Three composition dividing powder separating machine

A powder classifier and three-separation technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problems affecting grinding efficiency, mill output and power consumption, and over-grinding and other problems, to achieve the effect of reducing the phenomenon of over-grinding in the mill, improving the grinding efficiency and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

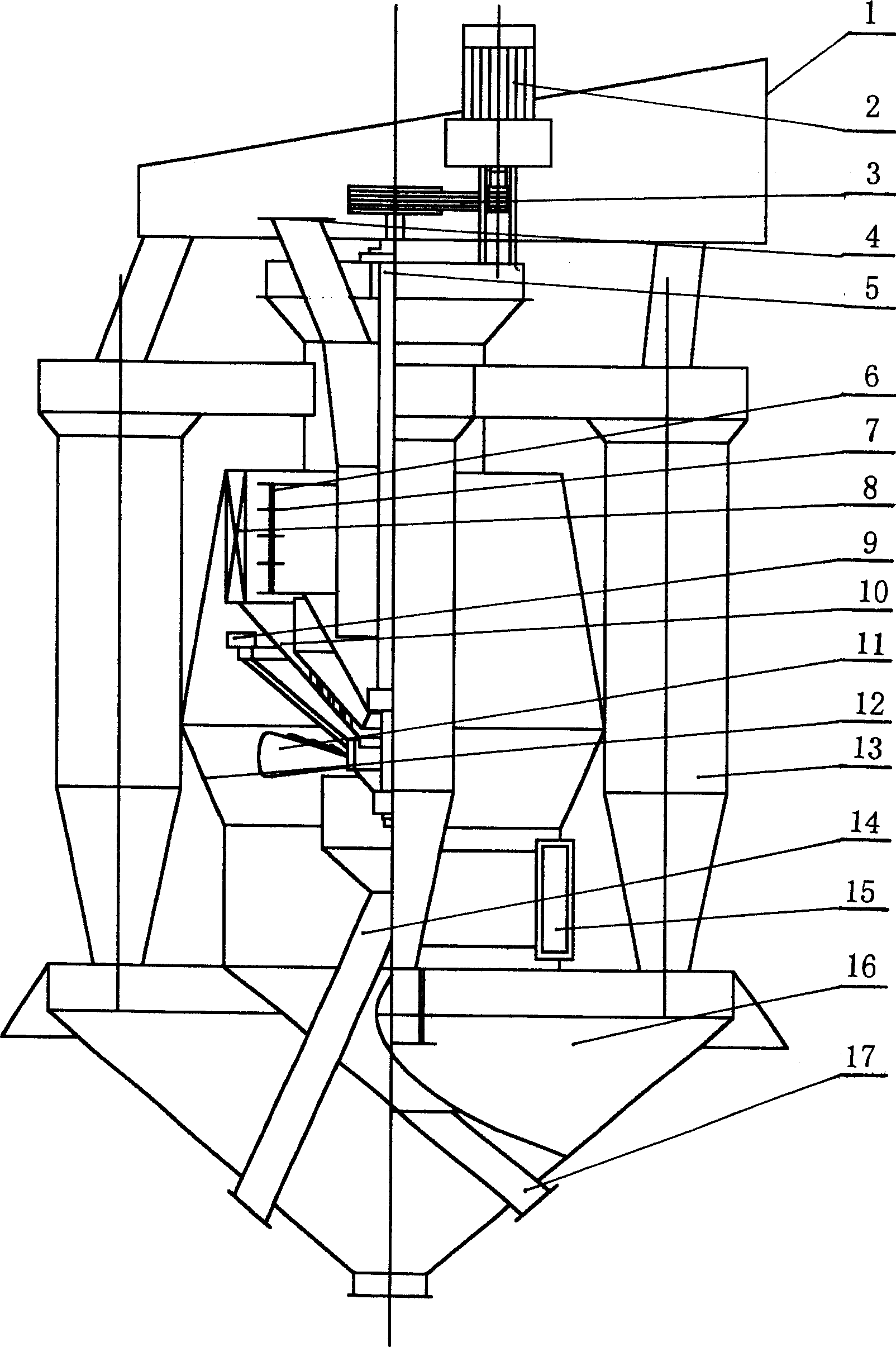

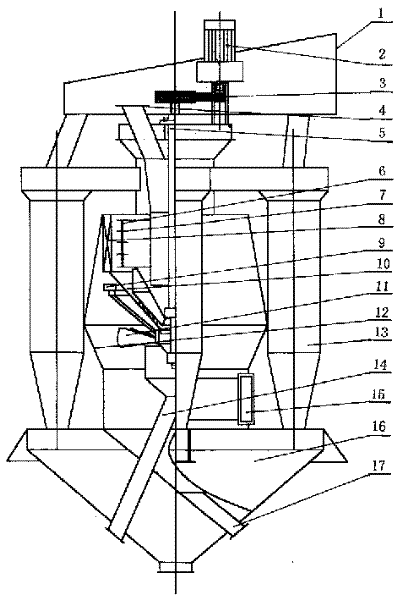

[0010] The speed regulating motor 2 and the vertical transmission shaft are installed on the top of the powder selection chamber 12, the motor 2 is connected with the vertical transmission shaft 5 through the transmission device 3, and the vertical transmission shaft 5 is installed on the top of the powder selection chamber 12 and placed in the powder selection chamber within 12. Several cyclone separators 13 are uniformly arranged on the periphery of the powder selection chamber 12, the upper part of the cyclone separator 13 communicates with the powder selection chamber 12, and the upper connecting pipe of the cyclone separator 13 is provided with an air outlet 1. A material inlet 4 is installed on the top of the powder selection chamber 12 . The powder selection chamber 12 is installed on the top of the fine powder collecting cone 16, and the bottom of the powder selection chamber 12 is provided with an air inlet 15. A coarse powder collection cone 17 is installed in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com