Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134results about How to "Meet shape requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wave-transmitting core clamping material of antenna cover and manufacturing method and application thereof

ActiveCN103660410AHigh mechanical strengthIncreased protectionSynthetic resin layered productsLaminationUltimate tensile strengthThermoplastic composites

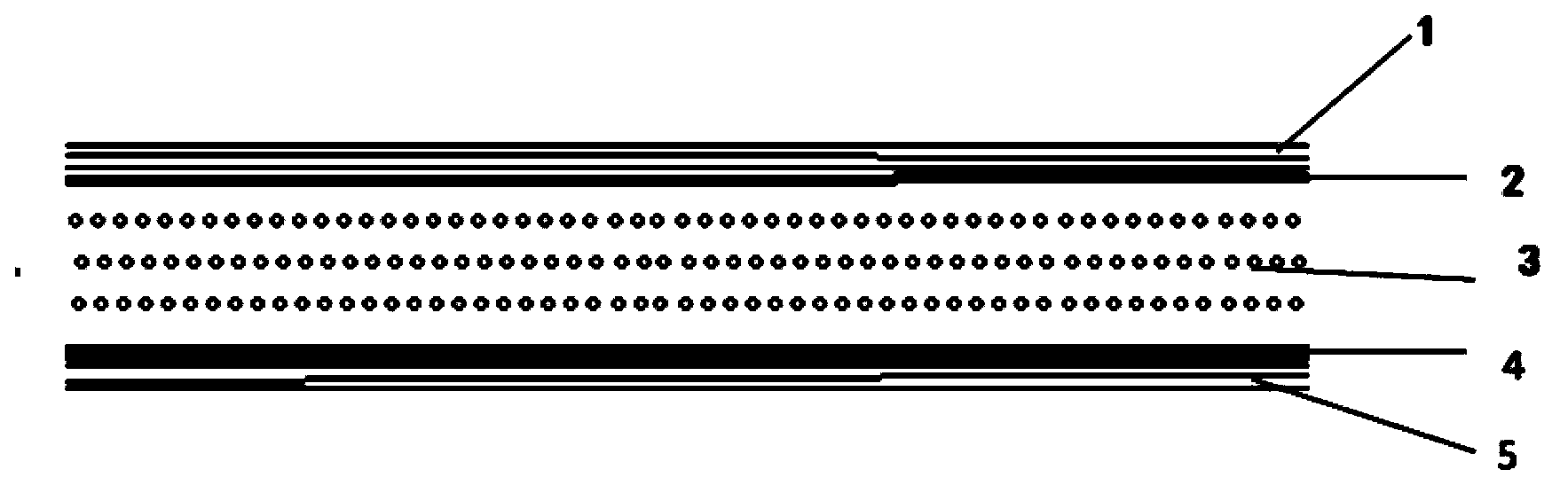

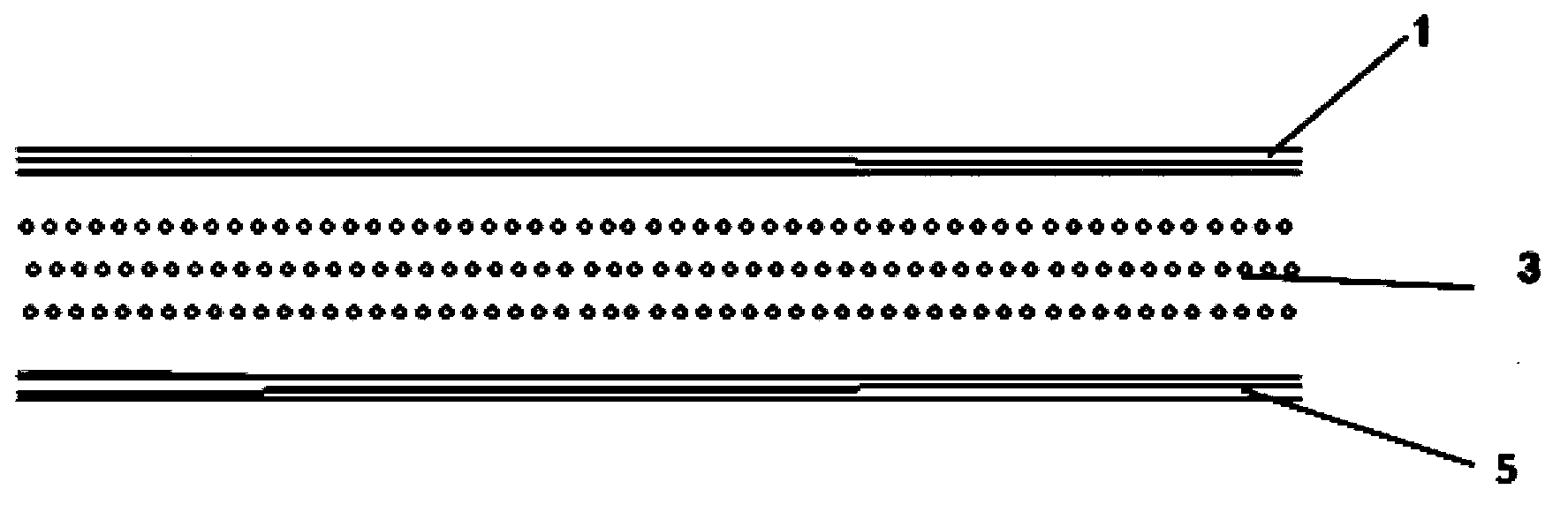

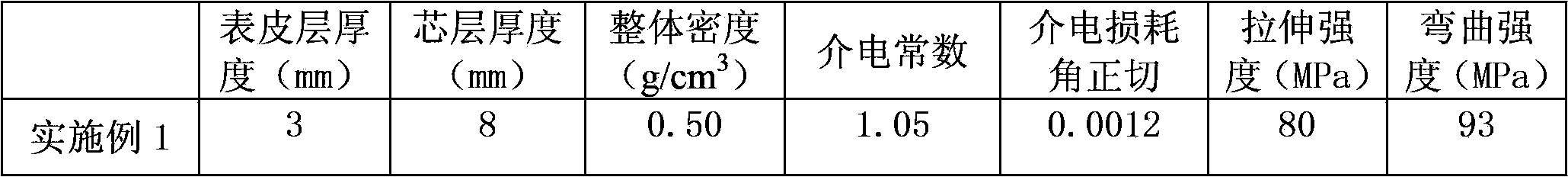

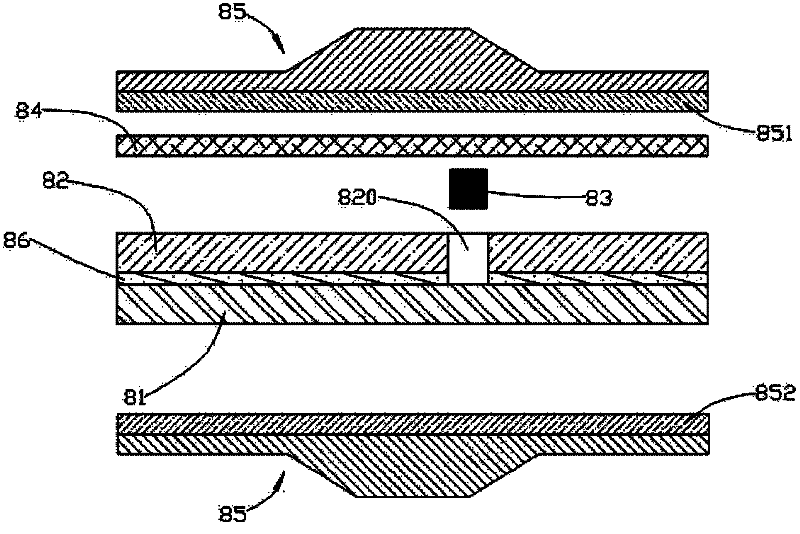

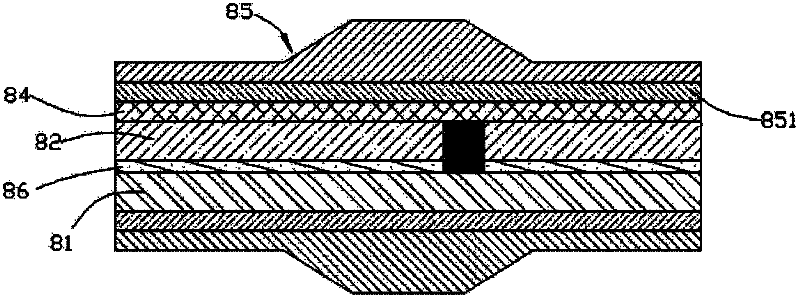

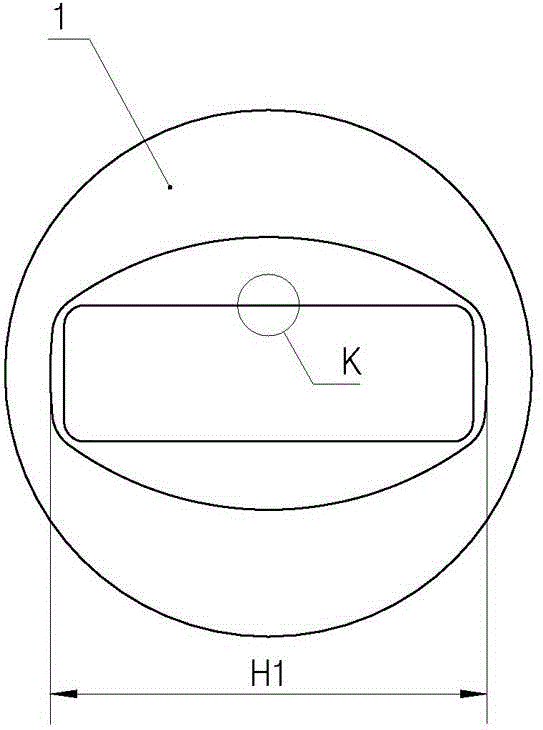

The invention belongs to the technical field of materials, and relates to a wave-transmitting core clamping material and a manufacturing method and application thereof. The wave-transmitting core clamping material comprises an upper skin layer, a core layer and a lower skin layer, wherein the upper skin layer and the lower skin layer are bonded on the two sides of the core layer, respectively; the upper skin layer and the lower skin layer are made of a fiber-reinforced thermoplastic composite material or a laminated material of the fiber-reinforced thermoplastic composite material and a transition material. The prepared wave-transmitting core clamping material provided by the invention has the characteristics that the quality is light, the intensity is high, the wave-transmitting property is good, the adaptive temperature range is wide, and the core clamping material is manufactured to be in different shapes through different manners of hot pressing, vacuum forming and the like so as to meet the requirement on the shape of an antenna cover.

Owner:上海吒吒新材料科技有限公司

Typical path planning method for 3D (three-dimensional) printing of continuous fiber reinforced composites

ActiveCN108891029AGuaranteed mechanical propertiesReduce molding defectsAdditive manufacturing apparatusManufacturing data aquisition/processingProcess mechanismComputer Aided Design

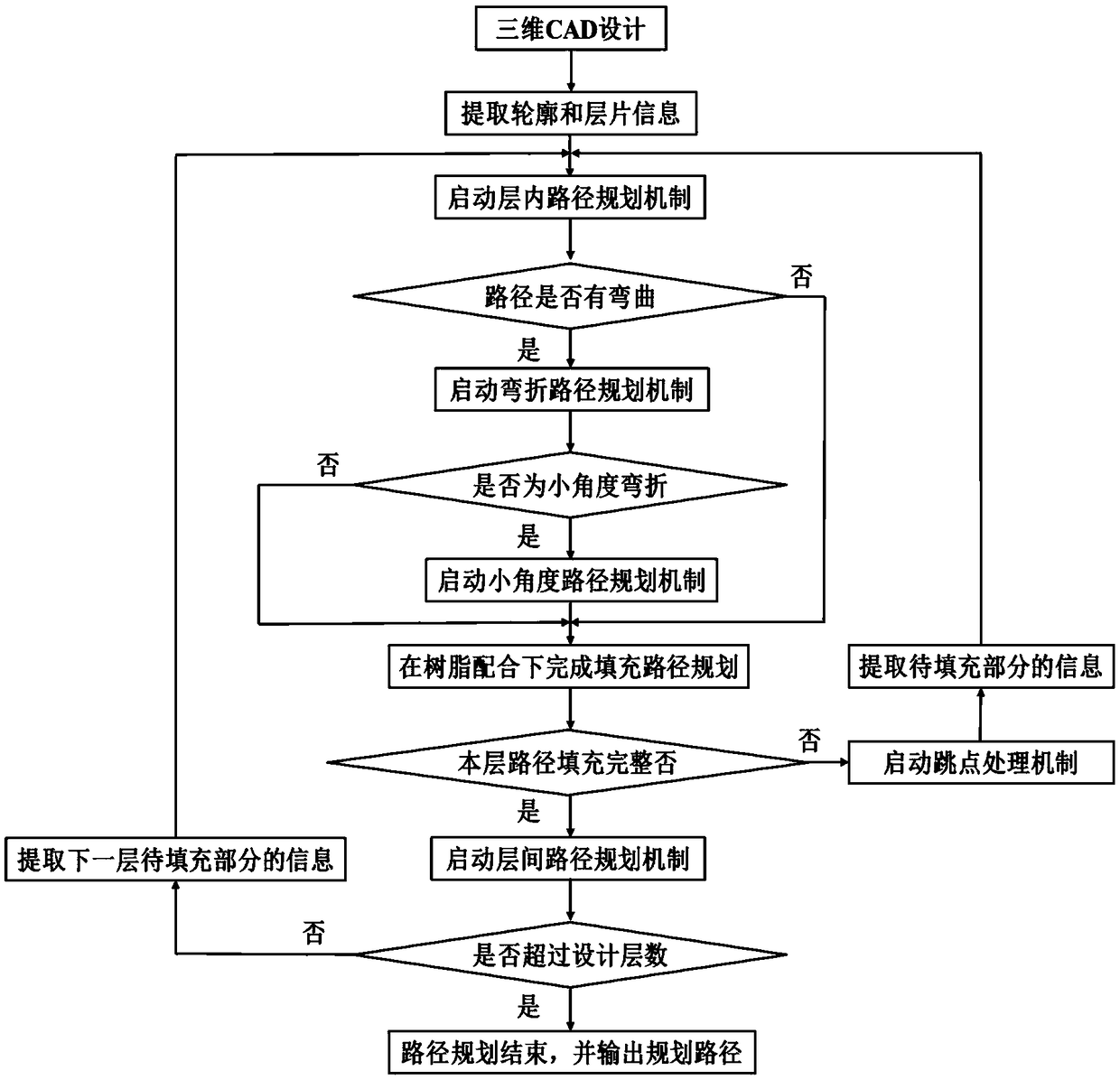

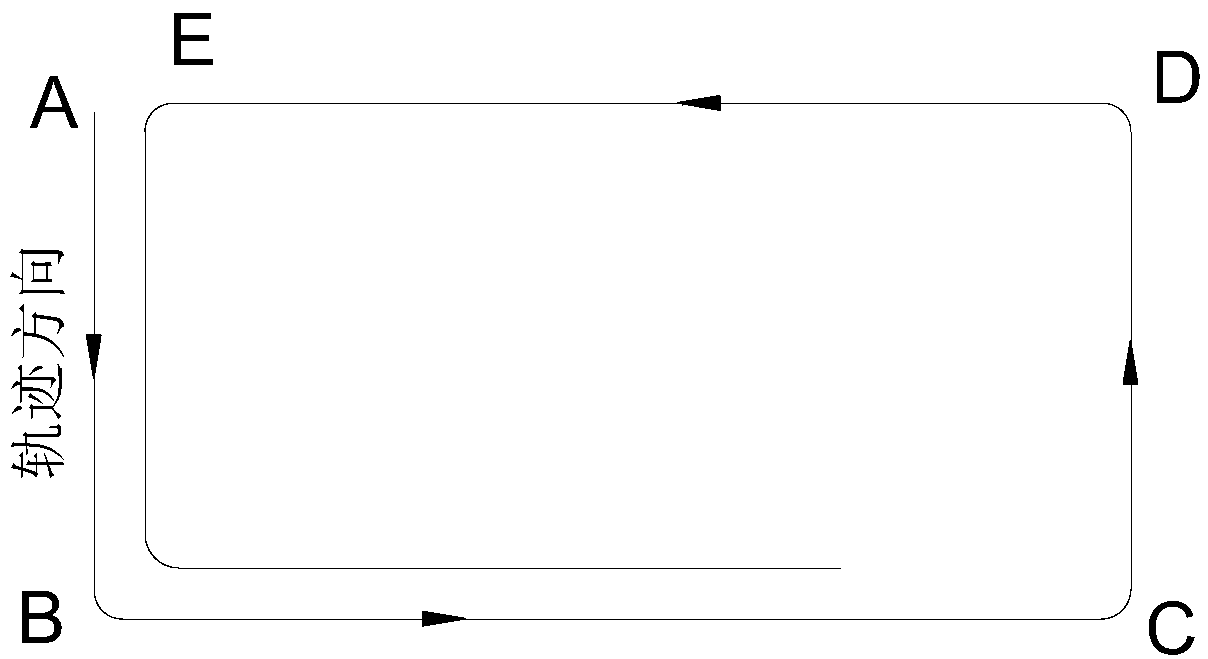

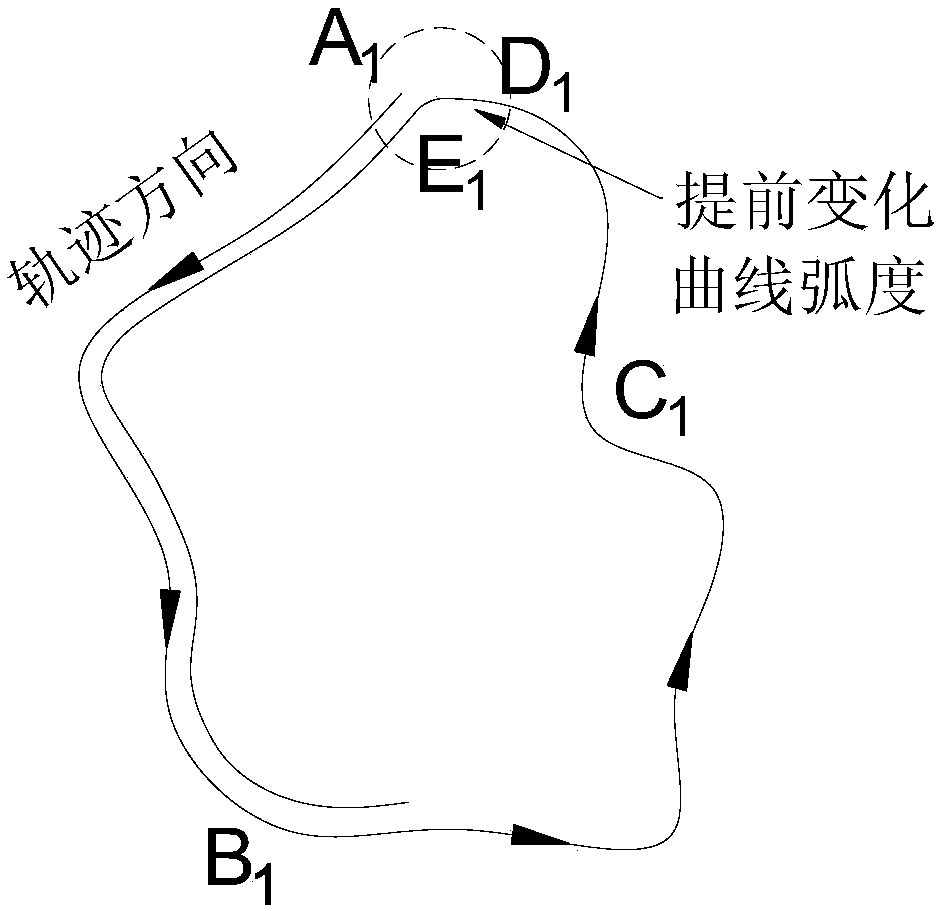

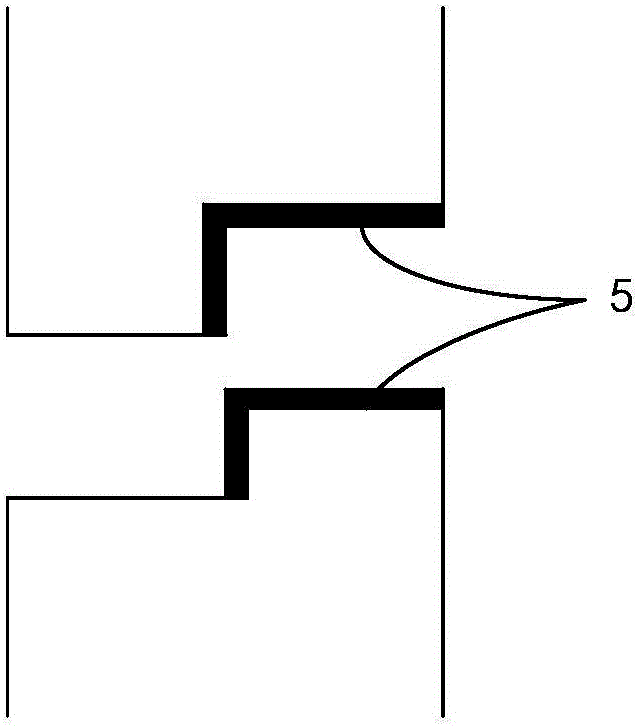

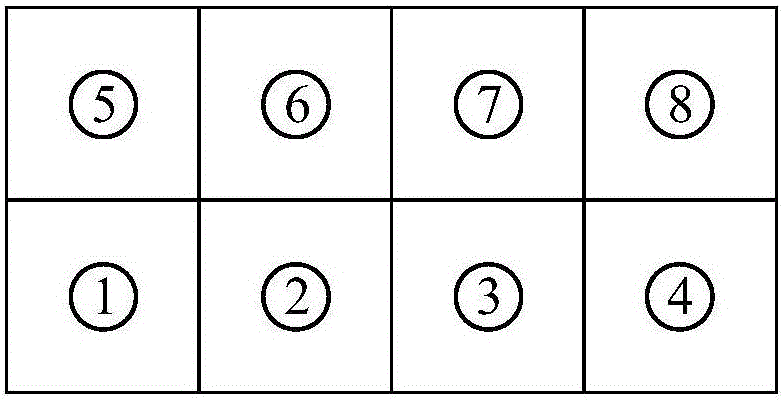

The invention discloses a typical path planning method for 3D (three-dimensional) printing of continuous fiber reinforced composites and belongs to the field of rapid prototyping of the composites. Inthe method, a three-dimensional model is built by using CAD (computer aided design) modeling software according to actual size requirements of forming components and is subjected to slice stratification by the aid of the three-dimensional software to acquire profile and slice information; the degree of path bending is judged and corresponding path planning mechanisms are started, and with the help of the jump point processing mechanism, jump points can be accurately located and the action of the jump points is completed; fiber interlayer conversion without breakpoint is realized by using an interlayer path planning mechanism, and high quality and high efficiency three-dimensional printing new path of the continuous fiber reinforced composites is realized. In the method, the printing pathwith the least breakpoints is planned out, and mechanical property of the continuous fiber reinforced composites is guaranteed; forming defects in the bending of continuous fiber are effectively reduced, binding force of the continuous fiber in the bending is improved, and integral performance of the forming components is improved.

Owner:DALIAN UNIV OF TECH

Telescoped type waterproof sealed wallboard

ActiveCN106193444AGuaranteed waterproof performanceImprove integrityWallsArchitectural engineeringWall plate

Owner:TSINGHUA UNIV

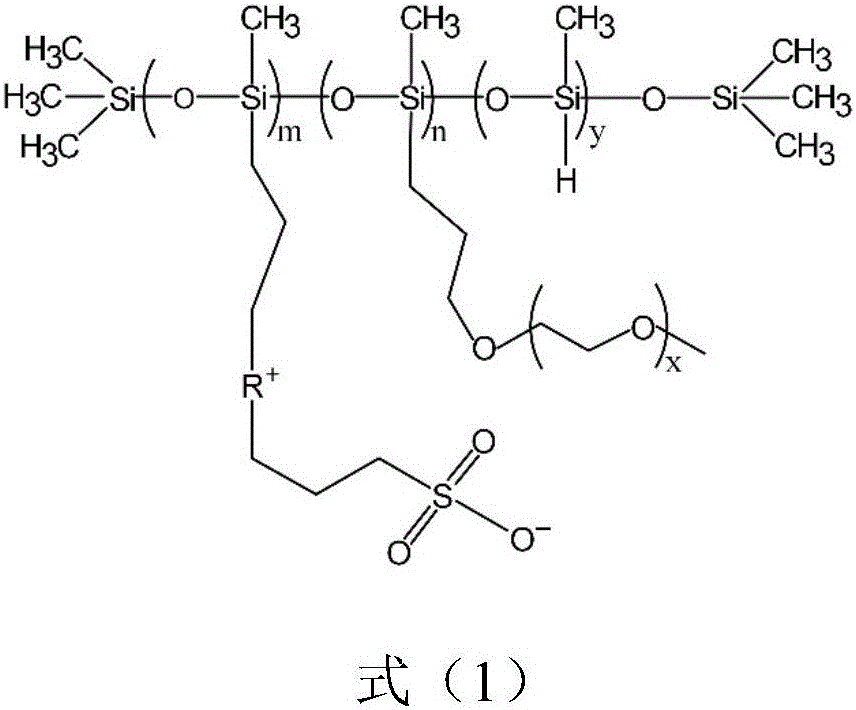

Zwitter-ion-containing all-solid-state polymer electrolyte membrane, and preparation method and use thereof

ActiveCN106549187AImprove chain movement abilityImprove Interface StabilityFinal product manufactureElectrolyte accumulators manufactureCross-linkPolymer science

The invention discloses a zwitter-ion-containing all-solid-state polymer electrolyte membrane, and a preparation method and use thereof. An all-solid-state polymer electrolyte disclosed by the invention is prepared from poly(methyl hydrogen silicomethane), N,N-dimethylallylamine, allyl capped polyether, 1,3-propyl sultone, lithium salt and a cross-linking agent. The preparation method comprises the following steps of: sufficiently mixing PHMS, PEO with DMAA in methylbenzene, and reacting by adding a chloroplatinic acid catalyst; reacting a prepared product with 1,3-PS again; and, mixing the lithium salt and the cross-linking agent in the reacted product in an acetonitrile solvent, crosslinking and forming a membrane in a vacuum oven after sufficiently stirring, and then, obtaining the zwitter-ion-containing all-solid-state polymer electrolyte membrane. The conductivity of the zwitter-ion-containing all-solid-state polymer electrolyte disclosed by the invention is greatly increased; the conductivity is up to 3.39*10<-4>Scm<-1>; an electrochemical window is beyond 5 V; and thus, the zwitter-ion-containing all-solid-state polymer electrolyte can be used for a lithium secondary battery.

Owner:ZHEJIANG UNIV

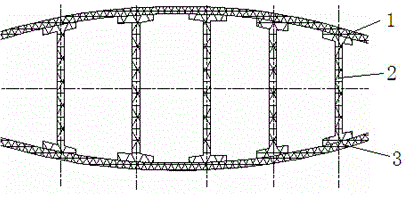

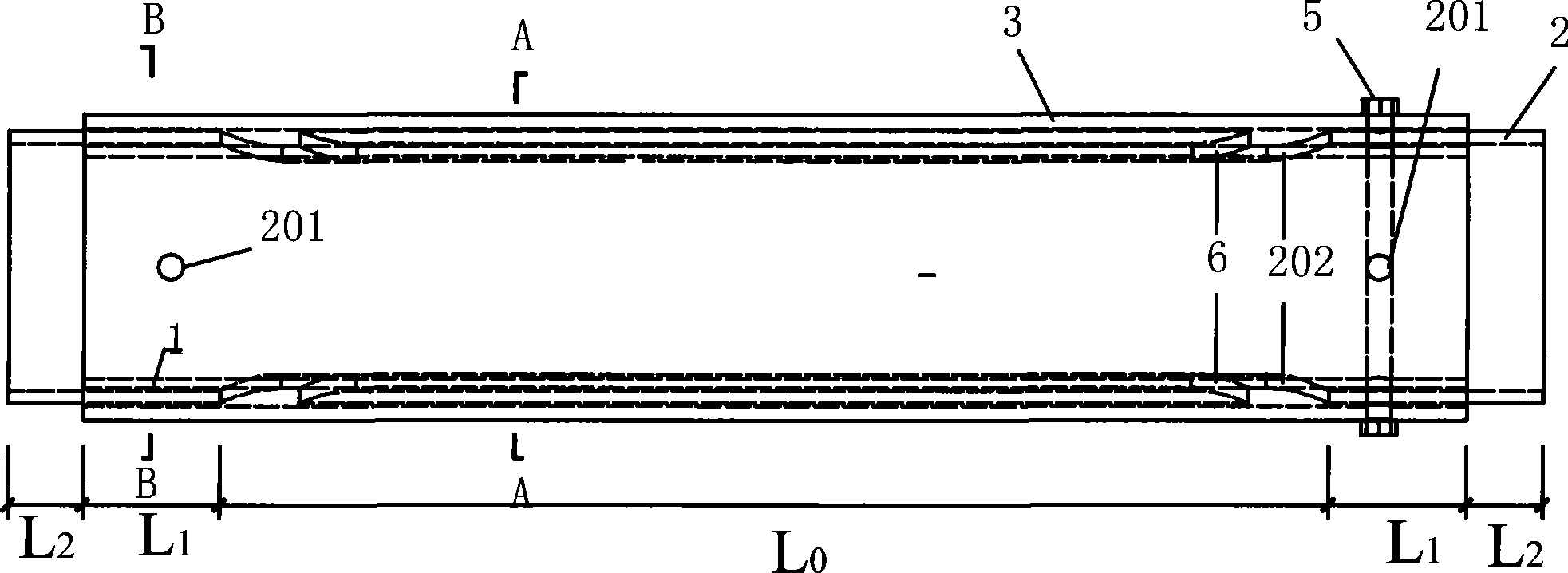

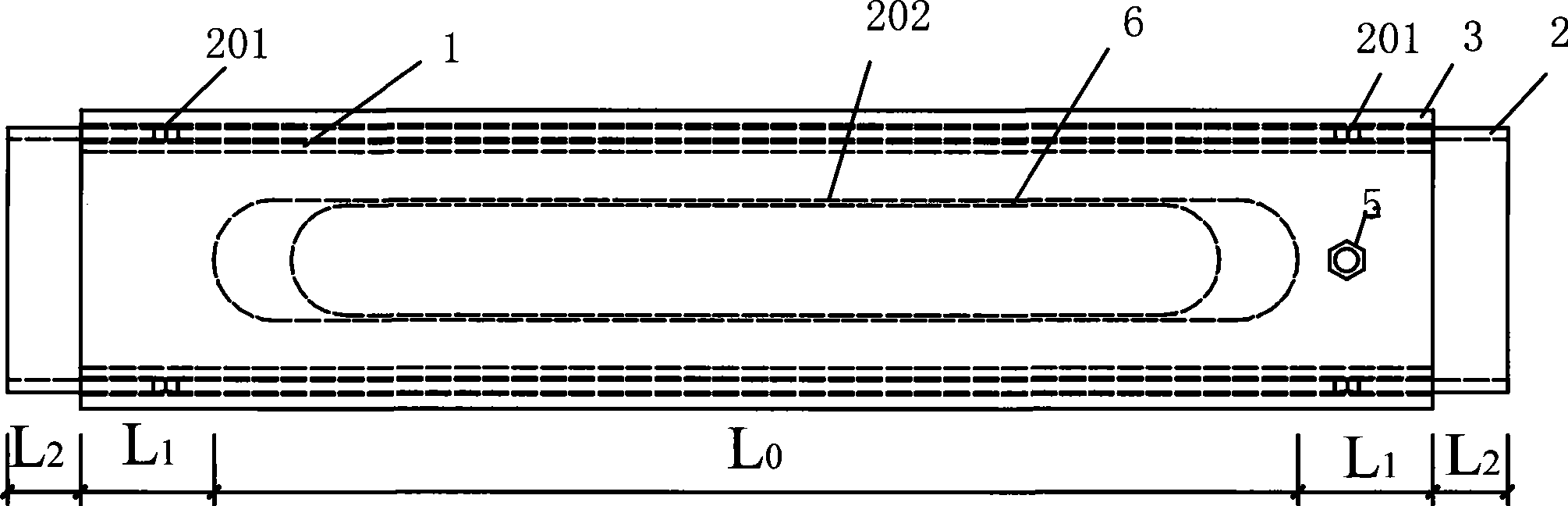

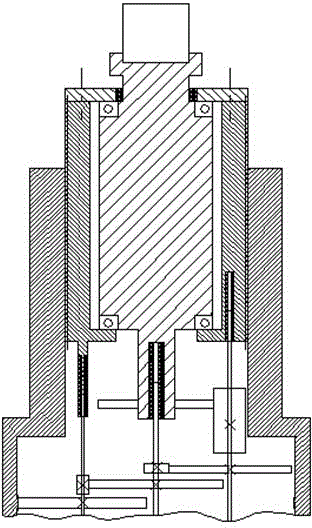

Internal supercharging method for composite material multi-rib siding structure cementing forming technology

The invention discloses an internal supercharging method for a composite material multi-rib siding structure cementing forming technology. A multi-rib siding structure includes an upper skin siding (1), wall bodies (2) and a lower skin siding (3), wherein the wall bodies (2) are cemented with the upper skin siding (1) and the lower skin siding (3) through a double faced gel mold (4) secondary cementing forming technology, and the multi-rib siding structure is characterized in that metal core molds (5) are arranged at the inner cavities of the wall body (2) sides of the multi-rib siding structure; a layer of 3 mm thick silicone rubber plate (6) formed after high temperature sulfuration is laid on each of the lower mold surfaces of the metal core molds (5); a layer of 6 mm thick swelled rubber plate (7) is laid on each of the upper mold surfaces of the metal core molds (5); after all the inner cavities of the wall body (2) sides of the multi-rib siding structure are subjected to the processes, entire heating is performed, when the temperature rises, the swelled rubber plates (7) swell to press flange areas of the wall bodies (2) to enable the wall bodies (2) to be glued to the upper skin siding (1) and the lower skin siding (3) in a clinging manner, and finally demoulding is performed after natural cooling and solidification of gel molds. According to the method, as the pressed assembly is adopted, all the wall body parts are accurately supported, as a result, the outline requirement of the cementing parts is met and the cementing quality is guaranteed.

Owner:JIANGXI HONGDU AVIATION IND GRP

Porous polylactic acid material for scaffold for tissue engineering and preparation method thereof

InactiveCN107670108AMeet special shape requirementsMeet shape requirementsPharmaceutical delivery mechanismProsthesisPorosityBiocompatibility Testing

The invention belongs to the field of polymer material processing and biomedicine and relates to a porous polylactic acid material for a scaffold for tissue engineering and a preparation method thereof. The preparation method of the porous polylactic acid material for the scaffold for tissue engineering comprises the steps that poly-L-lactic acid, poly-D-lactic acid and a pore-foaming agent are prepared into a polylactic acid steric blend through a solution casting method; the pore-foaming agent in the polylactic acid steric blend is removed, and then the porous polylactic acid material for the scaffold for tissue engineering is obtained through drying. The mass ratio of the poly-L-lactic acid to the poly-D-lactic acid is 1:9 to 9:1, the mass ratio of polylactic acid to the pore-foaming agent is 1:6 to 1:2, and the polylactic acid contains the poly-L-lactic acid and the poly-D-lactic acid. The obtained porous polylactic acid material for the scaffold for tissue engineering has highly controllable pore structure and pore size and very high aperture ratio, the porosity of the scaffold is 70-82%, and energy storage modulus can be up to 630-3327 MPa at the temperature of 37 DEG C. In addition, the porous polylactic acid material has very good biocompatibility.

Owner:SICHUAN UNIV

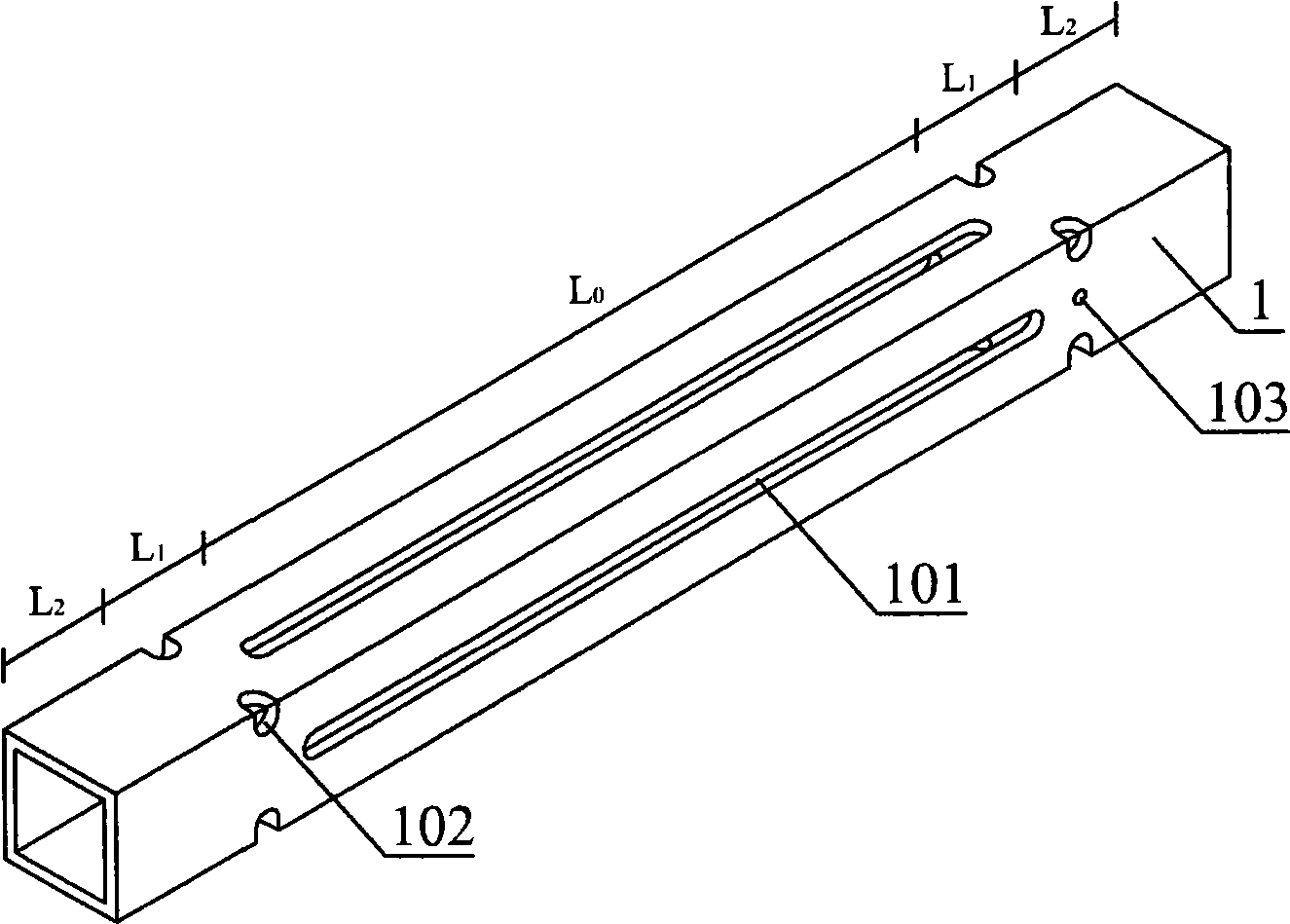

Triple-level metal rectangular pipe flection restriction support energy-dissipation device

InactiveCN101509282ASimple structureEasy to manufactureShock proofingBuckling-restrained braceEngineering

The invention relates to a triple metal rectangular pipe bending restricting supporting energy consumer. A core stressed member consists of a core stressed rectangular pipe (1), an inner restricting rectangular pipe (2) and an outer restricting rectangular pipe (3), wherein, the core stressed rectangular pipe (1) is arranged between the inner restricting rectangular pipe (2) and the outer restricting rectangular pipe (3), and the length thereof is larger than the length of the inner restricting rectangular pipe (2) and the outer restricting rectangular pipe (3); pilot pins (4) are used to fix one end of the core stressed rectangular pipe (1), the inner restricting rectangular pipe (2) and the outer restricting rectangular pipe (3); in the middle part of the core stressed rectangular pipe (1), 4 long grooves (4) are arranged along the periphery of the pipe with equal distance; stream guidance holes (102) are arranged on the core stressed rectangular pipe (1). The inner and outer rectangular pipes restrict local bending of the core stressed rectangular pipe and provide bending rigidity for preventing the overall bending of the energy consumer; the pilot pins are used to fix the relative position between the triple metal rectangular pipes.

Owner:SOUTHEAST UNIV

FRP (fiber reinforced plastic) rib preparation method and FRP rib prepared thereby

ActiveCN102233669AImprove performanceLow high temperature degradation rateExcavationsBulkheads/pilesFiberMolten state

The invention discloses an FRP (fiber reinforced plastic) rib preparation method. The preparation method solves the technical problems that in the prior art, the requirement for the equipment is high, the energy consumption is large, the production cost is high and the resins are in a high-temperature molten state for a long time to cause serious degradation and the like due to adoption of the process of dipping thermoplastic resins when the FRP rib is prepared. In order to solve the technical problems, the adopted technical scheme comprises the following steps of: taking thermoplastic resin fibers and inorganic reinforcing fibers as raw materials, and then carrying out the steps of drying, bundling, winding, drawing, preforming, forming, cooling, curing and cutting and the like. The adopted technical scheme has the advantages that the preparation process is simple, the energy consumption is less and the production cost is low. The invention also provides the FRP rib prepared by the method, and can be rapidly and widely applied in various engineering.

Owner:SHANGHAI KNP CHEM +1

Light triple-heavy metal circular tube flexion restriction support energy dissipating machine

InactiveCN101413298ASimple structureEasy to makeShock proofingBuckling-restrained braceFlexural rigidity

The invention relates to a light buckling-restrained brace energy dissipation device with triple metal circular tubes, which consists of a core stressed tube, buckling-restrained tubes, pilot pins and end part connecting pieces. The core stressed tube is made of a metal material with lower yield strength and good tensility, the end part section thereof is reinforced through opening a groove in the middle part to ensure that the end part section is in a flexible stressed state in the whole stressing process and is positioned between a buckling-restrained inner tube and a buckling-restrained outer tube; the buckling-restrained tube consists of an inner restraining tube, an outer restraining tube and a filling-in board, the inner and outer restraining tubes limit the core stressed tube to flex along a radial part and provide the flexural rigidity for preventing the energy dissipation device from flexing integrally; the filling-in board is axially connected with the inner tube along a brace and has considerable flexural rigidity to limit the movement of a yield section of the core tube along a tangent direction; and the pilot pins are used for fixing the relative positions of the triple metal circular tubes.

Owner:SOUTHEAST UNIV

Printed circuit board (PCB) processing method

ActiveCN102365005AEnsure functional integrityGuaranteed integrityMultilayer circuit manufactureEngineeringSilica gel

The invention relates to a printed circuit board (PCB) processing method. The method comprises the following steps: providing a first laminate; providing a second laminate which comprises a plurality of holes and placing the second laminate on a first laminate surface, wherein the hole can correspondingly form a concave structure after the second laminate is placed on the first laminate surface; isolation films are placed on an upper surface of the second laminate and an inner wall of the concave structure; filling a filler in the holes; a high temperature silicon sheet is placed on the uppersurface of the second laminate; providing hot-pressing equipment and carrying out hot-pressing processing to the hot-pressing equipment, the first laminate, the isolation films and the second laminate; removing the high temperature silicon sheet, the filler and the isolation films so as to form a multilayer board with the concave structure. By using the PCB processing method of the invention, thefiller and high temperature silica gel are isolated with the holes of the second laminate through the isolation films so that a bonding sheet or the high temperature silica gel can be prevented from infiltrating into the holes during a hot-pressing process and hole function completeness can be ensured. The high temperature silica gel can be recycled and production costs can be saved.

Owner:SHENZHEN WUZHU TECH +1

Processing technology and equipment for steel integral heterotype oil control ring wire rod moulding

ActiveCN104028575AGuaranteed accuracy requirementsGuaranteed dimensional accuracy requirementsWire rodCombustion

The invention relates to a manufacturing method of a steel integral heterotype oil control ring wire rod. The method includes: (1) selecting a round steel wire raw material; (2) rolling, namely, rolling a steel wire rod into a rectangular cross-section shape; (3) annealing, namely, subjecting the rolled wire rod to annealing, rolling and annealing again; (4) rolling a heterotype wire rod, namely, subjecting the wire rod to steps of pre-moulding, primary-moulding and refined moulding, and rolling to obtain a needed heterotype cross-section shape; (5) annealing, namely, subjecting the pre-moulded and primarily-moulded heterotype wire rod to annealing and rolling respectively; (6) quenching and tempering, namely, subjecting the heterotype wire rod after refined moulding to quenching and tempering treatment; and (7) performing laser drilling, namely, subjecting the wire rod after quenching tempering and moulding to oil return hole laser cutting so as to obtain the steel integral heterotype oil control ring wire rod. The method has characteristics of high machining precision, low cost, high yield of finished products, good product shape, high dimension precision and good quality, and can be used for manufacturing oil control rings of piston rings of internal combustion engines, thus meeting the technical requirements of the piston rings of the internal combustion engines.

Owner:福建东亚机械有限公司

Plasma etching method

ActiveCN1886824AInhibition of sharpeningInhibit side etchSemiconductor/solid-state device manufacturingHigh frequency powerMixed gas

A plasma etching method for forming a trench having a side wall of smooth shape while simultaneously satisfying the requirement of the shape of the trench and the requirement of the aspect ratio. A silicon substrate is placed on a lower electrode (120). An etching gas is supplied through a gas introducing port. Exhaustion through an exhaust port (150) is performed. High-frequency power is fed to an upper electrode (110) and the lower electrode (120) from the high-frequency power supplies (130a, 130b) so as to change the etching gas into a plasma by an ICP method and to produce active species. Thus, the silicon substrate is etched. The etching gas is a mixture gas composed mainly of SF6 gas and additionally O2 gas and He gas.

Owner:PANASONIC CORP

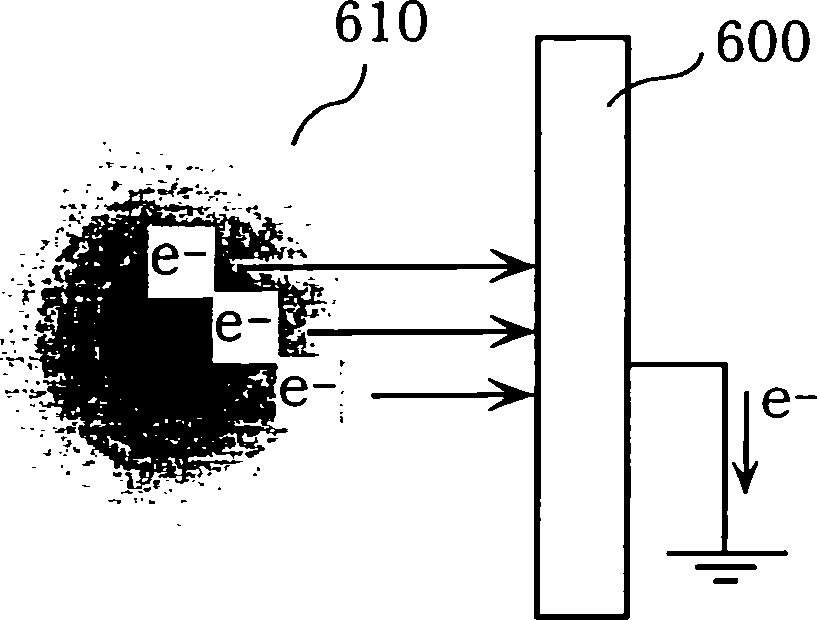

Method for preparing electric vacuum suction element molded by powder injection

ActiveCN101290851AMeet shape requirementsMeet the dimensional accuracy requirementsElectric discharge tubesTube/lamp vessel degassingElectricityPorosity

The invention provides a method for preparing an electric vacuum inspiration element by using powder injection molding, which belongs to the electric vacuum inspiration element manufacturing technical field. The preparation technology is as follows: Ti powder and Mo powder taken as raw materials are mixed in a mixer, the evenly-mixed raw material powder and adhesive are mixed according to the volume ratio, mixed in a mixing roll, cooled, then crushed into injection feedstock, and subject to the injection molding, two-step debinding process treatment is adopted to a blank formed by the injection molding, the blank formed by the injection molding undergoes solvent debinding and vacuum thermal debinding then, and finally vacuum sintering is carried out to the debound blank to prepare the vacuum inspiration element. The method has the advantages that: the method can prepare the inspiration elements with complicated shape and high dimension accuracy to meet the requirement of spaces with various shapes of various electric vacuum devices to the complicated shape and the dimension accuracy of the inspiration elements. The aperture and the degree of porosity of the product are evenly controlled, and the degree of porosity of the inspiration element can reach more than 50 percent.

Owner:GRIMAT ENG INST CO LTD

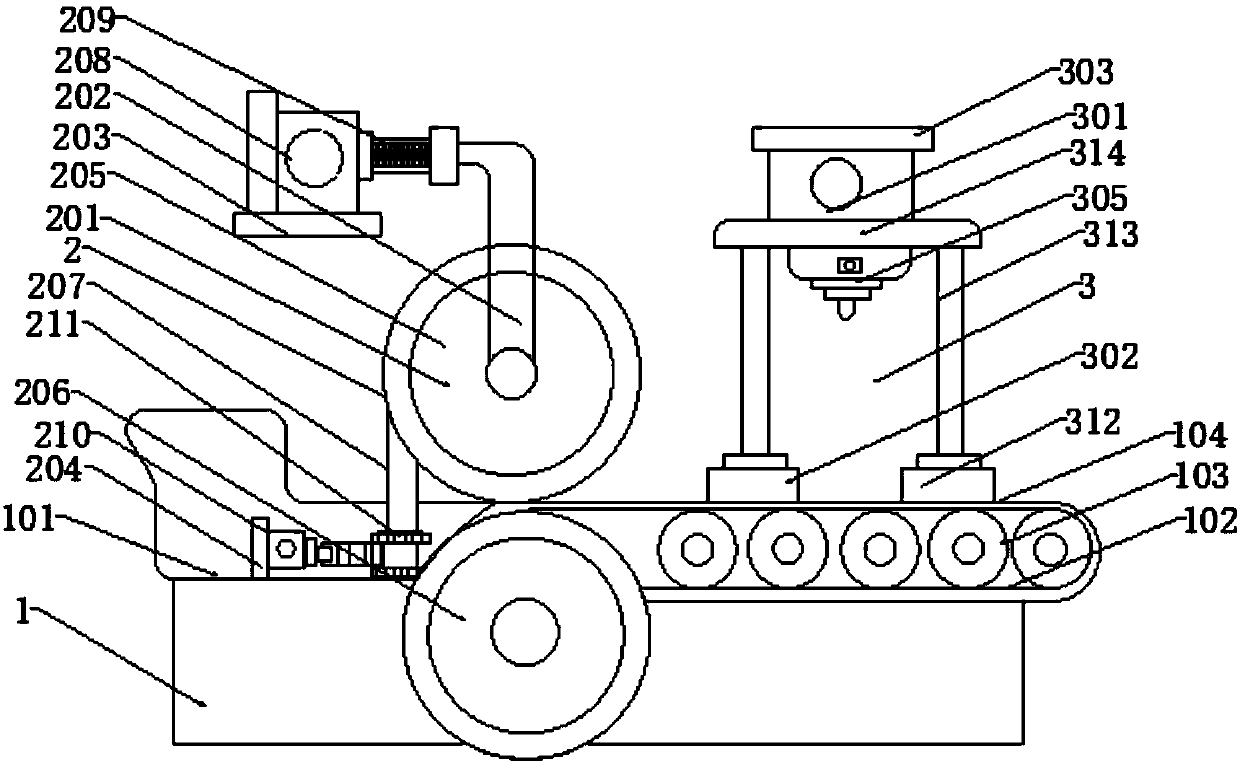

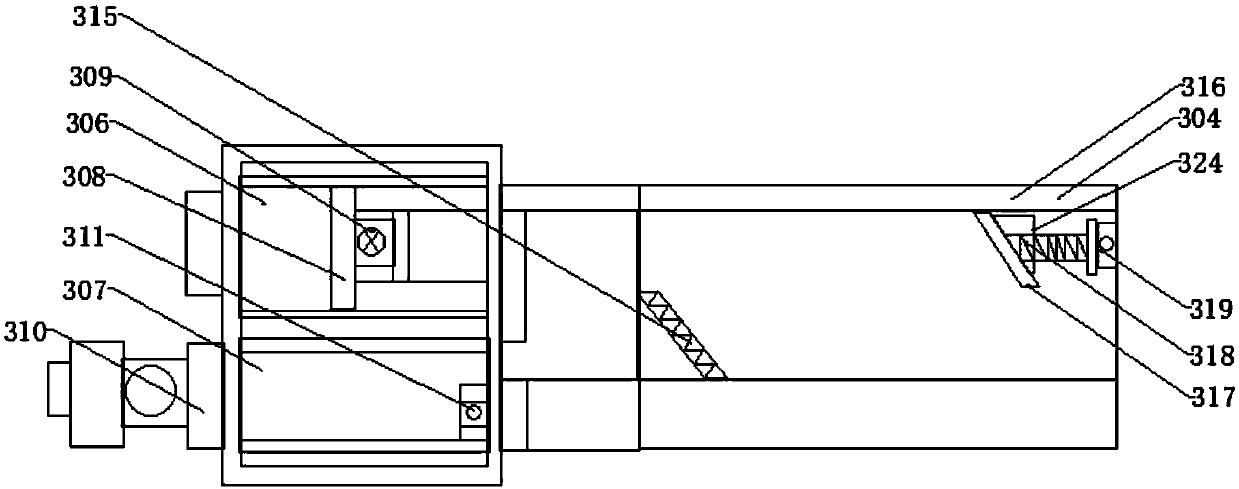

Calendering and directional cutting integrated equipment for automobile plates

ActiveCN108672949ARealization of automatic calenderingAchieve regulationLaser beam welding apparatusLight guideLaser cutting

The invention discloses calendering and directional cutting integrated equipment for automobile plates. The equipment comprises an automatic feeding mechanism, an automatic calendering mechanism and adirectional cutting mechanism. The automatic calendering mechanism comprises a hedging calendering roller, a curved bar connection shaft is connected with the center of a roller shaft of the hedgingcalendering roller in a penetrating mode, the other end of the curved bar connection shaft is connected with a pressing roller adjusting system, the side edge of the hedging calendering roller is further provided with a roller drum position adjusting device, the directional cutting device comprises a laser cutting system and an omni-directional supporting mechanism, the laser cutting system comprises a laser generator used for producing cutting laser light, a laser beam outlet of the laser generator is connected with a sealed light guide pipe used for stably transmitting light, and an output port of the sealed light guide pipe is connected with a laser cutting head. Calendering stretching and directional cutting operation for the automobile plates can be achieved, the good automatic adjusting function is achieved, the requirements of different plates are met, machining precision is high, and cutting in complex shapes can be achieved.

Owner:芜湖众梦电子科技有限公司

Construction method of vibration pressing type special-shaped multi-head bottom expanding pile

InactiveCN107794918AShorten the processing cycleFlexible manufacturing processBulkheads/pilesExtrusionBuilding construction

The invention discloses a construction method of a vibration pressing type special-shaped multi-head bottom expanding pile. The method comprises the steps that a, a sinking pipe is subject to vibration pressing, and a pile hole is formed; b, an inner casing pipe is pulled up, concrete is poured in, forced extrusion is carried out, an outer casing pipe is pulled up synchronously, and an expansion head is formed; c, after first-time bottom expanding, a pile driver is adopted to synchronously sink the inner casing pipe and the outer casing pipe, forced concrete extrusion is carried out again, second-time bottom expanding is carried out, and a final pile bottom expansion head is formed; d, after second-time bottom expanding construction is finished, the inner casing pipe is pulled up, concretefor forming a pile main body of the pile body is poured into the outer casing pipe, the pile driver is adopted to carry out sinking pipe vibration pressing on the inner casing pipe, the outer casingpipe is pulled up synchronously, concrete is extruded, and the pile main body is formed; e, when the pile main body is constructed to the preset position, the concrete on the preset position is subject to forced vibration pressing, and the pile main body is subject to radial expansion; f, after the pile main body expansion head is formed, concrete is poured into the outer casing pipe, the sinkingpipe is subject to vibration pressing, concrete is extruded, and the pile main body is formed; g, a steel reinforcement cage is inserted in the concrete.

Owner:JIANGXI JIYE SCI & TECH

Sensor injection-moulding technology

The invention discloses a sensor injection-moulding technology. A secondary injection-moulding method is adopted; in the first injection moulding, a sensor electronic element is coated by a thermosetting material; and in the second injection moulding, the semi-finished product obtained from the first injection moulding is subjected to second injection moulding by using a thermoplastic material. A secondary injection-moulding technology combining the thermosetting material with the thermoplastic material is utilized, and the sensor electronic element is coated by the thermosetting material, so that the purpose of protecting a PCB (printed circuit board) and the electronic element is achieved; the thermoplastic material is used for conducting second injection moulding, so that the purposes of coating the thermosetting material and meeting the appearance requirement are achieved, the usage amount of moulds can be reduced and the cost is lowered.

Owner:HAMLIN ELECTRONIC (SUZHOU) CO LTD

End mill and method for milling compressor scroll by using the same

InactiveCN102837053AImprove quality requirementsAvoid problemsMilling cuttersMilling equipment detailsHexagonal boron nitrideMilling cutter

The present invention relates to an end mill, which comprises a cutter body and cutter teeth, and is characterized in that the cutter teeth are multiple blade helix blade, and the hard alloy blade and the polycrystalline hexagonal boron nitride blade are arranged at intervals, such that a side wall and a bottom surface of a workpiece can be simultaneously milled. During a production process, with the end mill of the present invention, production cost can be reduced, and products with excellent quality can be obtained. The present invention further provides a method for milling a compressor scroll part by using the end mill. The method mainly comprises the following steps: adopting a corrugated rough milling cutter to carry out semi-finish milling on a machined compressor scroll part; adopting the end mill to carry out finish milling on the semi-finish milled compressor scroll part; and completing a milling process of the compressor scroll part.

Owner:DANFOSS (TIANJIN) CO LTD

Device and method for preparing high-melting-point alloy powder through electric arc

ActiveCN113145855ALow costEasy to implementAdditive manufacturing apparatusTransportation and packagingElectric arcTungsten electrode

The invention relates to the technical field of preparation of alloy powder, in particular to a device and method for preparing high-melting-point alloy powder through a high-temperature electric arc. The device comprises a powder collecting device, a consumable electrode and a non-consumable electrode, wherein the consumable electrode and the non-consumable electrode are used for generating electric arcs and are both inserted into an opening of the collecting device, a metal wire passes through the consumable electrode, a tungsten electrode is arranged in the non-consumable electrode, the metal wire passing through the consumable electrode is connected to a positive electrode of an arc generating power supply, a tungsten electrode is connected to a negative electrode of the arc generating power supply, an arc arches between the metal wire and the tungsten electrode, an atomizing spray pipe is arranged on one side of the electric arc, high-speed gas sprayed out of the atomizing spray pipe is directly sprayed to molten drops formed by combustion of the electric arc, bypass side blowing is carried out, the molten drops are further finely atomized, and a wire feeding device is used for conveying metal wires into the consumable electrode. The alloy powder prepared by the preparation method can meet the shape requirement of spherical powder, the particle size distribution of the powder is adjusted according to the current, the powder making efficiency is high, and the types of the prepared powder are flexible.

Owner:SHANDONG UNIV

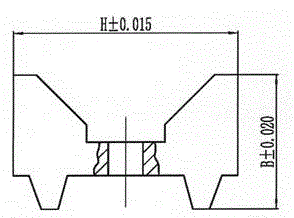

Drawing die for rectangular flat steel tube

The invention discloses a drawing die for a rectangular flat steel tube, which does not need to be corrected after heat treatment and can ensure the precision and surface flatness of the rectangular flat steel tube. The drawing die comprises a die body, wherein a drawhole of the drawing die comprises an inlet section, a transition section and a sizing section, and the sizing section comprises a pair of straight short surfaces, a pair of arc long surfaces and four corner arc surfaces which connect the straight short surfaces with the arc long surfaces; the transition section comprises four transition inclined planes which are joined with the straight short surfaces and the arc long surfaces and four transition corner curved surfaces which connect the two adjacent transition inclined planes; and the inlet section comprises four leading-in curved surfaces which are respectively joined with the corresponding transition inclined planes and protrude outwards and inlet corner curved surfaces which connect the two adjacent leading-in curved surfaces, the four leading-in curved surfaces are all quadric surfaces, and the opposite leading-in curved surfaces are symmetrically distributed. The drawing die is used for drawing a circular steel tube to form the rectangular steel tube.

Owner:JIANGSU HUACHENG IND PIPES

Magnesium alloy composite forming method

InactiveCN1593809AMeet shape requirementsMeet strength requirementsMetal-working apparatusMechanical propertySingle step

The invention relates to a kind of method of compound forming magnesium alloy. The method can produce the casting blank with only one step through suitable mould. Fist, heat the mould and the casting blank for about 10 to 30 minutes to 300 to 500 DEG C. With that temperature, form the casting blank at transfiguring speed of 300-900 mm / min, so as to produce the product with single step. The invention has good forming technique and low cost, meanwhile maintains the good quality and automatism of mould. The technique has advantages such as good quality, low cost, high efficiency, high yield and so on. And the magnesium alloy product produced has excellent all-round performance.

Owner:CHONGQING UNIV

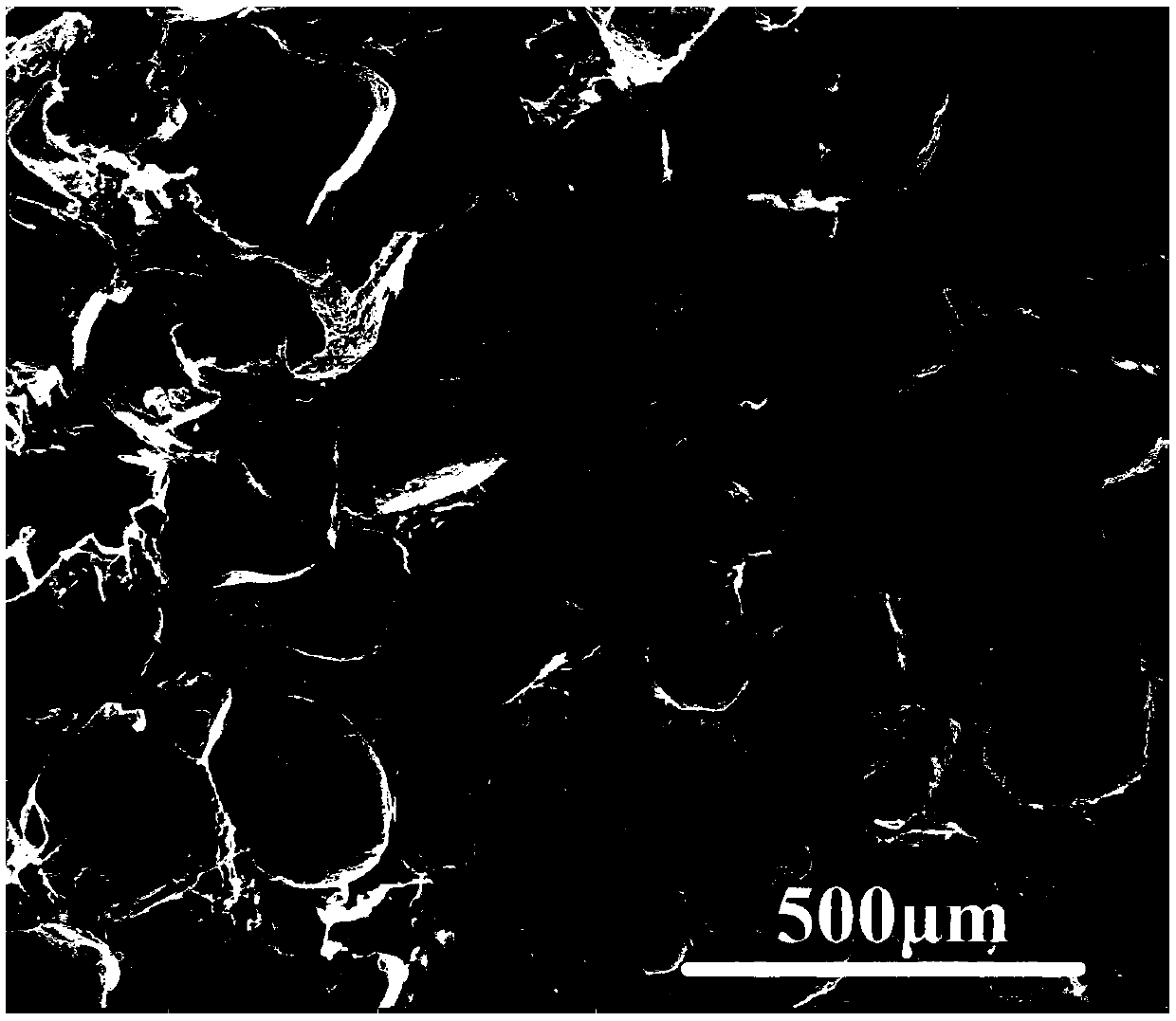

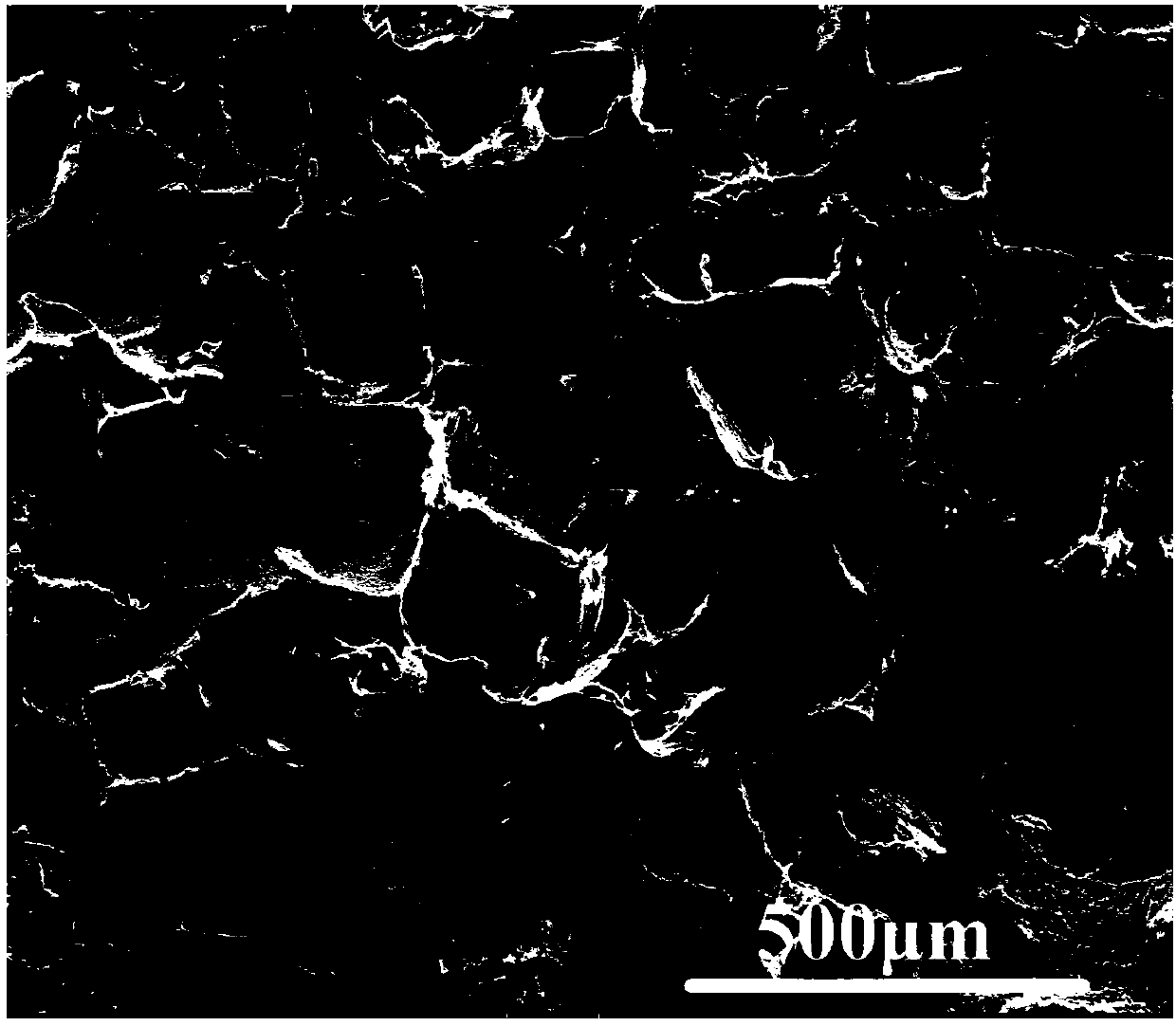

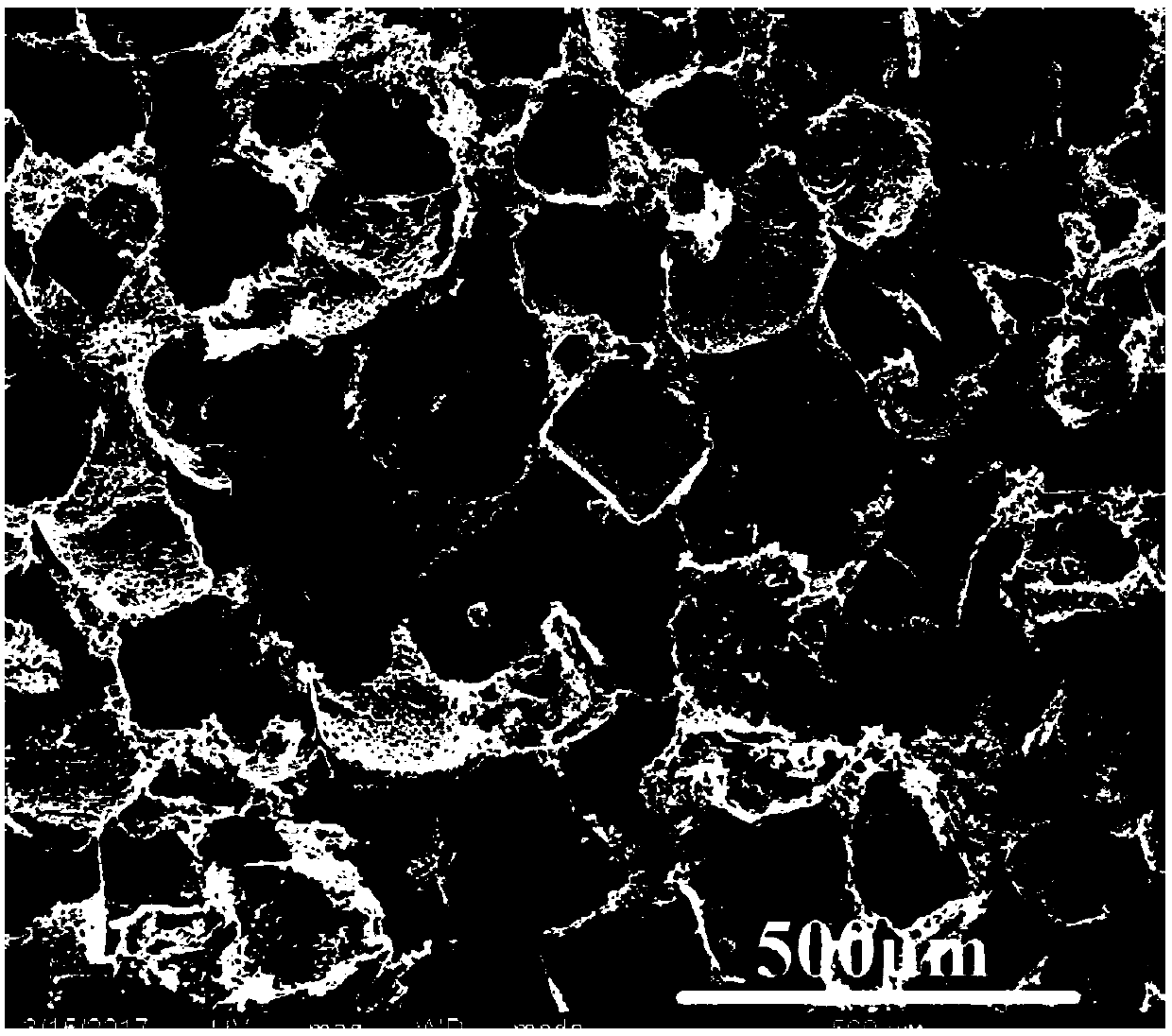

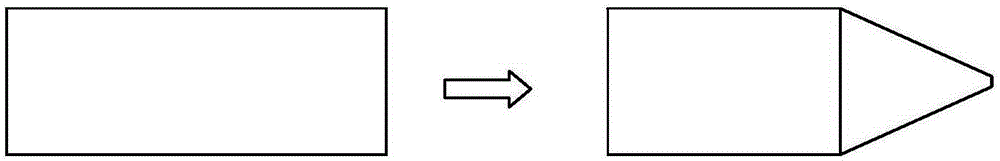

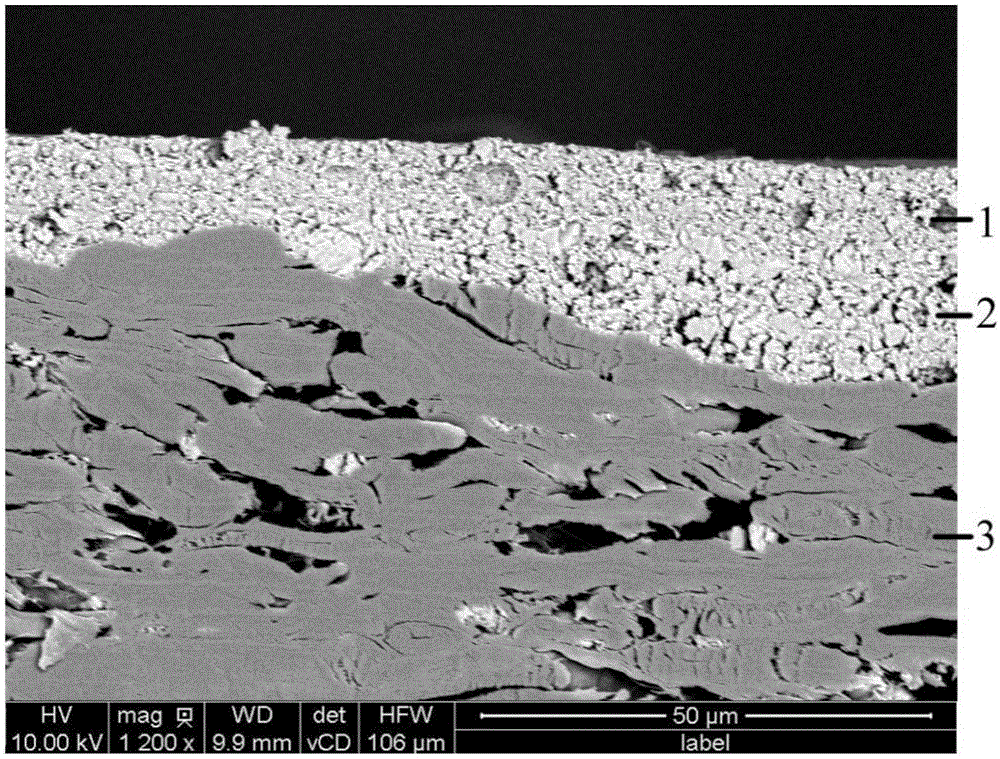

Scanning electron microscopy sample production method of coated white cardboard fracture

InactiveCN106442032AImprove flatnessReduce distortionPreparing sample for investigationCardboardScanning electron microscope

The invention provides a scanning electron microscopy sample production method of a coated white cardboard fracture. The method comprises the following steps: shearing a coated white cardboard to form a long strip, wherein one end of the long strip along the length direction is sharp-pointed, and the width of the tip is less than or equal to 0.5 mm; and slicing the tip of the long strip through adopting a mechanically propelled ultrathin slicing machine by using a diamond cutter at a slicing rate of below 0.5 mm / sec in order to obtain the coated white cardboard fracture. The coated white cardboard fracture produced by using the method is clean and flat without pollutant shielding, so the clear coated white cardboard fracture microscopic picture of the sample fracture is obtained, and analysis test of the thickness of a white cardboard coating and the particle size and the shape of particles is realized by using a scanning electron microscope.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Battery cell assembly for soft package button lithium ion battery and button battery

PendingCN111261926AMeet shape requirementsTaking into account battery life requirementsFinal product manufactureSecondary cellsPhysicsEngineering

The invention discloses a battery cell assembly for a soft package button lithium ion battery. The battery cell assembly comprises a positive plate, a negative plate, a positive tab, a negative tab and a diaphragm, wherein the positive plate and the negative plate are laminated and then wound into a cylindrical battery cell, and the diaphragm is arranged between the positive plate and the negativeplate; the cylindrical battery cell is provided with a bottom surface, a top surface and side surfaces, and the bottom surface or the top surface is in the shape of an axial section of a capsule; thelength of the bottom surface is within 20mm, and the width of the bottom surface is less than the length; the height of the side surface is within 10mm; the positive tab is fixedly connected to the positive plate, and the negative tab is fixedly connected to the negative plate. By using the cylindrical battery cell, a capsule-shaped soft package button lithium ion battery of which the appearanceis similar to that of a common medicine capsule can be prepared; the shape requirement of the continuously developed Bluetooth mobile equipment for the battery can be met, and the electricity storagecapacity equivalent to that of a button battery of a common cylinder specification can be provided at the same time, so that the endurance time requirement of the Bluetooth mobile equipment is also considered.

Owner:惠州市竤泰科技有限公司

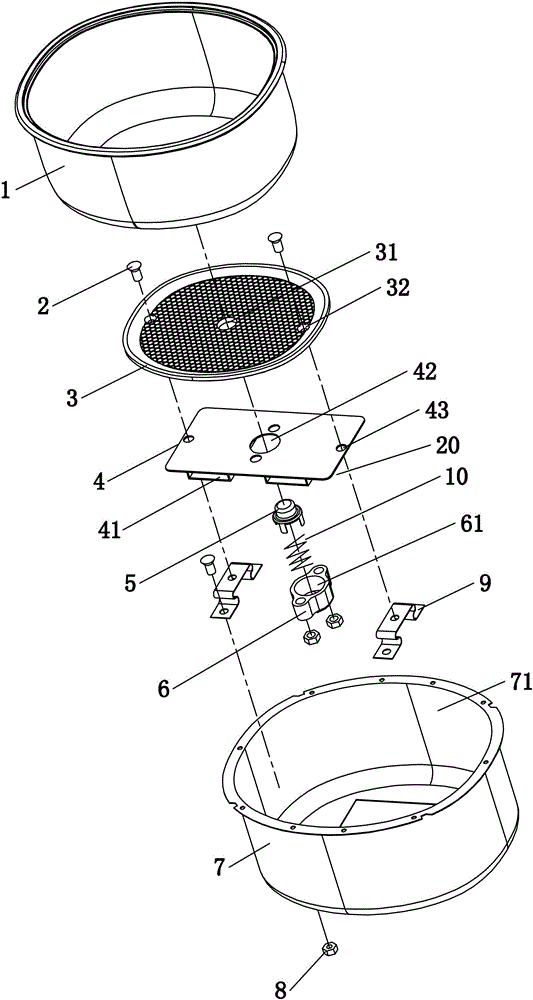

Heating body elastic supporting structure of mini electric cooker

InactiveCN105105619AChange horizontal positionPrevent easy lossWarming devicesElastomerHeat conducting

The invention relates to a heating body elastic supporting structure of a mini electric cooker. The heating body elastic supporting structure comprises an outer pot, an inner pot and an electric heating device. A middle layer is arranged in the outer pot and provided with an inner cavity. The electric heating device comprises a heat conducting tray and an electric heating body. The electric heating body is connected to the bottom of the heat conducting tray. The heating body elastic supporting structure is characterized in that the electric heating device is arranged at the lower portion of the inner cavity of the middle layer through a sheet elastic body, gaps are reserved between the electric heating device and the bottom wall of the inner cavity of the middle layer and between the electric heating device and the side wall of the inner cavity of the middle layer, the sheet elastic body is integrally formed by a bearing face, a supporting face and an elastic face, the bearing face and the supporting face are vertically staggered, the bearing face is connected with the electric heating body, the supporting face is connected with the middle layer, the elastic face is connected between the bearing face and the supporting face, and an inner container is arranged in the inner cavity of the middle layer and makes elastic contact with the heat conducting tray. The electric heating device of the mini electric cooker of the structure is supported by the sheet elastic body stably and reliably, so that it is guaranteed that the electric heating body makes contact with the inner container well, and the heat transfer effect is good.

Owner:何志雄

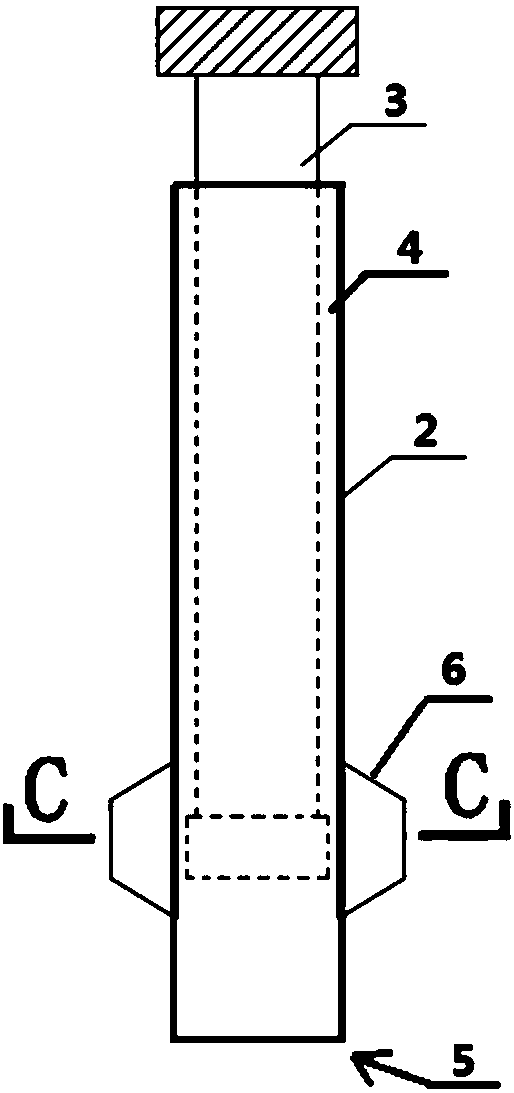

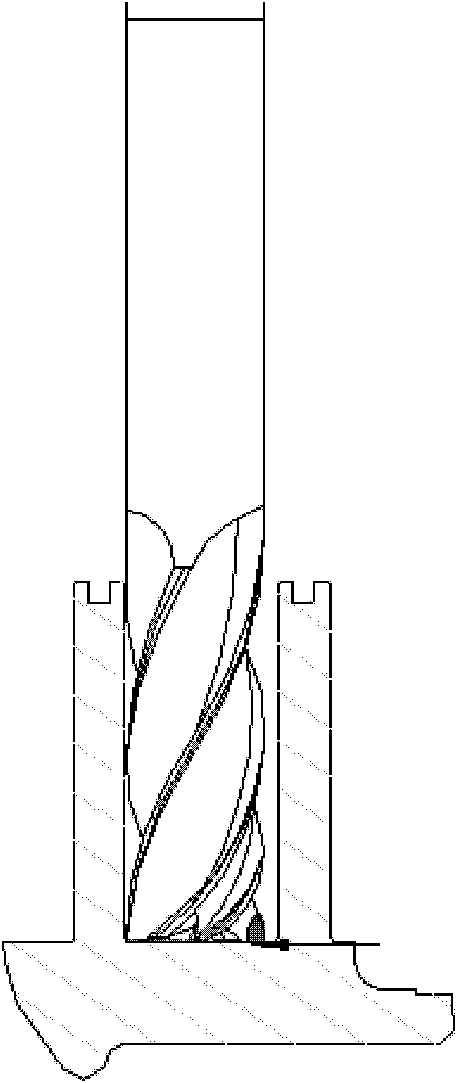

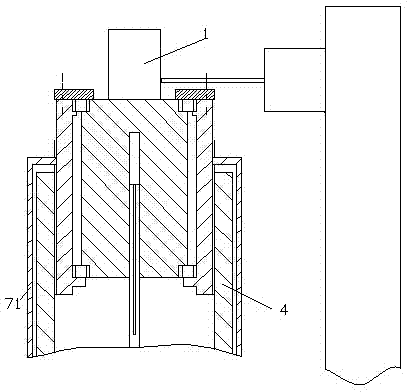

Worm machining device

The invention provides a worm machining device. The worm machining device is used for machining a blank (1) into a worm, and comprises a movement mechanism, a base (91), an upright column (92), a milling cutter rotating driving motor (93) and a milling cutter (94); the movement mechanism is fixed on the base (91); the lower end of the upright column (92) is fixedly connected with the base (91); the milling cutter rotating driving motor (93) is mounted on the upper end of the upright column (92) and used for driving the milling cutter (94) to rotate; the milling cutter (94) is mounted on the milling cutter rotating driving motor (93) and used for cutting the blank (1); the movement mechanism comprises a blank carrying piece (2), a sleeve (3) with external threads, a driving sleeve (4) with internal threads and a frame (7).

Owner:SHENYUE FUJIAN CASTING

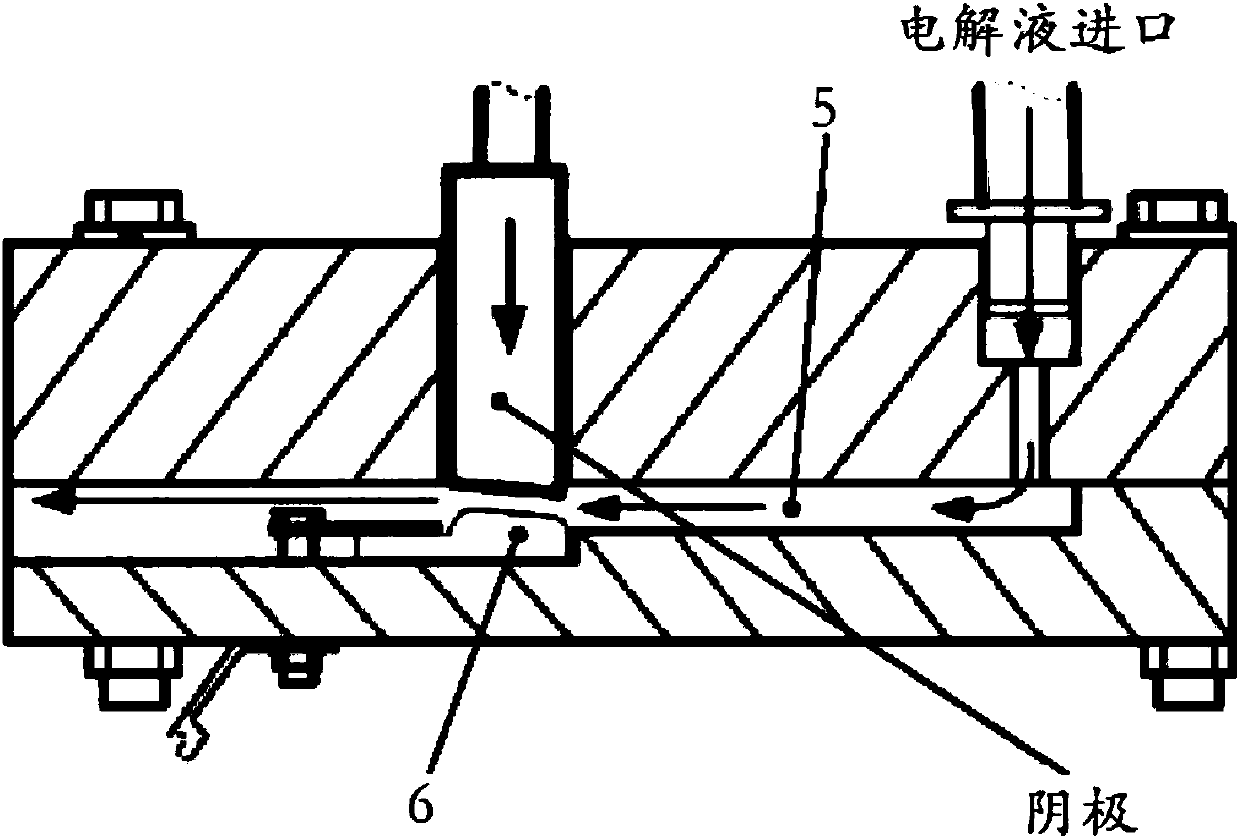

Electrolysis shaping method of TC4 titanium alloy turbine blade repairing layer

InactiveCN108031934AEliminate gougingHigh shaping accuracyElectrochemical machining apparatusTurbine bladeElectrolytic cell

The invention discloses an electrolysis shaping method of a TC4 titanium alloy turbine blade repairing layer. The method includes the steps of S1, building an electrolysis processing system which comprises a power system, an electrolyte circulating system, an electrolytic cell, a displacement platform, a cathode system and a control system, wherein the circulating pipe of the electrolyte circulating system is connected with the electrolyte inlet and the electrolyte channel of the cathode system, and the positive pole and the negative pole of the power system are connected with the cathode system; electrolyte is a 18% sodium chloride solution, and the rotation speed of an electrolyte circulating pump is 1800r / minute; S2, processing, to be more specific, using a TC4 titanium alloy sheet after sheet edge micro-arc build up welding as the turbine blade sample, using an epoxy resin insulating layer to protect the non-repairing face of the turbine blade, and placing the turbine blade samplein the channel of the cathode system to perform electrolysis repairing. The electrolysis shaping method has the advantages that an improved cathode process is used to perform electrolysis shaping on abuilding up welding repairing blade tip, the shaping time of the single blade is 80 seconds, and good reliability is achieved.

Owner:佛山租我科技有限公司

Four-axis driving-type helical gear processing mechanism

InactiveCN104400139AGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusMotor driveEngineering

The invention provides a four-axis driving-type helical gear processing mechanism which is used for processing a blank (85). The four-axis driving-type helical gear processing mechanism comprises a base (3), a rotary internal thread piece (1), an external thread piece (2) and a cylindrical workpiece carrying piece (8), wherein the rotary internal thread piece (1) comprises an upper cylinder part (11) and a lower cavity part (12); the lower cavity part (12) is connected with the base (3) by virtue of a bearing device (13) in a circumferential rotation and axial fixation manner; the external thread piece (2) is cylindrical, and the outer periphery surface of the external thread piece (2) is provided with external threads jointed with internal threads in the upper cylinder part (11); the base (3) is internally provided with a cavity (31); the cavity (31) is provided with a top wall (32); the cavity (31) is internally provided with a driving motor (4); the driving motor (4) is connected with the lower end of a motor driving shaft.

Owner:SHENYUE FUJIAN CASTING

Worm processing mechanism capable of automatically radiating heat

The invention discloses a worm processing mechanism capable of automatically radiating heat. The worm processing mechanism is used for processing a blank (1) into a worm. The worm processing mechanism comprises a blank bearing member (2), a sleeve (3) with an external thread, a drive sleeve (4) with an internal thread, and a rack (7), wherein the blank bearing member (2) is used for bearing the blank (1), the upper end and the lower end of the blank bearing member (2) are respectively fixedly arranged in the sleeve (3) with the external thread by means of an upper bearing (21) and a lower bearing (22) relative to the sleeve (3) with the external thread, the sleeve (3) with the external thread is in thread fit in the drive sleeve (4) with the internal thread, the lower end of the drive sleeve (4) with the internal thread can be rotatably arranged on the rack (7) by means of a thrust bearing (47), a cavity (72) is arranged inside the rack (7), and in the cavity (72), a drive motor (8) is fixedly arranged on the left-inner side wall of the cavity of the rack (7).

Owner:国网山东省电力公司沂源县供电公司

Wrench machining integrated forming process

The invention provides a wrench machining integrated forming process, and belongs to the technical field of wrench machining. The process comprises a workpiece blank machining step of machining a raw material into a workpiece blank, a formed blank machining step of clamping the workpiece blank on a lathe through a main shaft chuck to obtain a smooth formed blank for cold extrusion machining through turning and a forming step of placing the formed blank into a mold to obtain an integrally formed product through the cold extrusion machining. According to the wrench machining integrated forming process, the machining size control is more accurate, the appearance of the product is consistent, the machining error is small, processes such as polishing and grinding are saved, the machining efficiency is greatly improved, and the machining cost is reduced.

Owner:HANGZHOU SHUOGONG TOOLS CO LTD

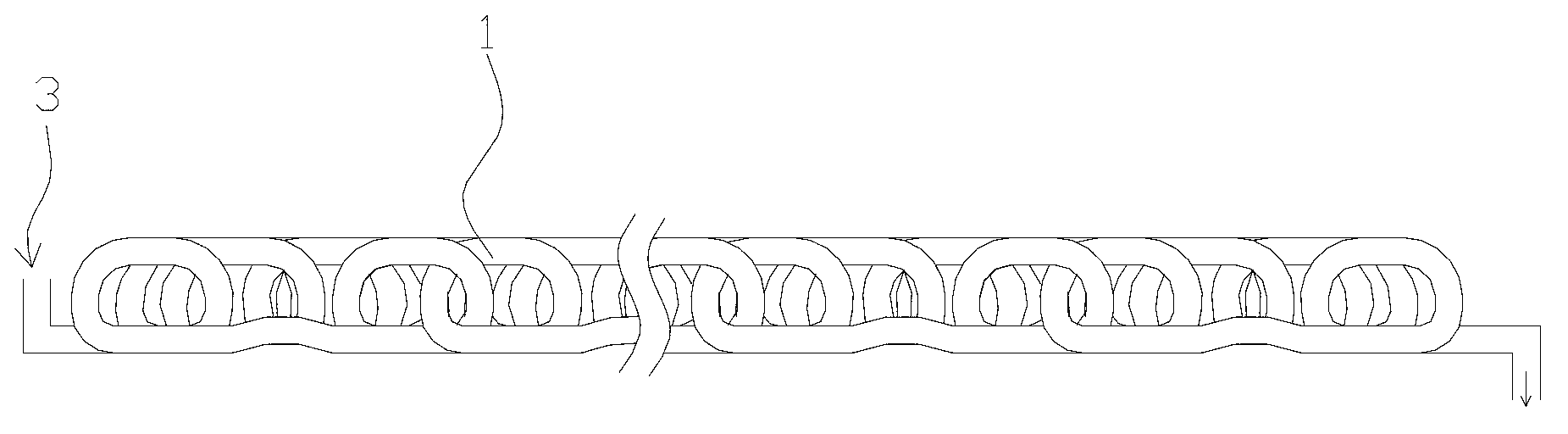

Gas spring with plurality of spiral columns

ActiveCN103075454AOvercome CorrosivityOvercome elasticitySpringsFluid mattressesGas springEngineering

The invention discloses a gas spring with a plurality of spiral columns, wherein a technical problem that conventional gas springs are complicated in structure and airproof up and down is solved. The gas spring comprises a spring body, and is characterized in that the spring body is formed by a bar-like air column which is provided with a pressure gas containing cavity; the air column repeatedly and alternately spirals from top to bottom or from bottom to top and forms the plurality of side-by-side and inclined spiral columns; the two adjacent spiral columns form a splay spiral unit; the adjacent spiral units are mutually connected; and at least one air hole for communicating the containing cavity is formed in the air column. According to the gas spring disclosed by the invention, the spiral columns are formed by one gas column, the interconnectedness is good, when the gas spring is subject to pressure, the spiral columns are mutually squeezed to buffer the pressure, the gas pressure is uniformly adjusted more conveniently, and the ventilation is good. Moisture of a mattress formed by the gas springs is easy to remove, hardness is convenient to adjust and the mattress is large in unidirectional deformation range; various requirements are met; the mattress also can be adjusted in real time; and the comfort level of the mattresses is increased.

Owner:XILINMEN FURNITURE

Spiral gear machining mechanism capable of quickly radiating heat

InactiveCN104400136AGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusEngineeringDrive motor

The invention relates to a spiral gear machining mechanism capable of quickly radiating heat, which is used for machining a blank (85). The spiral gear machining mechanism capable of quickly radiating heat comprises a base (3), a rotatable internal threaded piece (1), an external threaded piece (2) and a cylindrical workpiece bearing piece (8), wherein the rotatable internal threaded piece (1) comprises an upper cylindrical portion (11) and a lower chamber portion (12), the lower chamber portion (12) is connected with the base (3) through a bearing device 13) in a circumferentially rotatable and axial fixed manner, the external threaded piece (2) is cylindrical, external threads are arranged on the external circumferential surface of the external threaded piece (2) and are jointed with internal threads in the upper cylindrical portion (11), and a cavity (31) is formed in the base (3), the cavity (31) has a top wall (32) and a driving motor (4) is installed in the cavity (31).

Owner:吕英芬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com