Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

163 results about "Calcium propanoate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium propanoate or calcium propionate has the formula Ca(C₂H₅COO)₂. It is the calcium salt of propanoic acid.

Special fruit tree liquid fertilizer and preparation method thereof

InactiveCN104098399AIncrease productionImprove performanceFertilizer mixturesFruit treeManganese sulphate

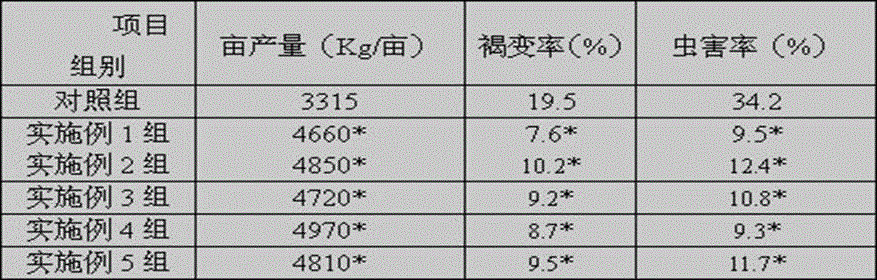

The invention discloses a special fruit tree liquid fertilizer. The special fruit tree liquid fertilizer mainly comprises the following components in parts by weight: 1 part of matrine, 2-8 parts of calcium propionate, 1-5 parts of salicylic acid, 6-10 parts of zinc chloride, 4-8 parts of manganese sulfate, 8-12 parts of ferrous sulphate, 1-5 parts of magnesium oxide, 1-5 parts of vitamin C, and 40-60 parts of organic matters. The invention further provides a preparation method for the special fruit tree liquid fertilizer. Compared with the prior art, the special fruit tree liquid fertilizer is stable in property, and multiple in functions, has no toxic or side effects, can effectively kill pests, can prevents fruits from being putrid, can improve yield of fruit trees, and has a favorable application prospect in the field of fruit tree planting.

Owner:JURONG TIANWANG TOWN DAIZHUANG ORGANIC AGRI PROFESSION COOP

Selenium-rich compound hard pellet feed for polyculture fishes and preparation method thereof

The invention discloses a selenium-rich compound hard pellet feed for polyculture fishes. The raw materials of the feed comprises a selenium-rich fermented raw material, red fish meal, spray-dried animal blood cells, cottonseed protein powder, flour, wheat, rapeseed meal, rice bran, a mineral premixture, monocalcium phosphate, fish oil, calcium propionate and oligosaccharide which are prepared into a feed base material by weight parts, and the feed base material is conditioned and cured by using a double-shaft differential conditioner under the conditions of certain steam pressure, humidity and temperature. The feed has the advantages of high utilization ratio, high resistance to trophic factor damages, high stability in water and small feed coefficient. When the feed is used for breeding polyculture fishes, water pollution can be reduced, the survival rate of the polyculture fishes can be improved, and the breeding cost can be reduced; and moreover, bred fishes have the advantages of good body shapes, delicious meat and abundant organic selenium content, and free radicals in the human bodies can be cleared away by eating the bred fishes, so that the selenium-rich compound hard pellet feed has a health-care effect on the health of the human bodies.

Owner:安徽天邦饲料科技有限公司

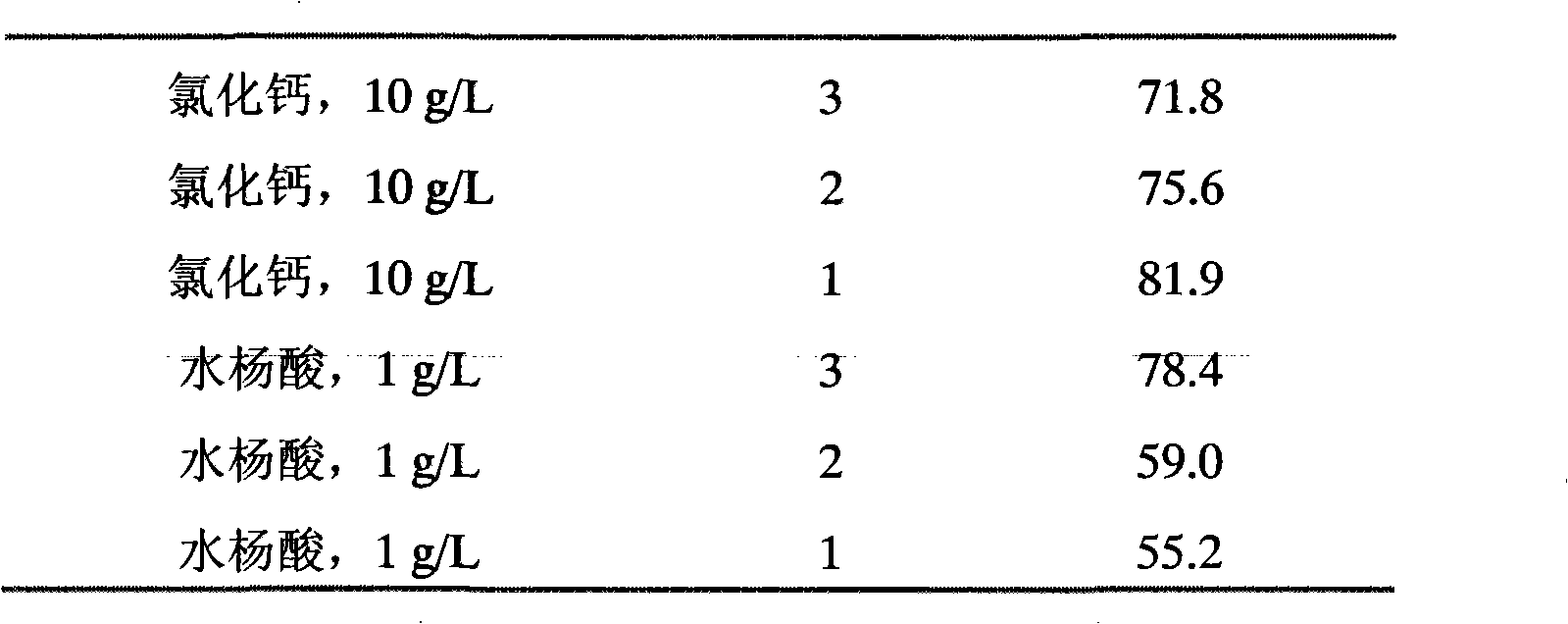

Fresh-keeping method for bramble and antistaling agent used before picking

The invention discloses a method for refreshing raspberries, which provides an antistaling agent for pre-picking treatment on raspberry fruits. The antistaling agent is prepared from 5 to 25g of calcium propionate, 5 to 25g of calcium chloride and 0.2 to 2g of salicylic acid in 1L of distilled water. The method comprises the following steps of spraying the pre-picking antistaling agent for one time three days before picking; picking raspberry fruits of which 70 percent is mature, and carrying out pre-cooling treatment on the picked raspberries for 24 hours in a cold storage warehouse at temperature of 1 DEG C; using cinnamic aldehyde with concentration of 60 ppm to carry out fumigation treatment for 24 hours to the raspberries after the pre-cooling treatment, and refrigerating the raspberries in the cold storage warehouse at temperature of 1 DEG C below zero and reaching 87.4 percent of fresh fruits after storing the raspberries for 17 days. The method has the advantages of safety, high efficiency and convenience, and can effectively reduce rotting rate of the raspberry fruit while the quality of the raspberries is maintained.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

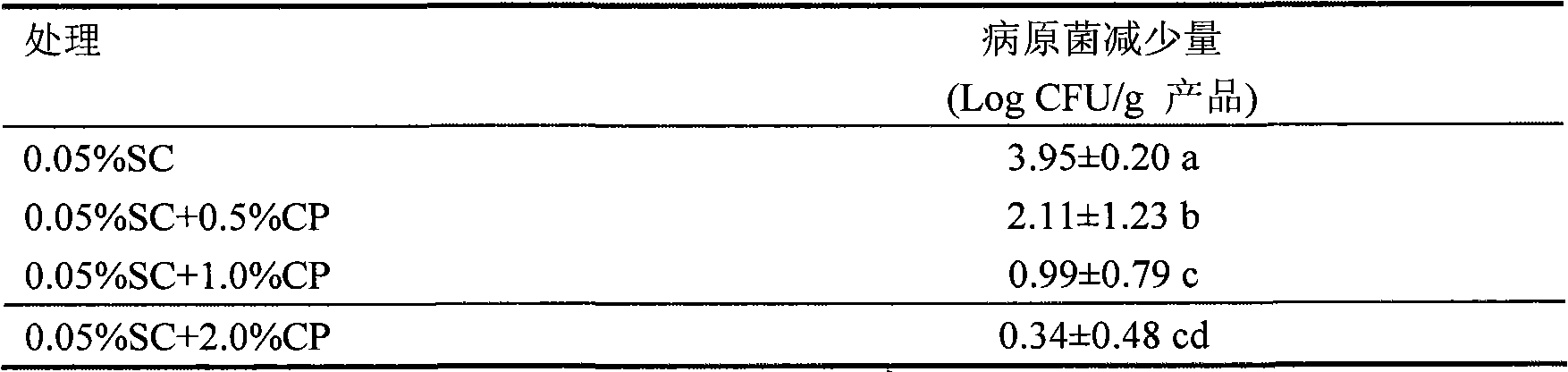

Antimicrobial compositions within antioxidant solutions used to protect whole protein foods

An antimicrobial composition within an antioxidant solution and used to protect whole protein food source is provided. The antimicrobial compound of the composition is selected preferably from a medium chain fatty acid (MCFA), a long chain fatty acid (LCFA), a phenolic acid, and derivatives or mixtures thereof, and has a pH between about 2 and 6. Antioxidant compounds for the composition are composed preferably from phenolic based compounds such as butylated hydroxyanisole (BHA), butylated hydroxytoluene (butylhydroxytoluene, BHT), propyl gallate (propyl 3,4,5-trihydroxybenzoate), tert-butylhydroquinone (TBHQ, tertiary butylhydroquinone), mixed tocopherols (tocopherols, Vitamin E), rosemary extract, oregano oil (origanum oil) and vegetable oil; other antioxidant compounds such as calcium propanoate (or calcium propionate) and ethyoxyquin; and derivatives or mixtures thereof.

Owner:FRASERMICH

Grey paper clay material for fabricating relief paintings and method for preparing paper clay material

The invention relates to a paper clay material for fabricating a relief stereo-painting. A grey paper clay material for fabricating a relief painting provided by the invention is prepared from paper pulp, polyvinyl alcohol, borax, white dextrin, Arabic gum, sesbania gum, bamboo charcoal powder, calcium propionate, potassium sorbate, talcum powder, gypsum powder, glycerol, sorbierite and water. The grey paper clay material is good in plasticity and excellent in tackiness and adhesion, thus being high in fixing capability; and after being air-dried and solidified, the material may not be crazed, and is resistant to insolation and acids-bases, anti-freezing, resistant to aging, and corrosion resistant antibacterial, as well as stable in chemical properties and long in service life.

Owner:浙江银太郎动漫文化股份有限公司

Hygroscopic state vermicelli antistaling agent and application thereof

InactiveCN104382187ALow costGuaranteed qualityFood preservationFood ingredient for microbe protectionAcetic acidPropionate

The invention discloses a hygroscopic state vermicelli antistaling agent and application thereof. The antistaling agent consists of calcium propionate, potassium lactate, sand sagebrush glue, glacial acetic acids and water. The antistaling agent disclosed by the invention has the advantages of high safety, high efficiency, simple operation and low cost. The antistaling agent disclosed by the invention is added, hygroscopic state vermicelli is not needed to be subjected to cold storage, and can be stored for a long term at a normal atmospheric temperature, the original quality of hygroscopic state vermicelli products can be better maintained, and the quality guarantee period of the hygroscopic state vermicelli products can be prolonged.

Owner:NANJING AGRICULTURAL UNIVERSITY

Multifunctional mildewproof dampproof agent

InactiveCN108184916ASmall doseLow costBiocideDispersed particle separationCalcium propanoateStearic acid

The invention relates to a multifunctional mildewproof dampproof agent. The multifunctional mildewproof dampproof agent comprises: in parts by mass, 20-40 parts of sorbic acid, 10-15 parts of tea polyphenols, 10-15 parts of adsorbent, 15-20 parts of chitosan, 5-10 parts of cinnamon essential oil, 15-18 parts of calcium propanoate, 5-10 parts of gelatin, 10-15 parts of modified alkyd resin, 2-3 parts of stearic acid and 60-80 parts of water. The mildewproof dampproof agent has the outstanding effect of inhibiting breeding of mold, fungi, bacteria, algae and other microorganisms in an organic medium, has the advantages of low dosage, economical cost, long sterilization duration, a wide application range of pH, convenient feeding and use safety, and can be widely applied to sterilization andmold prevention in various occasions.

Owner:钱小平

Processing method of ramie and pennisetum purpureum mixed silage

PendingCN112006157AMake up for the defect that silage is difficultIncrease dry matterFood processingAnimal feeding stuffBiotechnologyPennisetum purpureum

The invention provides a processing method of ramie and pennisetum purpureum mixed silage, and belongs to the field of feed additives. The processing method comprises the following specific steps: mixing 60%-80% of pennisetum purpureum and 20%-40% of ramie to obtain silage; then spraying fermentation liquor to the silage, spraying an additive at the same time, and then performing fermentation. Thefermentation liquor comprises compound bacteria, compound enzyme and water, and the compound bacteria comprise lactobacillus plantarum, lactobacillus buchneri, pediococcus pentosaceus and bacillus subtilis; the compound enzyme comprises cellulase, xylanase and laccase; and the additive comprises calcium propionate, molasses, urea, ethanol and water. According to the processing method of the silage, ramie and pennisetum purpureum mixed silage is adopted, nutrients are complemented, the fermentation liquid and the additive are combined for fermentation, the defect that ramie and pennisetum purpureum silage is difficult to silage is overcome, the dry matter and crude protein content and lactic acid bacteria of the silage are increased, and the crude ash content, the acid washing fiber content, the lignin content and the pH value are reduced.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION BUFFALO INST

Health care soybean sauce and preparation method thereof

ActiveCN103393076AAvoid damageEliminate side effectsFood preparationPolygonum odoratumPolygonatum odoratum

The invention relates to health care soybean sauce. The health care soybean sauce is characterized by comprising the following main components by weight percent: 15-20% of corn, 10-15% of green bean, 3-5% of Chinese angelica, 3-6% of almond, 2-5% of white atractylodes rhizome, 3-6% of medlar, 2-5% of polygonatum odoratum, 1-3% of honey, 1-2% of fermented vinegar, 1-2% of calcium propionate, 1-4% of potassium sorbate, 1-3% of spirulina, 1-3% of longan, 1-3% of Chinese yam and the balance of water. The health care soybean sauce has the function of preventing and treating diseases on the premise of guaranteeing a normal seasoning function, especially has obvious effects on treating and relieving constipation and malnutrition, and can be used for improving the immunity of a human body.

Owner:GUANGDONG YUESHIFU FLAVOR FOOD

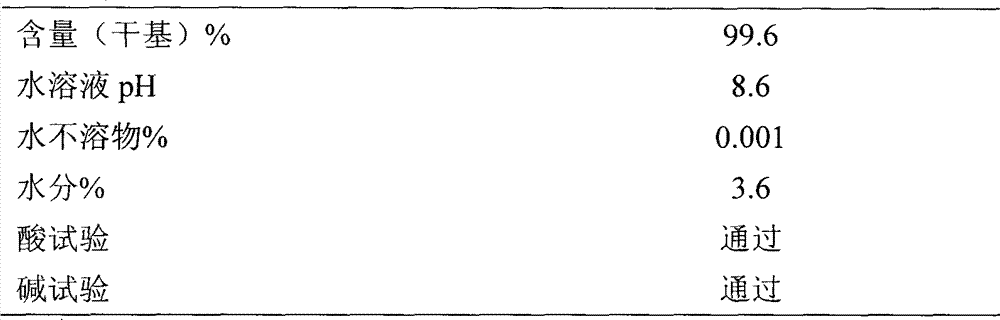

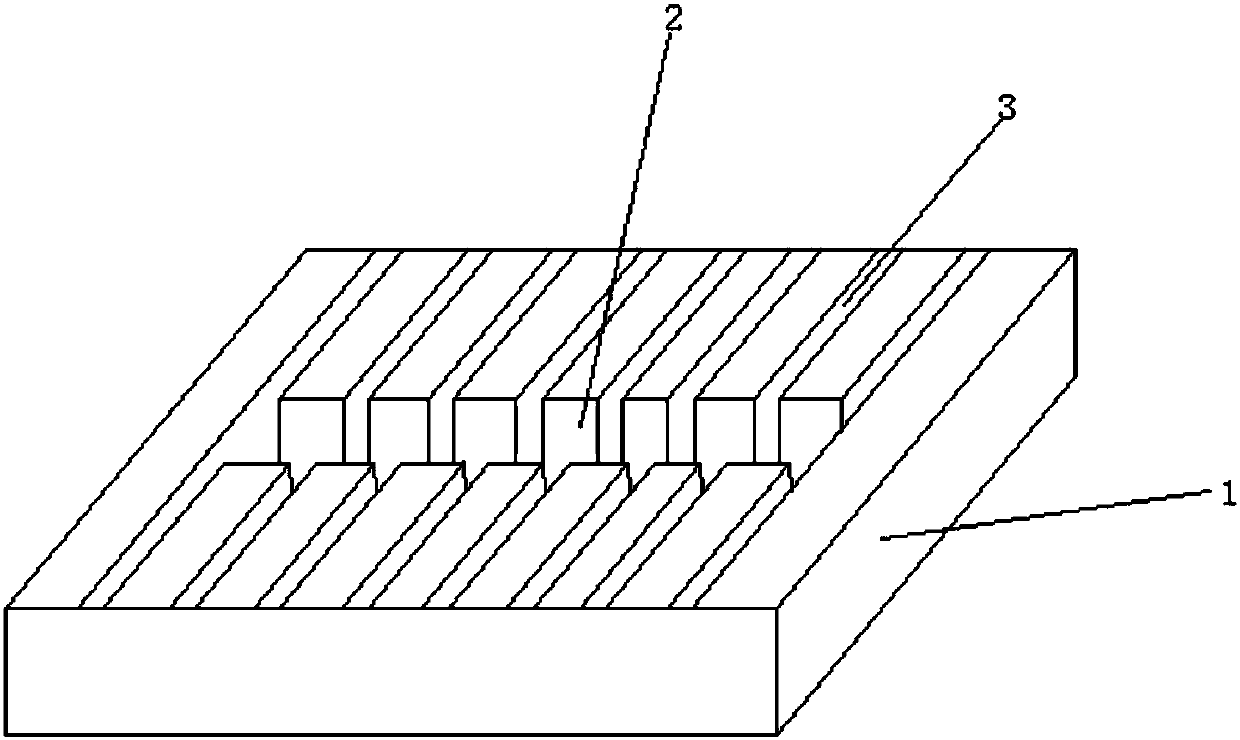

Preparation method of calcium propionate

InactiveCN103113213AEasy to manufactureWide range of usesCarboxylic acid salt preparationCarboxylic compound separation/purificationPropionateCalcium hydroxide

The invention aims at providing a preparation method of calcium propionate. The preparation method comprises the following steps of: reacting calcium hydroxide with metacetonic acid, controlling reaction pH value in the range from 6.5 to7.0 to remove alkali residue in a product, removing excessive acid in a drying process, adsorbing the filtrate after filtration through a mixed adsorbent to remove impurity caused by the metacetonic acid and the calcium hydroxide, and obtaining a calcium propionate product by spraying drying, wherein whiteness purity of the calcium propionate product is greater than 99%.

Owner:JIANGNAN UNIV

Compound preservative for tangerines

The present invention discloses a compound preservative for tangerines, and the compound preservative consists of chitosan (concentration, 5-15 g / L), vitamin C (concentration, 2-5.5 g / L), rosemary (concentration, 2-5.5 g / L), citric acid (concentration, 1-2 g / L), calcium propionate (concentration, 1-2 g / L), licorice extract (concentration, 5-8 g / L), phytic acid (mass percent concentration, 0.1-0.3%), carboxymethyl cellulose (concentration, 3.5-5.5 g / L), cordate houttuynia extract (concentration, 4-6 g / L), caulis impatientis extract (concentration, 5-12 g / L) and orange peel extract (concentration, 5-8 g / L), and the compound preservative uses water as solvent. Compared to the traditional chemical preservative, the compound preservative is green and safe, free of toxic side effects on human health, and excellent in preservation effect.

Owner:TAICANG YONGFA FARM SPECIALIZED COOP

Biological stimulant

InactiveCN106431596AImprove the ability to fight free radicalsIncrease vitalityCalcareous fertilisersMagnesium fertilisersMicrobial agentPhosphate

The invention discloses a biological stimulant. The biological stimulant comprises urea, potassium chloride, potassium dihydrogen phosphate, disodium EDTA, epsilon-polylysine, phenylalanine, matrine, calcium propionate, potassium fulvate, isopentenyladenine, 6-benzylaminopurine, a composite microbial agent and trace elements. The biological stimulant has an obvious effect on tomato plantation, meets vegetable growth demands, improves the growth and the fruit setting of vegetables, improves the free radical resistance of plants, enhances the vitality of the plants, increases the yield, adjusts distribution of nutrient substances, and improves the fruit content of fruits in order to substantially improve the fruit quality.

Owner:李怀峰

Pelteobagrus fulvidraco culturing feed and preparation method thereof

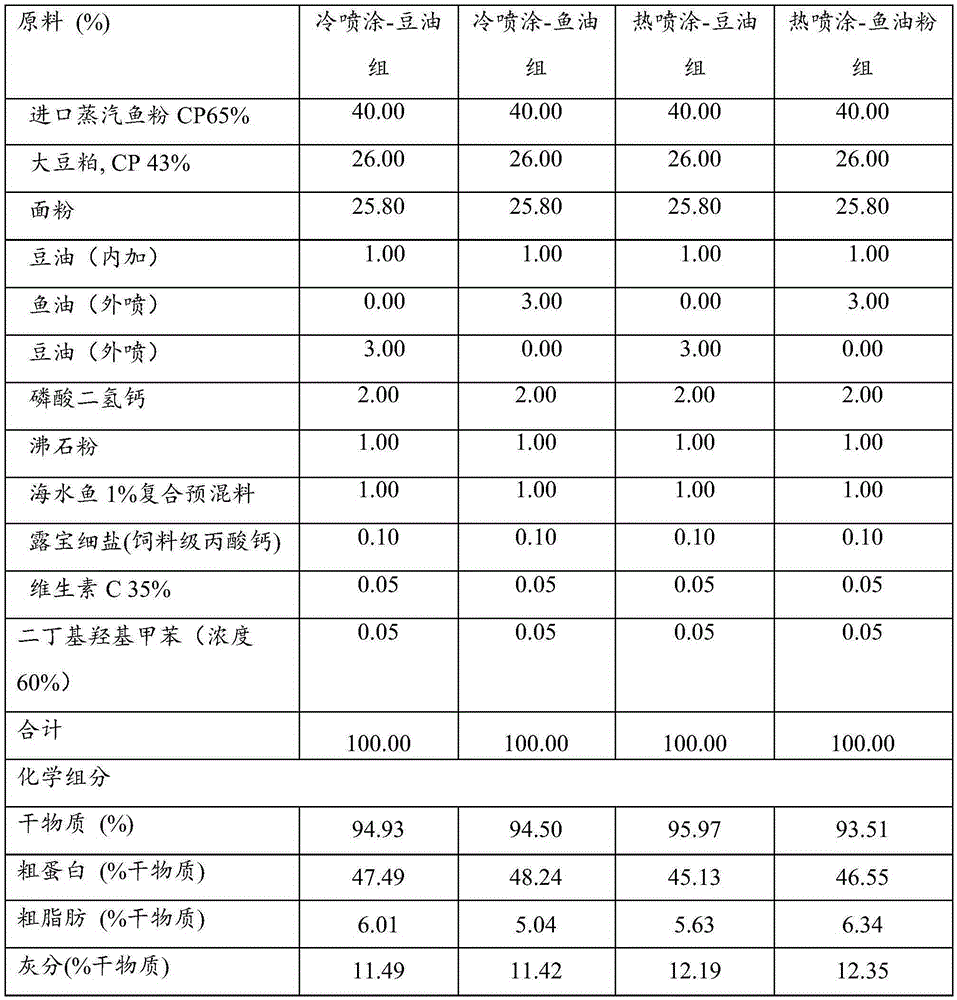

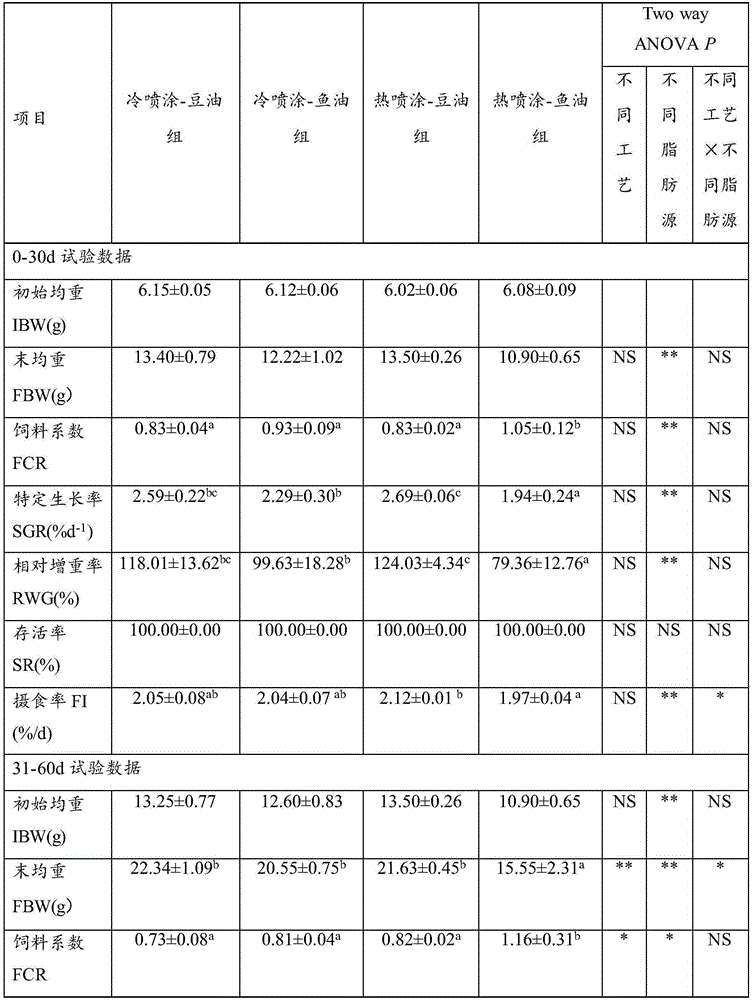

InactiveCN105341545AIncrease specific growth rateIncrease weight gainClimate change adaptationAnimal feeding stuffVitamin CAntioxidant

The invention relates to the field of aquatic feed processing, and discloses pelteobagrus fulvidraco culturing feed and a preparation method thereof. The feed provided by the invention is prepared from Peru fish meal, bean pulp, flour, soya-bean oil, monocalcium phosphate, zeolite powder, saltwater fish compound premix, feed grade calcium propionate, vitamin C and an antioxidant. The pelteobagrus fulvidraco culturing feed provided by the invention adopts multiple proper components, fish oil commonly used in a traditional feed formula is removed, meanwhile, a cold spraying technology of cooling the feed first and then spraying grease is adopted for preparation, the prepared feed can reduce the feed coefficients and increase the specific growth rate and relative weight gain rate of pelteobagrus fulvidraco.

Owner:COFCO FEED +1

Long-acting preservative for meat products

InactiveCN104970085ADoes not affect the tasteGood effectMeat/fish preservation using chemicalsBiotechnologySodium lactate

Owner:QINGDAO MAIKE 3D HI TECH CO LTD

Preservative for sterilization and color protection of fresh-cut fruits and vegetables

InactiveCN102018025AGuaranteed hardnessReduce in quantityFruit and vegetables preservationSurface moisturePropionate

The invention relates to a preservative with the dual functions of sterilization and color protection for fresh-cut fruits and vegetables, which consists of sodium chlorite and calcium propionate. A using process for the preservative comprises the following steps of: harvesting high-quality fruits and vegetables in a proper maturity stage, timely performing treatment or refrigeration in a refrigeration house of about 0 to 4 DEG C, selecting, grading and washing the fresh harvested or refrigerated fruits and vegetables, impregnating and sterilizing the selected, graded and washed fruits and vegetables for 1 to 5 min by adopting 100 mg / L sodium hypochlorite, performing fresh-cutting, impregnating the fresh-cut fruits and vegetables with composite solution consisting of 0.01 to 0.1 percent of sodium chlorite and 0.5 to 2 percent of calcium propionate, removing surface moisture, packaging the treated fruits and vegetables into plastic bags or boxes, and sealing the plastic bags or boxes for refrigeration, transportation or selling at 0 to 4 DEG C. In the new technology, the fresh-cut fruits and vegetables can be sterilized and kept fresh for about 10 to 20 days with original texture and color to be used as high-grade convenient fruit consumption products in meetings, banquets, catering for students and daily consumption.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN +1

Food preservative

InactiveCN102763886ARaw materials are easy to getSimple methodFood preservationBiotechnologySodium acetate

Owner:占协琼

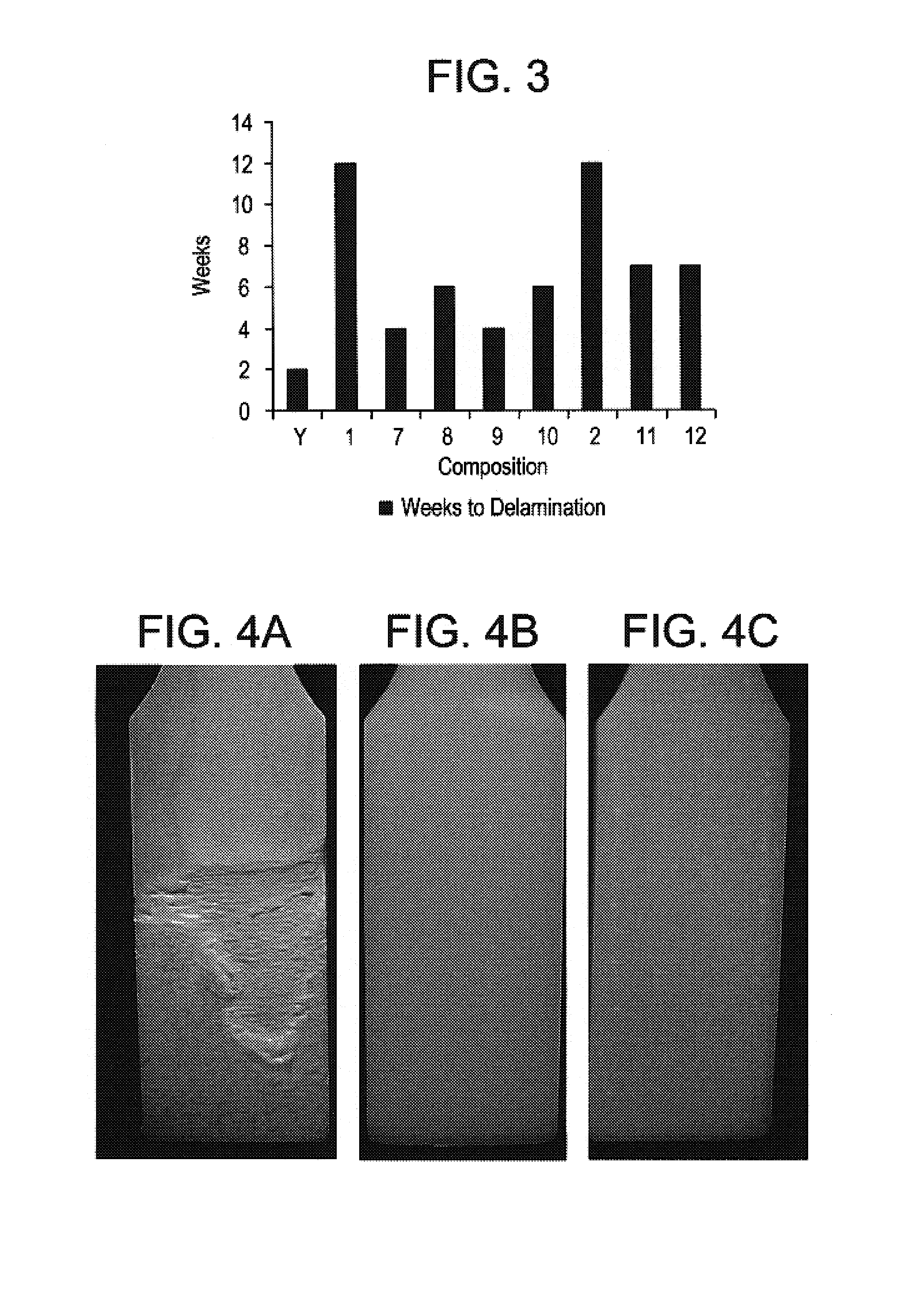

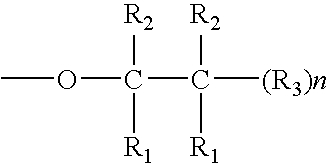

Polyacetals with improved resistance to bleach

A molding composition exhibiting bleach resistance includes a polyoxymethylene matrix polymer, from about 0.5 to about 10 weight percent of a bleach stabilizer selected from alkali metal or alkaline earth element carbonates or phosphates and mixtures thereof dispersed in the matrix resin. A bleach co-stabilizer is selected from the group consisting of: (a) a poly(alkoxy) stabilizer; (b) a zinc oxide stabilizer; (c) a color stabilizer consisting of a mixture of calcium citrate and calcium propionate, wherein the calcium citrate is the predominant component of the color stabilizer mixture; or (d) mixtures of two or more of (a), (b) and (c). The compositions exhibit a bleach resistance index of at least 2.0.

Owner:TICONA LLC

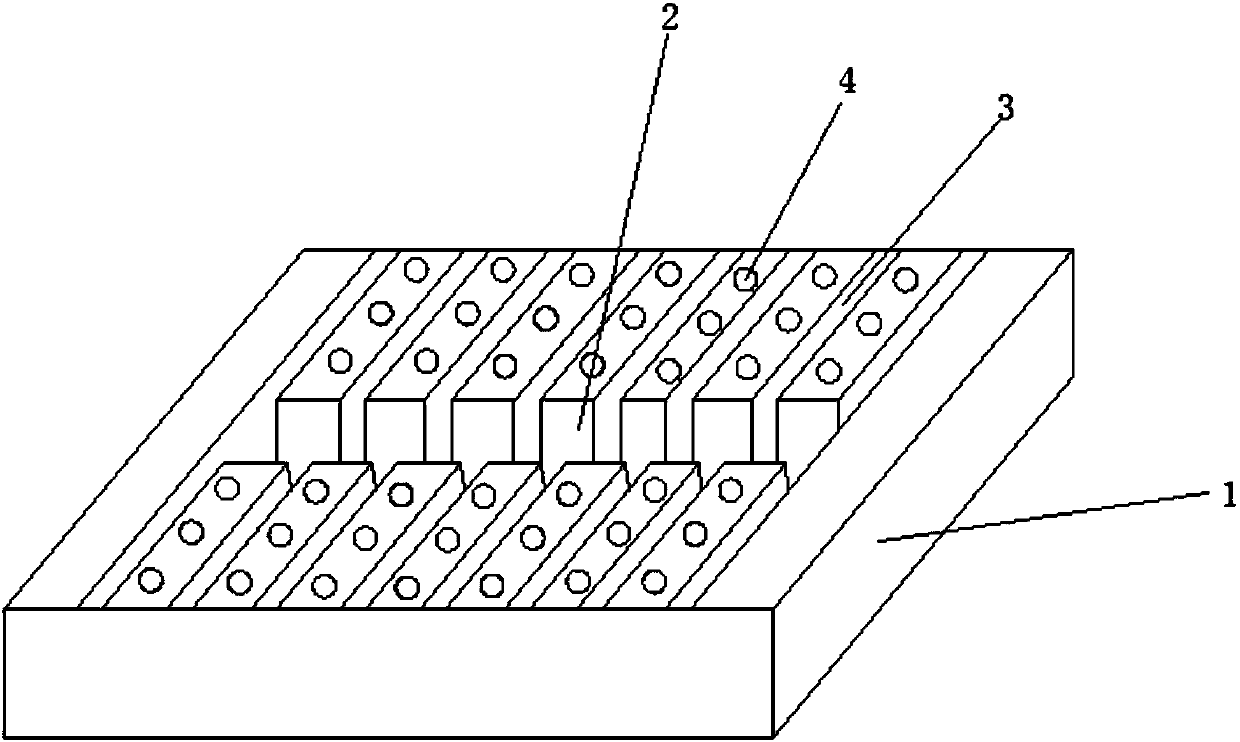

Biological brick used for the growth and reproduction of Hermetia illucens and its production and using method

PendingCN107593620APlay the role of attracting eggs for a long timeGuaranteed hatch rateAnimal feeding stuffWorking-up animal fodderBrickHermetia illucens

The invention discloses a biological brick used for the growth and reproduction of Hermetia illucens and its production and using method. The biological brick for the growth and reproduction of Hermetia illucens is made of the following components in parts by weight: 20-40 parts of bran, 10-30 parts of loess, 1-5 parts of CMC-Na, 0.3-3 parts of calcium propionate, and 10-50 parts of water. The biological brick has special shape and functions, integrates three major functions of egg collection, hatching and larva feeding in one, has wide sources of raw materials, low production cost, and shortgrowth cycle, can remarkably improve the efficiency of collecting eggs and the quality of the larvae, can be used as a nutrition enhancer for Hermetia illucens larvae, also can significantly improve the survival rate of Hermetia illucens larvae, has great potential in the popularization and application of large-scale and industrialized artificial reproduction of Hermetia illucens, and has better social and economic value.

Owner:HENAN AGRICULTURAL UNIVERSITY

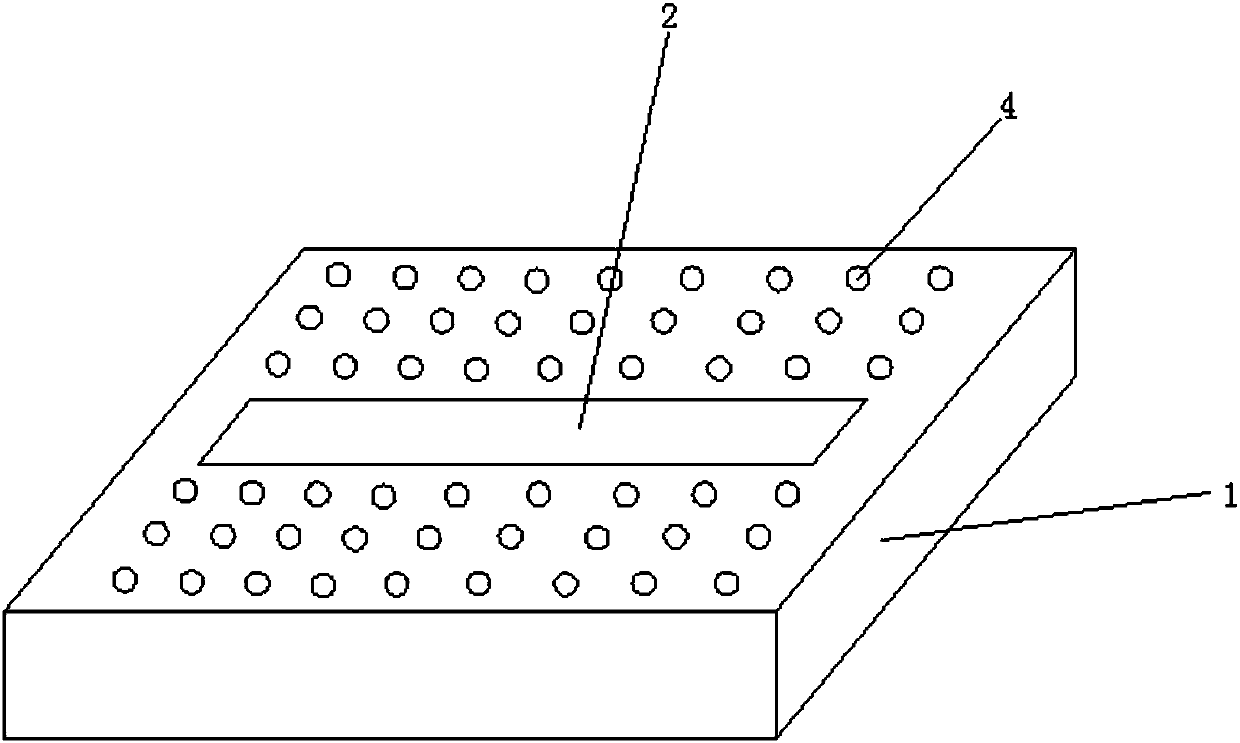

Biological disinfectant

The formula of the biological disinfectant comprises the following components in parts by mass: 10-40 parts of a biological enzyme composition, 30-50 parts of a traditional Chinese medicine extract, 1-5 parts of chitosan, 1-5 parts of nisin, 1-5 parts of calcium propionate and 10-40 parts of distilled water. The disinfectant has the main characteristics that the disinfectant is a novel disinfection method mainly used for solving the problem of accumulation poisoning due to large quantity of chemical disinfectant residues; meanwhile, by adding traditional Chinese medicine extracts, nisin, calcium propionate and the like to biological enzymes with the sterilization effect to jointly act on microorganisms such as bacteria, fungi and viruses, the efficient sterilization method has the advantages of being high in safety, rapid in sterilization effect, wide in sterilization range, free of pungent smells and the like.

Owner:宁夏乙征生物工程有限公司

Medical packaging film and preparation method thereof

ActiveCN111761898AWide variety of sourcesDegradableBio-packagingSynthetic resin layered productsPolymer sciencePropanoic acid

The invention is applicable to the technical field of materials, and provides a medical packaging film and a preparation method thereof. The medical packaging film comprises an outer film layer, an inner film layer and a phase-change energy storage material packaged between the outer film layer and the inner film layer, wherein the outer film layer is prepared from 65 to 80 parts of polylactide, 3to 9 parts of polybutylene succinate, 4 to 8 parts of nano cellulose and 3 to 8 parts of ethylene glycol isophthalate; the inner film layer is prepared from 65 to 80 parts of a polylactic acid-glycolic acid copolymer, 8 to 12 parts of a zinc chloride solution, 4 to 8 parts of nano cellulose, 4 to 8 parts of calcium propionate and 0.5 to 5 parts of polyethylene glycol terephthalate; the phase-change energy storage material is obtained by mixing a sodium chloride solution, starch water-absorbent resin, sodium polyacrylate and phase-change paraffin according to the weight ratio of 1:(3-5):(2-4):(0.01-0.03). The film layers are wide in raw material source, environmentally friendly, degradable, excellent in barrier property and mechanical property, high in transparency and capable of protecting medical articles, and meanwhile, the phase-change energy storage material is good and lasting in cold storage effect and high in repeated utilization rate.

Owner:潮州市潮安区恒昌印制有限公司

A feed additive and applications thereof

ActiveCN104304670AImprove antioxidant capacityImprove stress resistanceAnimal feeding stuffBiotechnologyPropionate

The invention relates to a feed additive and applications thereof. The feed additive and the applications are characterized in that: the feed additive comprises 8-12% by mass of extract products, 0.2-0.8% by mass of balm, 0.2-0.8% by mass of rosemary, 0.2-0.8% by mass of calcium butyrate, 0.2-0.8% by mass of calcium propionate, and 82-92% by mass of a carrier sepiolite; the extract products comprise a grape seed extract product and an onion extract product; and the mass ratio of the grape seed extract product to the onion extract product is 3-5:1. In the technical scheme, a large number of experiments prove that: addition of the grape seed extract product and the onion extract product largely enhances oxidation resistance for animals, enhances anti-stress capability, and improves meat quality, and the additive is a green antioxidant and is free of side effects.

Owner:江苏奥迈生物科技有限公司

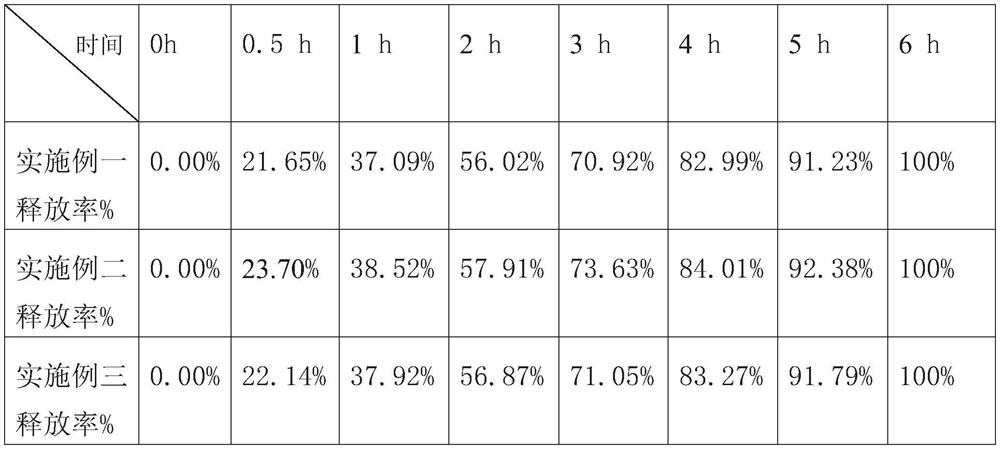

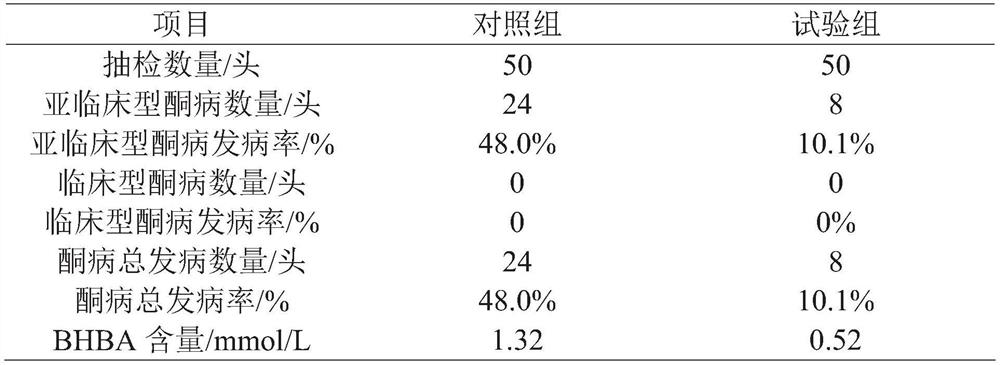

Rumen slow-release nutrition bar and preparation method thereof

PendingCN112335789AAdjust the dissolution rateReduce solubilityAccessory food factorsWorking-up animal fodderBiotechnologyPropanoic acid

The invention provides a rumen slow-release nutrition bar and a preparation method thereof. The problems that in the prior art, nutrient substances for preventing and treating ketosis and fatty liverof dairy cows in the perinatal period are poor in slow-release effect, and the ketosis cannot be prevented and treated are solved. The preparation method comprises the following steps: (1) respectively preparing choline chloride particles, calcium propionate particles and propylene glycol particles; (2) preparing a slow-release adhesive solution; and (3) fully mixing the three particles prepared in the step (1) with the slow-release adhesive solution prepared in the step (2), stirring at 80-90 DEG C for 5-10 minutes, carrying out injection molding to obtain a bar core, drying, cooling to roomtemperature, taking out, and spraying a layer of polyacrylic resin II on the outer surface of the bar core, thereby obtaining the product. By coating choline chloride, calcium propionate and propyleneglycol in proportion and adopting a slow-release treatment technology, the retention time of the two raw materials in rumen is prolonged, glycogen is provided for dairy cows, the liver burden of thedairy cows is reduced through choline, and the effect of preventing postpartum ketosis is achieved.

Owner:青岛润博特生物科技有限公司

Preparation process of neodymium-iron-boron magnet

ActiveCN112071616ASolve the problem of poor reliabilityImprove performanceInductances/transformers/magnets manufactureMagnetic materialsPropanoic acidCalcium propanoate

The invention discloses a preparation process of a neodymium-iron-boron magnet. The preparation process comprises the following steps: a, smelting: weighing raw materials in proportion, putting neodymium-iron-boron powder, Fe3O4, calcium carbonate powder, sodium benzoate, stearic acid and iron into a smelting furnace, carrying out heating to 1,500 DEG C and 1,600 DEG C, sequentially adding carbonblack, calcium propionate, SiO2 and single crystal magnesium oxide, continuing heating until all the raw materials are molten into a liquid state, adjusting a temperature to 2,750 DEG C and 2,860 DEGC, and keeping the temperature for 3-5 hours to obtain a crude permanent magnet product solution; b, powder preparation: cooling and curing the crude permanent magnet product solution to obtain a solid crude permanent magnet product, and feeding the solid crude permanent magnet product into a tube mill for continuous grinding for 3-5 hours to obtain permanent magnet powder with a particle size of0.5-1 [mu]m; c, pressing: placing the obtained permanent magnet powder in a magnetic field with a magnetic field intensity of 20,000-25,000 Gs for orientation and shaping under the action of argon shielding gas, and then carrying out pressing under a static pressure of 400 MPa to obtain a blank; d, cutting: cutting an inclined surface on the blank, and polishing the inclined surface; and e, tempering: placing the blank in a vacuum environment with a temperature of 800 DEG C to 900 DEG C for primary tempering to obtain the permanent magnet.

Owner:宁波四环磁业有限公司

Multi-surface tooth-cleaning sphere eaten by pet and processing technology thereof

ActiveCN108513922AIncrease interest in feedingReach playAnimal feeding stuffAccessory food factorsPhosphatePotato starch

The invention relates to a multi-surface tooth-cleaning sphere eaten by a pet and a processing technology thereof. The multi-surface tooth-cleaning sphere comprises the following components in parts by weight: 25-35 parts of modified starch, 15-20 parts of potato starch, 15-20 parts of soybean protein concentrate, 10-18 parts of glycerol, 0.2-0.5 part of composite phosphate, 0.2-0.5 part of tea polyphenol, 12-15 parts of cassava starch, 4-8 parts of dietary fibers, 1-3 parts of a pet attractant, 1-2 parts of xanthan gum, 0.5-1 part of glycerol monostearate, 0.5-1 part of citric acid, 0.2-0.5 part of pigment, 0.2-0.4 part of potassium sorbate and 0.1-0.3 part of calcium propionate. The product utilizes natural shapes common in life and is closer to life, and the sphere has a 3D effect, so that a dog can fully grind teeth at play.

Owner:上海中宠食品科技有限公司

Feed for breeding ducks on dry land

Feed for breeding ducks on a dry land is characterized in that 20 parts of corn flour, 10 parts of wheat bran, 20 parts of rice bran, 10 parts of lard oil, 20 parts of peanut oil residues, 20 parts of bean pulp, 0.2 part of vitamin E, 0.5 part of calcium propionate, 30 parts of cooked tapioca flour and 0.5 part of gypsum powder are mixed and mechanically pressed to form the feed. Various economical agricultural products with low price and comprehensive nutrition are used as main energy raw materials, gypsum is added into the feed, the body temperature of the ducks is automatically adjusted and reduced, and the ducks can be bred on the dry land.

Owner:蒋世芬

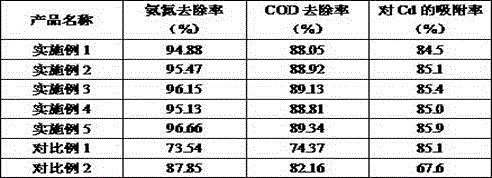

Novel ammonia-nitrogen wastewater treatment material and preparation method thereof

ActiveCN105582896ALow costHigh removal rateOther chemical processesWater/sewage treatment by sorptionPropanoic acidCalcium propanoate

The invention provides a novel ammonia-nitrogen wastewater treatment material and a preparation method thereof. The material is prepared form components as follows: silica, titanium dioxide, xonotlite, calcium oxide, carbamide, titanium isobutoxide, calcium propanoate, calcium chloride, propyl gallate, ethanol, anhydrous acetic acid and distilled water. The preparation method of the material comprises steps as follows: firstly, mixing carbamide, 50-80 parts of ethanol, distilled water and anhydrous acetic acid to obtain a solution; after mixing titanium isobutoxide, titanium dioxide and the rest ethanol, slowly adding the solution to the mixture while stirring all the time, leaving the mixture to stand, then drying the mixture, grinding the dried substance into powder, sieving the powder, mixing the powder with the rest components, evenly scattering the mixture in a muffle furnace for calcination, and taking out and cooling the product to obtain the material. The novel ammonia-nitrogen wastewater treatment material can effectively remove ammonia nitrogen and COD, is high in adsorbability, has a good removal effect on heavy metal Cd and improves the wastewater quality.

Owner:HENAN YISHUIYUAN WATER PURIFICATION MATERIAL TECH CO LTD

Red koji vinegar and production process thereof

InactiveCN103740577ASimple ingredientsThe brewing process is simpleVinegar preparationBiotechnologyPropionate

The invention discloses red koji vinegar which comprises the following components: 300 percent of Yongchun mature vinegar, 100 percent of soybean, 5.5-6.0 percent of apple juice, 3.5-4.0 percent of white granulated sugar, 0.2-0.25 percent of calcium propionate, 0.05-0.1 percent of L-malic acid, 0.6-0.8 percent of sodium citrate, and 0.1-0.15 percent of aspartame, wherein the aspartame contains phenylalanine. The production process comprises the following steps: 1, mixing the Yongchun mature vinegar, the apple juice, the white granulated sugar, calcium propionate, the L-malic acid, sodium citrate and the aspartame together to prepare a mixed solution; 2, picking; 3, sterilizing; 4, soaking; 5, filtering; 6, filling; 7, sterilizing; 8, detecting according to the national microbial standard. Compared with the prior art, the red koji vinegar and the production process thereof have the following advantages that the material preparation is simple, the brewing process is simpler, the production cycle is shorter, the cost is reduced, the large-scale industrial production is achieved, and the red koji vinegar contains rich amino acids and proteins, has a better health-care effect, and can be used as a beverage for drinking in daily diet.

Owner:福建永春顺德堂食品有限公司

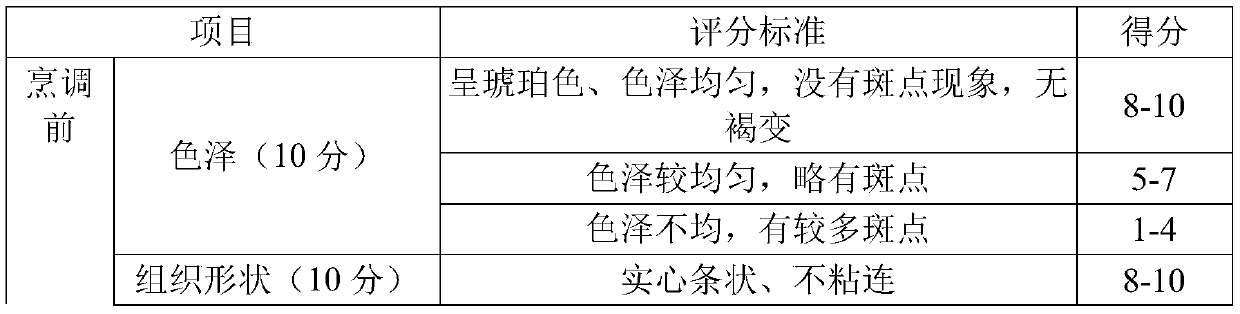

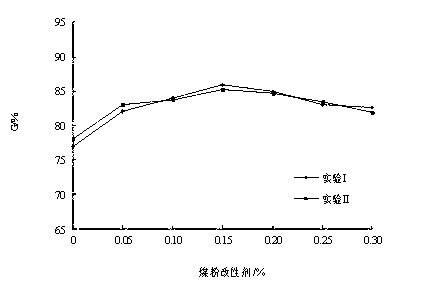

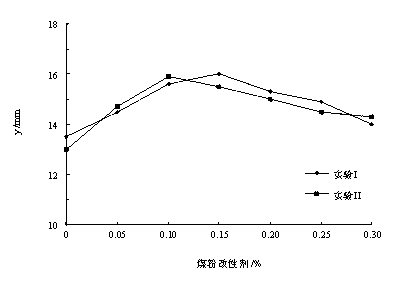

Semi-dry noodles and production method thereof

InactiveCN111436565AWith humidityNo browningFood ingredient for microbe protectionBiotechnologyCalcium propanoate

The invention discloses semi-dry noodles which comprise wheat flour, corn flour, edible alcohol, edible salt, water, natural carotene, gardenia yellow, calcium propionate, sorbitol liquid, propylene glycol, sodium carbonate and potassium carbonate. The invention also discloses a production method of the semi-dry noodles. The production method comprises the following steps: uniformly mixing sodiumcarbonate, potassium carbonate and edible salt to obtain a solid auxiliary material; mixing propylene glycol, sorbitol liquid and edible alcohol, adding natural carotene and solid auxiliary materials,and performing uniform mixing to obtain a substance A; stirring wheat flour and corn flour, adding water and the substance A, adding gardenia yellow and calcium propionate, and performing stirring toobtain a dough; and resting the dough, and sequentially carrying out calendering, primary sterilizing, drying sterilizing and packaging to obtain the semi-dry noodles. The method has the advantages that the moisture content of the prepared noodles is 23%-28%, the noodles have certain humidity, few bacteria and microorganisms exist in the noodles or even no bacteria and microorganisms exist in thenoodles, the noodles are free of browning, and thus the preservation time of the noodles is longer.

Owner:北京天第食圣食品有限公司

Low-carbon high-hydrogen coal dust modifier and coal blending coking method using same

The invention relates to a low-carbon high-hydrogen coal dust modifier and a coal blending coking method. The modifier comprises the following components in percentage by mass: 60 to 85% of boric acid, 1 to 20% of adipic acid or dodecanedioic acid or alanine or the mixture of two or three of the adipic acid and dodecanedioic acid and alanine, 1 to 25% of calcium propionate, and 1 to 20% of seconary alkane sulphonate sodium or potassium stearate or stearic calcium lactate or the mixture of two or three of the seconary alkane sulphonate sodium and potassium stearate and stearic calcium lactate. The coal blending coking method comprises the following steps: weighing 0.01 to 1%of coal dust modifier and 0.1 to 5.5% of low-carbon high-hydrogen coal dust according to the mass of the coking fitting coal; transferring the coal dust modifier and the low-carbon high-hydrogen coal dust into a modifying device for modifying; uniformly mixing and placing the modified coal and 45 to 99% of coking coal into a coke oven; and then preparing high-quality carbon according to the conventional production process. The coal blending coking method has the advantages that the mass percentage of the low-carbon high-hydrogen coal dust in the coking fitting coal can be improved, the coking cost is greatly reduced, and remarkable economic benefits are brought.

Owner:朱子宗

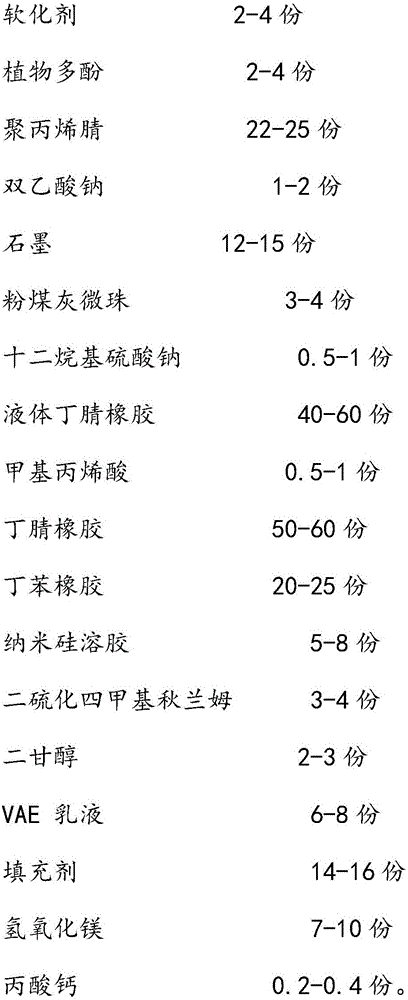

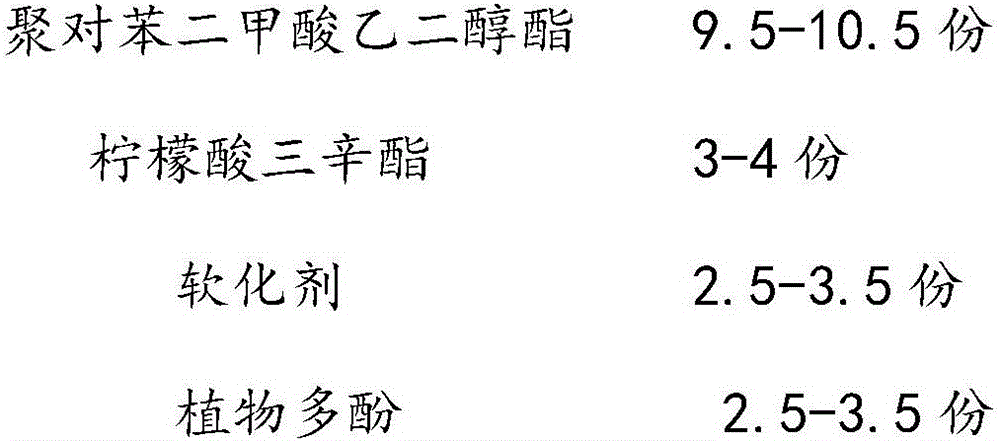

Anti-oxidizing rubber material

The invention discloses an anti-oxidizing rubber material including, by weight, 9-11 parts of polyethylene glycol terephthalate, 2-5 parts of trioctyl citrate, 2-4 parts of a softener, 2-4 parts of plant polyphenol, 22-25 parts of polyacrylonitrile, 1-2 parts of sodium diacetate, 12-15 parts of graphite, 3-4 parts of micro beads of fly ash, 0.5-1 part of lauryl sodium sulfate, 40-60 parts of liquid nitrile butadiene rubber, 0.5-1 part of methylacrylic acid, 50-60 parts of nitrile butadiene rubber, 20-25 parts of styrene butadiene rubber, 5-8 parts of nano silicon sol, 3-4 parts of tetramethyl thiuram disulfide, 2-3 parts of diethylene glycol, 6-8 parts of VAE emulsion, 14-16 parts of a filling agent, 7-10 parts of magnesium hydroxide, and 0.2-0.4 parts of calcium propanoate. The anti-oxidizing rubber material has excellent water proof performance, is acid-resistant, oil-resistant and flame-retarding and satisfies demands in production well.

Owner:ANHUI WEIWEI RUBBER PARTS GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com