Method for manufacturing large-size low-water-peak prefabricated rod

An optical fiber preform, low water peak technology, applied in the field of optical fiber manufacturing, can solve the problems of difficult switching of product types, increased cost, and high geometric accuracy of the casing, and achieve the effect of overcoming process switching, reducing manufacturing costs, and increasing annual production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

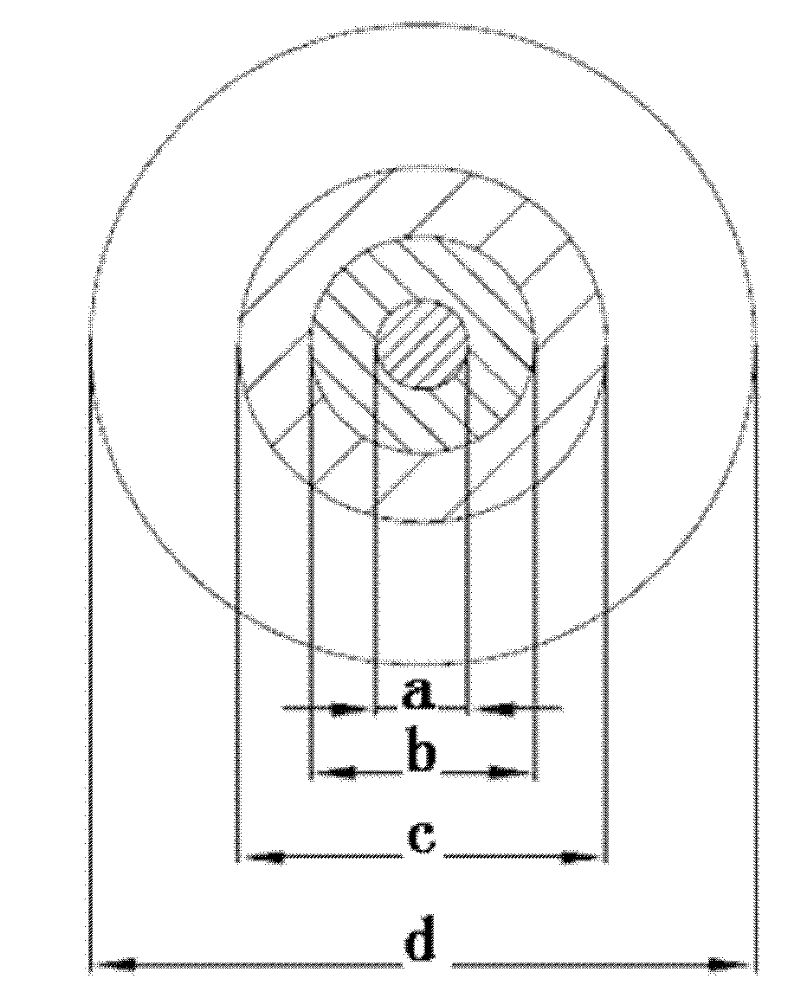

[0036]Embodiment 1: Embodiment of a large-scale low water peak preform of a single-mode optical fiber

[0037] According to the method of the present invention, Table 1 lists the structural parameters of preformed rods of three specifications, wherein the single-mode mandrels are all prepared by the existing PCVD process.

[0038] Table 1 Preform geometric parameters (and corresponding optical fiber geometric parameters)

[0039]

[0040]

[0041] The PCVD stage process is as follows: the mixed gas raw material requirement is O 2 The water content in is required to be less than or equal to 100ppb, C 2 f 6 The water content in it is required to be less than or equal to 1000ppb, and the dynamic leakage rate of the deposition lathe is less than or equal to 1.0×10 -5 mbar.l / s, the relative humidity of the environment during the preparation process is less than 25%, the relative humidity of the better environment is less than 15%, and the relative humidity of the more opti...

Embodiment 2

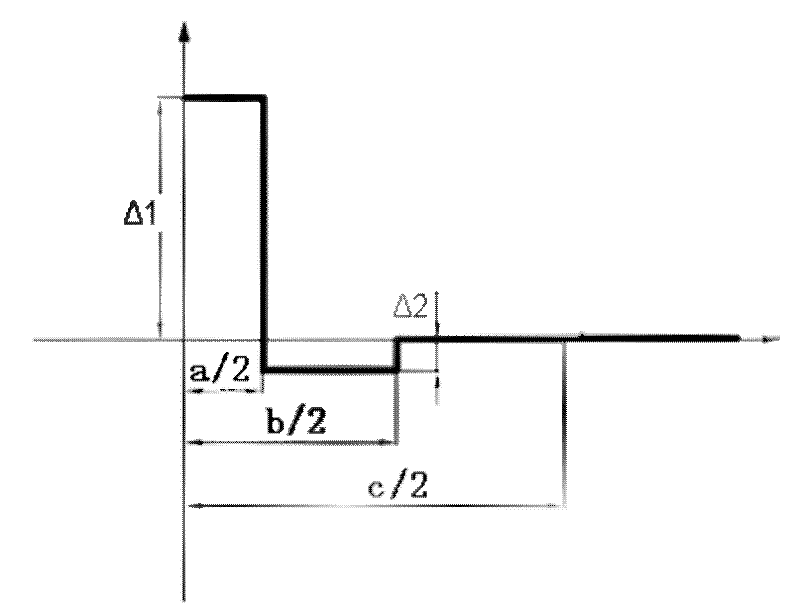

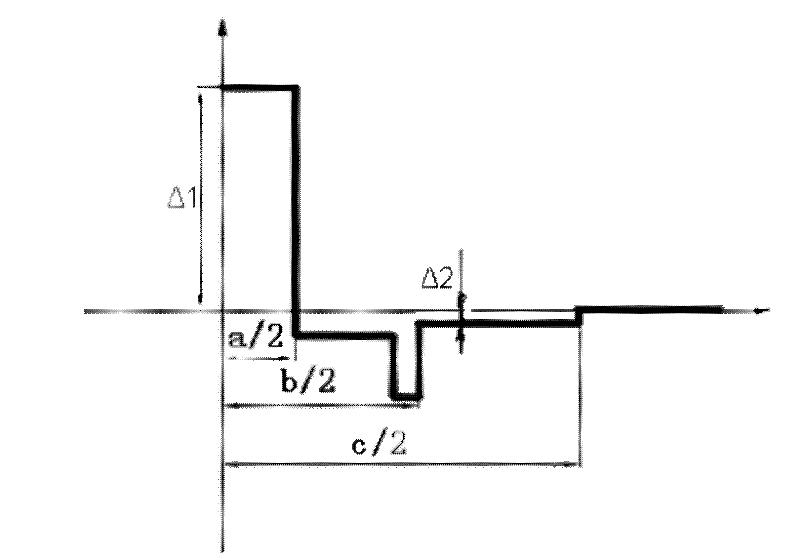

[0046] Embodiment 2: Embodiment of a large preform rod of a deep fluorine-doped cladding low water peak single-mode optical fiber

[0047] Using the mandrel manufacturing process similar to No. 1 in Table 1, the cross-sectional structure diagram of the optical fiber is shown in Figure 2(c). Taking advantage of the process advantage of the PCVD process, which is easy to do deep fluorine, a large preform of fluorine-doped low water peak single-mode optical fiber is prepared. In this embodiment, the liner is selected as a high-purity quartz synthetic tube doped with -0.25---0.35% F, and the hydroxyl content is not more than 100ppb. The refractive index contribution value of F doped in the core layer is -0.03---0.06%. The inner cladding prepared by PCVD process is a pure F-doped quartz material, and the F-doped refractive index contribution value is -0.30---0.45% close to the core area, and -0.40---0.70% away from the core area, where c / a can be approached 3.0. The mandrel direct...

Embodiment 3

[0048] Example 3: Example of G.657 large preform with low water peak

[0049] Using a mandrel manufacturing process similar to No. 2 in Table 1, the cross-sectional structure of the optical fiber is shown in Figure 2(d). Pure quartz synthetic tube, the refractive index contribution value of F-doped core layer is -0.03---0.12%, and the cladding layer F-doped refractive index contribution value is -0.10---0.25%, while satisfying b / a between 1.5-1.7 between. In order to meet the requirements of the waveguide structure, the core and the inner cladding can be adjusted with proper Ge doping to balance the refractive index distribution of the fiber. If a deep fluorine-doped layer is added to the PCVD inner cladding away from the core area, the typical amount can reach -0.70%, and the deepest can reach -1.00%, and the corresponding c / a can be close to 3.0. The final preform can ensure good bending performance and Low water peak performance. The directly melted mandrel can be direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com