Preparation method for superfine hard alloy cutter blank with preformed cutter groove

A cemented carbide, integral tool technology, used in adhesive types, metal processing equipment, polyether adhesives, etc. Alloy is easy to oxidize and other problems, so as to achieve the effect of less defects in green compact, lower friction resistance and significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

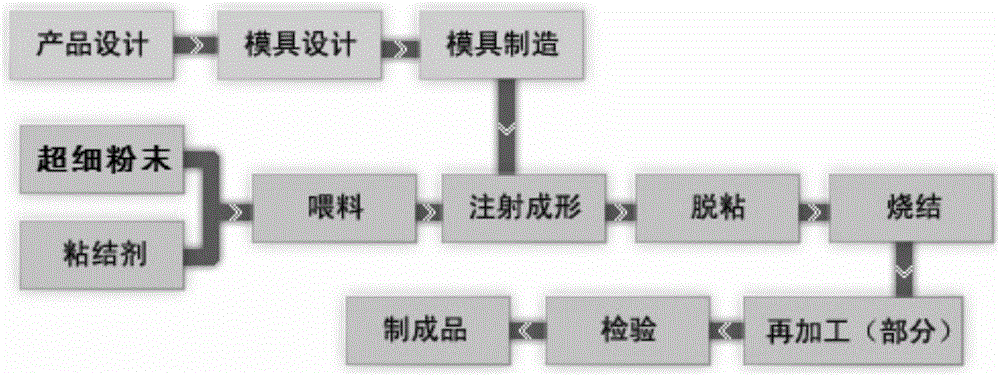

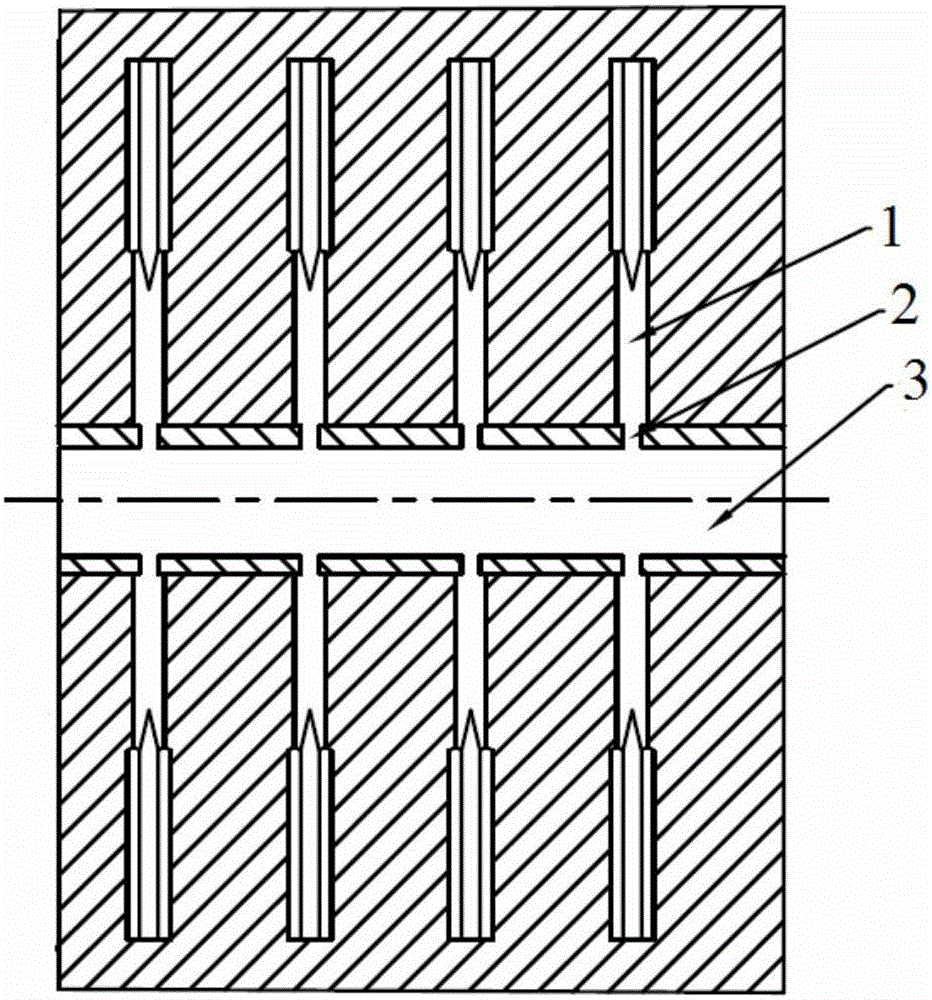

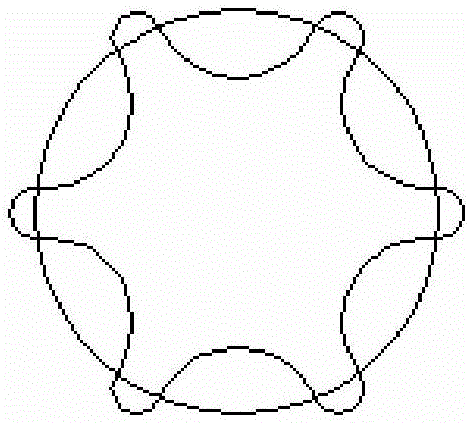

[0037] Embodiment 1~3: A kind of preparation method of ultra-fine cemented carbide preformed sipe integral tool body

[0038] The preparation method consists of the following steps:

[0039] In the first step, ultrafine WC, ultrafine Co, ultrafine VC and Cr 3 C 2 After 48 hours of wet mixing and ball milling, mix uniformly to obtain a uniform ultrafine mixture of components, wherein the ultrafine WC particle size is 0.5 μm, and the mass percentage in the ultrafine mixture is 87.2%. The ultrafine Co particle size is 0.8 μm, and the mass percentage in the ultrafine mixture is 12%, and the ultrafine VC particle size is 1 μm, and the mass percent in the ultrafine mixture is 0.3 %, the Cr 3 C 2 The particle size is 1.2 μm, and the mass percentage in the ultrafine mixture is 0.5%;

[0040] In the second step, after the ultrafine mixture is dried, add an adhesive that accounts for 10% of the weight of the ultrafine mixture in a vacuum kneader, knead for 30 minutes, and fully mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com