Reusable vacuum system applied to wind power cabin cover or flow guiding cover

A wind turbine cabin cover and vacuum system technology, which is applied in the field of reusable vacuum systems, can solve problems such as affecting product quality, waste of exhaust pipes, etc., and achieves the effects of excellent explosion-proof performance, convenient maintenance and trouble-free maintenance, and improved working efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

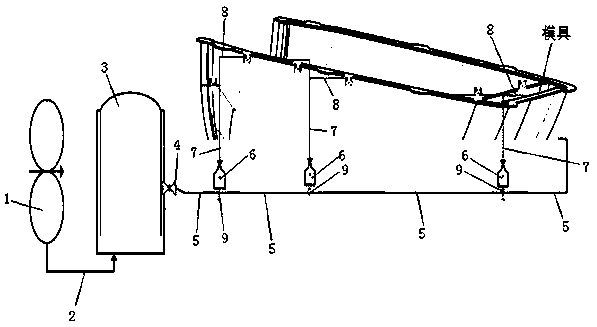

[0017] Such as figure 1 Shown is a reusable vacuum system applied to wind turbine cabin covers or shrouds, which consists of an air pumping vacuum assembly and an air guide and glue collection assembly used in conjunction with the air pumping assembly; the air pumping vacuum assembly, It includes a vacuum pump 1, a main gas-guiding pipeline 2 connected to the vacuum pump 1, a vacuum tank 3 connected to one end of the main gas-guiding pipeline 2, and a vacuum filling ball valve 4 arranged on the vacuum tank 3; the gas-guiding glue-collecting assembly , including the air guide pipe 5 connected with the vacuum filling ball valve 4, and the connection ball valves 9 of several glue collection barrels arranged on the air guide pipe 5, and the several glue collection barrels 6 connected with the connection ball valves 9 of several glue collection barrels, and with Several main road exhaust pipes 7 connected to several glue collection buckets 6, and several branch air suction pipes 8 ...

Embodiment 2

[0019] Such as figure 1 Shown is a reusable vacuum system applied to wind turbine cabin covers or shrouds, which consists of an air pumping vacuum assembly and an air guide and glue collection assembly used in conjunction with the air pumping assembly; the air pumping vacuum assembly, It includes a vacuum pump 1, a main gas-guiding pipeline 2 connected to the vacuum pump 1, a vacuum tank 3 connected to one end of the main gas-guiding pipeline 2, and a vacuum filling ball valve 4 arranged on the vacuum tank 3; the gas-guiding glue-collecting assembly , including the air guide pipe 5 connected with the vacuum filling ball valve 4, and the connection ball valves 9 of several glue collection barrels arranged on the air guide pipe 5, and the several glue collection barrels 6 connected with the connection ball valves 9 of several glue collection barrels, and with Several main road air extraction pipes 7 connected to several glue collection barrels 6, and several branch air extractio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com