Construction method of vibration pressing type special-shaped multi-head bottom expanding pile

A construction method and bottom-expanding pile technology are applied in sheet pile walls, foundation structure engineering, construction, etc., and can solve the problems of cumbersome manufacturing steps, insufficient pile uplift resistance and pile bearing capacity, and complicated equipment, etc. The production process is simple and fast, easy to replace and maintain, and the effect of reducing the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

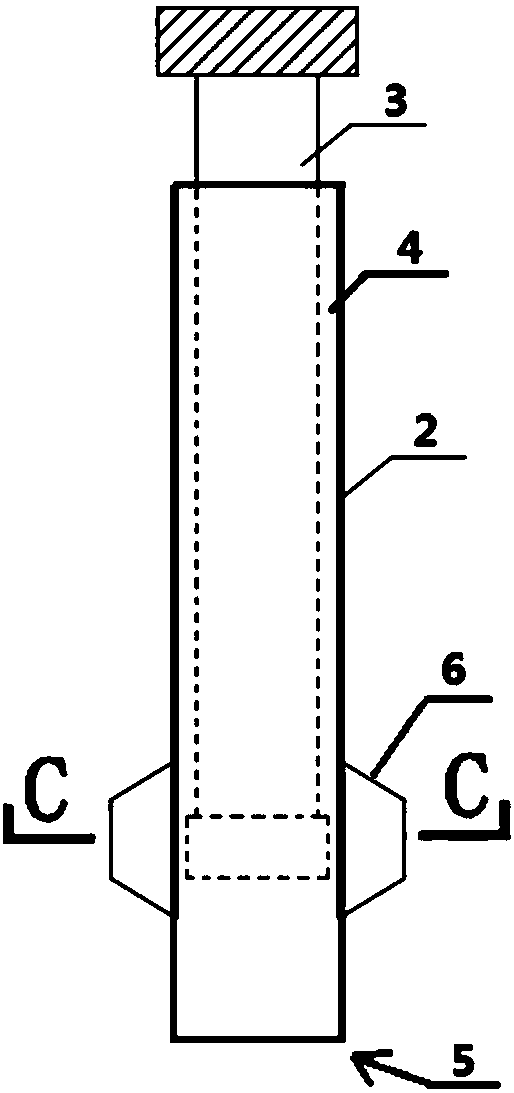

[0031] The construction method of the vibration pressure type special-shaped multi-head expanded bottom pile of the present embodiment specifically includes the following steps: a. using piling equipment to carry out vibration pressure sinking of the inner casing and the outer casing that are nested together at the pile position to form a pile hole; b. pull out the inner casing, pour the concrete needed to form the pile body in the outer casing, and sink the inner casing to forcibly vibrate the concrete in the outer casing, Synchronously pull out the outer casing to form a preliminary pile bottom expansion head for the first bottom expansion; c. After the first bottom expansion, then use the pile driver to sink the inner casing and the pile synchronously The outer casing forcibly vibrates the concrete again to carry out the second bottom expansion to form the final pile bottom expansion head; d. After the second bottom expansion is completed, pull up the inner casing, and place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com