Manufacturing method of advanced-generation TFT-grade fine-grain ITO target material

A manufacturing method and fine-grained technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of lack of reach, large grain size of target material, uneven composition, etc., and achieve reduction Firing temperature, accurate composition ratio, and the effect of improving sintering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

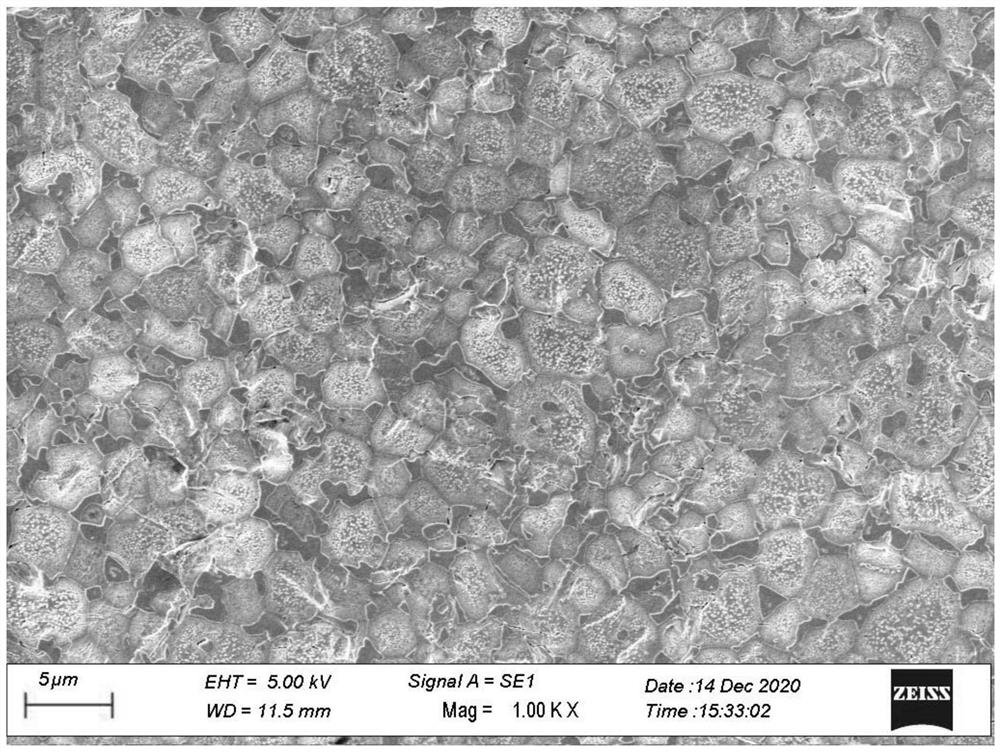

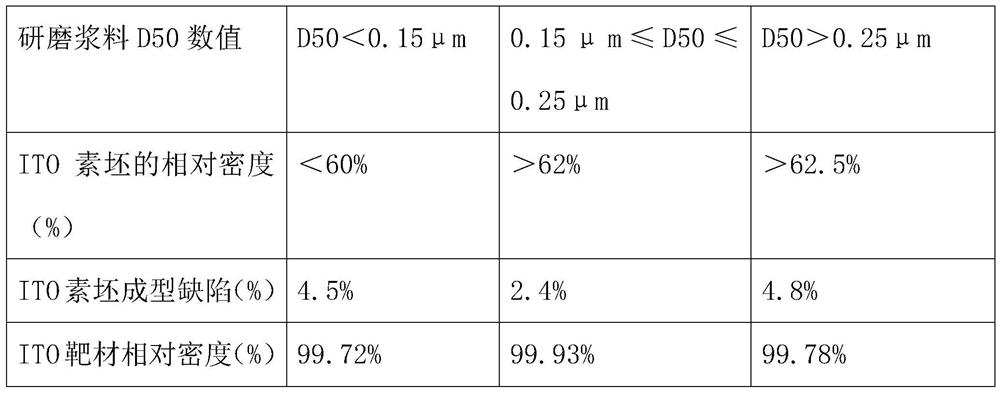

Embodiment 1

[0070] In the powder preparation step, indium oxide nanopowder and tin oxide nanopowder are respectively prepared. The purity of the two powders is greater than 99.99%. The indium oxide powder and tin oxide powder are respectively calcined at 750°C and subjected to rapid cooling to obtain indium oxide nanopowder. and tin oxide nanopowder. The specific surface area of indium oxide nanopowder BET = 14.2m 2 / g, the specific surface area of tin oxide nanopowder BET=17.8m 2 / g. Weigh 22.5kg of indium oxide nanopowder and 2.5kg of tin oxide nanopowder with a balance, add them into pure water equipped with dispersant, adhesive, and defoamer, start the sand mill for grinding, and detect the particle size of the slurry D50 = 0.22μm , stop grinding, spray-dry and granulate, and detect the particle size of the granulated powder D50=10.4 μm. The granulated powder is molded with a mold of 2000mm*290mm under a pressure of 50MPa, and the pressure holding time is 90s. The density of t...

Embodiment 2

[0072] Indium oxide nanopowder and tin oxide nanopowder were prepared respectively. The purity of the two powders was greater than 99.99%. The indium oxide powder and tin oxide powder were respectively calcined at 825°C and subjected to rapid cooling. The specific surface area of the indium oxide nanopowder was BET = 13.5m 2 / g, the specific surface area of tin oxide nanopowder BET=16.7m 2 / g. Weigh 22.5 kg of indium oxide powder and 2.5 kg of tin oxide powder with a balance, add them into pure water equipped with dispersant, adhesive, and defoamer, start the sand mill to grind, detect the particle size of the slurry D50 = 0.24 μm, stop Grinding, spray-drying and granulating, the particle size of the granulated powder was detected as D50=10.8 μm. The granulated powder is molded with a mold of 1310*288mm under a pressure of 50MPa, and the holding time is 90s. The formed blank is sealed in a flexible sheath, and then pressed in an isostatic press with a pressure of 350MPa a...

Embodiment 3

[0074] Indium oxide nanopowder and tin oxide nanopowder were prepared respectively. The purity of the two powders was greater than 99.99%. The indium oxide powder and tin oxide powder were respectively calcined at 850°C and subjected to rapid cooling. The specific surface area of the indium oxide nanopowder was BET = 12.5m 2 / g, the specific surface area of tin oxide nanopowder BET=18.6m 2 / g. Weigh 27kg of indium oxide powder and 3kg of tin oxide powder with a balance, add them into pure water equipped with dispersant, adhesive, and defoamer, start the sand mill for grinding, detect the slurry particle size D50=0.24 μm, stop grinding, Spray-dried and granulated, the particle size of the granulated powder was detected as D50=11.6 μm. The granulated powder was put into a tubular silicone flexible sheath and sealed, and then pressed in an isostatic press with a pressure of 380 MPa and a holding time of 600 s. The density of the biscuit was measured to be 62.6%. Put the bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com