Uniform heating device and method of magneto-controlled sputtering maglev vehicle target of ITO (indium tin oxide) film

A magnetron sputtering and uniform heating technology, which is applied in the direction of sputtering plating, ion implantation plating, metal material coating process, etc., can solve the problem of inaccurate and effective adjustment and control of temperature resistance uniformity, affecting displays, and instruments Service life, reduce the quality of ITO film products and other issues, to achieve the effect of simple method, saving production cost and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

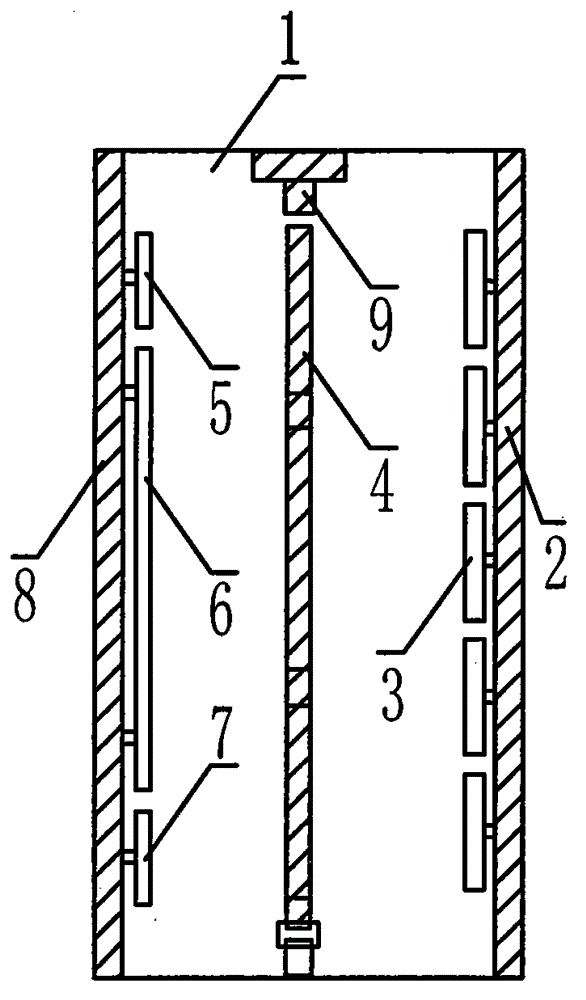

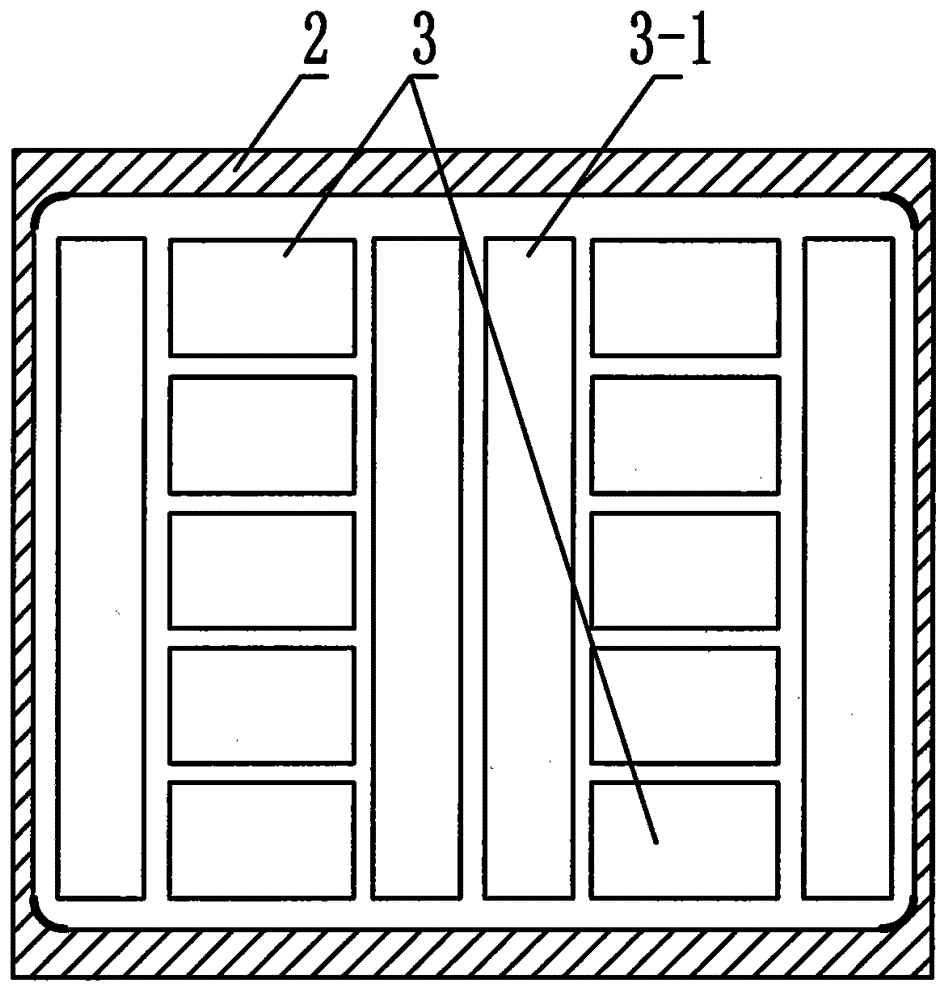

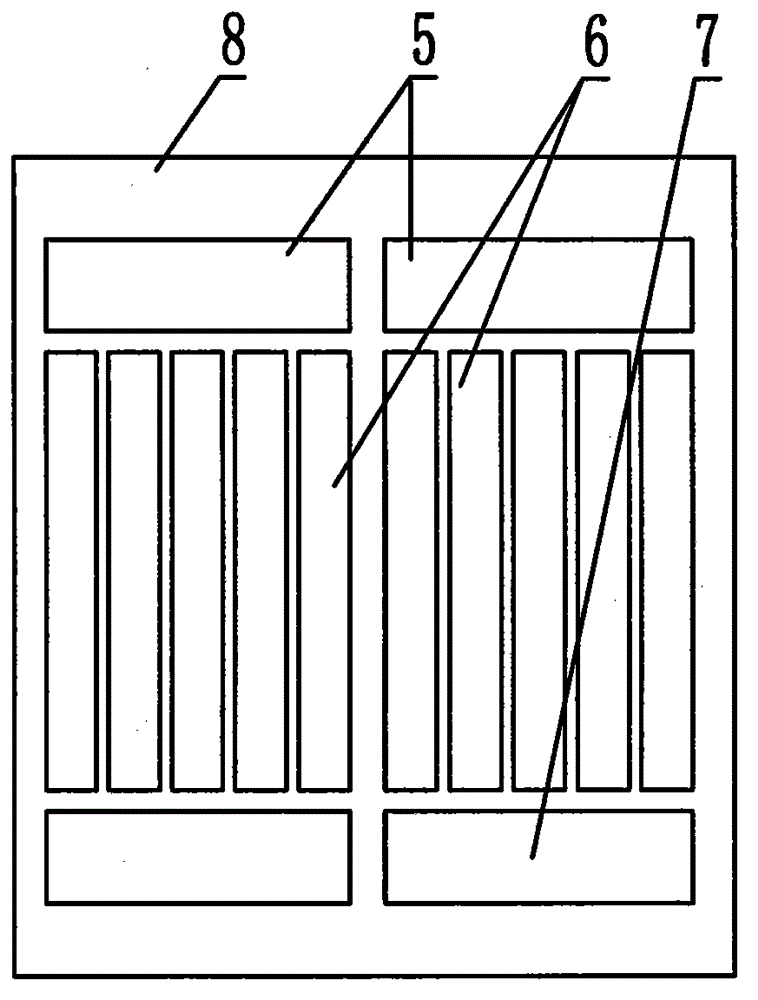

[0035] As shown in the figure, a uniform heating device for ITO film magnetron sputtering magnetic levitation vehicle target is composed of: continuous vacuum magnetron sputtering coating equipment room 1, vacuum room temperature control door 2, vacuum door heater 3, vacuum door Uniform temperature heater 3-1, magnetron sputtering magnetic levitation car target device 4, vacuum wall upper heater 5, vacuum wall middle heater 6, vacuum wall lower heater 7, vacuum room control rear wall 8 , a samarium-cobalt magnet device 9 is formed; it is characterized in that: one side of the continuous vacuum magnetron sputtering coating equipment room 1 is provided with a vacuum room temperature control door 2, and the other side is provided with a vacuum room temperature control rear wall 8; the vacuum room temperature A magnetron sputtering magnetic levitation car target device 4 is correspondingly arranged between the back wall body 8 and the vacuum room temperature control door 2, and a s...

Embodiment 2

[0042] As shown in the figure, a method for uniformly heating the ITO film magnetron sputtering magnetic levitation car target, the specific process method is as follows: start and run the ITO film continuous vacuum magnetron sputtering coating equipment, and continuously vacuum magnetron sputtering coating Vacuumize the equipment room 1 so that the background vacuum is 5×10 -4 Pa-6.8×10 -4 Pa, the sputtering gas Argon Ar and Oxygen O as a supplementary component 2 ; Under vacuum conditions, at least one rectangular target is loaded on the magnetron sputtering magnetic levitation vehicle target device 4, which is made of 3-10%SnO 2 and 90%-97%In 2 o 3 The formed powder is sintered by heat and static pressure to control the vacuum door heater 3, the vacuum door uniform temperature heater 3-1 and the vacuum wall upper heater 5, the vacuum wall intermediate heater 6, and the vacuum wall heater. The lower heater 7 evenly heats the target on the magnetron sputtering magnetic le...

Embodiment 3

[0046] As shown in the figure, a method for uniformly heating the ITO film magnetron sputtering magnetic levitation car target, the specific process method is as follows: start and run the ITO film continuous vacuum magnetron sputtering coating equipment, and continuously vacuum magnetron sputtering coating Vacuumize the equipment room 1 so that the background vacuum is 5×10 -4 Pa, the sputtering gas Argon Ar and Oxygen O as a supplementary component 2 ; Under vacuum conditions, at least one rectangular target is loaded on the magnetron sputtering magnetic levitation vehicle target device 4, which is made of 10% SnO 2 and 90%In 2 o 3 The formed powder is sintered by heat and static pressure to control the vacuum door heater 3, the vacuum door uniform temperature heater 3-1 and the vacuum wall upper heater 5, the vacuum wall intermediate heater 6, and the vacuum wall heater. The lower heater 7 evenly heats the target on the magnetron sputtering magnetic levitation vehicle ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com