Preparation method of sintered samarium-cobalt magnet

A samarium cobalt and system technology, applied in the direction of magnetic objects, magnetic materials, electrical components, etc., can solve problems such as cost, uniformity, safety hazard scheduling, etc., and achieve good overall particle size consistency, good fluidity, and overall uniformity control Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

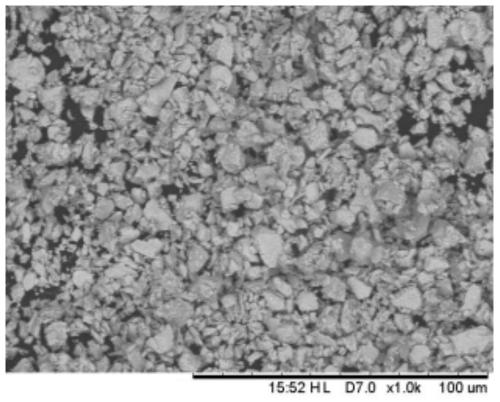

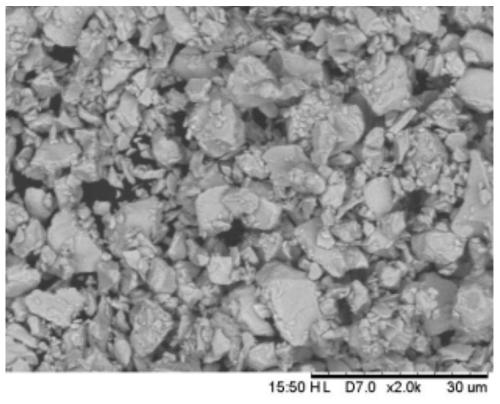

Embodiment 1

[0044] 200 kg of smelted 2:17 samarium-cobalt alloy ingots were crushed into alloy particles with a particle size of less than 2mm by a crusher. Add 0.5wt% organic solvent and mix well. With high purity N 2 Protective atmosphere and carrier gas are carried out, and the samarium-cobalt alloy particles are put into the jet mill equipment, under high-speed N 2 Under the blowing of the airflow, the powder particles collide with each other and break, and then pass through the high-speed rotating classification wheel to remove the coarse particles with a particle size above 10 μm, and then pass through the cyclone separator to remove the fine particles with a particle size below 2 μm, and obtain an average particle size of 2 to 10 μm of powder particles. During the entire jet milling process, the oxygen content is controlled at 100-300ppm. The powder particles were oriented in a magnetic field of 1.5T, and pre-pressed with a pressure of 12 MPa to obtain a samarium-cobalt powder b...

Embodiment 2

[0047] 200 kg of smelted 2:17 samarium-cobalt alloy ingots were crushed into alloy particles with a particle size of less than 2mm by a crusher. Add 0.05wt% organic solvent and mix well. With high purity N 2 Protective atmosphere and carrier gas are carried out, and the samarium-cobalt alloy particles are put into the jet mill equipment, and the 2 Under the blowing of the airflow, the powder particles collide with each other and break, and then pass through the high-speed rotating classification wheel to remove the coarse particles with a particle size above 10 μm, and then pass through the cyclone separator to remove the fine particles with a particle size below 2 μm, and obtain an average particle size of 2 to 10 μm of powder particles. During the entire jet milling process, the oxygen content is controlled at 100-300ppm. The powder particles were oriented in a magnetic field of 1.5T, and pre-pressed with a pressure of 12 MPa to obtain a samarium-cobalt powder block, and ...

Embodiment 3

[0049] 200 kg of smelted 2:17 samarium-cobalt alloy ingots were crushed into alloy particles with a particle size of less than 2mm by a crusher. Add 1wt% organic solvent and mix well. With high purity N 2 Protective atmosphere and carrier gas are carried out, and the samarium-cobalt alloy particles are put into the jet mill equipment, and the 2 Under the blowing of the airflow, the powder particles collide with each other and break, and then pass through the high-speed rotating classification wheel to remove the coarse particles with a particle size above 10 μm, and then pass through the cyclone separator to remove the fine particles with a particle size below 2 μm, and obtain an average particle size of 2 to 10 μm of powder particles. During the entire jet milling process, the oxygen content is controlled at 100-300ppm. The powder particles were oriented in a magnetic field of 1.5T, and pre-pressed with a pressure of 12 MPa to obtain a samarium-cobalt powder block, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com