A kind of low-carbon aluminum killed cold heading steel and production method thereof

A production method and technology for cold heading steel, applied in the field of metallurgy, can solve the problems that the cold heading performance needs to be further improved and the production cost is high, and achieve the effects of improving internal quality, low cracking rate and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

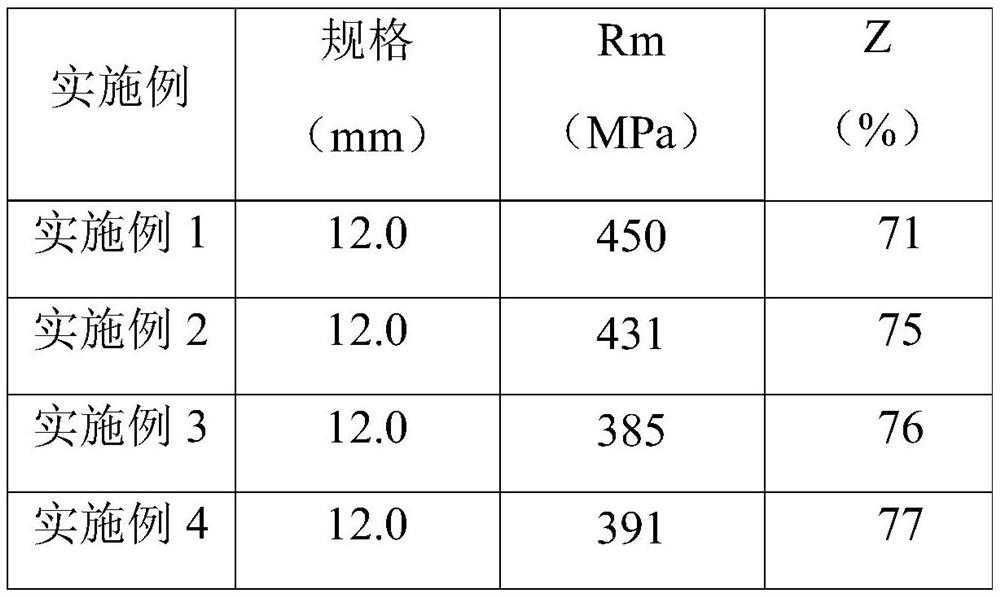

Examples

Embodiment 1

[0034] Embodiment of the present invention provides a low carbon aluminum killed steel, cold heading, specifications for a 12 mm diameter, its chemical composition is:

[0035] C 0.06%, Mn 0.50%, Si 0.06%, P 0.015%, S 0.010%, Al 0.020%, the balance being Fe and unavoidable impurities.

[0036] The above-described method of producing low carbon aluminum killed cold-forged steel is as follows:

[0037] Step one, the steelmaking process, converter control end component, S: 0.020%, P: 0.010%, C: 0.03%, the steel into the LF temperature was 1590 deg.] C, is added in an amount of deoxidizing agent 1.5kg / t; LF refining for Ca processing, Ca / Als = 0.11, white residue 16 minutes retention time;

[0038] Step two, casting process, superheat Tundish 30 ℃, controlling casting speed 1.7m / min;

[0039] Step three, the heating step of the rolling, the billet was charged 165 × 165mm heating furnace and heated, a heating temperature of 1010 deg.] C, a temperature difference billets head, mid...

Embodiment 2

[0043]Embodiments of the present invention provide a low carbon-aluminum sedation of calm-cooling steel, a specifications of φ12mm, and its chemical composition is:

[0044] C 0.09%, Mn 0.50%, Si 0.05%, P 0.013%, S 0.008%, Al 0.040%, and the margin is Fe and inevitable impurities.

[0045] The production method of the above-mentioned low carbon-aluminum sedation is as follows:

[0046] Step 1, Steelmaking Steel Steel Steel Steel Steel Steel Steel Steel Steel Steel Steel Steel Steel, 0.018%, P: 0.008%, C: 0.04%, the steel in the LF temperature of 1610 ° C, the dosage added is 3.0 kg / t; LF refining, CA / ALS = 0.12, white slag hold time 20 minutes;

[0047] Step two, the continuous casting process, the middle package steel water is 50 ° C, and the coil speed is controlled by 1.9 m / min;

[0048] Step three, heat the rolling step, load 165 × 165mm square billet into the heating furnace for heating, heat the temperature of 1025 ° C, continuous casting square blank head, central and...

Embodiment 3

[0052] Embodiments of the present invention provide a low carbon-aluminum sedation of calm-cooling steel, a specifications of φ12mm, and its chemical composition is:

[0053] C 0.07%, Mn 0.40%, Si 0.04%, P 0.012%, S 0.008%, Al 0.030%, and the margin is Fe and inevitable impurities.

[0054] The production method of the above-mentioned low carbon-aluminum sedation is as follows:

[0055] Steps, Steelmaking Steel Steel Steel Steel Steel, S: 0.017%, P: 0.007%, C: 0.035%, and the steel in the steel is 1600 ° C, the deoxidizer is added to 2.0kg / t; LF refinery CA Treatment, CA / ALS = 0.13, white slag hold time 18 minutes;

[0056] Step 2, the continuous casting process, the intermediate package steel is overheating 40 ° C, and the continuous cast pulsat is 1.8 m / min;

[0057] Step three, heat the rolling step, the 165 × 165mm square billet is loaded into the heating furnace for heating, the heating temperature is 1020 ° C, and the temperature of the casting member blank, the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com