Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

326results about How to "Reduce grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medical high-strength titanium alloy wire and preparation method thereof

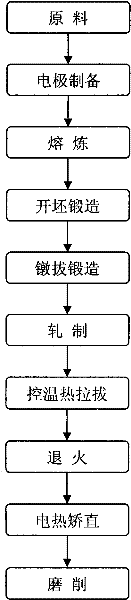

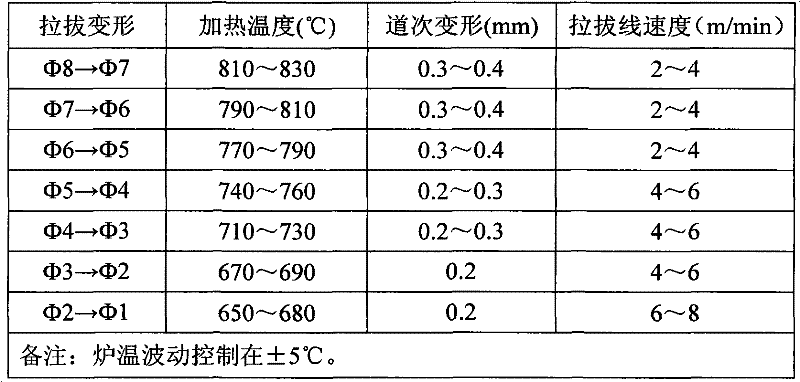

The invention provides a medical high-strength titanium alloy wire and a preparation method thereof and relates to component control of a Ti-6Al-4V titanium alloy wire having high strength and good cold molding characteristic and a preparation method thereof. The component control of the Ti-6Al-4V titanium alloy wire is as follows: based on weight percent, 6.0%-6.3% of main element Al, 4.2%-4.5% of V, 0.13-0.15% of interstitial element O and 0.08%-0.12% of Fe. The alloy obtained according to the component control is subjected to smelting, cogging and forging, multiple heating numbers of upsetting and forging, large-deformation rolling, temperature-control hot drawing, stress relief annealing, electric heating straightening and grinding processes so as to prepare the high-strength titanium alloy wire. The Ti-6Al-4V titanium alloy can obtain high strength (tensile strength of more than or equal to 1200Mpa and elongation A of more than or equal to 8%) and excellent plasticity, and can be applied to a medical Kirschner wire fixing system.

Owner:西安赛特金属材料开发有限公司

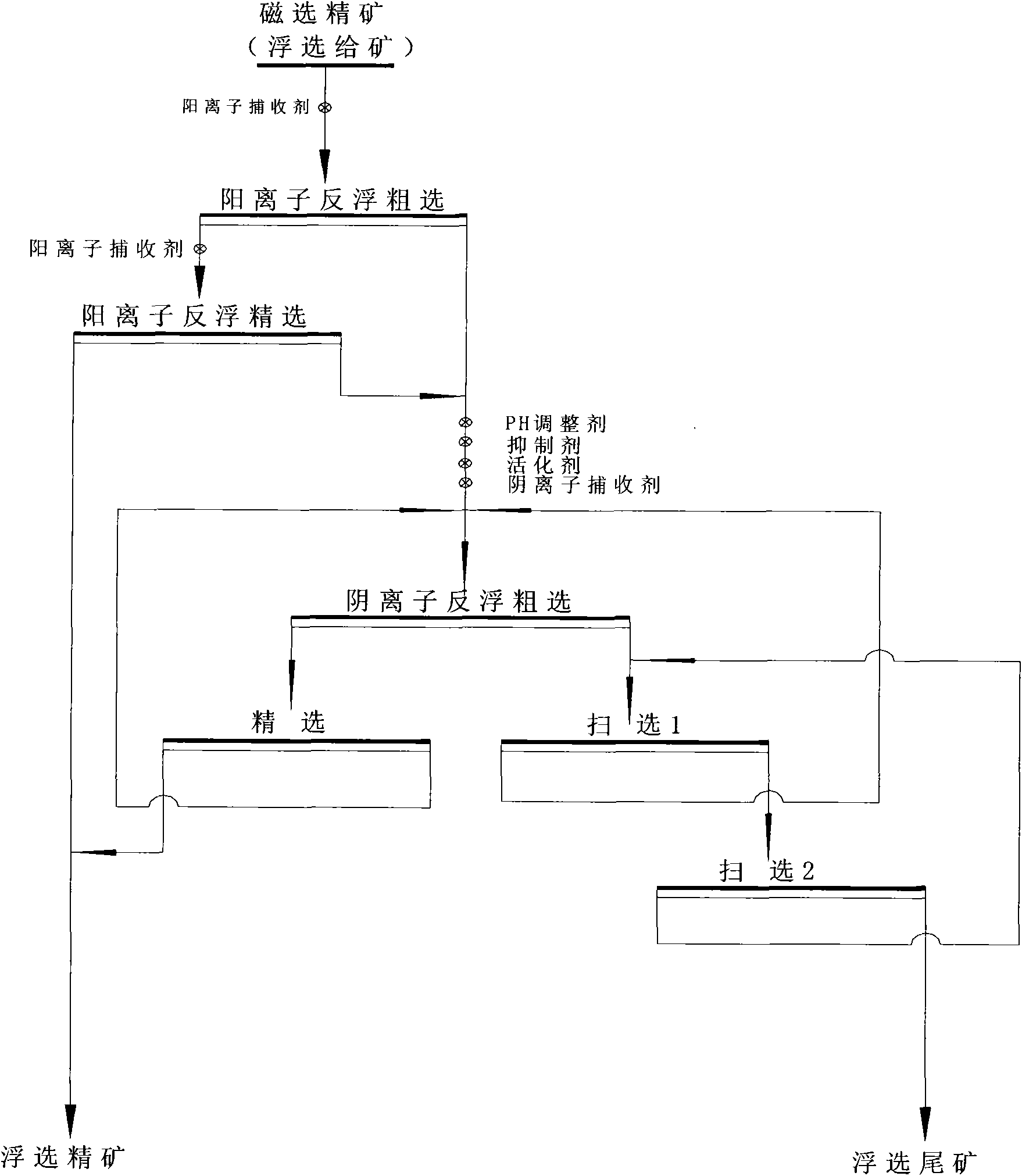

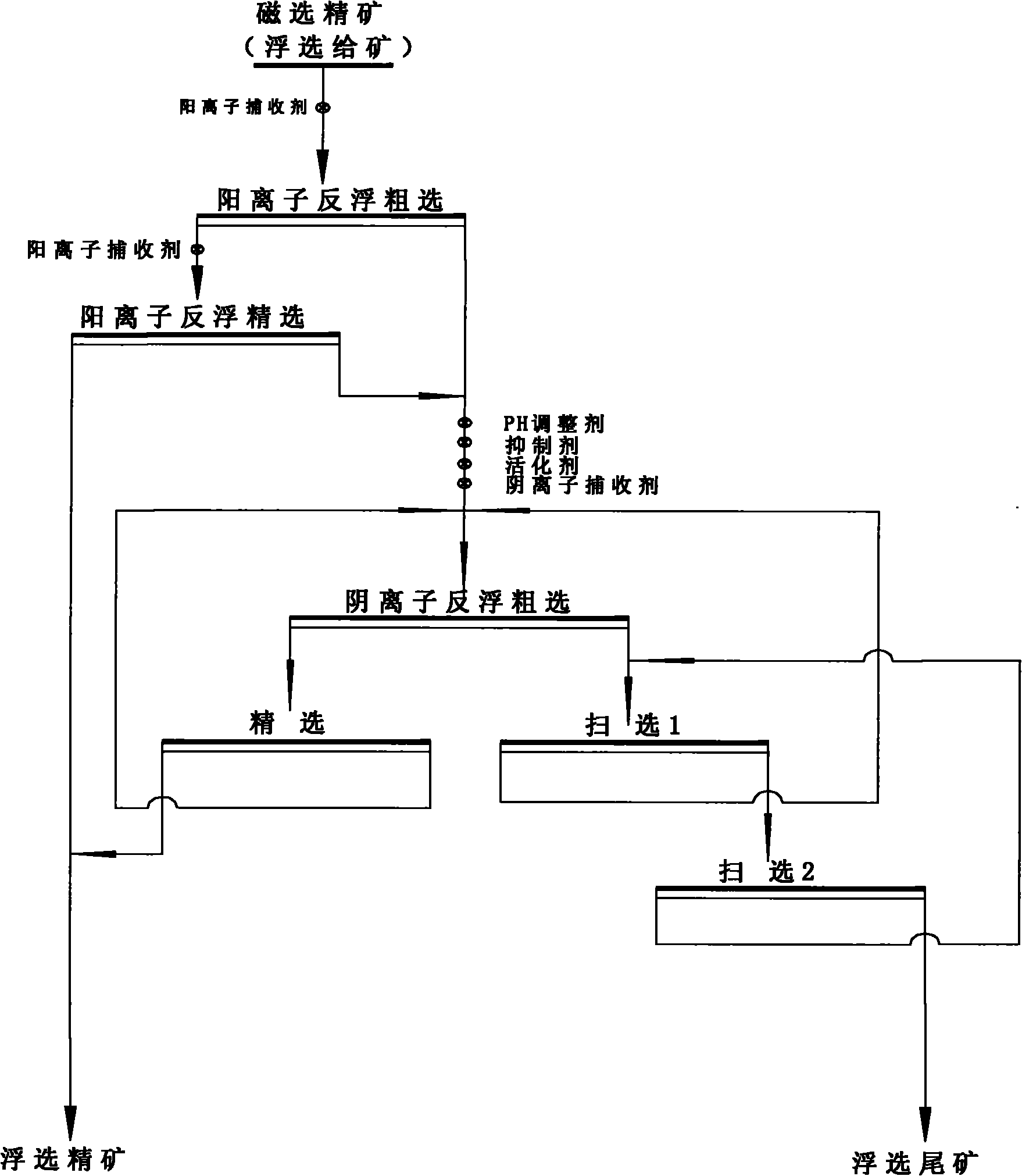

Beneficiation method for producing high-quality iron ore concentrate by low-grade magnetic iron ore

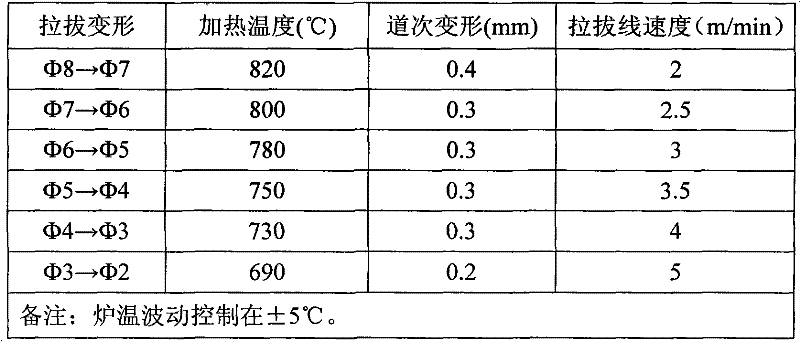

The invention discloses a beneficiation method for producing high-quality iron ore concentrate by low-grade magnetic iron ore, which comprises the following steps that a stage grinding-stage magnetic separation discarding tailing beneficiation process is adopted to produce magnetic separation ore concentrate with the iron ore concentrate grade TFe of 62-66%; a positive ion collector reverse flotation process is adopted on the magnetic separation ore concentrate to obtain positive ion collector reverse flotation iron ore concentrate and middling; a negative ion collector reverse flotation process is adopted on the middling obtained by positive ion collector reverse flotation to obtain negative ion collector reverse flotation iron ore concentrate; and the positive ion collector reverse flotation iron ore concentrate and the negative ion collector reverse flotation iron ore concentrate are combined to obtain the ultimate high-quality iron ore concentrate. The invention has the advantages of high grade of iron ore concentrate, high iron recovery rate, small loss of fine iron minerals, low beneficiation energy consumption and small consumption of medicaments, can relieve the industry difficulty of difficult filtration caused by adding starch into fine concentrate, greatly optimizes concentrate filtration operation, can be used for the sorting of magnetite ore, and can also be used for the sorting of weakly magnetic iron minerals such as hematite and the like.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Composite cement grinding aid and preparation method thereof

The invention discloses a composite cement grinding aid and its preparation method. According to a formula, the composite cement grinding aid comprises: a grinding agent, a reinforcing agent, a surfactant, molasses, N, N-bis(2-hydroxyethyl)isopropanolamine and water. The composite cement grinding aid can enhance the fluidity of materials during grinding, effectively reduce overgrinding phenomenon of a mill, improve adhesion of the materials to a grinding body, a lining board, and a bin partition board as well as the self agglomeration phenomenon of the materials, thus increasing the machine-hour yield of the cement grinding mill by l0%-20%, enhancing the cement specific surface area to 20-40m<2> / Kg, reducing the sieve residue, optimizing cement particle gradation, promoting cement clinker hydration, and improving the cement mixture activity. The 3-day compressive strength is increased by 3-5MPa, and the 28-day compressive strength is increased by 4-8MPa. The clinker consumption is reduced by 6-10%. The cement production cost is effectively reduced, the cement security is improved, and the adaptability of cement and concrete admixtures are improved.

Owner:ZHEJIANG HUAJUN BUILDING MATERIAL

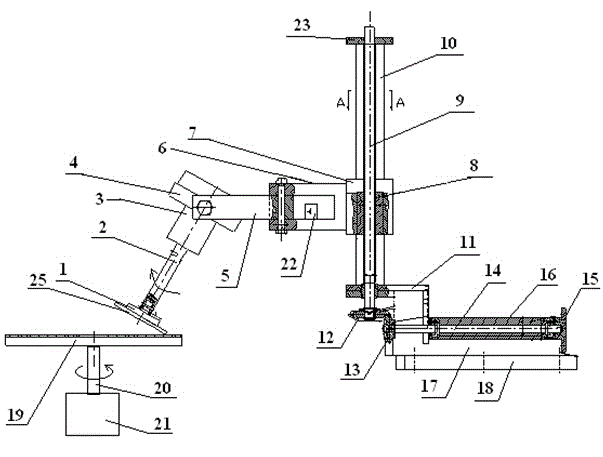

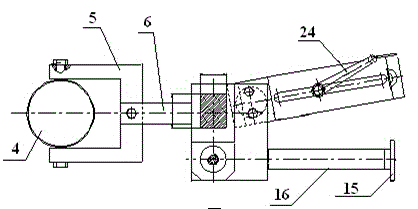

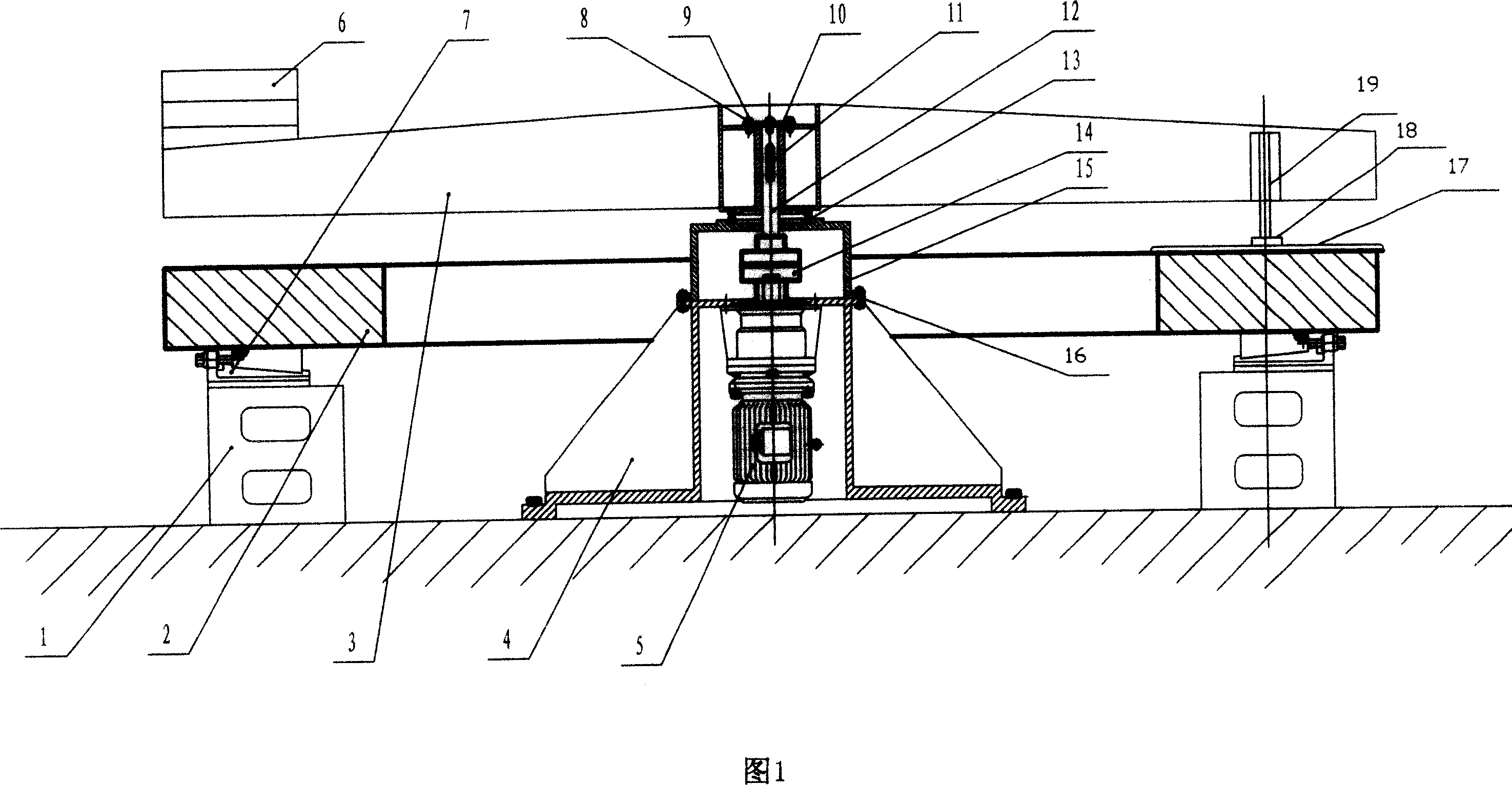

Silicon carbide wafer bevel grinding, milling and polishing machine and operation method thereof

ActiveCN104551900AAvoid chippingImprove processing qualityEdge grinding machinesPolishing machinesEngineeringDrive motor

The invention discloses a silicon carbide wafer bevel grinding, milling and polishing machine and an operation method thereof. The silicon carbide wafer bevel grinding, milling and polishing machine comprises a supporting sheet (1), a rotating shaft (2), a driving motor (3), a motor bracket (4), a vertical rotating arm (5), a horizontal rotating arm (6), a slide frame (7) and a screw rod (9) which are sequentially connected, wherein the lower end of the screw rod (9) is sequentially connected with a first cone gear (12), a second cone gear (13), an adjusting shaft (14) and a rotating wheel (15); a machining tool (19) of a silicon carbide wafer is arranged below the supporting sheet (1). The silicon carbide wafer bevel grinding, milling and polishing machine is reasonable in structural design, convenient to operate and high in working efficiency, bevel grinding, milling and polishing integrated machining can be performed on the silicon carbide wafer, the working efficiency is high, the roughness of a polished bevel can be smaller than 0.1 micron, the machining precision is high, and the applicability is high. The operation method can be applied to the bevel grinding, milling and polishing integrated machining on the silicon carbide wafer which is round or not round.

Owner:山东粤海金半导体科技有限公司

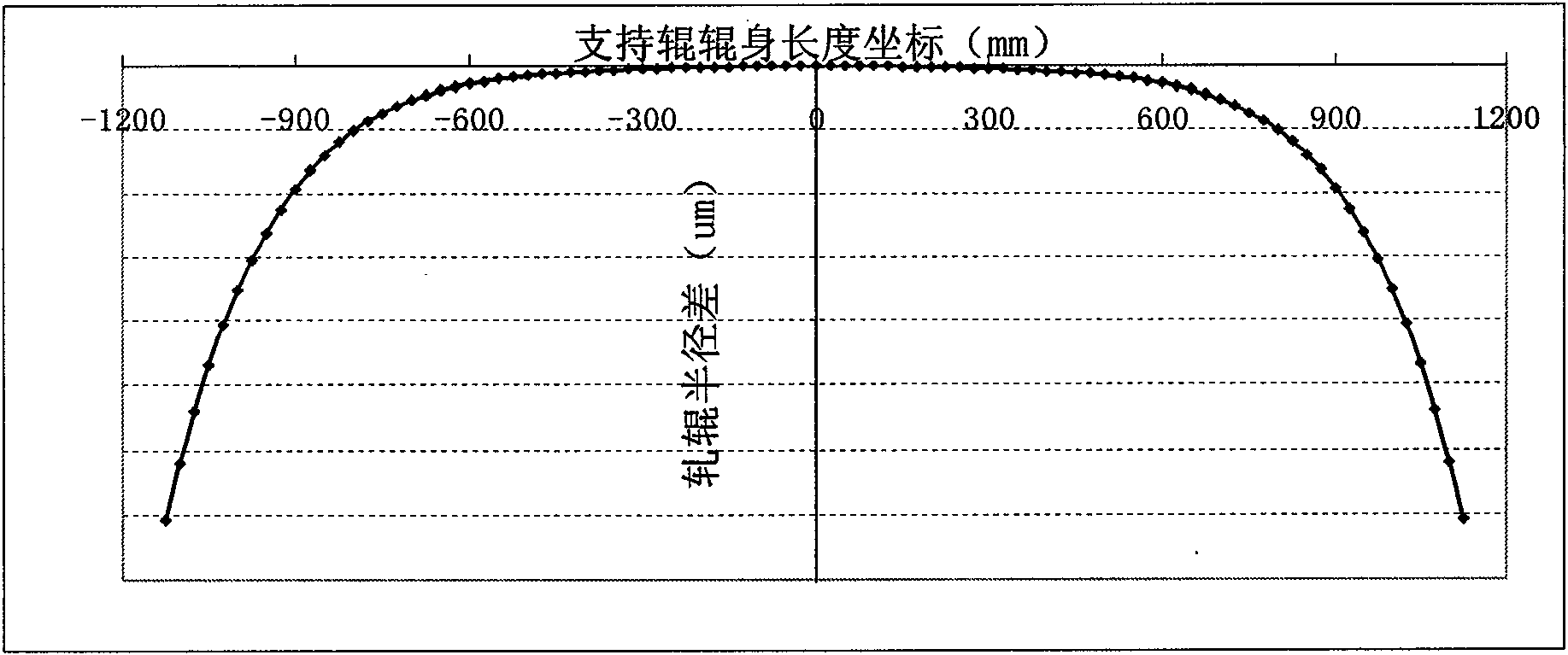

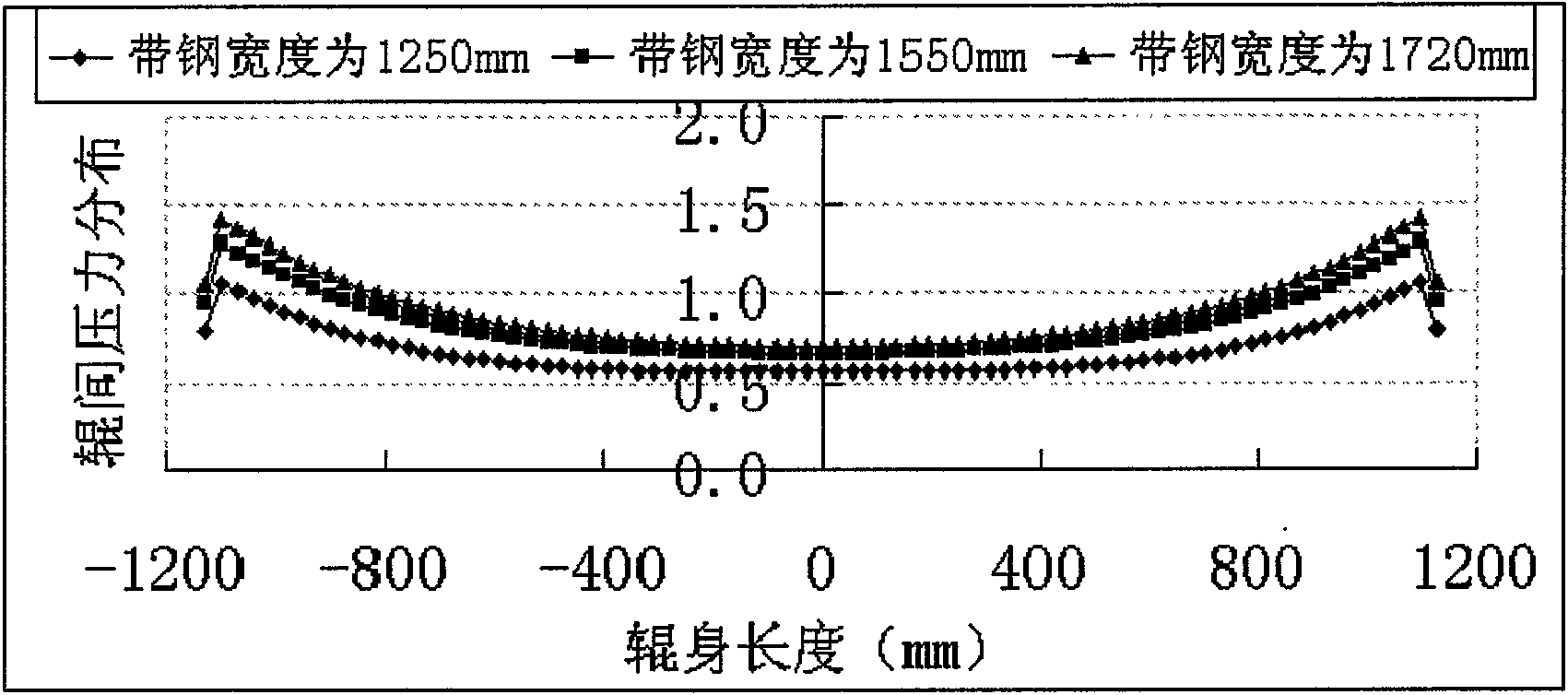

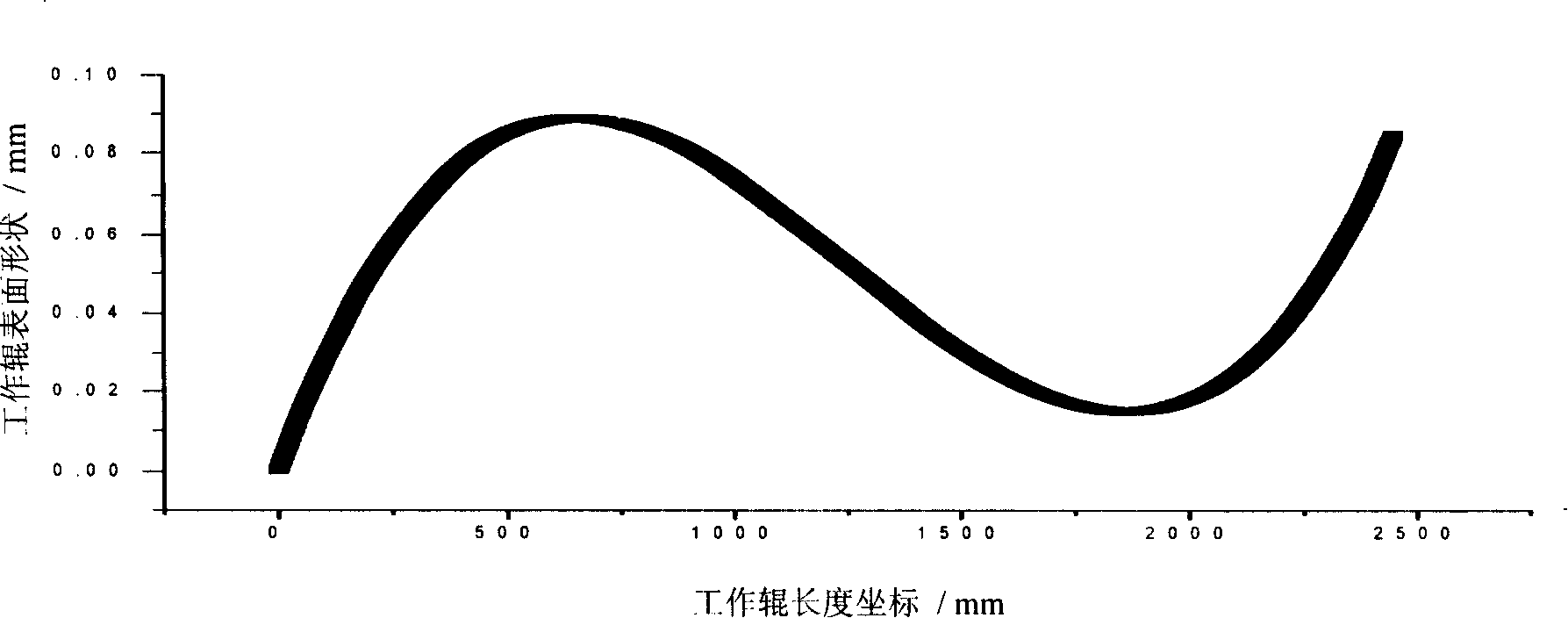

Method for configuring shape of supporting roll of four-high mill and shape of working roll thereof

ActiveCN101554635ASolve peelingSolve the large amount of wear and tearCounter-pressure devicesRollsProduction lineStress concentration

The invention relates to a method for configuring the shape of a supporting roll of a four-high mill and the shape of a working roll thereof, belonging to the technical field of steel rolling. According to three types of width specifications of band steel which are most rolled by hot-rolling band steel production line, sixth-power polynomial supporting roll shape technology and second-power working roll shape curve are used for configuration so as to lead the contact length of the supporting roll and the working roll and the width of the rolled band steel to be fit. The method has the advantages of eliminating hazardous contact areas in which the parts of the two ends of the supporting roll with the flat roll shape and the working roll expand out of the edge of the band steel to generate large deflection and deformation, solving the problems that the stress concentration of the edges of the supporting roll and the working roll in a hot continuous mill for wide band steel causes stripping and the mill roll with the flat roll shape has large wearing capacity and is not even, reducing the consumption of the mill rill, saving energy, reducing consumption and reducing cost for rolling steel; and by the technical configuration of R2 working roll shape and the supporting roll shape, the invention solves the plate-shape problems that the middle blank generates negative convexity and the wedge shape is large, and improves the control precision of the shape of hot-rolled band steel.

Owner:SHOUGANG CORPORATION

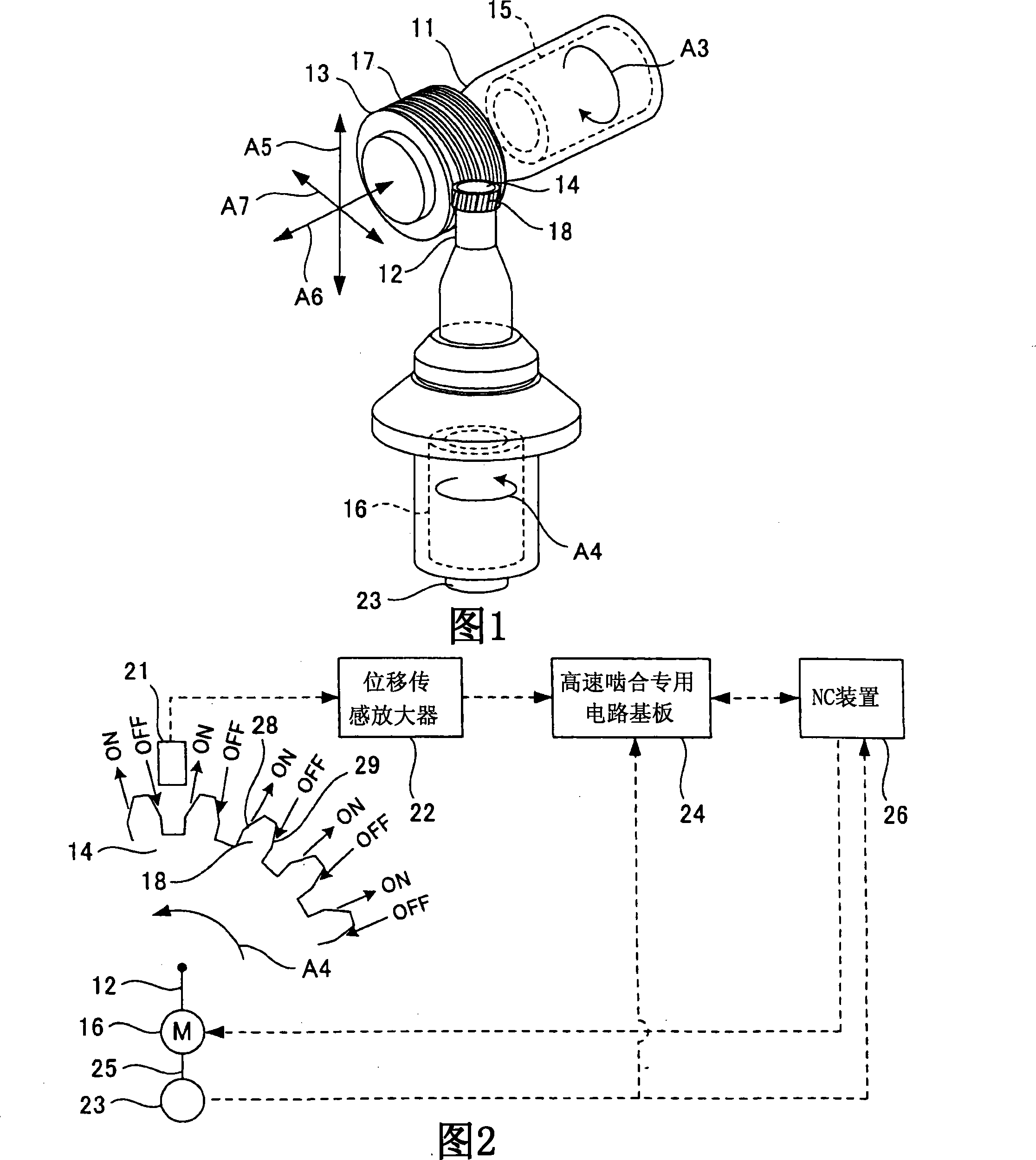

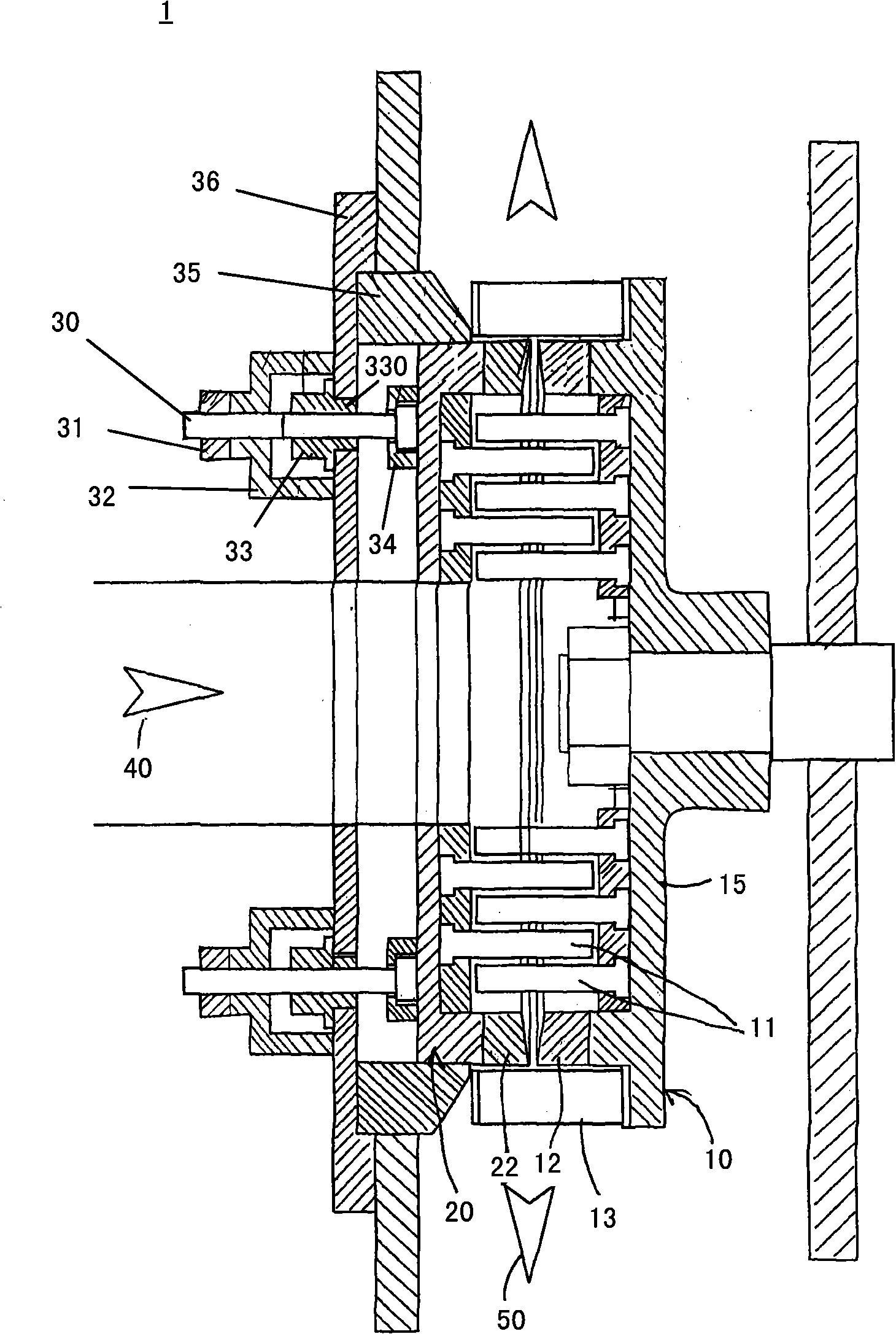

Method and device for detecting tooth matching angle of gear

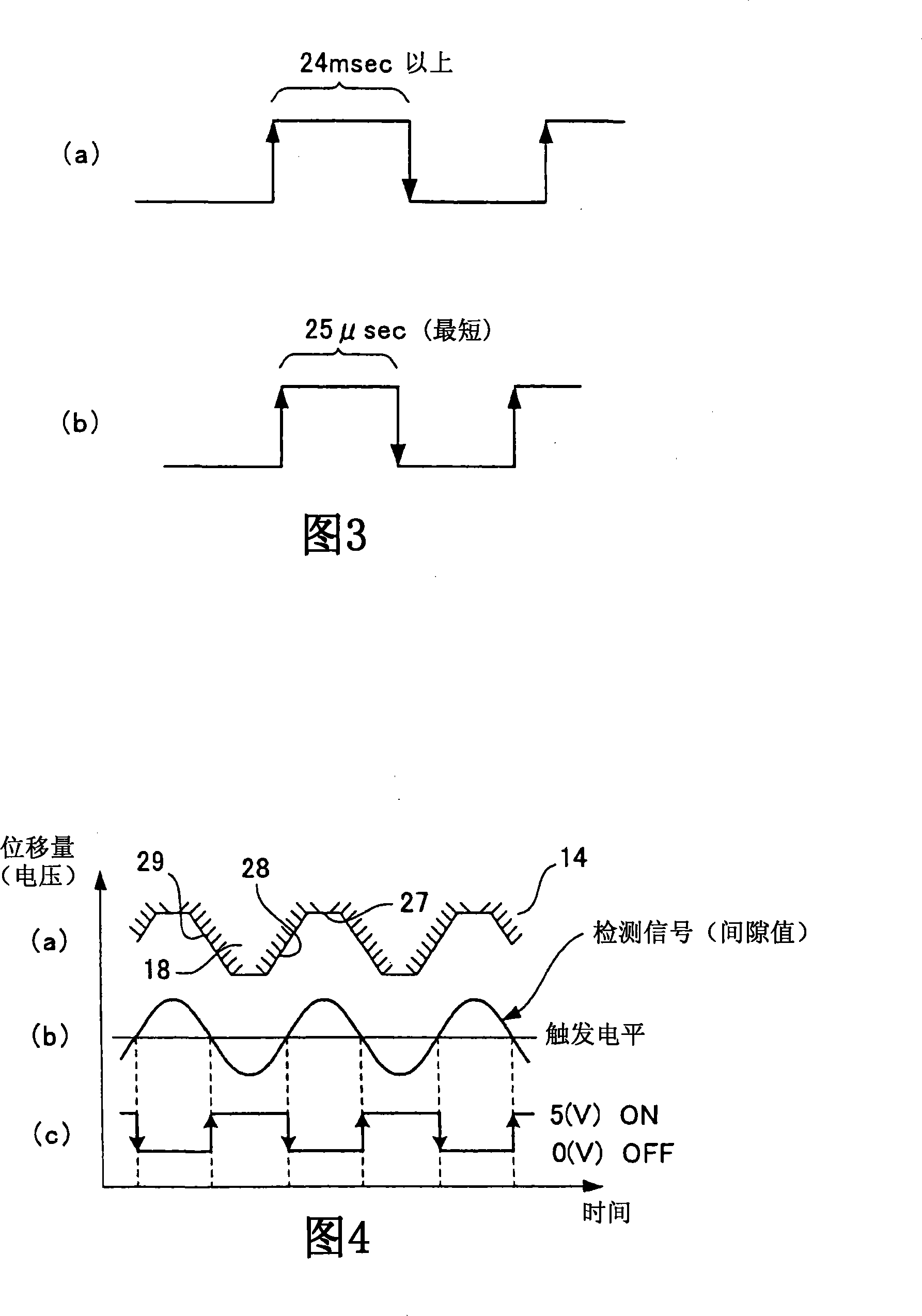

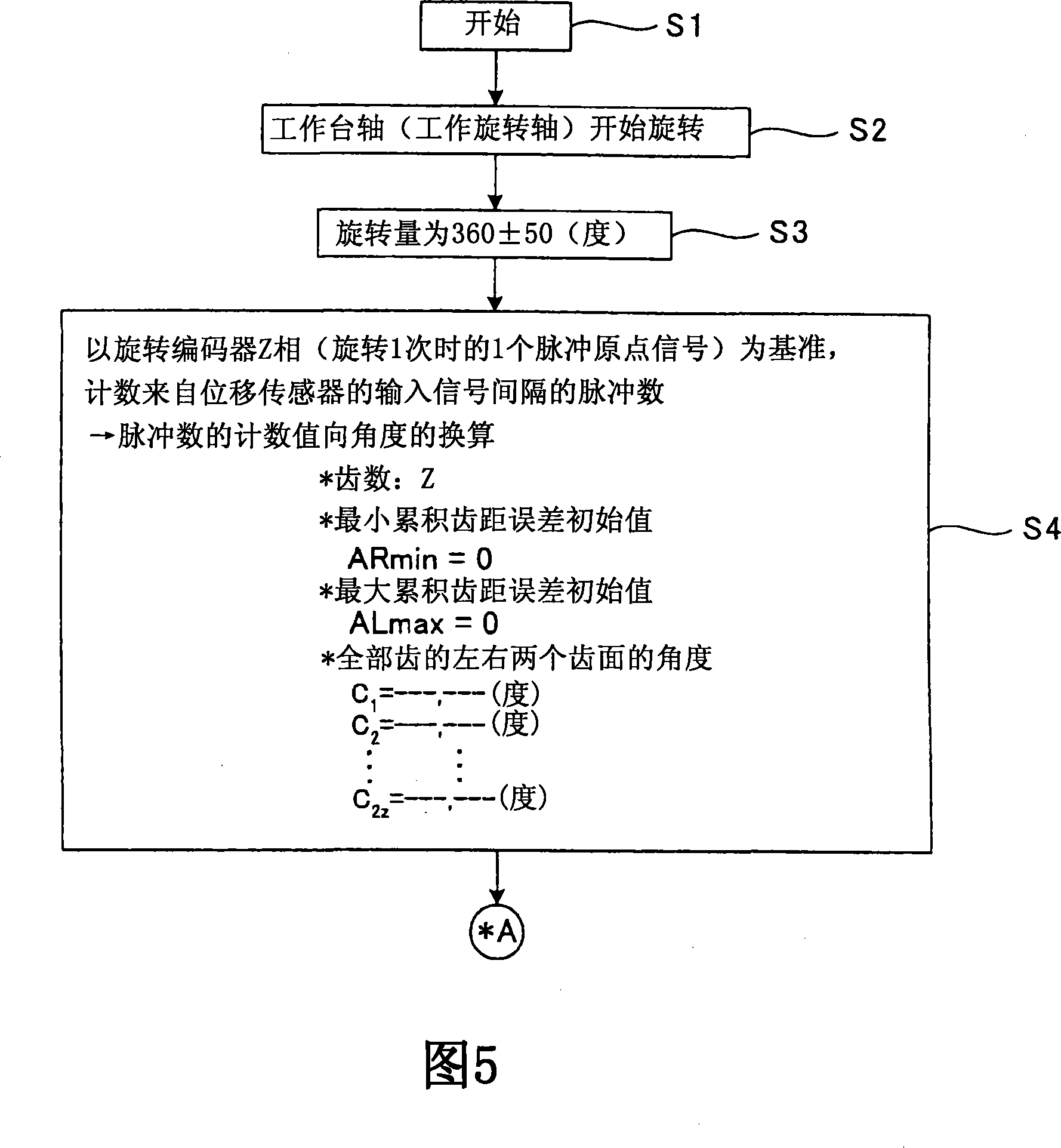

ActiveCN101173864ACumulative pitch error eliminationReduce grindingMachine gearing/transmission testingMeasurement/indication equipmentsPositive directionPitch error

The present invention provides a method and device for detecting the most suitable tooth matching angle of a gear by performing all tooth detection and its signal processing in a short time, thereby canceling the cumulative pitch errors of the left and right tooth surfaces, preventing cutting resides left on the left and right tooth surfaces, and reducing the cutting allowances of the left and right tooth surfaces to irreducible minimum values.According to the left tooth surface (28) which is most considered to leave cutting residue and having a maximum cumulative pitch error AL max (when the clockwise direction is a plus direction) and the right tooth surface(29) having a minimum cumulative error AR min (when the clockwise direction is a plus direction), these cumulative pitch errors are canceled. A correction value d for reducing the cumulative pitch errors after cutting is determined, a reference tooth groove angle 0 is corrected with the correction value d, and thus the tooth matching angle of a work gear(14) is determined.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

Manufacturing method for high-speed steel working roll at hot continuous rolling finish rolling rear section

The invention discloses a manufacturing method for a high-speed steel working roll at a hot continuous rolling finish rolling rear section. The working layer of a roll body comprises the following chemical components in percentages by weight: 2.00-3.50% of C, 0.40-2.00% of Si, 0.50-1.20% of Mn, 1.50-4.50% of Cr, 2.00-5.00% of Ni, 2.00-10.00% of Mo, V, W and Nb, 0-0.05% of S, 0-0.10% of P, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the steps of smelting, inoculation and spheroidizing and pouring, and heat treatment. Through the alloy compositions with reasonable design and the production technology, a special graphite and metallographic structure is obtained. According to the high-carbon high-speed steel roll at the hot continuous rolling finish rolling rear section, the quality of rear surface of a machine under the roll can be effectively controlled, and meanwhile the abrasive resistance and heat cracking resistance of the roll are improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Preparation method of silica shear thickening liquid

The invention discloses a preparation method of a silica shear thickening liquid. The preparation method comprises the following steps of: preparing monodisperse silica microspheres with certain grain size in an alcohol-water mixed liquid according to a multi-level seed growth method by utilizing tetraethoxysilane serves as a raw material and ammonia as a catalyst; after reaction is finished, adding shear thickening liquid dispersion media (polyethylene glycol, glycerol and the like) into a SiO2 suspension liquid; after mixing uniformly, removing ethanol, water and ammonia from the mixed liquid by adopting a heating and pressure-reducing method to finally prepare the silica shear thickening liquid, wherein the ethanol which is collected under reduced pressure can serve as a solvent and can be reused. In the preparation method, the SiO2 microspheres exist in the form of a uniformly dispersed suspension liquid from the synthesis link to the preparation link of the shear thickening liquid, so the agglomeration phenomenon of powder in drying and redispersion processes is avoided, and the stability and rheological property of the shear thickening liquid are improved.

Owner:浩华科技实业有限公司

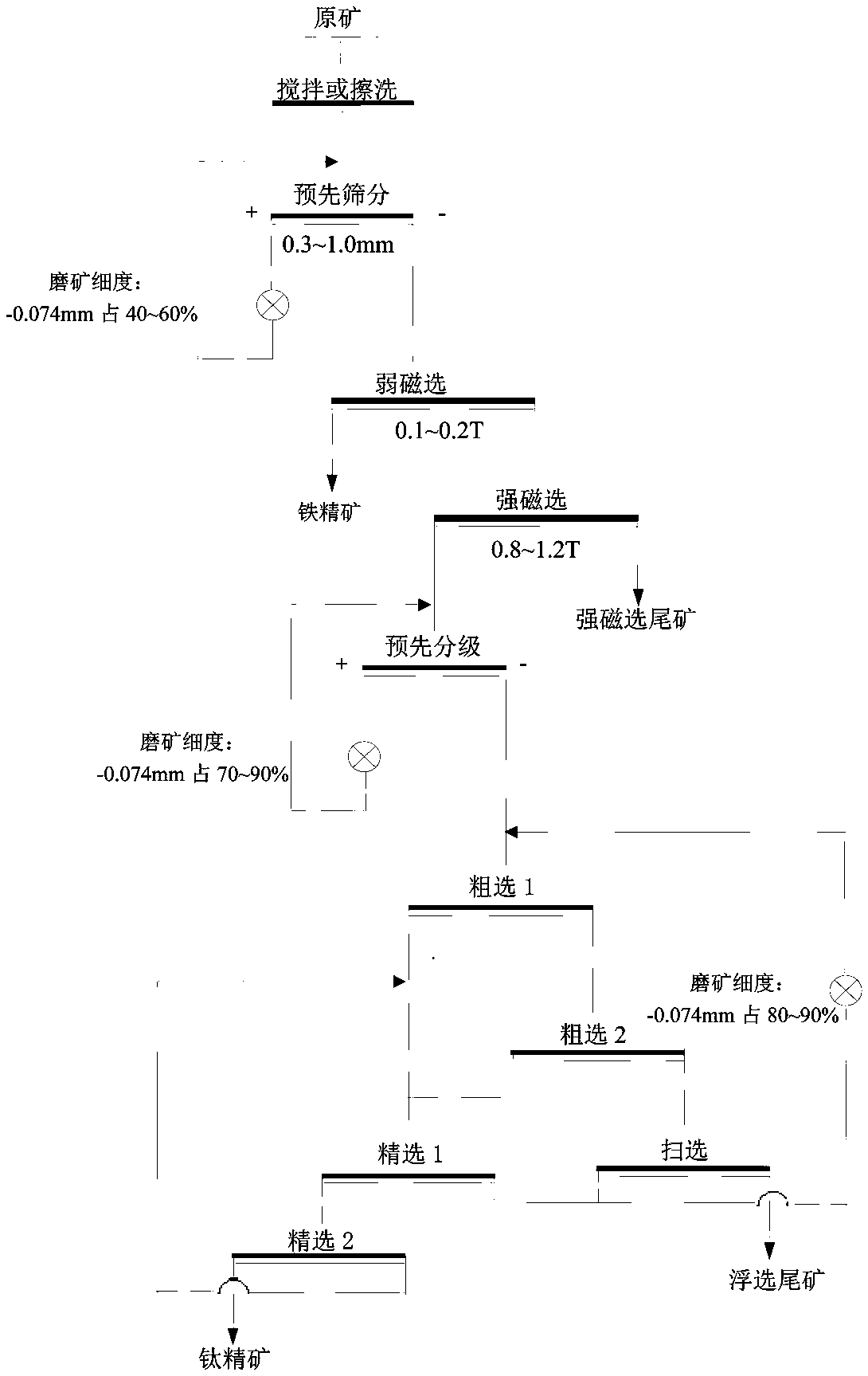

Weathering type ilmenite beneficiation treatment method

The invention discloses a weathering type ilmenite beneficiation treatment method. The beneficiation treatment method comprises the following steps that A prescreening is carried out; B, low intensitymagnetic separation is carried out; C, high intensity magnetic separation is carried out; D, preliminary classification is carried out; and E, flotation is carried out. According to the weathering type ilmenite beneficiation treatment method, the titanium recovery rate is effectively improved, titanium concentrate and iron ore concentrate are obtained at the same time, the technology is simple, the technological process is easily operated, and popularization is facilitated. Beneficiation according to the technical scheme is adopted, the particle size of monomer separation fine-fraction ilmenite in raw ore is protected, and excessive abrasion is avoided; the high intensity magnetic separation technology is used for discarding tailings, the follow-up handling quantity is greatly reduced, and the ore grinding cost and the beneficiation cost are reduced; and an environment-friendly collecting agent KM221 which is good in selectivity, low in cost, non-poisonous and harmless is adopted forflotation recovering of ilmenite ore, fine fraction titanium resources which are difficult to recover through the traditional technological process are effectively recovered, and the weathering type ilmenite resource using rate is improved.

Owner:KUNMING METALLURGY INST

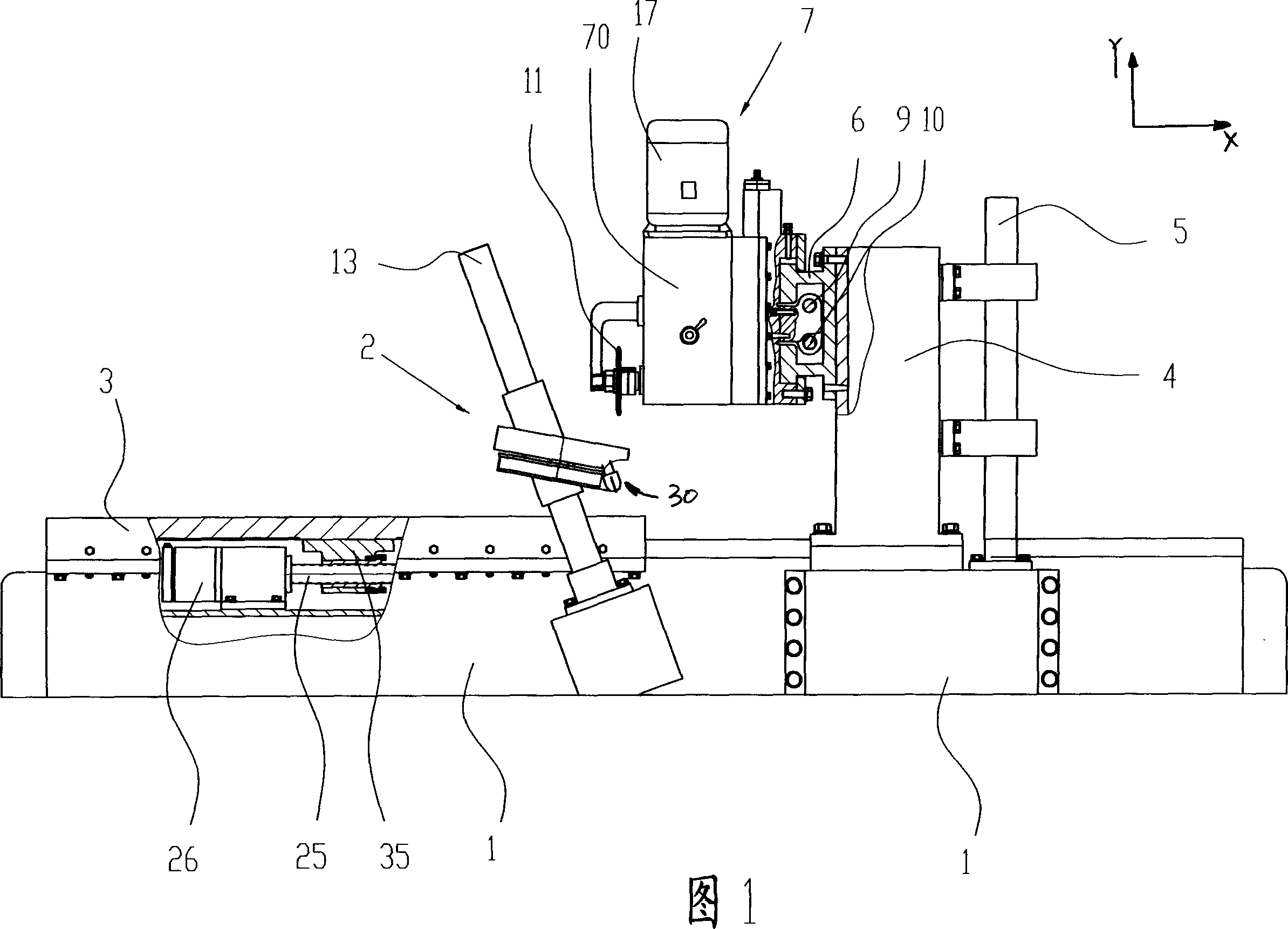

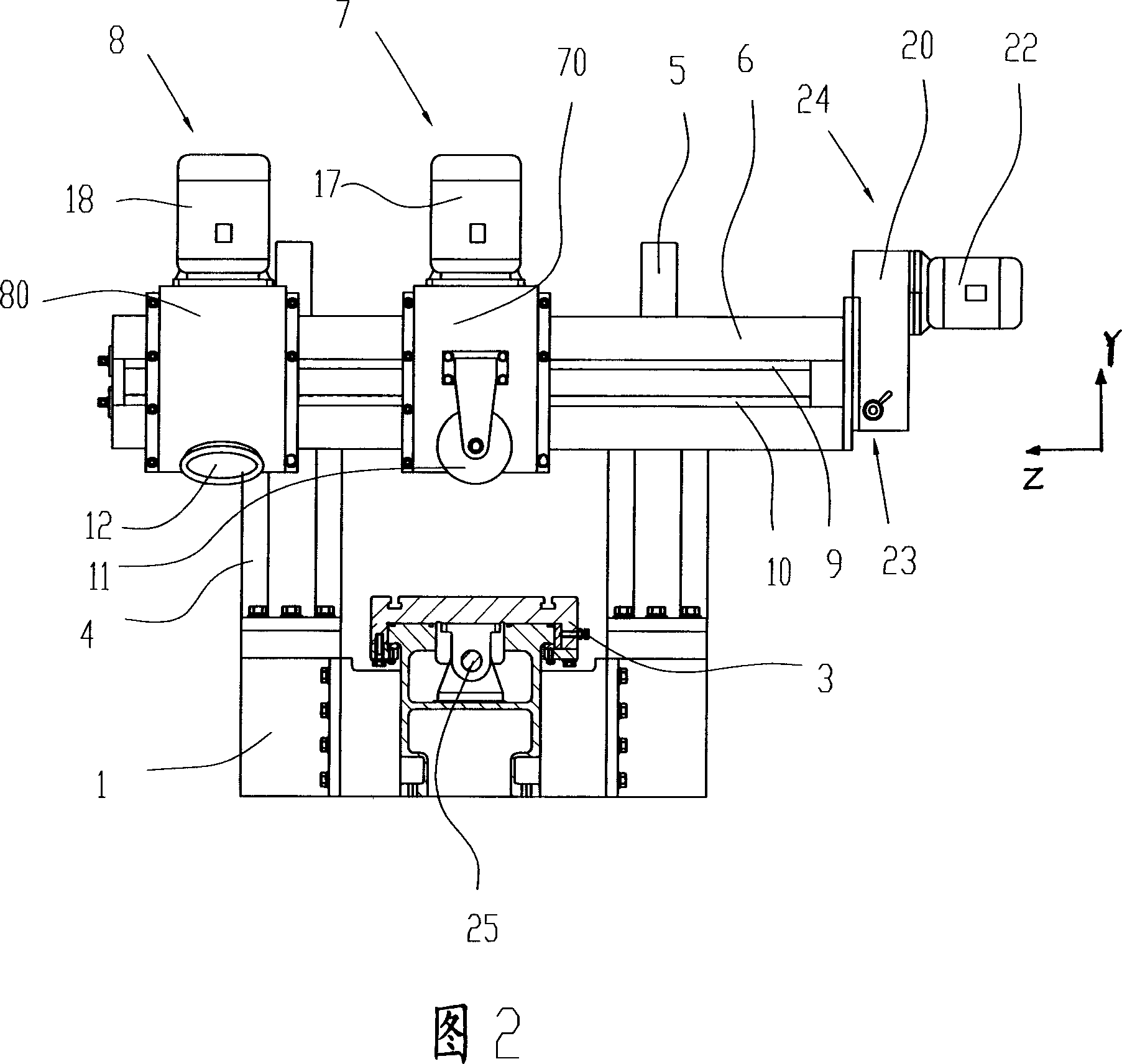

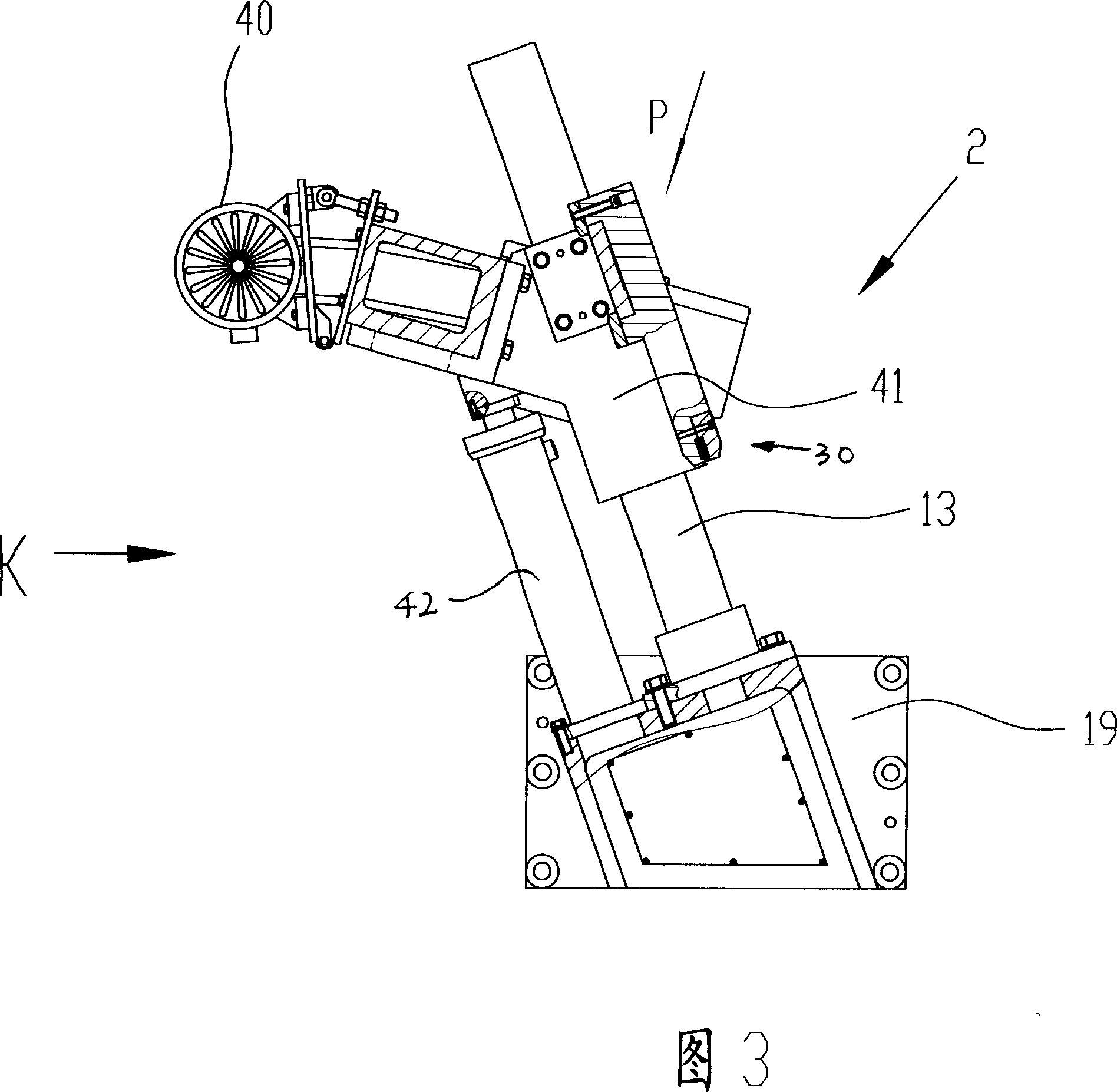

Processing method and apparatus for rack

InactiveCN101011787AImprove the finishShorten the timeMetal sawing devicesFeeding apparatusMachining timeMachine tool

A rack machining comprises drilling on the blank, cutting slot along the tangential line of the hole, milling the gear slot to form the rack, with less grinding effort and machining time with improved machining efficiency. The rack machining equipment comprises a machine base, working bench along the X axis in action, vertical post along Y axis, beam fixed with the post, No.2 milling device on the said beam along the Z axis in motion, with the second milling device composed No.2 generator, rotor shaft of the No.2 generator connected with No.2 gear box in motion, No.2 milling tool wit same output shaft and connected with the No.2 gear box, with the axle line of the output shaft of the No.2 gear box having a inclination angle of 20 degree with the said working bench.

Owner:黄开元

Method for manufacturing large-size low-water-peak prefabricated rod

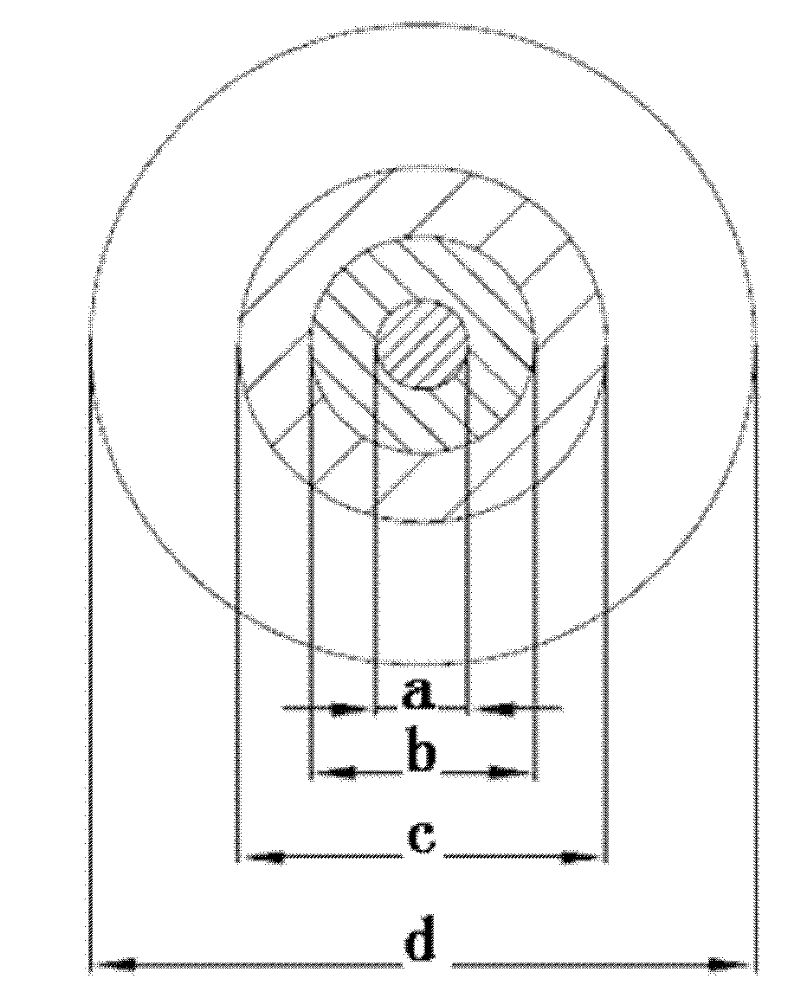

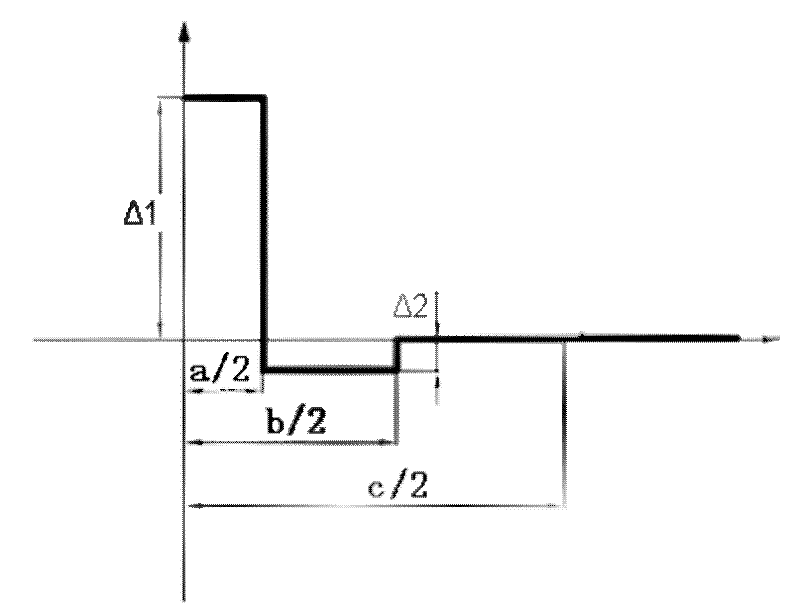

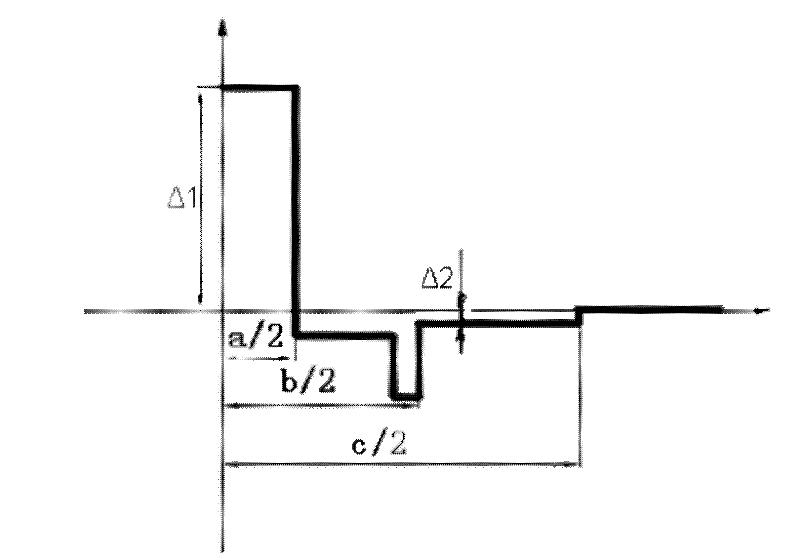

ActiveCN102249533AOmit polishingReduce stretchGlass making apparatusGlass fibre productsRefractive indexChemical vapor deposition

The invention relates to a method for preparing a large-size low-water-peak prefabricated rod, which comprises the following steps of: 1, depositing a core layer and partial cladding material in a quartz glass lining tube by using an in-tube chemical vapor deposition method to meet the requirement of a waveguide structure and optimize fluorine doped components, wherein the F-doped refractive index contribution of an inner cladding layer prepared by an in-tube method is not more than -0.10 percent and the F-doped refractive index contribution of the core layer is not more than -0.03 percent; 2, melting and shrinking the quartz glass lining tube deposited with the core layer and the partial cladding material at the temperature of between 1,900 and 2,300DEG C into a solid core rod, and manufacturing a core rod of which the b / a is more than or equal to 1.5 and less than or equal to 3.0 and the c / a is more than or equal to 2.3 and less than 4.5; 3, cladding a proper amount of uniform quartz loose body on the outer surface of the core rod directly by using an outside vapor deposition method to obtain a loose body prefabricated rod; and 4, slowly heating the loose body prefabricated rod at high temperature for dehydration, and sintering to obtain the transparent large-size low-water-peak prefabricated rod. The advantage of doping of the in-tube method and the advantage of large size of the outside method are combined, the process is simple, and the method is suitable for producing large-size low-water-peak prefabricated rods at low cost on a large scale.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Consolidation grinding material wire-electrode cutting method and cutting fluid

InactiveCN103121245AImprove line marksImprove micro damageOther chemical processesFine working devicesSurface roughnessEngineering

The invention relates to a consolidation grinding material wire-electrode cutting method and dedicated cutting fluid. The existing consolidation grinding material wire-electrode cutting is bad in cutting surface quality, possesses a plurality of deep check lines and tiny damage and is high in surface roughness, and meanwhile, swarf and dropped grinding material grains are easily adhered between the cutting line surface and grinding material grains to lower cutting force of cutting lines. The invention provides the novel consolidation grinding material cutting method and the dedicated cutting fluid used for the consolidation grinding material cutting method. Due to the development of the cutting fluid formula, the consolidation grinding material wire-electrode cutting method and the dedicated cutting fluid used for the consolidation grinding material cutting method overcome the technical limits, obviously improve check lines and tiny damage of the cutting surface, reduce roughness, reduce phenomenon of swarf attachment, improve cutting efficiency, reduce surface modification processing requirements such as grinding, polishing and the like of the cutting surface after cut and reduce cutting cost and follow-up process cost.

Owner:赵钧永

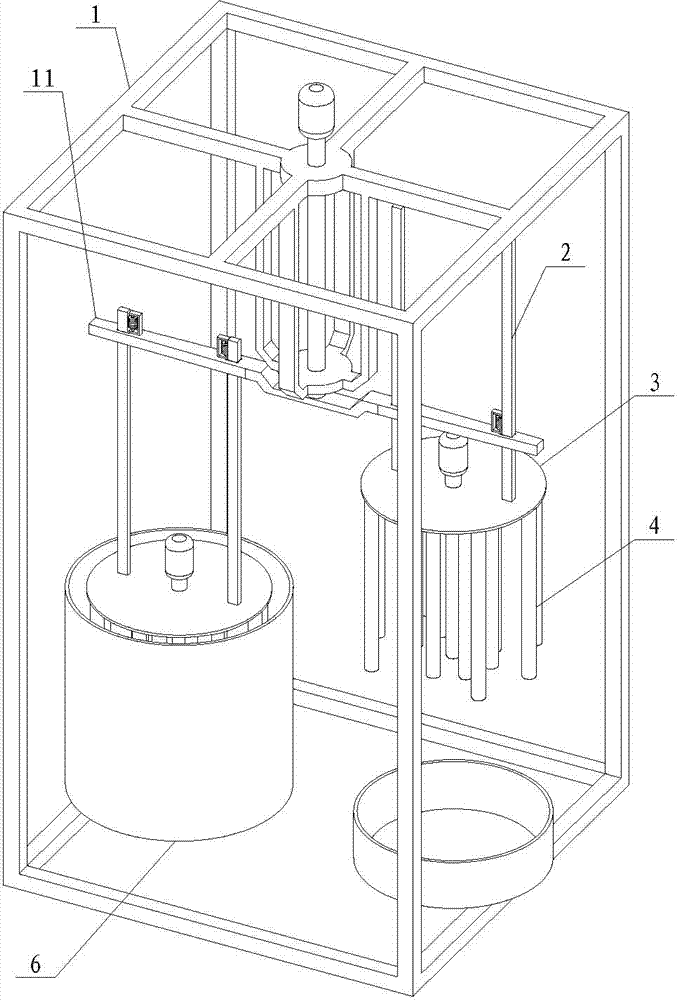

Method and equipment for eliminating iron scraps from raw materials

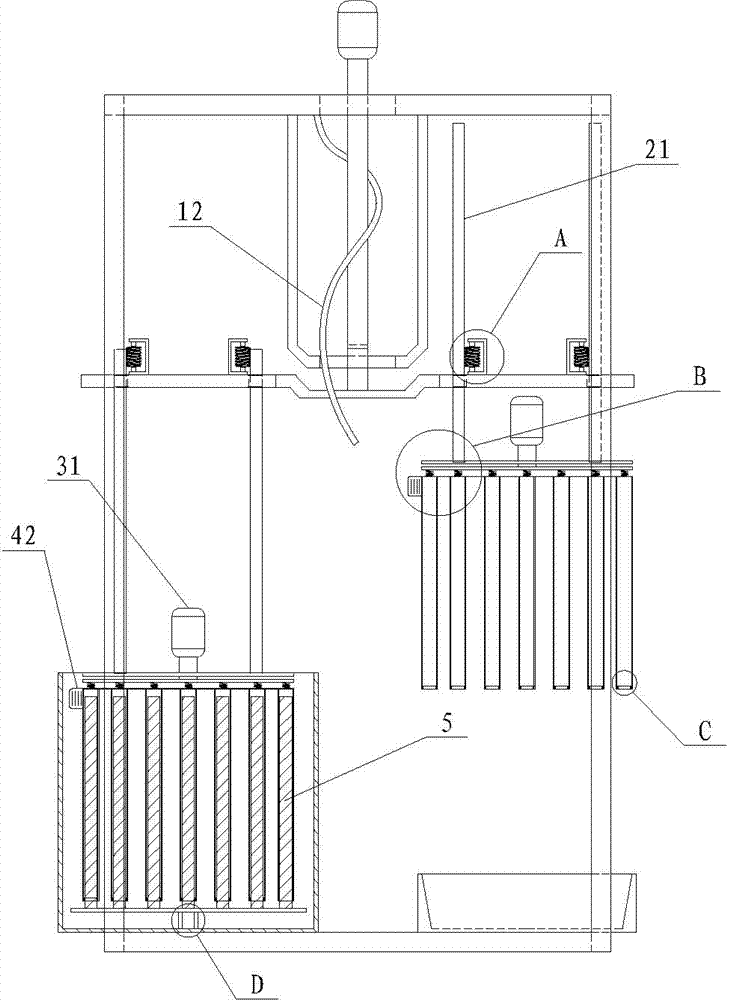

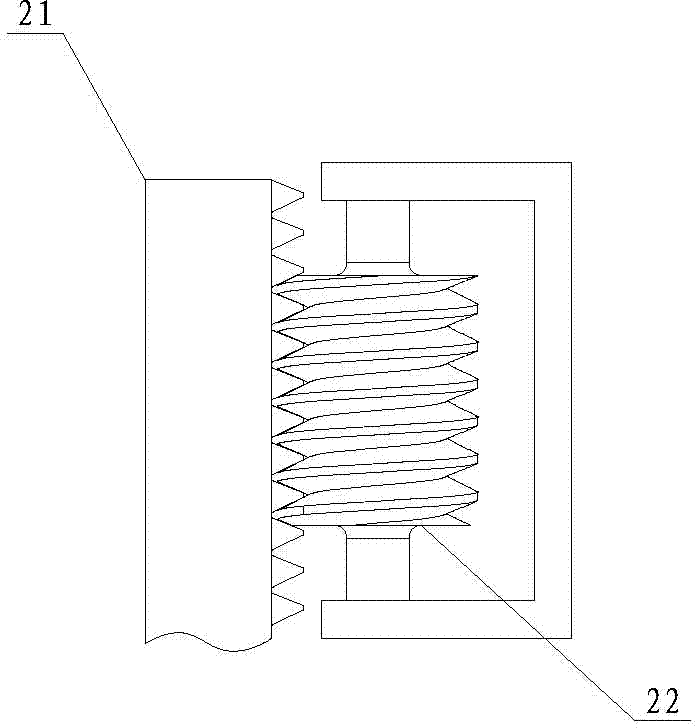

The invention discloses method and equipment for eliminating iron scraps from raw materials. The equipment comprises a rack, a charging bucket and a group of magnetic rods, and is characterized in that rotary arms are arranged on the rack and can horizontally rotate around the rack; a lifting mechanism is arranged on each of the rotary arms; rotary mechanisms are connected to the bottoms of the lifting mechanisms; a group of iron barrels are connected to the lower parts of each of the rotary mechanisms; a connection plate, a vibrator and an iron barrel connected with the connection plate are arranged in the group of iron barrels; the group of iron barrels is driven by the lifting mechanisms to sleeve iron barrels on the magnetic rods in the group of the magnetic rods; a motor, a rotary disc and a spring are arranged in each of the rotary mechanisms; each of the rotary disc is connected with each of the motors; a spring is fixed between each of the connection plates and each of the rotary discs; and vibrators are arranged on the connection plates. The method and the equipment have the beneficial effects that the iron barrels and the magnetic rods rotate in the charging bucket when irons are attracted, so that the contact probability of the iron barrels and slurries is increased, and the iron-attraction effect is improved; and when the iron barrels are subjected to iron removal, another group of iron barrels are quickly sleeved on the magnetic rods to perform the next round of iron attraction, so that the iron removal time is shortened, and the efficiency is improved.

Owner:ZIBO S & N MAGNET MFG

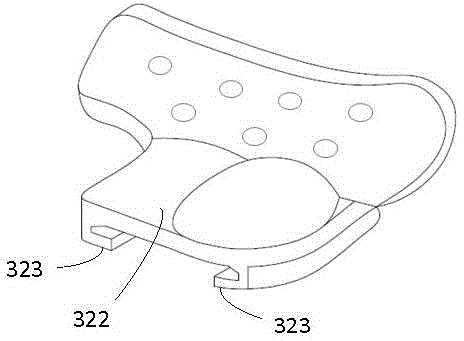

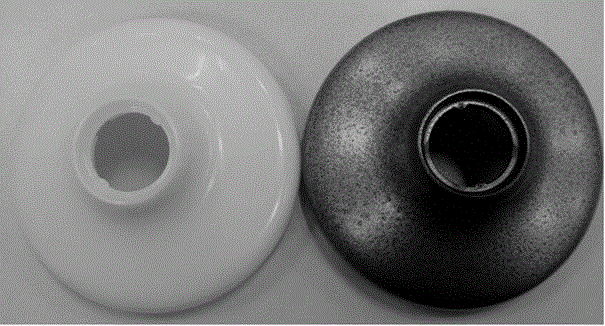

Total temporomandibular joint prosthesis

The invention discloses a total temporomandibular joint prosthesis. The total temporomandibular joint prosthesis comprises a mandible prosthesis, a condyloid process head prosthesis, a glenoid fossa bottom prosthesis and a glenoid fossa fossa prosthesis; the mandible prosthesis comprises a head part, a neck part and a lifting and supporting fixing part; the condyloid process head prosthesis is of a hollow ball body, and the hollow part is in a shape of a circular platform in match with the head part of the mandible prosthesis, and thus the head part of the mandible prosthesis is perfectly connected with the condyloid process head prosthesis; the glenoid fossa bottom prosthesis comprises a zygomatic arch fixing part and a connecting part; the glenoid fossa fossa prosthesis is cuboid, and clamping strips are arranged at the left side edge and the right side edge of the glenoid fossa fossa prosthesis; the clamping strips are connected with clamping slots in the fossa surface at a connecting part of the glenoid fossa bottom prosthesis by an inserting and drawing manner; the bottom surface of the glenoid fossa fossa prosthesis is a circular concave surface and is clung to the condyloid process head prosthesis. With the adoption of the total temporomandibular joint prosthesis, the postoperative wound can be reduced; the stability is high; the characteristic that the glenoid fossa of Chinese people is deeper than that of occidental; the articular tubercle is avoided grinding which leads to damage to basis cranii in operation.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

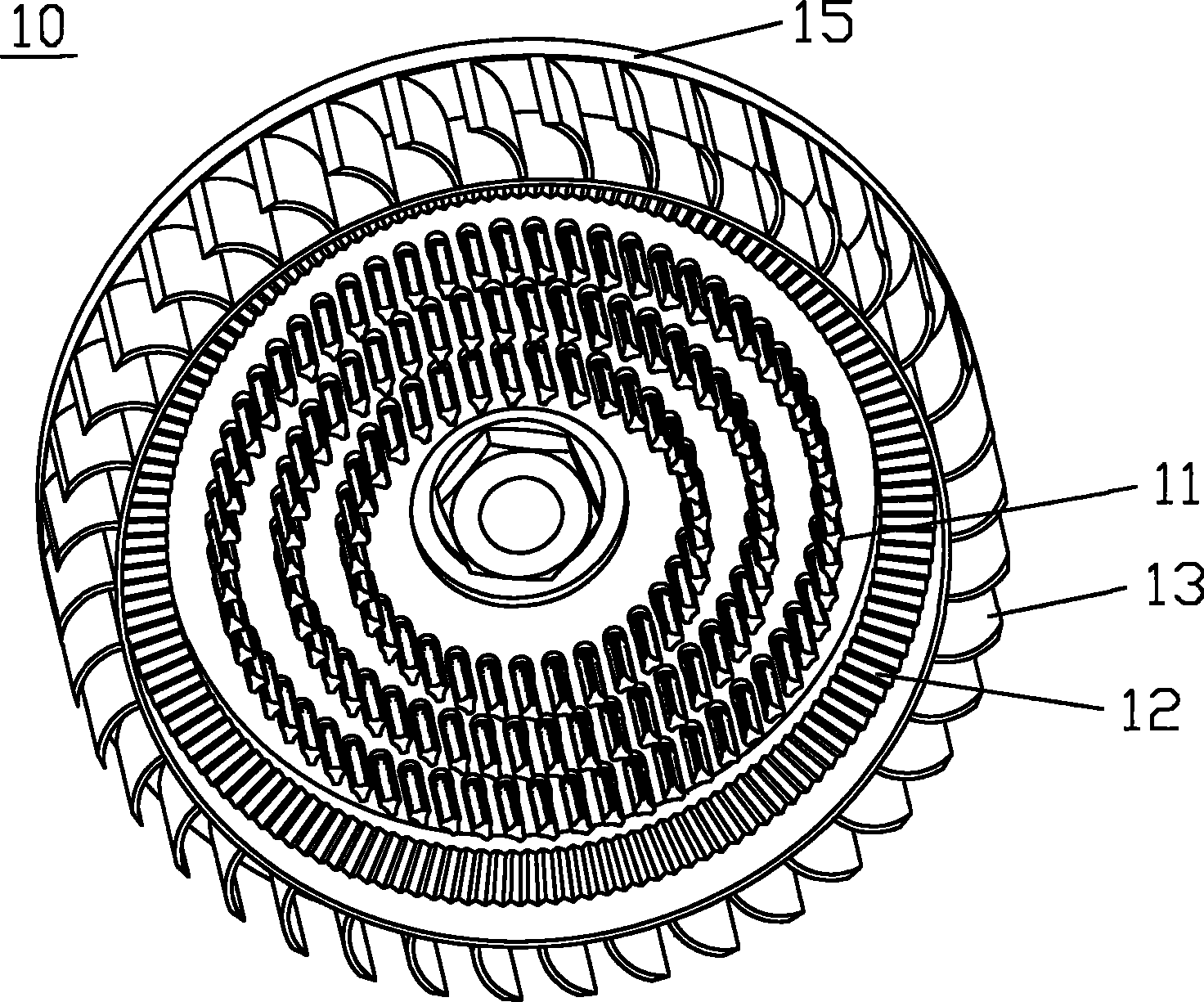

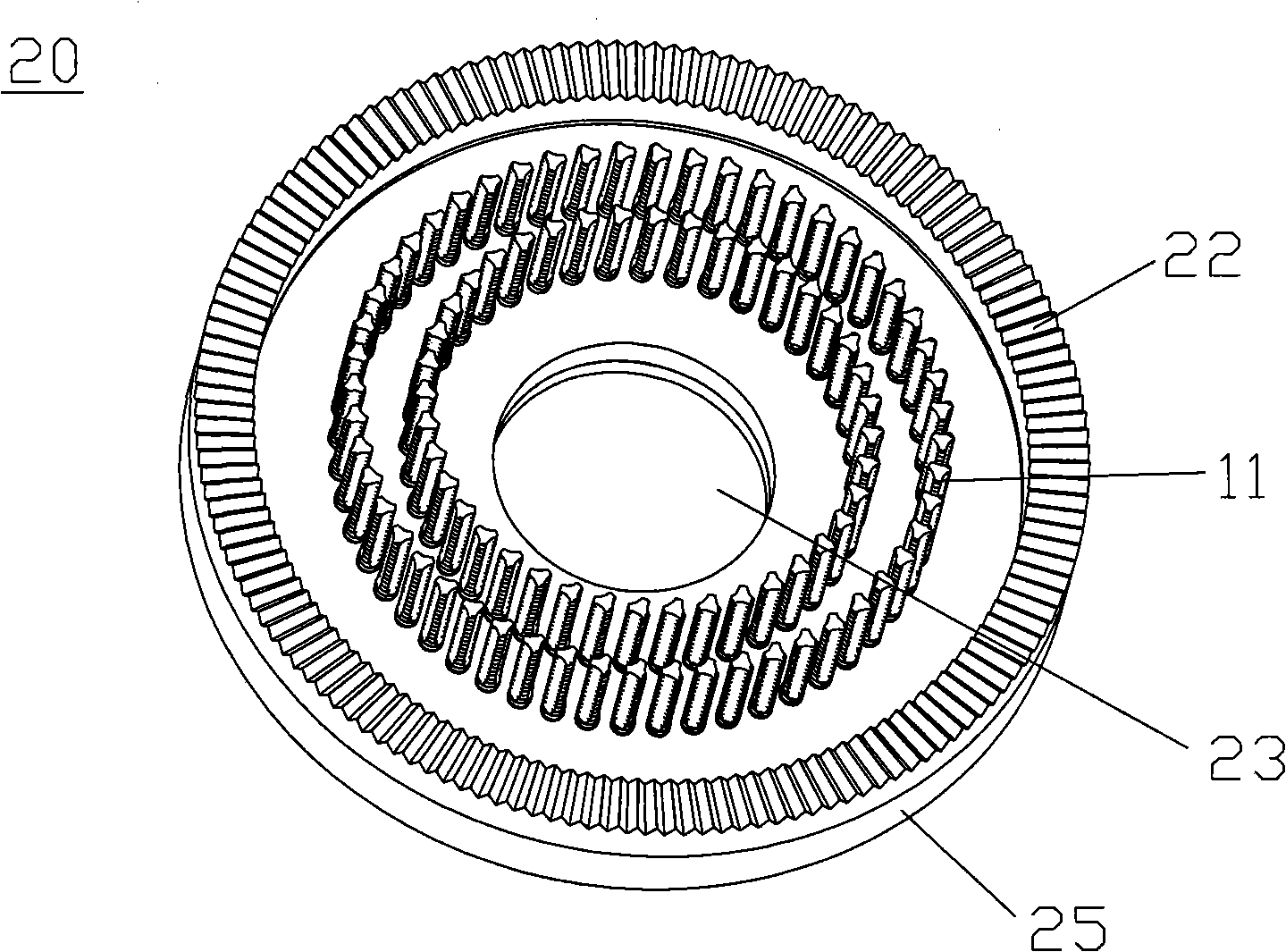

Steel mill of grain mill

The invention discloses a steel mill of a grain mill. The steel mill comprises a movable cutter disc and a fixed cutter disc which are arranged at a predetermined gap, wherein the movable cutter disc and the fixed cutter disc are provided with grinding cutters respectively; the inner ring of the grinding cutter of the movable cutter disc is provided with at least one circle of crushing cutters; the inner ring of the grinding cutter of the fixed cutter disc is provided with at least one circle of crushing cutters; and the outer ring of the grinding cutter on the movable cutter disc is provided with a plurality of centrifugal blades which are arranged annularly.

Owner:上海宏麟电子科技有限公司

Manufacturing method of zirconia ceramic large-scale thin-wall device

A manufacturing method of a zirconia ceramic large-scale thin-wall device is disclosed. After compression moulding of a zirconia ceramic thin-wall device and before sintering in a furnace, the zirconia ceramic thin-wall device is placed onto a supporting mould with its inner surface consistent with the appearance of the zirconia ceramic thin-wall device and with thickness being greater than thickness of the zirconia ceramic thin-wall device; then, the zirconia ceramic thin-wall device is covered with a cover plate and the zirconia ceramic thin-wall device fits closely between the supporting mould and the cover plate; and finally, the zirconia ceramic thin-wall device, the supporting mould and the cover plate together undergo oil immersion, degreasing and furnace-sintering so as to prevent the zirconia ceramic thin-wall device from deforming.

Owner:JIANGSU HENGXIN TECH CO LTD

Composite cement grinding aid

The invention discloses a composite cement grinding aid, which is characterized by being prepared from the following components in percentage by weight: 5-15 percent of triethanolamine, 20-30 percent of diisopropanolamine, 15-20 percent of polymeric alkylol amine, 5-10 percent of sodium polyphosphate, 10-20 percent of lignosulfonate, 5-10 percent of syrup and the balance of water. By adopting the composite cement grinding aid, the grinding assisting effect of the conventional grinding aid is kept, the fluidity and dispersity of a material in a grinder can be enhanced remarkably, the bonding property of the material is reduced, the graduation of particles in the grinder is changed, the activity of the material is excited, the grinding efficiency is increased by 3-8 percent, the using amount of cement clinker is reduced by 4-10 percent, the hourly output of a cement grinding table is increased by 8-15 percent, the tensile strength of cement is enhanced by 4.1-5MPa within three days, the tensile strength of cement is enhanced by 6.7-7.9MPa within two days, the adaptability of an additive is enhanced, the cement production cost is reduced effectively, and a good energy-saving effect is achieved.

Owner:惠州市富力新技术有限公司

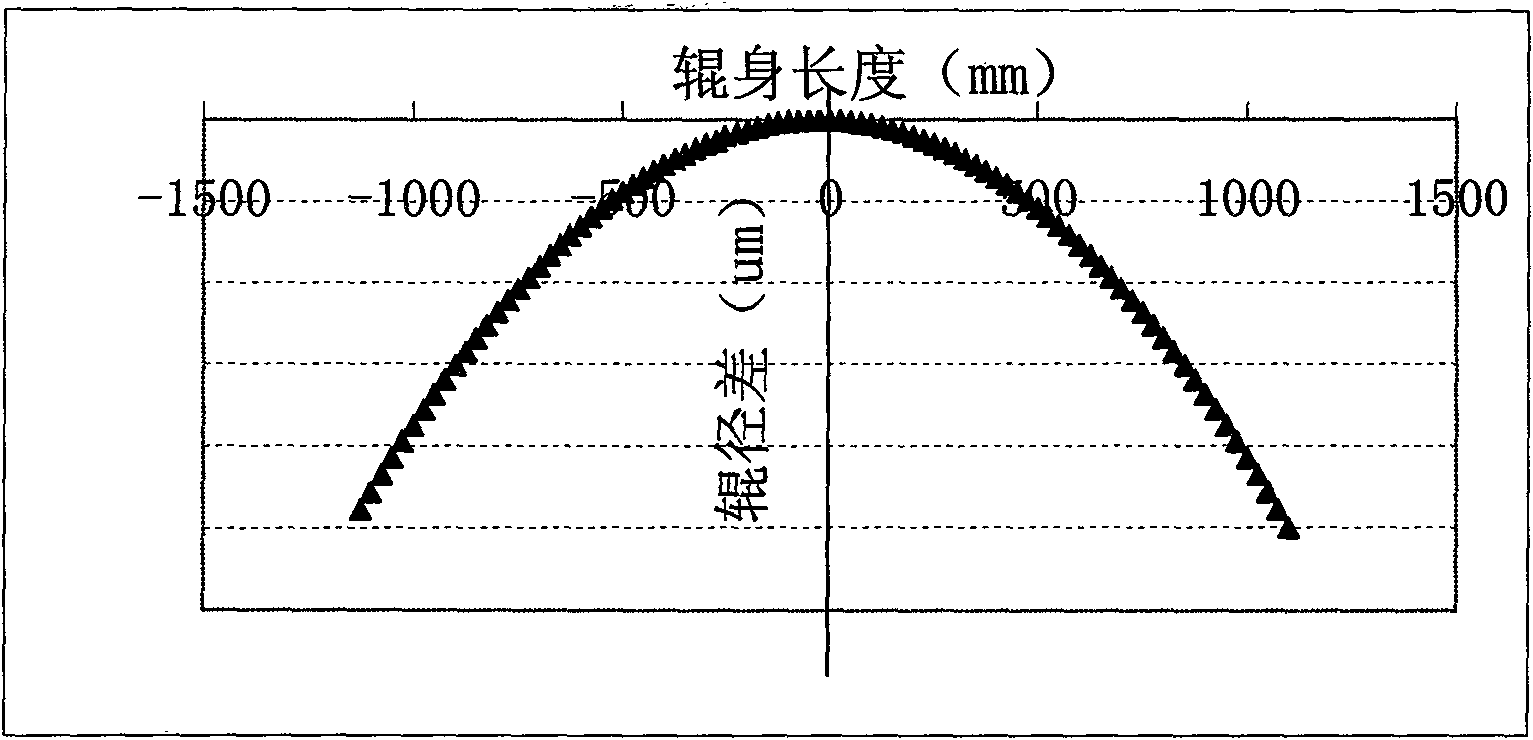

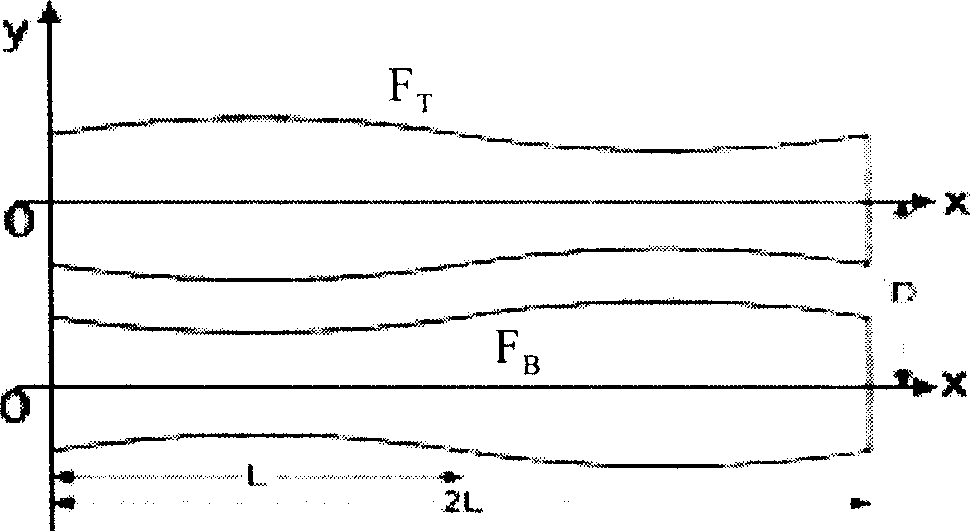

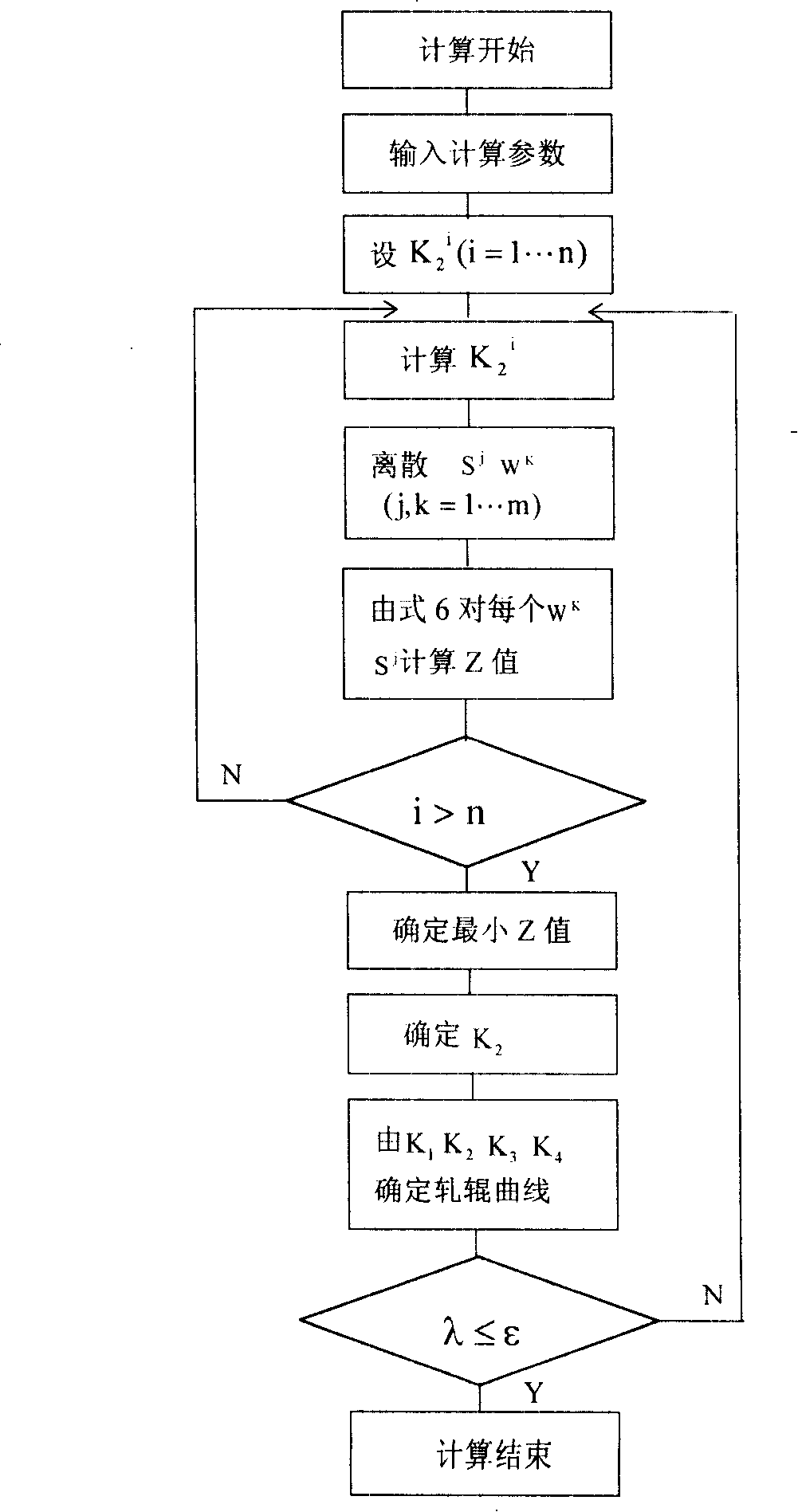

Four-high mill plate control work roll curve design method for strip rolling

InactiveCN101211372AReduce axial resistanceReduce grindingProgramme controlComputer controlWork rollStrip mill

The invention discloses a roll-shaped curve design method for work rollers in a four-roller rolling machine sheet profile control work for tape and sheet rolling treatment. The method is optimized to design in the premises of guaranteeing the equivalent convex that is necessary for tape steel sheet profile control effects, and meanwhile, with the constraint conditions of the wearing volume of rollers being the minimum and roller axial resistance being the minimum. With the help of the axial movement of the vertical work rolls in the roll shape, it is possible to continuously modify the equivalent convex of roll seams, so as to meet the requirements for controlling the shapes of sheets produced by rolling tape steel of different materials and sizes. It is shown in actual application that, utilization of the roll-shaped rollers can effectively control profile quality of different types and sizes of tape steel sheets, and meanwhile, lower the wearing cost in roller utilization process. Besides, since the axial resistance is lowered during the working process of the rollers, the invention can further increase the utilization period of the rollers and rolling machine mechanical devices.

Owner:ANGANG STEEL CO LTD

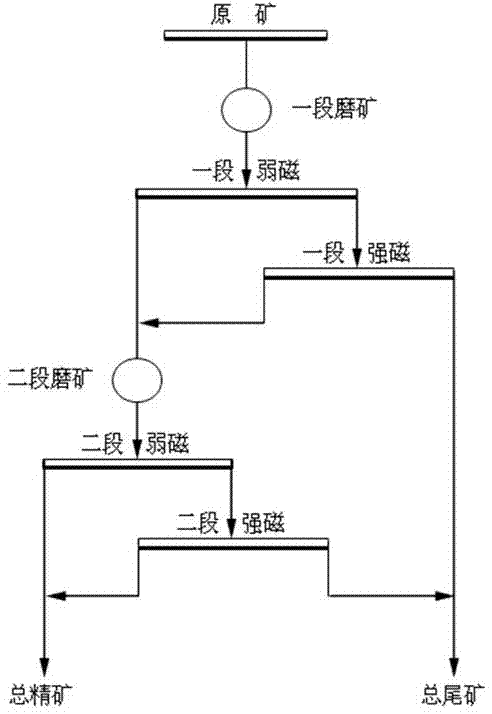

Beneficiation method of efficiently recovering fine-grain low-grade magnetite

The invention discloses a mineral processing method for efficiently recovering fine-grained low-grade magnetite. Iron concentrate I and tailings I can be obtained by weak magnetic separation with a magnetic induction intensity of 1100-1300Oe; iron concentrate II and tailings II can be obtained from tailings I by strong magnetic separation with a magnetic induction intensity of 0.9-1T; iron concentrate I and iron Concentrate II is combined and ground to -0.045mm, accounting for 75-85% to obtain fine-grained ore II; fine-grained ore II is subjected to weak magnetic separation with a magnetic induction intensity of 1000-1200Oe to obtain iron concentrate III and tailings III; Iron concentrate IV and tailings IV are obtained by strong magnetic separation with a magnetic induction intensity of 0.560-0.783T, and iron concentrate III and iron concentrate IV are combined to obtain a total concentrate, and tailings II and tailings IV are combined to throw tailings. The invention has the characteristics of short process flow, less grinding amount, high beneficiation efficiency, iron recovery rate and high concentrate grade.

Owner:YUXI DAHONGSHAN MINING

Electroplating-free antique metal surface treatment method

ActiveCN104384088AReduce pollutionReduce grindingPretreated surfacesPolyurea/polyurethane coatingsSolution treatmentAcrylic resin

The invention discloses an electroplating-free antique metal surface treatment method. After a material surface is subjected to deoiling and surface activation, a primer is firstly sprayed and cured and then a finish paint is sprayed, wherein the primer consists of color paste, metal powder, polyurethane resin or acrylic resin and an assistant. According to the method, electroplating, chemical dyeing solution treatment and the like are not required, so that the environment pollution caused by the electroplating and the chemical dyeing solution is greatly reduced, processes such as grinding and wire drawing are also reduced, a production process is simplified, the production cost is reduced, and the technological process is environment-friendly; a texture effect of an antique metal layer is formed on the material surface, so that the product function and quality are improved.

Owner:XIAMEN RUNNER IND CORP

Method for preparing large-size hard alloy

The invention provides a method for preparing large-size hard alloy, which comprises the following steps of: (S1) preparing several segments of small-size hard alloy blanks by using a compression molding method; (S2) performing first vacuum sintering on each hard alloy blank to obtain a semi-finished hard alloy product; (S3) flat grinding the end face of each semi-finished hard alloy product, and successively butting the end faces; and (S4) performing second vacuum sintering on the several segments of entire butted semi-finished hard alloy products to obtain the finished large-size hard alloy product, wherein the highest temperature of second vacuum sintering is 1400-1420 DEG C, the heating speed in the second vacuum sintering process is 3-7 DEG C / min, and the temperature is maintained for 45-80 min after a liquid phase occurs during the second vacuum sintering process. The invention overcomes the limitation that the large-size hard alloy product can only be produced by isostatic pressing in the prior art. Compared with the isostatic pressing production method, the method provided by the invention has greatly reduced cost and greatly shortened production period, and the grinding amount of the product is small.

Owner:株洲金鼎硬质合金有限公司

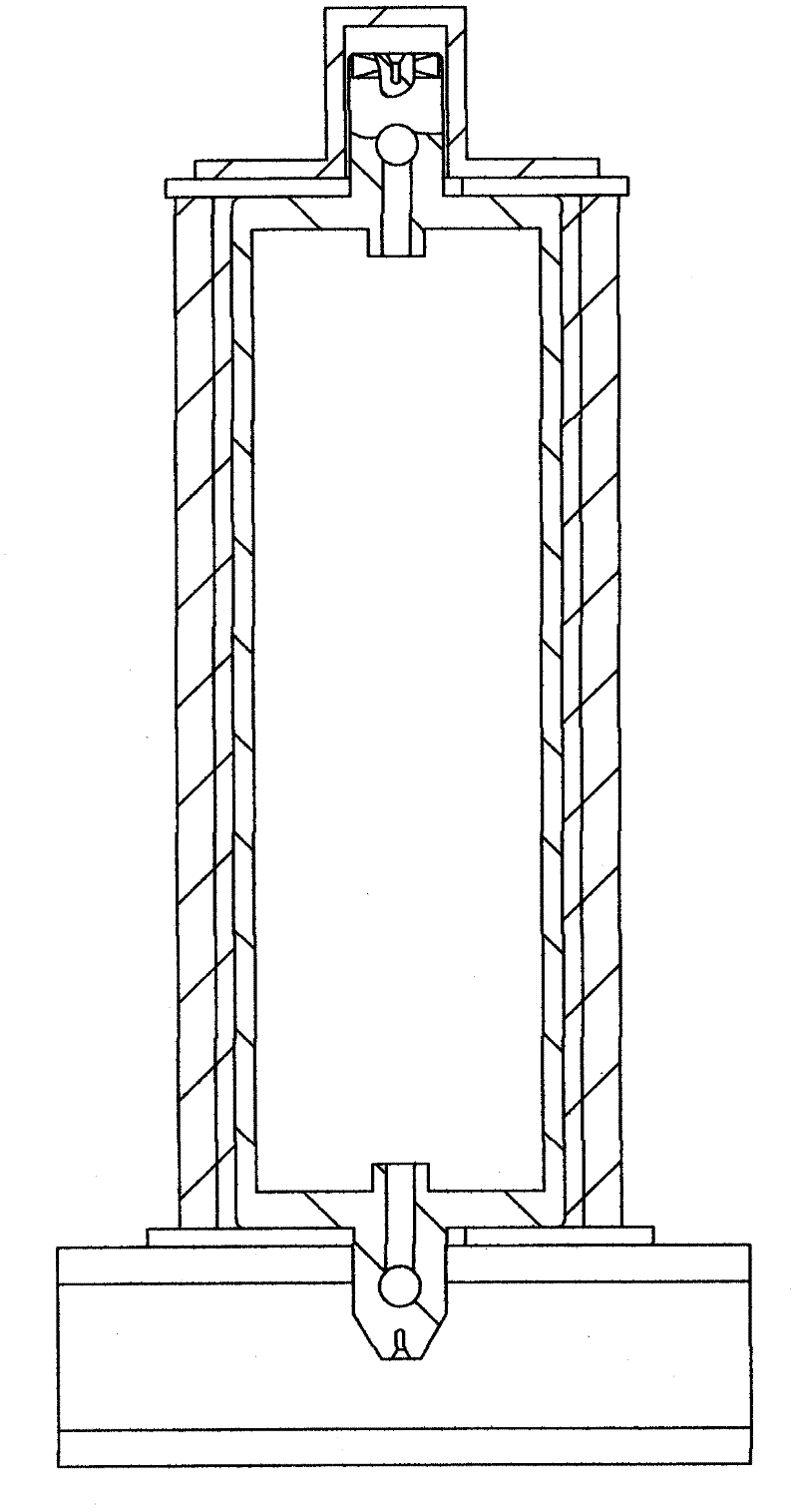

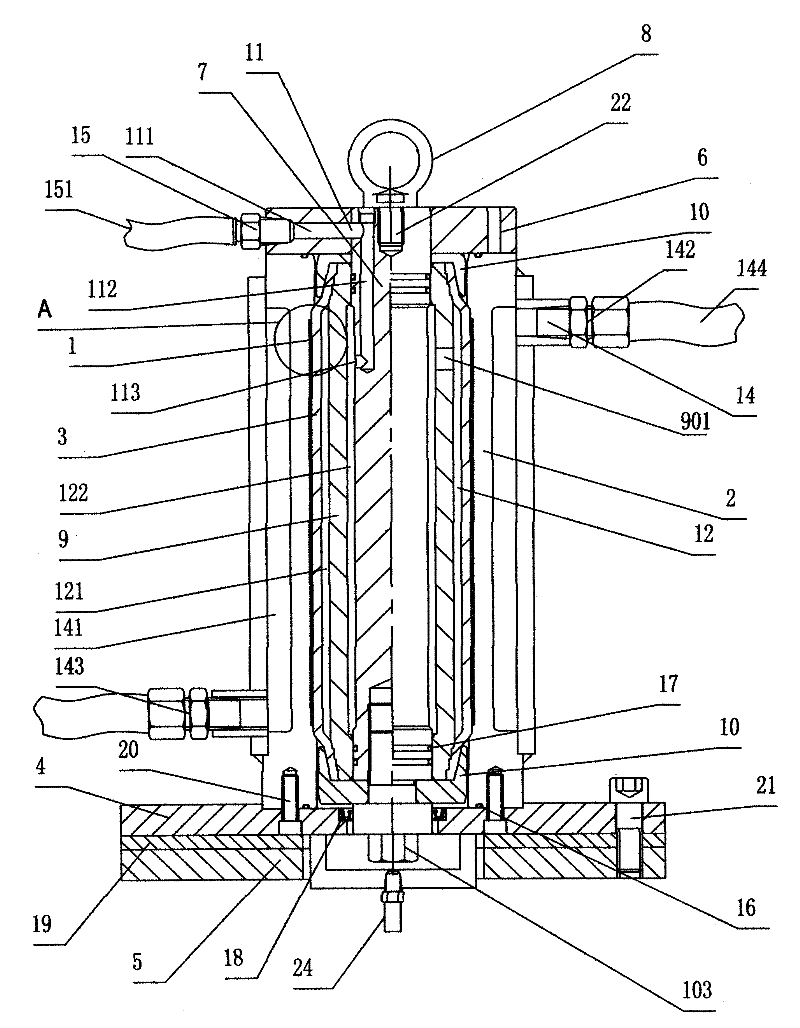

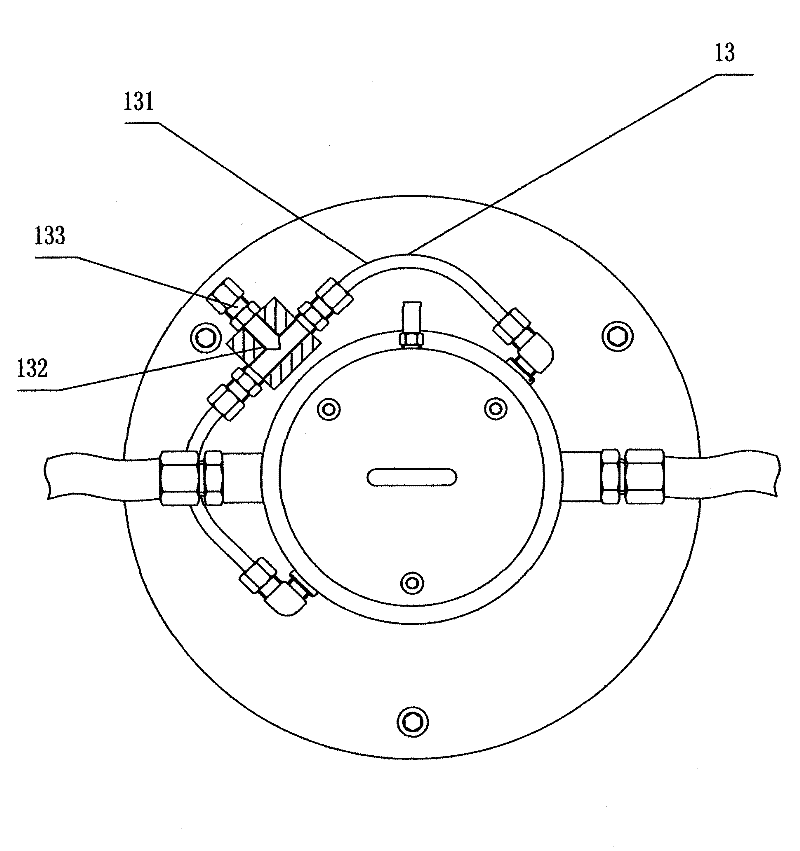

Hydraulic generator mirror plate grinding apparatus and process

InactiveCN1974130ADoes not affect geometric tolerancesGuarantee processing qualityPolishing machinesKeroseneThrust bearing

The hydraulic generator runner plate grinding apparatus includes one hollow pedestal possessing horizontal top plate with one central hole, one coaxial hollow bottomless upper bracket possessing horizontal top plate with one thrust bearing, one horizontal rotating arm on the thrust bearing and with one vertical shaft stretching into the upper bracket space and one grinding mechanism in the work end, one vertical reducing drive unit with one output shaft penetrating the central hole in the pedestal and stretching into the upper bracket space, and one pair of shaft couplers to connect the rotating arm shaft and the output shaft separately. The grinding process includes the following steps: fixing the runner plate and the grinding plate levelly on the platform, grinding while adding engine oil and W20 emery and in the grinding head linear speed of 2.7-3.5 m / s and grinding head pressure of 0.6-1.0 kg / sq cm, and polishing with polishing disc while adding kerosene and grinding paste.

Owner:DEYANG DONGRUI POWER STATION EQUIP

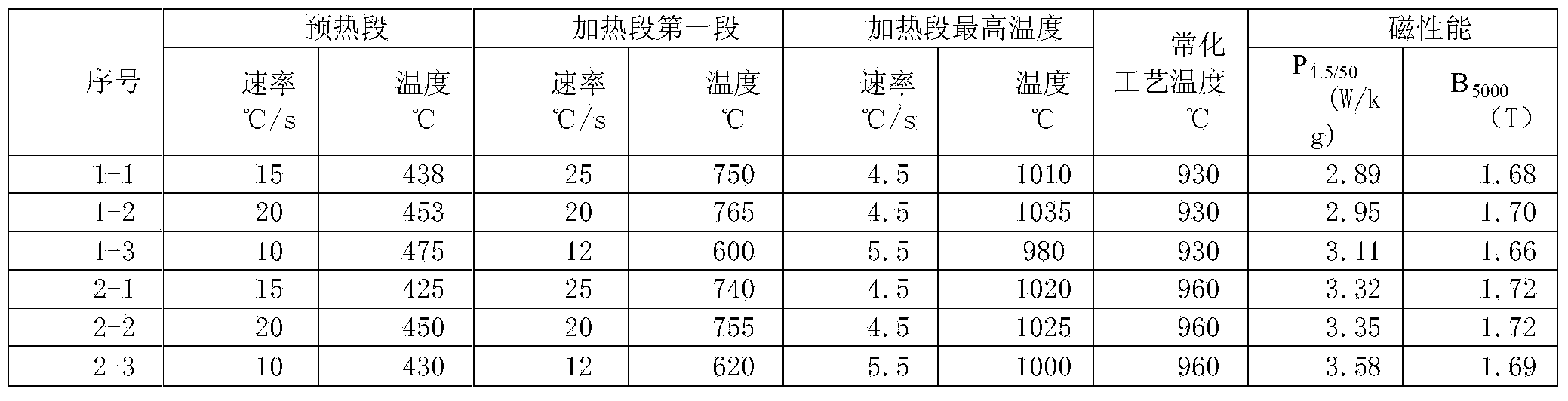

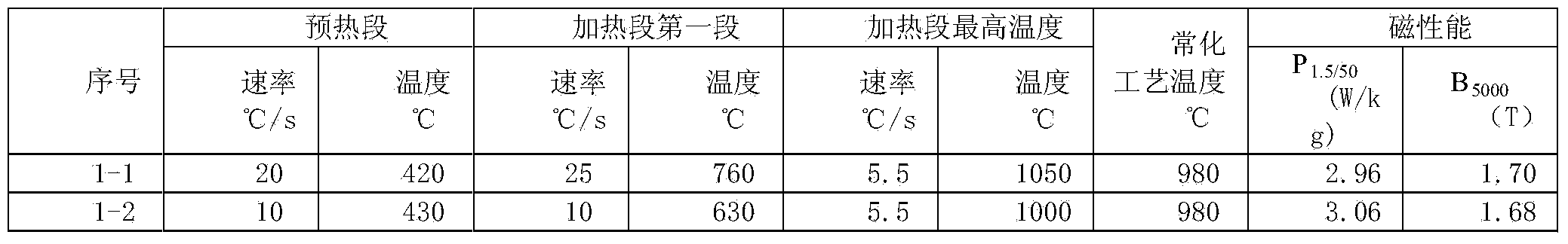

Non-oriented electrical steel with high magnetic induction and manufacturing method thereof

The invention relates to non-oriented electrical steel with high magnetic induction and a manufacturing method of the steel. According to the manufacturing method of the steel, high-quality board raw materials are provided for the subsequent processes by controlling heating speed of a normalizing and heating stage, controlling a speed of a normalizing and cooling stage and using cooperation of proper blasting and pickling processes. The magnetic induction B50 of the manufactured non-oriented electrical steel is increased by 200-500 gausses, and the quality level of the iron loss material object is increased by 3-5% under the conditions that additional alloy elements are not added and the annealing process of the finished product is not changed; and the magnetic property of the manufactured non-oriented electrical steel is further improved by optimizing the annealing process, so that the magnetic induction is further improved. The manufactured non-oriented electrical steel can meet the requirements of normal motors and also can meet the requirement of high magnetic induction of electrical steel applied to iron cores of efficient motors and frequency-variable motors; the efficiency of the motors can be improved; and the energy consumption and the noise of the manufactured non-oriented electrical steel can be reduced.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

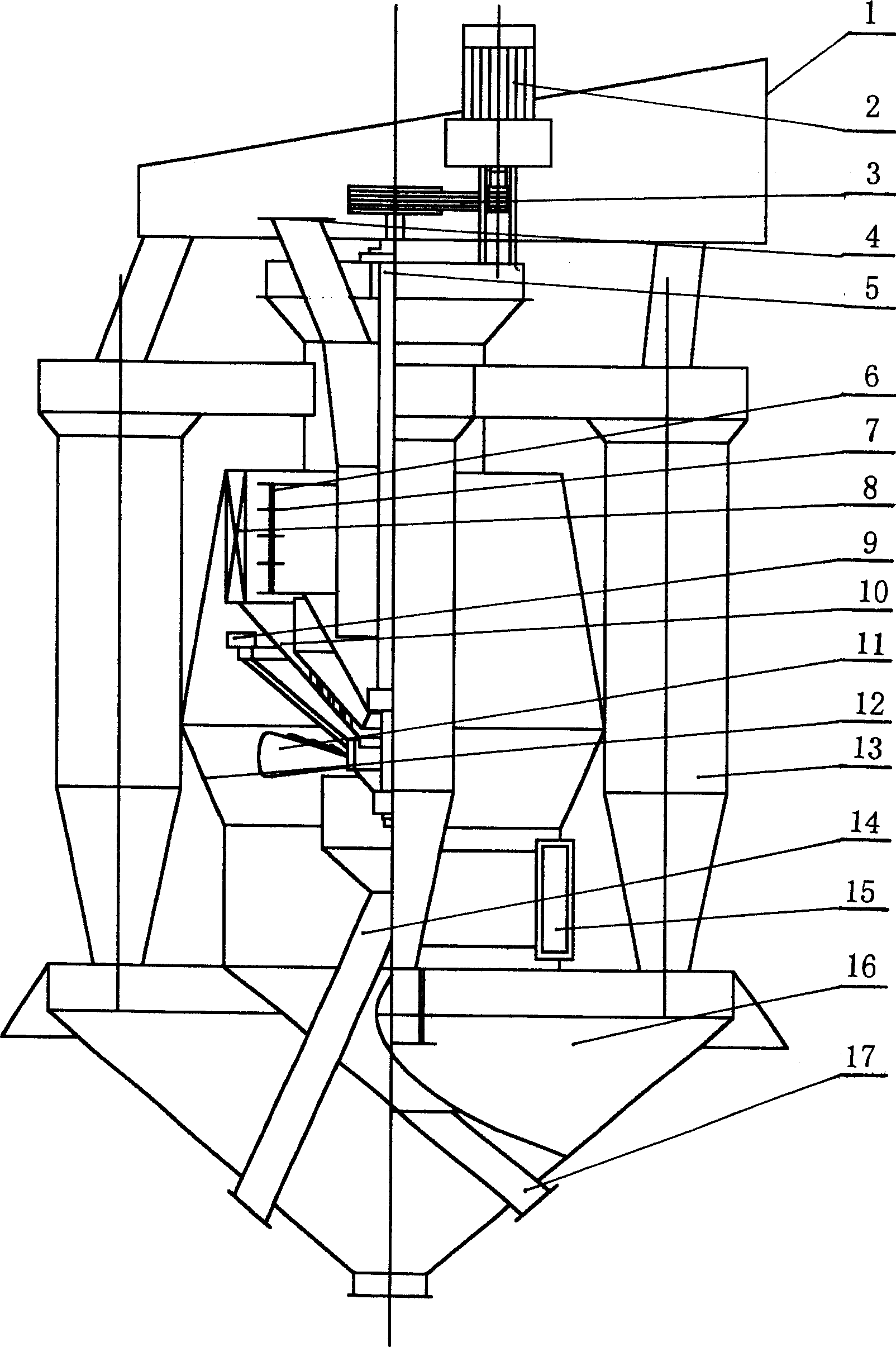

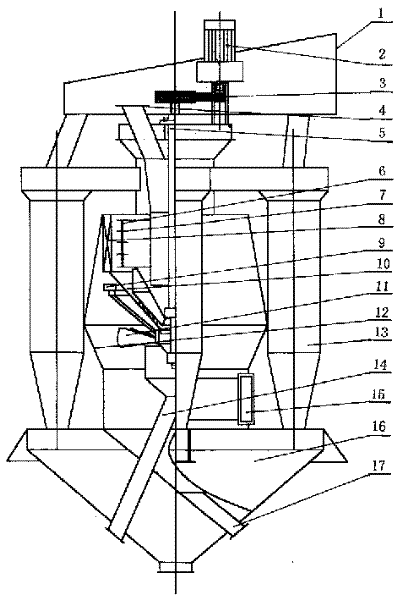

Three composition dividing powder separating machine

InactiveCN1485149AReduce grindingImprove grinding efficiencyGas current separationDrive shaftEngineering

An three-separate selecting flour machine comprises the selecting powder room, vortex separator, upright transmission shaft, big fan, collection cone for meal, collection cone for fine flour, tray for strewing material, collection cone for middle meal, upright guiding fan, rotor. The collecting cone for middle meal is over the tray for strewing material, comprises the upper cone the lower cone. There has a path between the upper cone and the lower cone. The upright guiding fans are over the circumference of the lower cone. A rotor is over the two circumferences of the upper and the lower cones. A separating board is at the pole of the rotor. The rotor is installed below the upright transmission shaft and over the tray for straying material. The invention could screen fine flour, middle meal, meal from material unloaded from the grind.

Owner:吕海峰

Preparation method of high-performance molded elastic multi-wedge belt and mold device therefor

The invention relates to the field of driving belts, and discloses a preparation method of a high-performance molded elastic multi-wedge belt and a mold device therefor. The preparation method solves the problems that the existing multi-wedge belt preparation technology usually adopts a production mode of preparing a wedge by a profiling grinding wheel, and thus in production, raw material consumption and energy consumption are high and in multi-wedge belt running, large noise and wedge wearing can be produced easily. The preparation method of the high-performance molded elastic multi-wedge belt comprises the following steps of A, preparing a rubber sleeve, B, carrying out pretreatment on a rubber sheet, C, rolling the pretreated rubber sheet, D, pasting the rolled rubber sheet to obtain a belt cylinder, E, vulcanizing the belt cylinder, and F, cooling and cutting to obtain a finished product. The preparation method of the high-performance molded elastic multi-wedge belt has the advantages of low raw material consumption, low energy consumption and excellent product quality.

Owner:NINGBO GUL TZ RUBBER BELT

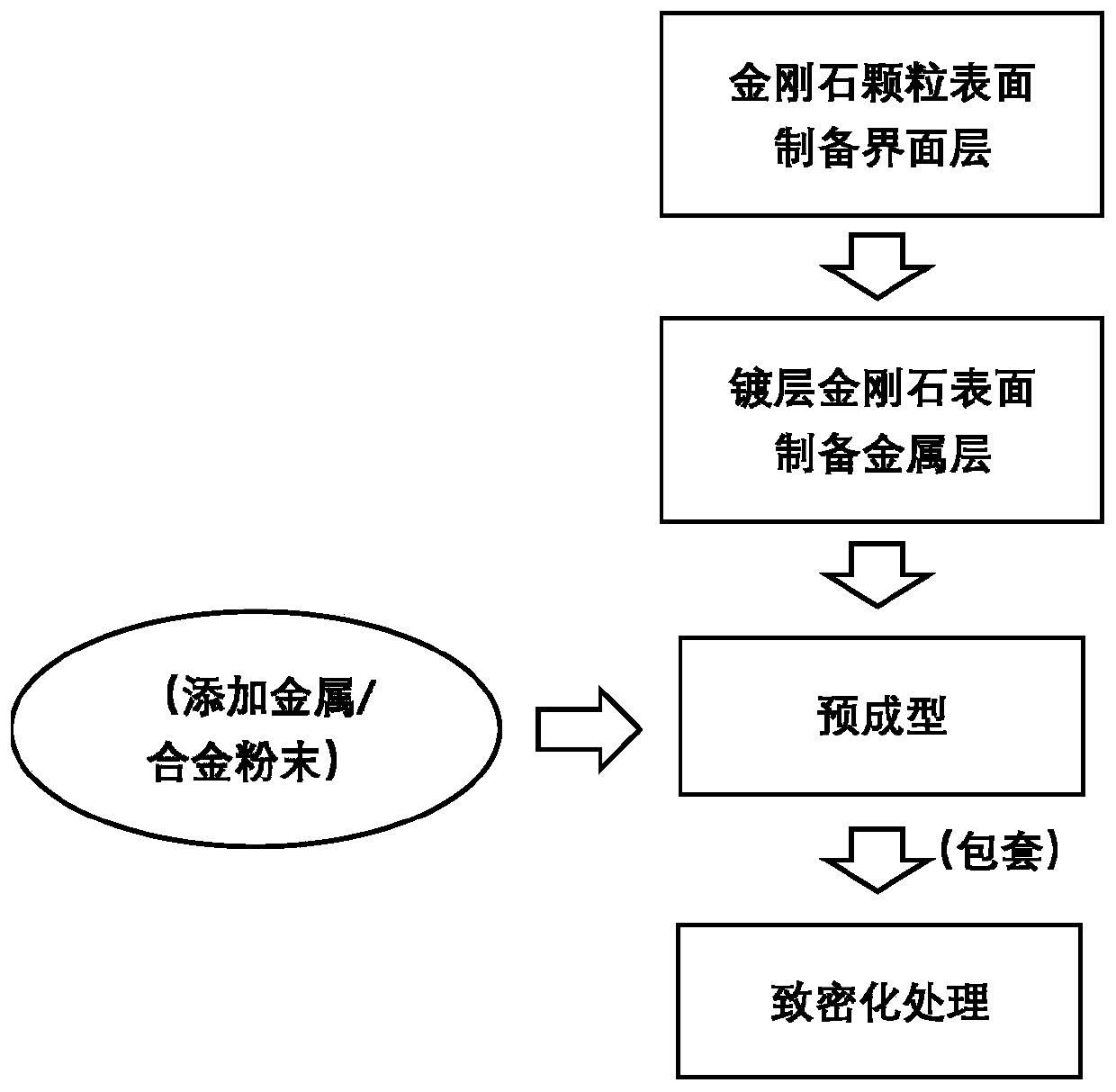

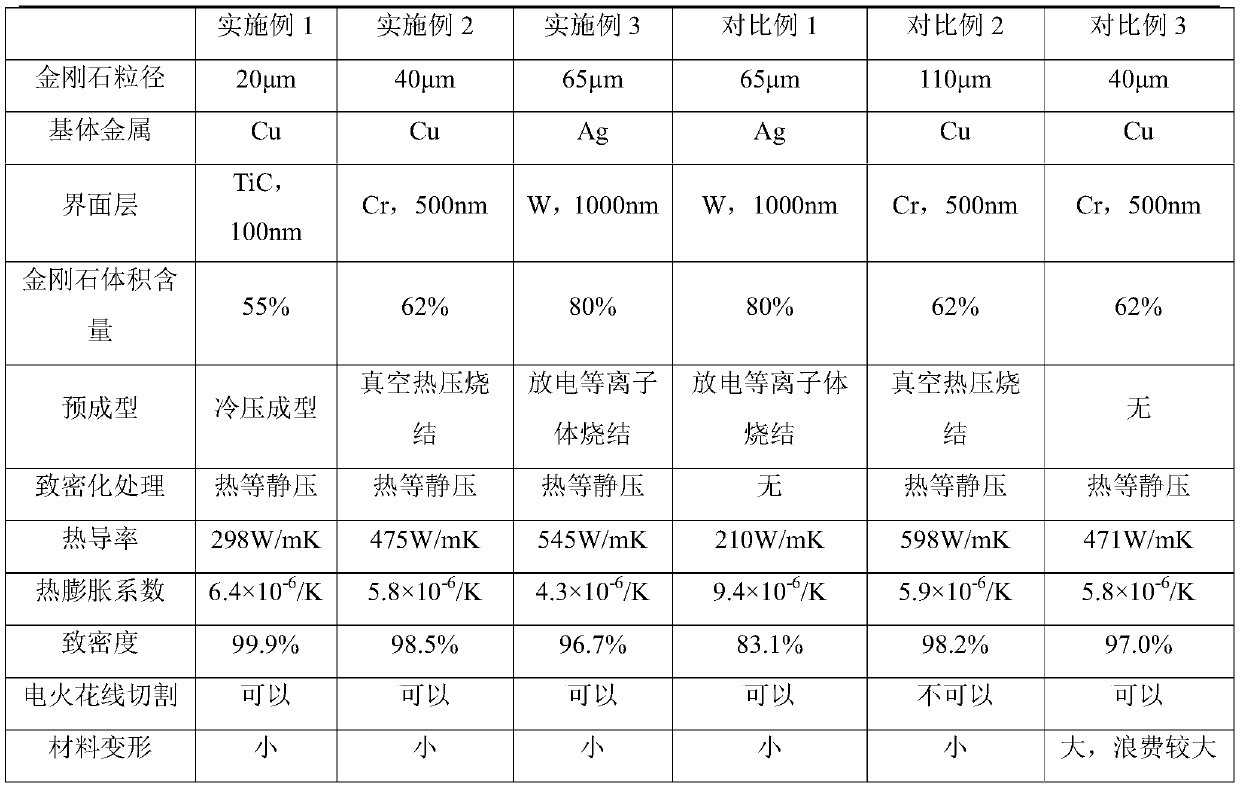

Diamond particle reinforced metal matrix composite material and preparation method and application thereof

InactiveCN111519076AEliminate uneven powder mixingHigh thermal conductivityTransportation and packagingMetal-working apparatusInterface layerThermal expansion

The invention discloses a diamond particle reinforced metal matrix composite material and a preparation method and application thereof. The preparation method comprises the steps of 1, preparing an interface layer; 2, preparing a metal layer; 3, premolding; and 4, carrying out densification treatment. According to the diamond particle reinforced metal matrix composite material and the preparationmethod and application thereof, the adopted sintering of a two-step solid-phase method combined with the premolding and densification treatment is characterized by complementing for each other, fostering strengths and circumventing weaknesses, so that the the characteristic that the solid-phase sintering method capable of preparing a material with smaller particle size is retained, the size of thematerial prepared in a single batch is larger, the thickness reaches the centimeter level or a higher level, the production efficiency is higher, and the cost is greatly reduced; the prepared material has higher thermal conductivity, adjustable thermal expansion coefficient and better uniformity and reliability, and can be directly cut for processing by an electric spark wire; and meanwhile, thepremolding before the densification treatment can solve the problem that a bag sintered by directly adopting hot isostatic pressing is deformed too much so as to result in too much waste of the material, and the material utilization rate is higher.

Owner:成都本征新材料技术有限公司

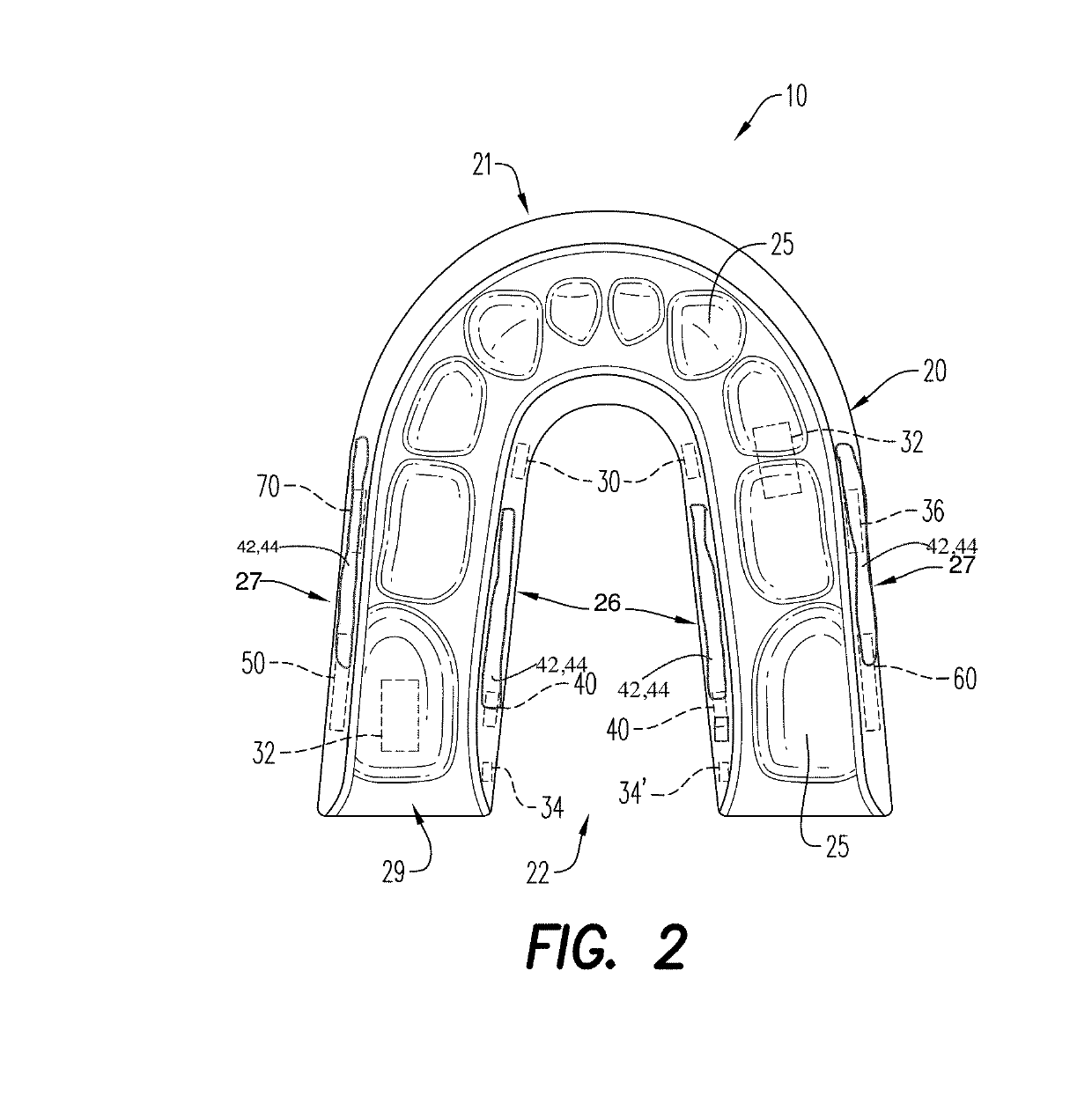

Removable mandibular pharmaceutical delivery device

ActiveUS20190091061A1Reducing clenchingReduce grindingHead electrodesMedical devicesActigraphyNoise level

An oral appliance for the treatment of sleep disorders, such as obstructive sleep apnea, in a user is presented. The oral appliance may include a mouthpiece configured to receive a user's dentition. The mouthpiece may include an oxygen sensor, a pressure sensor, an airflow sensor, an actigraphy sensor, a noise detector, and at least one stimulator for providing stimulation to a user's tongue in the event of decreased oxygen saturation levels, increased pressure applied to occlusal surfaces of the user's dentition, decreased actual airflow levels and / or increased noise levels. The mouthpiece may be provided with pharmaceutical compound reservoirs that deliver pharmaceutical compounds to the oral mucosa of the user, which compounds treat symptoms of sleep apnea. The mouthpiece may further include a microprocessor that receives data from the oxygen sensor, pressure sensor, airflow sensor, actigraphy sensor and noise detector, and activates the at least one stimulator and / or pharmaceutical compound reservoirs.

Owner:ACHAEMENID LLC

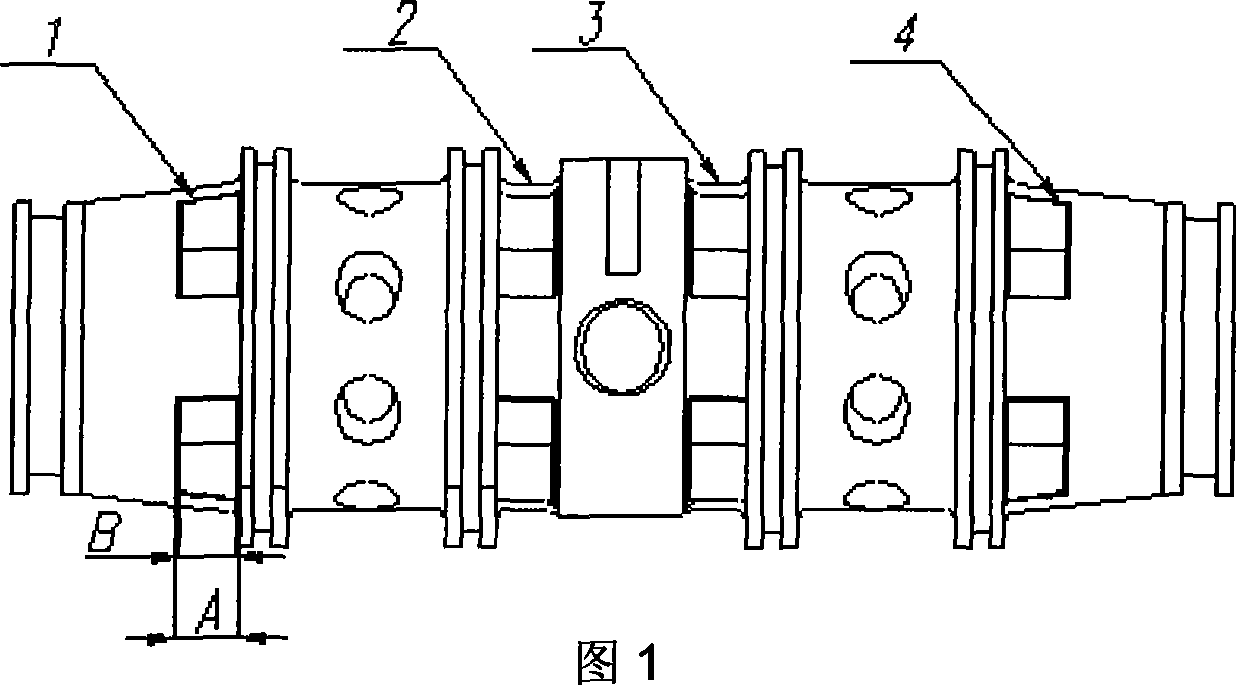

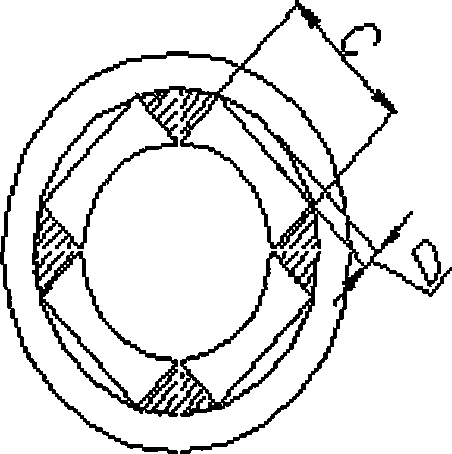

Valve housing used for opening square hole on electro-hydraulic servo valve in steam turbine power generation and processing method thereof

InactiveCN101446368AEasy to processReduce the amount of cuttingOperating means/releasing devices for valvesMultiple way valvesWire cuttingElectro hydraulic

The invention relates to a valve housing used for opening square holes on an electro-hydraulic servo valve in steam turbine power generation and a processing method thereof. The method is characterized by comprising the steps as follows: (1) two pairs of planes in proper size are milled in advance above a working edge of a processed valve housing, the size of the milled planes is slightly larger than the size of the square holes to be opened; (2) two pairs of square holes including a hole (1), a hole (2), a hole (3) and a hole (4) are cut out on the planes by linear cutting; and the intersection edges of the two pairs of square holes are crossed outside a valve core matching surface, so as to ensure complete opening. The valve housing of the electro-hydraulic servo valve used in the steam turbine power generation is processed by the method that a plane is milled on blank material in advance, and then the square holes are processed by the processing method of linear cutting. The plane which is milled in advance can reduce the cutting quantity and the abrasive magnitude of the linear cutting. The valve housing is simple for processing, saves a lot of time and improves the work efficiency.

Owner:SHANGHAI NUOMA HYDRAULIC SYST

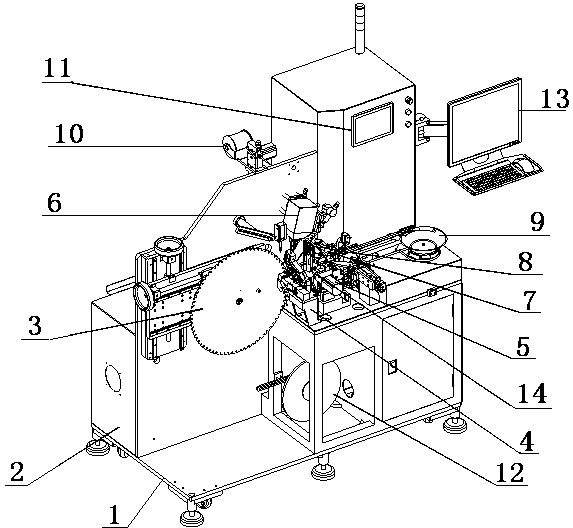

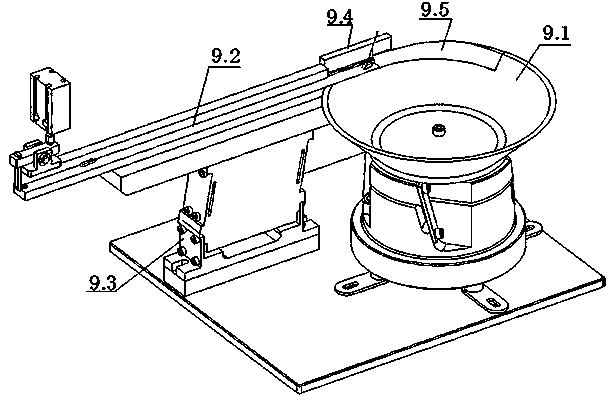

Automatic soldering machine

ActiveCN103962645AReduced grinding volume and wear of grinding wheelsShorten adjustment timeMetal sawing tool makingWelding/cutting auxillary devicesSolderingEngineering

The invention discloses an automatic soldering machine which comprises a machine frame, a case arranged on the machine frame, a saw blade automatic positioning mechanism arranged on the case, a saw blade automatic detecting and clamping mechanism matched with the saw blade automatic positioning mechanism, a soldering lug automatic cutoff forming and positioning mechanism connected with the saw blade automatic detecting and clamping mechanism, an alloy knife grain automatic positioning mechanism connected with the soldering lug automatic cutoff forming and positioning mechanism, a soldering mechanism arranged above the soldering lug automatic cutoff forming and positioning mechanism, and a soldering flux tape reel arranged below the soldering lug automatic cutoff forming and positioning mechanism. All the mechanisms are controlled by a touch screen operating system, and the touch screen operating system is connected with a computer. According to the automatic soldering machine, soldering flux pieces can be automatically formed and machined, precision and stability during soldering are guaranteed, soldering efficiency and product quality are improved, and manufacturing cost is reduced.

Owner:ZHEJIANG AET INTELLIGENT TECH

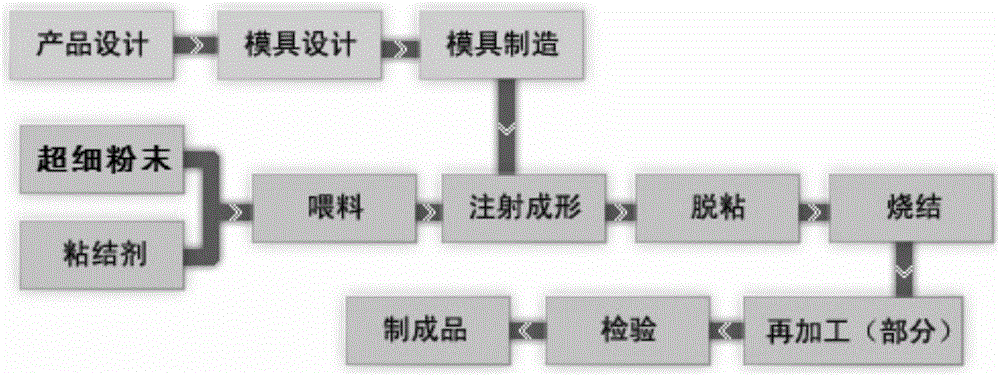

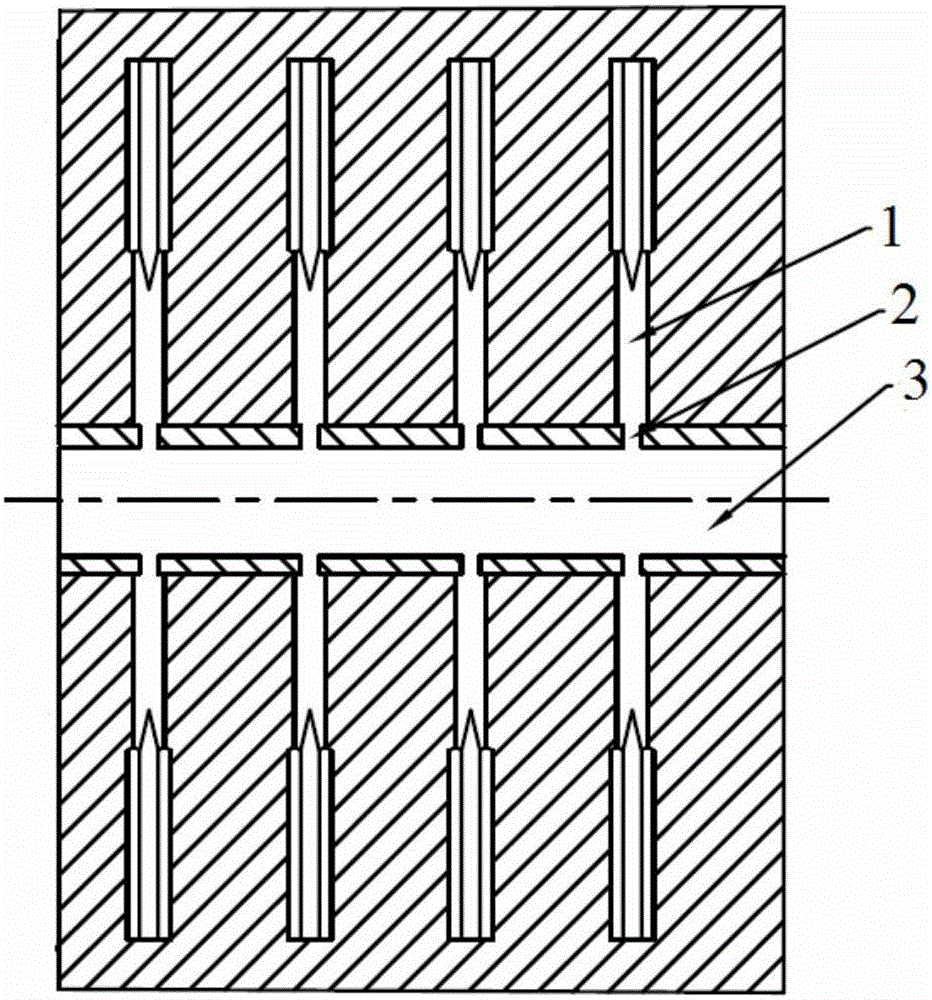

Preparation method for superfine hard alloy cutter blank with preformed cutter groove

ActiveCN106312074AHigh strengthImprove adhesionNon-macromolecular adhesive additivesTransportation and packagingMolten stateAdhesive

The invention provides a preparation method for a superfine hard alloy cutter blank with a preformed cutter groove. The preparation method is characterized by comprising the following steps: step 1, performing wet mixing and ball milling on superfine WC, superfine Co, superfine VC and Cr3C2, and then performing uniform mixing to obtain a superfine mixture of which all the components are uniform; step 2, adding an adhesive into a vacuum kneading machine, performing kneading till the superfine mixture and the adhesive are uniformly mixed, pelletizing the superfine mixture doped with the adhesive, heating the pelletized material in an injection molding machine till the pelletized material enters a molten state, injecting the molten material into a mold cavity by an injection molding mode, and dissolving and removing the adhesive in a superfine hard alloy soft blank in water; and step 3, performing sintering at 1340-1420 DEG C in a low-pressure sintering furnace, and performing argon gas pressurization at 1-10 MPa to prepare the superfine hard alloy cutter blank with the preformed cutter groove. When the superfine hard alloy cutter blank with the preformed cutter groove is produced by adopting the preparation method provided by the invention, the grinding amount during cutter production can be greatly reduced, the cutter production efficiency can be greatly improved, and the waste of tungsten resources can be reduced.

Owner:SUZHOU SAITERUI PRECISION MACHINERY PARTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com