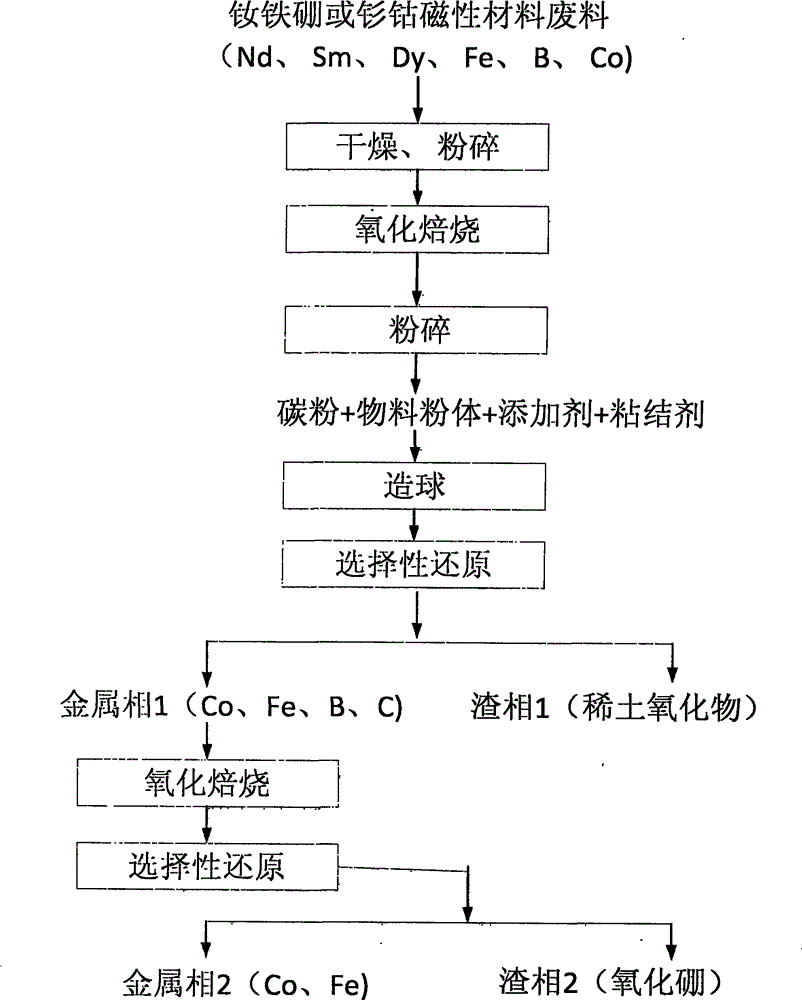

Method for recovering rare earth and other metals from neodymium iron boron and samarium cobalt magnetic material waste

A technology for recycling NdFeB and magnetic materials, applied in the direction of improving process efficiency, etc., can solve problems such as cobalt, high concentration of ammonia nitrogen, and limited NdFeB waste, and achieve the effect of recycling waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Put 300g of muddy NdFeB waste (mainly containing Nd, Dy, Fe, Co, B) into an alumina crucible, put the crucible into a box-type atmosphere furnace, and feed 500mL / min of oxygen into the furnace , the furnace temperature was raised from room temperature to 900°C, and kept at this temperature for 4 hours, then the sample was cooled to near room temperature, and the sample was taken out. Grind the roasted solid into a powder with a particle size of less than 0.1 mm, add 78 g of activated carbon powder with a particle size of less than 0.1 mm and 12 g of boron oxide powder with a particle size of less than 0.1 mm, and then add 40 ml of yeast slime aqueous solution to make the above mixed powder into many pellets with a particle size of 20 mm. After the pellets were dried at 80°C for 2 hours, they were put into a high-purity graphite crucible, and then the crucible was put into a box-type atmosphere furnace. During the whole experiment, argon gas was used as a protective atmos...

Embodiment 2

[0034] Put 300g of slimy samarium-cobalt waste (mainly containing Sm, Co, Fe) into an alumina crucible, put the crucible into a box-type atmosphere furnace, feed 500mL / min of oxygen into the furnace, and raise the furnace temperature from The room temperature was raised to 900°C and kept at this temperature for 4 hours, then the sample was cooled to near room temperature, and the sample was taken out. Grind the roasted solid into a powder with a particle size of less than 0.1 mm, add 80 g of metallurgical coke carbon powder with a particle size of less than 0.1 mm, and then add 38 ml of yeast slurry aqueous solution to make the mixed powder into many pellets with a particle size of 20 mm. After the pellets were dried at 80°C for 2 hours, they were put into a high-purity graphite crucible, and then the crucible was put into a box-type atmosphere furnace. During the whole experiment, argon gas was used as a protective atmosphere, and the furnace temperature was raised from room t...

Embodiment 3

[0036] Put 300g of muddy NdFeB waste (mainly containing Nd, Dy, Fe, Co, B) into an alumina crucible, put the crucible into a box-type atmosphere furnace, and feed 500mL / min of oxygen into the furnace , the furnace temperature was raised from room temperature to 900°C, and kept at this temperature for 4 hours, then the sample was cooled to near room temperature, and the sample was taken out. After roasting, the solid is crushed into a powder with a particle size of less than 0.1 mm, 100 g of metallurgical coke with a particle size of less than 0.1 mm is added, and then 42 ml of yeast slime aqueous solution is added to make the above mixed powder into many pellets with a particle size of 20 mm. After the pellets were dried at 80°C for 2 hours, they were put into a high-purity graphite crucible, and then the crucible was put into a box-type atmosphere furnace. During the whole experiment, argon gas was used as a protective atmosphere, and the furnace temperature was raised from ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com