Corner strengthened unequal thickness corrugated steel plate and manufacturing method

A corrugated steel plate and a manufacturing method technology, applied in sheet/board, building elements, etc., can solve problems such as fibrous cracks, achieve the effect of high structural strength and reduce the probability of forming defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

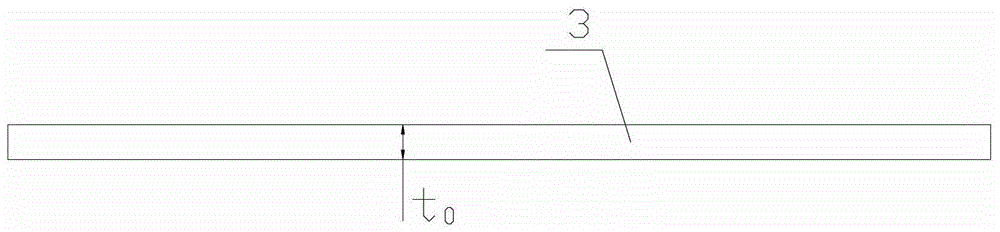

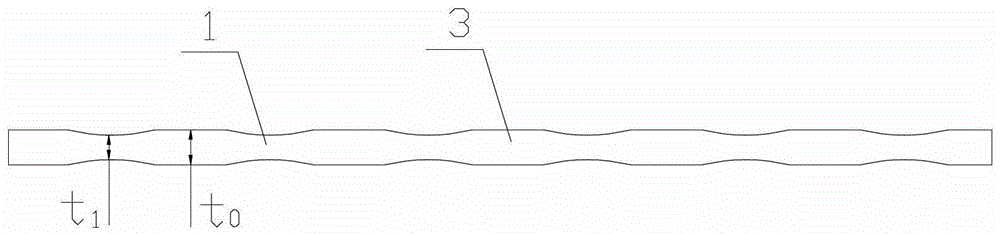

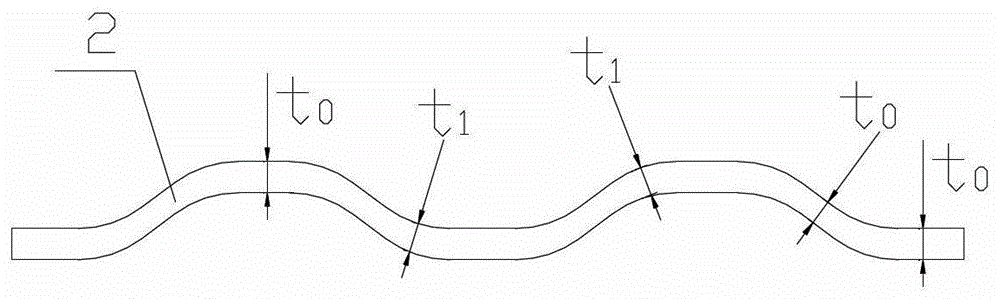

[0030] A corner strengthened unequal thickness corrugated steel plate, such as Figure 1 to Figure 7 As shown, it includes a straight unit and a corner unit 1, and the thickness of the steel plate at the corner unit 1 is t 1 Less than the thickness t of the original steel plate of the flat unit 0 , t 1 =98.1%t 0 .

[0031] The corner unit 1 is composed of a first straight line segment 11, a first rebound transition arc 12, a corner arc 13, a second rebound transition arc 14, and a second straight line segment 15. The radius R of the corner arc 13 is 7 times the thickness of the steel plate, and the first The radii of the bouncing transition arc 12 and the second bouncing transition arc 14 are gradually changed from infinity to the radius R of the corner arc 13 . The first bounce transition arc 12 includes a bounce arc 121 and a transition arc 122 . The radius of the first bounce transition arc 12, the second bounce transition arc 14 and the first straight line segment 11,...

Embodiment 2

[0039] Corner reinforced unequal thickness corrugated steel plates, such as Figure 1 to Figure 7 As shown, it includes a straight unit and a corner unit 1, and the thickness of the steel plate at the corner unit 1 is t 1 Less than the thickness t of the original steel plate of the flat unit 0 , t 1 =95.1%t 0 .

[0040] The corner unit 1 is composed of a first straight line segment 11, a first rebound transition arc 12, a corner arc 13, a second rebound transition arc 14, and a second straight line segment 15. The radius R of the corner arc 13 is 7 times the thickness of the steel plate, and the first The radii of the bouncing transition arc 12 and the second bouncing transition arc 14 are gradually changed from infinity to the radius R of the corner arc 13 .

[0041] The first bounce transition arc 12 includes a bounce arc 121 and a transition arc 122 . The changing range of the radius of the rebound arc 121 is: 3R→+∞, and the changing range of the radius of the transiti...

Embodiment 3

[0048] Corner reinforced unequal thickness corrugated steel plates, such as Figures 1 to 8 As shown, including the straight unit and the corner unit 1, the thickness of the steel plate at the corner unit 1 is t 1 Less than the thickness t of the original steel plate of the flat unit 0 , 98.5%t 0 ≥t 1 ≥93.2%t 0 .

[0049] The corner unit 1 is composed of a first straight line segment 11, a first rebound transition arc 12, a corner arc 13, a second rebound transition arc 14, and a second straight line segment 15. The radius R of the corner arc 13 is 8 times the thickness of the steel plate, and the first The radii of the bouncing transition arc 12 and the second bouncing transition arc 14 are gradually changed from infinity to the radius R of the corner arc 13 . The radius R of the corner arc 13 is 8 times the thickness of the steel plate. Through the setting of the first rebound transition arc 12 and the second rebound transition arc 14, the intergranular slip at the corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com