Weathering type ilmenite beneficiation treatment method

A processing method and technology for ilmenite, applied in chemical instruments and methods, flotation, magnetic separation, etc., can solve the problems of loss of fine-grained titanium minerals, low resource utilization rate, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

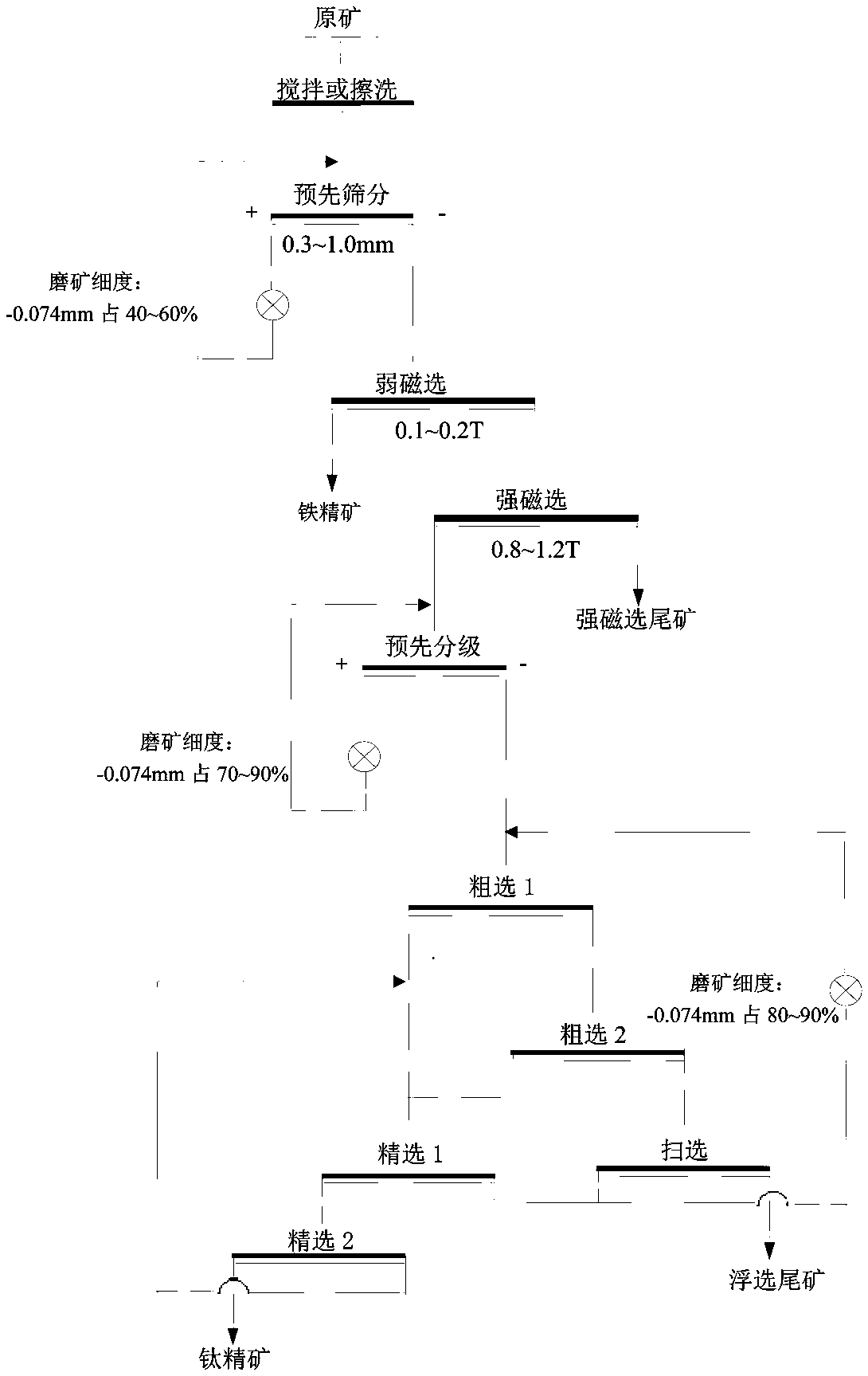

Image

Examples

Embodiment 1

[0033] Composition of weathered ilmenite raw ore: TiO 2: 6.93%, Fe: 14.82%, CaO: 3.02%, MgO: 2.09%, Al 2 o 3 : 8.69%, SiO 2 : 38.41%.

[0034] The mineral processing method of the weathered ilmenite (raw ore) comprises the following steps:

[0035] (1) Stir the raw ore with a mixer in advance for 20 minutes;

[0036] (2) After stirring, the ore pulp is pre-classified through a vibrating screen with a screen hole of 0.5 mm, and the on-screen material enters a ball mill, and the ball mill and vibrating screen are sieved to form a closed-circuit grinding process, and the fineness of the grinding product is -0.074 mm, accounting for 40%;

[0037] (3) The products under the sieve are magnetically separated by a weak magnetic separator with a magnetic field strength of 0.2T. Weak magnetic separation tailings are obtained after removing ferromagnetic minerals by weak magnetic separation;

[0038] (4) The tailings of the weak magnetic separation are magnetically separated and di...

Embodiment 2

[0044] Composition of weathered ilmenite raw ore processed (including): TiO 2 : 4.02%, Fe: 16.26%, CaO: 2.32%, MgO: 5.37%, Al 2 o 3 : 9.32%, SiO 2 : 42.27%.

[0045] The mineral processing method of the weathered ilmenite (raw ore) comprises the following steps:

[0046] (1) Scrub the raw ore in advance with a scrubber for 10 minutes;

[0047] (2) After scrubbing, the pulp is pre-classified through a vibrating screen with a sieve hole of 0.4mm, and the on-screen material enters the ball mill, and the ball mill and the vibrating screen form a closed circuit, and the fineness of the grinding product is -0.074mm accounting for 45%;

[0048] (3) The products under the sieve are magnetically separated by a weak magnetic separator with a magnetic field strength of 0.1T. Weak magnetic separation tailings are obtained after removing ferromagnetic minerals by weak magnetic separation;

[0049] (4) The tailings of the weak magnetic separation are magnetically separated and discard...

Embodiment 3

[0055] A kind of beneficiation processing method of weathering type ilmenite, comprises the following steps:

[0056] A. Pre-screening: The raw ore is stirred or scrubbed with a mixer in advance, and the pulp after stirring or scrubbing is pre-screened through a vibrating screen with a sieve hole of 0.3mm, and the oversize enters a ball mill. The degree is -0.074mm and accounts for 40%, and the ball mill and the vibrating screen are classified to form a closed circuit; the raw ore includes the following components by weight percentage: TiO 2 4%, Fe10%, SiO 2 35%, Al 2 o 3 8%;

[0057] B, weak magnetic separation: the product under the sieve is subjected to weak magnetic separation, the magnetic field strength of weak magnetic separation is 0.1T, iron concentrate and tailings of weak magnetic separation are obtained after weak magnetic separation removes ferromagnetic minerals; The grade is Fe: 50%, TiO 2 : 12%;

[0058] C. Strong magnetic separation: the weak magnetic se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com