Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Reduce molding defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

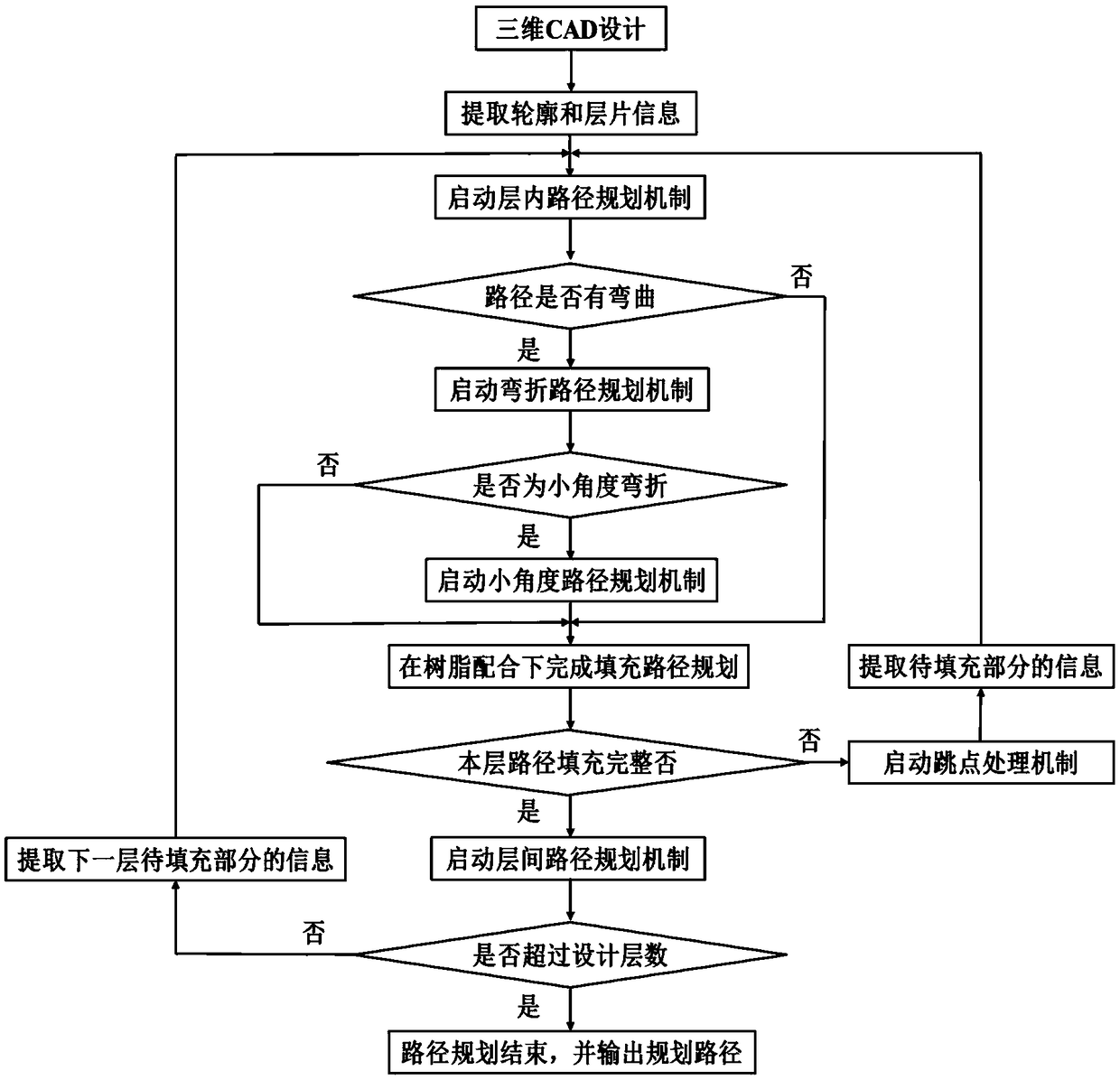

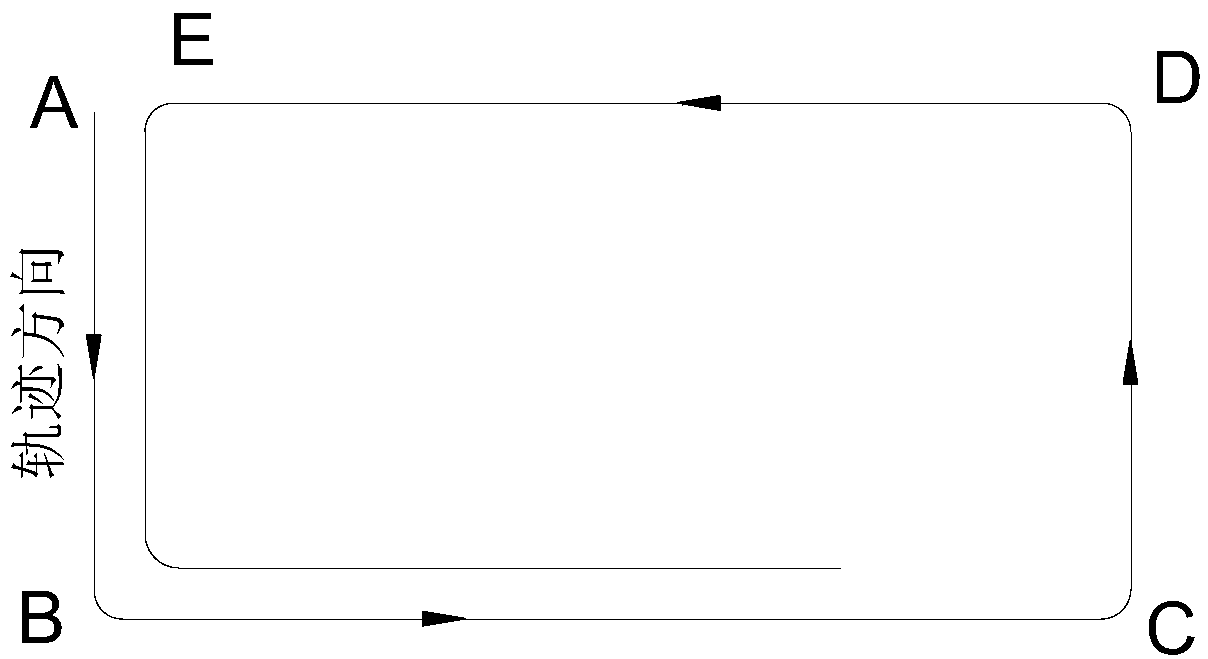

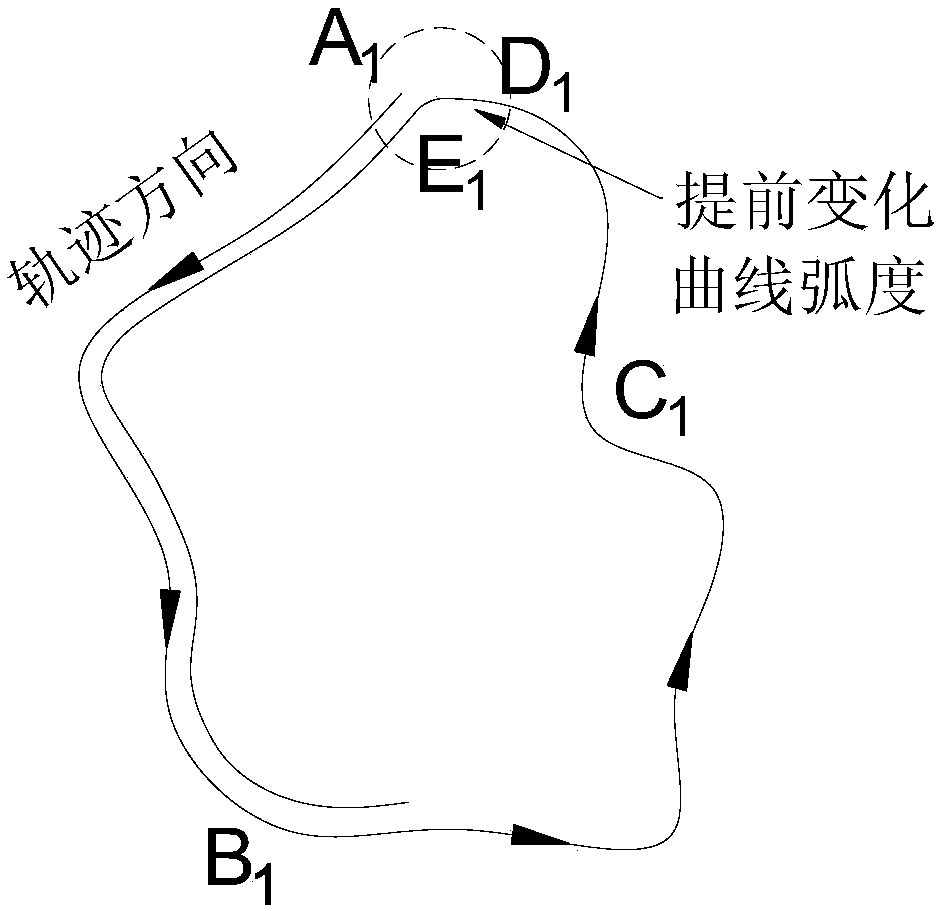

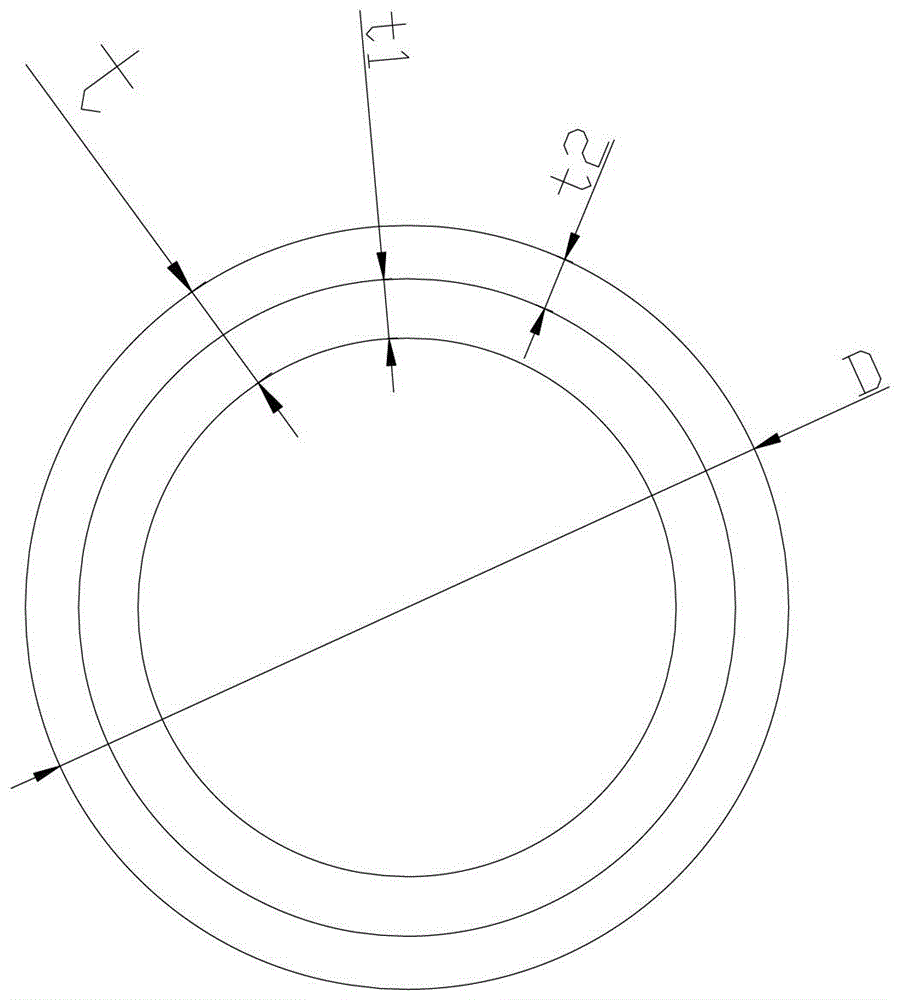

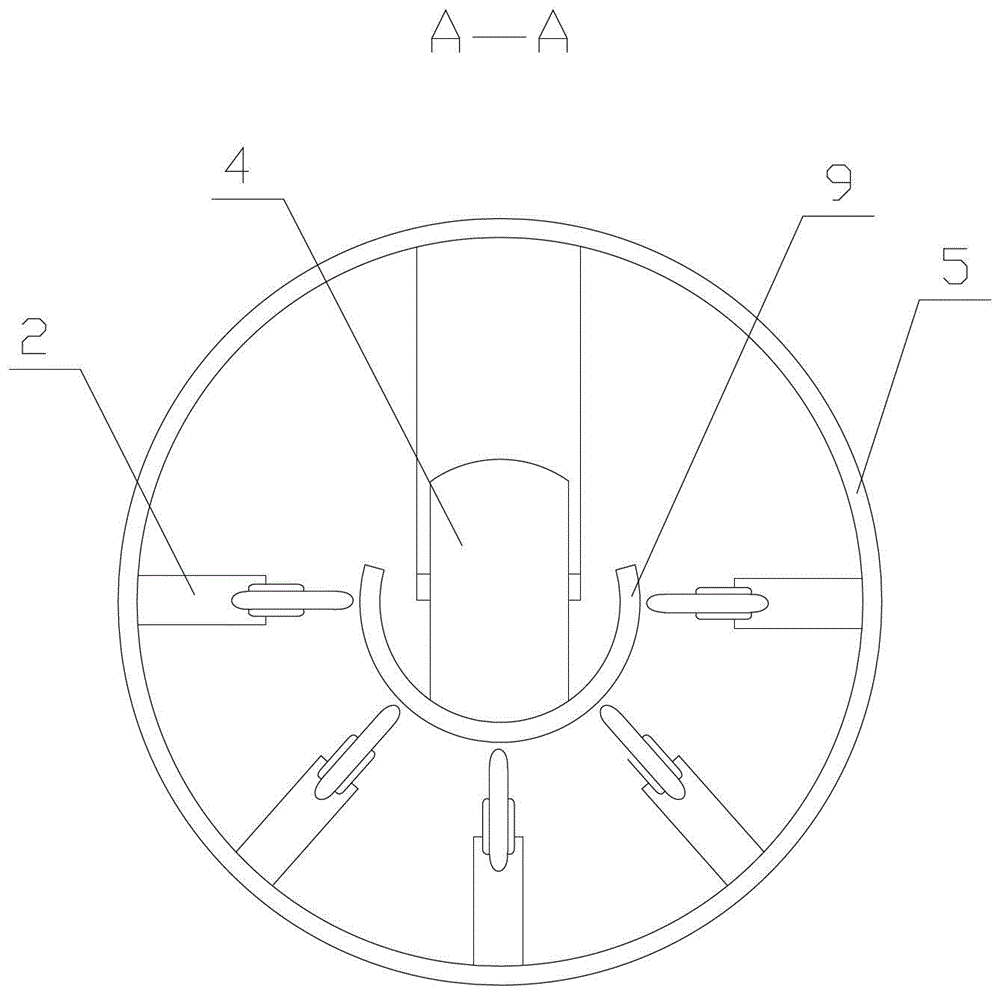

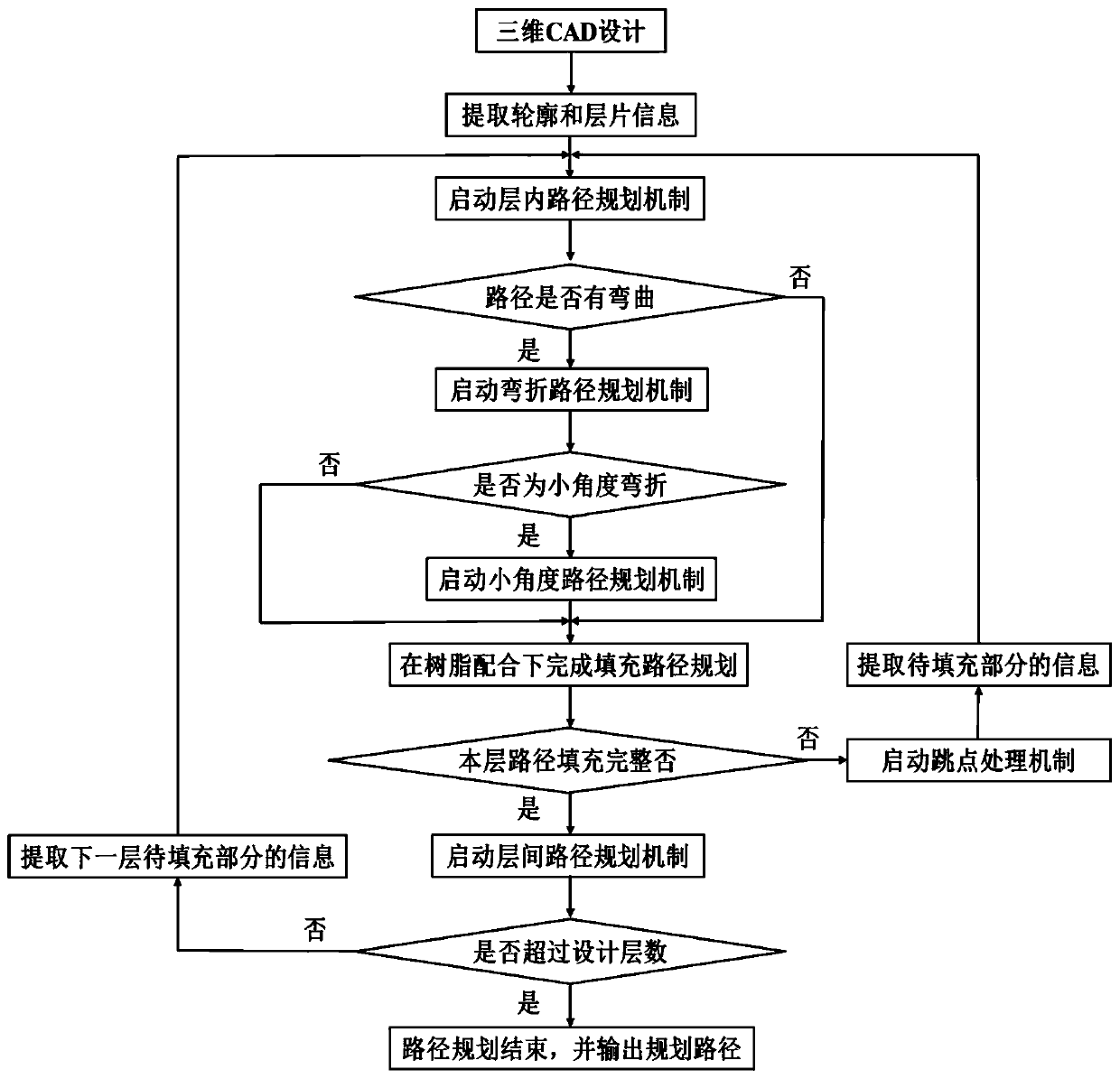

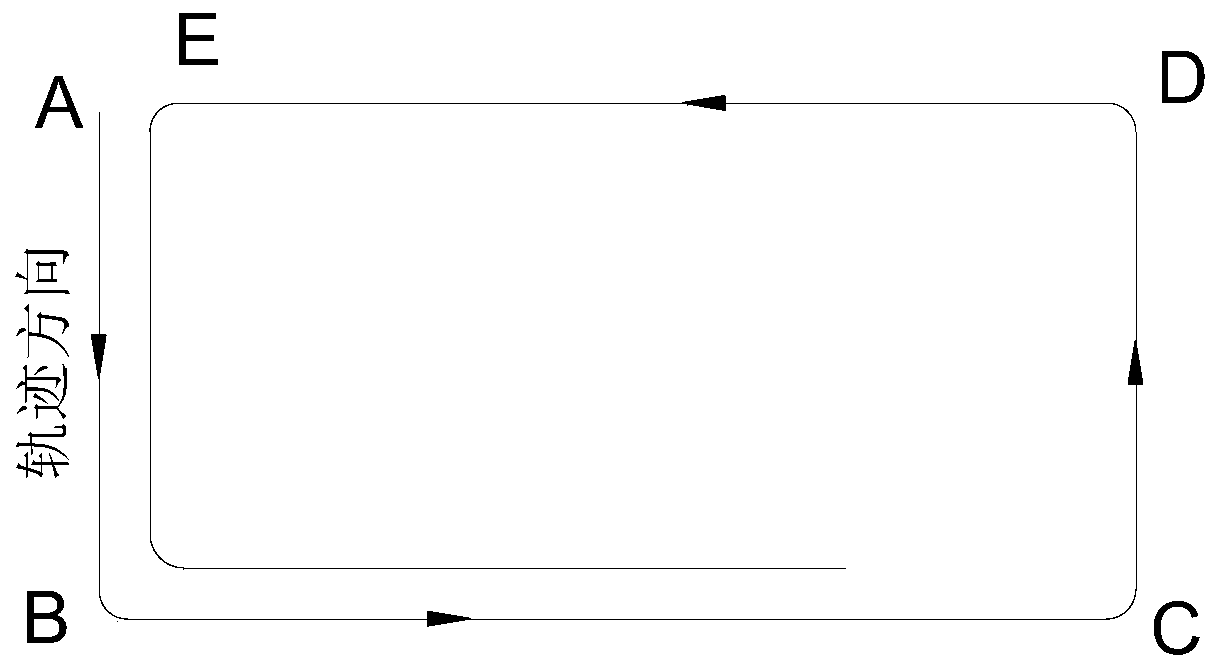

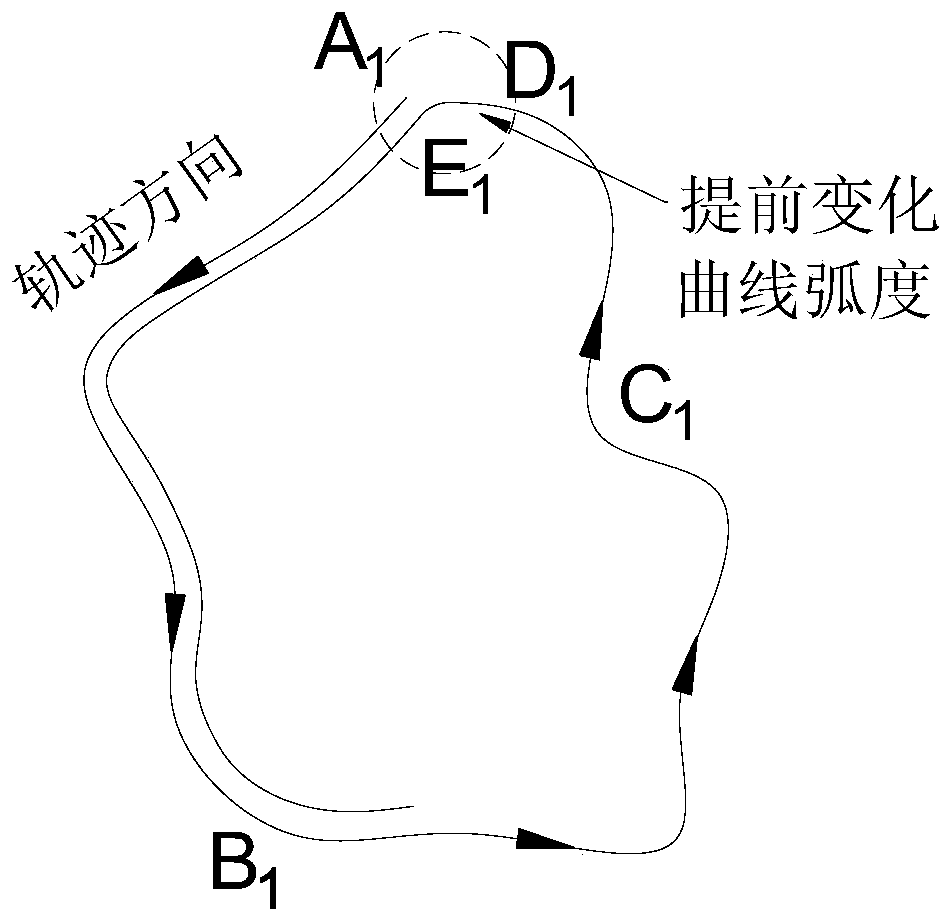

Typical path planning method for 3D (three-dimensional) printing of continuous fiber reinforced composites

ActiveCN108891029AGuaranteed mechanical propertiesReduce molding defectsAdditive manufacturing apparatusManufacturing data aquisition/processingProcess mechanismComputer Aided Design

The invention discloses a typical path planning method for 3D (three-dimensional) printing of continuous fiber reinforced composites and belongs to the field of rapid prototyping of the composites. Inthe method, a three-dimensional model is built by using CAD (computer aided design) modeling software according to actual size requirements of forming components and is subjected to slice stratification by the aid of the three-dimensional software to acquire profile and slice information; the degree of path bending is judged and corresponding path planning mechanisms are started, and with the help of the jump point processing mechanism, jump points can be accurately located and the action of the jump points is completed; fiber interlayer conversion without breakpoint is realized by using an interlayer path planning mechanism, and high quality and high efficiency three-dimensional printing new path of the continuous fiber reinforced composites is realized. In the method, the printing pathwith the least breakpoints is planned out, and mechanical property of the continuous fiber reinforced composites is guaranteed; forming defects in the bending of continuous fiber are effectively reduced, binding force of the continuous fiber in the bending is improved, and integral performance of the forming components is improved.

Owner:DALIAN UNIV OF TECH

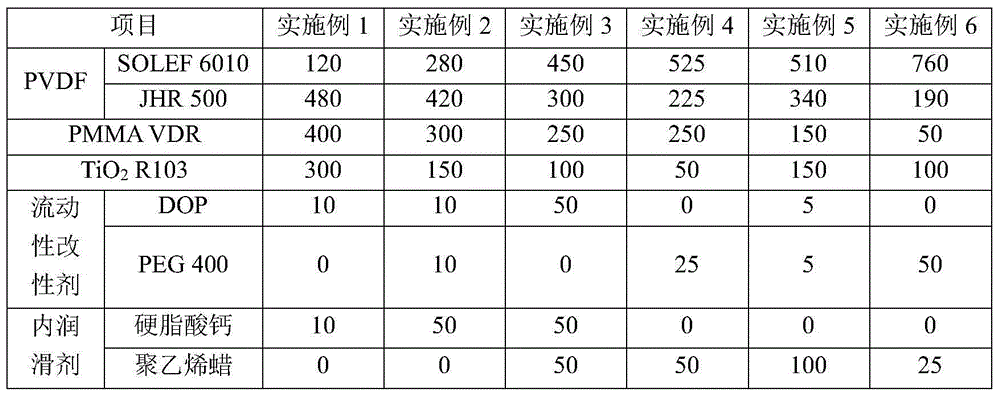

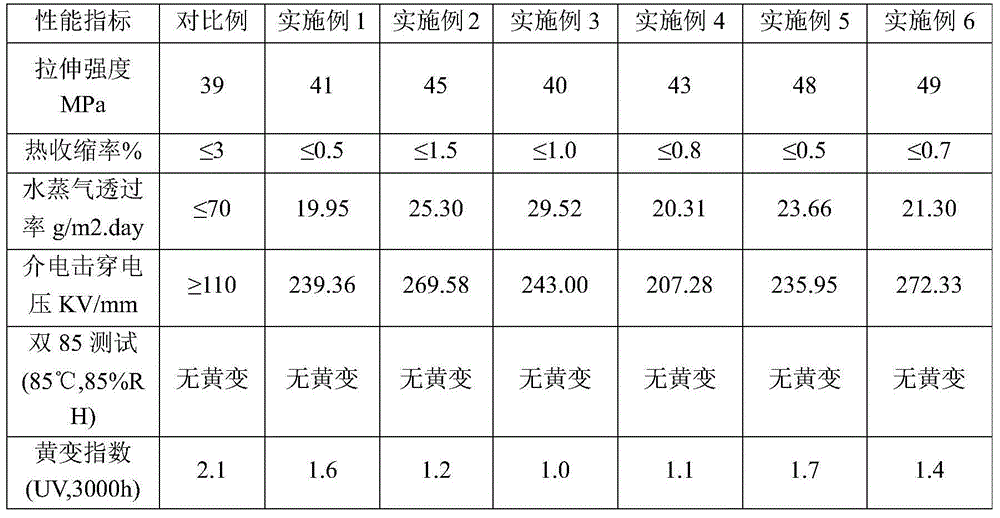

Preparation method and application of master batch used for polyvinylidene fluoride film

The invention discloses a preparation method of a master batch used for a polyvinylidene fluoride film. The preparation method comprises the steps of mixing a polyvinylidene fluoride A resin, a polyvinylidene fluoride B resin, polymethyl methacrylate, titanium dioxide, a mobility modifier and an inner lubricating agent at a room temperature until the materials are stirred uniformly, melt-extruding, cooling and granulating at a temperature of 150-250 DEG C, and drying to obtain the master batch. According to a standard of GB / T3682-2000, melt indexes of the polyvinylidene fluoride A resin and polyvinylidene fluoride B resin at a temperature of 230 DEG C and a load of 5 kg is 30-60 g / 10 min and 3-20 g / 10 min respectively. Performances such as tensile strength and thermal shrinkage of the film prepared by the preparation method provided by the invention are greatly improved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

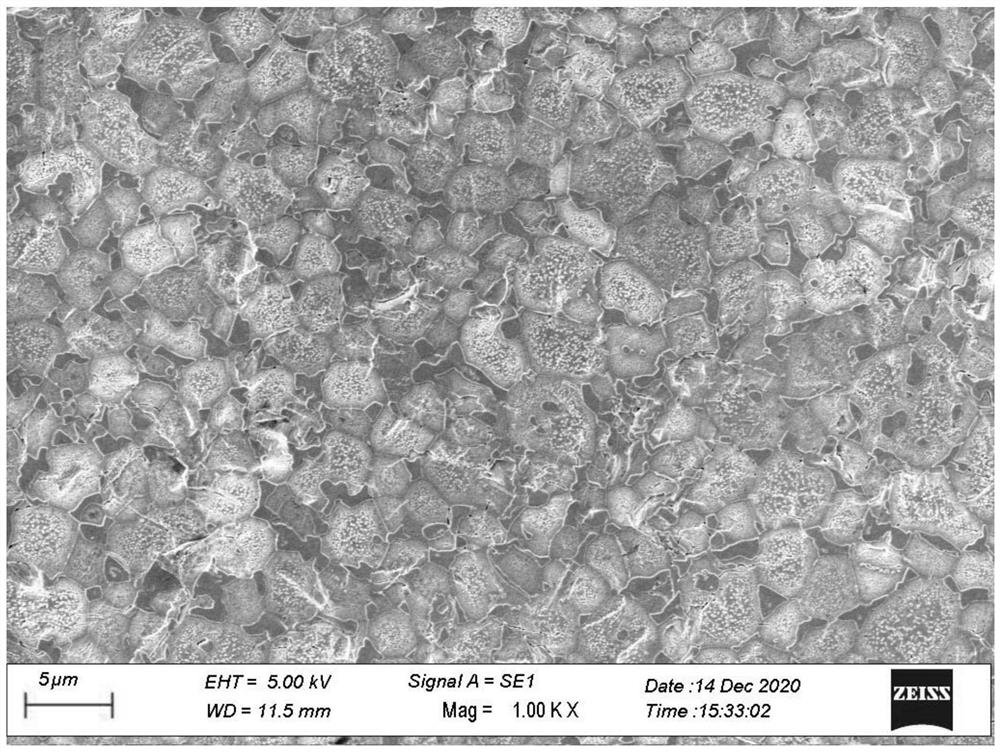

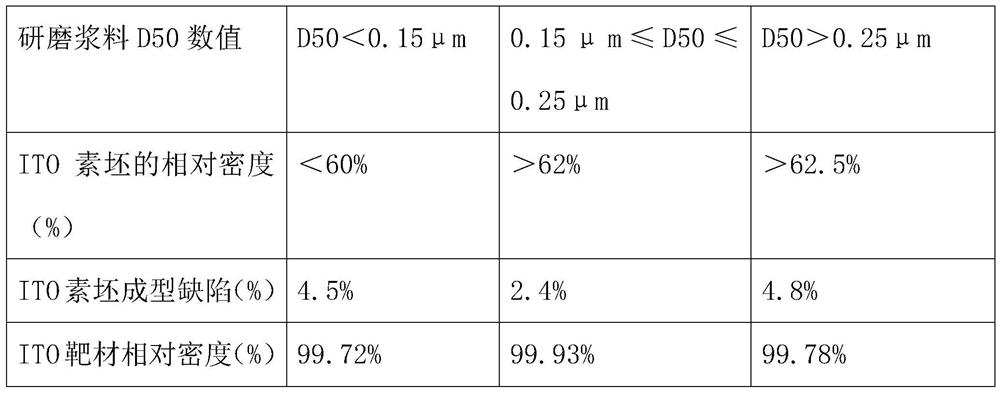

Manufacturing method of advanced-generation TFT-grade fine-grain ITO target material

PendingCN112723863APrecise ratio of ingredientsHigh sintering activityVacuum evaporation coatingSputtering coatingSpray GranulationCompression molding

The invention discloses a manufacturing method of an advanced-generation TFT fine-grain ITO target material. The manufacturing method comprises a powder preparation step, a mixing and grinding step, a spray granulation step, a compression molding step and a sinter molding step. According to the manufacturing method of the ITO target material, the ITO target material with large-size and high-density crystal grains can be manufactured, the density of the target material is larger than 99.9%, and the average crystal grain diameter is controlled to be 3-5 [mu]m.

Owner:韶关市欧莱高纯材料技术有限公司

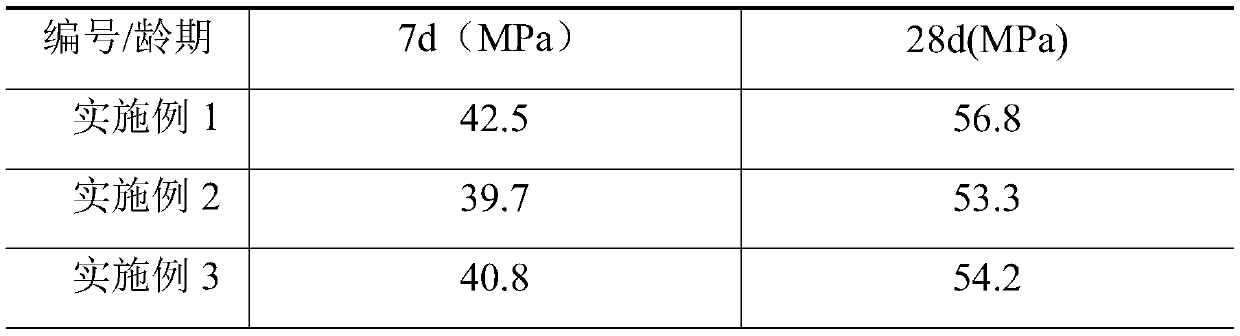

High-performance fair-faced concrete

The invention discloses high-performance fair-faced concrete, and solves the problem that use performance and appearance performance of fair-faced concrete in the prior art cannot be taken into account at the same time. The high-performance fair-faced concrete comprises the following components, in parts by weight: 420-460 parts of cement, 1050-1080 parts of coarse aggregate, 710-760 parts of fineaggregate, 145-165 parts of water, 15-25 parts of stone powder, 15-25 parts of silicon powder, 12-14 parts of an admixture, 20-40 parts of an expanding agent, and 1.5-3.0 parts of fibers. The fair-faced concrete provided by the invention has scientific design and a reasonable ratio; and the prepared fair-faced concrete can form a concrete building having extremely-low porosity, a uniform color, and excellent crack resistance and compression and folding resistance after being molded by casting.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

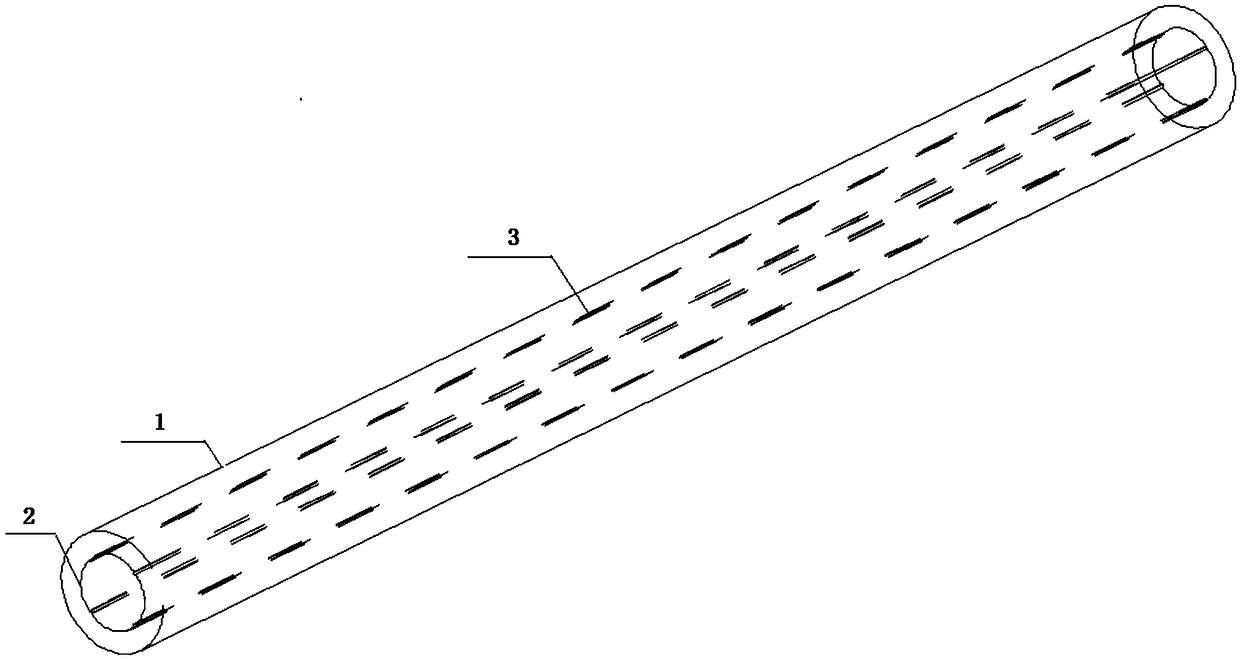

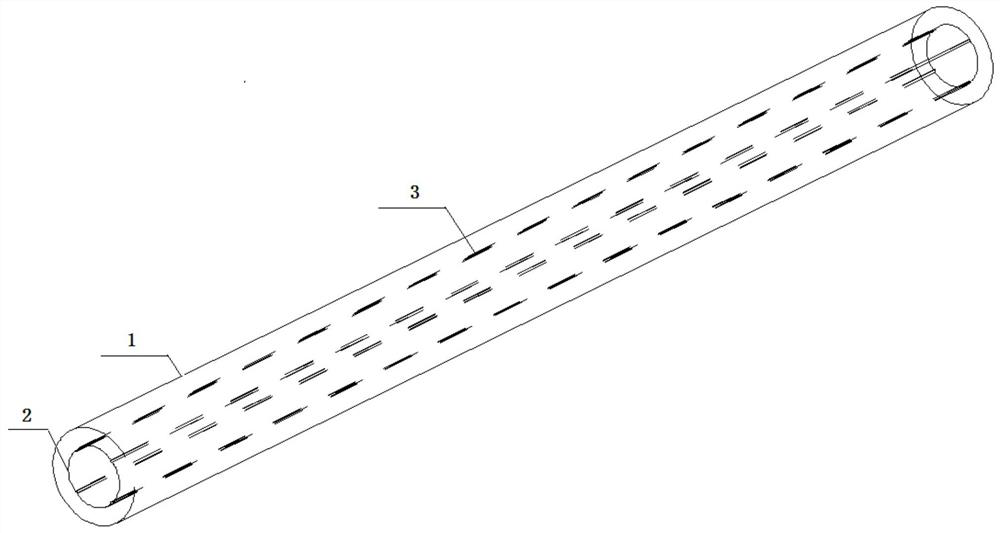

Composite material shaft as well as preparation method and application thereof

ActiveCN109109340AQuickly and effectively rule outEfficient exclusionShaftsTension compressionDrive shaft

The invention discloses a preparation method of a composite material shaft. The method comprises the following steps: (1) dipping aramid fiber woven cloth or carbon fiber cloth in thermosetting resinto obtain a pre-dipped material; (2) winding the pre-dipped material on an expanding shaft; and (3) enabling a cylindrical cavity and the expanding shaft, on which the pre-dipped material is wound, tobe assembled, rotating the rotating arm of the expanding shaft to send the material into a hot-pressing tank to mold, opening the tank finally, shrinking the expanding shaft, demolding and completingthe preparation of the composite material shaft. The composite material shaft is prepared through adopting a vacuum inner expansion molding mode, bubbles in a shaft body can be quickly and effectively eliminated in a vacuum state, and molding defects are reduced; inner expanding extrusion can guarantee that woven cloth layers are uniformly distributed, and the defect that resin and fiber are notuniformly distributed cannot appear; compared with existing winding molding, the composite material shaft can further bear relatively great tension-compression stress when transmitting a large torquewhile a traditional winding molding transmission shaft cannot bear great tension stress.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

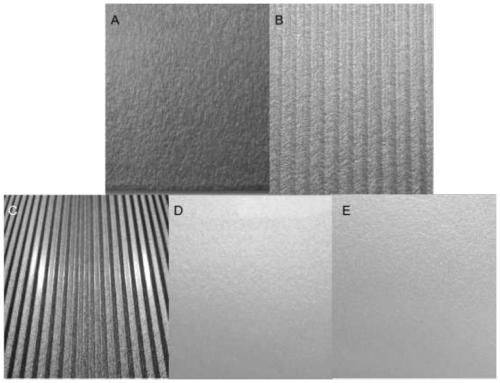

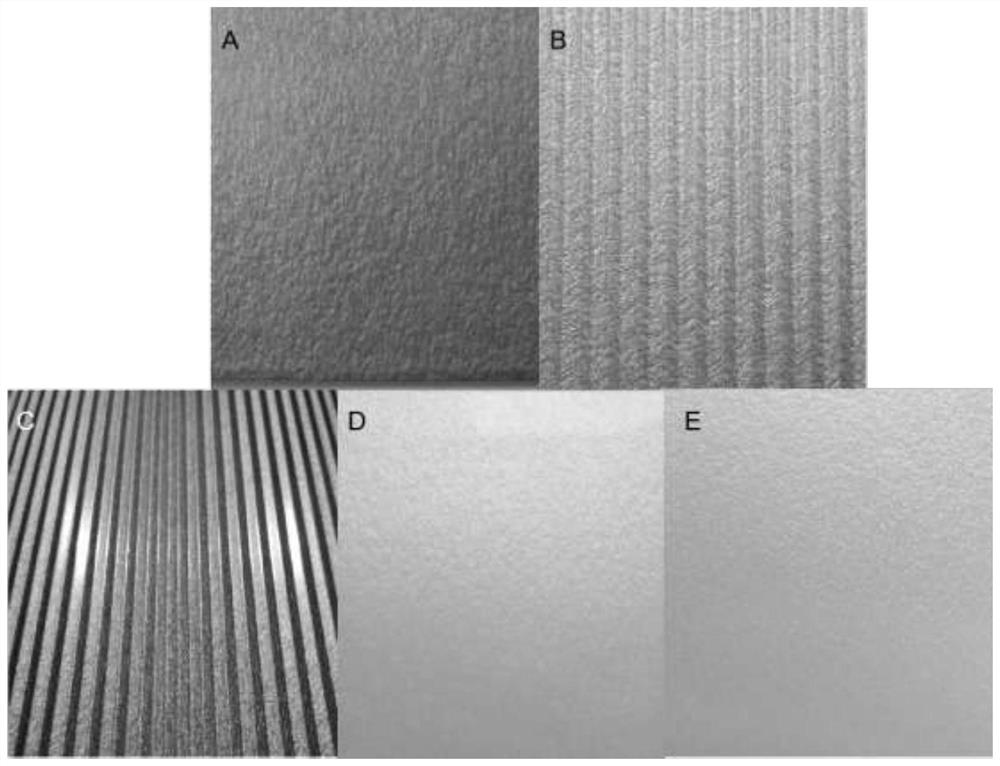

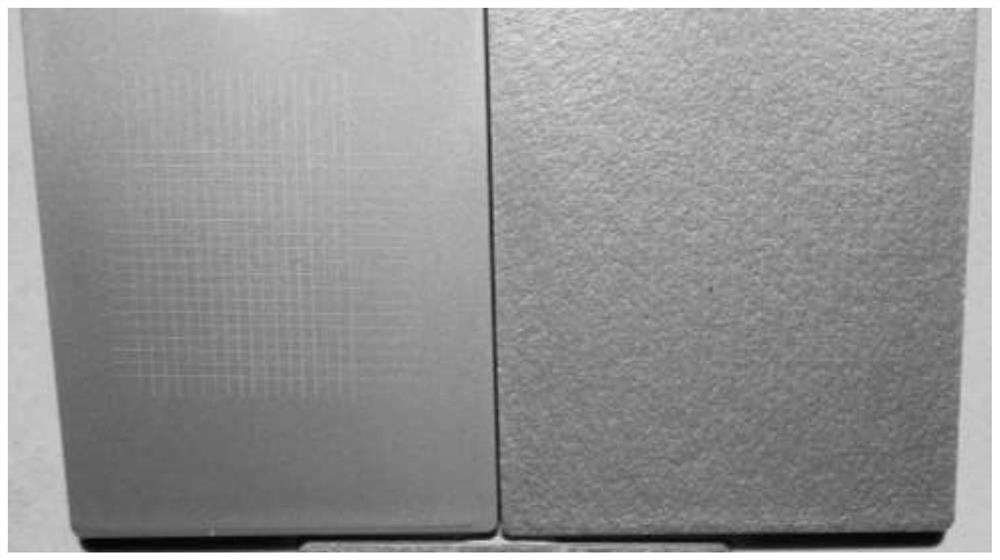

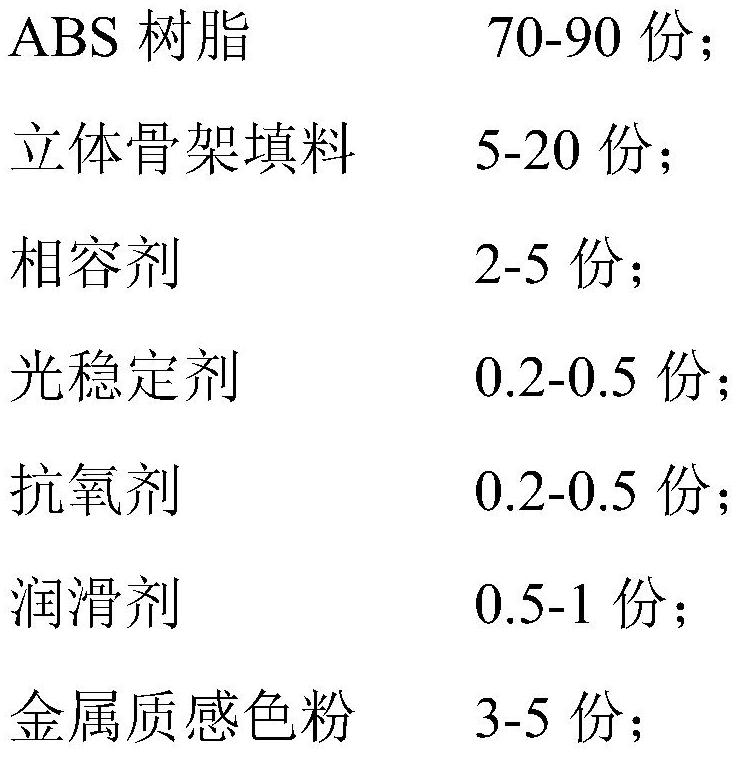

Highlight three-dimensional vein material and preparation method thereof

The invention discloses a highlight three-dimensional vein material and a preparation method thereof. The highlight three-dimensional vein material is prepared from the following ingredients in partsby weight: 70 to 90 parts of ABS resin, 5 to 20 parts of three-dimensional framework filing materials, 2 to 5 parts of compatibilizers, 0.2 to 0.5 part of light stabilizing agents, 0.2 to 0.5 part ofantioxidants, 0.5 to 1 part of lubricating agents and 3 to 5 parts of metal texture color powder. A three-dimensional framework filling material with high length-diameter ratio is used as filling; inthe injection molding shaping process, a space structure framework is formed; the flaky metal texture color powder achieves the orientation guiding effect; the prepared material has a visual angle change effect. The prepared highlight three-dimensional vein material has good three-dimensional vein effects; meanwhile, the vein three-dimensional effect has the angle change features; in addition, thematerial injection molding element has the high luster degree and low shaping defects. The highlight three-dimensional vein material can be widely applied to the appearance material in the fields ofautomobiles and electronic electric appliances.

Owner:ORINKO NEW MATERIAL CO LTD

Method of molding and manufacturing for fluidic device reagent testing cartridge and pods

PendingUS20220118439A1Extended periodReduce mold defectLaboratory glasswaresBiological testingInternal stressStructural engineering

A cartridge for detecting one or more characteristics of a fluid in a diagnostic assay system includes a plurality of chambers. At least one of the plurality of chambers includes a wall. The wall includes an intermediate portion disposed between an exterior surface and an interior surface of the wall. The intermediate portion can include a hygroscopic element configured to extend an active period of detection of a reagent. The intermediate portion can include a dummy material configured to slow a wetting of a reagent by the fluid. The intermediate portion can include an air gap configured to reduce internal stress and / or strain in the cartridge. A reagent can be enclosed by the wall of the at least one of the plurality of chambers. The reagent can be a lyophilized reagent.

Owner:ENPLAS CORP

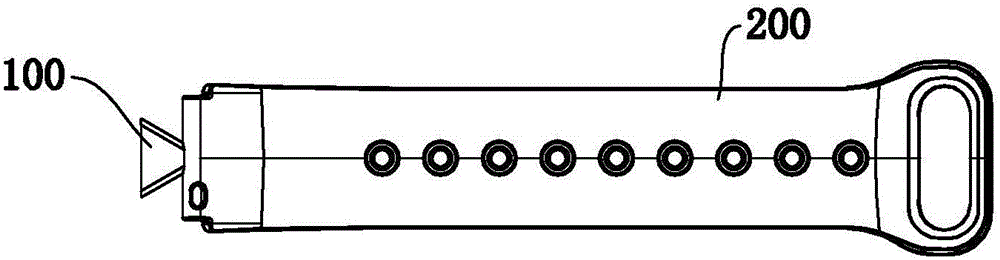

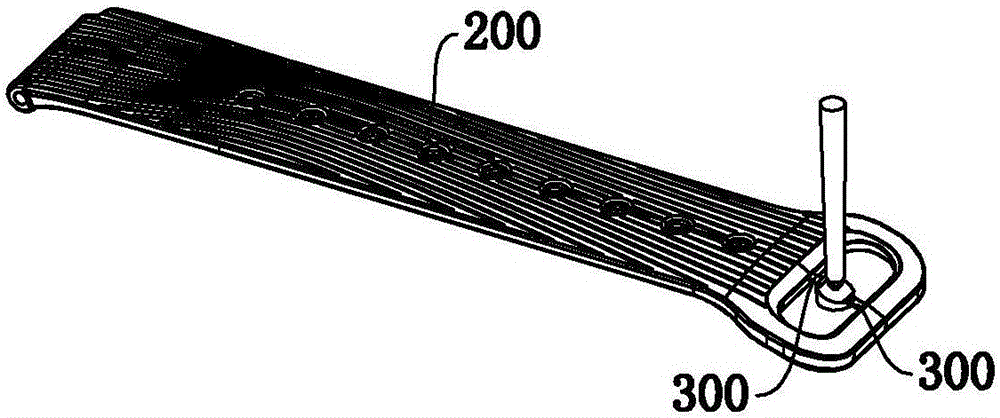

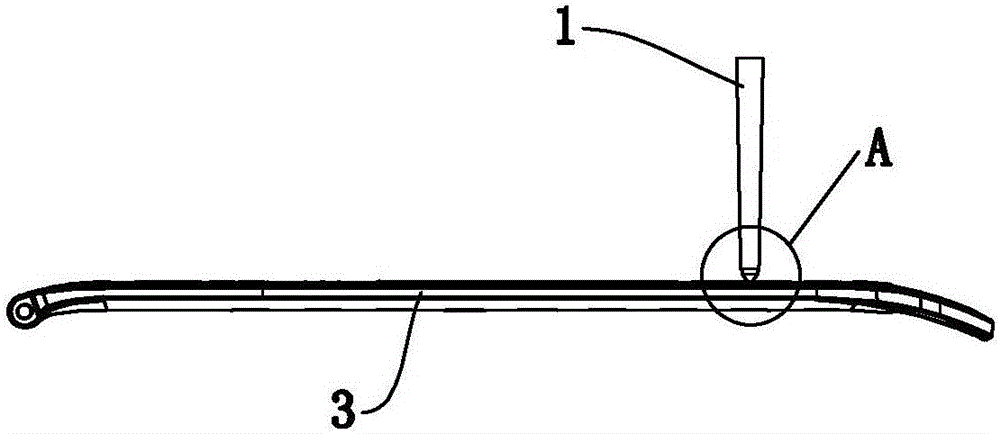

Pouring gate structure of injection mold of soft rubber watchband type product and molding method

InactiveCN105856507AOptimize the pruning processDoes not affect aestheticsEngineeringInjection molding machine

The invention discloses a pouring gate structure of an injection mold of a soft rubber watchband type product and belongs to the technical field of injection molds. The pouring gate structure comprises a flow channel arranged on the injection mold; a point pouring gate is arranged between the tail end of the flow channel and a mold cavity of the injection mold; the point pouring gate is correspondingly arranged at a watchband hole position of a soft rubber watchband type product. The invention further discloses a molding method of the soft rubber watchband type product. By virtue of the pouring gate structure of the injection mold of the soft rubber watchband type product, the molding method comprises a mold closing step, a fusing step, an injection molding step, a cooling and metering step, a mold opening step and an ejection step, wherein in the injection molding step, fused raw materials are injected into the injection mold through a nozzle of an injection molding machine by adopting a multi-grade injection molding process and the pressure is kept. After the pouring gate is removed, traces remained on the product are not obvious and the quality of the soft rubber watchband type product is improved; and an operation flow is optimized, the stability of a production cycle is guaranteed, the working efficiency is improved and the production cost is reduced.

Owner:GOERTEK INC

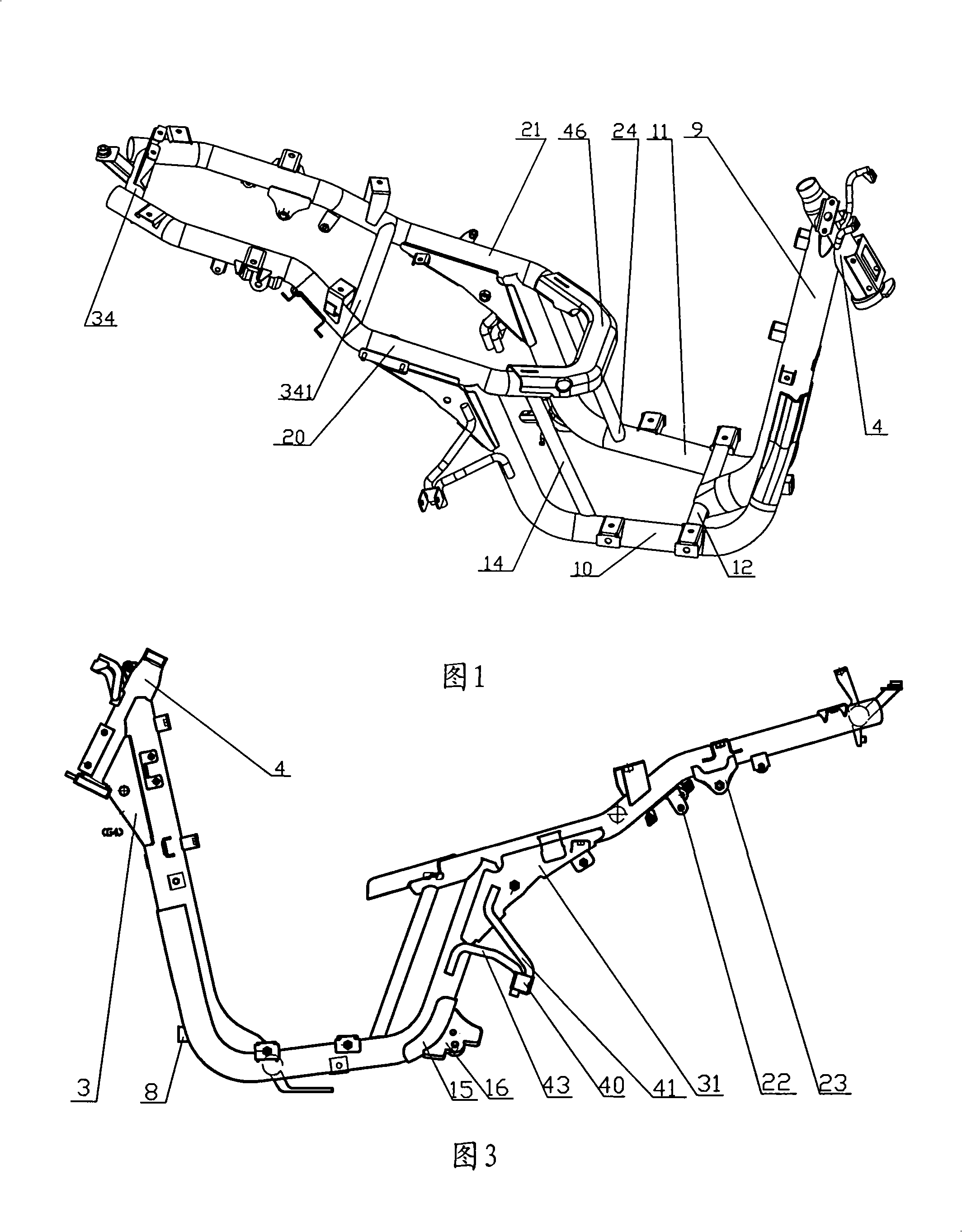

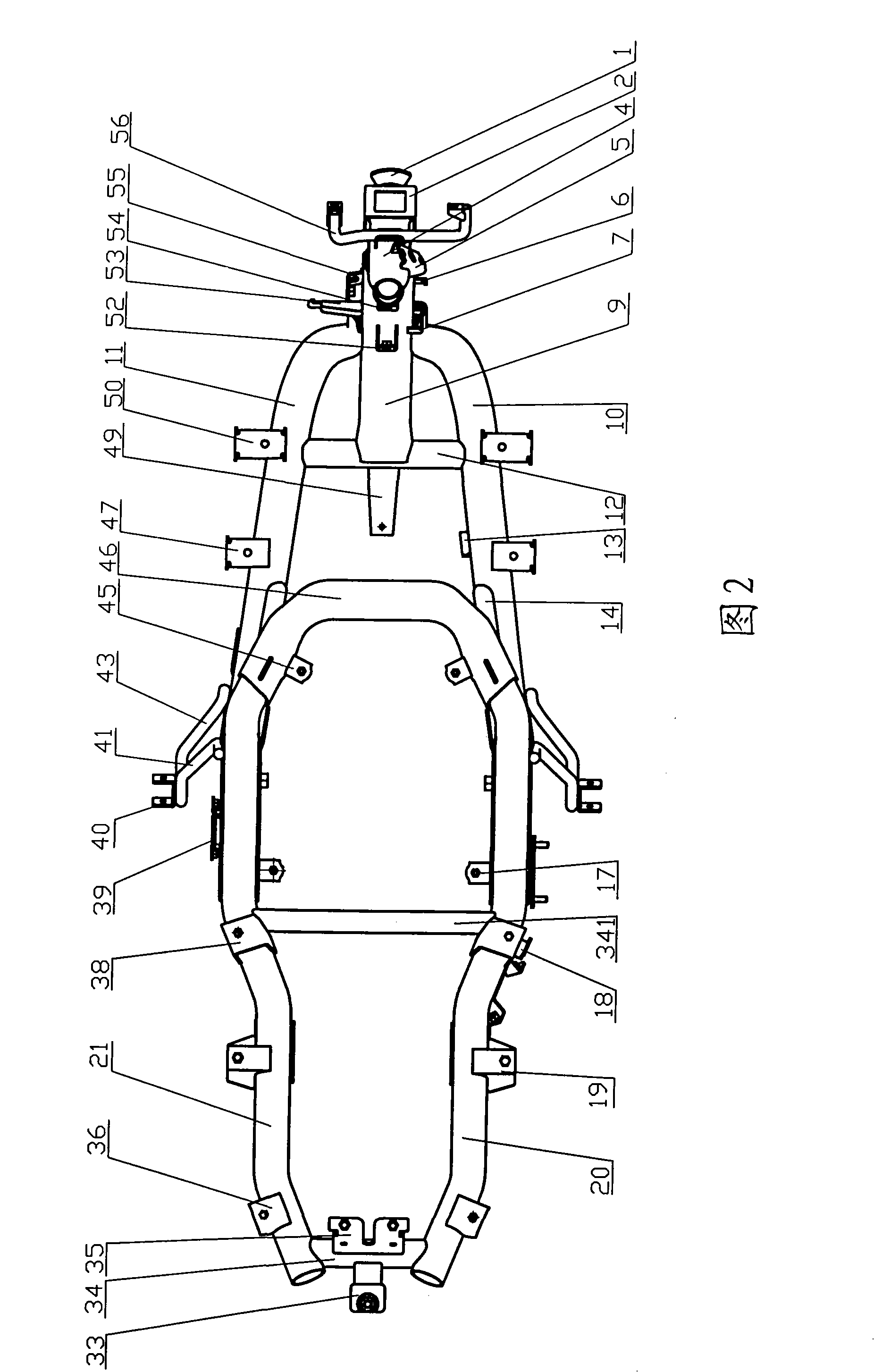

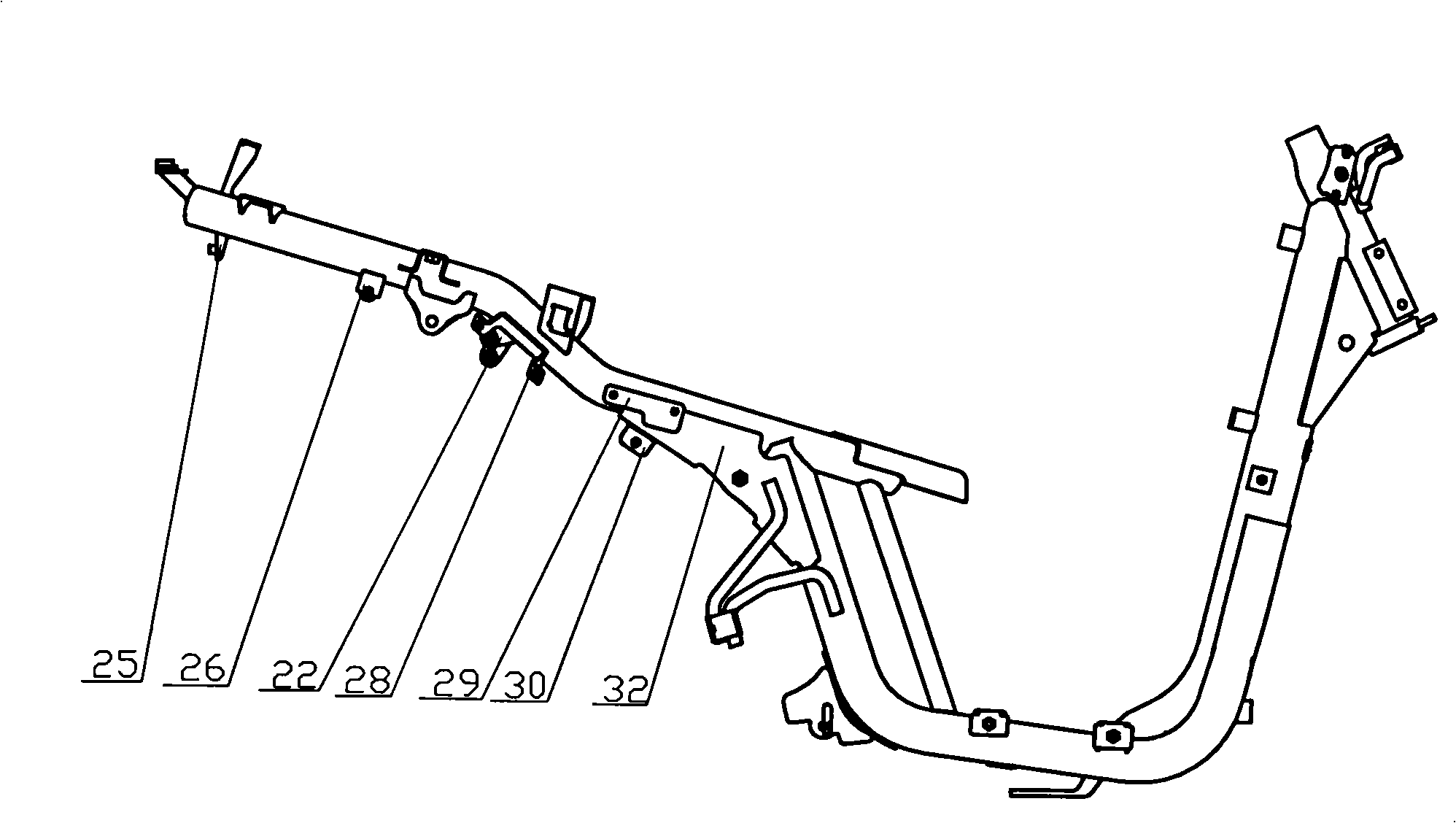

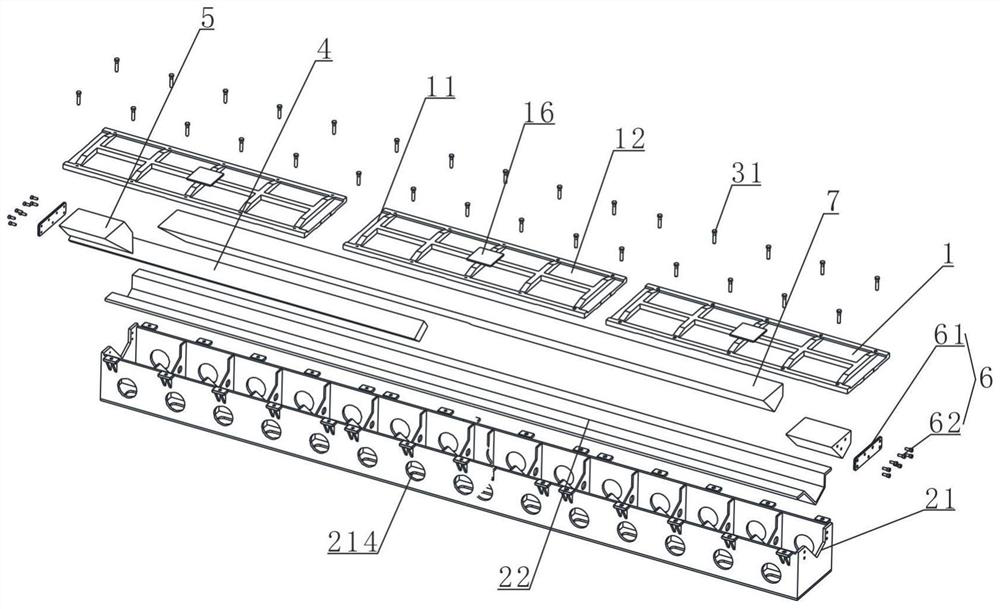

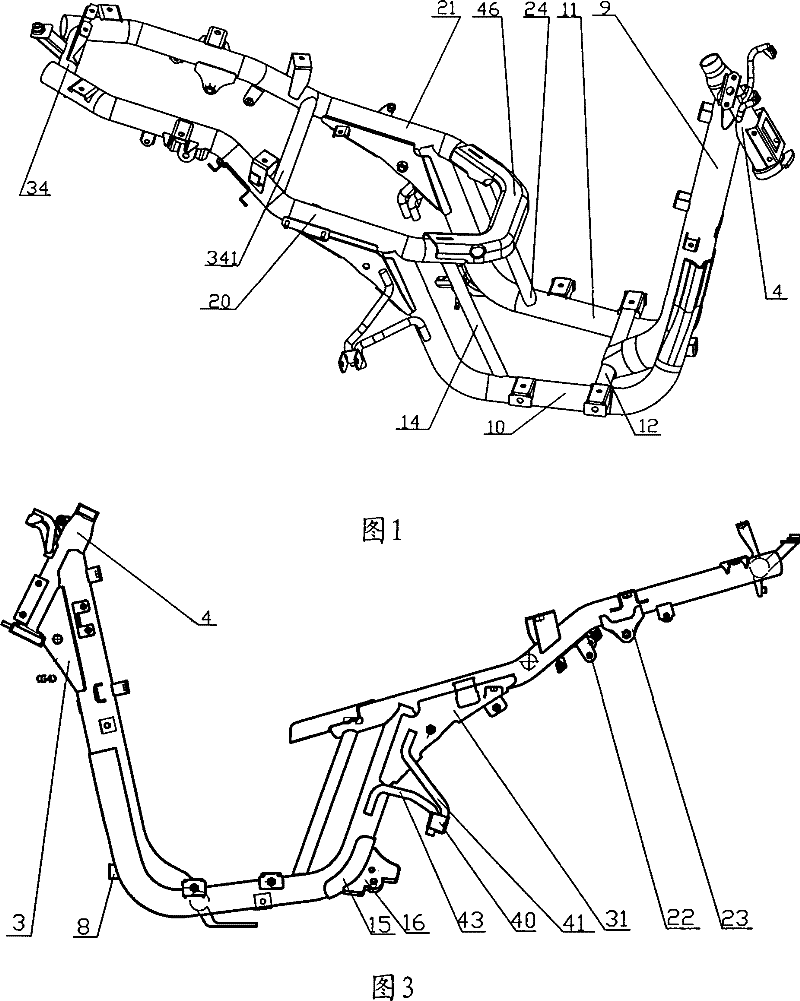

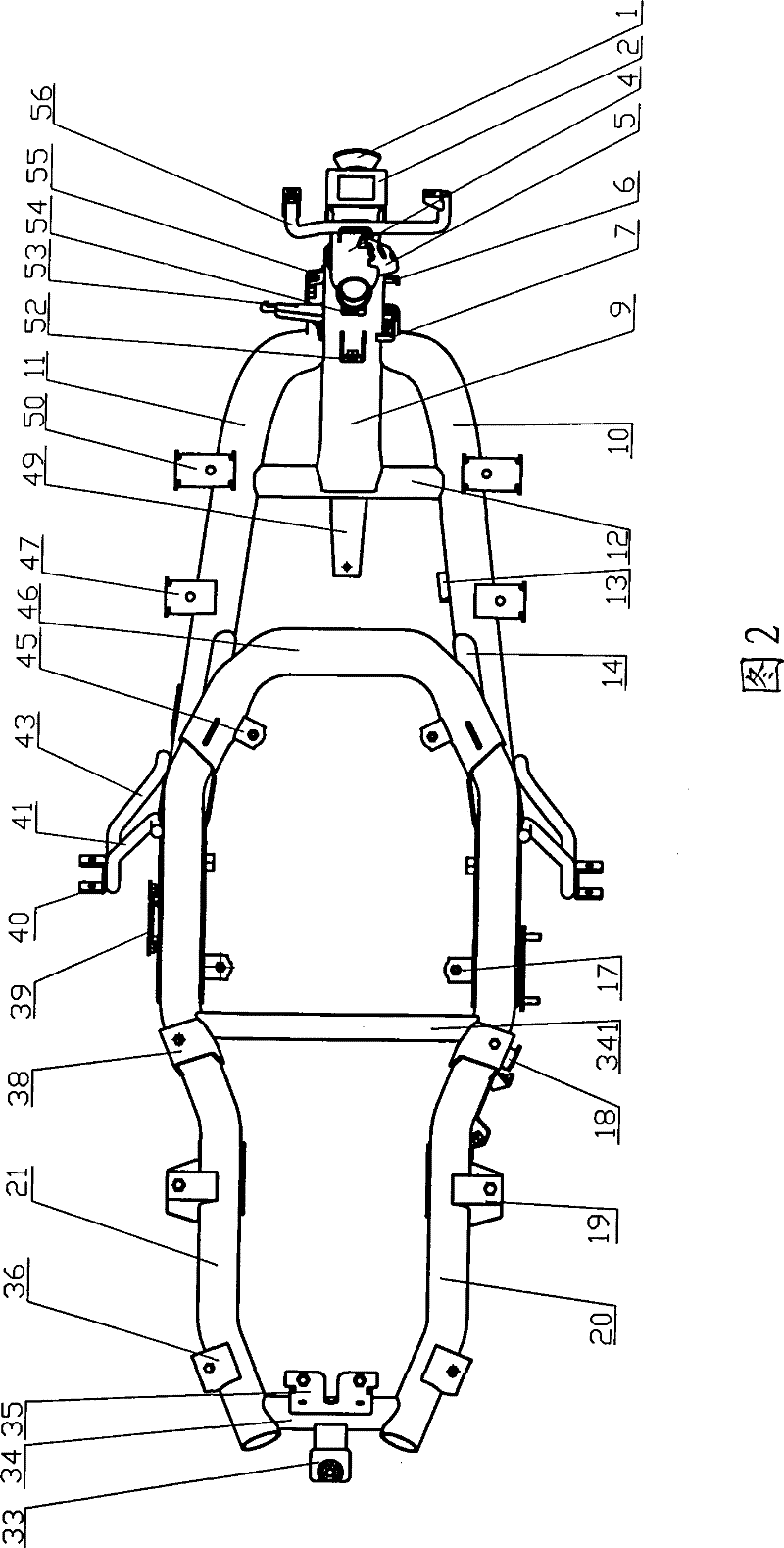

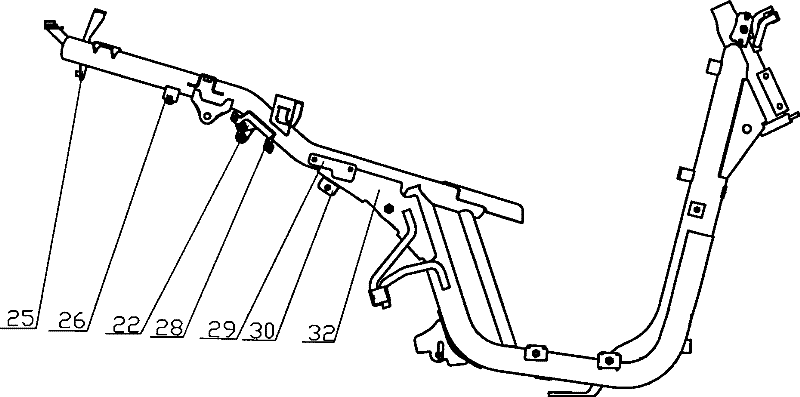

Cycle frame structure of pedal motorcycle

InactiveCN101402384AReduce the difficulty of manufacturing processReduce molding defectsMotorcyclesCycle framesPedal cycleVehicle frame

The invention discloses a frame structure for a pedal motorcycle, which comprises a frame main girder, a lower right pipe and a lower left pipe which are symmetrically arranged, and a right pipe and a left pipe which are symmetrically arranged, wherein front ends of the right pipe and the left pipe are connected through a stamping part with a U-shaped cross section; the opening of the stamping part with the U-shaped cross section is downwards; the stamping part with the U-shaped cross section coats the right pipe and the left pipe into the stamping part and connects the right pipe and the left pipe into a whole; and a left reinforcement tube and a right reinforcement tube for connecting the left and the right are welded between the front end of the right pipe and the U-shaped bottom of the lower right pipe, and between the front end of the left pipe and the U-shaped bottom of the lower left pipe respectively. The frame structure for the pedal motorcycle reduces the difficulty and the cost of the manufacturing technology of a vehicle frame, has better strength, is more convenient to assemble, provides a larger space for assembling an engine, can meet the space demand for assembling the engine without performing secondary processing on the vehicle frame, and particularly further reinforces the rigidity and the strength of the frame by making the lower left pipe and the lower right pipe form a quadrangular frame structure through arrangement of the left reinforcement tube and the right reinforcement tube.

Owner:CHONGQING LONCIN MOTOR

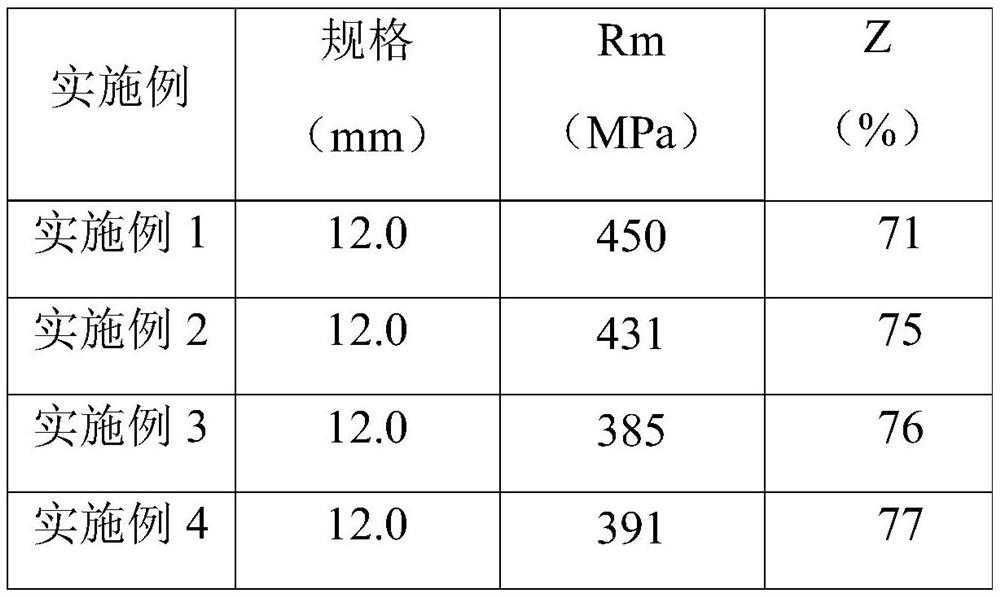

Low-carbon aluminum killed cold heading steel and production method thereof

ActiveCN112609131AReduced intensity indexImprove performanceTemperature control deviceShrinkage rateSteelmaking continuous casting

The invention relates to the technical field of metallurgy, and particularly discloses low-carbon aluminum killed cold heading steel and a production method thereof. Components of the cold heading steel comprise 0.06-0.09% of C, 0.30-0.50% of Mn, 0.03-0.06% of Si, not larger than 0.015% of P, not larger than 0.010% of S, 0.020-0.040% of Al and the balance Fe and inevitable impurities. The low-carbon aluminum killed cold heading steel is prepared through the procedures of steelmaking, continuous casting, heating rolling and spinning. Through component adjustment and process optimization, the mechanical property of the prepared cold heading steel meets the conditions that the tensile strength Rm is smaller than or equal to 450 N / mm < 2 > and the shrinkage rate Z is larger than or equal to 70%, the produced cold heading steel completely meets the use requirement, the mechanical property is stable, and large-scale application and popularization can be achieved.

Owner:HEBEI IRON AND STEEL

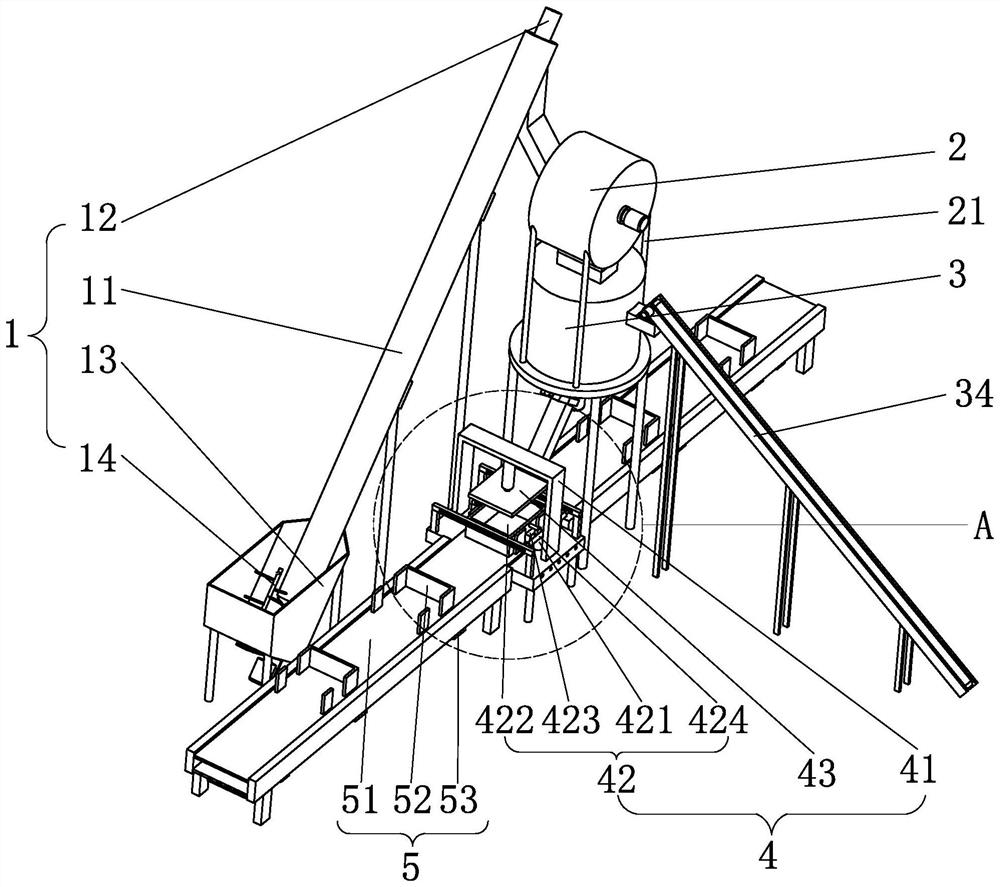

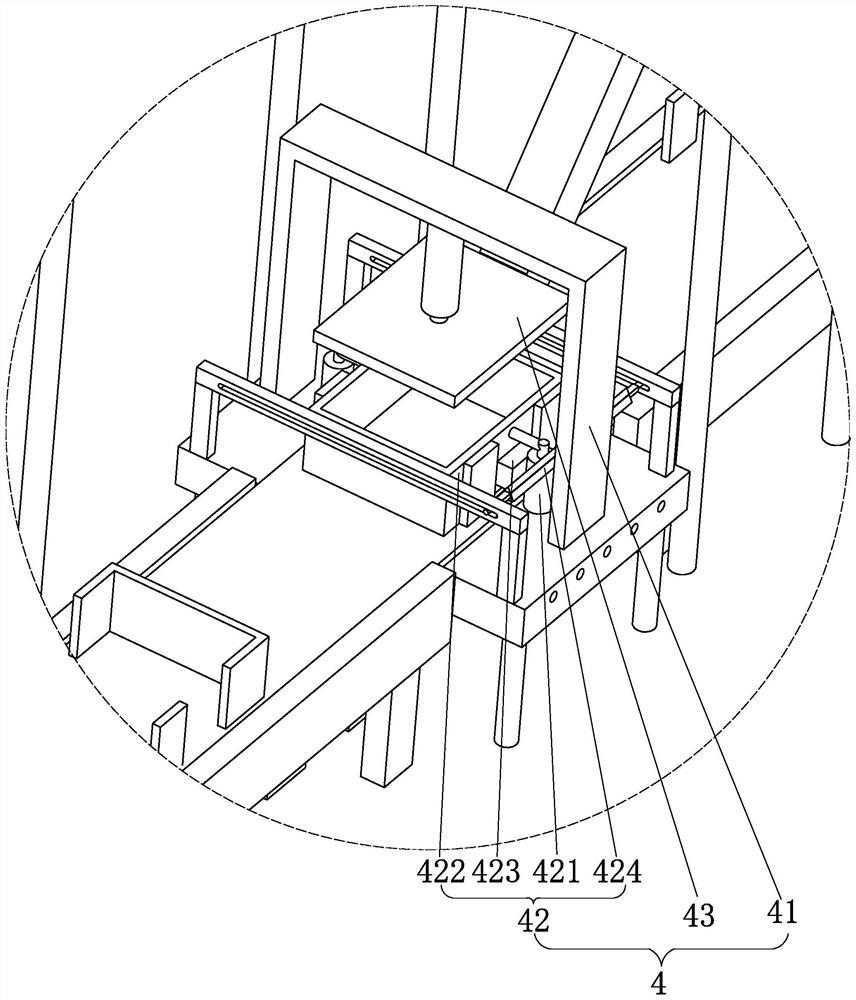

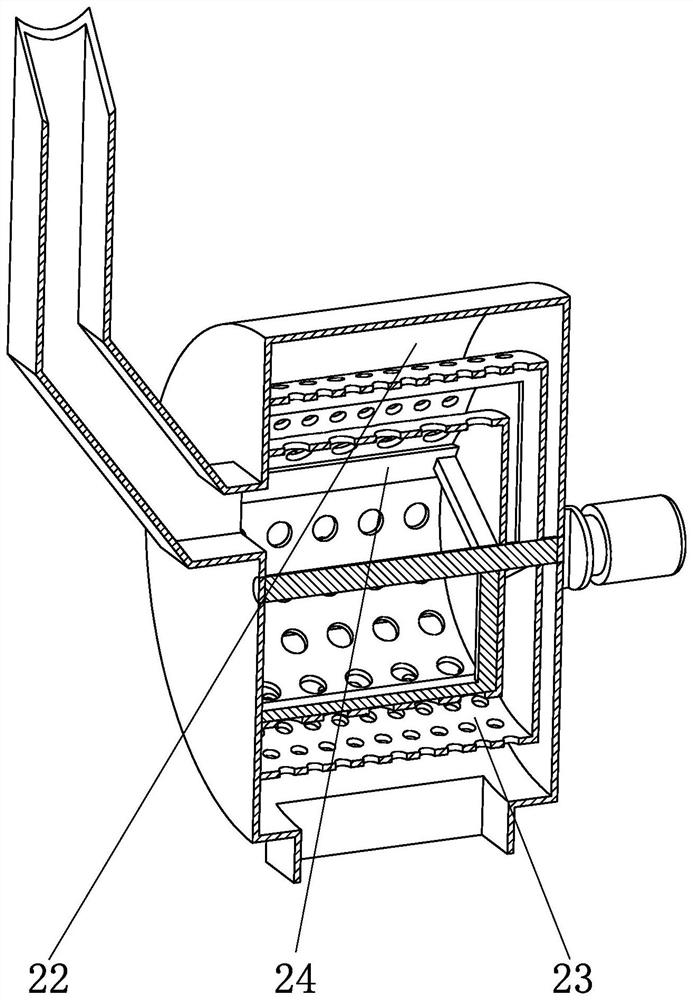

Environment-friendly regenerated brick preparation system

InactiveCN114102839AImprove compactnessReduce molding defectsDischarging arrangementMixing operation control apparatusEngineeringPolymer science

The invention relates to an environment-friendly regenerated brick preparation system, and mainly relates to the technical field of environment-friendly regenerated brick preparation, the environment-friendly regenerated brick preparation system comprises a feeding device, a crushing device connected with the feeding device, a mixing and stirring device arranged below the crushing device, a pressing device arranged at the discharging end of the mixing and stirring device, and a conveying device arranged below the pressing device; the pressing device comprises a supporting frame, a sliding mold arranged on the supporting frame and a downward pressing assembly arranged on the supporting frame. The sliding die comprises a die cylinder arranged on the supporting frame in a sleeving mode, a die connected with the telescopic end of the die cylinder, vibration exciters symmetrically arranged on the die, and a scraping plate arranged on the die in a sliding mode. The environment-friendly regenerated brick has the advantages of being good in quality and high in bearing capacity.

Owner:深圳市文浩环保再生有限公司

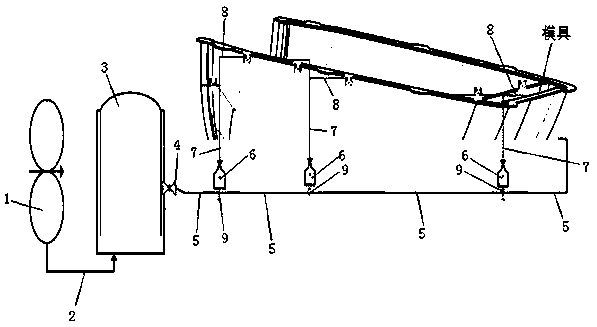

Reusable vacuum system applied to wind power cabin cover or flow guiding cover

The invention belongs to the technical field of preparation and application of wind power accessories and particularly discloses a reusable vacuum system applied to a wind power cabin cover or a flowguiding cover. The reusable vacuum system is composed of a vacuumizing assembly and an air-guiding glue-collecting assembly. The reusable vacuum system has the beneficial effects that 1, the design isreasonable, the vacuumizing assembly and the air-guiding glue-collecting assembly cooperate, the number of air extracting pipes adopted during air extracting is reduced by about 80%, the system is reusable, maintenance is convenient and free of troubles, and wastes during operation and product forming defects caused by air extracting pipe deformation and blockage are reduced; 2, a pipeline pressure sensor, a vacuum pump, a vacuum tank, a vacuum tank ball valve, a plurality of glue collecting barrel connecting ball valves, a touch display screen, a data transceiving unit, an early warning unitand a single chip microcomputer cooperate, the purpose of intelligent production control operation can be achieved, the operation efficiency and operation safety can be improved; and 3, whole structure is convenient o assemble and maintain, the anti-explosion property is good, and the security coefficient is high.

Owner:江苏携之创科技有限公司

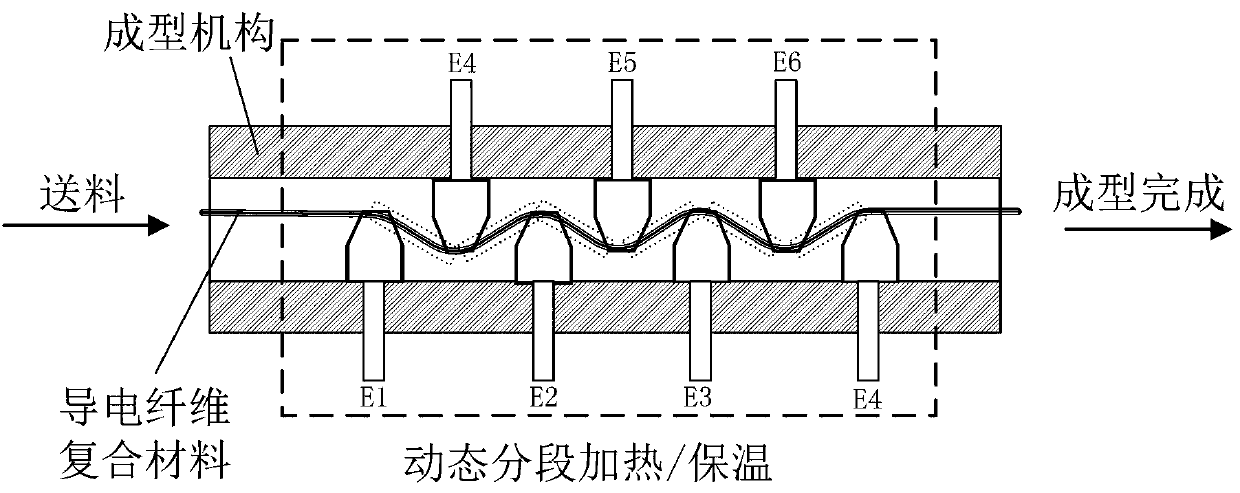

Fast in-situ molding method for conductive fiber reinforced composite material

ActiveCN109648895AAchieve step-by-step heatingSave time and costManufacturing cost reductionFiber-reinforced composite

The invention discloses a fast in-situ molding method for a conductive fiber reinforced composite material. The fast in-situ molding method is characterized in that a plurality of metal contacts withpotential differences are arranged on a molding mechanism, the dynamical-transmitted conductive fiber is in sliding or rolling contact with the metal contacts, the conductive fiber produces the electrical loss to generate heat among the multi-stage metal contacts, and according to each stage temperature monitored by sensors, dynamic adjusting and controlling of input electrical energy of each stage is conducted; and the composite material is heated stage by stage to the molding temperature, and the fast in-situ molding is completed. The fast in-situ molding method uses the material conductivity loss as the heat source, an external heat source does not need to be applied, in the extrusion, paving, pulling fiber composite material directional movement molding process, the high-speed heatingfinal in-situ molding of the composite material is achieved, the heat response speed of the composite material is high, fiber heating is uniform, the energy utilization is high, the method can greatlyimprove the quality of the composite material in-situ molding, shorten the manufacturing cycle of the fiber reinforced composite material, and reduce the manufacturing costs.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Crystal jade-like ceramic and production method thereof

The invention provides a crystal jade-like ceramic and a production method thereof. Firstly, magnesium, aluminum, barium, strontium, calcium and lithium serving as main components are synthesized into a composite base ceramic material; and then, the composite material and additive are used as raw materials and are prepared into the crystal, smooth and jade-like ceramic with high strength and highhardness by adopting the production processes such as sol-gel injection molding and surface polishing process and the like.

Owner:中国轻工业陶瓷研究所

A high-gloss three-dimensional texture material and its preparation method

Owner:ORINKO NEW MATERIAL CO LTD

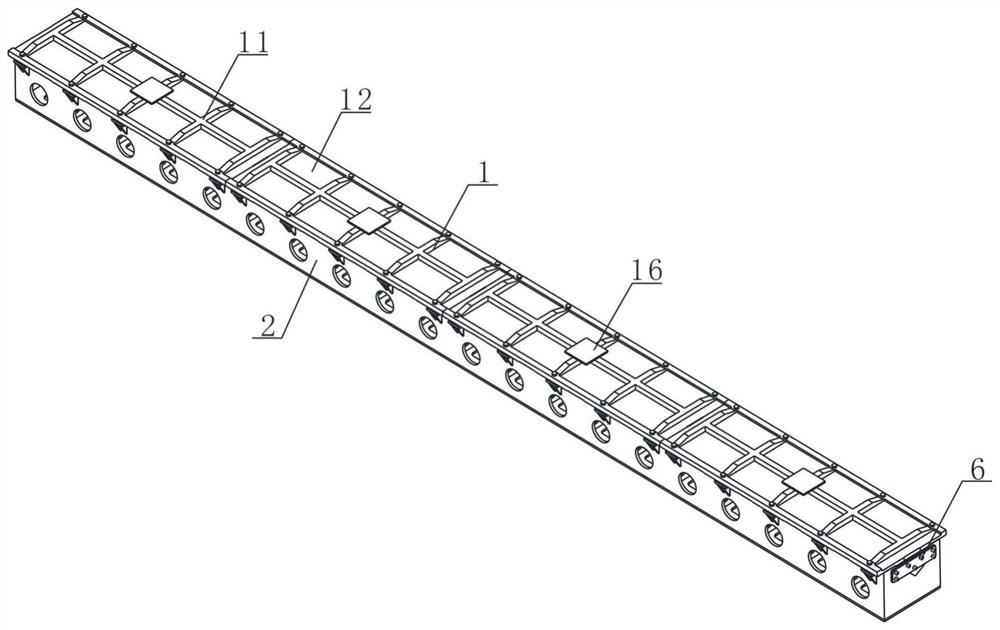

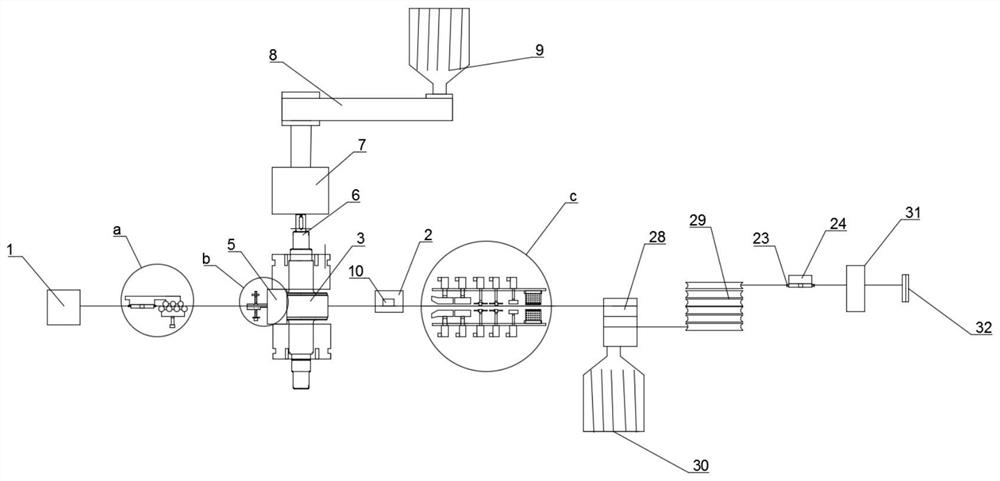

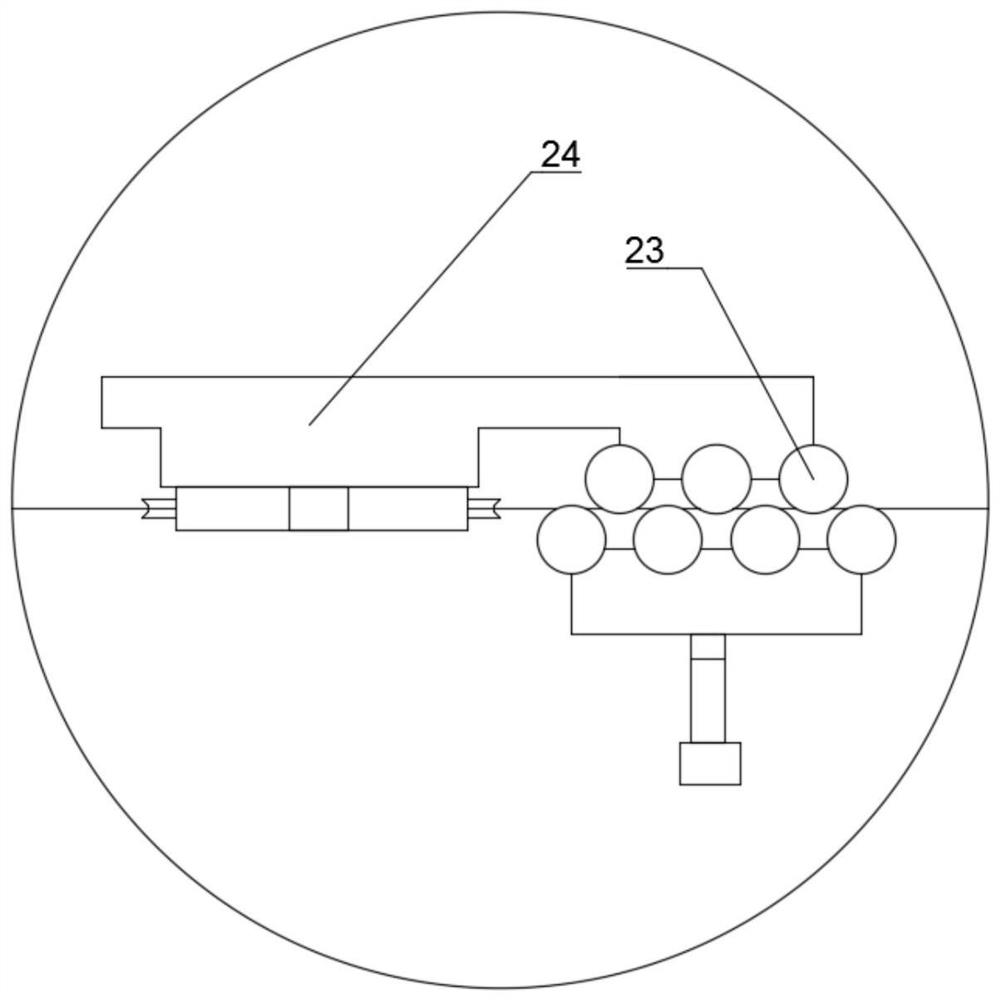

Small-diameter-thick-ratio cold-drawn coiled-welded steel pipe and combined rotating die-drawn coiled pipe equipment

ActiveCN103418627BReduce molding defectsPlay a secondary strengthening roleOther manufacturing equipments/toolsTube drawingTension stress

The invention relates to a steel pipe and steel pipe manufacturing equipment, and discloses a cold-drawing roll-welded steel pipe with small diameter-thickness ratio and combined die rotating drawing type pipe rolling equipment. The cold-drawing roll-welded steel pipe with small diameter-thickness ratio is characterized in that the external diameter of a steel pipe (9) is D, the wall thickness of the steel pipe (9) is t, the diameter-thickness ratio (D / t) of the steel pipe (9) is not greater than 21, and the wall thickness of the steel pipe (9) coiled from a steel plate (8) is not less than 4mm. The equipment comprises a conveying roller device (1), a combined die rotating device (2) and a traction device, wherein the combined die rotating device (2) comprises more than one arc gears (21). According to the invention, the radial constraining formation method and the tunnel die rotating technology are adopted, so that the tensile stress on the outer side basically counteracts the pressure stress constrained by the length, the pressure stress on the inner side is multiplied, the formation defect that fibrous cracks are caused on the outer side of the steel plate due to stretching can be reduced, and the steel plate is secondarily reinforced due to multiplication of pressure on the inner side of the steel pipe.

Owner:ZHEJIANG CTB WAVEFORM STEEL WEB

Planning method of typical path for 3D printing of continuous fiber reinforced composites

ActiveCN108891029BGuaranteed mechanical propertiesReduce molding defectsAdditive manufacturing apparatusManufacturing data aquisition/processingComputer Aided DesignModeling software

Owner:DALIAN UNIV OF TECH

Corner strengthened unequal thickness corrugated steel plate and manufacturing method

ActiveCN103423580BReduce molding defectsImprove structural strengthSheets/panelsUltimate tensile strengthForming processes

Owner:ZHEJIANG CTB WAVEFORM STEEL WEB

A kind of low-carbon aluminum killed cold heading steel and production method thereof

InactiveCN112609131BReduce intensityReduce hardnessTemperature control deviceShrinkage rateSteelmaking continuous casting

The invention relates to the technical field of metallurgy, and specifically discloses a low-carbon aluminum-killed cold heading steel and a production method thereof. The composition of the cold heading steel is: C 0.06~0.09%, Mn 0.30~0.50%, Si 0.03~0.06%, P≤0.015%, S≤0.010%, Al 0.020~0.040%, the balance is Fe and unavoidable The low-carbon aluminum-killed cold-heading steel is prepared through steelmaking, continuous casting, hot-rolling and spinning processes. The present invention makes the mechanical properties of the prepared cold heading steel satisfy the tensile strength Rm≤450N / mm through composition adjustment and process optimization 2 , the shrinkage rate Z≥70%, the cold heading steel produced fully meets the requirements of use, and has stable mechanical properties, which can be popularized and used on a large scale.

Owner:HEBEI IRON AND STEEL

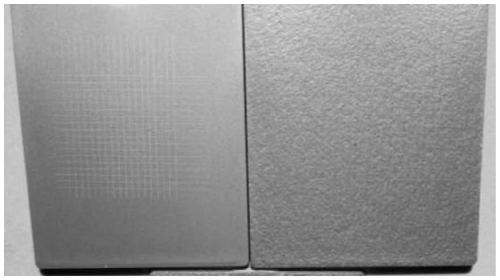

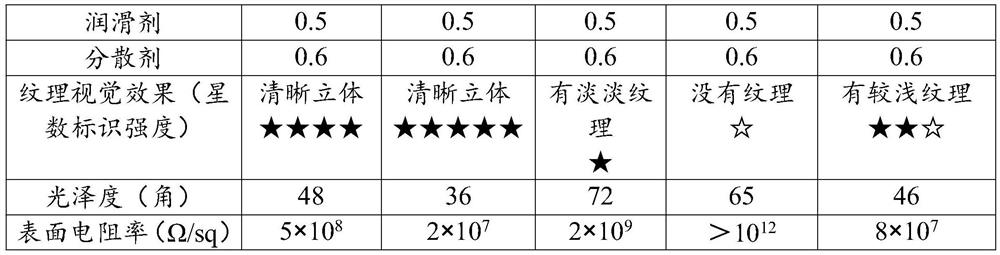

Antistatic imitated cloth three-dimensional texture material for household appliances and preparation method of antistatic imitated cloth three-dimensional texture material

The invention discloses an antistatic imitated cloth three-dimensional texture material for household appliances and a preparation method of the antistatic imitated cloth three-dimensional texture material. The antistatic imitated cloth three-dimensional texture material is prepared from the following components: ABS (Acrylonitrile Butadiene Styrene) resin, a macromolecular antistatic agent, special visual fibers, three-dimensional reticular filler, a reactant, an initiator, a compatilizer, a light stabilizer, an antioxidant, a lubricant and a dispersing agent. Compared with natural cloth, the three-dimensional effect is the same, the texture three-dimensional effect is clear and remarkable, the overall antistatic capacity is high, the application range is wide, and compared with a traditional material, when the composite material is applied to appearance materials of various household appliances, the electrostatic adsorption capacity of dust on the surface of a plastic part is greatly reduced, and harm of electromagnetic radiation attached to the dust to the human body is reduced; textures on the surface of an injection molded part easily form diffuse reflection on the resin surface, the overall glossiness is low, the visual effect is close to that of woven cloth, and furniture decoration and fusion are easy. The problems of poor texture effect and antistatic effect, easiness in dust adhesion and difficulty in cleaning of a cloth texture imitating material for household appliances are solved.

Owner:重庆会通科技有限公司

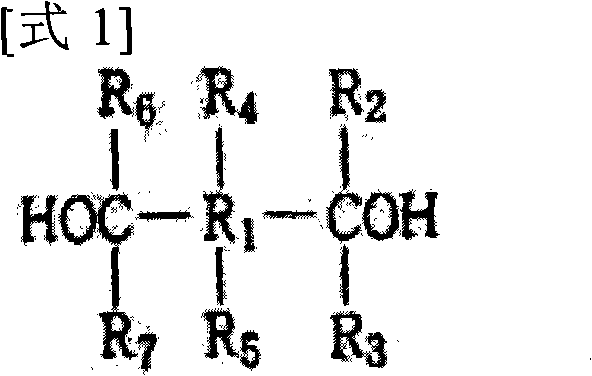

Copolymer polyester resin and molded product using same

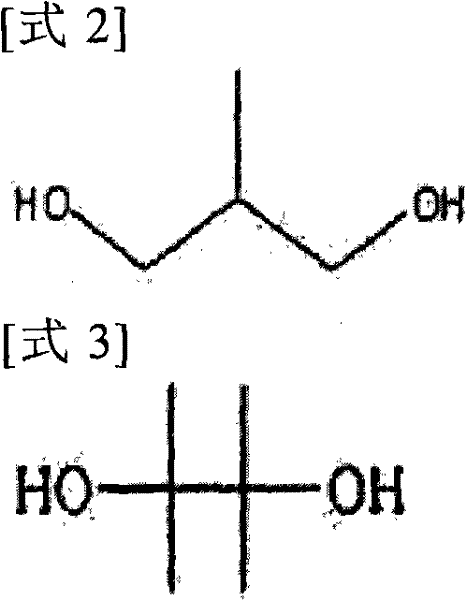

The present invention relates to a copolymer polyester resin and a molded product using the same and more specifically to a copolymer polyester resin that contains 10-80 mol% of 1,4-cyclohexane dimethanol, 0.1-50 mol% of a diol compound expressed as HO-R6CR7-R4R1R5-COHR2R3 (where R1 is an alkyl group with a carbon number of 0-10,and R2-R7 are hydrogens or alkyl groups with a carbon number of 1-10), and ethylene glycol as the remainder so that the sum of the entire diol composition is 100 mol% relative to aromatic dicarboxylic acid. The copolymer polyester resin of the present invention enables reduction of cycle time and improvement of product moldability and prevention of PET bottle deformation during mold processing with a heat-shrinking label by complementing low temperature shrinkage, maintaining a high shrinkage rate, and reducing shrinkage stress.

Owner:SK CHEM CO LTD

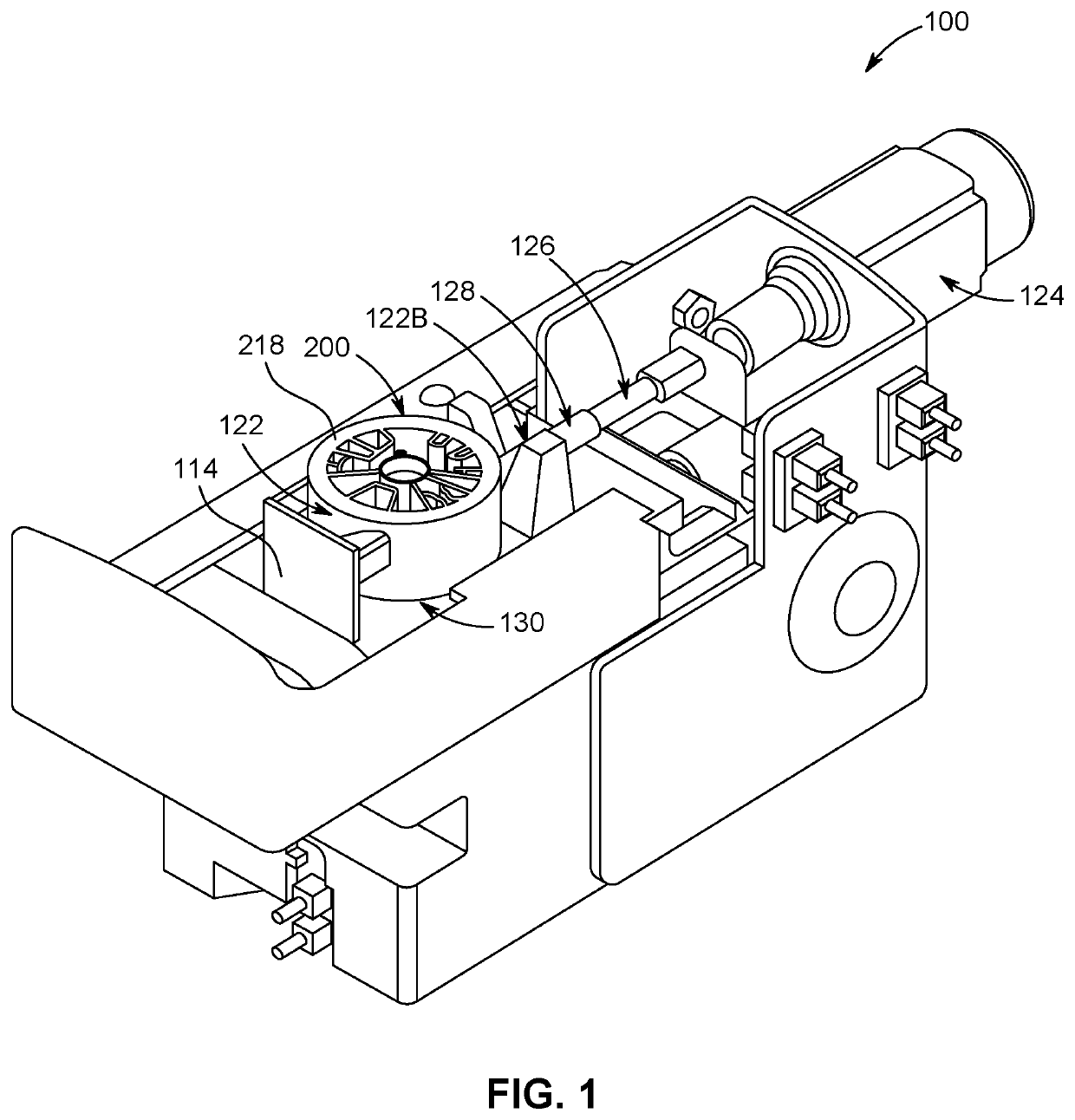

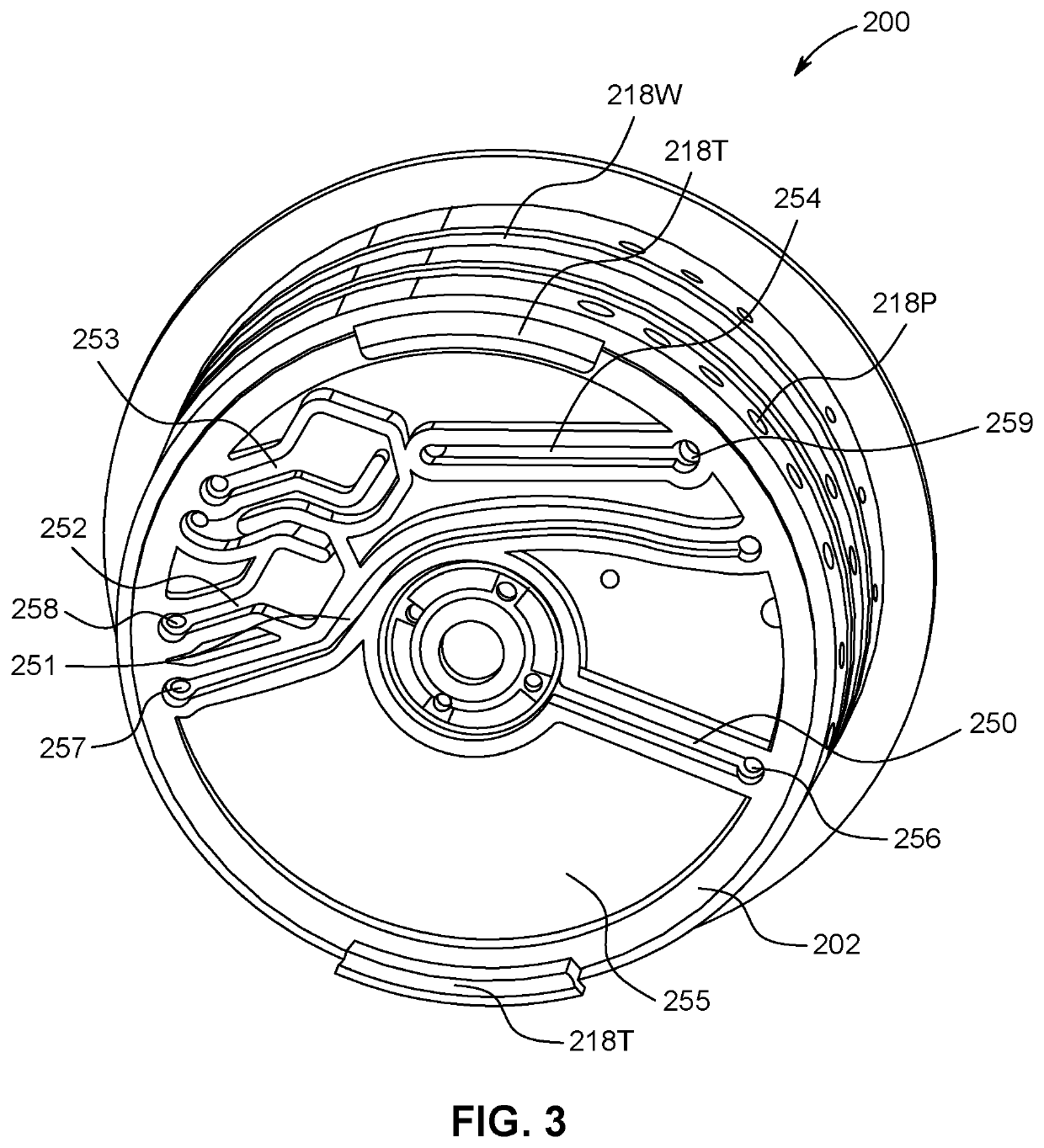

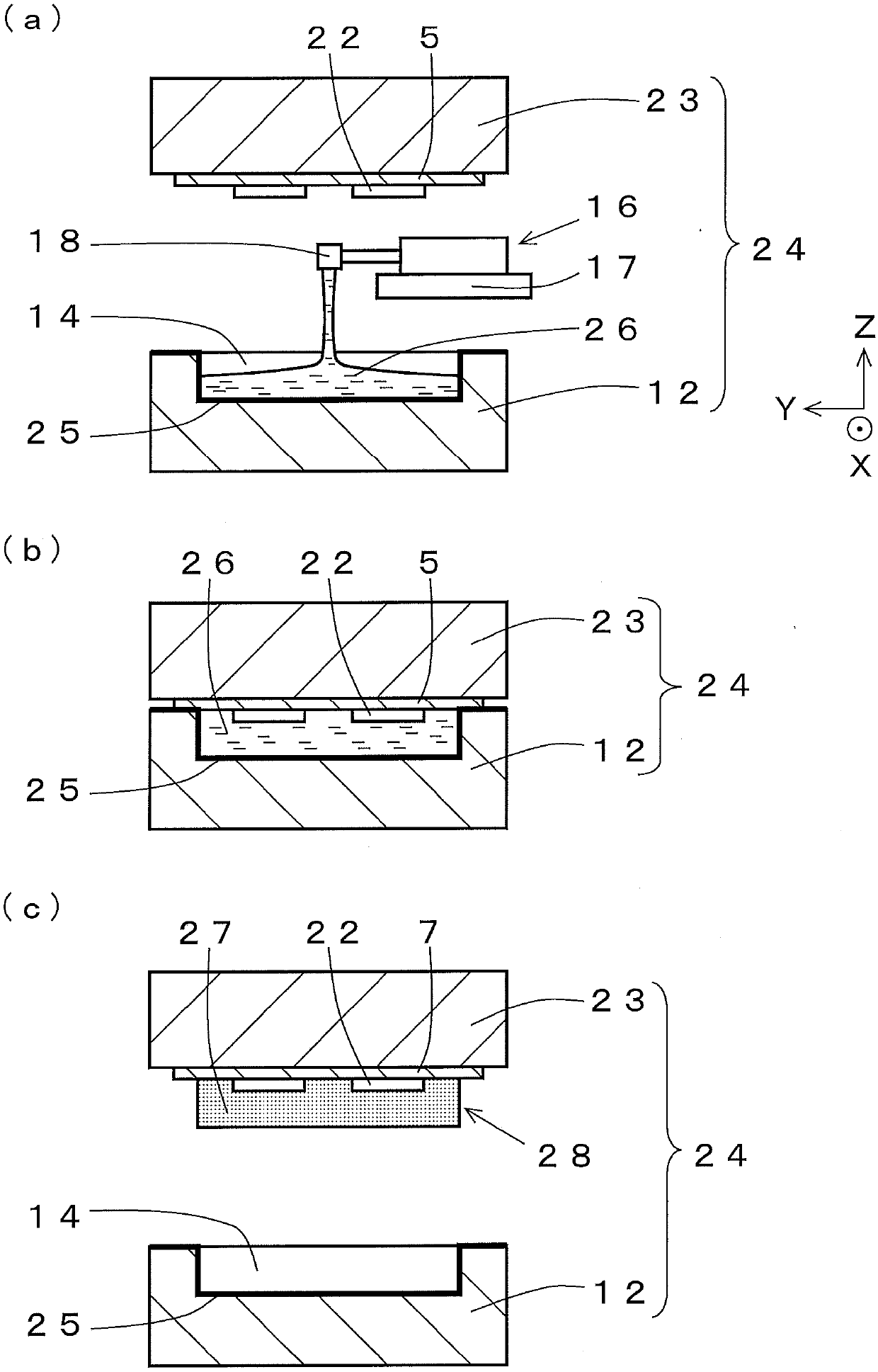

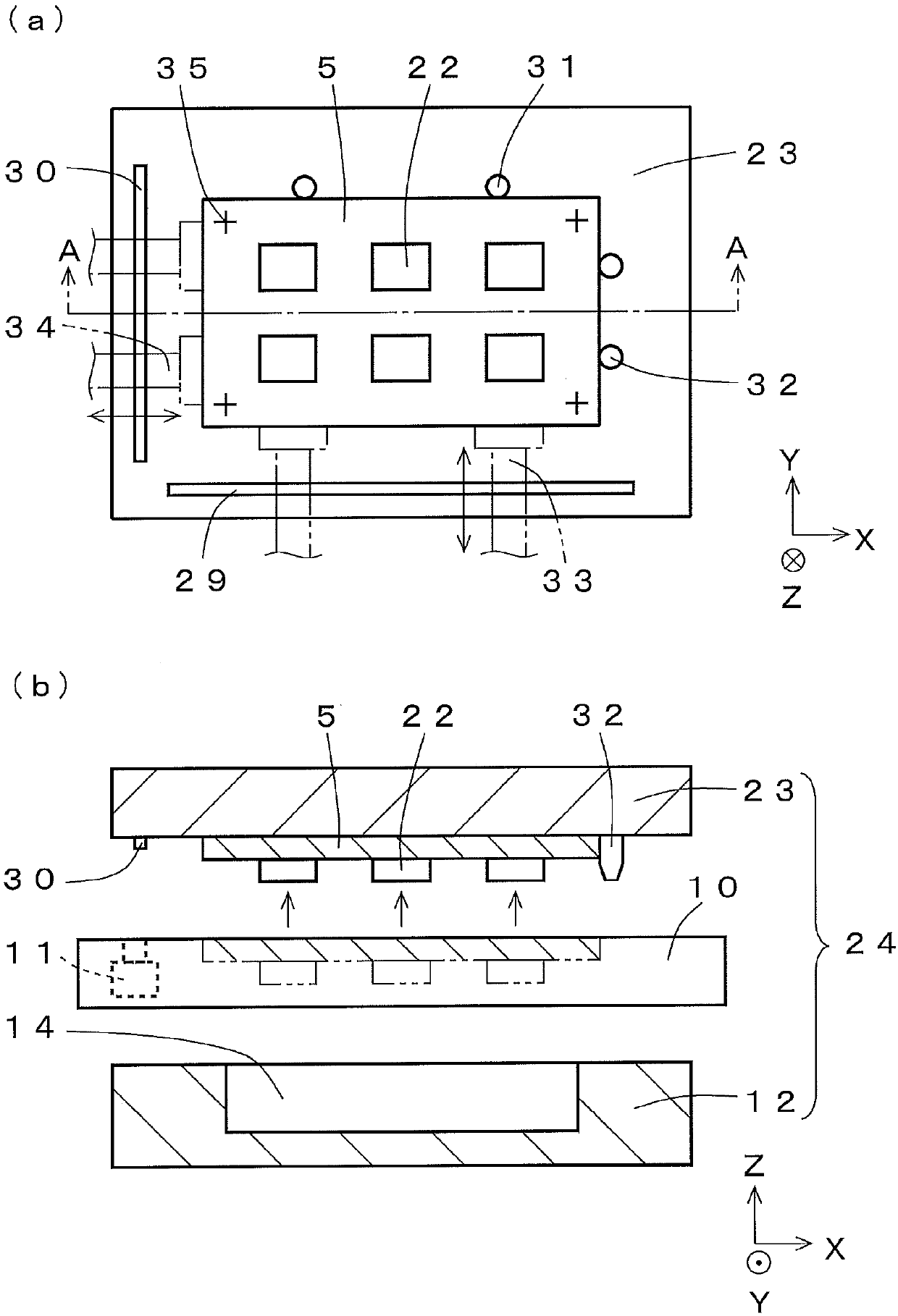

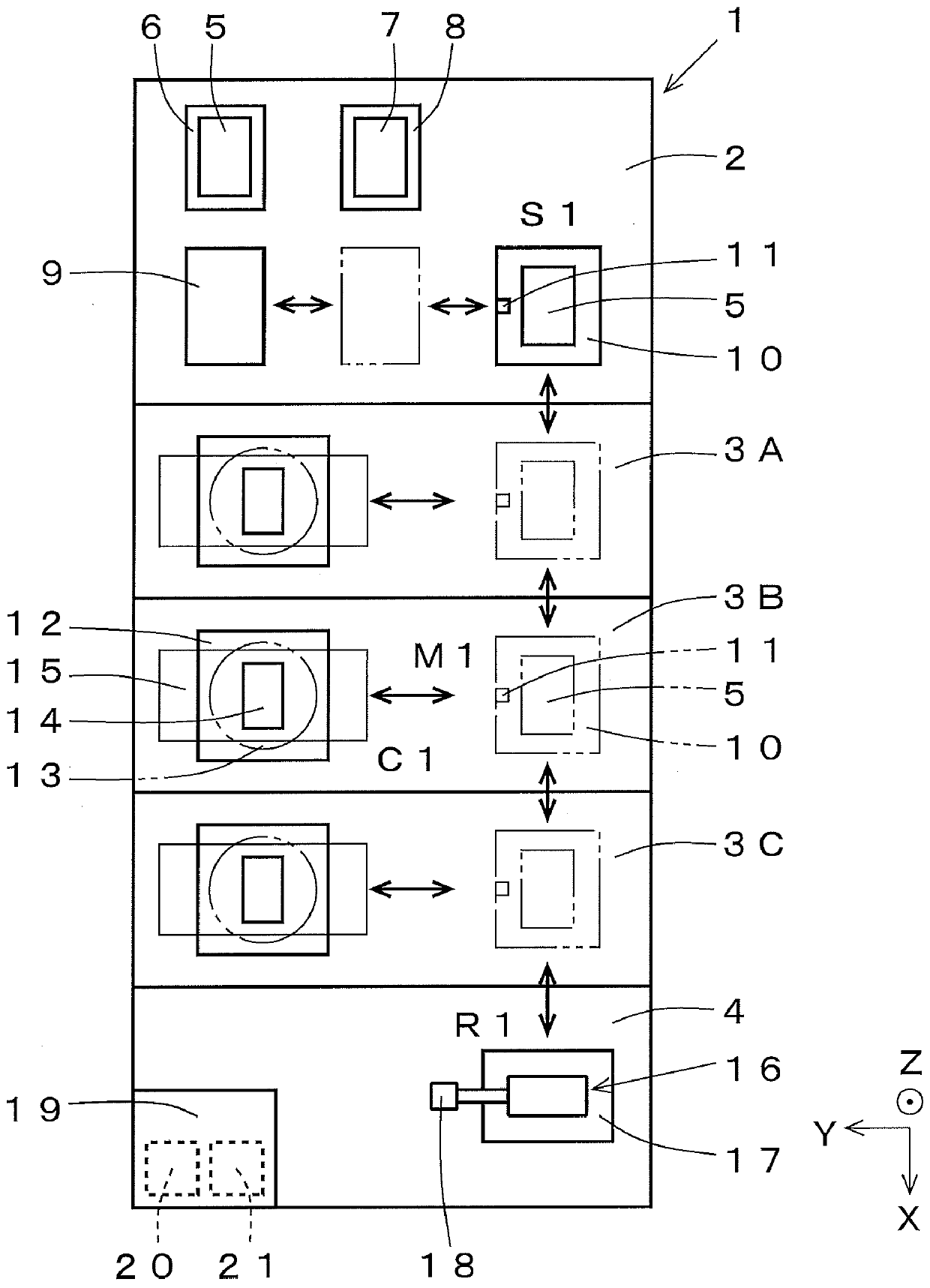

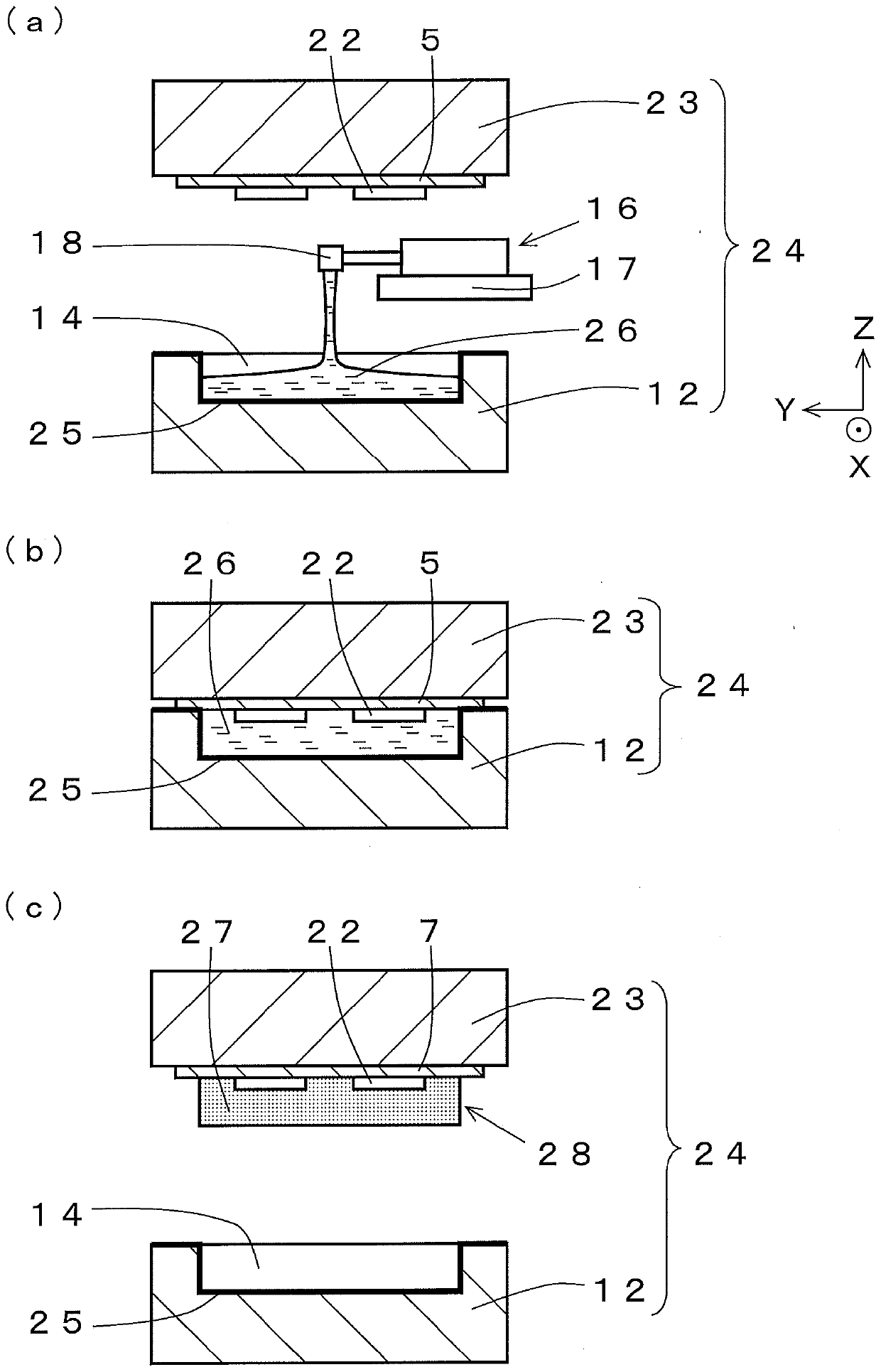

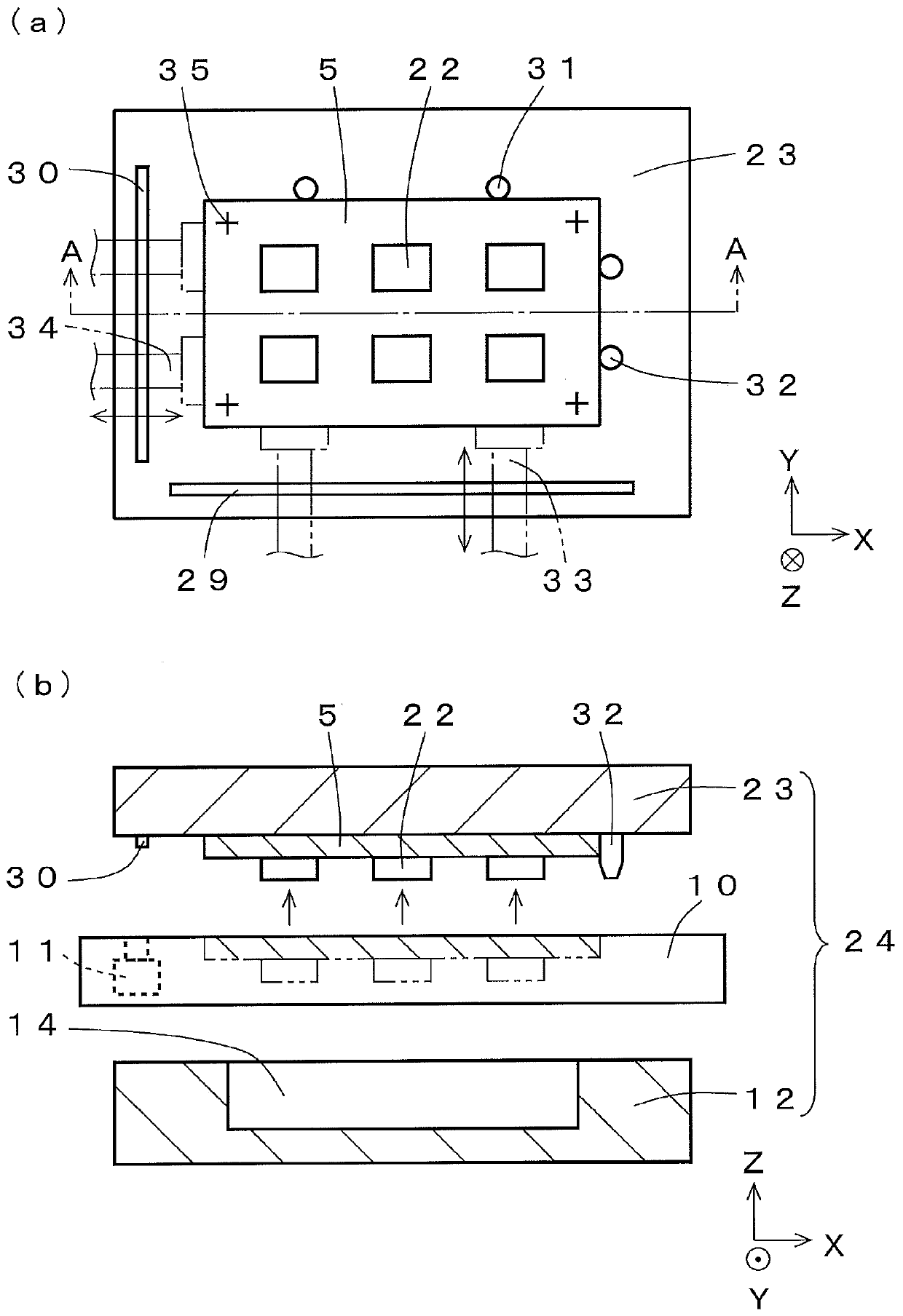

Resin molding apparatus and method for manufacturing resin molded product

ActiveCN107553799AReduce molding defectsSemiconductor/solid-state device manufacturingEngineeringImaging data

The invention relates to a resin molding apparatus and a method of manufacturing a resin molded product that verify whether a substrate supplied to a molding die is properly positioned or not. The apparatus includes a molding die 24 having a first die 23 and a second die 12 opposed to each other, a substrate feeding mechanism 10 for feeding a substrate to a die surface of the first die 23, a positioning mechanism that positions a positioning object 5 that includes at least a substrate; a mold clamping mechanism that molds the molding die 24; a camera 11 that is disposed between the first die and the second die when the molding die 24 is opened; and a processor that performs processing on image data captured by the camera. The first die has reference marks 29,30 which can be identified through photographing of the camera 11, and the camera 11 takes an image of the positioned object 5 and the reference marks 29 and 30. The processor 11 determines whether the object 5 is normally positioned according to the image data of the object 5 and the reference marks 29,30 captured by camera 11.

Owner:TOWA

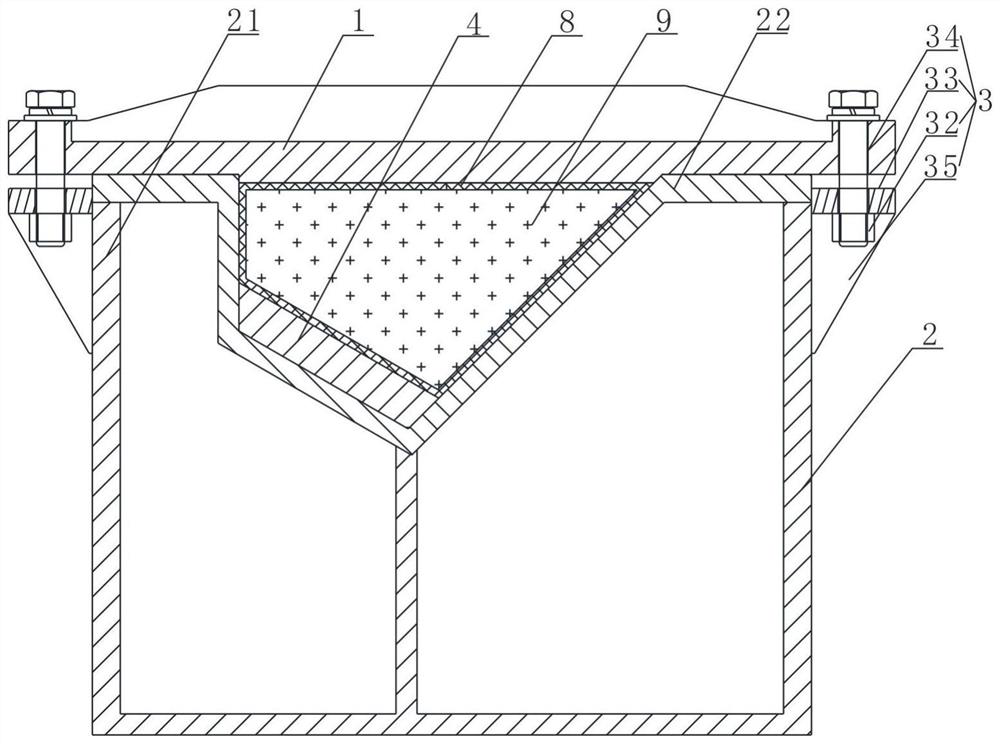

Composite material launching box guide rail forming mold and guide rail forming method

The invention provides a composite material launching box guide rail forming mold and a guide rail forming method.The guide rail forming mold comprises a lower mold, an upper mold, an insert and a bolt assembly, the lower mold is provided with a guide rail cavity, the upper mold is formed by splicing multiple sections, and the multiple sections of upper mold are connected with the lower mold through the bolt assembly; pressure generated by connection of the bolt assembly enables the guide rail to be formed to be pressurized, cured and formed in the guide rail forming mold cavity. By means of the guide rail forming die, the forming size precision, the surface smoothness and the material compactness of the launching box guide rail can be effectively guaranteed, and high-precision and ultra-slenderness-ratio composite guide rail forming can be economically and efficiently achieved. The guide rail is formed by adopting a resin pre-soaking method pressure forming process method, so that the production efficiency can be remarkably improved, the waste of auxiliary materials is reduced, and the cost is reduced.

Owner:SICHUAN AEROSPACE TUOXIN BASALT IND

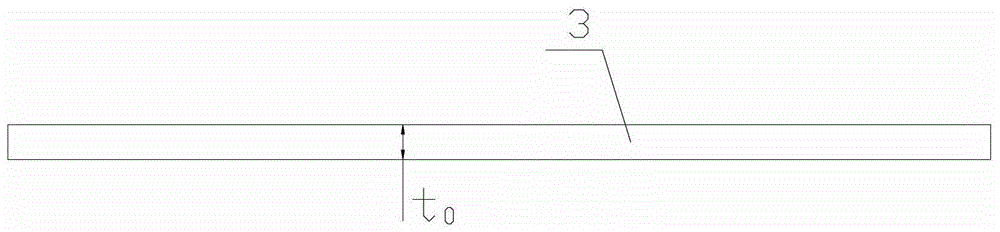

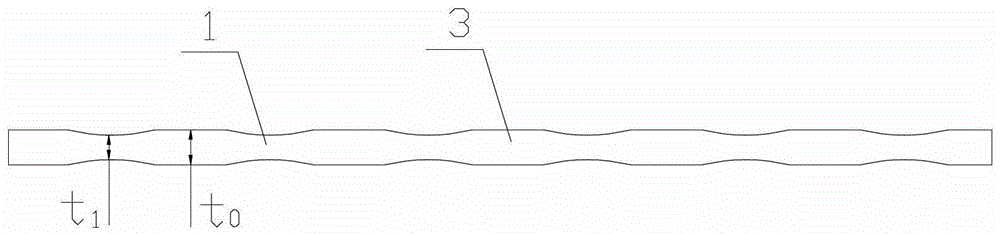

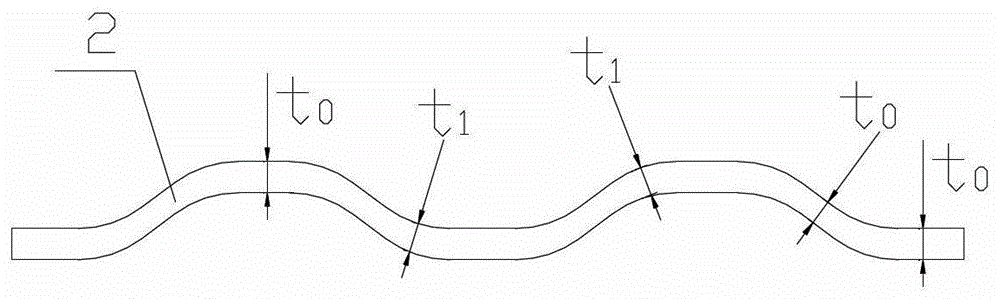

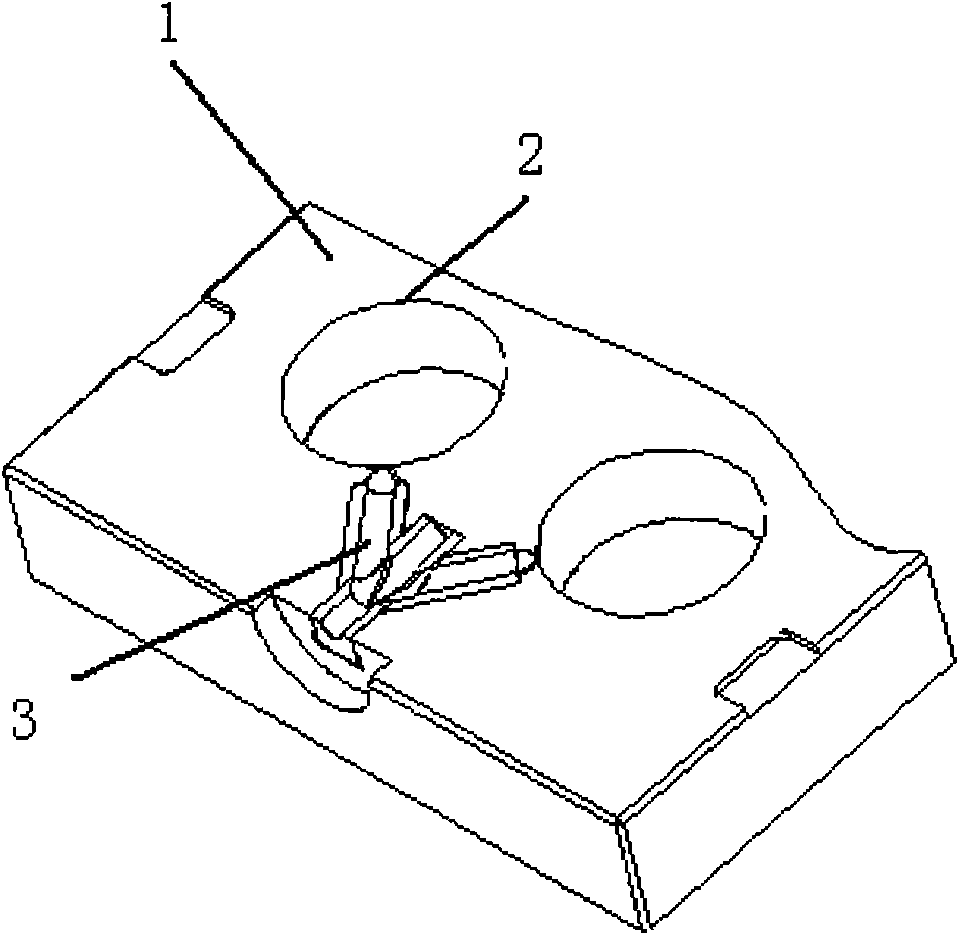

Internal structure of material injection nozzle of mould in APG process

The invention relates to an internal structure of a material injection nozzle of a mould in an APG process. The internal structure comprises a body (1) which comprises a pouring gate (2), and a material injection nozzle (3), wherein the inner wall of the material injection nozzle (3) is coated by a layer of polyfluortetraethylene material. The internal structure ensures the relatively low temperature of the material injection nozzle all the time, can maximally delay the solidification at the material injection nozzle so as to be beneficial to subsequent feeding of a formed product, maximally reduces formation defects such as product deformation, watermarks, air holes, and the like, and can well improve the qualification rate of components.

Owner:SHANGHAI ROX ELECTRIC

Cycle frame structure of pedal motorcycle

InactiveCN101402384BReduce the difficulty of manufacturing processReduce molding defectsMotorcyclesCycle framesVehicle frameManufacturing technology

The invention discloses a frame structure for a pedal motorcycle, which comprises a frame main girder, a lower right pipe and a lower left pipe which are symmetrically arranged, and a right pipe and a left pipe which are symmetrically arranged, wherein front ends of the right pipe and the left pipe are connected through a stamping part with a U-shaped cross section; the opening of the stamping part with the U-shaped cross section is downwards; the stamping part with the U-shaped cross section coats the right pipe and the left pipe into the stamping part and connects the right pipe and the left pipe into a whole; and a left reinforcement tube and a right reinforcement tube for connecting the left and the right are welded between the front end of the right pipe and the U-shaped bottom of the lower right pipe, and between the front end of the left pipe and the U-shaped bottom of the lower left pipe respectively. The frame structure for the pedal motorcycle reduces the difficulty and the cost of the manufacturing technology of a vehicle frame, has better strength, is more convenient to assemble, provides a larger space for assembling an engine, can meet the space demand for assemblingthe engine without performing secondary processing on the vehicle frame, and particularly further reinforces the rigidity and the strength of the frame by making the lower left pipe and the lower right pipe form a quadrangular frame structure through arrangement of the left reinforcement tube and the right reinforcement tube.

Owner:CHONGQING LONCIN MOTOR

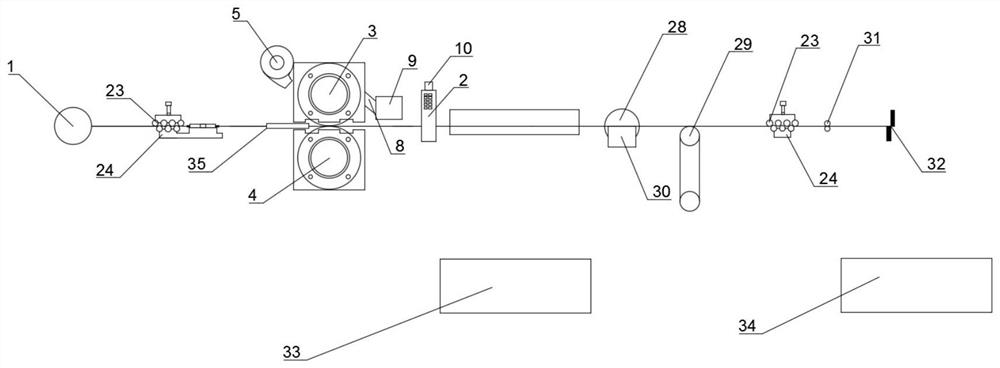

Tin sheet preparation device

PendingCN112808891AReduce molding defectsAvoid deformationMetal working apparatusElectric machineCoupling

The invention discloses a tin sheet preparation device. The tin sheet preparation device comprises a pay-off wheel, a straightening mold, a guide mechanism, a pressing mechanism, a diameter measuring instrument, a correcting mechanism and a storage mechanism which are horizontally arranged in sequence, the pressing mechanism comprises an upper roller and a lower roller, a variable frequency air cooler is arranged at the top of the upper roller, and universal couplings are fixed to the ends, at the same side, of the upper roller and the lower roller correspondingly; and gearboxes are arranged at output ends of two universal couplings and connected with a motor in a driving manner through a synchronous belt. According to the tin sheet preparation device, one or more tin soldering wires can be pressed and cut simultaneously, the tin soldering sheets which are standard in size, neat and attractive are produced, and the tin soldering wire pressing and cutting device is reasonable in structure, stable, reliable, easy to operate and high in automation degree; and operators can manage a plurality of machines simultaneously, so that the production efficiency is greatly improved.

Owner:BAODING YITONG PV SCI & TECH

Resin molding device and method for manufacturing resin molded product

ActiveCN107553799BReduce molding defectsSemiconductor/solid-state device manufacturingImaging dataMaterials science

Owner:TOWA

A kind of composite shaft and its preparation method and application

The invention discloses a preparation method of a composite material shaft. The method comprises the following steps: (1) dipping aramid fiber woven cloth or carbon fiber cloth in thermosetting resinto obtain a pre-dipped material; (2) winding the pre-dipped material on an expanding shaft; and (3) enabling a cylindrical cavity and the expanding shaft, on which the pre-dipped material is wound, tobe assembled, rotating the rotating arm of the expanding shaft to send the material into a hot-pressing tank to mold, opening the tank finally, shrinking the expanding shaft, demolding and completingthe preparation of the composite material shaft. The composite material shaft is prepared through adopting a vacuum inner expansion molding mode, bubbles in a shaft body can be quickly and effectively eliminated in a vacuum state, and molding defects are reduced; inner expanding extrusion can guarantee that woven cloth layers are uniformly distributed, and the defect that resin and fiber are notuniformly distributed cannot appear; compared with existing winding molding, the composite material shaft can further bear relatively great tension-compression stress when transmitting a large torquewhile a traditional winding molding transmission shaft cannot bear great tension stress.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

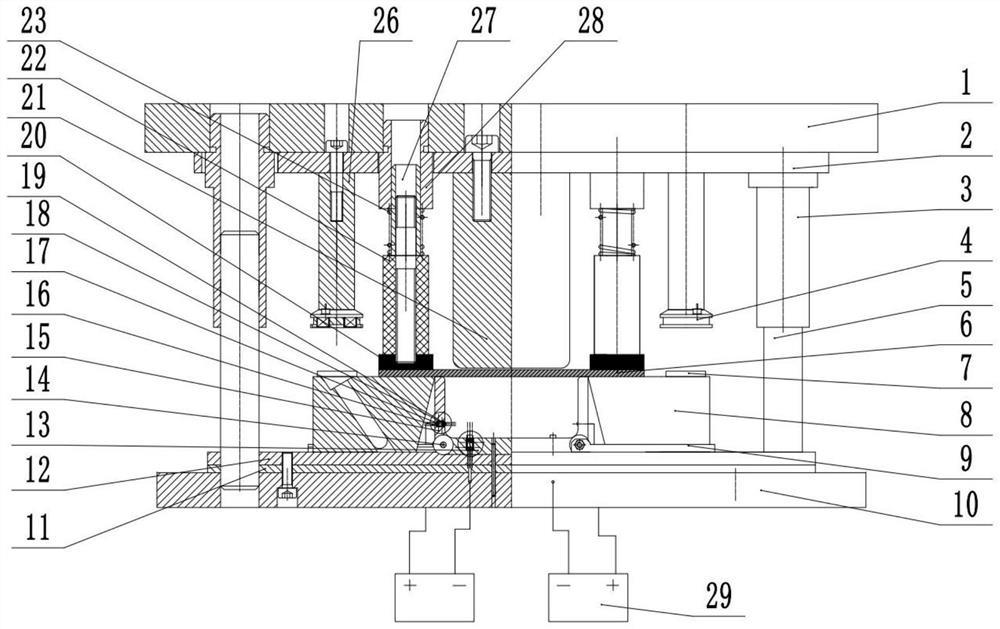

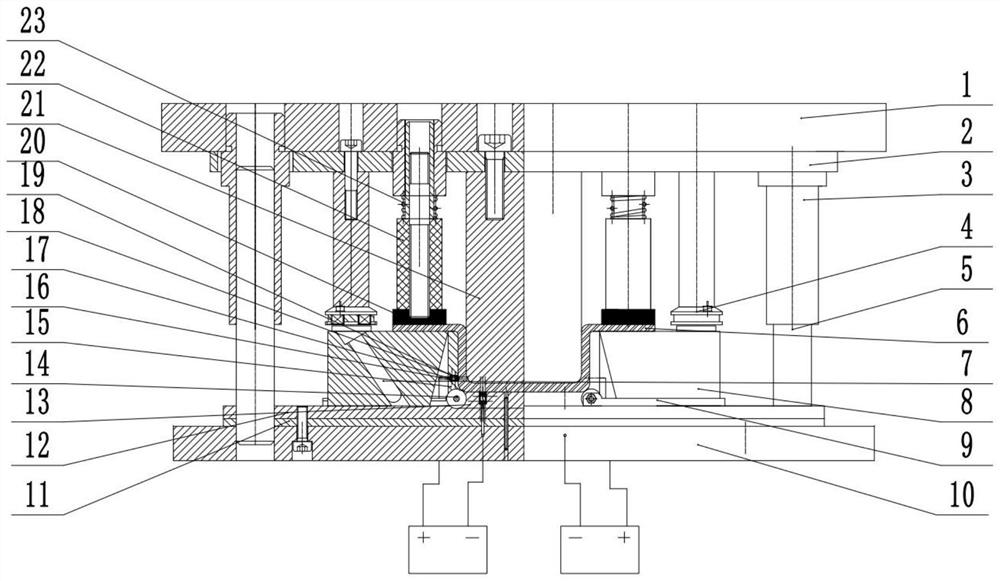

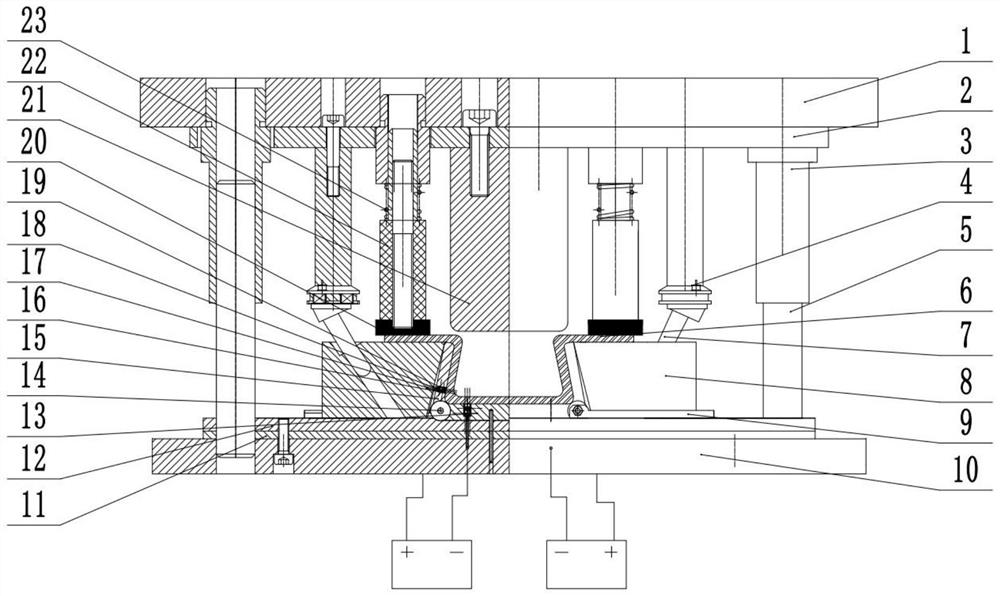

Forming die for inhibiting bending springback of plate and forming method of forming die

ActiveCN114433669AReduce molding defectsImprove work efficiencyShaping toolsStructural engineeringMachining process

The invention provides a forming die for restraining bending springback of a plate and a forming method of the forming die. The forming die comprises a male die assembly, a female die assembly and a springback compensation assembly. The second guide sleeve is connected with the first end of the second guide column in a matched mode, and the second end of the second guide column penetrates through the second spring through the insulating rubber sleeve to be connected with the edge pressing plate. The fixed end of the sliding block guide rail is fixedly connected with the installation end of the female die fixing plate, the sliding end of the sliding block guide rail is connected with the lower end of the female die sliding block, an inclined guide column is arranged in the female die sliding block, the female die push plate is connected with the female die bottom through a fixing shaft, and electrode through holes are formed in the female die base plate, the female die fixing plate, the female die bottom and the female die push plate. The first end of the electrode sequentially penetrates through the first spring and the interior of the elastic block to be connected with the electrode through hole, and the second end of the electrode is connected with an external power source. By means of the springback compensation assembly, in the bending machining process, the forming defects caused by the bending springback phenomenon to the plate are reduced, secondary machining is reduced, the production process is automatic, and the working efficiency is improved.

Owner:YANSHAN UNIV

High-entropy alloy reinforced high-speed steel wear-resistant material and preparation method thereof

ActiveCN114875288AHigh hardnessImprove wear resistanceAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysMetallic materials

The invention belongs to the technical field of metal materials, and relates to a high-entropy alloy reinforced high-speed steel wear-resistant material which is formed by compounding a high-entropy alloy and a high-speed steel matrix, the high-entropy alloy is FeCrCoNiHf (0.2 + x) B (0.8-x), the atomic ratio of Fe, Cr, Co, Ni, Hf and B in the high-entropy alloy is 1: 1: 1: 1: (0.2 + x): (0.8-x), x is equal to 0-0.6, the matrix is a high-speed steel material, and the high-entropy alloy is FeCrCoNiHf (0.2 + x) B (0.8-x). The mass fraction ratio of the high-entropy alloy to the high-speed steel matrix is (3-10): (97-90). The invention also discloses a preparation method of the material. The comprehensive performance of the wear-resistant material disclosed by the invention is greatly improved, particularly, key wear-resistant indexes such as high-temperature toughness and red hardness are superior to those of the existing high-speed steel wear-resistant material, the forming defects are few, and major defect accidents such as material stripping and meat falling accidents are controlled; and the high-entropy alloy is added to replace strengthening phases such as carbides separated out by depending on element supersaturation in high-alloy high-speed steel, alloying elements of the wear-resistant material are reduced, and the cost is reduced. The service life is prolonged, and the dimensional stability and the material forming finishing degree are improved.

Owner:河北中凯新创耐磨材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com