Samarium-cobalt alloy material, samarium-cobalt alloy powder, preparation method thereof, and samarium-cobalt-based magnet

A technology of alloy powder and alloy materials, which is applied in the field of samarium-cobalt-based magnets, can solve the problems of sensitive production conditions of samarium-cobalt magnets, the inability to stably prepare samarium-cobalt magnets, and the decline in yield, so as to achieve the optimization of hydrogen absorption industry and the improvement of hydrogen absorption performance , The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of samarium-cobalt alloy powder, which comprises the following steps:

[0034] S1, according to the above Sm(Co 1-a-b-c-d Fe a Cu b Zr c tm d ) z Prepare the samarium-cobalt alloy ingot with the ratio of each element in it;

[0035] S2, the samarium-cobalt alloy ingot is absorbed by hydrogen at a hydrogen pressure of 0.2MPa-0.5MPa and normal temperature for 0.5-5 hours, and then dehydrogenated by heat preservation to obtain samarium-cobalt alloy powder.

[0036] In step S2, the crushing mechanism of the hydrogen crushing process includes intergranular fracture and transgranular fracture. Compared with the mechanical crushing process, the hydrogen crushing process is more conducive to improving the degree of orientation of the material, thereby improving the remanence of the magnet. The hydrogen pressure range of the hydrogen absorption is 0.2MPa-0.3Mpa, and the hydrogen absorption time is 0.5 hour-1 hour. ...

Embodiment 1

[0050] According to the stoichiometric formula Sm(Co 0.655 Fe 0.2 Cu 0.08 Zr 0.025 mn 0.04 ) 7.2 The ratio of each element in the formula is to weigh the raw materials, put the raw materials in the induction melting furnace, and evacuate to 2×10 -2 Below Pa, then fill it with 0.06MPa high-purity argon gas, heat it with electricity, and pour it into a water-cooled splint copper mold after the raw material is completely melted into a liquid to obtain a samarium-cobalt alloy ingot.

[0051] Put the samarium-cobalt alloy ingot obtained above into a hydrogen furnace, pump the vacuum in the furnace to below 5Pa through a mechanical pump, and then fill it with hydrogen until the pressure is -0.08MPa, and then use a mechanical pump to reduce the vacuum in the furnace to below 5Pa. This is pumped down to below 5Pa, repeated scrubbing twice, then filled with hydrogen to a pressure of 300KPa, and then kept at room temperature for 1.5h for hydrogen absorption and crushing. Vacuumize...

Embodiment 2

[0055] The preparation method of the samarium-cobalt alloy powder of embodiment 2 is basically the same as that of embodiment 1, and the difference is that the raw material stoichiometric formula of the samarium-cobalt alloy powder is Sm(Co 0.655 Fe 0.2 Cu 0.08 Zr 0.025 Cr 0.04 ) 7.2 .

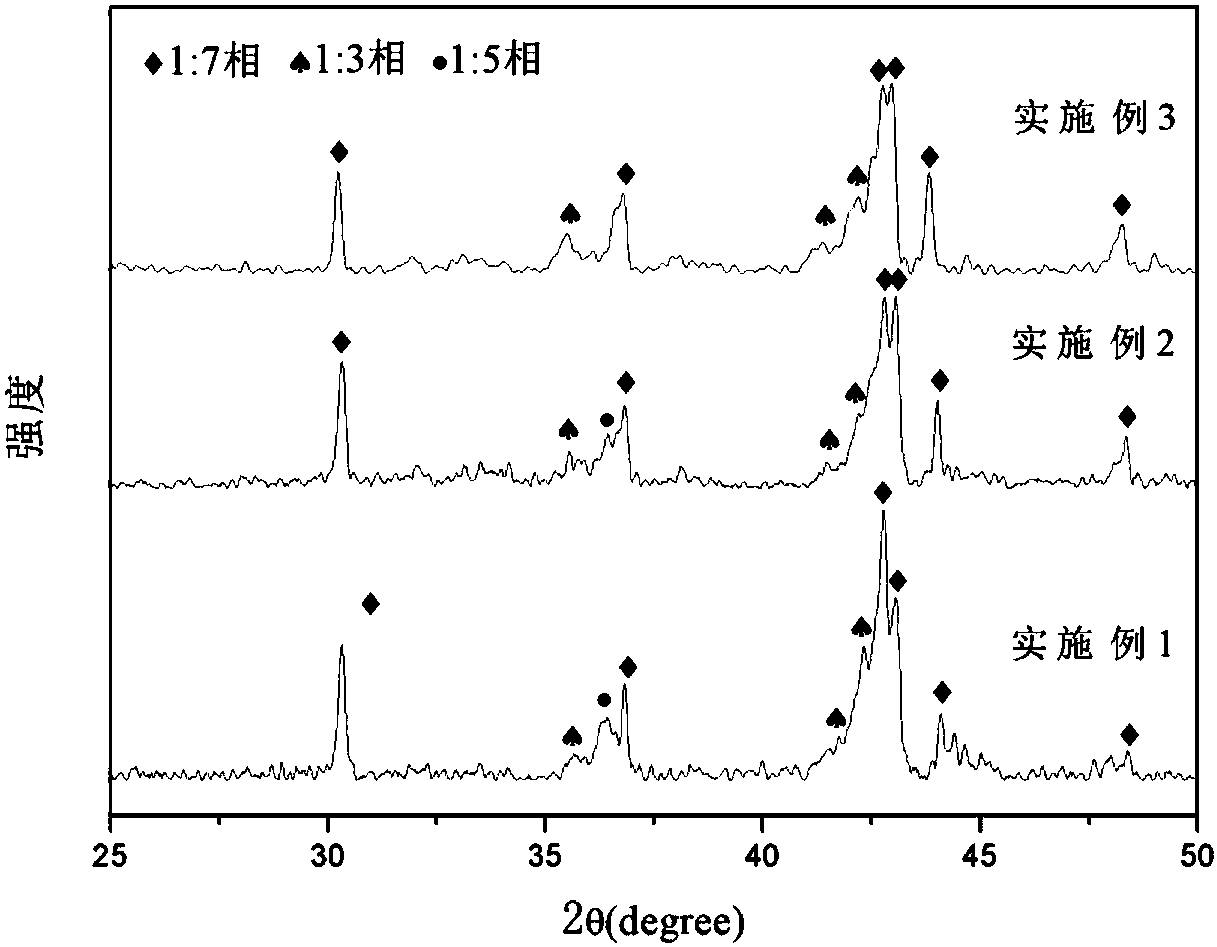

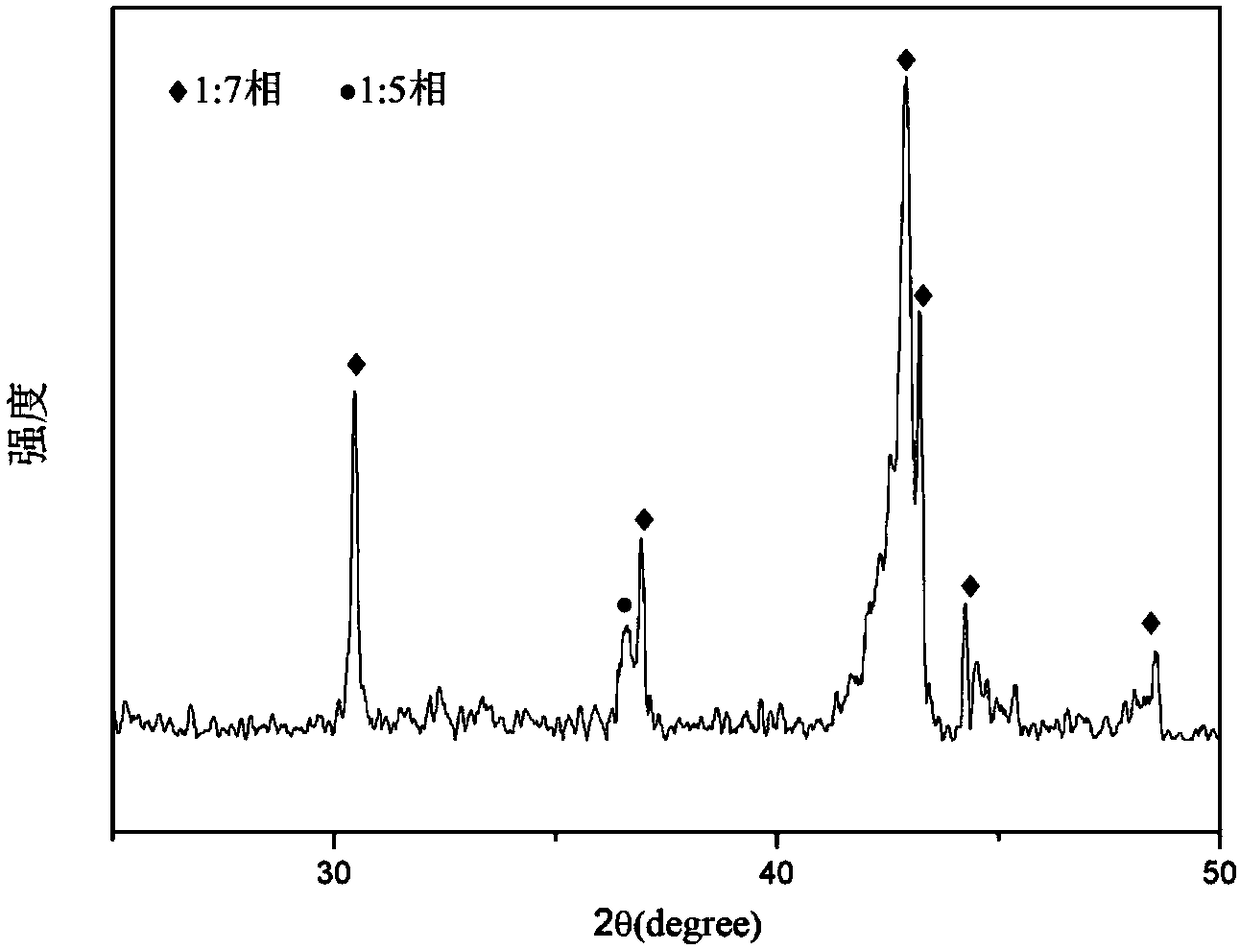

[0056] Carry out X-ray diffraction test to the obtained samarium-cobalt alloy powder, the result is shown in figure 1 . Depend on figure 1 It can be seen that the samarium cobalt alloy powder is made of SmCo 7 Phase, SmCo 5 Phase and SmCo 3 phase composition.

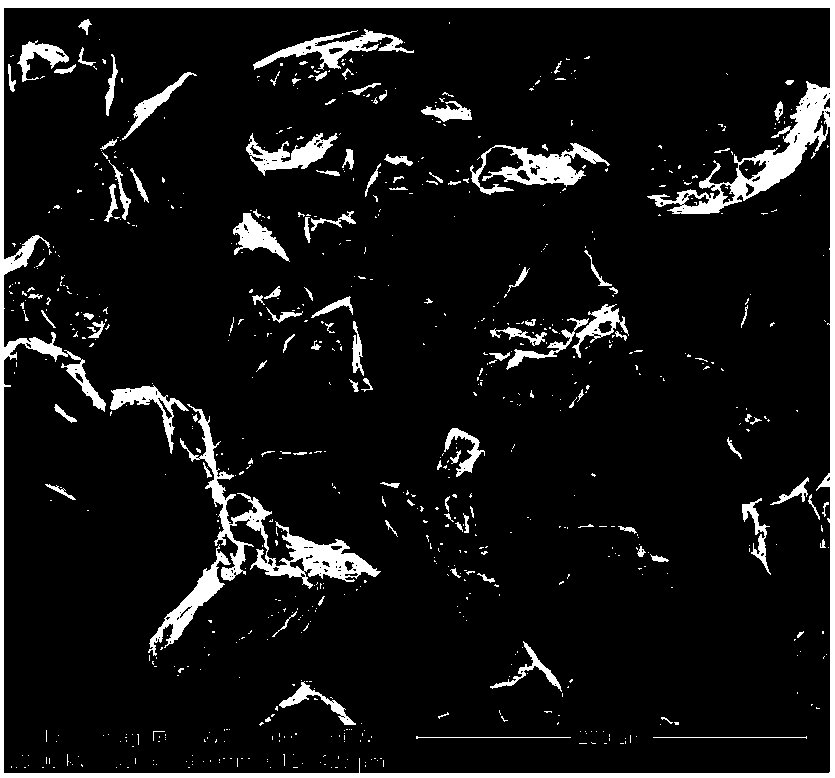

[0057] The obtained samarium-cobalt alloy powder is subjected to a morphology test, and the results are shown in Figure 4 . Depend on Figure 4 It can be seen that the samarium-cobalt alloy is successfully broken into particles of 10 μm to 150 μm, and the hydrogen-absorbing broken methods include intergranular fracture and transgranular fracture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com