Manufacturing method of mobile phone middle frame

A mobile phone middle frame and frame technology, which is applied to branch office equipment, telephone structure, anodic oxidation, etc., can solve the problem of only corroding aluminum alloy and not corroding stainless steel, so as to reduce the processing cycle and processing cost, reduce processing volume, process The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

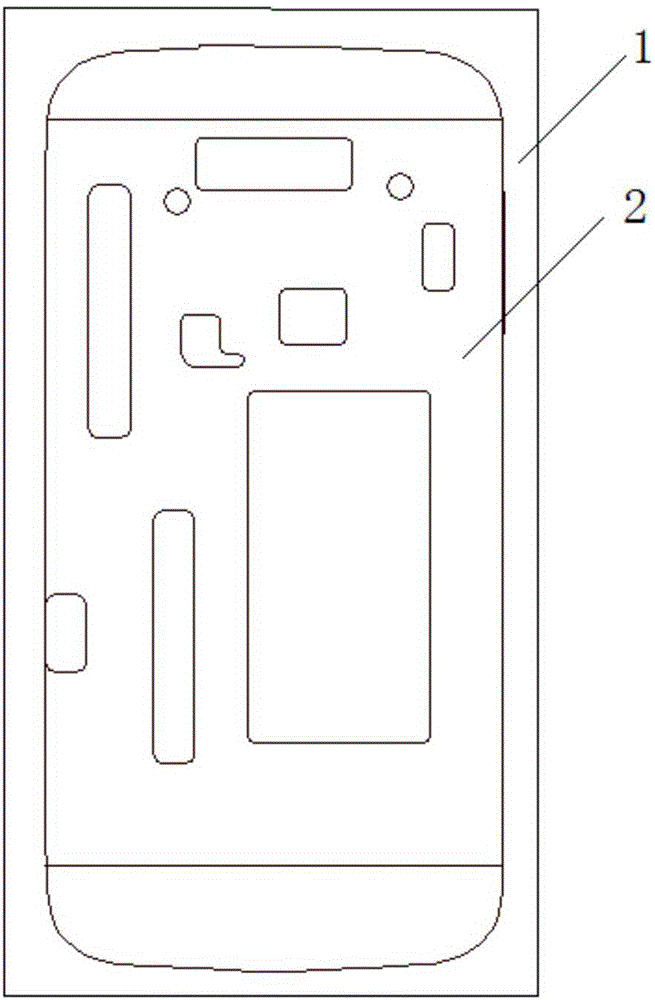

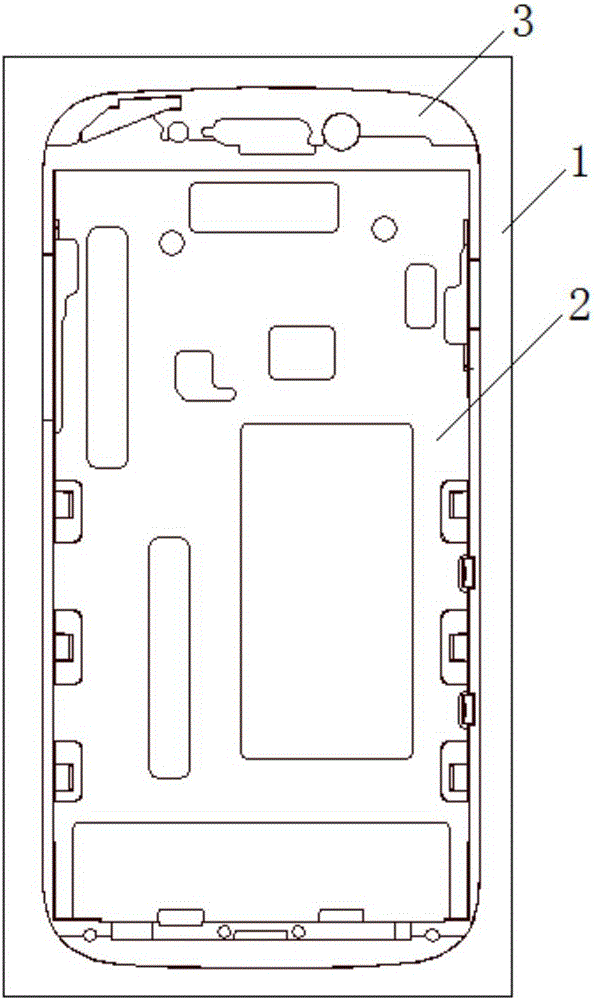

[0030] refer to Figure 1 to Figure 4 , in one embodiment, a method for preparing a middle frame of a mobile phone, comprising the following steps:

[0031] Step S1, preparing the stainless steel frame 1;

[0032] Step S2, put the stainless steel frame 1 into the die-casting mold, then add the smelted aluminum alloy liquid into the die-casting mold, and then die-cast and form the aluminum alloy middle plate 2, the aluminum alloy middle plate 2 and the stainless steel frame 1 Integral molding of aluminum alloy stainless steel middle frame;

[0033] Step S3, first cover the aluminum alloy middle plate 2 with a protective glue resistant to acid and alkali corrosion, and then put the aluminum alloy stainless steel middle frame into the microporous treatment solution to corrode to form micropores. Remove after this step;

[0034] Step S4, forming a plastic structural part 3 on the aluminum alloy stainless steel middle frame by injection molding;

[0035] Step S5, post-processin...

Embodiment 1

[0053] Equipment and materials: ADC12 aluminum alloy gold ingot, die-casting mold, die-casting machine, high cycle furnace, 304 stainless steel plate, degreasing powder 402, Boen 10026 protective glue, sulfuric acid solution, hydrochloric acid solution, sodium chloride solution, oleic acid base Hydroxyethyl imidazoline, sodium sulfate, deionized water, 30% glass fiber modified PBT, injection molding machine, CNC engraving machine.

[0054] Die-cast aluminum plate

[0055] Put the ADC12 aluminum alloy gold ingot into the high-cycle furnace to melt the aluminum liquid mixture, then put the CNC-processed 304 stainless steel plate into the die-casting mold, and then pour the melted aluminum alloy mixture into the die-casting machine for feeding At the mouth, start to die-cast the aluminum alloy middle plate, keep the mold pressure for 10-20s, wait until the mold temperature cools to room temperature, take out the casting to get the stainless steel aluminum alloy middle frame produ...

Embodiment 2

[0061] Equipment and materials: ADC12 aluminum alloy gold ingot, die-casting mold, die-casting machine, high cycle furnace, 316 stainless steel plate, degreasing powder 402, Boen 10026 protective glue, sulfuric acid solution, hydrochloric acid solution, zinc chloride solution, 2-mercapto -5-methoxybenzimidazole, sodium sulfate, deionized water, 30% glass fiber modified PBT, injection molding machine, CNC engraving machine.

[0062] Die-cast aluminum plate

[0063] Put the ADC12 aluminum alloy gold ingot into the high-cycle furnace to melt the aluminum liquid mixture, then put the CNC-processed 316 stainless steel plate into the die-casting mold, and then pour the melted aluminum alloy mixture into the die-casting machine for feeding At the mouth, start to die-cast the aluminum alloy middle plate, keep the mold pressure for 10-20s, wait until the mold temperature cools to room temperature, take out the casting to get the stainless steel aluminum alloy middle frame product.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com