Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71 results about "Samarium–cobalt magnet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A samarium–cobalt (SmCo) magnet, a type of rare earth magnet, is a strong permanent magnet made of two basic elements samarium and cobalt. Actually, samarium is substituted by a portion of other rare earth elements including praseodymium, cerium and gadolinium, and cobalt is substituted by a portion of other transition metals including iron, copper and zirconium. They are available in two "series", namely SmCo₅ magnets and Sm₂Co₁₇ magnets. They were developed in the early 1960s based on work done by Karl Strnat and Alden Ray at Wright-Patterson Air Force Base and the University of Dayton, respectively. In particular, Strnat and Ray developed the first formulation of SmCo₅. They are generally ranked similarly in strength to neodymium magnets, but have higher temperature ratings and higher coercivity. They are brittle, and prone to cracking and chipping. Samarium–cobalt magnets have maximum energy products (BHₘₐₓ) that range from 14 megagauss-oersteds (MG·Oe) to 33 MG·Oe, that is approx. 112 kJ/m³ to 264 kJ/m³; their theoretical limit is 34 MG·Oe, about 272 kJ/m³.

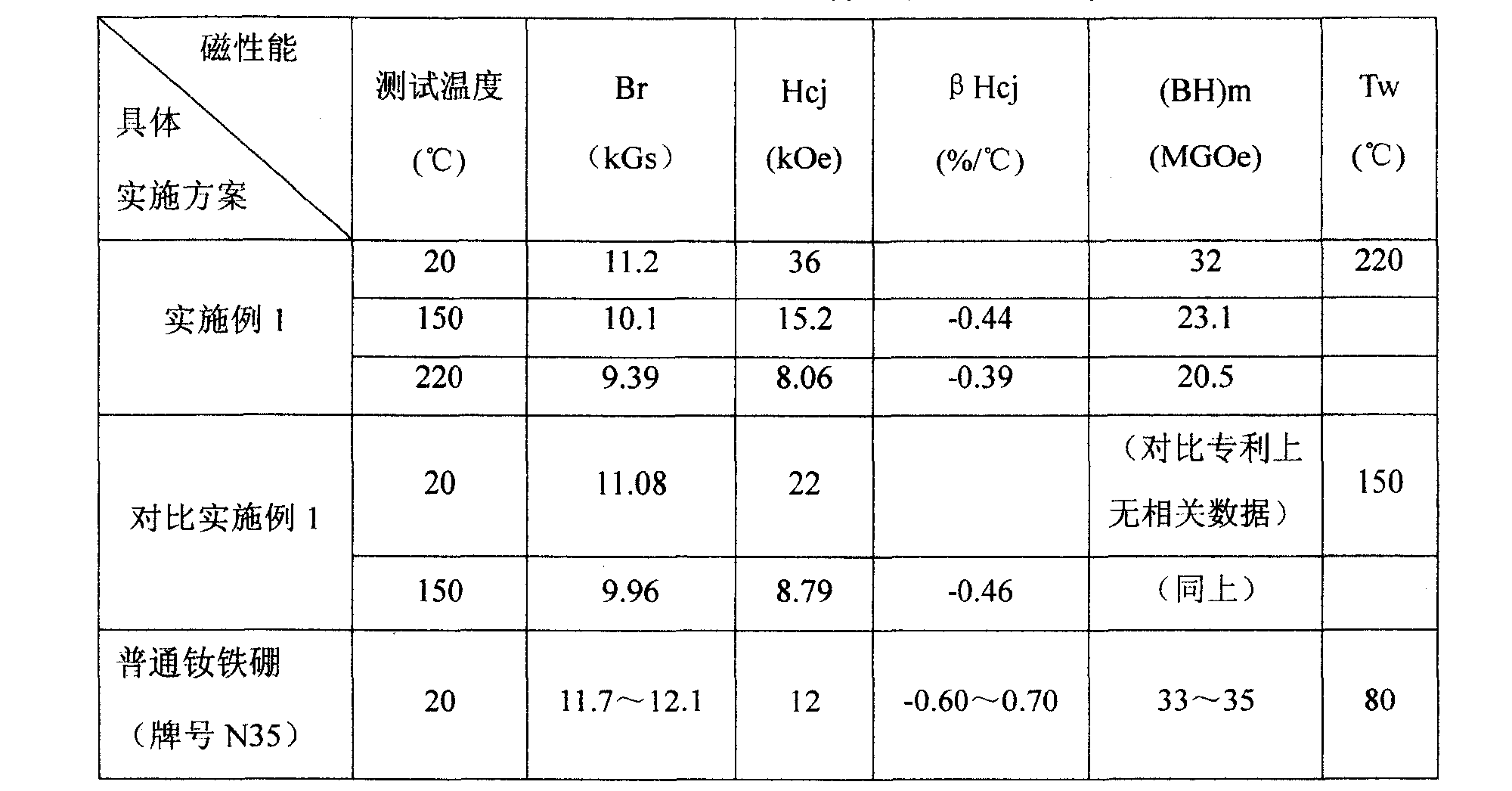

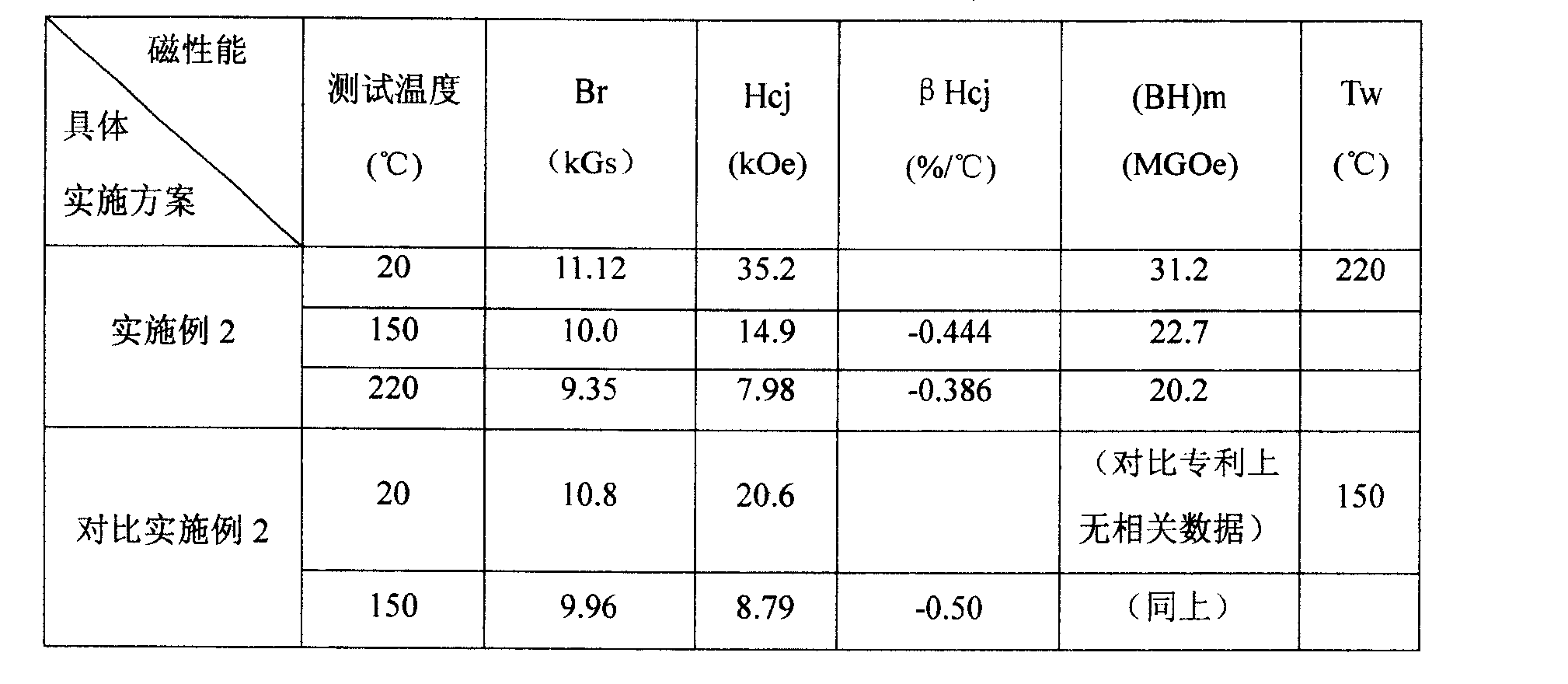

Permanent magnetic RE material and preparation thereof

ActiveCN101364465ASmall temperature coefficientLow coercivityInorganic material magnetismCrystalline oxideSamarium–cobalt magnet

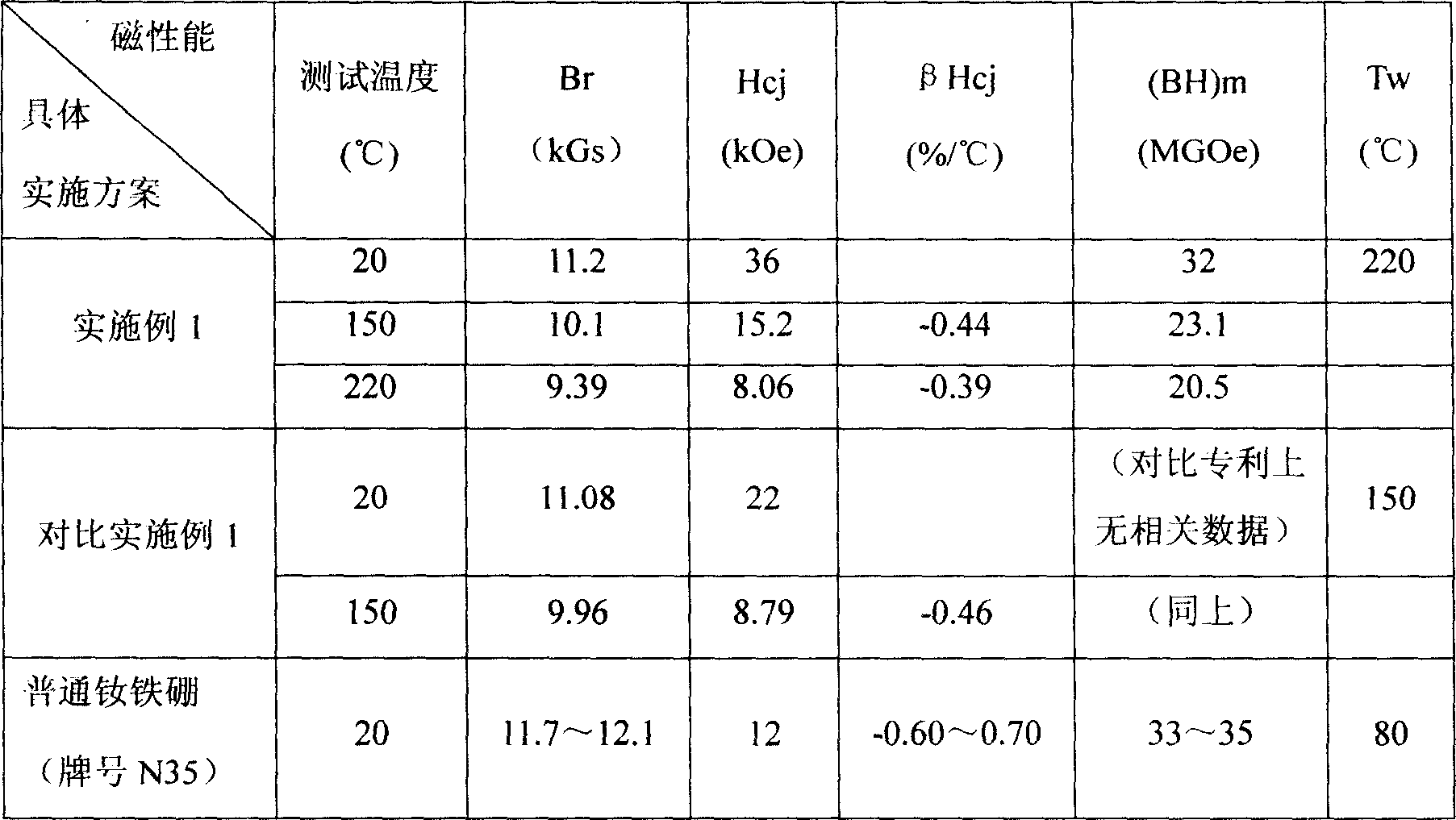

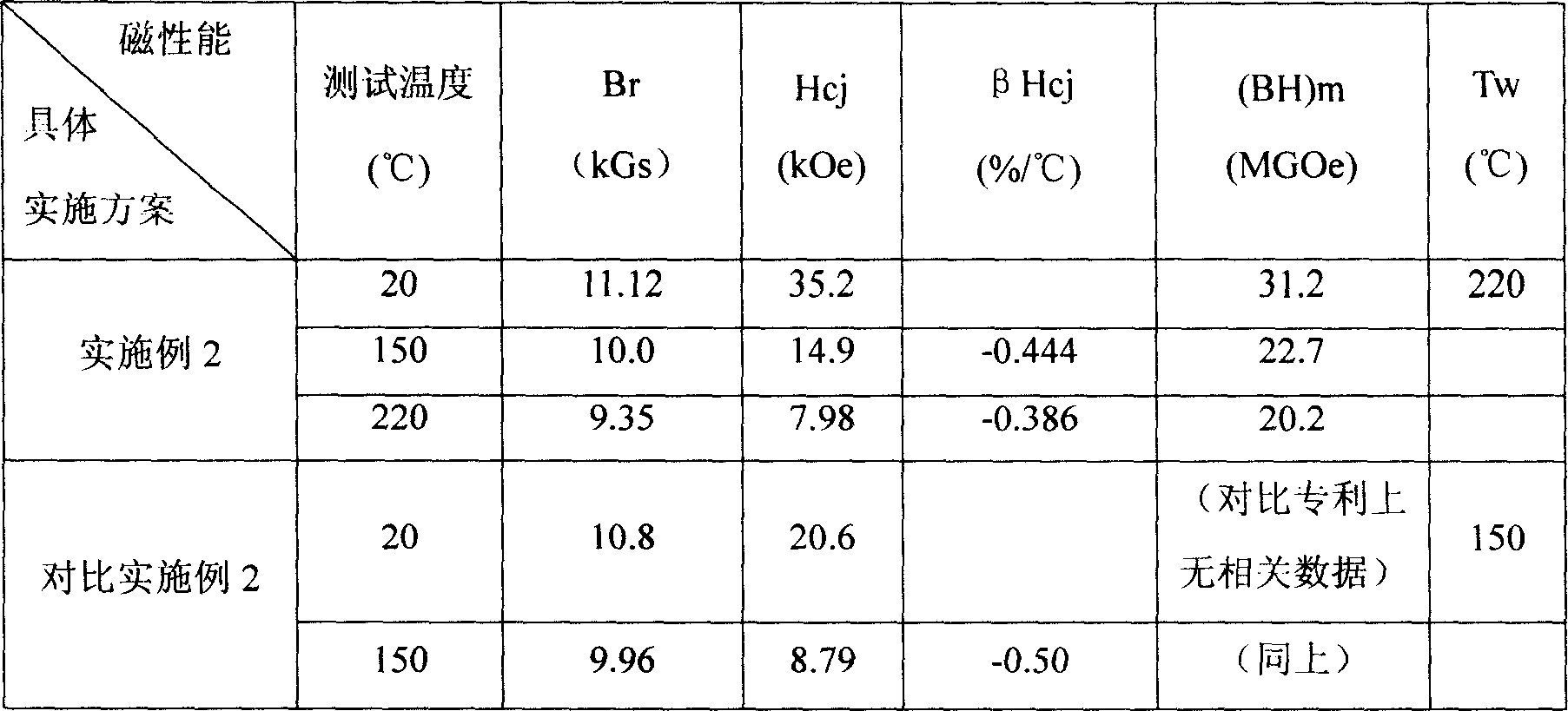

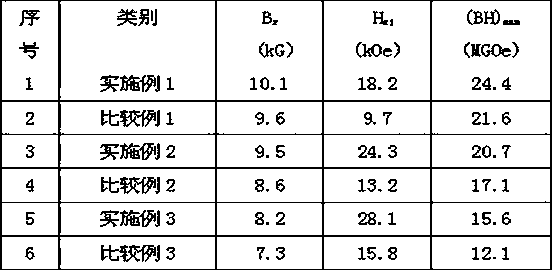

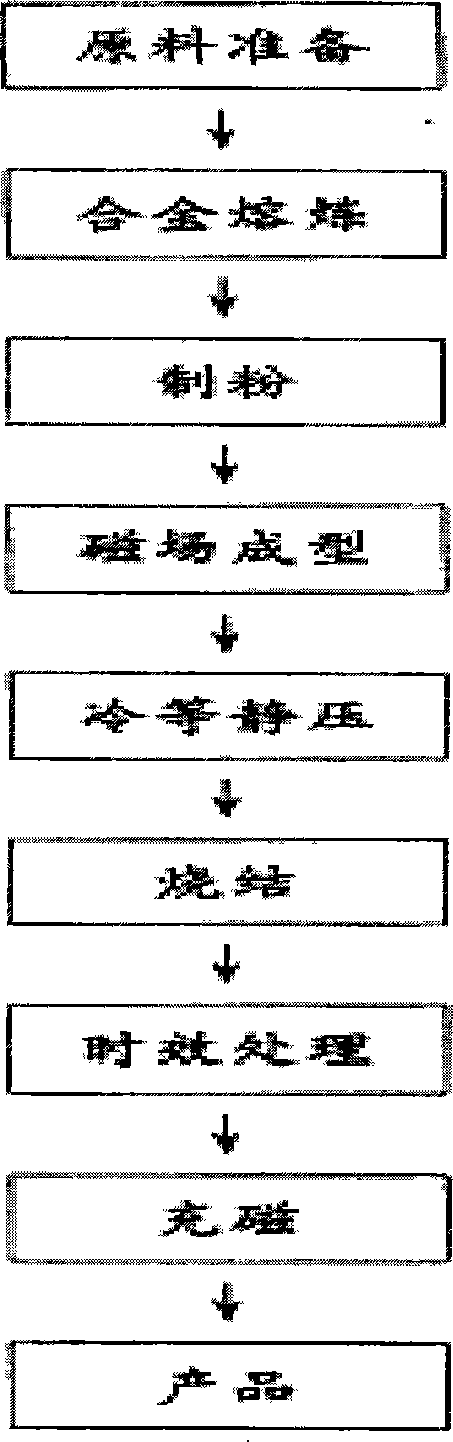

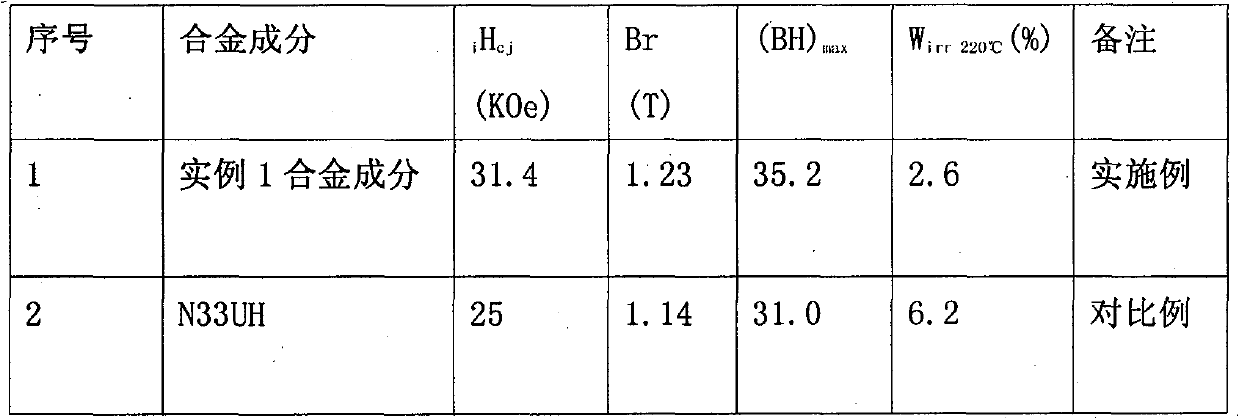

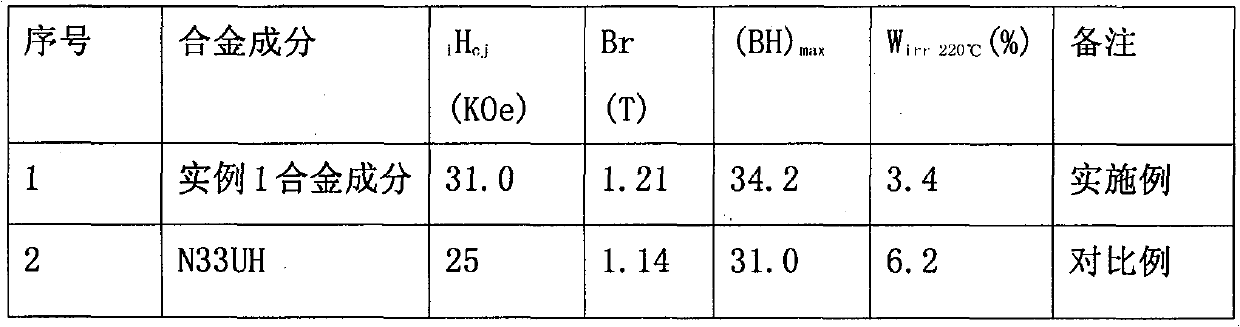

The invention relates to a rare earth permanent magnetic material and a preparation method thereof. The rare earth permanent magnetic material comprises a (Pr, Nd)-Fe-R-Co-Al-Cu-B-M system, and the rare earth as a main phase component has a phase volume ratio of 90%-98%; wherein R is at least two elements selected from Nb, Tb, Dy and Ho; M is at least two nanometer crystalline oxides with particle size of 10-100 nm selected from ZrO2, MgO and ZnO; and the weight of the nanometer crystalline oxides is 0.1%-3% of the total weight. The rare earth permanent magnetic material is a compound nanometer oxidizer enhanced and sintered praseodymium (Pr)-neodymium (Nd)-based permanent magnet with high coercitive force. The inventive product has magnetic features of low temperature coefficient, high coercitive force, low cost and 220 DEG C working temperature, and can overcome the shortcomings of lower coercitive force, high temperature coefficient and high cost of the prior sintered Nd-Fe-B permanent magnet and the sintered samarium-cobalt magnet in application of large motor products. The preparation method provides a powerful guarantee for realizing the positive effects.

Owner:浙江西子富沃德电机有限公司

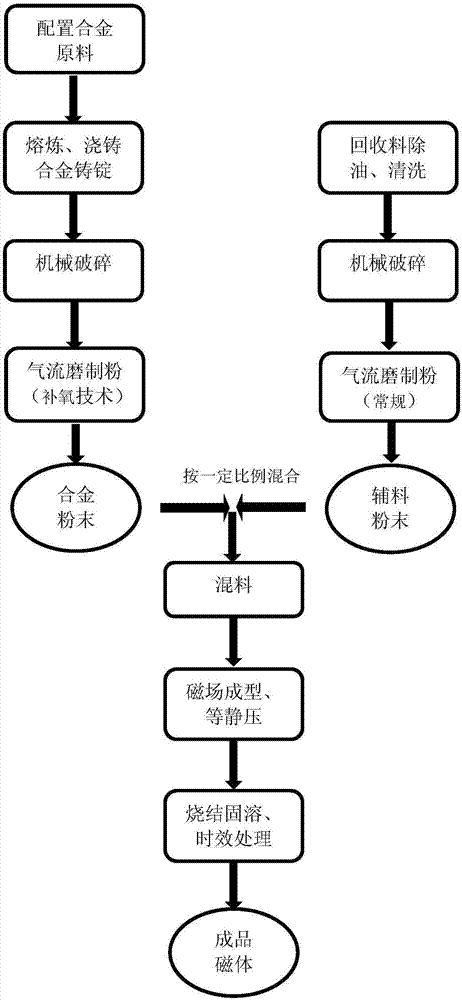

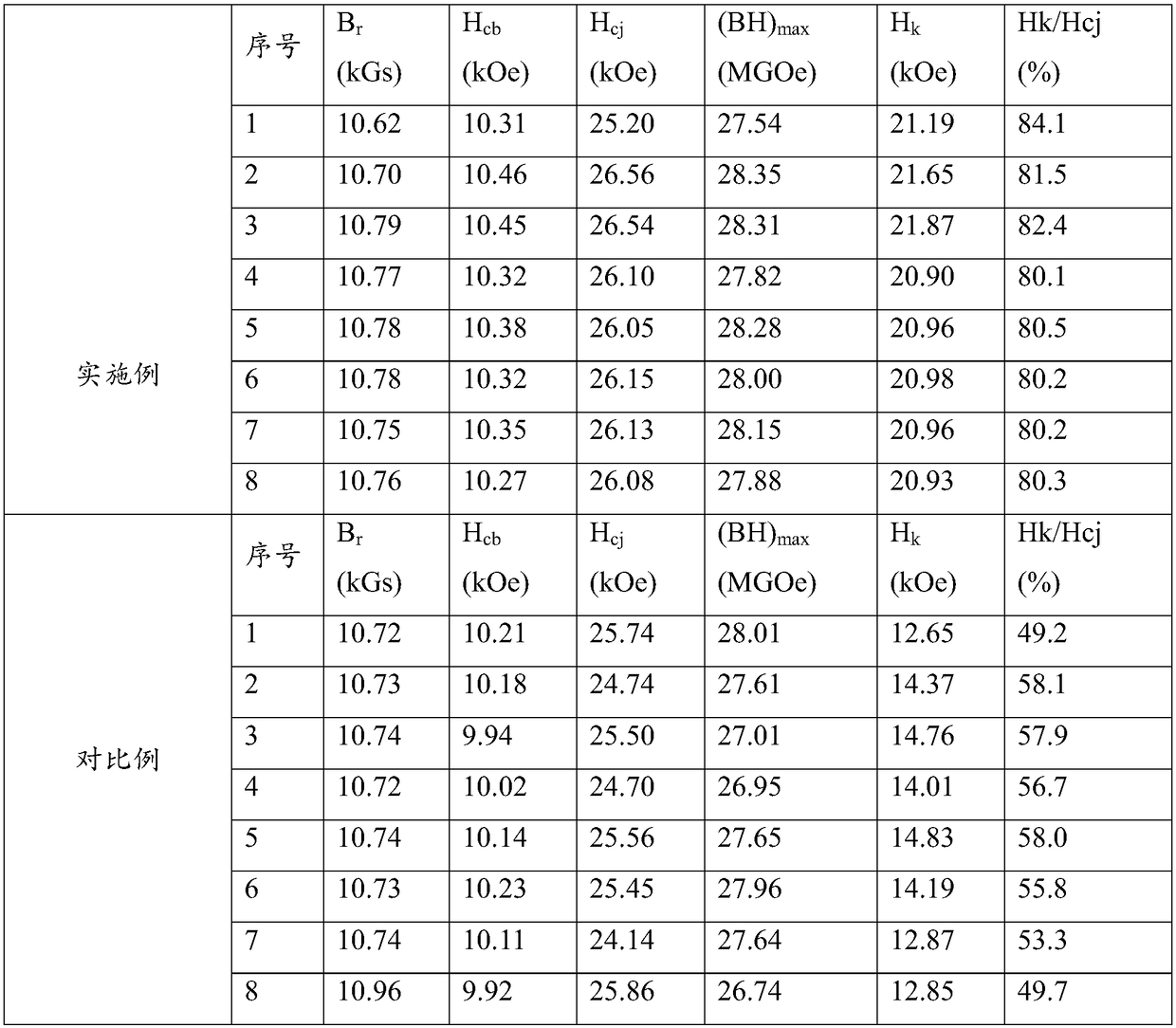

Preparation method of sintered samarium-cobalt magnet

ActiveCN107316726AControl magnet oxygen contentGood mechanical propertiesInductances/transformers/magnets manufactureMagnetic materialsSamarium–cobalt magnetAlloy

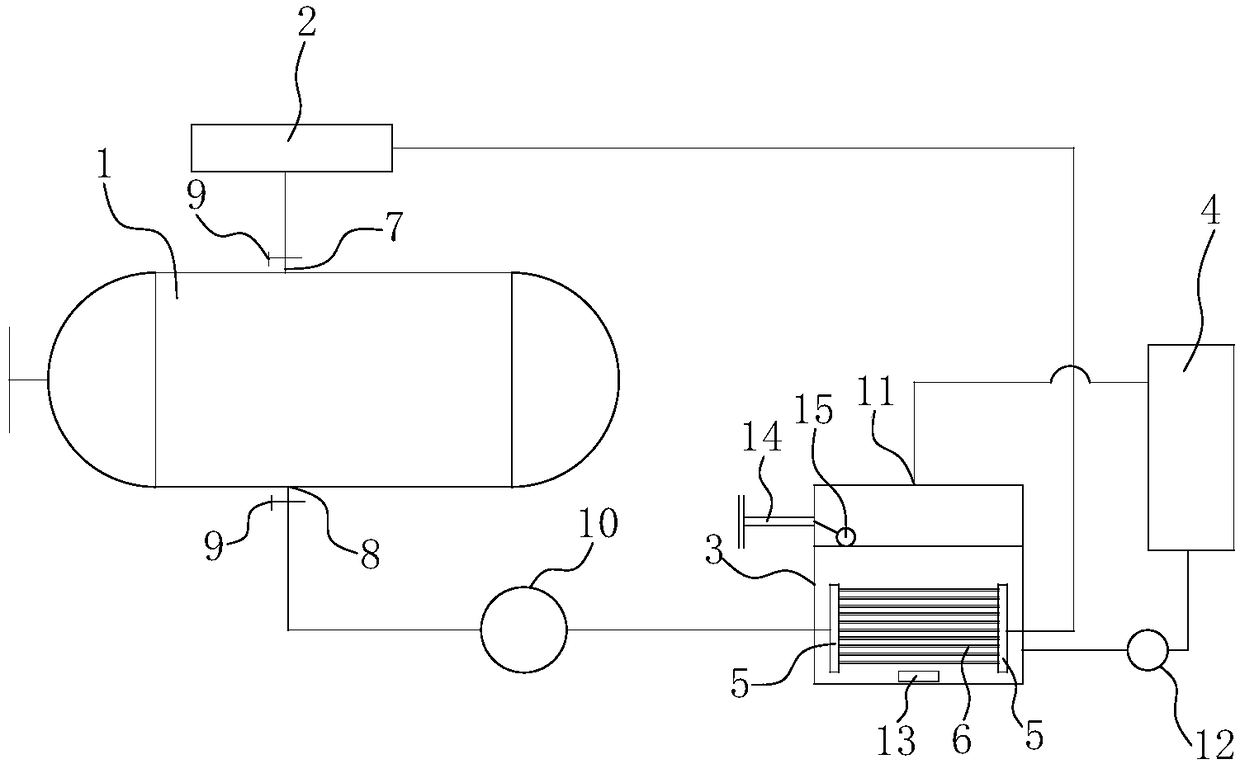

The invention relates to a preparation method of a sintered samarium-cobalt magnet. The preparation method comprises the steps that alloy powder is prepared, wherein samarium-cobalt alloy raw materials are prepared, by weight, 25%-27% of (Sml-xRx), 6%-25% of Fe, 2%-3.5% of Zr, 3%-8% of Cu and the balance Co, 0<=x<=0.9, R is one or more of Ce, Pr, Nd, Gd, Tb, Dy, Ho and Er, and the samarium-cobalt alloy raw materials are subjected to smelting, casting and mechanical crushing and then subjected to an oxygen supplementary flow powder grinding technique to prepare the alloy powder; 2, leftover materials and waste materials which have the components similar to those of the alloy powder are subjected to cleaning, crushing and conventional air flow powder grinding and then fully mixed with a lubricant to prepare auxiliary material powder; 3, the materials are mixed, wherein the alloy powder and the auxiliary material powder are mixed in proportion to prepare samarium-cobalt alloy powder; 4, magnetic field molding and isostatic pressing are conducted to prepare a green body; and 5, sintering, solid solution and aging processing is conducted, and the samarium-cobalt magnet is prepared. The sintered samarium-cobalt magnet prepared through the method has the good mechanical performance and has the bending strength higher than 100 MPa.

Owner:CENT IRON & STEEL RES INST

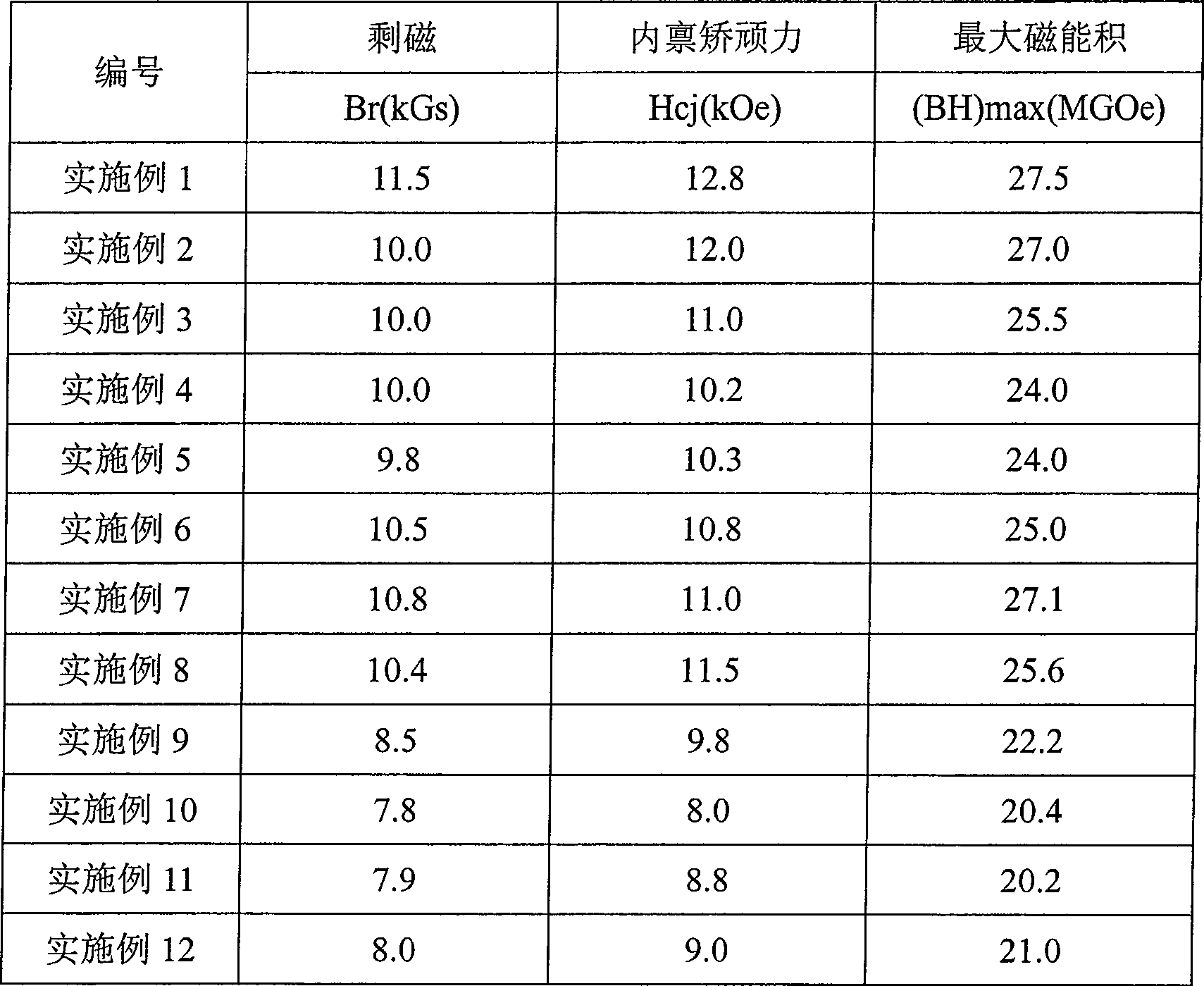

Method for preparing sintered samarium-cobalt magnet

ActiveCN103065788AGet over the actual ingredientsTo overcome the large deviation of design componentsInorganic material magnetismInductances/transformers/magnets manufactureRemanenceSamarium–cobalt magnet

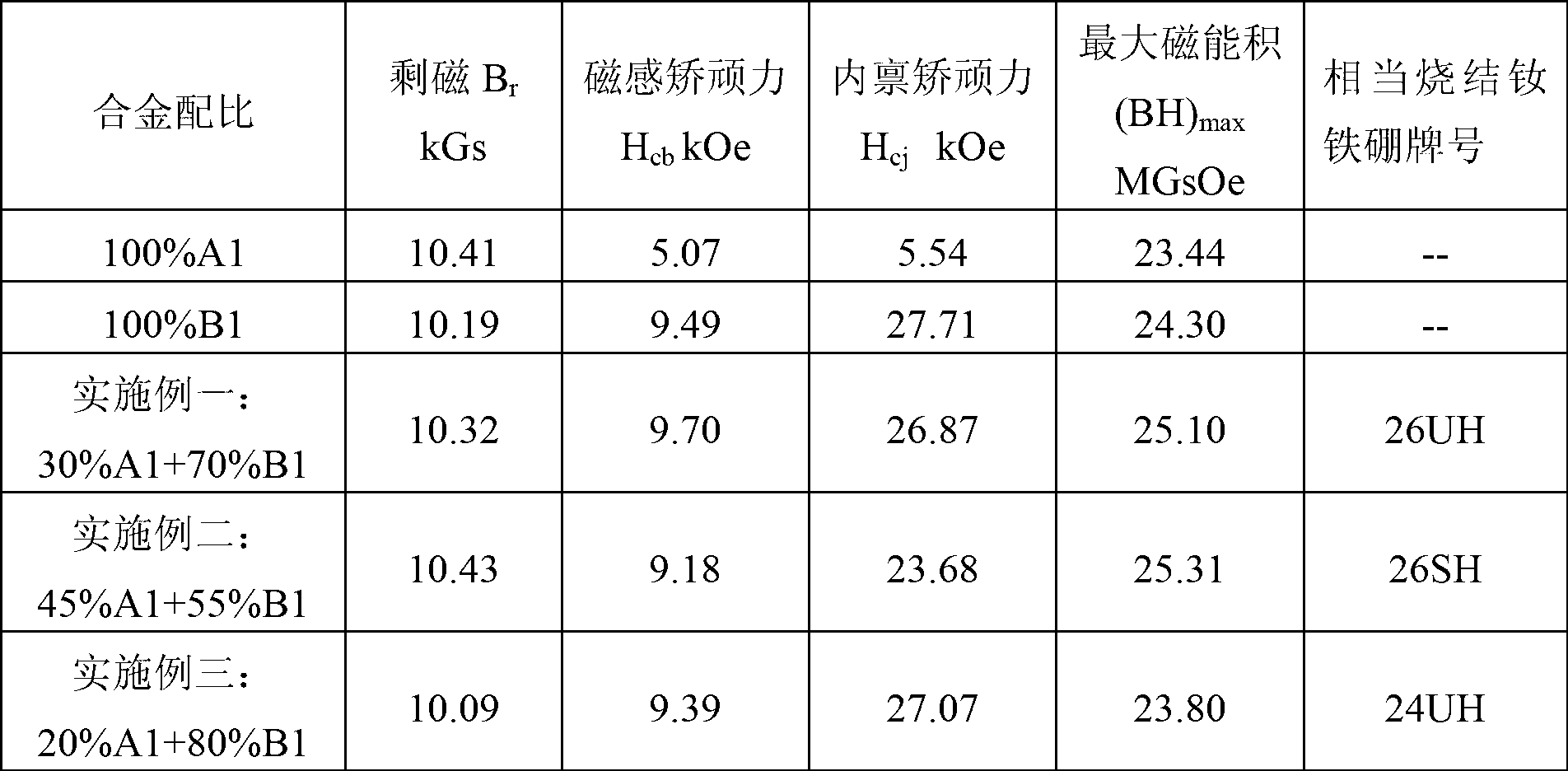

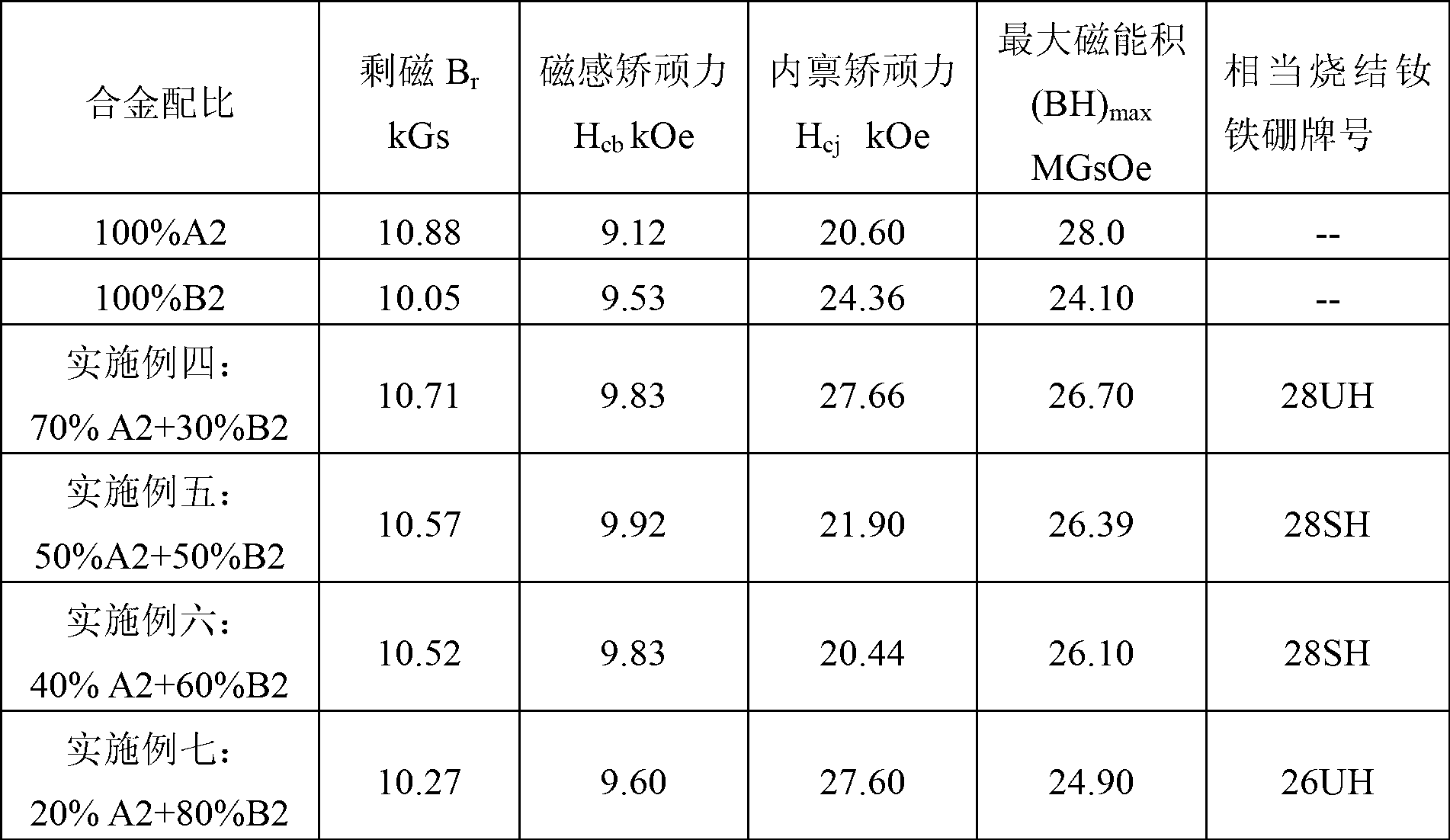

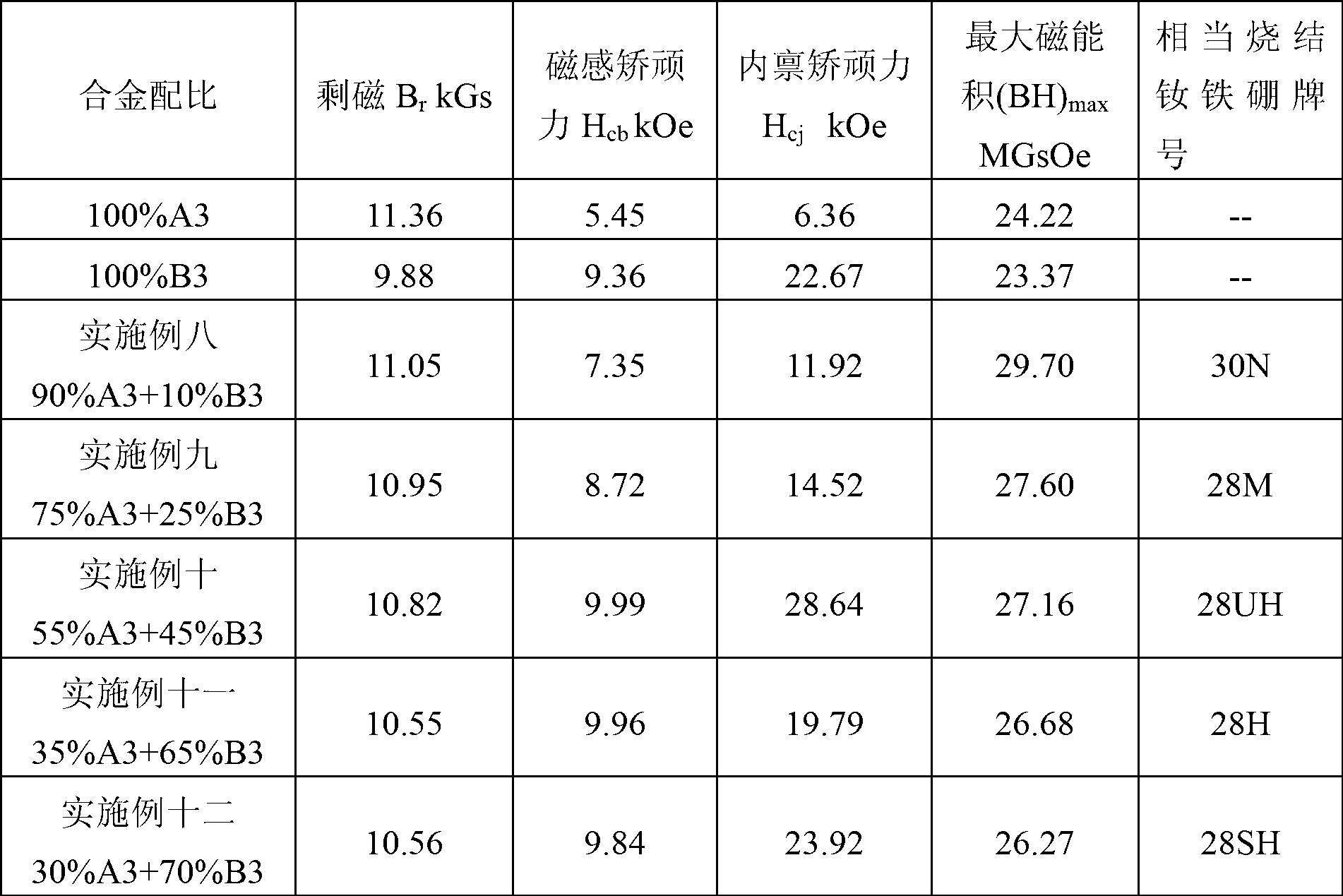

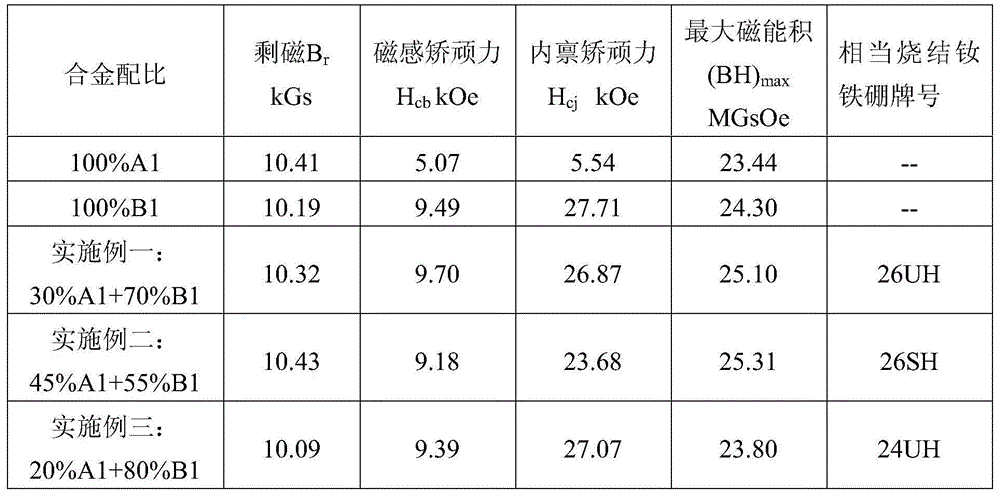

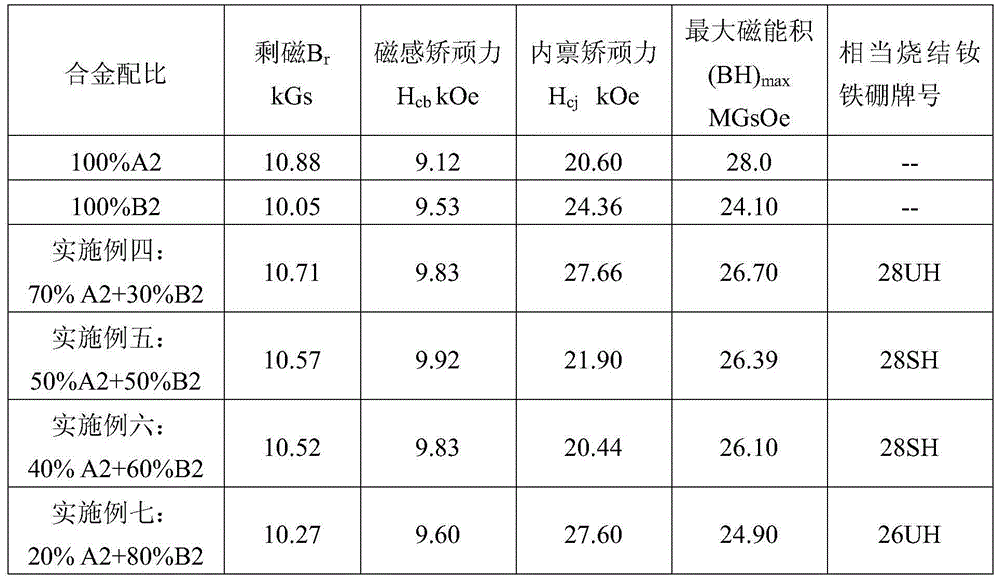

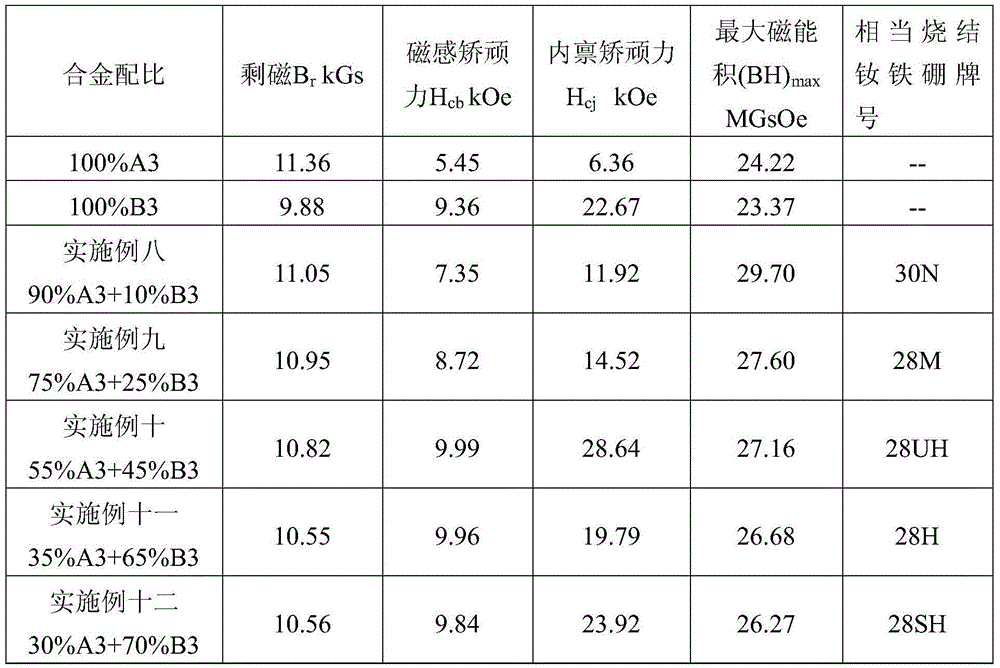

The invention discloses a method for preparing a sintered samarium-cobalt magnet. The method comprises the following steps of: preparing a first samarium-cobalt alloy and a second samarium-cobalt alloy; performing primary crushing on the first samarium-cobalt alloy and the second samarium-cobalt alloy; mixing first samarium-cobalt alloy primarily crushed magnetic powder and second samarium-cobalt alloy primarily crushed magnetic powder, and performing fine crushing, so that primarily crushed mixed magnetic powder is refined, and components are homogenized; and performing magnetic field orientation forming, cold isostatic pressing, sintering, solid solution treatment and ageing treatment on samarium-cobalt magnetic powder obtained by fine crushing in sequence. The method has the advantages that the first samarium-cobalt alloy has high remanence component characteristic, the second samarium-cobalt alloy has high coercivity component characteristic, the sintered samarium-cobalt magnets with various magnetic properties can be obtained by adjusting the mixing ratio of the first samarium-cobalt alloy primarily crushed magnetic powder to the second samarium-cobalt alloy primarily crushed magnetic powder, and the process is stable and low in cost.

Owner:NINGBO YUNSHENG +3

Ultra-high coercive force sintered Nd-Fe-B magnetic material and preparing process thereof

ActiveCN1862717AReasonable distributionMake up for temperature gapsInorganic material magnetismSamarium–cobalt magnetIngot casting

This invention relates to super-high coercive force sintering neodymium iron boron magnet and its preparation method. the alloy molecular general formula is NdxDyyTbzFe(100%-x-y-z-x1-y1-z1-w-w1)Cox1Nby1Cuz1(Ga)wBw1, intrinsic coercive force more than 35k0e(2786kA / m) sintering neodymium iron boron magnet are made through traditional normal ingot casting method. The highest work temperature is 220 degrees centigrade, so the using temperature frees position in traditional sintering neodymium iron boron magnet and sintering samarium cobalt magnet.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

High-performance and high-resistivity sintered samarium-cobalt permanent-magnet material and preparation method and application thereof

ActiveCN108305735AHigh resistivitySmall sizeInorganic material magnetismInductances/transformers/magnets manufactureSamarium–cobalt magnetHigh resistivity

The invention provides a high-performance and high-resistivity sintered samarium-cobalt permanent-magnet material and preparation method and application thereof. The chemical formula of the high-performance and high-resistivity sintered samarium-cobalt permanent-magnet material is Sm<Co<1-a-b-c>FeCuZr<c>M<y>)<z>, wherein a is more than 0 but less than 0.5, b is more than 0 but less than 0.15, c is more than 0 but less than or equal to 0.025, y is more than 0 but less than 0.04, z is more than 6.5 but less than 8.5, and M is a high-resistivity element. The preparation method comprises thestep of sequentially performing processes of directional formation, sintering, thermal processing and equal-temperature aging on alloy with the chemical formula being Sm<Co<1-a-b-c>FeCuZr<c>M<y>)<z> to obtain the high-performance and high-resistivity sintered samarium-cobalt permanent-magnet material. Compared with the prior art, the samarium-cobalt permanent-magnet material has the advantages that a high-resistivity compound is combined without a complicated process, the process flow of the sintered samarium-cobalt magnet is not needed to be changed, the production cost is low, and theresistivity of the magnet can be obviously improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

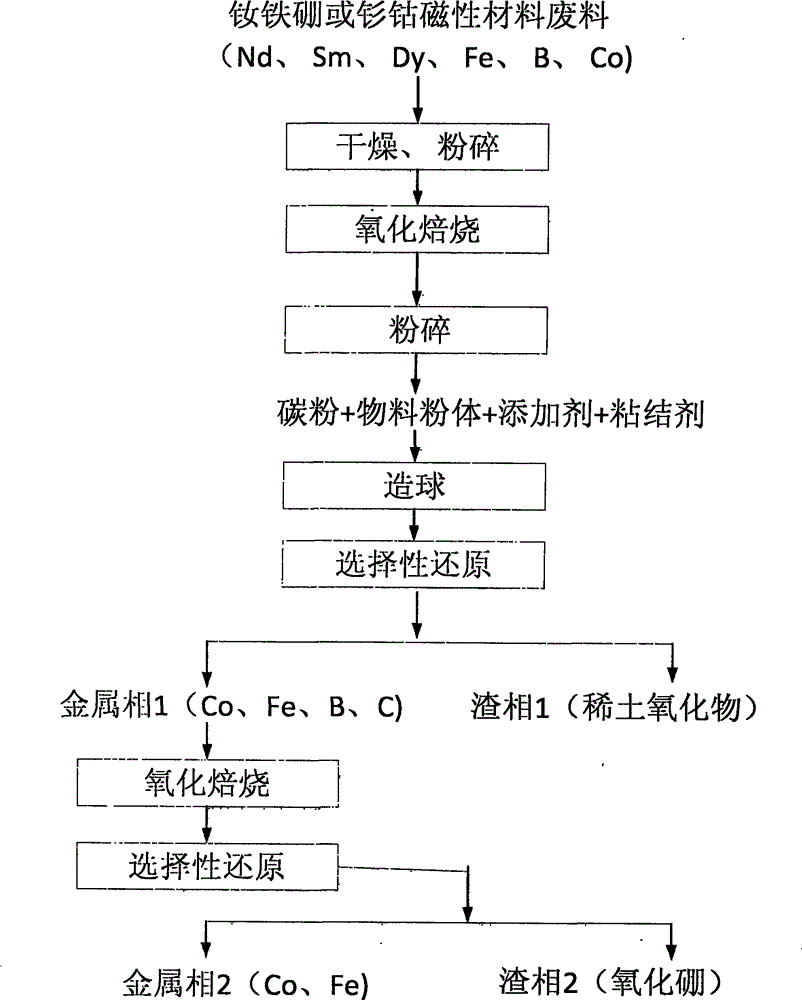

Method for recovering rare earth and other metals from neodymium iron boron and samarium cobalt magnetic material waste

InactiveCN102978401AAchieve recyclingRealize continuous productionProcess efficiency improvementAdhesiveSamarium–cobalt magnet

The invention relates to a method for recovering rare earth and other metals from neodymium iron boron and samarium cobalt magnetic material waste. The method comprises the following steps of: drying and grinding the fine-particle muddy neodymium iron boron or samarium cobalt waste, and performing oxidizing roasting; grinding the obtained solid; adding carbon powder, additive powder and an adhesive and pelletizing; performing selective reduction and melting on the pellets with carbon at a high temperature to obtain a rare earth oxide slag phase 1 and a carbon-containing metal phase 1; grinding the carbon-containing metal phase 1, and performing oxidizing roasting, selective reduction and melting; and for the neodymium iron boron waste, separating to obtain a boron oxide slag phase product 2 and a Fe-Co metal phase product 2, and for samarium cobalt waste, separating to only obtain a Fe-Co metal phase product 2, wherein the rare earth oxide slag phase 1 and the Fe-Co metal phase product 2 can be used as the primary raw materials for manufacturing samarium cobalt magnet; and the rare earth oxide slag phase 1, the Fe-Co metal phase product 2 and the boron oxide slag phase product 2 can be used as the primary raw materials for manufacturing neodymium iron boron magnet.

Owner:沈少波

Anisotropic SmCo/MnBi composite magnet, and preparation method thereof

ActiveCN109448946ASuppressed interdiffusionAchieve compositeInductances/transformers/magnets manufactureMagnetic materialsSamarium–cobalt magnetRare earth

The invention belongs to the technical field of magnetic materials, and discloses a preparation method of an anisotropic SmCo / MnBi composite magnet. The preparation method comprises the following steps: 1) respectively preparing SmCo magnetic powders and MnBi magnetic powders; and 2) uniformly mixing the SmCo magnetic powders and the MnBi magnetic powders according to a certain ratio, carrying outoriented forming to prepare a compact, and carrying out low-temperature fast sintering on the compact through the high magnetic field assisted laser low-temperature sintering technology to prepare the anisotropic SmCo / MnBi composite magnet. The preparation method disclosed by the invention has the advantages that through the high magnetic field assisted laser low-temperature sintering technology,the technical bottleneck that the coercivity of a samarium-cobalt magnet is reduced during high-temperature densification is effectively solved, and a low-melting-point phase in a MnBi magnet is reasonably utilized, so that the density of the SmCo / MnBi composite magnet is improved, and residual magnetism in the magnet is optimized; and meanwhile, the rare earth content in the magnet is reduced, so that the cost is lowered.

Owner:CHINA JILIANG UNIV

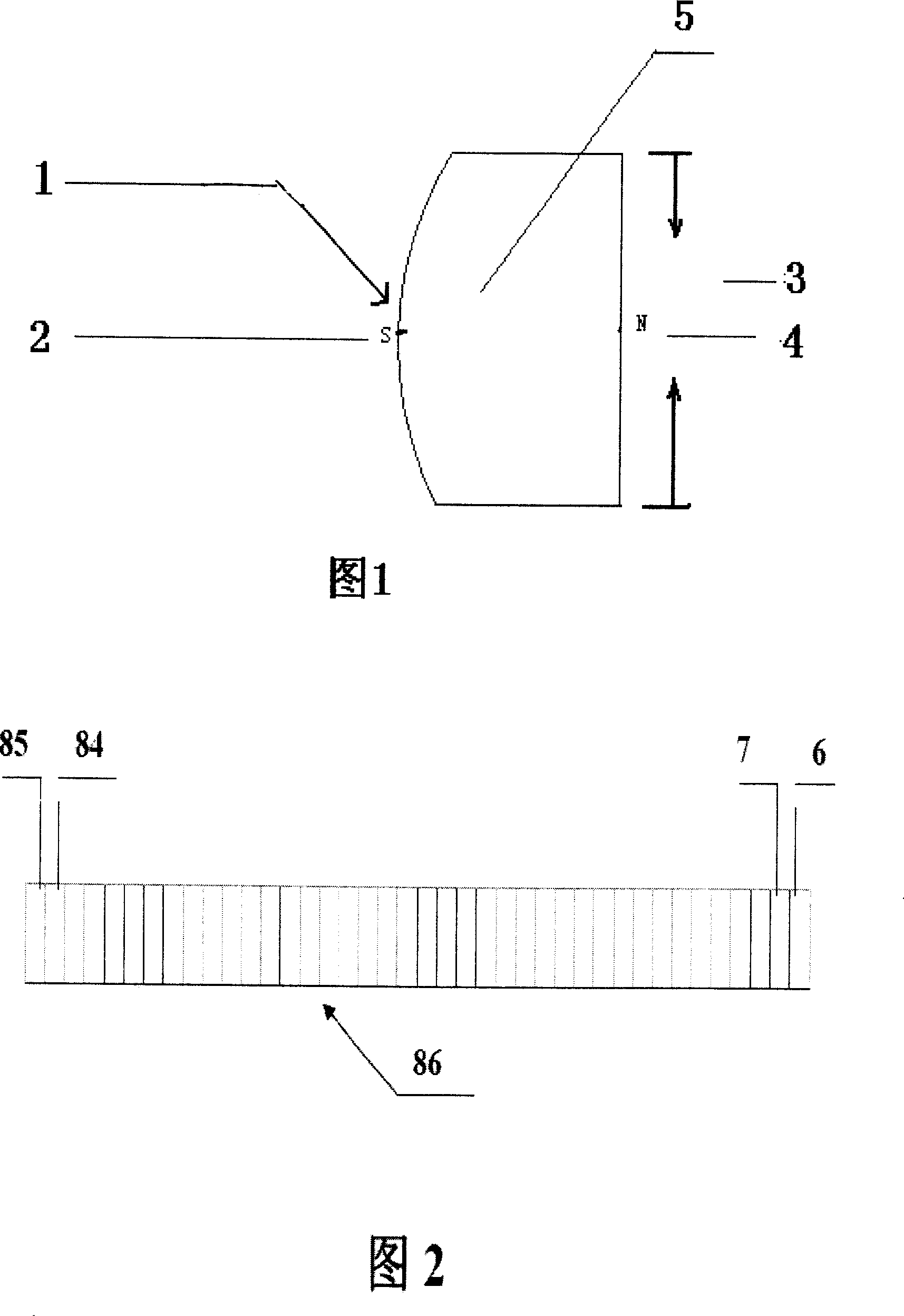

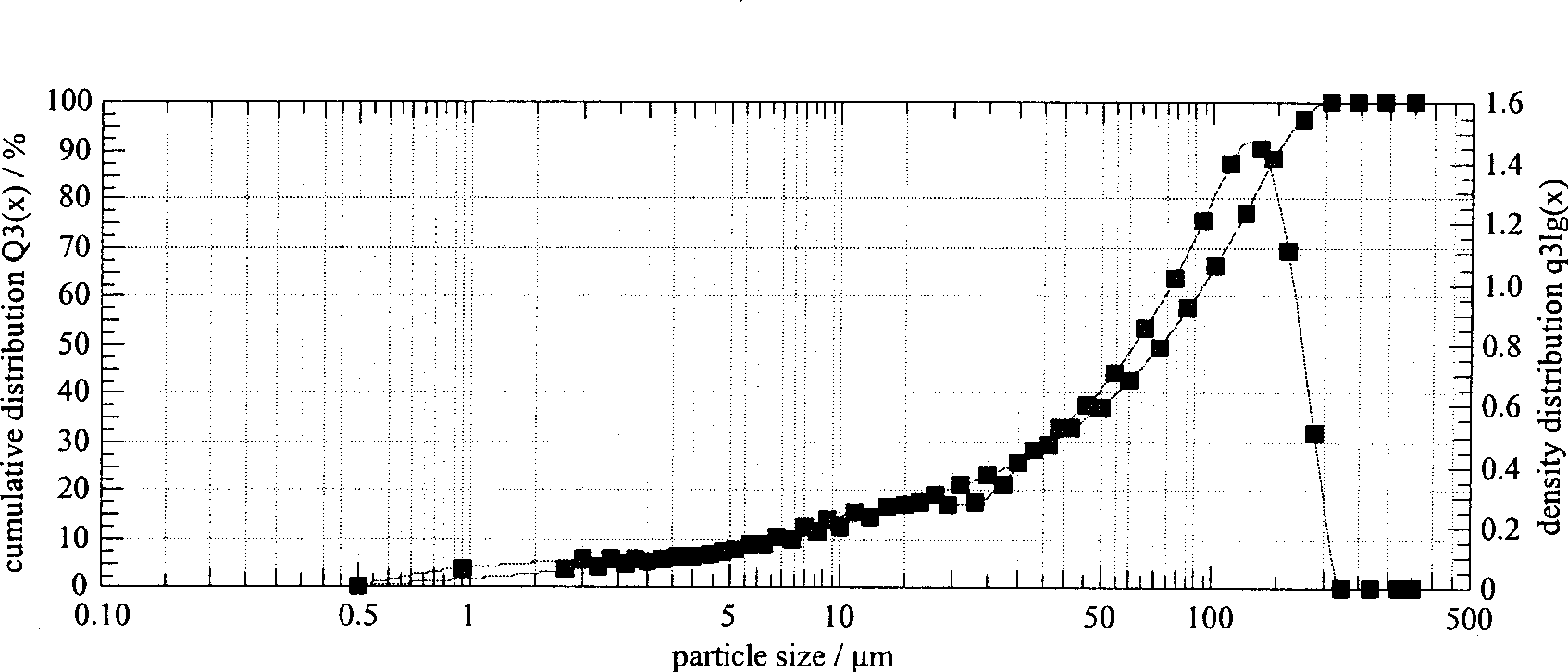

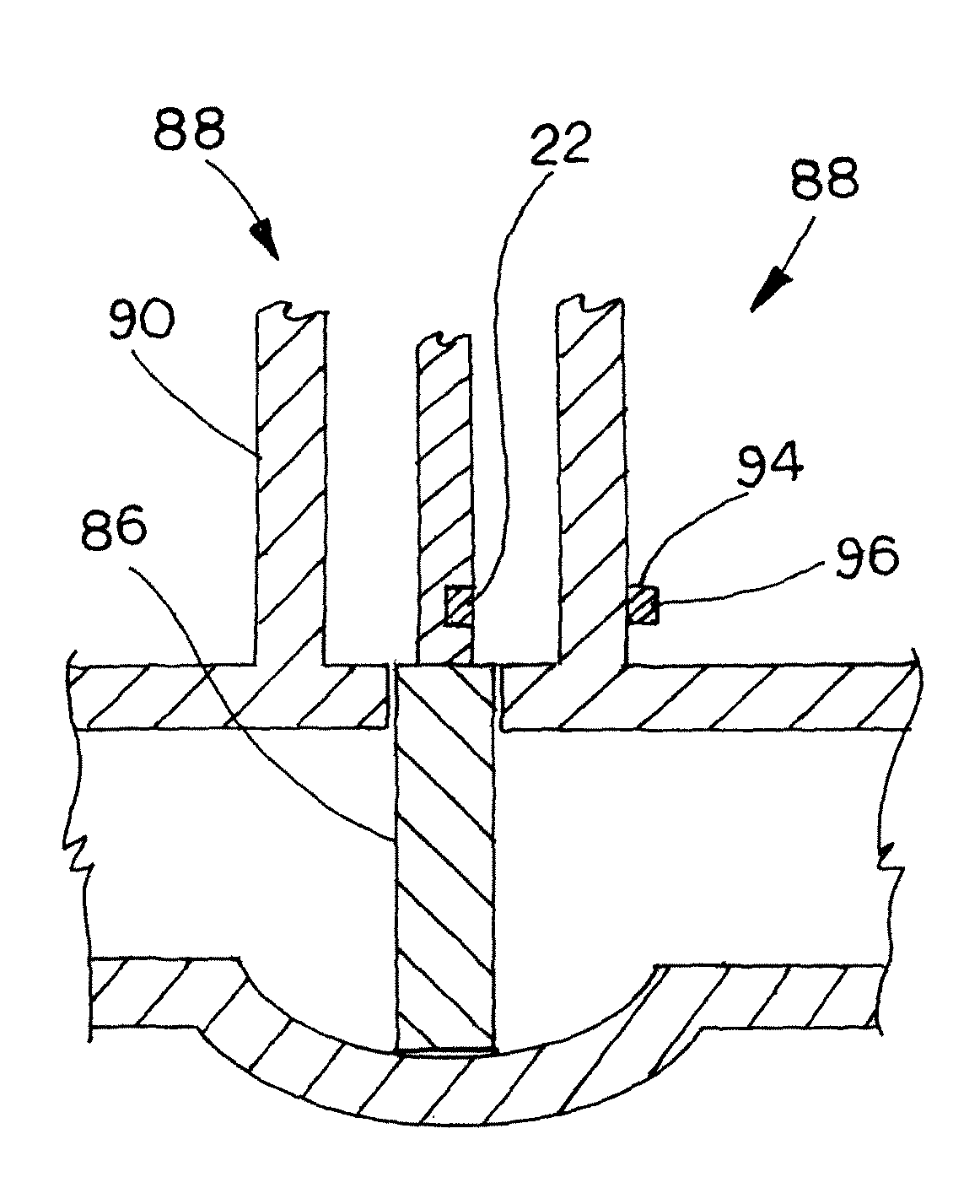

Permanent magnet for NMR logging instrument probe

InactiveCN101097799ASimple structureImprove bearing strengthPermanent magnetsNMR - Nuclear magnetic resonanceSamarium–cobalt magnet

A nuclear magnetic resonance well logging machine probe permanent magnet for generating gradient magnetic field in ground layer, engaged with nuclear magnetic resonance well logging machine to check the physical information of ground layer, is characterized in that a magnet post (86)is composed of adhered at least one small magnetic block (6), wherein the magnet is one portion of one cylinder. The invention sticks the magnet on well wall, while the magnet is N30 high-energy-accumulation samarium-cobalt magnet, with small volume, strong magnetic field, and high detection length. The invention simplifies the probe structure, improves the bearing strength of whole probe, improves the length of pre-polarized magnet, and improves detection speed, which can avoid blind area at the well wall direction, to improve detection accuracy, and generate gradient magnetic field along the well wall, to realize multi-dimension well logging.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

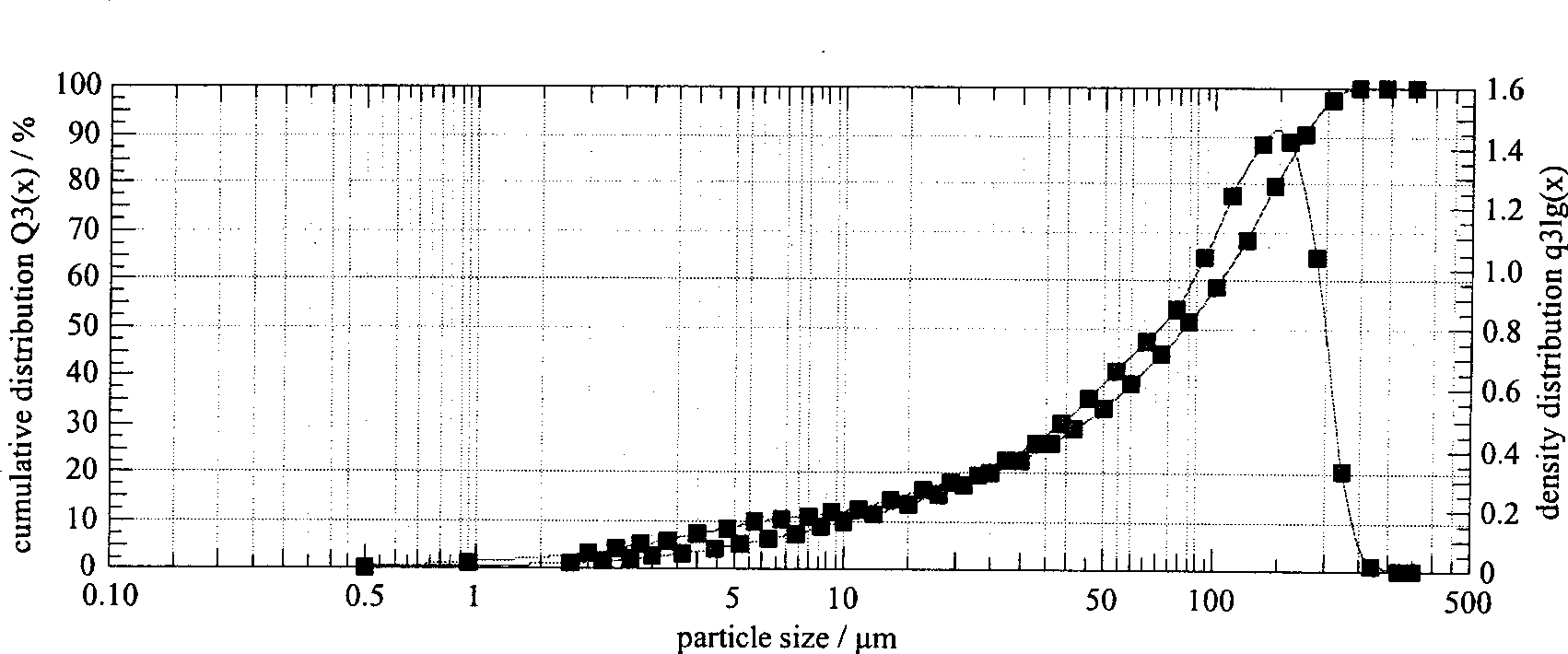

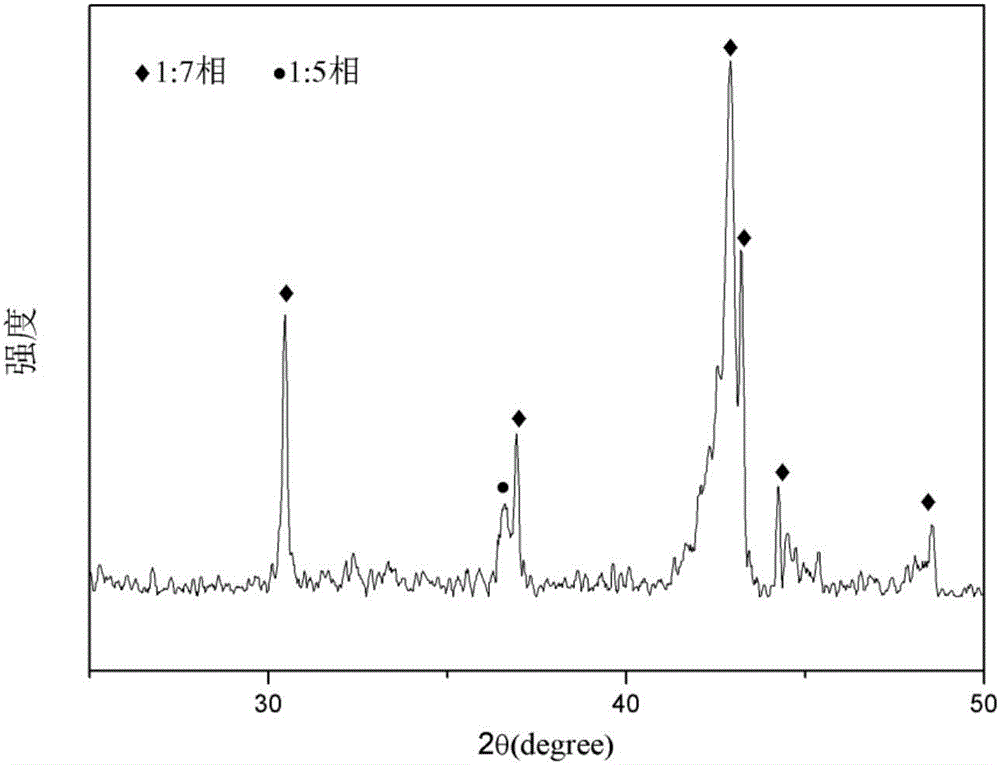

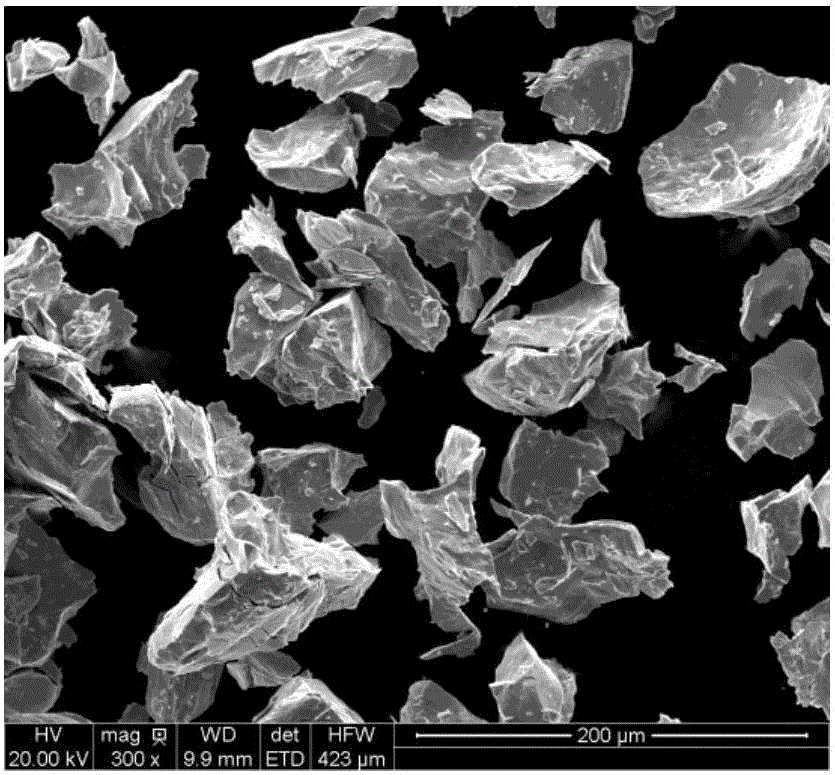

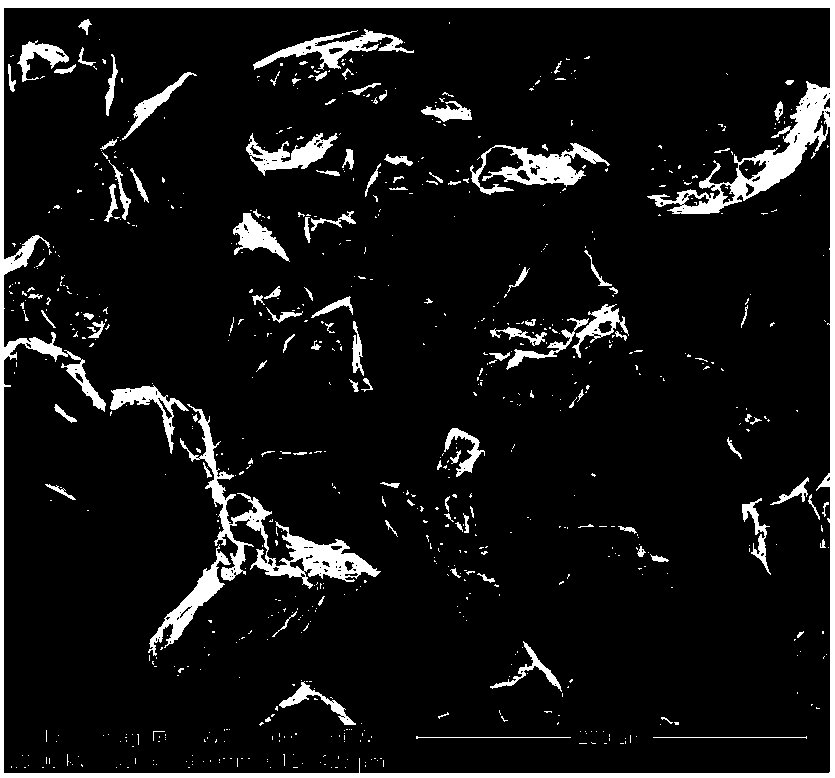

Samarium - cobalt magnetic powder and preparation thereof

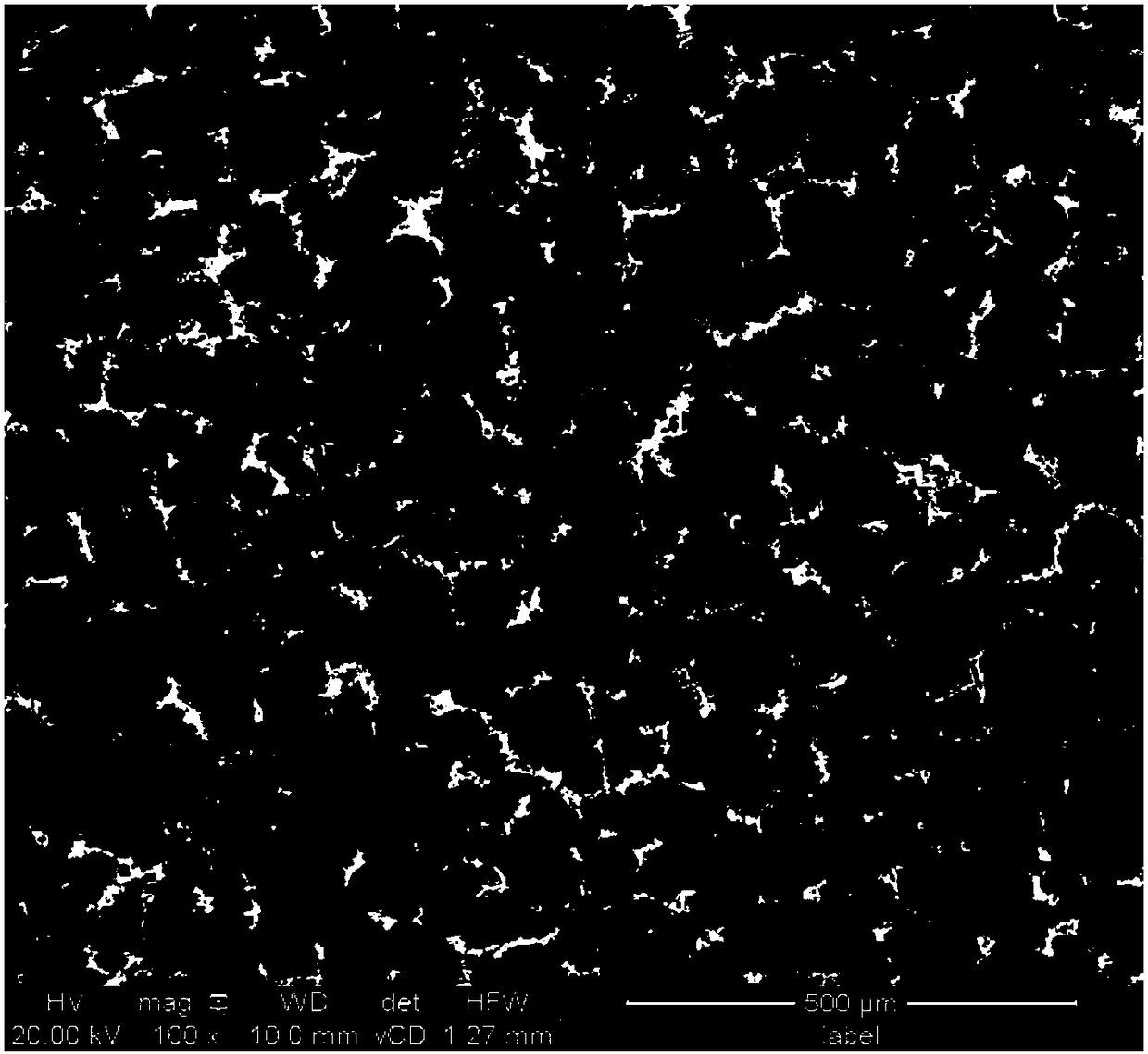

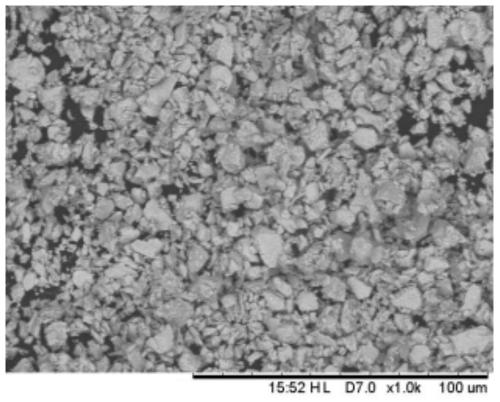

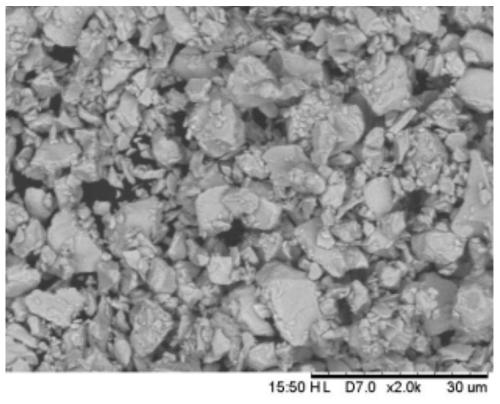

ActiveCN101477863AHigh proportion of crystallineUniform particle sizeInorganic material magnetismSamarium–cobalt magnetOxygen content

The invention discloses anisotropic samarium-cobalt magnetic powder and a preparation method thereof. The magnetic powder crystal is of mainly columnar crystal type; and the width of the columnar crystal is 1 to 30 Mums, the length thereof is 1 to 200 Mums, and the volume thereof is larger than 80%. The percentage of powder with a magnetic powder particle size between 50 to 200 Mums is larger than 60%; the particle sizes of the magnetic powder are well-distributed; the proportion of the columnar crystal is high; and the oxygen content is low. Therefore, an anisotropic samarium-cobalt magnet with high performance is suitable for preparation.

Owner:GRIREM ADVANCED MATERIALS CO LTD

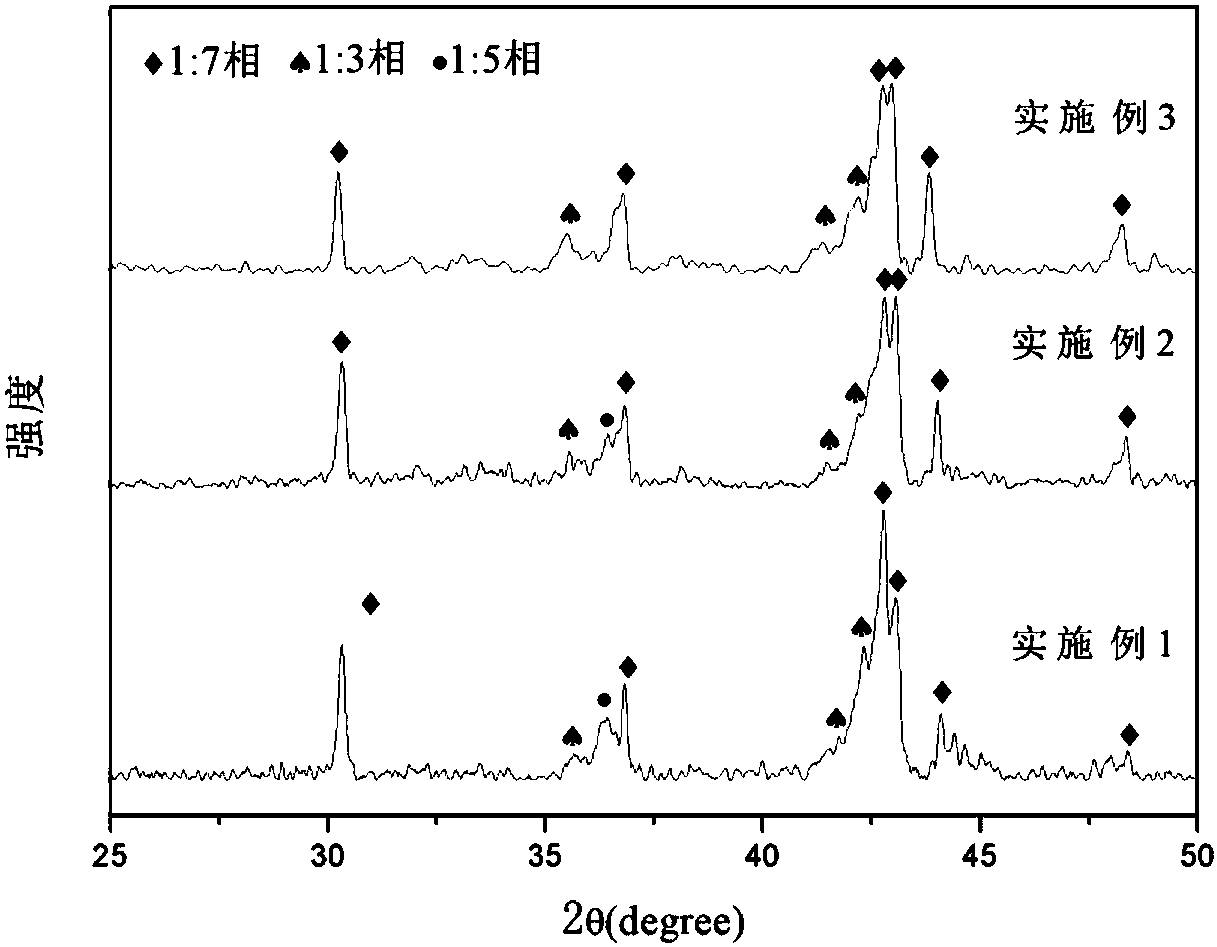

Preparation method of light rare earth complex modified sintered samarium-cobalt magnet

ActiveCN106024234AReduced oxygen uptakeImprove magnetismInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementAntioxidant

The invention discloses a preparation method of a light rare earth complex modified sintered samarium-cobalt magnet. The method includes the following steps of melting an Sm-Co-Fe-Cu-Zr master alloy cast ingot, smashing the cast ingot into powder through rough breaking and jet milling, injecting an antioxidant, adding mixed liquid of light rare earth complex and methyl acetate to a samarium-cobalt powder material, conducting high-energy ball-milling, crushing and even mixing, pressing the mixed material into a blank magnet according to magnetic alignment, putting the blank magnet into a vacuum sintering furnace to be subjected to sintering and solution treatment, then conducting ageing treatment, and conducting natural cooling to the room temperature to obtain the samarium-cobalt magnet. By adding light rare earth complex to the mixed material and combining the high-energy ball-milling technology, sintered light rare earth elements are mainly distributed on cell walls, cellular structures are greatly refined, and therefore the coercivity and magnetic energy product of the sintered samarium-cobalt magnet are improved. The method is simple in process, easy to operate and suitable for mass production.

Owner:东阳富仕特磁业有限公司

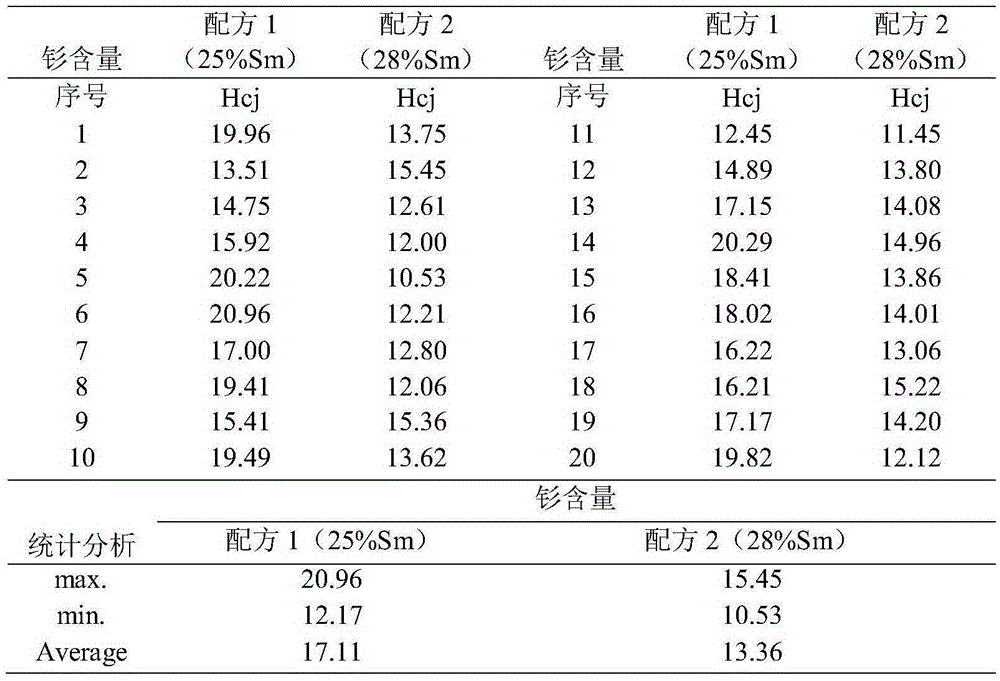

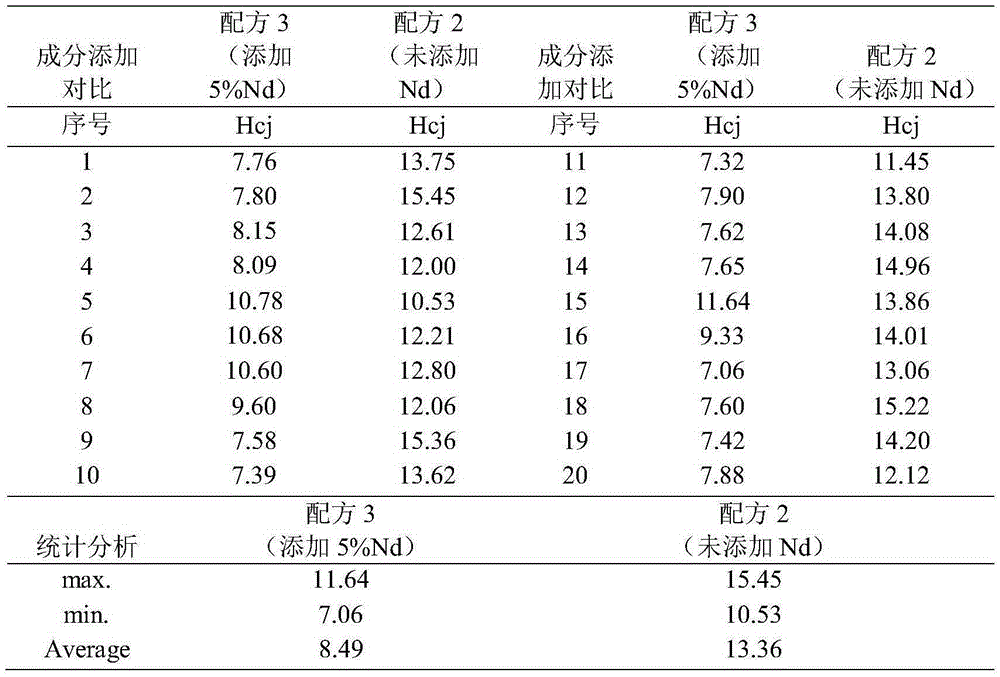

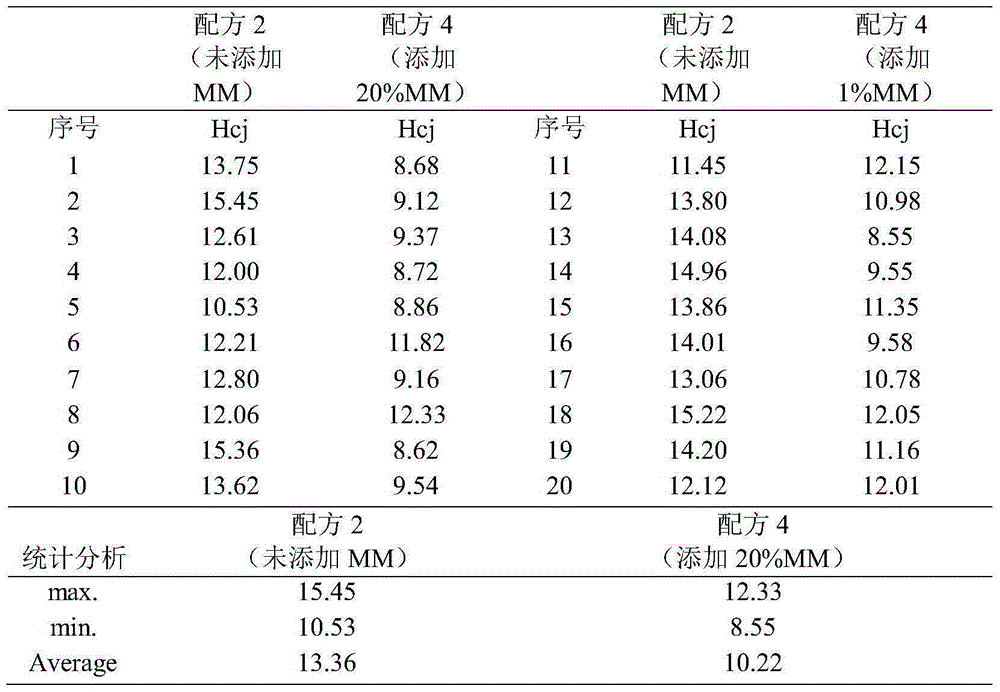

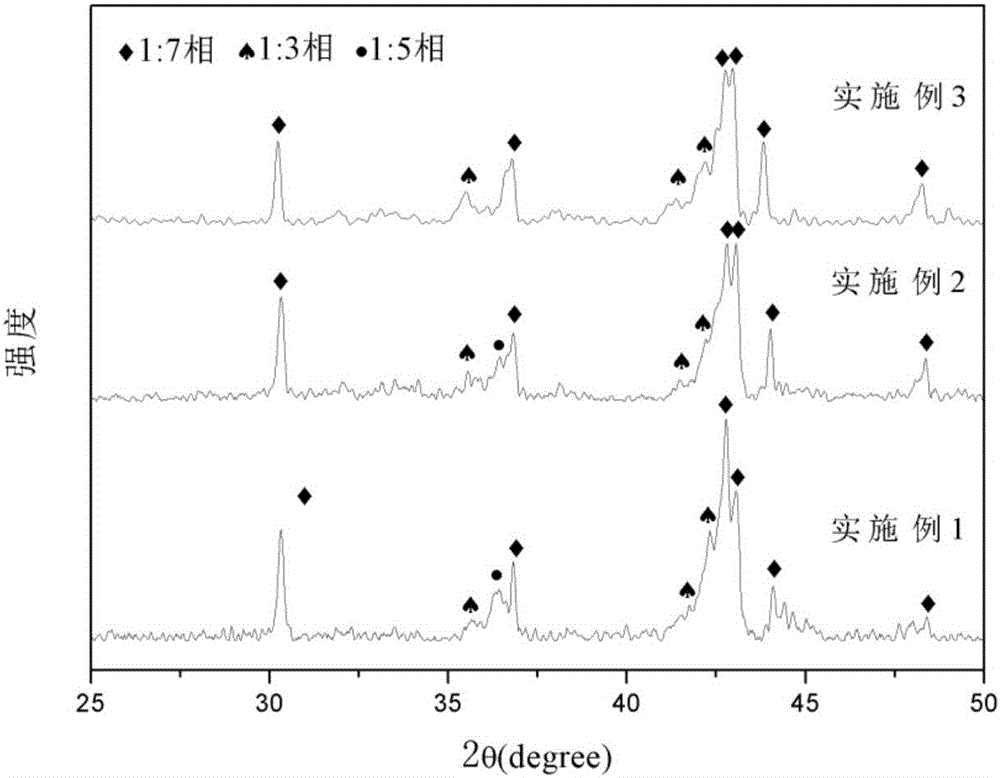

Low-coercive-force samarium-cobalt magnet and preparation method thereof

ActiveCN105355352AHcj lowFulfil requirementsInductances/transformers/magnets manufactureMagnetic materialsChemical compositionSamarium–cobalt magnet

The invention discloses a low-coercive-force samarium-cobalt magnet and a preparation method thereof. The chemical component of the samarium-cobalt magnet is as follows: (Sm1-zREz)aCo(1-a-b-c-d)CubFedZrc, wherein RE is at least one of Nd, Gd and MM; a is equal to 25%-29%, b is equal to 6%-9%, c is equal to 2%-3% and d is equal to 13%-17%; and z is equal to 0-0.4. The samarium-cobalt magnet takes the samarium-cobalt magnet at the ratio of 2 to 17 as a basis; the element composition and the component ratio are finely adjusted so that the intrinsic coercive force Hcj of a samarium-cobalt magnet product is greatly reduced and the technical requirements that a magnetizing magnetic field is relatively low under special conditions and saturated magnetization is needed are met very well.

Owner:CHENGDU GALAXY MAGNETAB

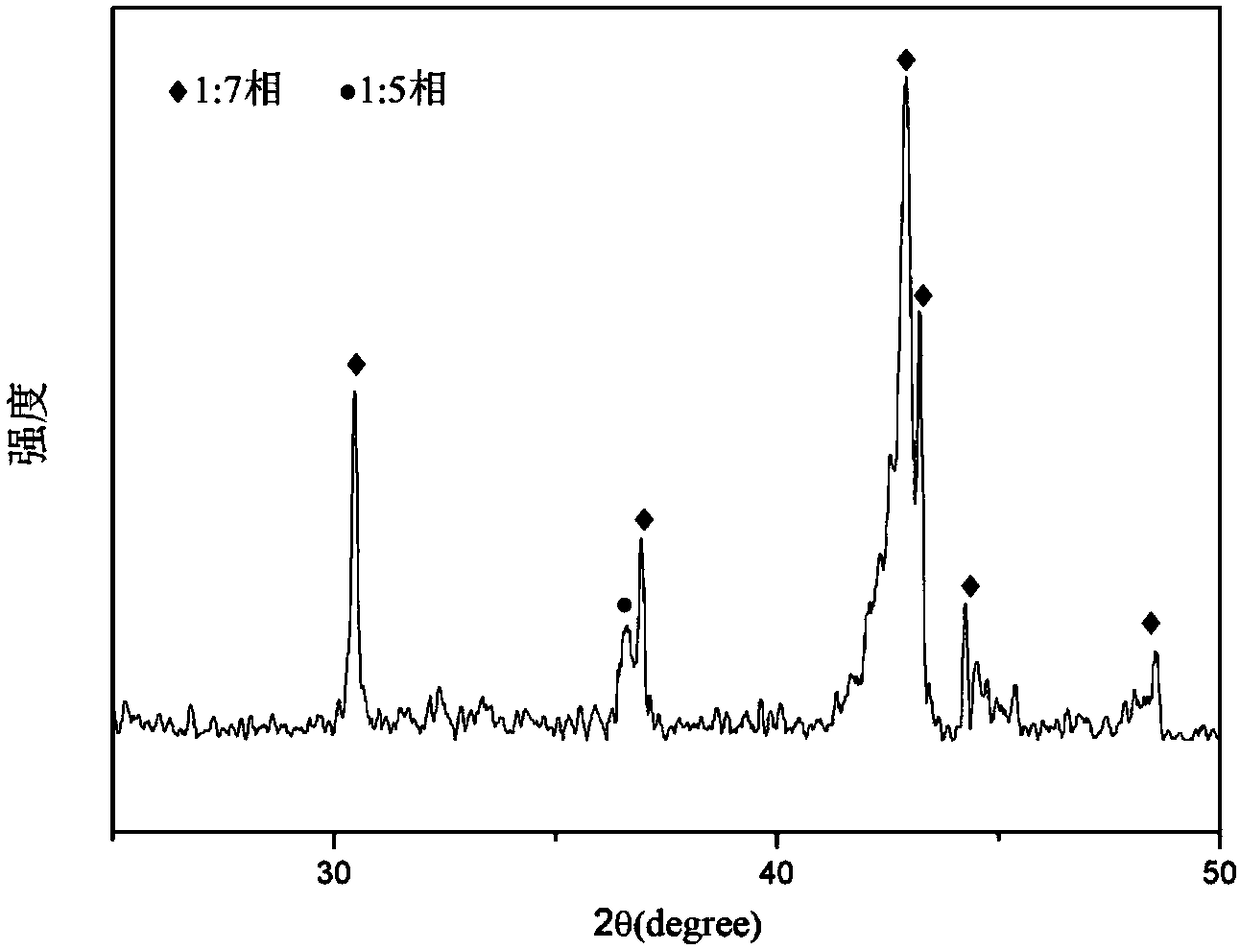

Samarium cobalt alloy material, samarium cobalt alloy powder, samarium cobalt magnet base and method of producing samarium cobalt alloy powder

ActiveCN106531383AStrong hydrogen absorption capacityLow electronegativityMagnetic materialsSamarium–cobalt magnetAlloy

The invention discloses a samarium cobalt alloy material. The stoichiometric formula of the samarium cobalt alloy material is Sm(Co1-a-b-c-d Fea Cub Zrc TMd)z. The elements, which constitute TM, include Mn.Cr.V.Ti.Sc.Nb.Ta.Mo.W and TM consists of at least one of these elements. The content of each element is that a >=0 and <= 0.25, b >=0 and <=0.15, c >=0 and <= 0.04, d >0 and <= 0.1 and z >=6.8 and <= 8.5. The invention also discloses a samarium cobalt alloy powder, a method of producing the samarium cobalt alloy powder and a samarium cobalt magnet base.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing composite bonded permanent magnet

InactiveCN103295770ACost-effectiveReduce the use of rare earthsInorganic material magnetismInductances/transformers/magnets manufactureSamarium–cobalt magnetSamarium

The invention relates to a method for preparing a composite bonded permanent magnet. The method includes the following steps that (1), samarium-cobalt-based permanent powder is prepared; (2), the permanent powder is mixed and granulation is performed; (3), injection molding is performed. According to the prepared composite bonded permanent magnet, samarium cobalt magnet material and neodymium iron boron material are composite, wherein the samarium cobalt magnet material and the neodymium iron boron material have good high-temperature performance, and the high-temperature magnetic performance of the permanent magnet is improved. Meanwhile, the usage amount of rare earth of the material is reduced, and the overall cost performance of the magnet is improved.

Owner:嘉兴集禾电子商务有限公司

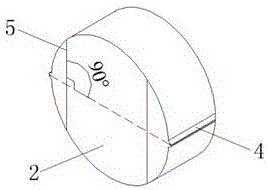

Manufacturing method for large-dimension high-precision samarium-cobalt magnet

ActiveCN106158200AOvercome the problem of difficult processingInductances/transformers/magnets manufactureMagnetic materialsSamarium–cobalt magnetMagnetic poles

The invention relates to a manufacturing method for a large-dimension high-precision samarium-cobalt magnet. The manufacturing method comprises the steps of trimming, roughly grinding, vertically grinding, scribing lines, horizontally grinding, assembling and excircle grinding. According to the manufacturing method, assembling and gluing steps are performed; small-dimension products are manufactured firstly; then the small-dimension products are glued into large-dimension products; the problem of difficulty in manufacturing the large-dimension magnet is solved; geometrical tolerance of perpendicularity, depth of parallelism and cylindricity and the like is ensured through the processes of excircle grinding, horizontally grinding and the like; meanwhile, a technological method for marking magnetic pole boundary under a non-magnetic state is provided; and therefore, a feasible manufacturing scheme is provided for products with relatively large dimensions and relatively high requirement on tolerance.

Owner:杭州科德磁业有限公司

Permanent magnetic RE material and preparation thereof

ActiveCN101364465BSmall temperature coefficientLow coercivityInorganic material magnetismCrystalline oxideSamarium–cobalt magnet

The invention relates to a rare earth permanent magnetic material and a preparation method thereof. The rare earth permanent magnetic material comprises a (Pr, Nd)-Fe-R-Co-Al-Cu-B-M system, and the rare earth as a main phase component has a phase volume ratio of 90%-98%; wherein R is at least two elements selected from Nb, Tb, Dy and Ho; M is at least two nanometer crystalline oxides with particle size of 10-100 nm selected from ZrO2, MgO and ZnO; and the weight of the nanometer crystalline oxides is 0.1%-3% of the total weight. The rare earth permanent magnetic material is a compound nanometer oxidizer enhanced and sintered praseodymium (Pr)-neodymium (Nd)-based permanent magnet with high coercitive force. The inventive product has magnetic features of low temperature coefficient, high coercitive force, low cost and 220 DEG C working temperature, and can overcome the shortcomings of lower coercitive force, high temperature coefficient and high cost of the prior sintered Nd-Fe-B permanent magnet and the sintered samarium-cobalt magnet in application of large motor products. The preparation method provides a powerful guarantee for realizing the positive effects.

Owner:浙江西子富沃德电机有限公司

Samarium cobalt magnet and method for producing same

ActiveCN109712770AHas a positive temperature coefficient of remanenceImprove remanenceInductances/transformers/magnets manufactureMagnetic materialsSamarium–cobalt magnetGadolinium

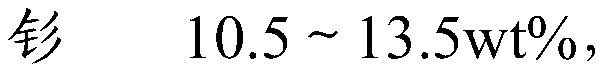

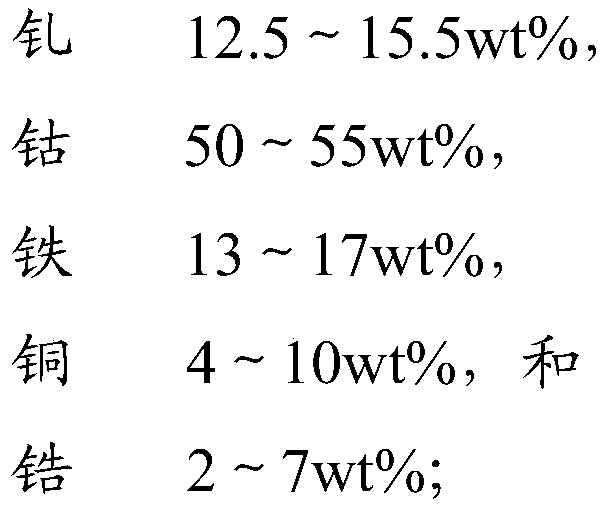

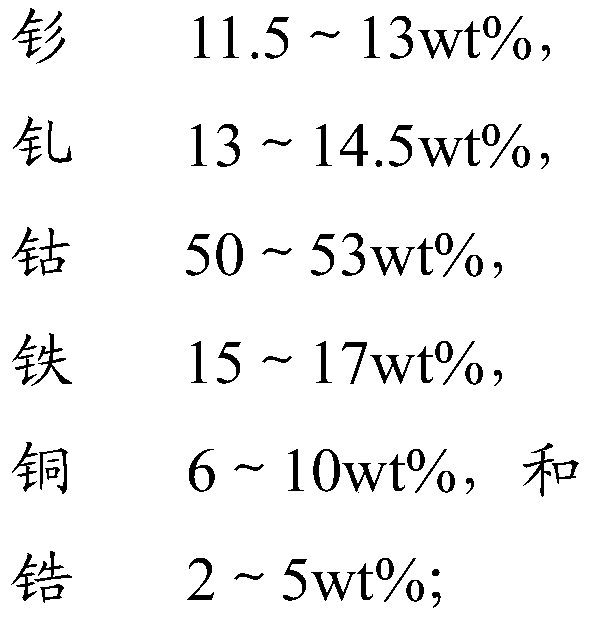

The invention discloses a samarium-cobalt magnet and a manufacturing method thereof. The method comprises the following steps of: obtaining a sample; mixing the alloy powder with 0.1-0.35 wt% of zirconium powder based on the weight of the alloy powder to form a mixture, wherein the alloy powder is prepared from 10.5-13.5 wt% of samarium, 12.5-15.5 wt% of gadolinium, 50-55wt% of cobalt, 13-17wt% ofiron, 4-10wt% of copper and 2-7wt% of zirconium. By means of the method, the samarium-cobalt magnet with the positive residual magnetism temperature coefficient can be obtained in a low-cost mode.

Owner:BAOTOU TIANHE MAGNETICS TECH CO LTD

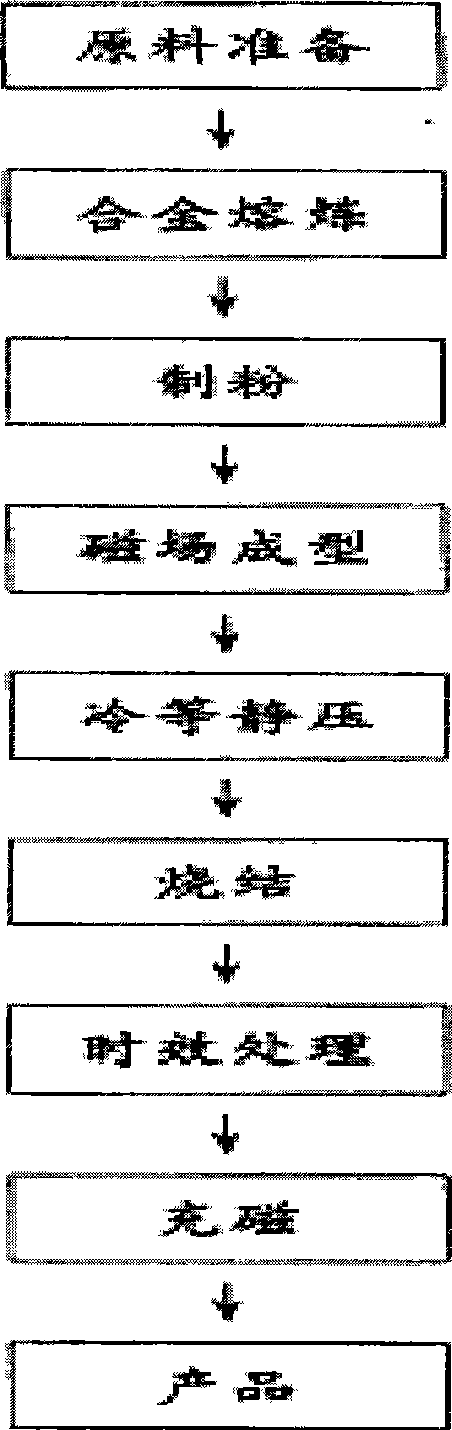

Fabrication process of samarium-cobalt magnet

ActiveCN109411225AInductances/transformers/magnets manufactureMagnetic materialsMaterials preparationSamarium–cobalt magnet

The invention provides a fabrication process of a samarium-cobalt magnet. The fabrication process comprises the steps of material preparation, alloy smelting, ingot casting, powder preparation, formation, sintering and tempering. Before solid solution is ended, a subsequent sintering process is performed on a formed blank after partial pressure process operation, air cooling is performed to a roomtemperature and then annealing is performed to obtain the product samarium-cobalt magnet after a temperature in a sintering furnace is reduced to 100 DEG C or below. Before the solid solution is ended, the partial pressure process operation is performed on the formed blank, on one hand, the temperature uniformity of the furnace can be improved, the magnetic property uniformity of a sample under the same sintering condition can be relatively good, volatilization of Sm can be suppressed, air holes are eliminated, and the blank density is improved; and on the other hand, harmful gas generated bysintering also can be timely discharged out of the furnace by constantly filling inert gas, the sintering atmosphere is good, and the service lifetime of an instrument can be prolonged.

Owner:HANGZHOU PERMANENT MAGNET GRP

Preparation method of sintered samarium-cobalt magnet

InactiveCN109706338ASolve the problem of difficult schedulingAvoid high cost of use, potential safety hazards, etc.Magnetic materialsSamarium–cobalt magnetNitrogen

The invention discloses a preparation method of a sintered samarium-cobalt magnet. The preparation method comprises the following steps: 1 crushing sintered samarium-cobalt alloy ingot to obtain samarium-cobalt alloy particles; 2, feeding the samarium-cobalt alloy particles in jet mill equipment protected by nitrogen, enabling the powder particle to collide with each other under blowing of nitrogen airflow; and adopting a grading wheel to screen the crushed samarium-cobalt alloy powder to remove coarse particles, and then adopting a cyclone separator to remove fine particles through screeningto obtain samarium-cobalt alloy powder with the averaged particle size being 2-10 microns; and 3, carrying out orientation and prepressing forming on the samarium-cobalt alloy powder in a magnetic field, then, carrying out isostatic pressing forming, and finally carrying out sintering forming at 1170-1199 DEG C to obtain the sintered samarium-cobalt magnet. According to the preparation method, thepowder preparation cost is low, the flammable solvent is not used, the potential safety hazard is avoided, the samarium-cobalt alloy powder is excellent in uniformity, the sintered magnet is easy tocontrol, the magnetic property of the product is steadier and better, and the product with various high properties or special property requirements can be prepared.

Owner:CHENGDU GALAXY MAGNETAB

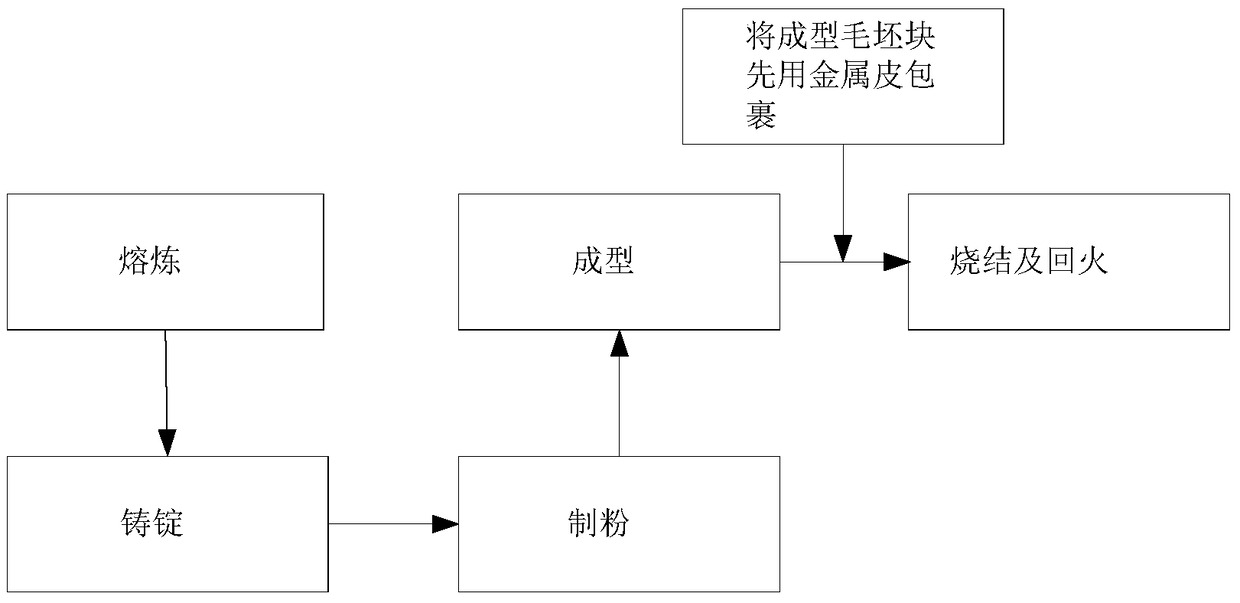

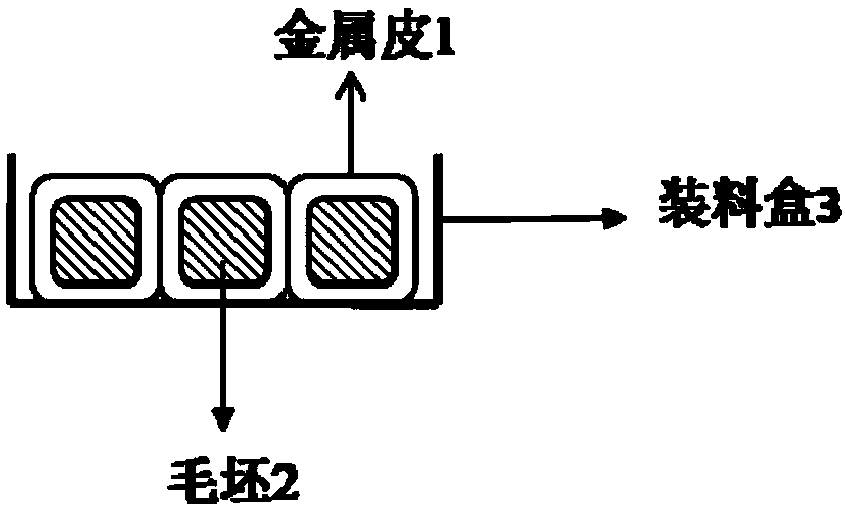

A preparation process of samarium cobalt magnet

ActiveCN109216007AEvenly heatedReduce frictionInductances/transformers/magnets manufactureMagnetic materialsSamarium–cobalt magnetMetallurgy

The invention provides a preparation process of a samarium-cobalt magnet, comprising the following steps: alloy melting, ingot casting, powder making, molding, sintering and tempering; Wherein, the formed blank obtained by cold isostatic pressing is firstly wrapped with a metal skin and then subjected to a subsequent sintering process, and when the temperature in the sintering furnace is reduced to below 100 DEG C, the air is cooled to normal temperature, the metal skin is removed, and the product is tempered to obtain the product. The green blank obtained in the molding process is firstly wrapped with a metal skin and then sintered, so that the temperature transmission rate is increased, the green blank is heated uniformly, harmful gases outside the sintering furnace can be effectively blocked, and the sintering atmosphere is good; At the same time, the friction and collision between magnets and cartridges can be effectively alleviated by wrapping the blank block with metal sheets. The probability of edge impact and angle impact of magnets is obviously reduced, and the eligibility rate is greatly improved. In addition, the metal skin can be recycled, suitable for industrial applications.

Owner:HANGZHOU PERMANENT MAGNET GRP

Ultra-high coercive force sintered Nd-Fe-B magnetic material and preparing process thereof

ActiveCN100461308CReasonable distributionMake up for temperature gapsInorganic material magnetismSamarium–cobalt magnetMetallurgy

This invention relates to super-high coercive force sintering neodymium iron boron magnet and its preparation method. the alloy molecular general formula is NdxDyyTbzFe(100%-x-y-z-x1-y1-z1-w-w1)Cox1Nby1Cuz1(Ga)wBw1, intrinsic coercive force more than 35k0e(2786kA / m) sintering neodymium iron boron magnet are made through traditional normal ingot casting method. The highest work temperature is 220 degrees centigrade, so the using temperature frees position in traditional sintering neodymium iron boron magnet and sintering samarium cobalt magnet.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

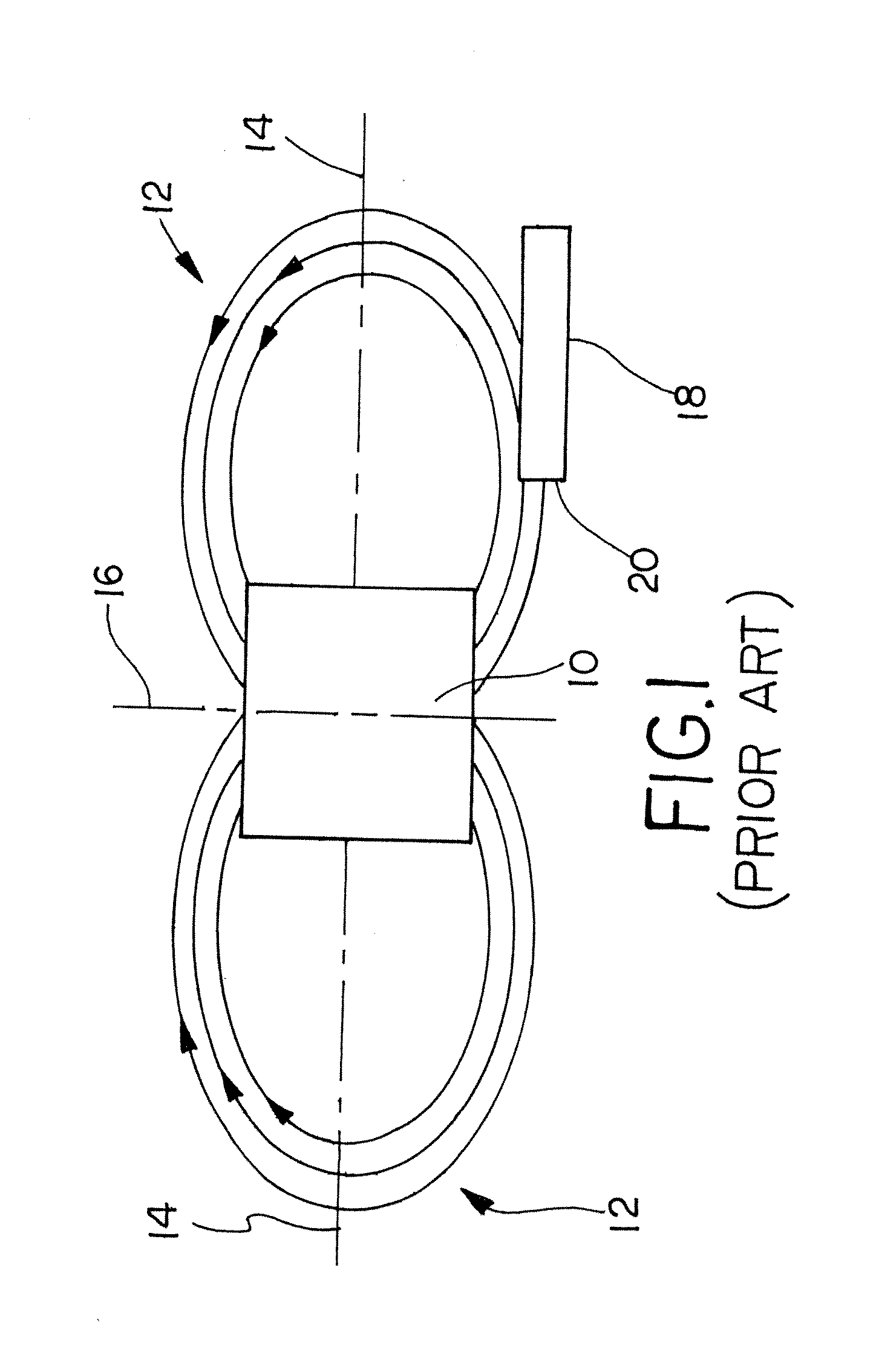

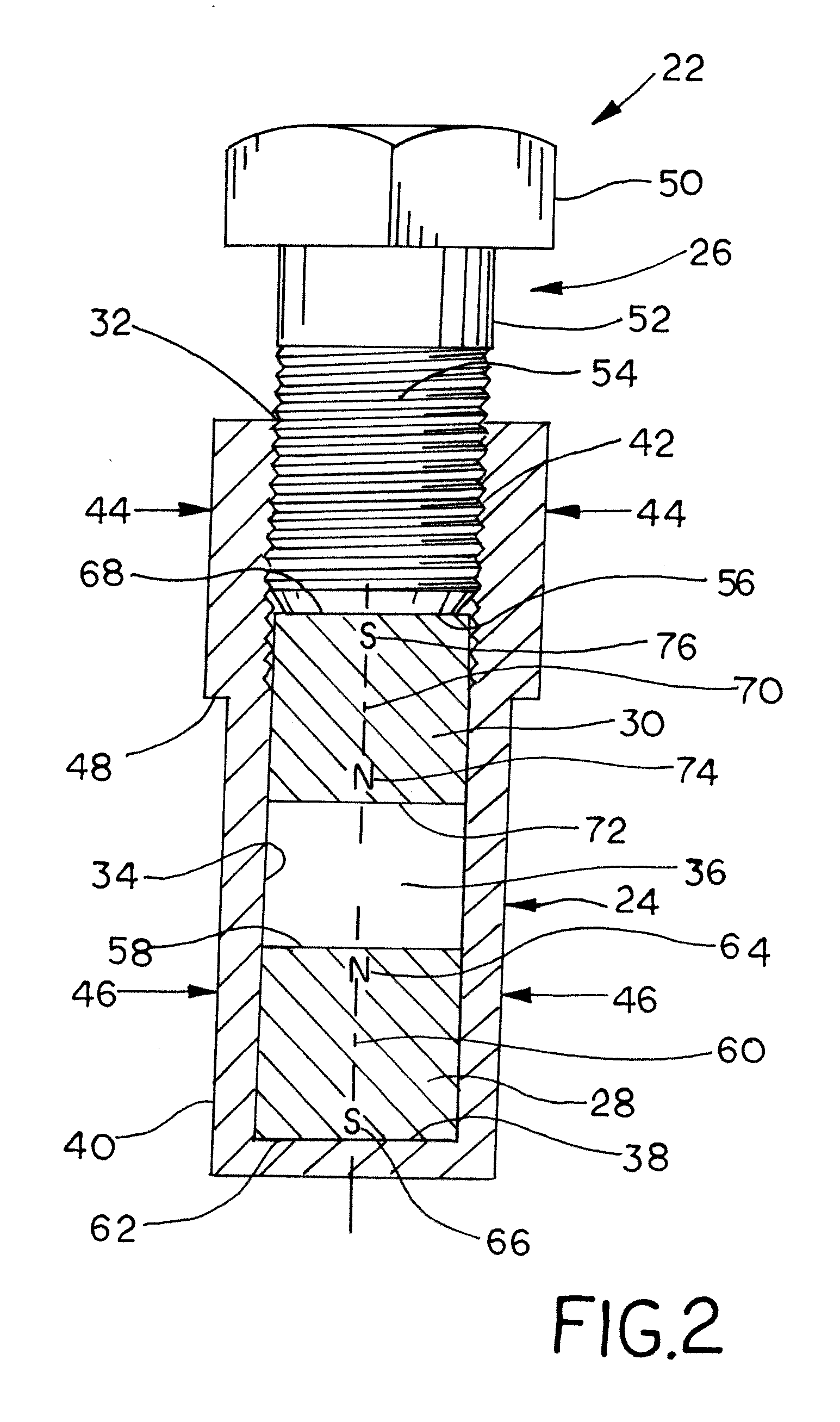

Adjustable Magnetic Target

ActiveUS20110050373A1Shorten the vertical distancePermanent magnetsMagnetic/electric field switchesNeodymium magnetSamarium–cobalt magnet

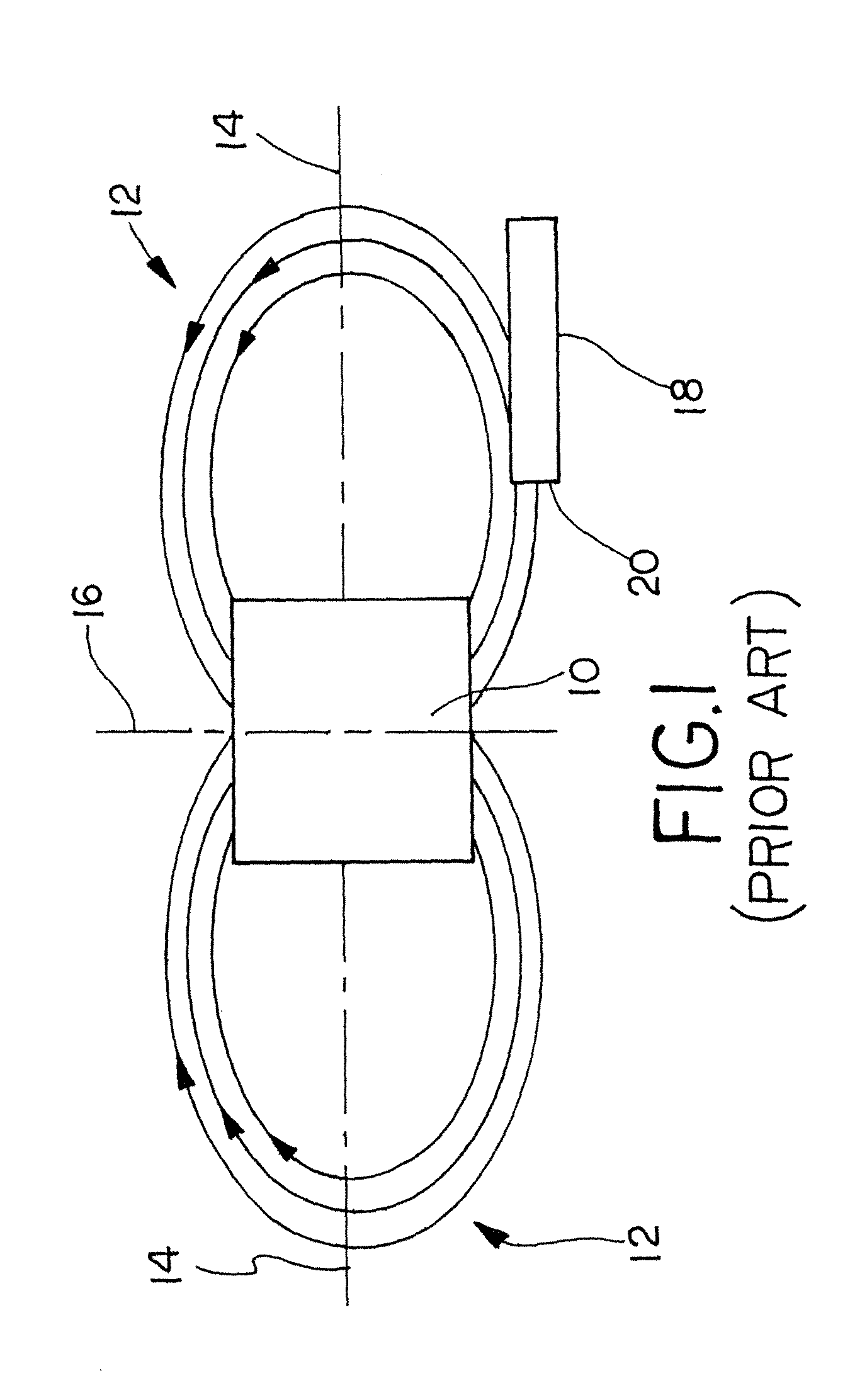

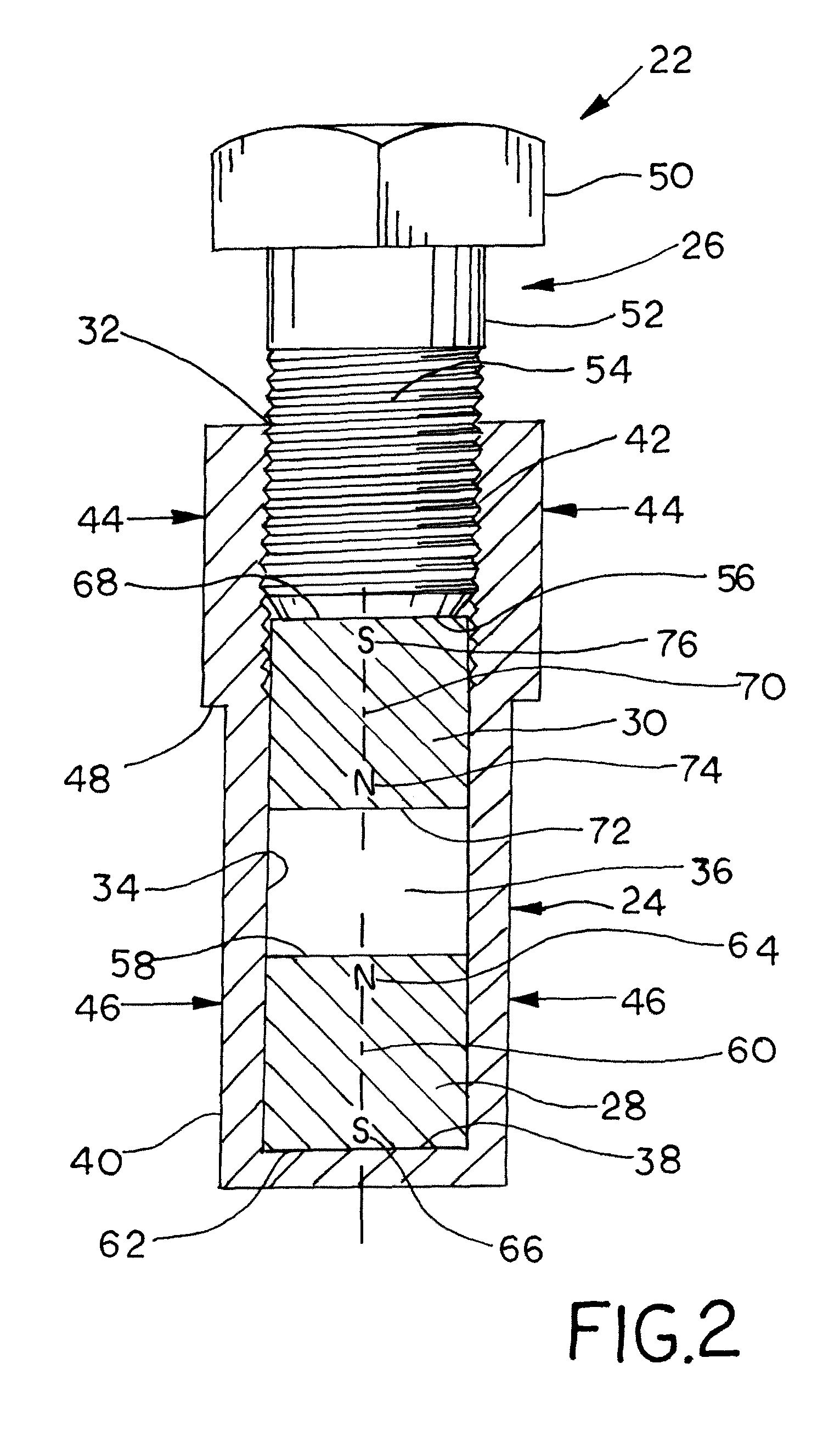

A magnetic target is provided for use with a magnetic proximity switch. The magnetic target includes a cylindrical body tube having an open end that partially defines a bore. A stationary magnet is located within the bore opposite the open end, and a movable magnet is disposed within the bore between the stationary magnet and the open end. An adjusting member is received into the bore, and a contact surface of the adjusting member engages the movable magnet. When the adjusting member is axially displaced, the contact surface causes a corresponding displacement of the movable magnet relative to the stationary magnet, eventually causing the magnetic flux field of each magnet to expand in a radial direction away from the longitudinal axis of each magnet. The stationary magnet and the movable magnet may be either axially-magnetized samarium-cobalt magnets or axially-magnetized neodymium magnets.

Owner:GENERAL EQUIP & MFG COMPANY INC D B A TOPWORX

Adjustable magnetic target

ActiveUS8264309B2Shorten the vertical distancePermanent magnetsMagnetic/electric field switchesNeodymium magnetSamarium–cobalt magnet

A magnetic target is provided for use with a magnetic proximity switch. The magnetic target includes a cylindrical body tube having an open end that partially defines a bore. A stationary magnet is located within the bore opposite the open end, and a movable magnet is disposed within the bore between the stationary magnet and the open end. An adjusting member is received into the bore, and a contact surface of the adjusting member engages the movable magnet. When the adjusting member is axially displaced, the contact surface causes a corresponding displacement of the movable magnet relative to the stationary magnet, eventually causing the magnetic flux field of each magnet to expand in a radial direction away from the longitudinal axis of each magnet. The stationary magnet and the movable magnet may be either axially-magnetized samarium-cobalt magnets or axially-magnetized neodymium magnets.

Owner:GENERAL EQUIP & MFG COMPANY INC D B A TOPWORX

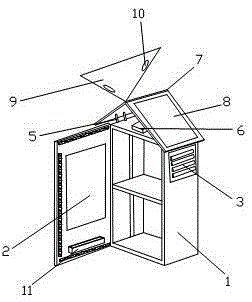

Outdoor electric power cabinet

InactiveCN105238109AAvoid enteringExcellent water absorption and drying abilitySubstation/switching arrangement casingsReflecting/signal paintsSamarium–cobalt magnetElectrical connection

The invention discloses an outdoor electric power cabinet. The outdoor electric power cabinet comprises a cabinet body and a cabinet door; the cabinet body is provided with a thermal reflective coating layer and a detachable heat dissipation louver; the detachable heat dissipation louver is provided with a stainless steel box; the stainless steel box is provided with air holes, and is filled with anhydrous calcium chloride, phosphorus pentoxide, and soda lime; the upper part of the cabinet body is provided with a supporting rod and a micro dehumidifier; the supporting rod is provided with a triangular top cover; the triangular top cover is provided with a hinge joint part and a solar cell panel; the hinge joint part is provided with a side plate; the side plate is provided with a samarium-cobalt magnet; and the solar cell panel is connected with the micro dehumidifier via electrical connection. The outdoor electric power cabinet possesses excellent moisture-proof performance.

Owner:李聪

Method for preparing sintered samarium-cobalt magnet

ActiveCN103065788BOvercoming the problem of poor composition consistencyImprove coercive forceInorganic material magnetismInductances/transformers/magnets manufactureRemanenceSamarium–cobalt magnet

The invention discloses a method for preparing a sintered samarium-cobalt magnet. The method comprises the following steps of: preparing a first samarium-cobalt alloy and a second samarium-cobalt alloy; performing primary crushing on the first samarium-cobalt alloy and the second samarium-cobalt alloy; mixing first samarium-cobalt alloy primarily crushed magnetic powder and second samarium-cobalt alloy primarily crushed magnetic powder, and performing fine crushing, so that primarily crushed mixed magnetic powder is refined, and components are homogenized; and performing magnetic field orientation forming, cold isostatic pressing, sintering, solid solution treatment and ageing treatment on samarium-cobalt magnetic powder obtained by fine crushing in sequence. The method has the advantages that the first samarium-cobalt alloy has high remanence component characteristic, the second samarium-cobalt alloy has high coercivity component characteristic, the sintered samarium-cobalt magnets with various magnetic properties can be obtained by adjusting the mixing ratio of the first samarium-cobalt alloy primarily crushed magnetic powder to the second samarium-cobalt alloy primarily crushed magnetic powder, and the process is stable and low in cost.

Owner:NINGBO YUNSHENG +3

High-safety machining technology of samarium cobalt magnet

InactiveCN108806909AImprove toughnessImprove machinabilityInorganic material magnetismInductances/transformers/magnets manufactureSamarium–cobalt magnetCopper

The invention relates to the technical field of samarium cobalt magnet machining, and provides a high-safety machining technology of a samarium cobalt magnet. By means of the technology, the yield andmachining speed of the samarium cobalt magnet can be effectively improved. The high-safety machining technology of the samarium cobalt magnet comprises the following steps of A, smelting, wherein samarium, cobalt, copper, iron, zirconium and aluminum are added into a vacuum induction furnace for smelting in the mass ratio of 20:35:12:20:3:0.5; B, powder preparation; C, formation of a magnetic field; D, sintering; E, machining. The method can effectively improve the yield and machining speed of the samarium cobalt magnet.

Owner:绵阳信和磁性材料有限公司

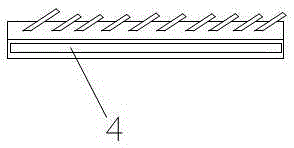

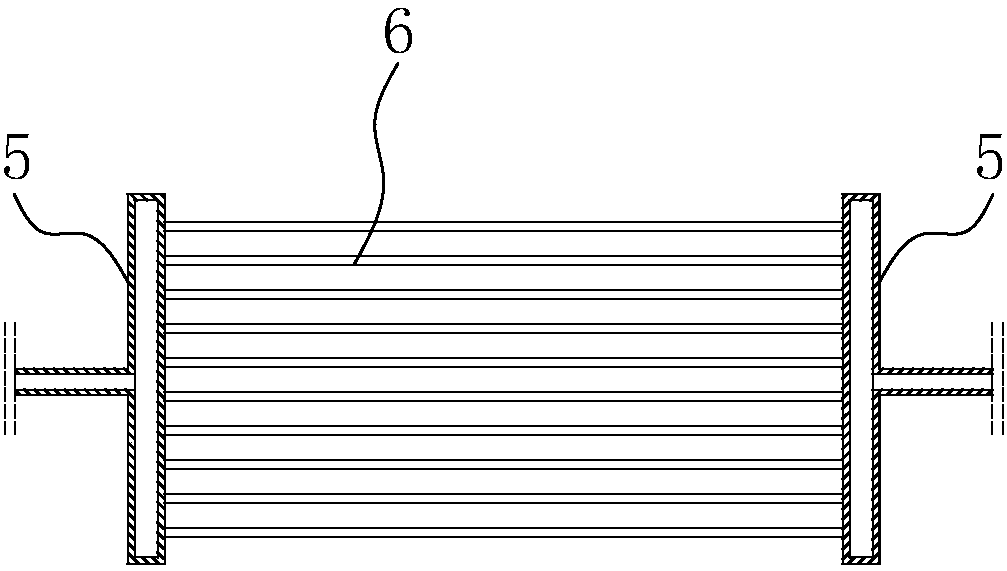

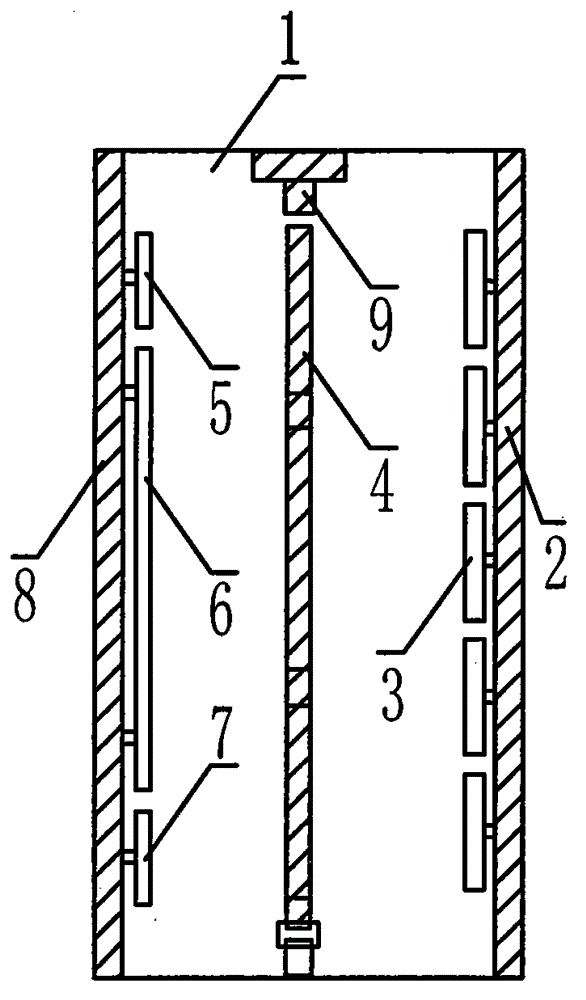

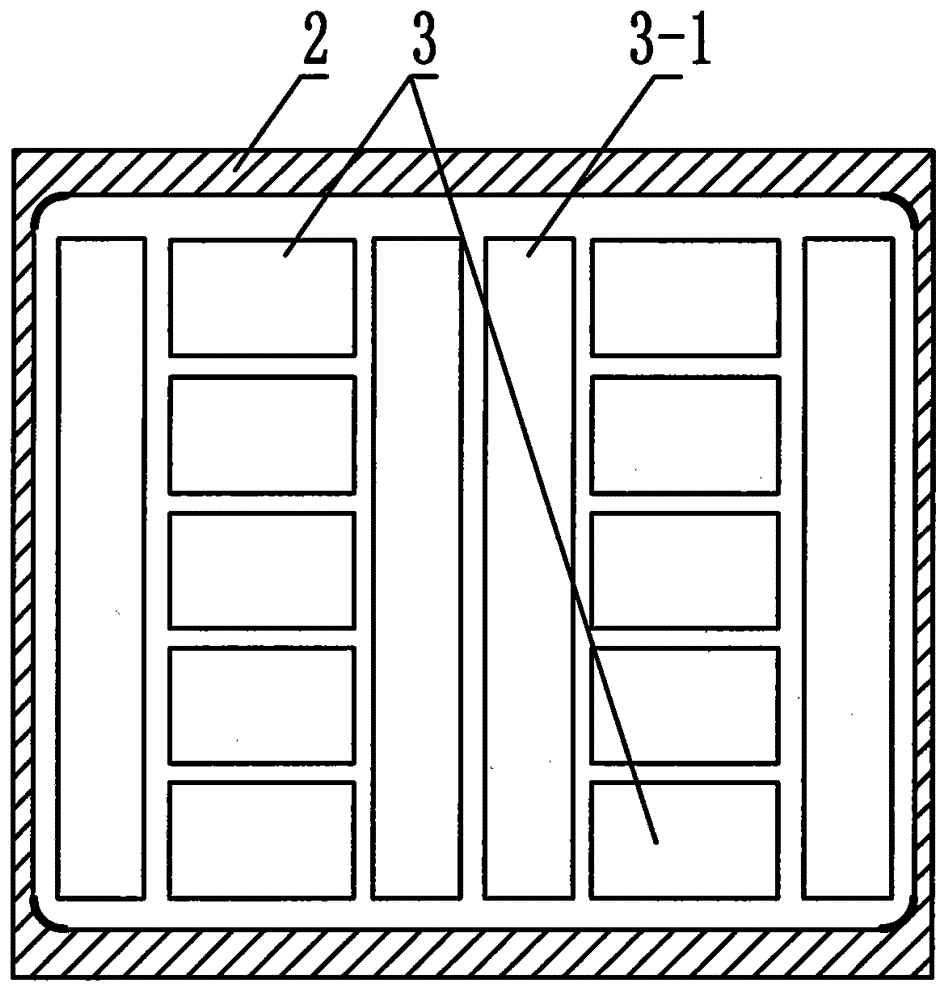

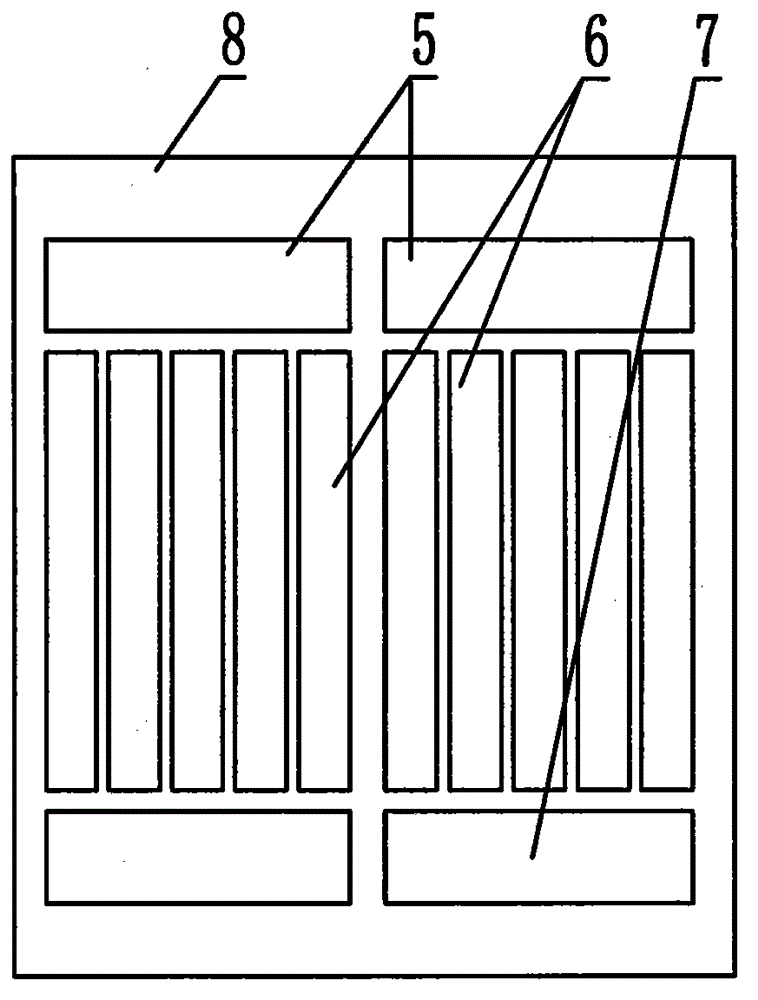

Uniform heating device and method of magneto-controlled sputtering maglev vehicle target of ITO (indium tin oxide) film

ActiveCN104372302AImprove product qualityExtended service lifeVacuum evaporation coatingSputtering coatingSamarium–cobalt magnetLow vacuum

Disclosed is a uniform heating device and method of a magneto-controlled sputtering maglev vehicle target of ITO (indium tin oxide) film. During large-scale continuous production of ITO film, by controlling heating temperatures of all parts of the magneto-controlled sputtering maglev vehicle target, uniform resistor is acquired by the ITO thin film, with electrical resistivity reaching 2*10-4Omega / cm and transmittance reaching 90% or above. Product quality of the ITO thin film is improved, work efficiency is greatly increased, production cost is saved, service life is prolonged by two times or above, and energy consumption and environment protection are achieved. The uniform heating device is composed of a continuous vacuum magneto-controlled sputter coating equipment chamber, a vacuum chamber temperature control door, vacuum door heaters, vacuum door isothermal heaters, magneto-controlled sputtering maglev vehicle target device, upper vacuum wall-mounted heaters, middle vacuum wall-mounted heaters, lower vacuum wall-mounted heaters, a rear temperature-control wall of the vacuum chamber and a samarium cobalt magnet device.

Owner:LUOYANG KANGYAO ELECTRONICS

Samarium-cobalt alloy material, samarium-cobalt alloy powder, preparation method thereof, and samarium-cobalt-based magnet

ActiveCN106531383BStrong hydrogen absorption capacityLow electronegativityMagnetic materialsSamarium–cobalt magnetAlloy

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

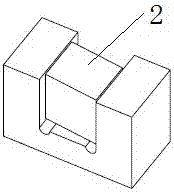

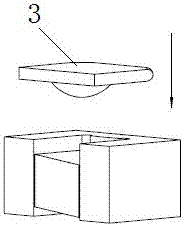

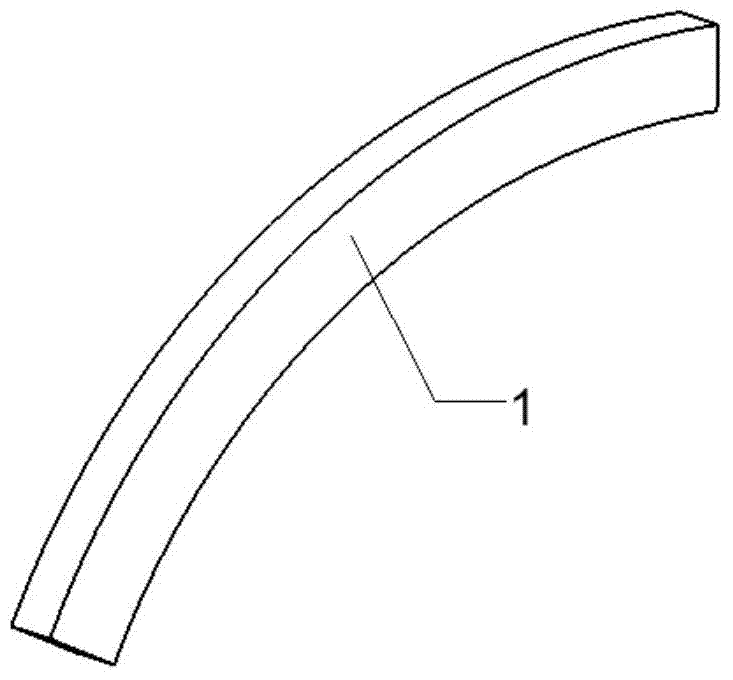

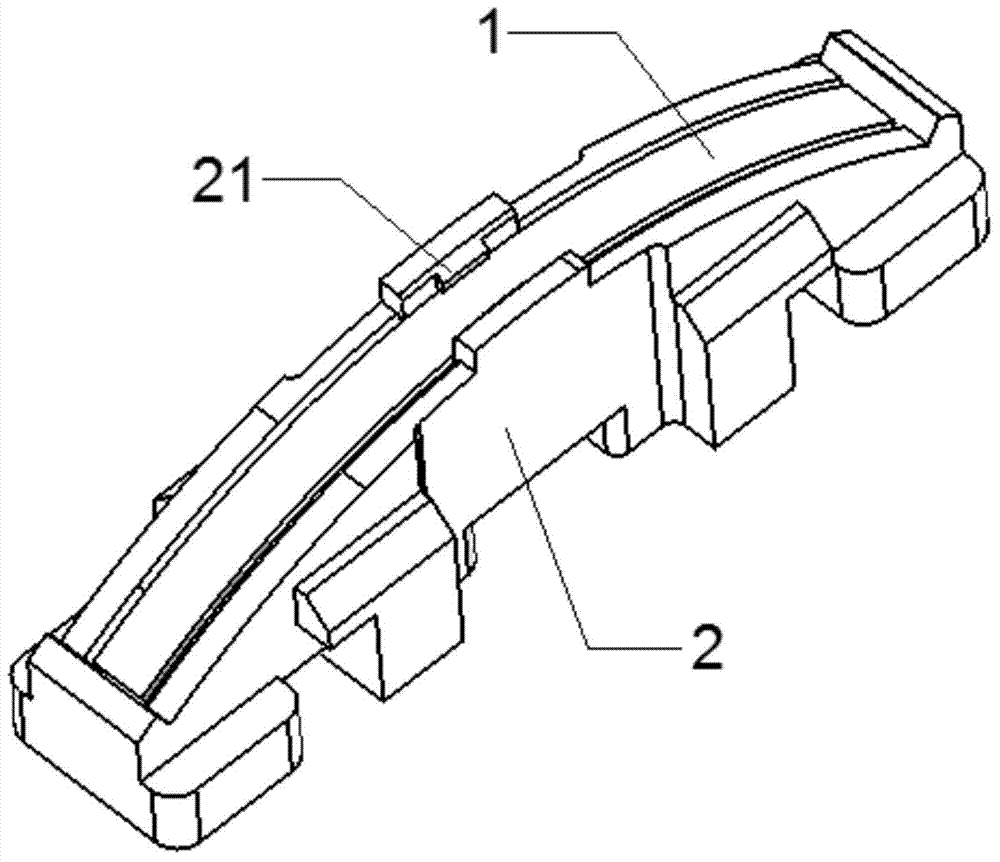

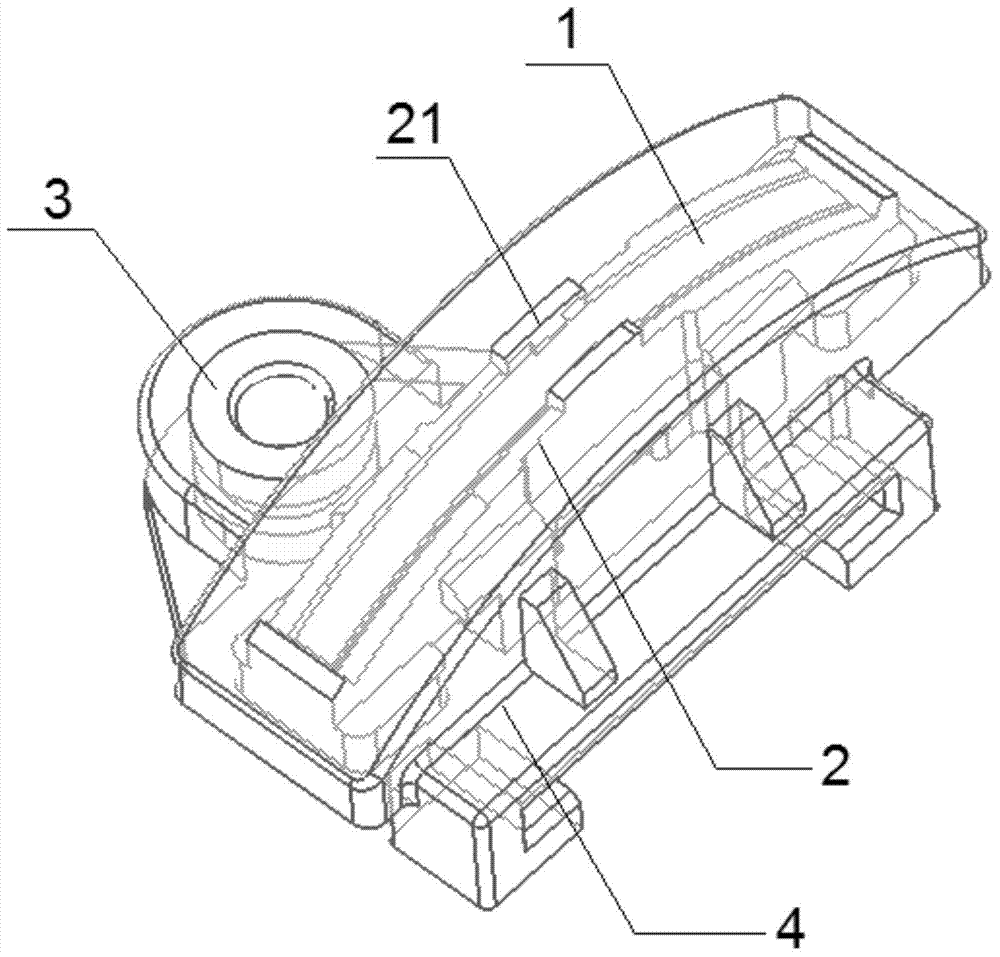

Device for coupling spatial light with optical fiber

PendingCN106959490ASmall space requirementImprove coupling efficiencyCoupling light guidesSamarium–cobalt magnetEngineering

The invention relates to a device for coupling spatial light with an optical fiber. The device comprises a recessed samarium cobalt magnet. The samarium cobalt magnet is provided with a mounting trough. The bottom of the mounting trough is provided with a glue guiding trough. The mounting trough is internally provided with a single-order isolator. A coupling lens is arranged above the single-order isolator. The single-order isolator is a hexahedron. The side surface of the single-order isolator contacts with two inner walls of the mounting trough. The coupling lens comprises a spherical surface and a flat surface. An included angle between the top surface of the single-order isolator flat surface and an included angle between the bottom surface of the single-order isolator and the flat surface are 6-8 DEG. The spherical surface is next to the side of the single-order isolator. The single-order isolator does not contact with the top point of the spherical surface of the coupling lens. The physical aperture of the coupling lens at the spherical surface side is smaller than the optical aperture of the single-order isolator. The lens center of the coupling lens is coaxial with the optical center of the single-order isolator. The device provided by the invention has advantages of small size, effective process simplification and effective random error reduction. An optical isolating function and a coupling function are integrated in the device with total thickness which does not exceed 1.4mm, thereby satisfying requirements of maximal coupling efficiency and smallest size.

Owner:莱特巴斯光学仪器(镇江)有限公司

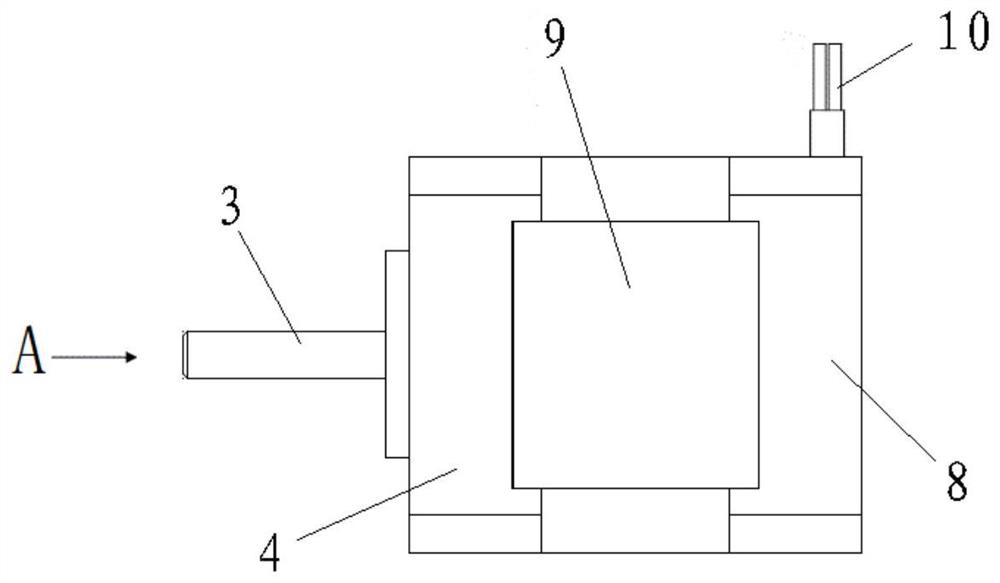

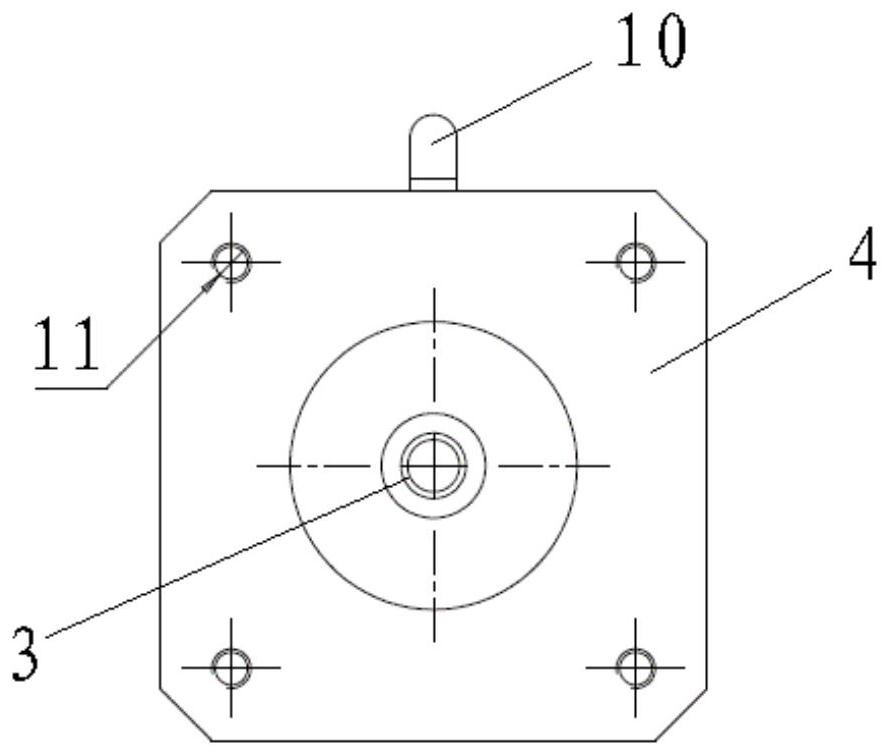

High-temperature-resistant and radiation-resistant stepping motor

ActiveCN112737265AReduce volumeReduce weightWindings insulation materialMagnetic circuit rotating partsNeutron irradiationSamarium–cobalt magnet

The invention belongs to the technical field of motors, and particularly relates to a high-temperature-resistant and radiation-resistant stepping motor, which comprises a non-magnetic rotating shaft (3) provided with two rotors (12) connected in series, a stator (1) positioned at the peripheries of the rotors (12), a winding coil (7) wound on the stator (1), a front-end bearing (5) and a rear-end bearing (6) which are respectively arranged at the front end and the rear end of a non-magnetic rotating shaft (3), and permanent magnet steel (2) located between the two rotors (12), wherein the permanent magnet steel (2) is made of a samarium-cobalt magnet, the chemical component of the permanent magnet steel (2) is SmCo28, and the heat-resistant temperature is 300 DEG C. The high-temperature-resistant and radiation-resistant stepping motor provided by the invention can resist high temperature and neutron / gamma irradiation, has the advantages of small size, light weight, large torque, high control precision and high response speed, and can be used in aerospace and nuclear industries.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Magnetic induction module for automobile neutral-gear switch and manufacture method thereof

InactiveCN104494042AAccurate locationRealize integrationMagnetic/electric field switchesDomestic articlesEpoxySamarium–cobalt magnet

The invention discloses a magnetic induction module for an automobile neutral-gear switch and a manufacture method thereof; samarium cobalt magnet steel (1) is put into a lining part (2) to be precisely located; and then, a magnet steel combination and a copper sleeve (3) are put into another pair of plastic moulds to be injected for the second time, so that an integral body is formed. The structure of the magnetic induction module is formed by utilizing an injection mould; the manufacture efficiency and the size precision of the magnetic induction module for the neutral-gear switch are greatly increased; multiple disadvantages in filling and sealing by using epoxy resin adhesive in the traditional manufacture process are avoided; the manufacture cost of the product is reduced; and the quality and the reliably of the product are increased.

Owner:ATECH AUTOMOTIVE WUHU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com