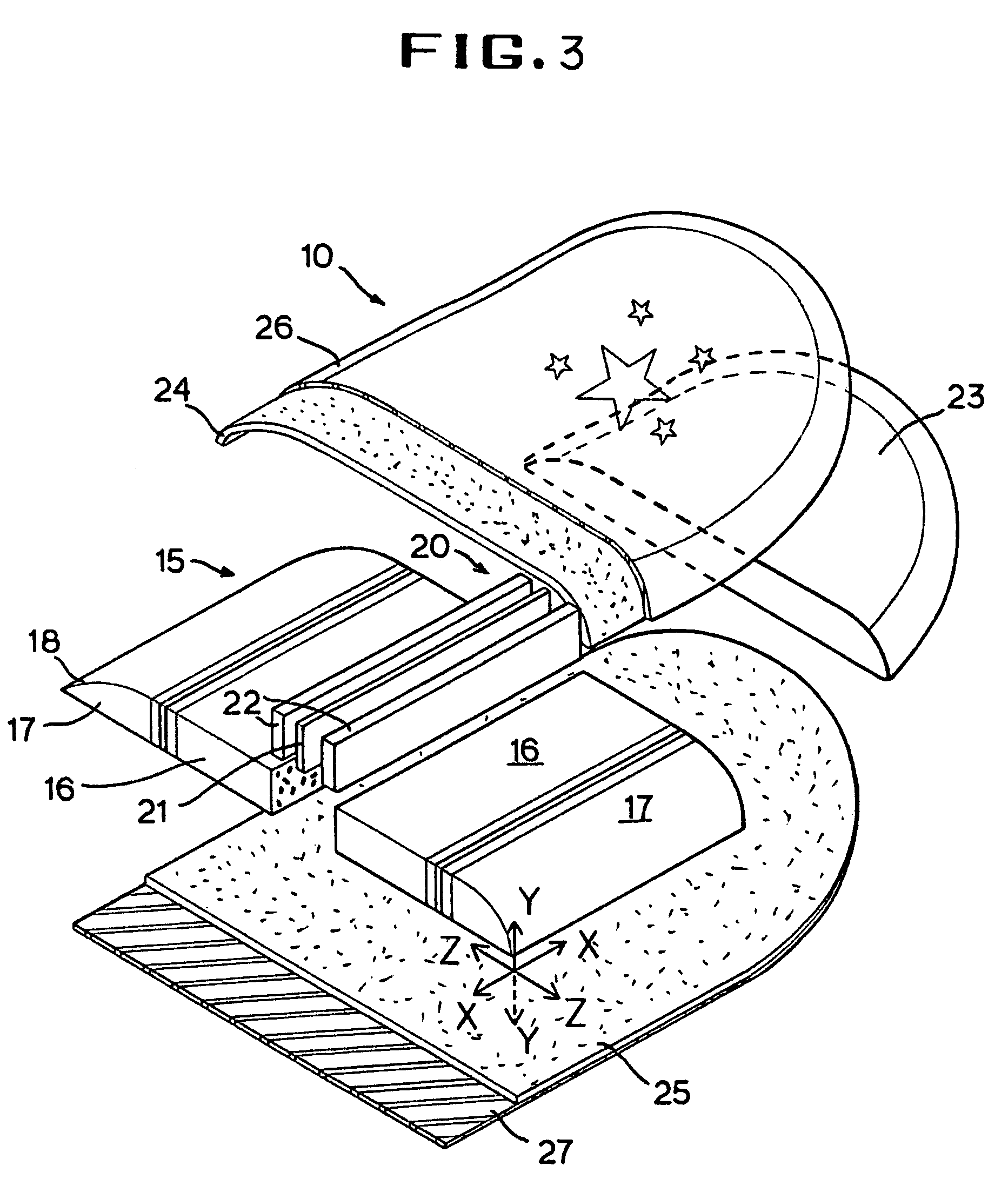

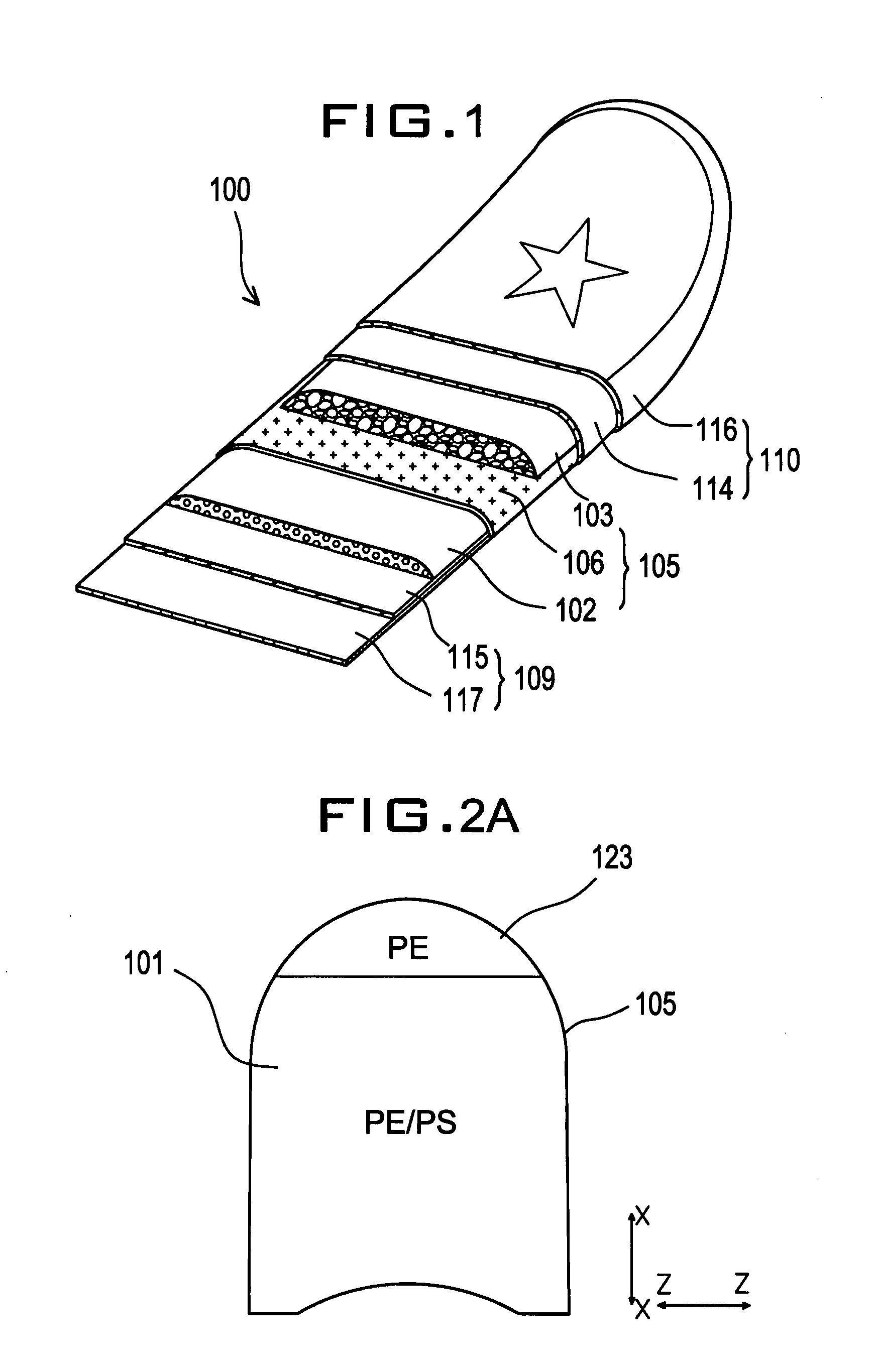

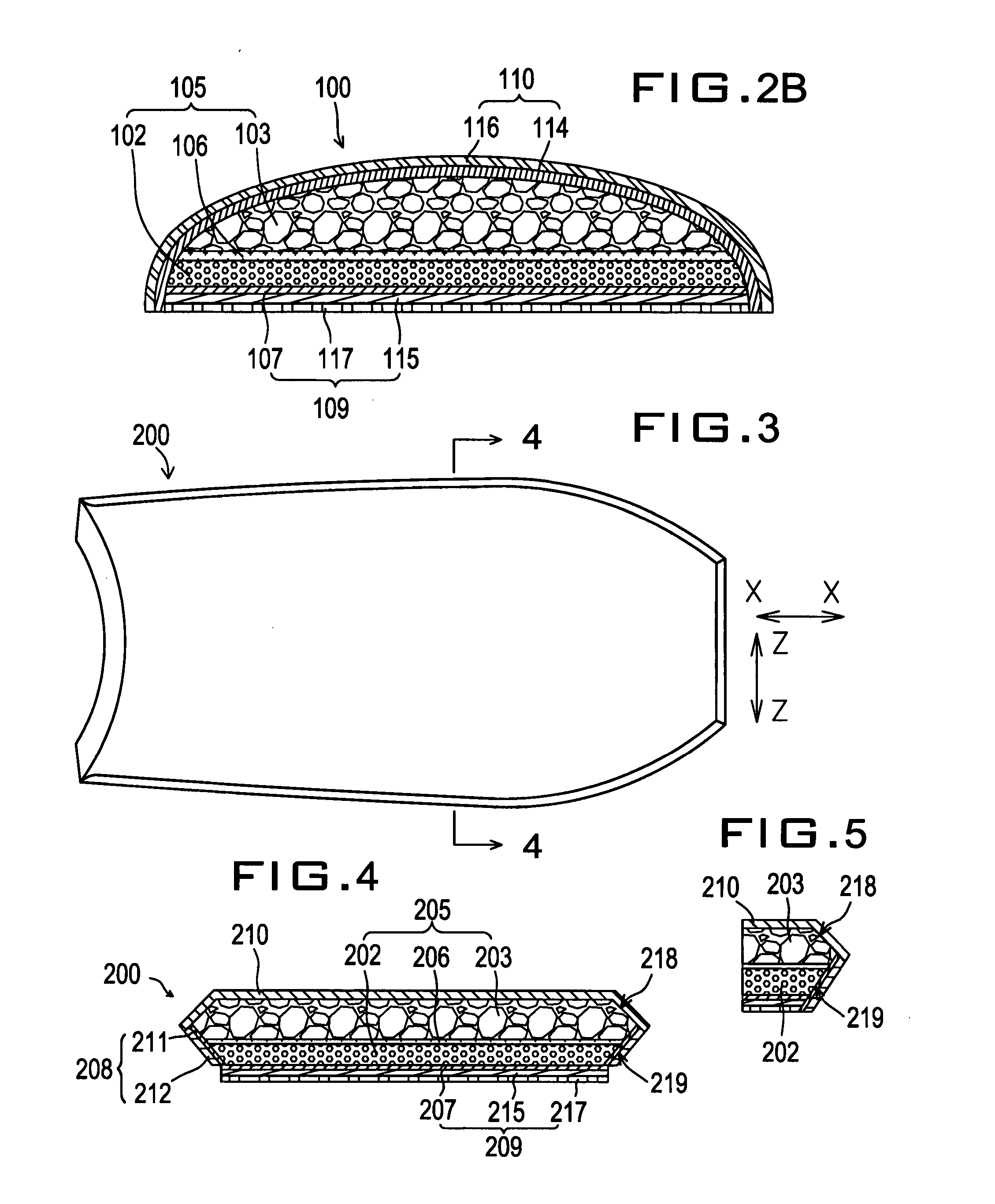

Sports board with integral laminated stiffening element

InactiveUS7246568B1Uniform stiffnessImproves compression resistanceNon-magnetic metal hullsWater sport boardsPolyolefinPliability

A sport board for snow sledding or surf body boarding comprises a multi-layered laminated composite foam core coupled with stiffening elements for mechanical strengthening of the board. The composite foam core comprises laminates of polyolefin foam base and stiffening elements composed of substantially polymer foam and has substantial higher compressive strength and flexural strength than the foam base. A front section may be made of the same blank material as the low density polyolefin foam base and is bonded to the front end of the foam core complex to give a full frontal flexibility for a higher directional control by the rider and improved shock absorbing property. Upper and lower polyethylene foam sheets wrap the foam core complex subassembly and head section for sled integrity and graphic film finishes the sled top, the bottom is also finished with a polyethylene sheet for slickness.

Owner:CHEUNG WAH KAN

Coal rock grouting reinforcement material and preparation method thereof

The invention discloses a novel styrene-butadiene latex modified cement based grouting reinforcement material used for reinforcing coal rock and a preparation method thereof. The high-performance styrene-butadiene latex cement based grouting material is prepared from common silicate cement, styrene-butadiene latex, water reducing agent, defoaming agent, coagulation regulating agent and the like in a certain mass ratio. The grouting material has higher water-cement ratio, strong water-retaining property, good liquidity and grouting property, good volume stability and controllable slurry coagulation time, and can keep long-term conveying without bleeding; and the construction is simple and the operation is convenient. The material has good bonding power with the coal rock and proper strength when reinforcing the coal rock, the slurry is innocuous, and the material has low price and can be widely applied to the reinforcement of various crushed coal rocks.

Owner:UNIV OF SCI & TECH BEIJING

Composite Ceramic and Method for Making the Same

InactiveUS20080118722A1Improve toughnessLow mechanical strengthLayered productsThin material handlingAlkaline earth metalComposite ceramic

A composite ceramic of the present invention includes granular alumina particles (A) having an aspect ratio of 3 or less, granular zirconia particles (B) having an aspect ratio of 3 or less, and a columnar crystal (C) having an aspect ratio of 3 or more, the columnar crystal including a complex metal oxide containing an alkaline-earth metal element and aluminum element. The composite ceramic has high flexural strength, toughness, and hardness, and achieves excellent hot-water resistance and high flexural strength after hydrothermal degradation resistance test.

Owner:KYOCERA CORP

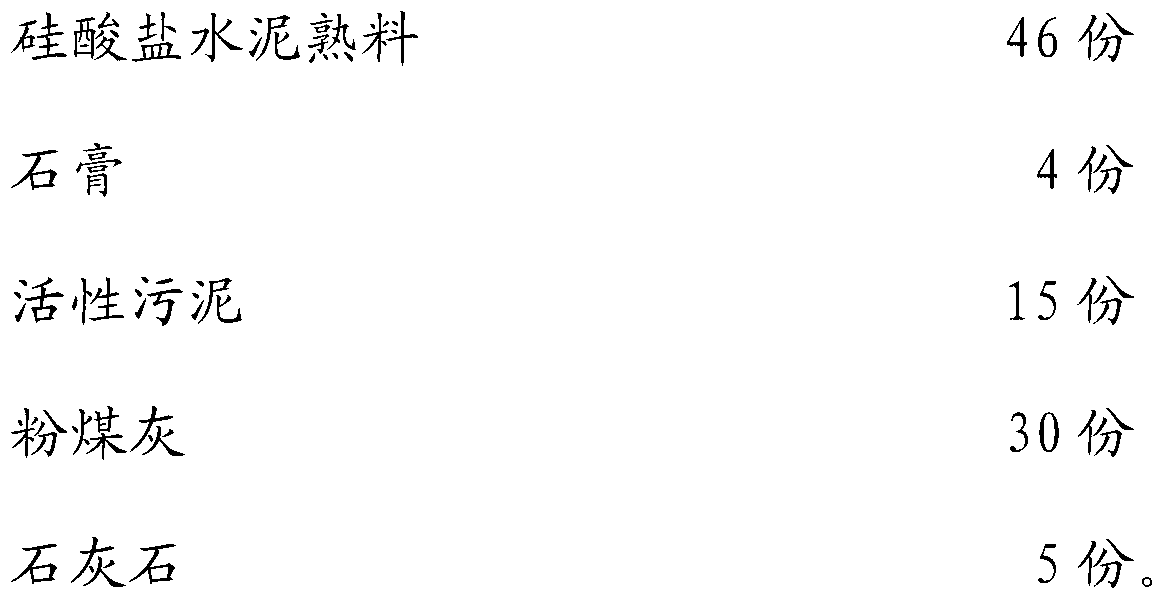

Composite cement and preparation method thereof

InactiveCN103253877AAccelerated hydration hardeningHigh flexural strengthCement productionGypsumBuilding material

The invention relates to a type of cement and a preparation method thereof, and particularly relates to a composite cement and a preparation method thereof, belonging to the technical field of building materials. The composite cement obtained by grinding 46-70 parts of portland cement clinker, 4-8 parts of gypsum, 10-15 parts of activated sludge, 10-30 parts of fly ash, and 2-5 parts of limestone until the specific surface area is greater than 300 m<2> / Kg is high in early strength, thus solving the key technical problems that the early strength of the composite cement is increased and water for treating sludge is effectively utilized. The compressive strengths of the composite cement achieve 17-25 MPa and 45-60 MPa, and the flexural strengths of the composite cement achieve 3.5-5 MPa and 6-8 MPa in 3 days and 28 days respectively; and the composite cement is provided with a micro-expansion characteristic, is capable of giving compensating shrinkage performance to mortar and concrete, and improving the anti-crack capacity of mortar and concrete, and is suitable for production for mortar, concrete and products.

Owner:NANJING COLLEGE OF CHEM TECH

Color pencil lead with high flexural strength and preparation method thereof

ActiveCN108129914AImprove erasabilityHigh flexural strengthPencil leadsNon-propelling pencilsFlexural strengthSolvent

The invention discloses a color pencil lead with high flexural strength and a preparation method thereof. The preparation method comprises blending 20-40 parts by mass of a thermosetting resin, 10-30parts by mass of a thermoplastic resin, 30-50 parts by mass of base raw materials, 10-20 parts by mass of pigment powder, 3-7 parts by mass of an enhancing filler and a solvent under heating, removinga part of the solvent, carrying out roller mixing at 100-120 DEG C until uniform dispersion, extruding the mixture through a bar extruding machine to obtain bars, extruding the bars to obtain pencilleads, and then cutting the pencil leads to obtain color pencil leads with high flexural strength. The preparation method can produce a color pencil lead with high flexural strength, high writing markscrubbability and bright color, has simple processes, realizes a low cost and has high efficiency. The method is suitable for direct large-scale production of color pencil leads with various specifications in the traditional large-scale production factory without new equipment.

Owner:烟台好前程文具有限公司

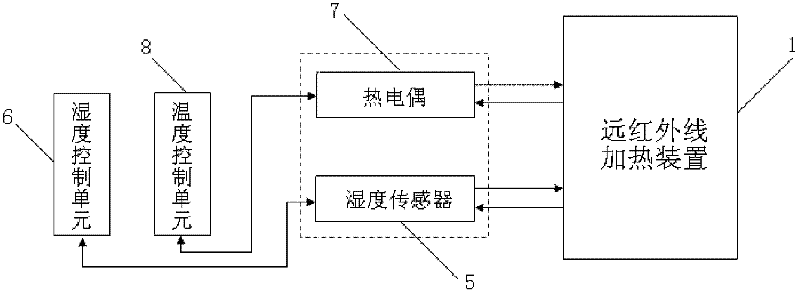

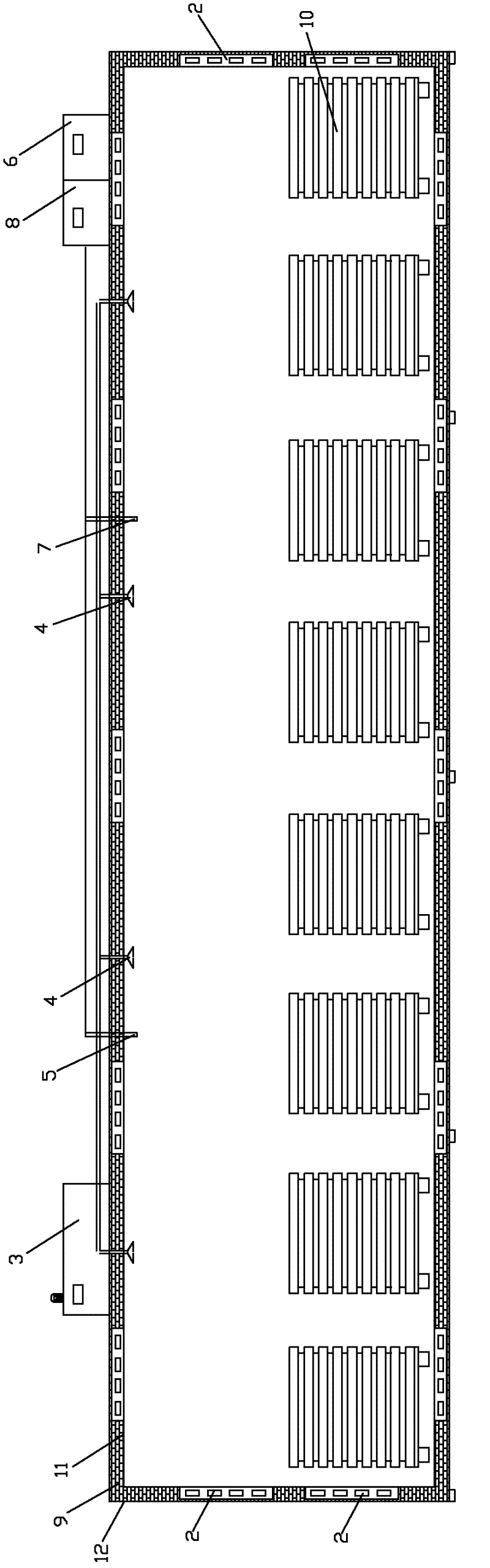

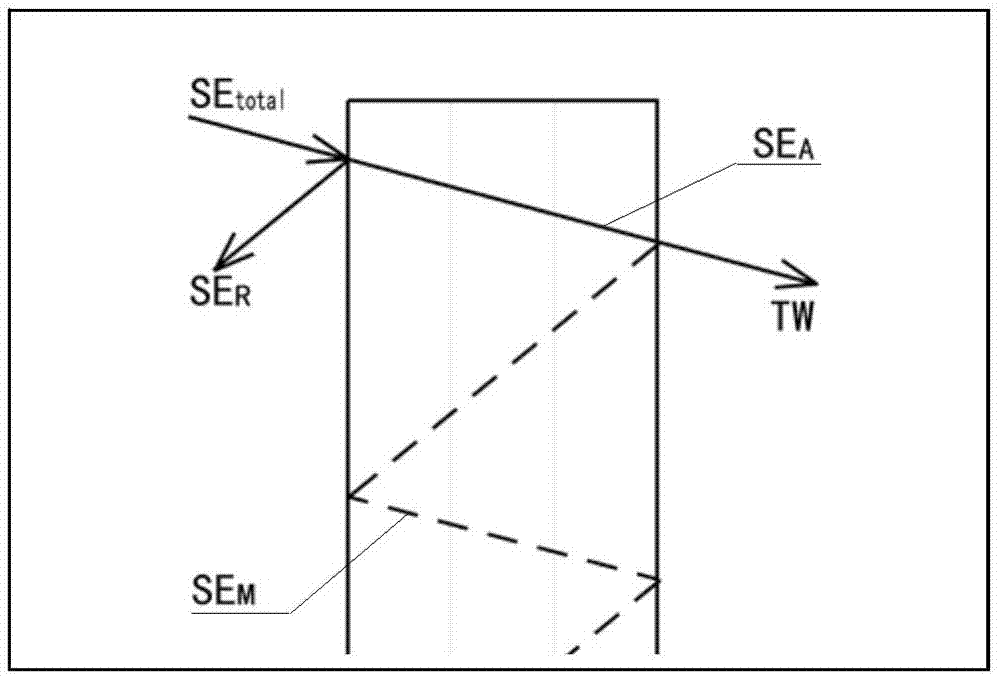

Cement-based wave-absorbing material doped by graphene oxide and preparation method thereof

InactiveCN107311555AHigh flexural strengthExcellent performance in absorbing and shielding electromagnetic wavesSilica fumeFerriferrous Oxide

The invention discloses a cement-based wave-absorbing material doped by graphene oxide and a preparation method thereof. The preparation method comprises the following steps: weighing cement for subsequent usage; weighing silica fume according to a certain mass ratio, pouring the cement and silica fume into a stirring pot, carrying out uniform mixing under stirring, then weighing nanometer ferriferrous oxide and nanometer nickel according to a certain mass ratio, pouring the weighed nanometer ferriferrous oxide and nanometer nickel into the stirring pot and carrying out low-speed stirring for 2 to 5 min; adding dispersion liquid of graphene oxide into a mixture obtained in the previous step and carrying out ultrasonic vibration; and finally, weighing water and a water reducer according to a mass ratio, adding the weighed water and water reducer into the mixture, carrying out low-speed stirring with an agitator for 2 to 5 min, stopping stirring for 10 to 30 s, then carrying out high-speed stirring for 2 to 5 min, injecting obtained slurry into a mold, carrying out vibration molding, then carrying out maintenance in a constant-temperature constant-humidity case, carrying out demolding in 24 h and then continuing maintenance under same conditions so as to obtain the cement-based wave-absorbing material. The cement-based wave-absorbing material doped by graphene oxide has the advantages of good wave absorption performance, wide frequency range, environment friendliness and no radioactivity; the preparation method is simple in process, easy in shaping and suitable for standard production; and the prepared material can be well bonded with buildings.

Owner:YANCHENG INST OF TECH

Environment-friendly wall fireproof heat-preserving board and preparation method thereof

The invention discloses an environment-friendly wall fireproof heat-preserving board and a preparation method thereof. The environment-friendly wall fireproof heat-preserving board is prepared from the following raw materials in parts by weight: 26-60 parts of straw powder, 0.2-3 parts of guanylurea phosphate, 0.1-1.2 parts of boric acid, 15-45 parts of magnesium oxide, 5-15 parts of magnesium chloride or magnesium sulfate, 1-30 parts of coal ash or diatomite in powder, 0-30 parts of crushed crude pearlite or leech powder, 0.1-0.5 part of a styrene-acrylic emulsion, 0.1-0.5 part of calcium lignosulphonate and 5-25 parts of tap water. The preparation method comprises the following steps: first, mixing straw powder, guanylurea phosphate, boric acid, magnesium oxide, coal ash or the diatomite in powder, crushed crude pearlite or leech powder and calcium lignosulphonate; then, adding magnesium chloride or magnesium sulfate, the styrene-acrylic emulsion and tap water; and after fully and uniformly stirring at normal temperature, putting in a template, rolling, maintaining and demoulding to prepare the wall fireproof heat-preserving board. The environment-friendly wall fireproof heat-preserving board has the characteristics of high compression and breaking strength, good moisture absorption, water adsorption, flame retardant and anti-freezing performances, small heat conductivity coefficient, no formaldehyde, environmental friendliness, fireproofness and heat preservation.

Owner:ANHUI ZHONGYI NEW MATERIAL TECH CO LTD +1

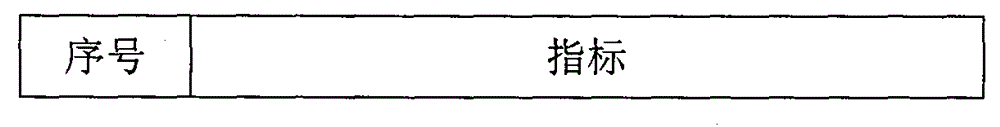

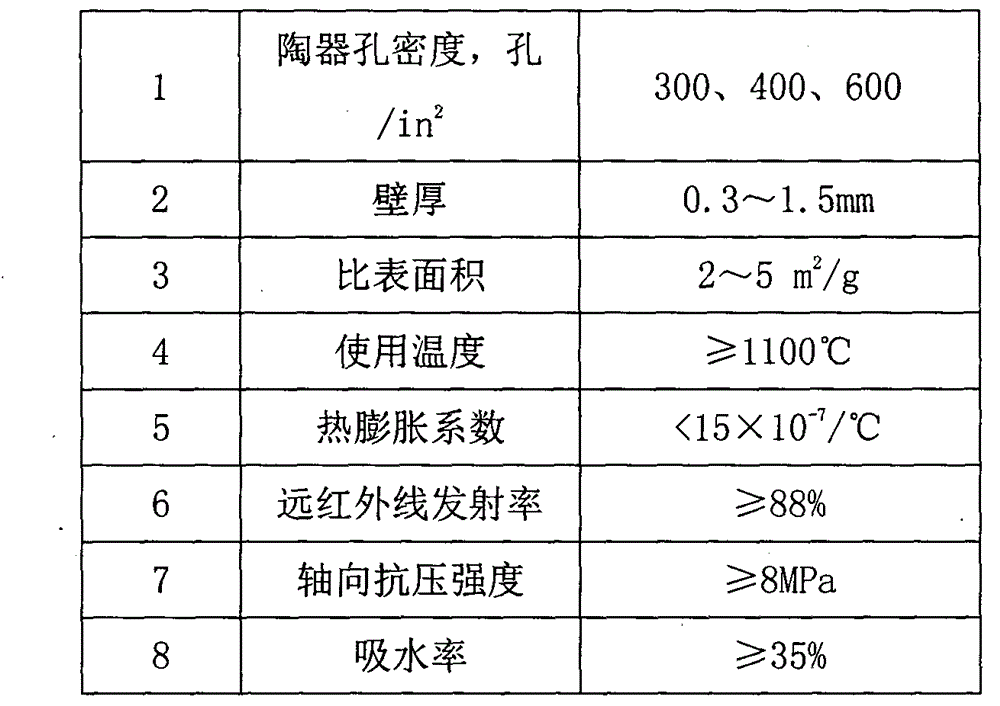

Microcrystalline bamboo-charcoal cellular pottery-texture air filter panel with catalytic function and preparation method thereof

ActiveCN104474791ALow firing shrinkageHigh flexural strengthPhysical/chemical process catalystsDispersed particle separationBamboo charcoalMicrocrystalline

A microcrystalline bamboo-charcoal cellular pottery-texture air filter panel with catalytic function is prepared by using a catalytic material to coat a microcrystalline bamboo-charcoal cellular pottery-texture air filter panel prepared from the following compositions in percent by weight: 20-40% of bamboo charcoal powder, 40-60% of porous nonmetal mineral powder, 10-30% of clay and 2-5% of a binder. The preparation method of the air filter panel comprises: adding the catalytic material into a silica gel water dispersion, stirring to form a suspension, and then putting the microcrystalline bamboo-charcoal cellular pottery-texture air filter panel into the suspension for dipping, taking out and drying. The photocatalytic function of the catalytic material and the adsorption function of the microcrystalline bamboo-charcoal cellular pottery-texture air filter panel are integrated, so that the photocatalytic effect of the catalytic material is improved, and the preparation method is simple and convenient to apply.

Owner:桂林新竹大自然生物材料有限公司

Polyamide moulding composition and multi-layered structure made therefrom

ActiveUS20180112059A1Improve heat resistanceImprove mechanical propertiesSynthetic resin layered productsLaminationPolymer sciencePolyamide

The present invention refers to a polyamide moulding composition having an excellent adhesion to metal surfaces. Moreover, the present invention refers to structural parts with a metal component directly bonded to a thermoplastic component (interconnected without using a bonding agent / layer). The present invention also relates to a method for manufacturing of such structural parts by an injection moulding or extrusion processes.

Owner:EMS PATENT AG

High-temperature-resistant colored pencil core and preparation method thereof

ActiveCN103937330AImprove temperature resistanceIncrease drying temperaturePencil leadsAdhesiveFlexural strength

The invention discloses a high-temperature-resistant colored pencil core which comprises the following components in parts by weight: 40-70 parts of clay, 5-15 parts of constitution raw material, 5-20 parts of pigment powder, 1-12 parts of wax, 1-10 parts of grease, 1-8 parts of adhesive and 10-40 parts of water. The invention also discloses a preparation method of the high-temperature-resistant colored pencil core. The modified cellulose and modified synthetic wax are adopted to increase the high temperature resistance of the mixture and enhance the temperature of the drying oven, thereby shortening the lead drying time to less than 12 hours, greatly shortening the time of the whole technique and enhancing the production efficiency. The vacuum core extrusion technique is adopted to enhance the density of the lead core, thereby enhancing the flexural strength of the lead core, the core tip stress of the penpoint, lowering the breaking rate of in the sharpening process and improving the wear resistance of the pencil; and the appearance of the lead core is more smooth, and the quality of the product is upgraded.

Owner:AXUS STATIONERY (SHANGHAI) CO LTD

Carbon fiber thermoplastic resin prepreg, carbon fiber composite material and producing method

ActiveUS20150044470A1High flexural strengthExcellent characteristicSynthetic resin layered productsCellulosic plastic layered productsCarbon fiber compositeFineness

Provided are a carbon fibre thermoplastic resin prepreg which is a carbon fibre prepreg obtained by impregnating a PAN-based carbon fibre in which the average fibre fineness of a single fibre is 1.0 dtex to 2.4 dtex with a thermoplastic resin, wherein the thermoplastic resin satisfies 20≦(FM / FS)≦40 (where FM: flexural modulus (MPa) of a resin sheet comprising only the thermoplastic resin, and FS: flexural strength (MPa) of the resin sheet), a method for manufacturing the same, and a carbon fibre composite material employing the carbon fibre prepreg.

Owner:MITSUBISHI CHEM CORP

High-tenacity dental ceramic bracket material and preparation method thereof

The invention relates to a high-tenacity dental ceramic bracket material and a preparation method thereof. The high-tenacity dental ceramic bracket material is characterized by taking aluminum oxide as a main component, nanometer zirconium oxide powder as a toughening agent, nanometer yttrium oxide as a phase stabilizing agent and fatty acid as a powder surface modifying agent, and comprises the nanometer zirconium oxide powder, nanometer yttrium oxide powder, the fatty acid, magnesium oxide and the aluminum oxide. The preparation method comprises the following steps of: uniformly mixing the nanometer zirconium oxide powder, the nanometer yttrium oxide powder and the fatty acid in a ball-milling mode; and adding the magnesium oxide and the aluminum oxide, and continuously performing ball-milling mixing until the mixture is uniform. The flexural strength of a dental ceramic bracket prepared by the method is obviously improved compared with that of other common dental ceramic brackets; and the flexural strength of a common dental ceramic bracket is not more than 700MPa commonly, but the flexural strength of the dental ceramic bracket prepared by the method can reach 900MPa.

Owner:WUHAN UNIV

Steel pipe reactive powder concrete column-flat beam-shear wall structure system

The invention relates to a steel pipe reactive powder concrete column-flat beam-shear wall structure system, which comprises steel pipe concrete columns, reinforcing steel bar concrete beams and reinforcing steel bar concrete shear walls, wherein each steel pipe concrete column is a steel pipe reactive powder concrete column formed by pouring reactive powder concrete, and each reinforcing steel bar concrete beam is a flat beam, namely the width of each reinforcing steel bar concrete beam is larger than or equal to the height of the same. Since the compression strength of the reactive powder concrete (RPC) is 4-10 times of that of common concrete, the RPC and steel pipes are combined to form the steel pipe RPC columns, the section size of each column is greatly reduced, and the usable area of a building is increased. Additionally, the structure system has the advantages of a flat beam structure, such as capability of lowering story height, avoiding pipelines to penetrate through the beams and the like, thereby having extremely good comprehensive economic benefits and being suitable for large-scale popularization and application.

Owner:FUZHOU UNIVERSITY

White thermosetting silicone resin composition for a light-emitting semiconductor device and a case for installing a light-emitting semiconductor element

ActiveUS20150353733A1Low light transmittance rateHigh flexural strengthSolid-state devicesSolid ballsSilicone resinBoiling point

The present invention provides a case for installing semiconductor element for use in LED etc. formed from a white thermosetting silicone resin composition and a cured material thereof that have low light transmittance rate, excellent moldability and are difficult to cause a burr to occur in molding. Provided is a white thermosetting silicone resin composition for a light-emitting semiconductor device, comprising: (A) a resin organopolysiloxane having a hydroxy group, and exhibiting a weight-average molecular weight of 500 to 20,000 based on polystyrene conversion, (B) an organopolysiloxane having a straight-chain diorganopolysiloxane residue, (C) a white pigment, (D) an inorganic filler other than (C), (E) a silane coupling agent in which a refractive index difference from the resin organopolysiloxane (A) is higher than or equal to 0.02 and a boiling point at atmospheric pressure is higher than or equal to 200° C., and (F) a curing catalyst.

Owner:SHIN ETSU CHEM IND CO LTD

Plant fiber recycled concrete block and preparation method thereof

InactiveCN105601185AHigh flexural strengthHigh tensile strengthSolid waste managementFiberConstruction aggregate

The invention discloses a plant fiber recycled concrete block and a preparation method thereof. The block is made from water, cement, sand, coarse aggregate and plant fiber, wherein the coarse aggregate adopts the mixture of natural macadam and recycled macadam; the ratio of the recycled macadam to the coarse aggregate is 30 to 50 percent; the ratio of plant fiber to the concrete block is 1 to 2 percent. Compared with the existing recycled concrete block, the plant fiber recycled concrete block has the advantages that the plant fiber recycled concrete block not only utilizes construction waste as the coarse aggregate of concrete, and meanwhile is mixed with waste crops to combined with the coarse aggregate, although the compressive strength of the axis of the block is reduced to a certain extent as compared with the existing recycled concrete block without recycled aggregate mixed, the tensile strength of the concrete is improved due to the influence of the plant fiber, the strength meets the requirements, and the plant fiber recycled concrete block can be applied to load-bearing blocks.

Owner:HARBIN INST OF TECH

Novel road steel slag cement and preparation method and application thereof

The invention relates to novel road steel slag cement formula development and application and provides novel road steel slag cement simple in preparation and excellent in performance and a preparation method and application thereof. The novel road steel slag cement is prepared from, by mass, 68-72 parts of cement clinker, 18-22 parts of steel slag, 4.6-5.4 parts of mineral slag, 4.1-4.8 parts of gypsum and 0.4-0.6 part of concrete activating agent. By proportional mixing the recycled steel slag with the cement clinker, the mineral slag and the like, freezing resistance, corrosion resistance and volume stability of the cement are improved, cement dry shrinkage changes are reduced, and hydration heat is reduced. The novel road steel slag cement in application of road construction has advantages of high strength, abrasion resistance, skid resistance, high durability, low maintenance cost, prolonging of service lives of expressways and the like. The novel road steel slag cement is applicable to the field of pavement materials.

Owner:河北长大交通科技有限公司

Building high-strength grouting material and preparation method thereof

The invention discloses a building high-strength grouting material. The building high-strength grouting material is prepared from, by weight, 44 parts of Portland cement, 33 parts of silver sand, 5 parts of fiber mixture, 4.5 parts of superfine slag powder, 2 parts of expanding agent, 1.5 parts of water reducing agent, 2 parts of defoaming agent, 3 parts of organic silicon microspheres, 4 parts ofglass beads and 1.2 parts of tetraethylenepentamine. The building high-strength grouting material is good in heat preservation and physical strength performance and high in compressive strength and breaking strength and has the high practical value and the good application prospect.

Owner:段宝荣

Autoclaved lime-sand brick and production method thereof

The invention discloses an autoclaved lime-sand brick and a production method thereof. The autoclaved lime-sand brick is produced through a dehydrated mud cake drying step, a crushing and grinding step , a proportioning and stirring step, a digestion aging step, a compaction molding step and an autoclave curing step of raw materials containing exposed aggregate finish, sandstones, cement and building mud cakes. The obtained autoclaved lime-sand brick has good mechanical properties and meets the requirements of national standard GB50574-2010, and the method realizes the recycling of solid wasteconstruction mud cakes, reduces the production cost of the autoclaved lime-sand brick, reduces the occupied land of construction wastes, and has a good industrial prospects and a great social significance.

Owner:ROAD ENVIRONMENT TECH

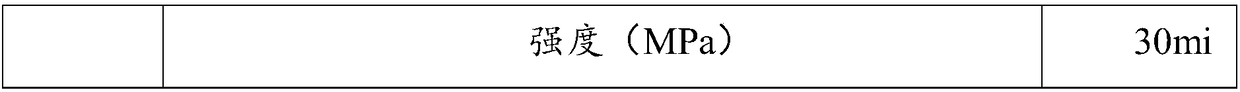

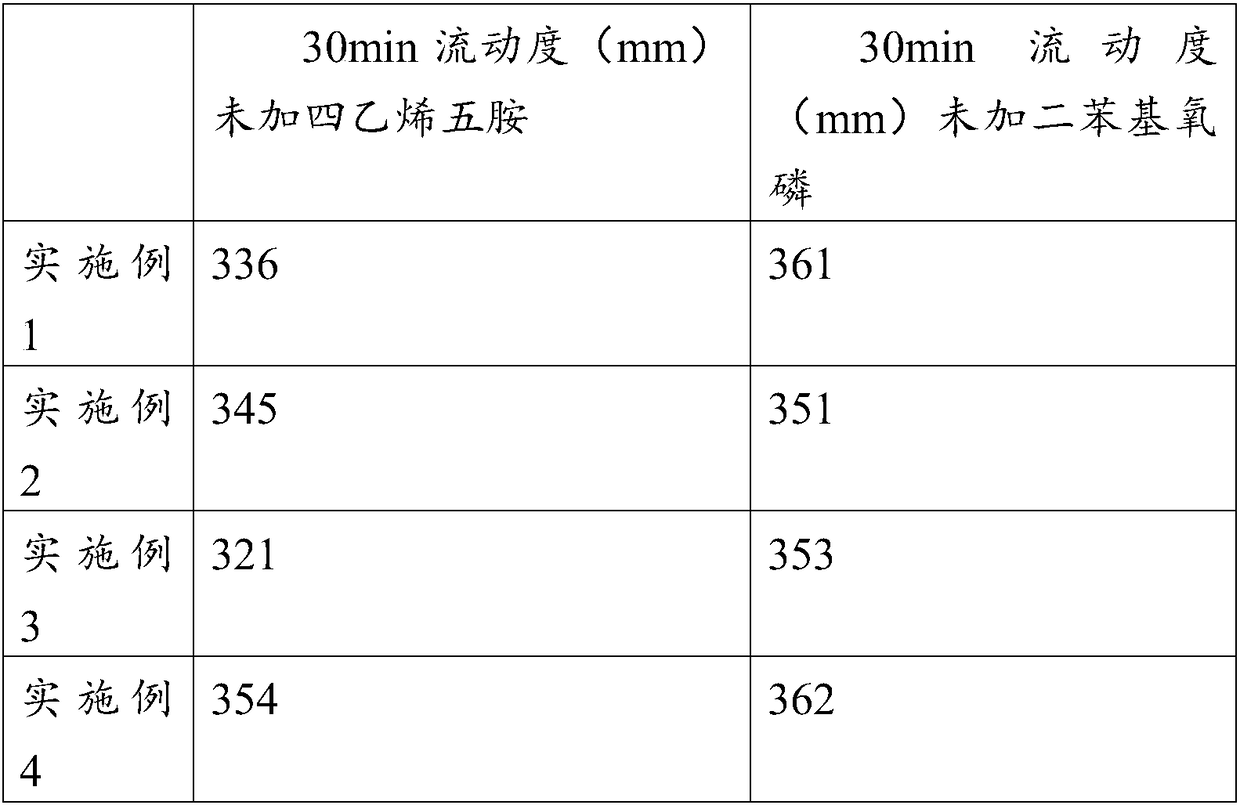

Self-leveling mortar and preparation method thereof

The invention discloses a self-leveling mortar and a preparation method thereof. The self-leveling mortar comprises the following raw materials in parts by weight: 3-11% of cement; 35%-45% of desulfurized gypsum; 20%-30% of a filler; 1-3% of silica fume; 1%-2% of an amorphous calcium aluminate cement rapid hardening agent; 0.5 to 1% of eucalyptol; 0.2%-0.6% of apiezon grease; 2-4% of calcium propionate; 1-2% of lithium carbonate; 2-4% of titanium dioxide; 1-2% of a thickening agent; 1-2% of a water reducing agent; 2-3% of polyether sulfone; 2-4% of a polyvinyl chloride thermoplastic elastomer;and 1-5% of an additive. The self-leveling mortar is high in breaking strength, high in compressive strength, high in fluidity and high in ground bonding force, and the overall comprehensive performance is greatly improved.

Owner:XINYANG LINGSHI TECH CO LTD

Preparation method of zirconia ceramic rear cover of mobile phone

The invention discloses a preparation method of a zirconia ceramic rear cover of a mobile phone. The method comprises steps as follows: S1, modified zirconia powder and yttrium oxide powder are mixeduniformly, and mixed powder is obtained; S2, the mixed powder is dissolved in absolute ethyl alcohol, ammonium polyacrylate is added, wet grinding is performed for 20-36 h, and pretreated powder is obtained after drying treatment; S3, polyethylene glycol, isopropyl alcohol and zinc stearate are added to the pretreated powder, ultrasonic dispersion is performed, and tape casting slurry is obtained;S4, the tape casting slurry is subjected to vacuum defoaming, and a green body is obtained through tape casting; S5, the green body is subjected to three-stage thermal treatment and then subjected toshaping processing treatment, and the zirconia ceramic rear cover of the mobile phone is obtained. The prepared zirconia ceramic rear cover of the mobile phone has high hardness and bending strength,high anti-breaking capability, uniform texture and stable quality; the preparation method is simple, adopts a preparation process which is easy to operate, and is suitable for large-scale promotion.

Owner:泉州市智通联科技发展有限公司

Sports board with integral laminated stiffening element

InactiveUS20070243780A1Uniform stiffnessImproves compression resistanceNon-magnetic metal hullsWater sport boardsPolyolefinFlexural strength

A sport board for snow sledding or surf body boarding comprises a multi-layered laminated composite foam core coupled with stiffening elements for mechanical strengthening of the board. The composite foam core comprises laminates of polyolefin foam base and stiffening elements composed of substantially polymer foam and has substantial higher compressive strength and flexural strength than the foam base. A front section may be made of the same blank material as the low density polyolefin foam base and is bonded to the front end of the foam core complex to give a full frontal flexibility for a higher directional control by the rider and improved shock absorbing property. Polyethylene foam sheets wrap the foam core complex subassembly and head section for sled integrity and graphic film finishes the sled top, the bottom is also finished with a polyethylene sheet for slickness.

Owner:CHEUNG WAH KAN

Activated carbon material with high crack resistance

InactiveCN109133056AImprove adsorption performanceHigh flexural strengthCarbon compoundsActivated carbonOrganic component

The invention discloses an activated carbon material with high crack resistance, and belongs to the field of chemical engineering. The activated carbon material has the advantages that the activated carbon material is made from coconut shells, organic components such as glucose and pentosan in the coconut shells can be sufficiently exposed in glycerin and hydrogenated castor oil ball-milling procedures, systems of the activated carbon material can be connected with one another by the organic components, rigid nanometer SiO2 and high-activity sodium humate, and accordingly the breaking strengthof the systems can be effectively improved; bacterial celluloses, octenyl succinic starch ester and the like are used as wall materials for the activated carbon material, oil is used as a core material for the activated carbon material, calcium bicarbonate solution is used as an inorganic flocculating agent, terephthalaldehyde is used as a cross-linking agent, the added nanometer SiO2 has extremely large specific surface areas, surface atoms are extremely high in unsaturation, accordingly, the impact energy dispersive capacity and absorptive capacity of the activated carbon material can be improved, the bending strength and the compressive strength can be improved, and the problems of poor bending strength and compressive strength of existing common activated carbon materials can be solved by the aid of the activated carbon material.

Owner:FOSHAN CHANCHENG DISTRICT NUOGAO ENVIRONMENTAL PROTECTION TECH CO LTD

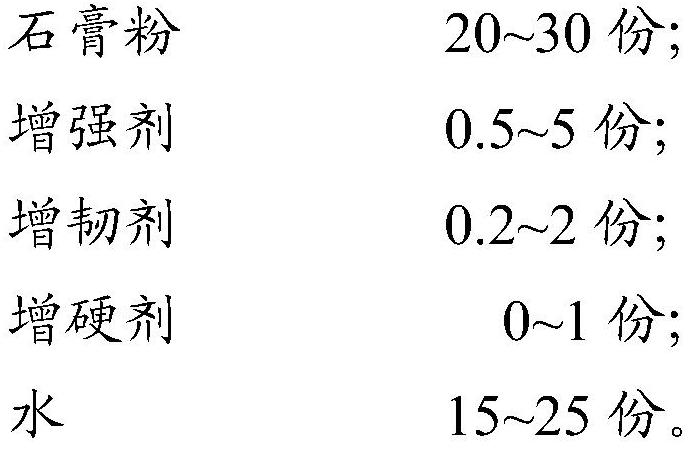

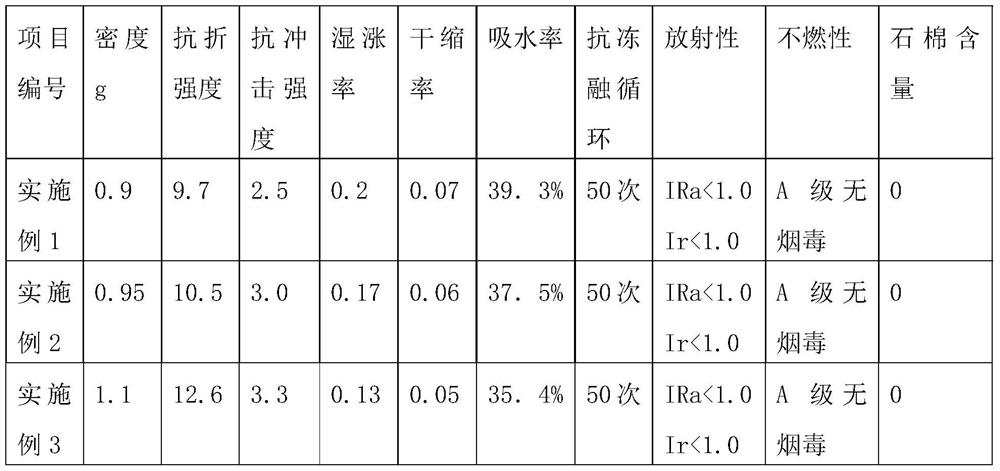

Method for improving mechanical properties of gypsum-based material

ActiveCN112408936AImprove mechanical propertiesHigh flexural strengthSolid waste managementSodium silicateAcrylic acid

The invention belongs to the field of building materials, and relates to a method for improving the mechanical property of a gypsum-based material. The method comprises the following steps that: a) gypsum powder, a reinforcing agent, a toughening agent, a hardening agent and water are mixed to obtain gypsum slurry, wherein the reinforcing agent comprises an acrylic polymer, polyisocyanate polyester, polyalkyd resin and the like, wherein the toughening agent comprises glass fibers, paper fibers and wood fibers, and the hardening agent comprises sodium silicate, quartz powder and sand; and b) solidifying and molding the gypsum slurry, and then performing drying to obtain the high-strength gypsum-based material. According to the method provided by the invention, the reinforcing agent, the toughening agent and the hardening agent of specific types are doped into the gypsum, so that the breaking strength, hardness and shearing strength of the gypsum-based material are greatly improved. Withthe method adopted, the problem of poorer mechanical property of a traditional gypsum-based material can be solved; the mechanical strength and nail-holding power of the prepared gypsum-based material can be comparable with those of a blockboard, and the gypsum-based material has a higher fireproof grade than the blockboard.

Owner:TAISHAN GYPSUM CO LTD

Method for preparing concrete floor tile with high strength

The invention discloses a method for preparing a concrete floor tile with high strength. The method comprises the following steps that light calcium carbonate, building rubbish, fly ash, vermiculite power and polyamide resin are evenly mixed to obtain a premix a; cement, quick lime, blast furnace slag, hollow glass beads, kieselguhr, gravel, microcrystalline cellulose, wollastonite powder and aluminum borate whisker are evenly mixed to obtain a premix b; the premix a, the premix b and water are evenly mixed, vibration and extrusion molding, demoulding and maintenance are carried out to obtainthe concrete floor tile with the high strength. The provided method for preparing the concrete floor tile with the high strength has the advantages that the obtained concrete floor tile has small volume weight, excellent compressive strength and rupture strength, and good thermal insulation performance.

Owner:蚌埠市宝运商品混凝土有限公司

Calcination-free phosphogypsum brick and manufacturing method thereof

InactiveCN111635209AHigh flexural strengthGood durability and frost resistanceCeramic shaping apparatusBuilding materialPre treatment

The invention discloses a calcination-free phosphogypsum brick and a manufacturing method thereof, and belongs to the field of building materials. The formula comprises phosphogypsum, aggregate, cement and an alkaline activator. The preparation method comprises the following steps: proportionally mixing the raw materials, stirring, crushing, carrying out extrusion molding, and curing to finally obtain the finished product calcination-free phosphogypsum brick. The calcination-free phosphogypsum brick prepared by the method is high in compression strength and breaking strength and good in waterresistance, freezing resistance and durability. According to the invention, the main raw materials are a large amount of solid wastes such as phosphogypsum, aggregate and the like, and the wastes areactivated and reasonably doped into the phosphogypsum brick, so that complicated pretreatment processes such as washing, drying, calcining and the like of phosphogypsum are avoided, and greenhouse gassuch as CO2, NO2, SO2 and the like, wastewater and secondary solid wastes are not discharged. According to the method, the utilization rate of phosphogypsum is greatly increased, accumulation of phosphogypsum is reduced, the land pollution rate is reduced, and great contribution is made to environmental protection.

Owner:JINGMEN YIXIANG CONSTR MACHINERY

Preparation method capable of improving mechanical properties of mortar

InactiveCN108840636AHigh flexural strengthHigh compressive strengthIndustrial wasteEnvironmental resistance

The invention discloses a preparation method capable of improving mechanical properties of mortar. Materials used in the preparation method include lithium slag, fly ash or steel slag as a mineral admixture, ordinary Portland cement, standard sand, water and a polycarboxylate water reducing agent, wherein 450 parts of the ordinary Portland cement, 405-1350 parts of the standard sand, 405-1350 parts of the lithium slag or fly ash or steel slag, 225 parts of water and 0-5 parts of the polycarboxylic acid water reducing agent are used. The flexural strength and the compressive strength of the cement mortar prepared by the preparation method are increased by 128% and 83% at most respectively, and the density is reduced by 24% at most; when the mechanical properties of the mortar reach the maximums, the using amounts of the lithium slag, the fly ash and the steel slag in the scheme are 3 times, 4.5 times and 15 times of that of replaced cement. Therefore, the mortar prepared by the preparation method has the functions of reinforcement and light weight; meanwhile, a large amount of industrial waste is used, so that environmental pollution of the industrial waste is reduced, and relatively large social, economic and environmental benefits can be brought.

Owner:GUIZHOU NORMAL UNIVERSITY

Low-carbon magnesia carbon brick with oxidation resistance and preparation method thereof

The invention relates to the technical field of refractory materials, in particular to a low-carbon magnesia carbon brick with oxidation resistance and a preparation method thereof. The low-carbon magnesia carbon brick comprises the following components in parts by weight: 88-96 parts of fused magnesite, 1-3 parts of metal aluminum powder, 3 parts of resin, 1-3 parts of a ZrB2-Cr7C3 multi-phase material, 1-3 parts of high-temperature asphalt and 1-3 parts of -196 graphite. Through the structural design of the low-carbon magnesia carbon brick with oxidation resistance, the technical problems that in the prior art, the excellent performance of the magnesia carbon brick depends on the existence of carbon in the brick, the oxidation of the carbon easily causes the deterioration of the product structure in the use process, slag intrudes into the brick along gaps to erode MgO particles, and the service life of the MgO-C brick is shortened are solved.

Owner:北京利尔高温材料股份有限公司

Preparation and formula of high-strength, high-toughness and low-density wood fiber calcium silicate board

The invention discloses preparation and a formula of a high-strength, high-toughness and low-density wood fiber calcium silicate board. The board is low in density and high in breaking strength, especially the impact strength is greatly improved, and compared with a low-density calcium silicate board on the market at present, the breaking strength is generally about 8 Mpa, even 6 Mpa and 7 Mpa, the impact strength is lower, and no requirement is made. More than 50% of paper pulp is replaced by the wood fibers, perlite, diatomite and the like are not used, the cost is greatly reduced, steam isrecycled, perlite calcined at high energy consumption is not used, and energy conservation and emission reduction are achieved; the water absorption rate of the board is greatly reduced, and lithium silicate and potassium silicate are generated on the fiber surface in the board, so that the bonding capacity is improved, and the waterproof effect is achieved.

Owner:GUANGDONG SOBEN GREEN NEW MATERIAL CO LTD

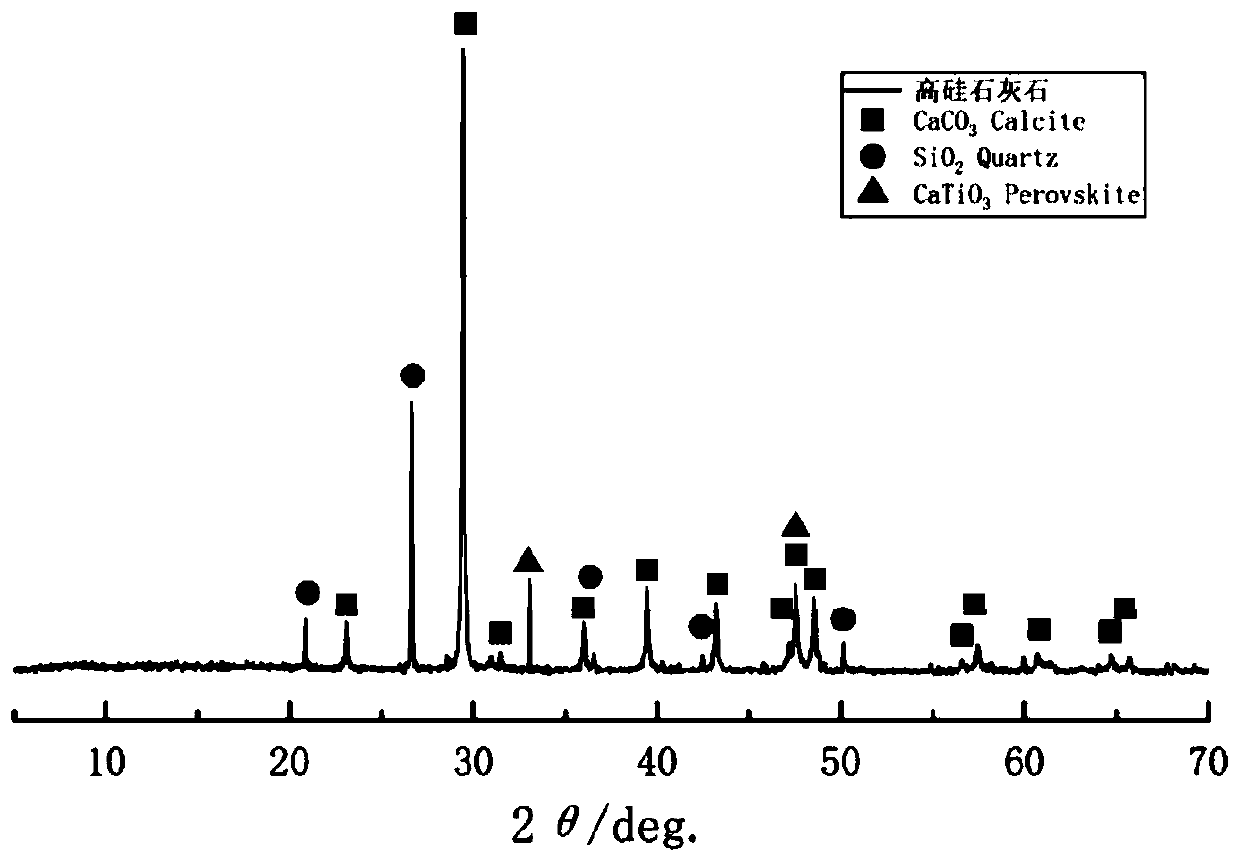

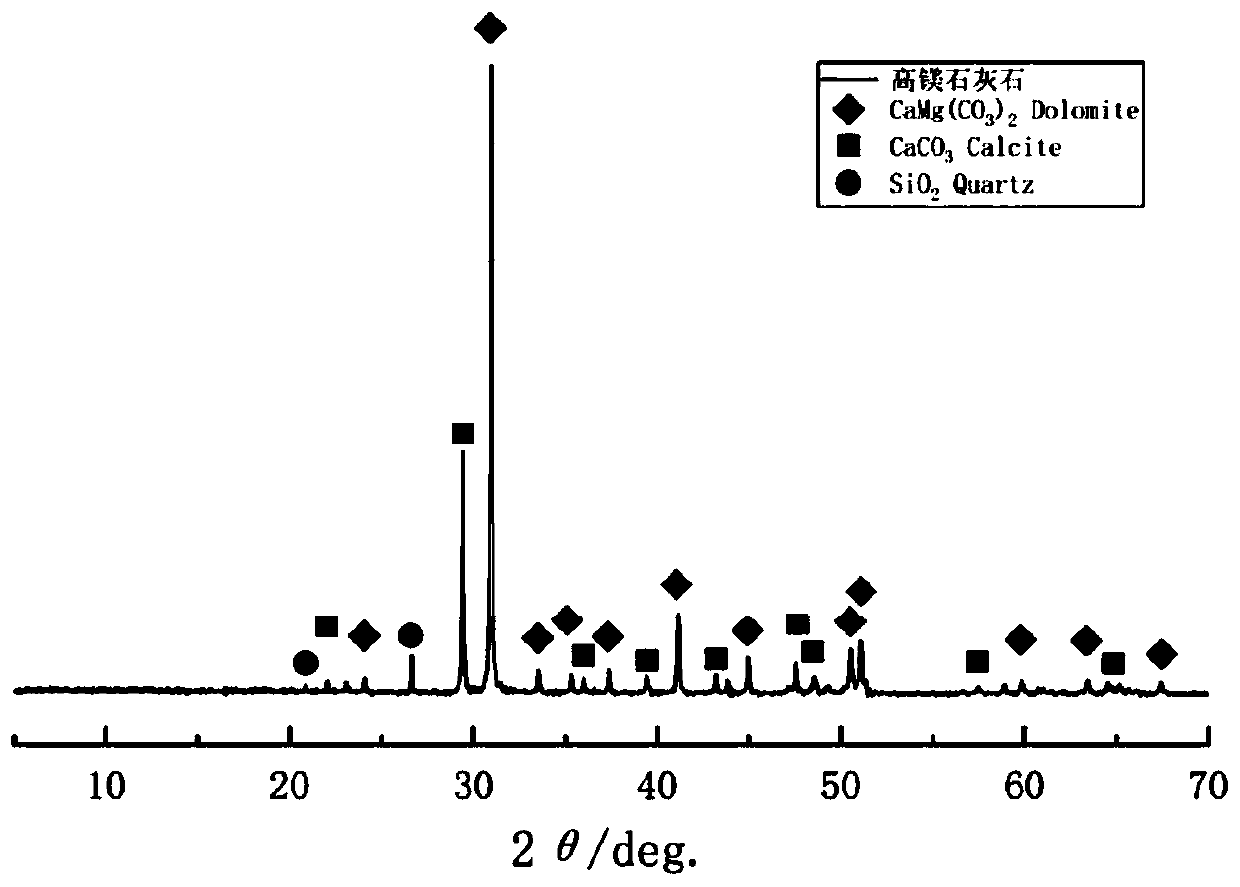

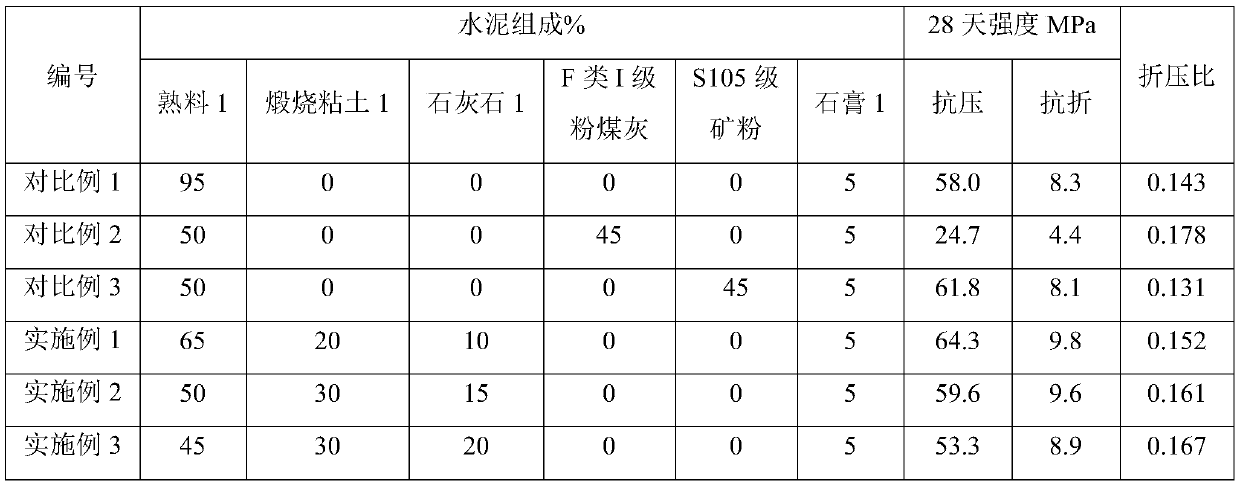

High flexural strength composite Portland cement and preparation method thereof

ActiveCN110436801AHigh flexural strengthImprove the structural strength in all directionsGypsumBuilding material

The invention belongs to the field of building materials, and especially relates to a high flexural strength composite Portland cement and a preparation method thereof. The high flexural strength composite Portland cement is prepared from, by weight, 35-65 parts of a Portland cement clinker, 17.5-40 parts of calcined clay, 10-22.5 parts of limestone and 1.5-5 parts of gypsum. The high flexural strength composite Portland cement mainly prepared from the ordinary Portland cement clinker, calcined clay and low-grade limestone concrete is prepared by starting from the concrete core raw material cement and improving the ratio of bending-compressive strength and the flexural strength of cement on the premise of ensuring a high compressive strength, and the preparation method has the characteristics of simple process, and suitableness for industrial production.

Owner:SINOMA INT ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com