A lithium-containing graphene oxide three-dimensional framework hydrogen storage material and its preparation method

A technology of three-dimensional skeleton and hydrogen storage materials, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as inability to store hydrogen well, achieve the effects of enhancing chemical stability, preventing oxidation, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The method for preparing lithium-containing graphene oxide three-dimensional framework hydrogen storage material in this embodiment includes the following steps:

[0051] 1). Preparation of graphene oxide sheets and connection monomers;

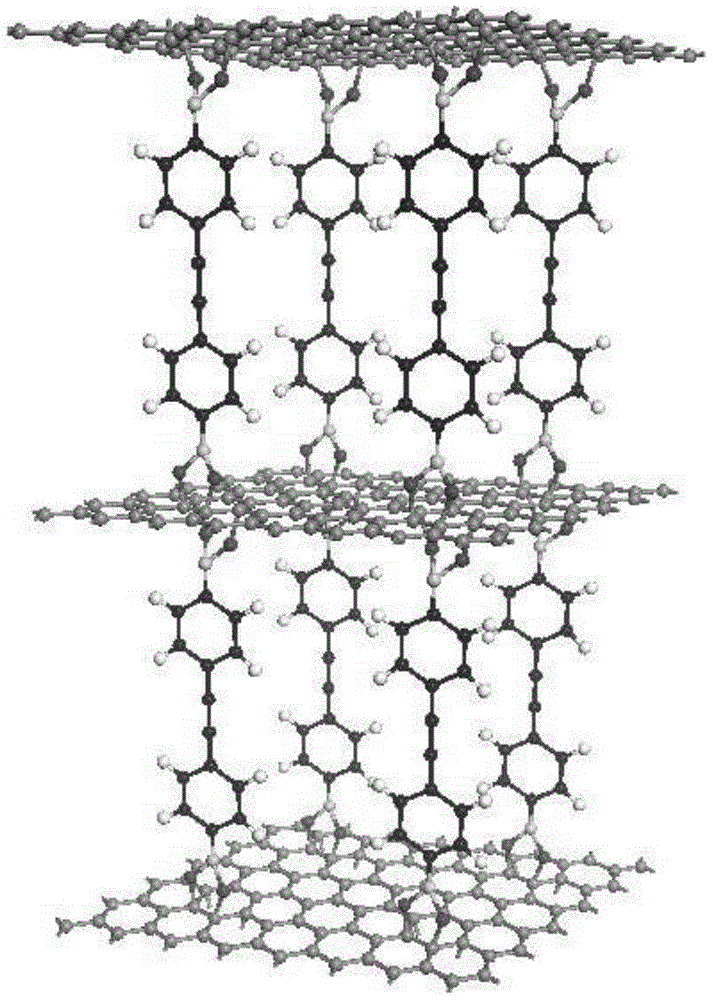

[0052] 2) Using the graphene sheets obtained in step 1) and connecting monomers to prepare a three-dimensional graphene oxide skeleton;

[0053] 3) Using lithium naphthalene and the three-dimensional graphene oxide obtained in step 2) to react to prepare a graphene oxide framework material intermediate;

[0054] 4) Use carbon dioxide to react with the graphene oxide framework material intermediate obtained in step 3) to prepare lithium-containing graphene oxide three-dimensional framework hydrogen storage materials; the reaction process of (step 3) and 4) is as follows Figure 4 Shown)

[0055] among them:

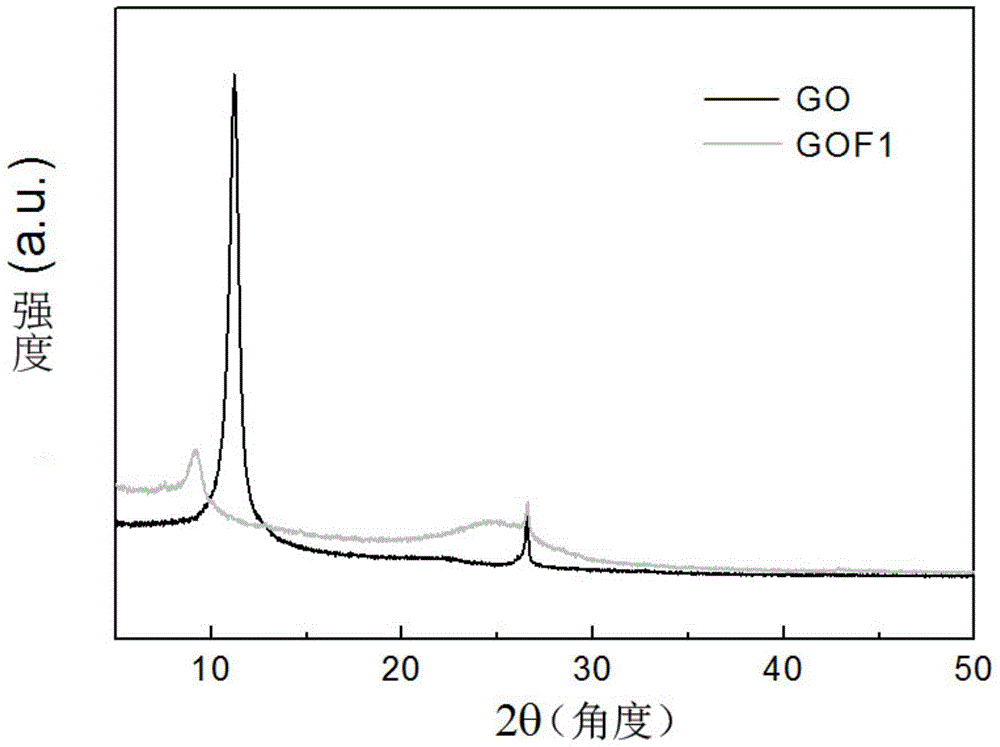

[0056] Step 1) Using the Hummers method to prepare graphene oxide sheets, the thickness of the obtained graphene oxide sheets is 0.5-1.5nm, ...

Embodiment 2

[0066] The difference between this embodiment and embodiment 1 is that the linking agent of this embodiment is 4,4'-diphenylbutadiyne (diboric acid);

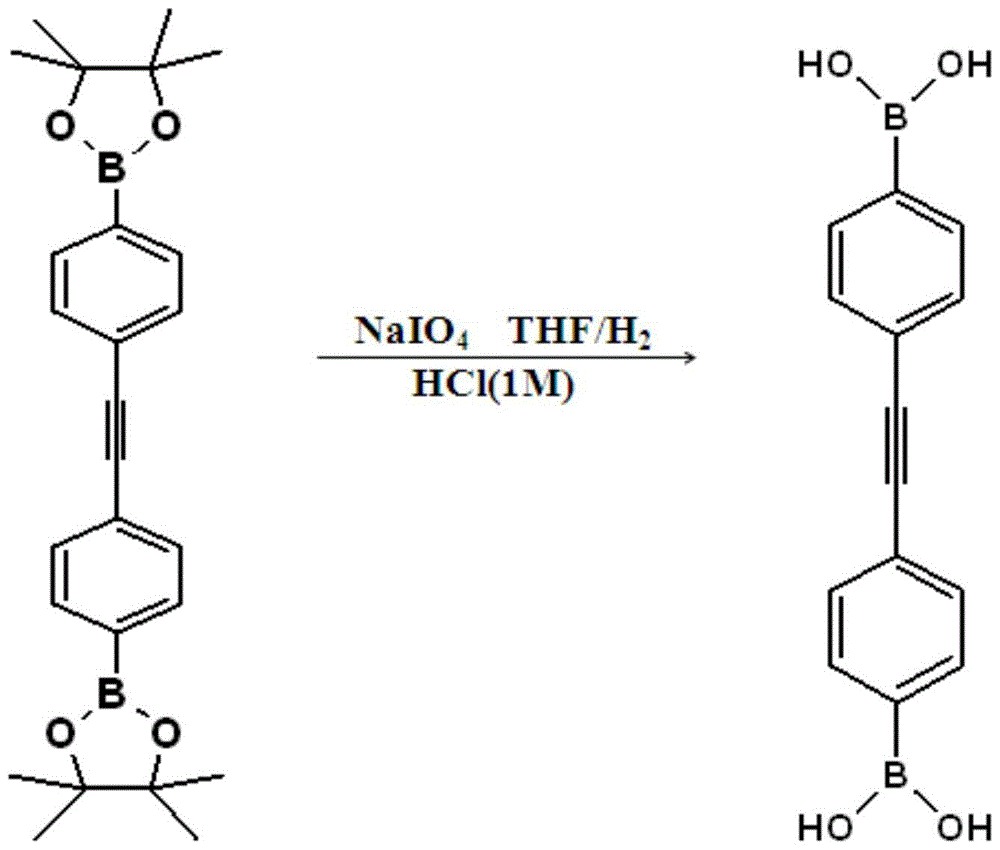

[0067] Step 1) Use 4-ethynylphenylboronic acid pinacol ester as raw material to prepare linking agent through coupling reaction and hydrolysis reaction (the process is as Figure 5 Shown), specifically including the following steps:

[0068] a) Take tetramethylethylenediamine (TMEDA), cuprous iodide and nickel chloride to dissolve nickel chloride and dissolve it in acetone (the ratio of each component is 4:1:1);

[0069] b) Add 4-ethynylphenylboronic acid pinacol ester to the solution obtained in a), and the mixture is stirred for 8-15 hours and then recrystallized in acetonitrile;

[0070] c), the crystalline product of step b) and NaIO 4 Dissolve in a mixed solvent of tetrahydrofuran (THF) and water, stir at 15-35°C for 1-3 hours;

[0071] d). Add 0.8-1.2mol / L hydrochloric acid to the solution obtained in step c), and stir and react f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com