A kind of long-acting anticorrosion graphene modified solvent-free epoxy coating and preparation method thereof

A graphene modification and long-term anti-corrosion technology, which is applied in anti-corrosion coatings, coatings, etc., can solve the problems of low environmental protection and achieve the effect of improving corrosion resistance, high shielding performance, and long-term anti-corrosion performance guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

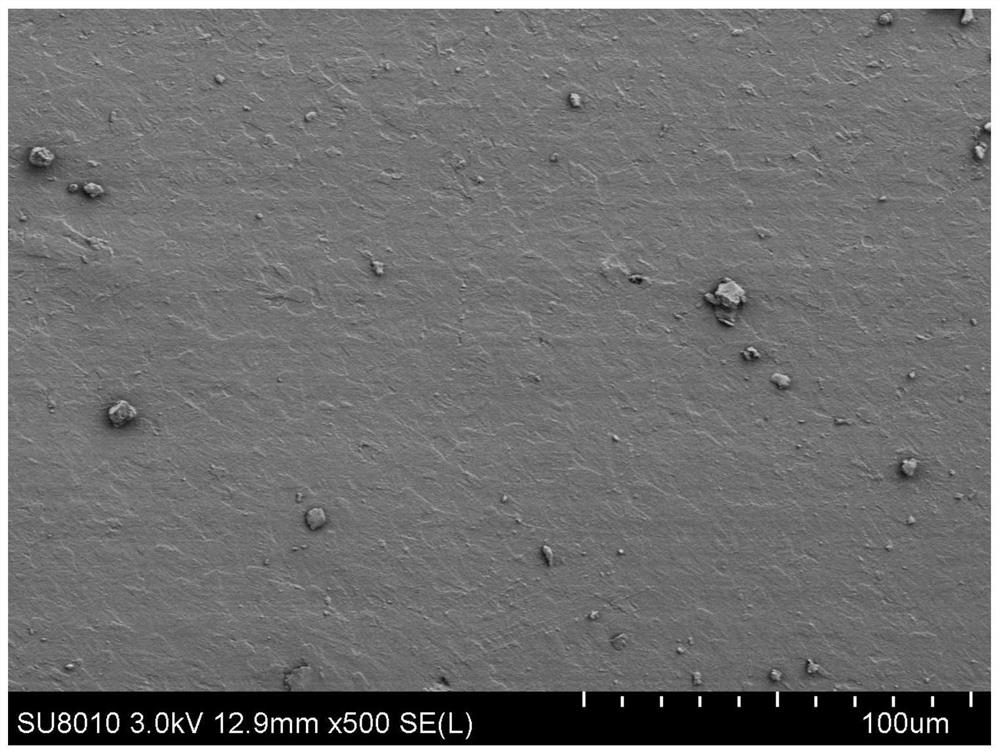

[0046] Example 1: Add 1 g of polyurethane-modified graphene microchips into 20 g of solvent-free epoxy resin, and stir for 20 to 60 minutes at 60°C to 80°C to prepare the matrix resin of the coating;

[0047] Step (2) Add 1g of wetting and dispersing agent, 1g of anti-rust pigment, and 1g of thickener to the matrix resin at one time, and use a sand mill to grind at room temperature, with the speed controlled at 1000-2500r / min, and grind for 2-5 hours;

[0048] Step (3) Add 1 g of defoamer in batches during the grinding process, control the dosage to no more than 5% of the total formula, grind until the fineness reaches below 50 μm, and filter and encapsulate with a 200-mesh filter to prepare the coating base material;

[0049]Step (4) Stir and mature the coating base material for 30-40 minutes before coating, and then mix it with 10 g of curing agent according to the above ratio to obtain a long-acting anti-corrosion graphene-modified solvent-free epoxy coating that can be coat...

Embodiment 2

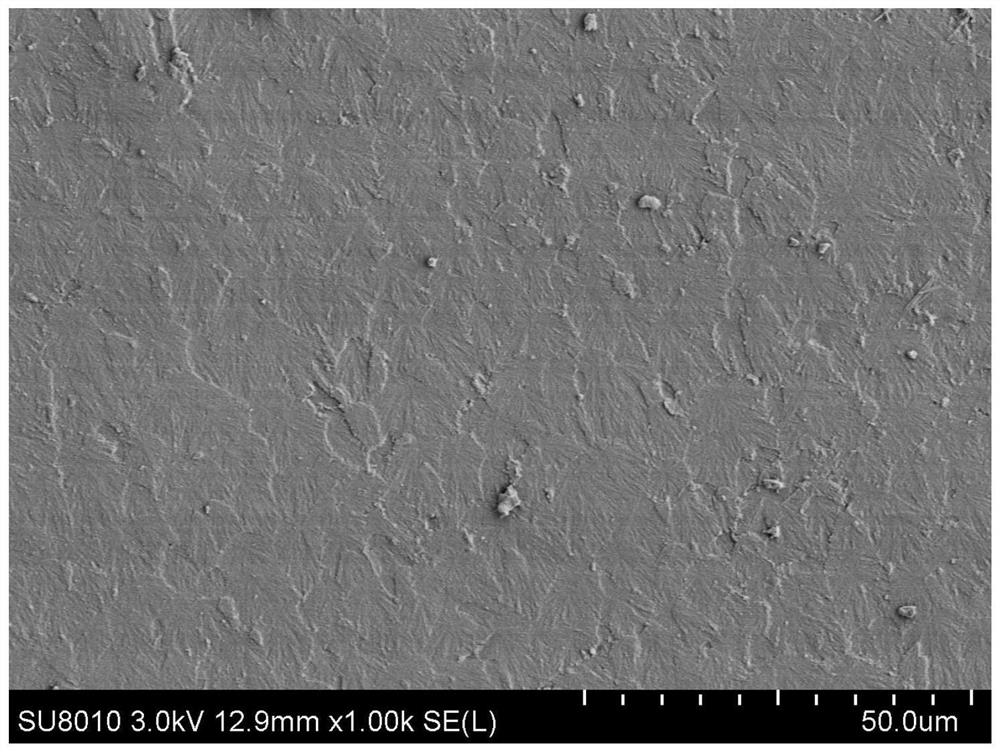

[0054] Example 2: Add 2g of polyurethane-modified graphene microchips into 25g of solvent-free epoxy resin, and stir at 60°C to 80°C for 20 to 60 minutes to prepare the matrix resin of the coating;

[0055] Step (2) Add 2g of wetting and dispersing agent, 1g of anti-rust pigment, and 2g of thickener to the matrix resin at one time, use a sand mill to grind at room temperature, control the speed at 1000-2500r / min, and grind for 2-5 hours;

[0056] Step (3) Add 1 g of defoamer in batches during the grinding process, control the dosage to no more than 5% of the total formula, grind until the fineness reaches below 50 μm, and filter and encapsulate with a 200-mesh filter to prepare the coating base material;

[0057] Step (4) Stir and mature the coating base material for 30-40 minutes before coating, and then mix it with 10 g of curing agent according to the above ratio to obtain a long-acting anti-corrosion graphene-modified solvent-free epoxy coating that can be coated.

[0058]...

Embodiment 3

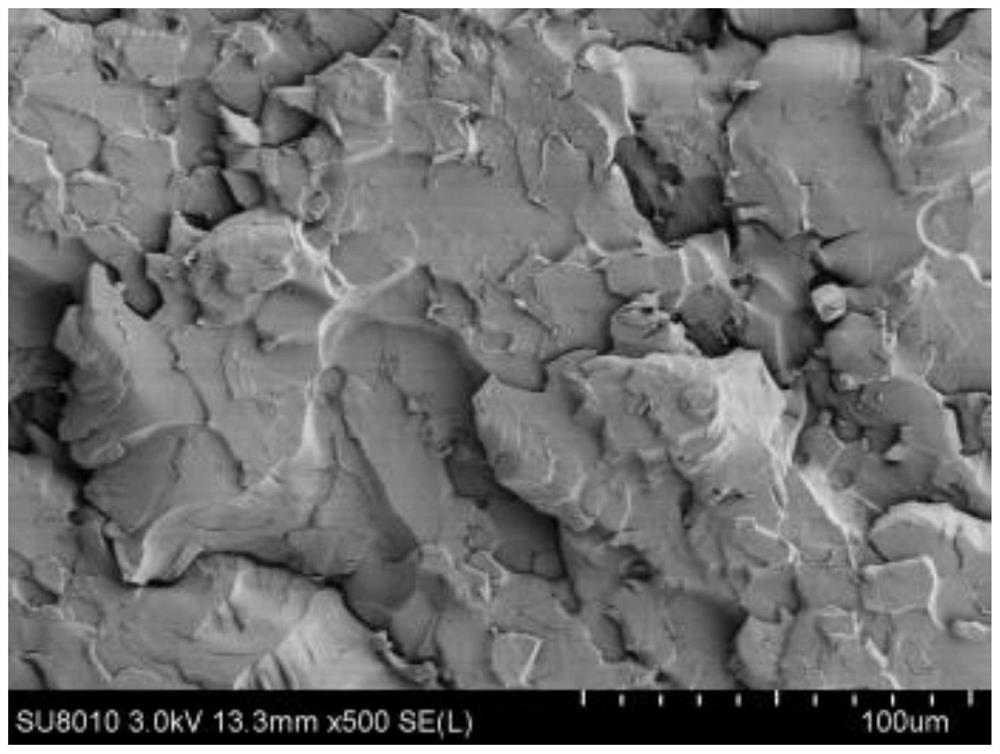

[0062] Embodiment 3: adding 10 g of polyurethane-modified graphene microchips into 25 g of solvent-free epoxy resin, stirring at 60°C to 80°C for 20 to 60 minutes, to obtain the matrix resin of the coating;

[0063] Step (2) Add 3g of anti-rust pigment and 2g of thickener to the matrix resin at one time, use a sand mill to grind at room temperature, control the speed at 1000-2500r / min, and grind for 2-5 hours;

[0064] Step (3) Add 2 g of defoamer in batches during the grinding process, control the dosage to no more than 5% of the total formula, grind until the fineness reaches below 50 μm, and filter and encapsulate with a 200-mesh filter to prepare the coating base material;

[0065] Step (4) Stir and mature the coating base material for 30-40 minutes before coating, and then mix it with 10 g of curing agent according to the above ratio to obtain a long-acting anti-corrosion graphene-modified solvent-free epoxy coating that can be coated.

[0066] Corresponding performance t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com