Samarium cobalt rare earth magnet and preparation method thereof

A rare-earth magnet, samarium-cobalt technology, applied in the direction of magnetic objects, inductors/transformers/magnets, magnetic materials, etc., can solve the problems of casting composition segregation, solidified structure with many impurities, uneven distribution of samarium content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 of the present invention also provides the following examples and comparative examples:

[0035] Wherein, embodiment and comparative example all adopt the magnet composition as shown in table 1:

[0036] Table 1

[0037] element Sm(at%) Co(at%) Fe(at%) Cu(at%) Zr(at%) Proportion 11.45 56.15 25.9 5 1.5

[0038] Embodiment and comparative example all adopt following preparation method, specifically comprise the following steps:

[0039] (1) Batching: batching is carried out according to the magnet composition in Table 1;

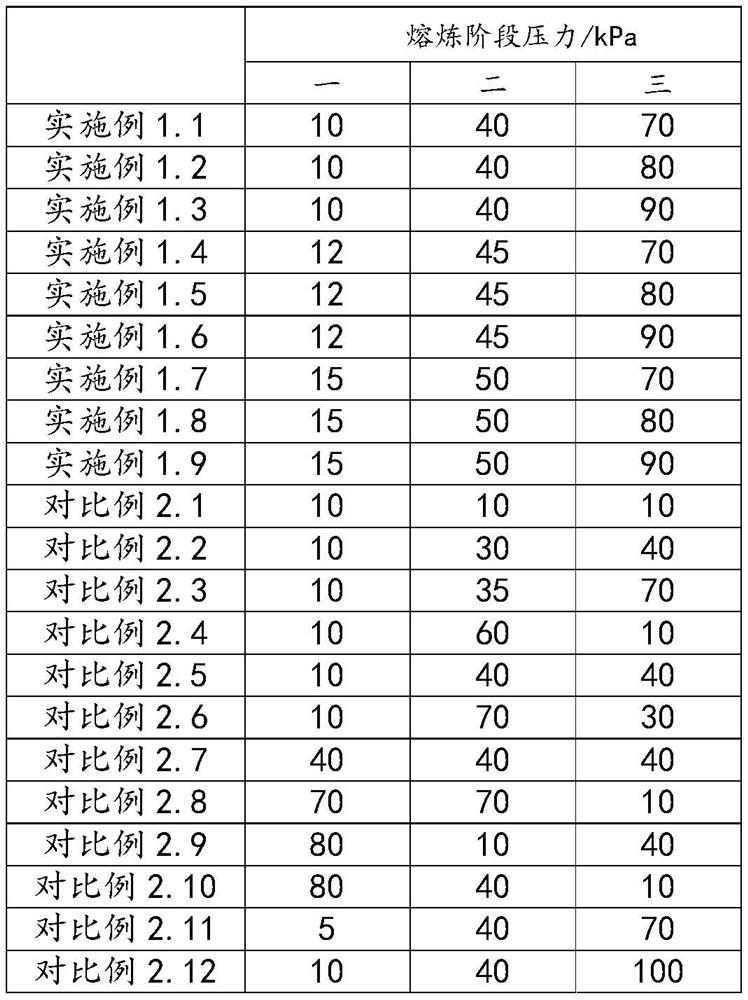

[0040] (2) Smelting and casting: the medium frequency induction melting method is adopted to successively go through the first melting stage, the second melting stage and the third melting stage to melt the metal material and cast the alloy ingot by rotating the cooling roller wall. The first melting stage Use an infrared thermometer to continuously monitor the temperature of the material in the crucible,...

Embodiment 2

[0069] Embodiment 2 of the present invention also provides the following examples and comparative examples:

[0070] Wherein, embodiment and comparative example all adopt the magnet composition as shown in table 8:

[0071] Table 8

[0072] element Sm(at%) Co(at%) Fe(at%) Cu(at%) Zr(at%) Proportion 11.6 53.5 28 5.5 1.4

[0073] Embodiment and comparative example all adopt following preparation method, specifically comprise the following steps:

[0074] (1) Batching: batching according to the magnet composition designed in Table 8;

[0075] (2) Smelting and casting: the method of intermediate frequency induction melting is adopted to go through the first melting stage, the second melting stage and the third melting stage in sequence to melt the metal material and cast the alloy ingot by rotating the cooling roller. In the first melting stage, Fill in Ar gas to keep the vacuum degree of the smelting chamber at 12kPa, use an infrared thermomete...

Embodiment 3

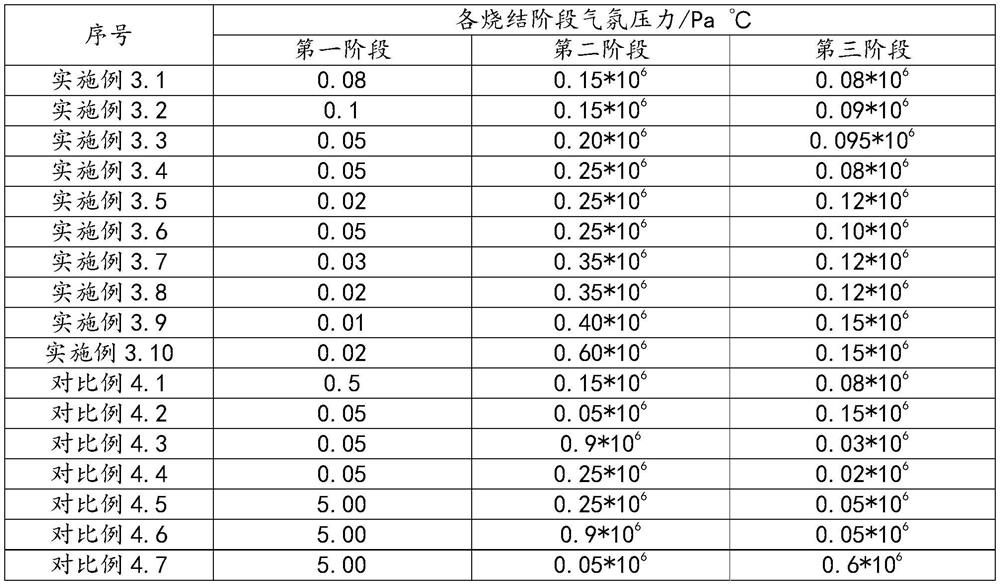

[0101] The third embodiment of the present invention also provides the following examples and comparative examples:

[0102] Wherein, embodiment and comparative example all adopt the magnet composition as shown in table 14:

[0103] Table 14

[0104] element Sm(at%) Co(at%) Fe(at%) Cu(at%) Ti(at%) Proportion 11.65 58.25 23.5 4.5 2.1

[0105] Adopt following preparation method, specifically comprise the following steps:

[0106] (1) Batching: batching according to the magnet composition in Table 14;

[0107] (2) Smelting and casting: the method of medium frequency induction melting is adopted to go through the first melting stage, the second melting stage and the third melting stage in turn to melt the metal material and cast the alloy ingot by rotating and cooling the ring wall. The first melting stage , filled with Ar gas to keep the vacuum degree of the smelting chamber at 12kPa, and continuously monitored the temperature of the material i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com