Printed circuit board (PCB) processing method

A processing method and circuit board technology, applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of increasing production costs, waste of resources, pollution of holes 820, etc., and achieve the effects of saving production costs, meeting shape requirements, and ensuring functional integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

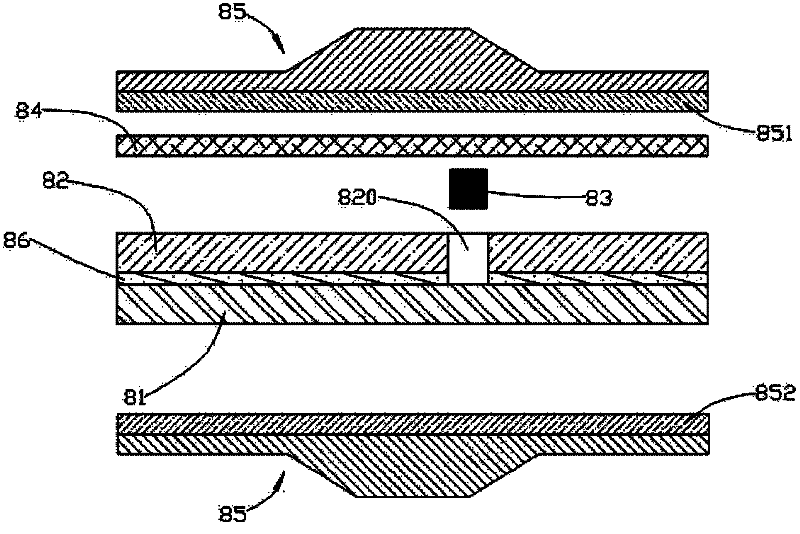

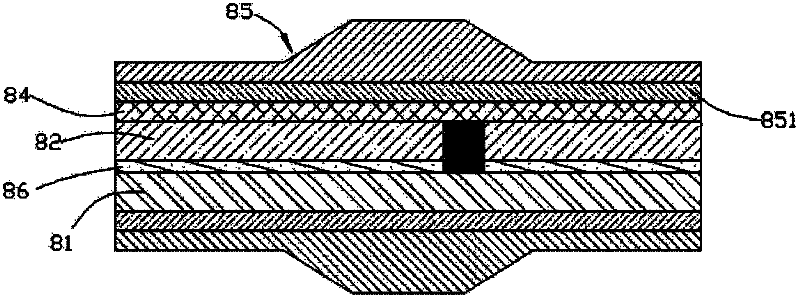

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] Circuit boards can be divided into single-panel, double-panel and multi-layer boards according to their wiring levels. A single-sided board is a circuit board with conductive patterns on only one side. It is generally made of phenolic paper-based copper clad laminates, and epoxy paper-based or epoxy glass cloth copper clad laminates are often used.

[0029] The printed graphics of single-sided panels are relatively simple. Generally, the screen printing method is used to transfer the graphics, and then the circuit board is etched out, and some are produced by photochemical methods.

[0030] Double-sided circuit boards are circuit boards with conductive patterns on both sides. Obviously, the area of the double-sided panel is twice as large as that of the single-sided panel, and it is suitable for more complex circuits than the single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com