Self-leveling mortar and preparation method thereof

A self-leveling mortar and quartz sand technology, applied in the field of mortar, can solve the problems of poor water resistance, low strength, and obstacles to the promotion of gypsum-based self-leveling materials, and achieve smooth hand feeling, high flexural strength, strong decorative effect and ornamental Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention also discloses a method for preparing self-leveling mortar, comprising the following steps:

[0036] 1) drying 35-45% by weight of desulfurized gypsum until the moisture content is less than 5%, and then mixing it with 3-11% by weight of cement to obtain a mixture A;

[0037] 2) 1-3% by weight of silica fume, 1-2% by weight of amorphous calcium aluminate cement quick-hardening agent, 2-4% by weight of calcium propionate, 1-2% by weight of carbonic acid Lithium, 2-4% by weight of titanium dioxide, 1-2% by weight of thickener, 1-2% by weight of water reducer, 2-3% by weight of polyethersulfone, 2-4% by weight The polyvinyl chloride thermoplastic elastomer is mixed with 1 to 5% by weight of the additive, and stirred evenly to obtain the mixture B;

[0038] 3) After mixing the mixture A and the mixture B, add 20 to 30% of the filler by weight, and pour 0.5 to 1% of eucalyptol and 0.2 to 0.6% by weight of eucalyptol while stirring evenly. Part of Apisson oil,...

Embodiment 1

[0043] 1) Drying 35% by weight of desulfurized gypsum until the water content is less than 5%, and then mixing it with 3% by weight of cement to obtain Mixture A;

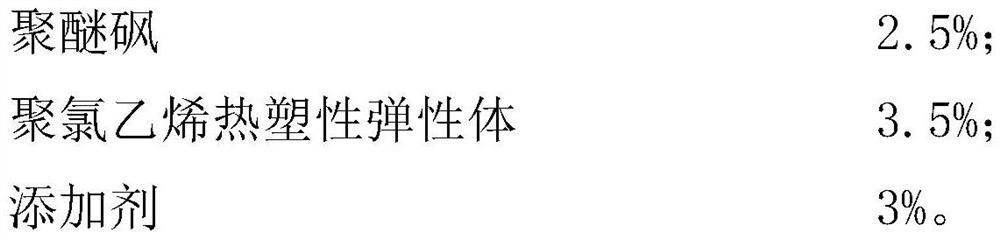

[0044] 2) 1% by weight of silica fume, 1% by weight of amorphous calcium aluminate cement quick-hardening agent, 2% by weight of calcium propionate, 1% by weight of lithium carbonate, 2% by weight of titanium dioxide , 1% by weight of thickener, 1% by weight of water reducer, 2% by weight of polyethersulfone, 2% by weight of polyvinyl chloride thermoplastic elastomer and 1% by weight of additives are mixed, stirred Evenly, mixture B is obtained;

[0045] 3) After mixing the mixture A and the mixture B, add 20% of the filler by weight, and pour 0.5% of eucalyptol and 0.2% of apisson oil into it while stirring well , and then add an appropriate amount of water while stirring, and you can get a self-leveling mortar after preparation.

[0046] The filler includes ceramsite, sand, stone particles, wood fiber and quart...

Embodiment 2

[0051] 1) Dry 45% by weight of desulfurized gypsum until the water content is less than 5%, and then mix it with 11% by weight of cement to obtain admixture A;

[0052]2) 3% by weight of silica fume, 2% by weight of amorphous calcium aluminate cement quick-hardening agent, 4% by weight of calcium propionate, 2% by weight of lithium carbonate, 4% by weight of titanium dioxide , 2% by weight of thickener, 2% by weight of water reducer, 3% by weight of polyethersulfone, 4% by weight of polyvinyl chloride thermoplastic elastomer and 5% by weight of additives are mixed, stirred Evenly, mixture B is obtained;

[0053] 3) After mixing the mixture A and the mixture B, add 30% of the filler by weight, and pour 1% of eucalyptol and 0.6% of apisson oil into it while stirring evenly , and then add an appropriate amount of water while stirring, and you can get a self-leveling mortar after preparation.

[0054] The filler includes ceramsite, sand, stone particles, wood fiber and quartz sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com