Antistatic imitated cloth three-dimensional texture material for household appliances and preparation method of antistatic imitated cloth three-dimensional texture material

A three-dimensional texture and anti-static technology, which is applied in the field of anti-static cloth-like texture three-dimensional texture materials for household appliances and its preparation, can solve the problems of difficult cleaning, easy dusting, poor texture effect and anti-static effect, etc., and achieves soft gloss of the material. , The overall gloss is low, the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

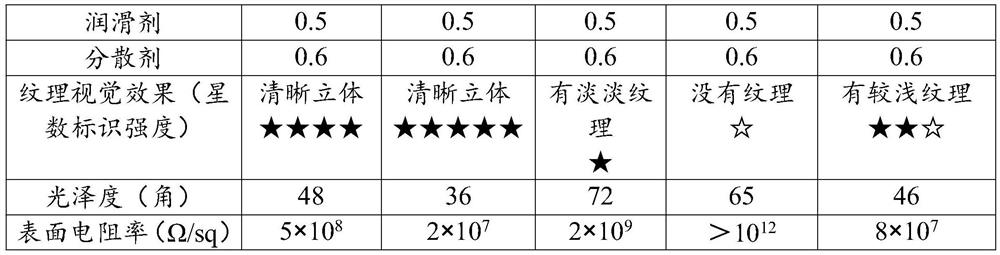

Examples

preparation example Construction

[0051] A method for preparing an antistatic cloth-like three-dimensional texture material for household appliances, comprising the following steps:

[0052] S1, primary mixed material

[0053] Weigh the ABS resin, compatibilizer, antioxidant, light stabilizer, lubricant and dispersant according to the mass ratio and add them to the high mixer under nitrogen protection for mixing to form the first mixture;

[0054] S2, secondary mixed material

[0055] Take macromolecular antistatic agent, special visual effect fiber, three-dimensional network filler, reactant and initiator by mass proportion and add in the high-mixer of nitrogen protection and mix, form the second mixture;

[0056] S3, extrusion granulation

[0057] The first mixture is fed into the main feeding port of the twin-screw extruder under the protection of nitrogen, and the second mixture is fed into the side feeding port of the twin-screw extruder under the protection of nitrogen, and extruded and granulated afte...

Embodiment 1

[0060] S1, primary mixed material

[0061] Weigh 78 kg of ABS resin, 3 kg of compatibilizer, 0.4 kg of antioxidant, 0.4 kg of light stabilizer, 0.5 kg of lubricant and 0.6 kg of dispersant according to the mass ratio, add the above-mentioned selected materials at a temperature of 40 ° C and Mix for 5 minutes in a high-mixer with nitrogen protection to form the first mixture, wherein the ABS resin is acrylonitrile-butadiene-styrene copolymer, the compatibilizer is a carboxylic acid grafted compatibilizer, and an antioxidant It is a hindered phenol antioxidant, the light stabilizer is a benzotriazole light stabilizer, the lubricant is a fatty acid amide lubricant, and the dispersant is a polymethacrylic acid derivative dispersant;

[0062] S2, secondary mixed material

[0063] Weigh 8 kg of polymer antistatic agent, 3 kg of special visual effect fiber, 5 kg of three-dimensional network filler, 1 kg of reactant and 0.1 kg of initiator according to the mass ratio, add the above-men...

Embodiment 2

[0067] S1, primary mixed material

[0068] Weigh 62.9 kg of ABS resin, 3 kg of compatibilizer, 0.4 kg of antioxidant, 0.5 kg of light stabilizer, 0.5 kg of lubricant and 0.6 kg of dispersant according to the mass ratio, add the above selected materials to a temperature of 60 ° C and Mix for 10 minutes in a high-mixer with nitrogen protection to form the first mixture, wherein the ABS resin is acrylonitrile-butadiene-styrene copolymer, the compatibilizer is a carboxylic acid grafted compatibilizer, an antioxidant It is a hindered phenol antioxidant, the light stabilizer is a benzotriazole light stabilizer, the lubricant is a fatty acid amide lubricant, and the dispersant is a polymethacrylic acid derivative dispersant;

[0069] S2, secondary mixed material

[0070] Weigh 15 kg of polymer antistatic agent, 5 kg of special visual effect fiber, 10 kg of three-dimensional network filler, 2 kg of reactant and 0.2 kg of initiator according to the mass ratio, add the above-mentioned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com