Novel road steel slag cement and preparation method and application thereof

A steel slag and cement technology, which is applied in the development and application of new road steel slag cement formulations, can solve the problems of large environmental impact, low utilization rate, and high cost, and achieve the effects of reducing the proportion of clinker mixing, improving performance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

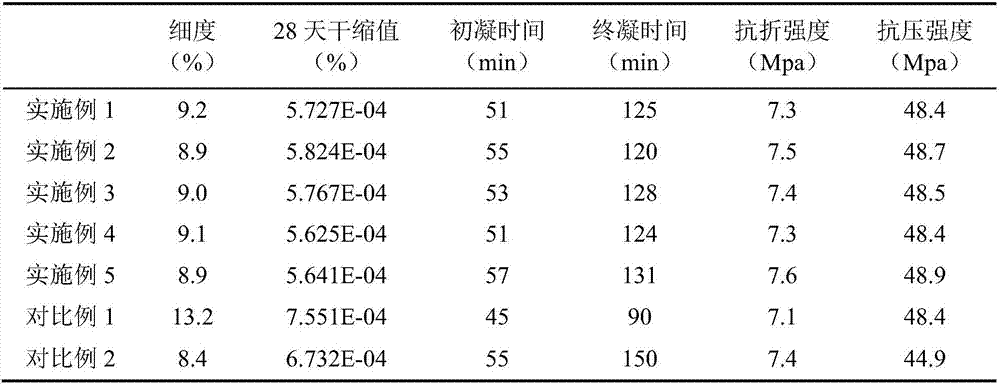

Examples

Embodiment 1

[0028] The novel road steel slag cement of present embodiment is prepared according to the following steps:

[0029] (1) Weighing raw materials: Weigh 68kg cement clinker, 20kg steel slag, 5kg slag, 4.7kg gypsum and 0.45kg concrete stimulator respectively;

[0030] (2) Raw material crushing: the raw material taken in step (1) is crushed respectively and passed through a 2mm sieve respectively to obtain the crushed raw material;

[0031] (3) Grinding: After grinding the cement clinker in the crushed raw materials obtained in step (2) with a small mill, pass through a 80 μm square hole sieve, and the sieve residue is 9.2kg; the crushed raw materials except cement clinker Grind for 40min with a small mill; Mix evenly to obtain the novel road steel slag cement of the present invention;

[0032] The sieve balance in step (3) refers to the remaining quality after the material is sieved.

Embodiment 2

[0034] The novel road steel slag cement of present embodiment is prepared according to the following steps:

[0035] (1) Weighing raw materials: Weigh 71kg cement clinker, 19kg steel slag, 4.8kg slag, 4.3kg gypsum and 0.5kg concrete stimulator respectively;

[0036] (2) Raw material crushing: the raw material taken in step (1) is crushed respectively and passed through a 2mm sieve respectively to obtain the crushed raw material;

[0037] (3) Grinding: After grinding the cement clinker in the crushed raw materials obtained in step (2) with a small mill, pass through a 80 μm square hole sieve, and the sieve residue is 3.8kg; the crushed raw materials except cement clinker Grind with a small mill for 50min; mix evenly to obtain the novel road steel slag cement of the present invention;

[0038] The sieve balance in step (3) refers to the remaining quality after the material is sieved.

Embodiment 3

[0040] The novel road steel slag cement of present embodiment is prepared according to the following steps:

[0041] (1) Weighing raw materials: Weigh 70kg cement clinker, 21kg steel slag, 5.4kg slag, 4.1kg gypsum and 0.4kg concrete stimulator respectively;

[0042] (2) Raw material crushing: the raw material taken in step (1) is crushed respectively and passed through a 2mm sieve respectively to obtain the crushed raw material;

[0043] (3) Grinding: After the cement clinker in the crushed raw materials obtained in step (2) is ground with a small mill, pass through a 80 μm square hole sieve, and the sieve residue is 5kg; the raw materials after crushing except cement clinker are used Small mill grinds 60min; Mix evenly, promptly obtain the novel road steel slag cement of the present invention;

[0044] The sieve balance in step (3) refers to the remaining quality after the material is sieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com