Preparation process of neodymium-iron-boron magnet

A preparation process, NdFeB technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve problems such as poor reliability of product surface coatings, improve performance and use methods, and achieve the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

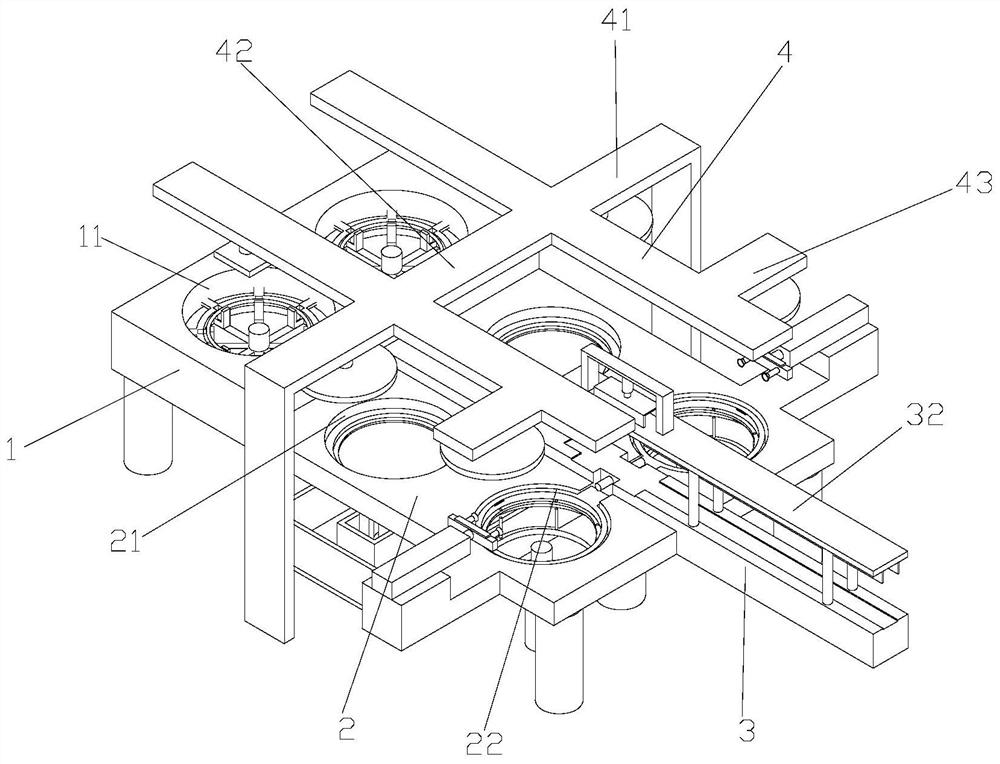

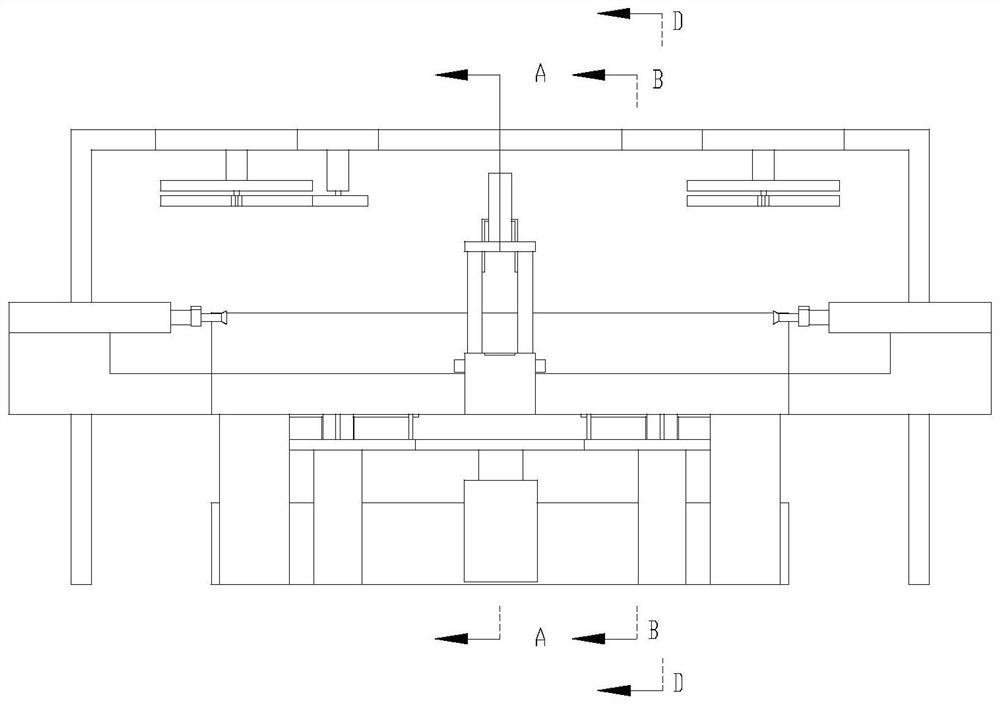

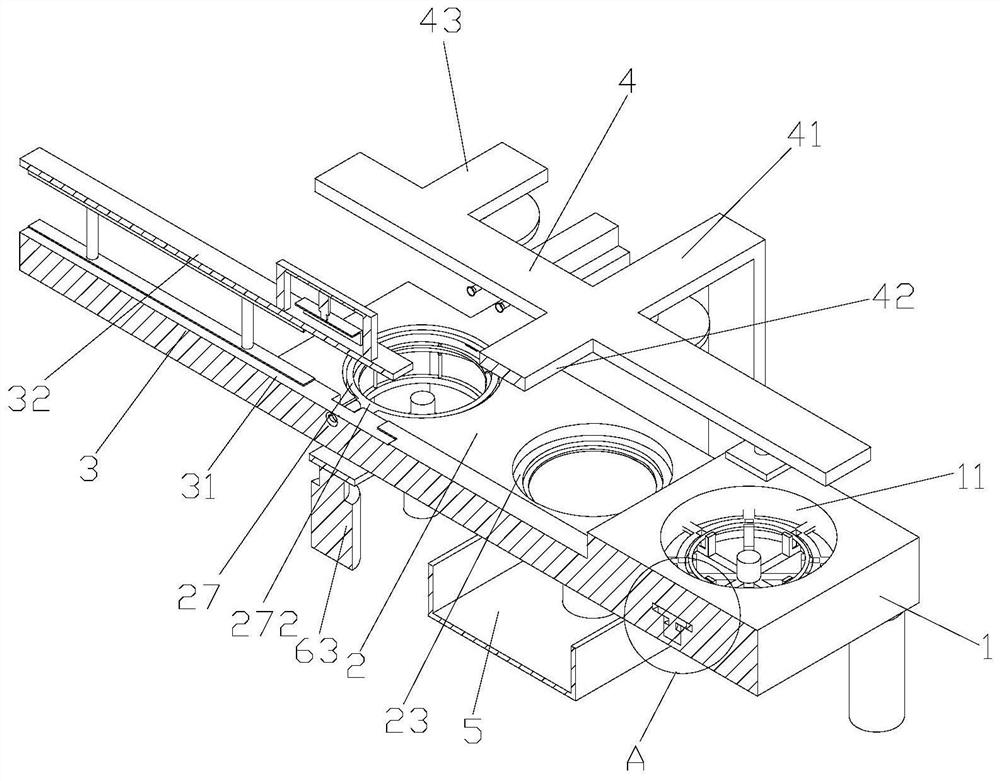

Image

Examples

Embodiment 1

[0051] A preparation process of neodymium iron boron magnets, comprising:

[0052] a. Melting: After weighing the raw materials according to the ratio, put NdFeB powder, Fe3O4, calcium carbonate powder, sodium benzoate, stearic acid and iron into the melting furnace, heat up to 1500 °C, and then add carbon black and propionic acid in sequence Calcium, SiO2 and single crystal magnesium oxide, continue to heat up until all raw materials melt into liquid state, then adjust the temperature to be 2750 ℃:, keep 3-5h, obtain permanent magnet crude product solution;

[0053] b. Milling: Cool and solidify the permanent magnet rough product solution to obtain a solid rough product permanent magnet, send it into a tube mill for continuous grinding for 3 hours, and obtain a permanent magnet powder with a particle size of 0.5 microns;

[0054] c. Pressing: put the obtained permanent magnet powder into a magnetic field with a magnetic field strength of 20000Gs under the action of argon prot...

Embodiment 2

[0087] A preparation process of neodymium iron boron magnets, comprising:

[0088] a. Melting: After weighing the raw materials according to the proportion, put NdFeB powder, Fe3O4, calcium carbonate powder, sodium benzoate, stearic acid and iron into the melting furnace, raise the temperature to 1600 ° C, and then add carbon black and propionic acid in sequence Calcium, SiO2 and single crystal magnesium oxide, continue to heat up until all raw materials melt into liquid state, then adjust the temperature to 2860 ° C, keep for 5 hours, and obtain the permanent magnet crude product solution;

[0089] b. Milling: Cool and solidify the permanent magnet rough product solution to obtain a solid rough product permanent magnet, send it into a tube mill for continuous grinding for 5 hours, and obtain a permanent magnet powder with a particle size of 1 micron;

[0090] c. Pressing: put the obtained permanent magnet powder into a magnetic field with a magnetic field strength of 25000Gs un...

Embodiment 3

[0105] A preparation process of neodymium iron boron magnets, comprising:

[0106] a. Melting: After weighing the raw materials according to the ratio, put NdFeB powder, Fe3O4, calcium carbonate powder, sodium benzoate, stearic acid and iron into the melting furnace, heat up to 1550 °C, and then add carbon black and propionic acid in sequence Calcium, SiO2 and single crystal magnesium oxide, continue to heat up until all raw materials are melted into liquid, then adjust the temperature to 2800 ° C, keep for 4 hours, and obtain the permanent magnet crude product solution;

[0107] b. Milling: cooling and solidifying the permanent magnet rough product solution to obtain a solid rough product permanent magnet, and sending it into a tube mill for continuous grinding for 4 hours to obtain a permanent magnet powder with a particle size of 1 micron;

[0108] c. Pressing: put the obtained permanent magnet powder into a magnetic field with a magnetic field strength of 24000Gs under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com