Preparation method of calcium propionate

A technology of calcium propionate and propionic acid, which is applied in the field of food additives, can solve the problems of dust-producing calcium carbonate impurities, high labor intensity, excessive alkali content, etc., and achieve the effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

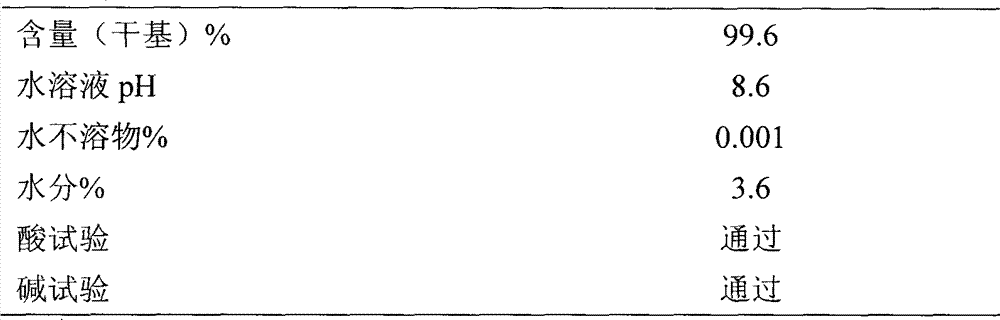

Embodiment 1

[0014] Add 1 kg of calcium hydroxide to 9.8 kg of water, adjust the pH to 6.9 with propionic acid under stirring, and filter. 10 grams of activated carbon and 10 grams of diatomaceous earth were added to the filtrate, stirred and adsorbed for 10 minutes, filtered through micropores, and the filtrate was spray-dried to obtain a product with a purity of 99.6%.

Embodiment 2

[0016] Add 1 kg of calcium hydroxide to 14 kg of water, adjust the pH to 6.9 with propionic acid under stirring, and filter. 10 grams of activated carbon and 10 grams of diatomaceous earth were added to the filtrate, stirred and adsorbed for 10 minutes, filtered through micropores, and the filtrate was spray-dried to obtain a product with a purity of 99.2%.

Embodiment 3

[0018] Add 1 kg of calcium hydroxide to 9.8 kg of water, adjust the pH to 6.9 with propionic acid under stirring, and filter. 20 grams of activated carbon and 10 grams of diatomaceous earth were added to the filtrate, stirred and adsorbed for 10 minutes, filtered through micropores, and the filtrate was spray-dried to obtain a product with a purity of 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com