Method for improving mechanical properties of gypsum-based material

A material mechanics, gypsum-based technology, applied in the field of improving the mechanical properties of gypsum-based materials, can solve problems such as failure to support or hang heavy objects, and achieve the effects of solving poor mechanical properties, improving mechanical properties, and high fire rating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

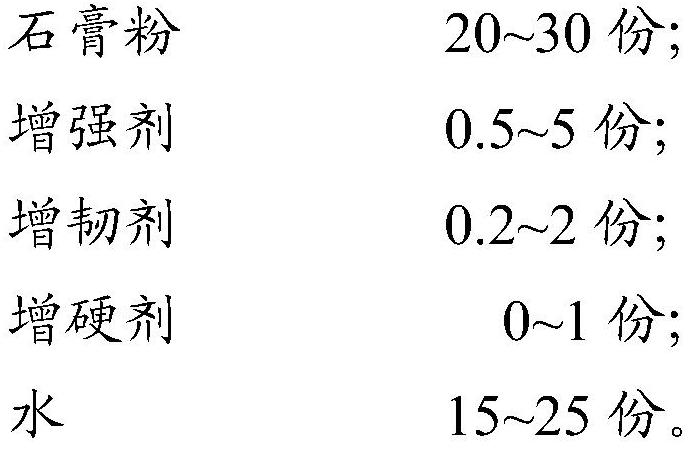

Method used

Image

Examples

Embodiment 1

[0043] In parts by weight, 20 parts of construction gypsum powder (Taishan Gypsum No. 20~25μm, D75 is 45~50μm, D90 is 70~80μm, specific surface area is 4502m 2 / g), 16 parts of water, 1 part of mixing enhancer, said mixing enhancer consists of polyalkyd resin (389-9A, Shandong Aohui Paint Industry Co., Ltd.), polyacrylic acid emulsion (25 ℃ viscosity 12pa·s, solid Content 40wt%, BASF (China) Co., Ltd.), polyvinyl acetate-ethylene copolymer emulsion (vinyl acetate content in the copolymer is 25wt%, 25 ℃ viscosity 30Mpa s, solid content 10wt%, Changchun Chemical Co., Ltd.) according to Mixed with a mass ratio of 1:1:1, 0.5 parts of glass fiber (diameter 15μm, length 12mm, Taishan Fiberglass Co., Ltd.), mixed evenly by a mixer, poured into a mold of 40mm×40mm×160mm, solidified and formed, and then Dry at 150°C for 1 hour (the ambient relative humidity during the drying process is 10%), and then dry at 45°C to constant weight (the ambient relative humidity during the drying proce...

Embodiment 2

[0048] In parts by weight, 30 parts of construction gypsum powder (Taishan Gypsum No. 20~25μm, D75 is 45~50μm, D90 is 70~80μm, specific surface area is 4502m 2 / g), 24 parts of water, 1.2 parts of mixing enhancer, said mixing enhancer consists of phenolic resin (9021, Shandong Runda New Material Co., Ltd.), polyacrylic acid emulsion (25 ℃ viscosity 12pa s, solid content 40wt%, BASF (China) Co., Ltd.), polyvinyl acetate-ethylene copolymer emulsion (vinyl acetate content 25wt% in the copolymer, 25 ℃ viscosity 30Mpa s, solid content 10wt%, Changchun Chemical Co., Ltd.) according to mass ratio 2: It is made by mixing 1:1, 0.5 parts of glass fiber (diameter 15μm, length 12mm, Taishan Glass Fiber Co., Ltd.), after being mixed evenly by a mixer, poured into a mold of 40mm×40mm×160mm, solidified and formed, and then dried at 150°C 1h (the relative humidity of the environment during the drying process is 10%), and then dried at 45° C. to a constant weight (the relative humidity of the...

Embodiment 3

[0053]In parts by weight, 30 parts of building gypsum powder (Taishan Gypsum No. 20~25μm, D75 is 45~50μm, D90 is 70~80μm, specific surface area is 4502m 2 / g), 24 parts of water, 1.2 parts of mixing reinforcing agent, described mixing reinforcing agent is made of phenolic resin (9021, Shandong Runda New Material Co., Ltd.), polyvinyl acetate (6036, Changchun Chemical Co., Ltd.), epoxy resin (RDP-777, Shandong Runda New Material Co., Ltd.) mixed according to the mass ratio of 2:1:2, 0.5 parts of glass fiber (diameter 15μm, length 12mm, Taishan Glass Fiber Co., Ltd.), after mixing evenly with a mixer, inject In a mold of 40mm×40mm×160mm, solidify and form, then dry at 150°C for 1h (the relative humidity of the environment during the drying process is 10%), and then dry at 45°C to constant weight (the relative humidity of the environment during the drying process is 15%) to obtain high-strength gypsum-based materials.

[0054] According to the detection method in GB / T9775-2008 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com