Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Reduced oxygen uptake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

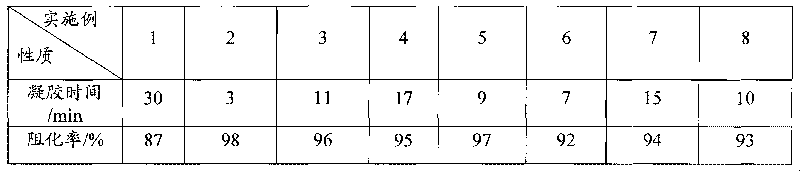

Composite gel inhibitor for preventing and controlling spontaneous combustion of coal in coal mine and preparation method thereof

InactiveCN101713296AReduced oxygen uptakeEasy to isolate and contactOther chemical processesDust removalSpontaneous combustionWater soluble

The invention relates to a composite gel inhibitor for preventing and controlling spontaneous combustion of coal in a coal mine and a preparation method thereof. The composite gel inhibitor provided by the invention comprises the following components in percentage by weight: 10 to 65.0 percent of graft copolymer, 0 to 4.00 percent of flame retardant, 20 to 60.0 percent of water glass, and the balance of water. The graft copolymer containing a -COOH functional group is obtained by adopting a water soluble polymer and unsaturated carboxylic acid monomers to perform graft copolymerization, and the composite gel inhibitor for preventing and controlling the spontaneous combustion of the coal in the coal mine is obtained by adding the flame retardant and the water glass into the graft copolymer. The flame retardant provided by the invention has the advantages of excellent retarding effect, environmental friendliness and the like.

Owner:府谷能源投资集团五一矿业有限公司

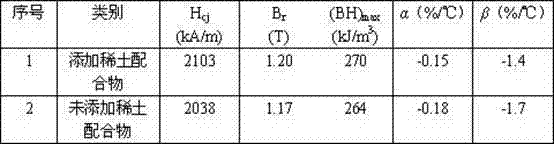

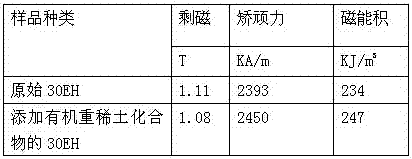

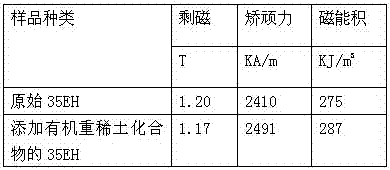

Preparation method of rare earth complex crystal boundary modification sintered neodymium-iron-boron magnetic body

ActiveCN102184776AAvoid contactReduced oxygen uptakeInductances/transformers/magnets manufactureTemperature coefficientDecomposition

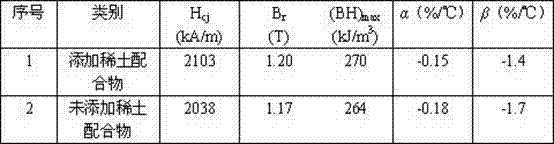

The invention discloses a preparation method of a rare earth complex crystal boundary modification sintered neodymium-iron-boron magnetic body. The preparation method comprises the following steps of: preparing neodymium-iron-boron alloy particles, smashing the neodymium-iron-boron alloy particles into powder and injecting an antioxidant; ejecting mixed liquid of a rare earth complex and petroleum into neodymium-iron-boron powder in a spraying manner and mixing uniformly; and pressing the mixture into a blank magnetic body in magnetic aligning and sintering. In the preparation method, the mixture of the rare earth complex and the petroleum is added in the spraying manner, so that contact of the particles with oxygen can be effectively prevented, the oxygen absorption in the magnetic body preparing process is lowered, and the magnetic performance of the sintered magnetic body is enhanced. The rare earth complex is added and a rare earth product left by the decomposition of the sintered rare earth complex is mainly positioned at a crystal boundary, so that the prepared sintered neodymium-iron-boron magnetic body has a higher coercive force value and a lower temperature coefficient compared with the conventional sintered neodymium-iron-boron magnetic body. Moreover, the preparation method has a simple process, is easy to operate, and is suitable for batch production.

Owner:浙江凯文磁业有限公司

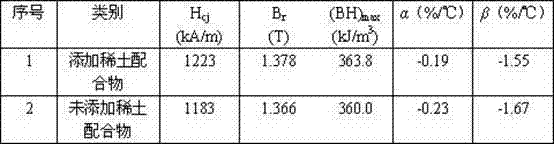

Preparation method of light rare earth complex modified sintered samarium-cobalt magnet

ActiveCN106024234AReduced oxygen uptakeImprove magnetismInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementAntioxidant

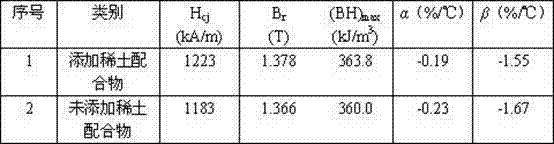

The invention discloses a preparation method of a light rare earth complex modified sintered samarium-cobalt magnet. The method includes the following steps of melting an Sm-Co-Fe-Cu-Zr master alloy cast ingot, smashing the cast ingot into powder through rough breaking and jet milling, injecting an antioxidant, adding mixed liquid of light rare earth complex and methyl acetate to a samarium-cobalt powder material, conducting high-energy ball-milling, crushing and even mixing, pressing the mixed material into a blank magnet according to magnetic alignment, putting the blank magnet into a vacuum sintering furnace to be subjected to sintering and solution treatment, then conducting ageing treatment, and conducting natural cooling to the room temperature to obtain the samarium-cobalt magnet. By adding light rare earth complex to the mixed material and combining the high-energy ball-milling technology, sintered light rare earth elements are mainly distributed on cell walls, cellular structures are greatly refined, and therefore the coercivity and magnetic energy product of the sintered samarium-cobalt magnet are improved. The method is simple in process, easy to operate and suitable for mass production.

Owner:东阳富仕特磁业有限公司

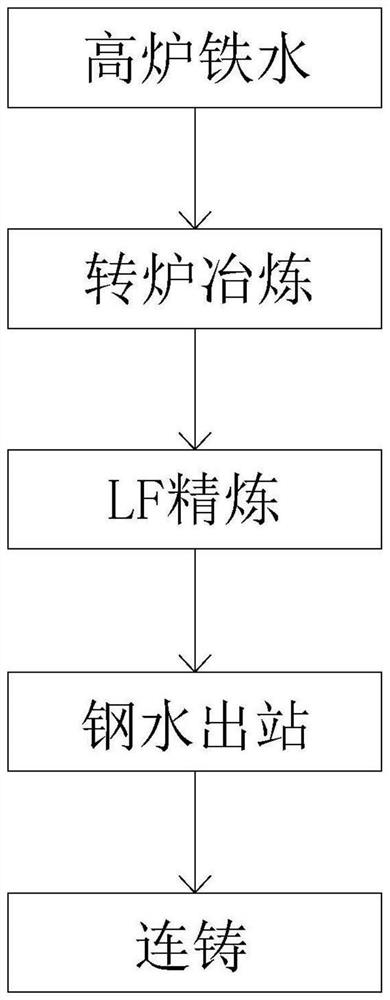

Smelting method of welding rod steel H08Mn

InactiveCN112280923APrevent thinningReduce exposed areaManufacturing convertersProcess efficiency improvementRefining (metallurgy)Oxide

The invention provides a smelting method of welding rod steel H08Mn, and particularly relates to the field of ferrous metallurgy. The smelting method includes the steps of converter smelting: blast furnace molten iron is smelted in a converter to control the endpoint carbon content at 0.03-0.04%, slag-stopping tapping is carried out, pre-deoxidation is carried out by using an aluminum-manganese-iron alloy in the tapping process, and a medium-carbon manganese-iron alloy and active lime are added after tapping; and LF refining: oxygen determination and temperature measurement are performed before each time of temperature rise, an aluminum wire is fed according to a fixed oxygen value, a refining slag modifier is added, the refining temperature rise time is predicted according to a temperature measurement value, the adding amount of the refining slag modifier is increased along with the prolonging of the temperature rise time, and the slag modifier is decomposed to form CO2, the CO2 continuously escapes to form foam slag, so that air is effectively isolated, and molten steel oxygen uptake is weakened; and the oxygen content of molten steel can be controlled to be 0.0030%-0.0060%, theAls content can be controlled to be 0.0035%-0.0065%, then the molten steel is fed into a silicon-calcium line to be subjected to calcium treatment, soft blowing is conducted for 8 min-10 min, and thenthe molten steel is poured on a table. The smelting method of the welding rod steel H08Mn has the characteristics of weakening the oxygen uptake degree of the molten steel, overcoming the bubble defect of a casting blank, reducing the aluminum oxide inclusion formation amount of the molten steel, improving the castability of the molten steel, and ensuring the stable oxygen content of the molten steel.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

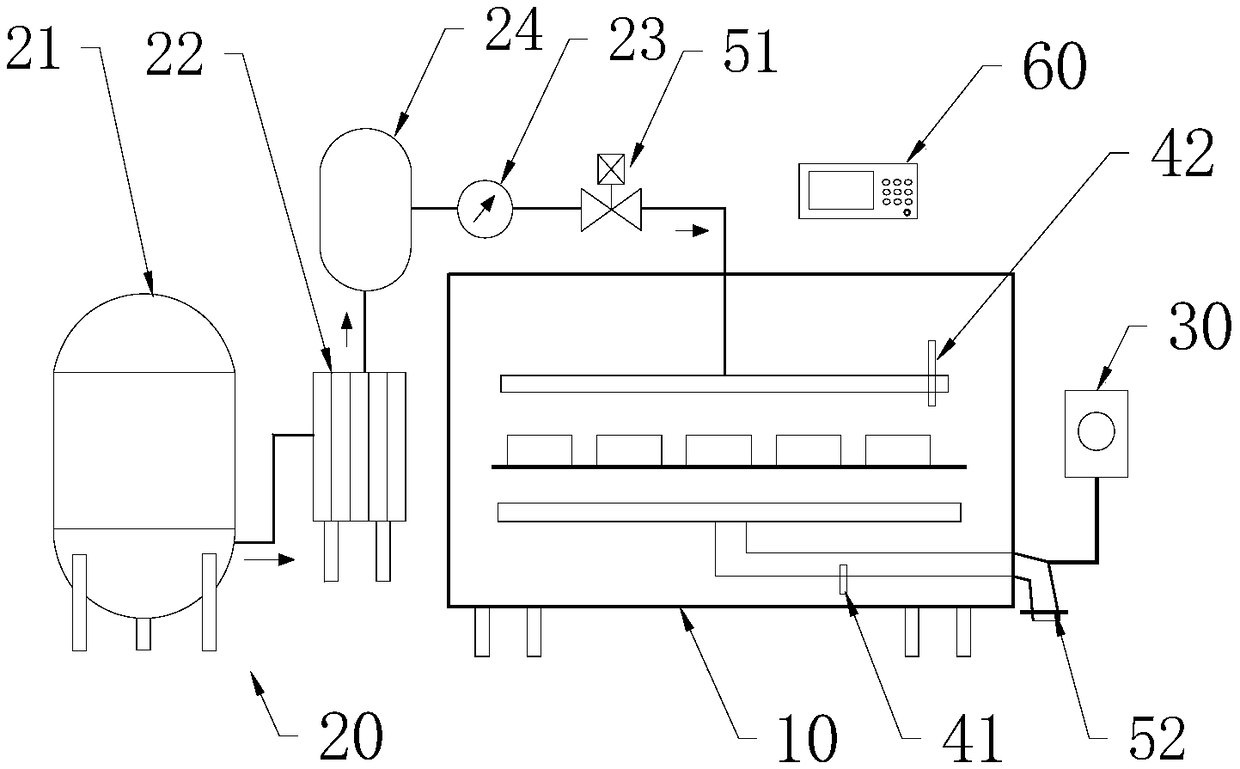

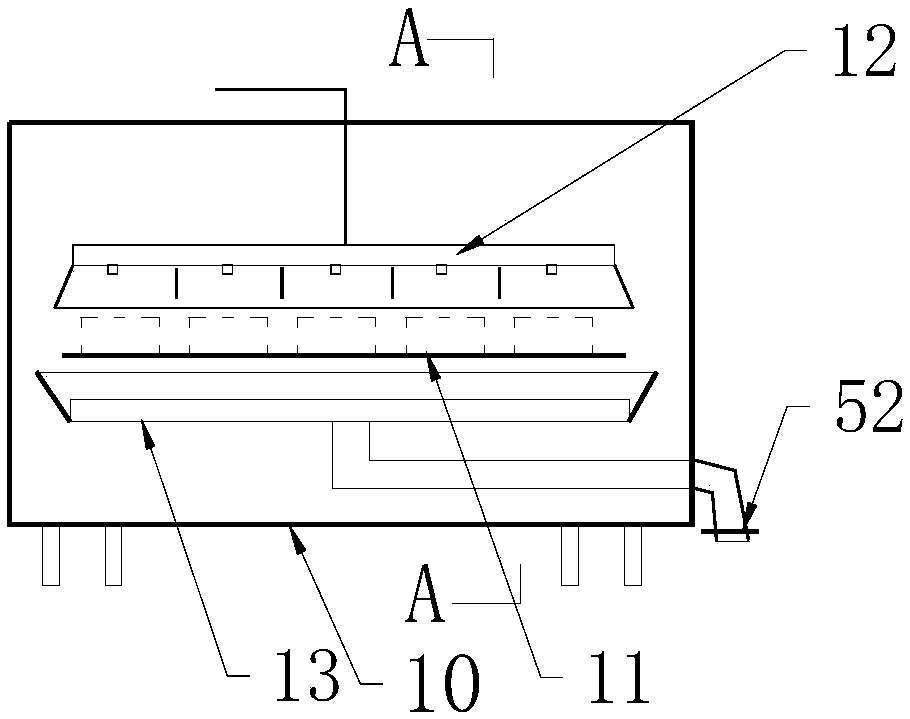

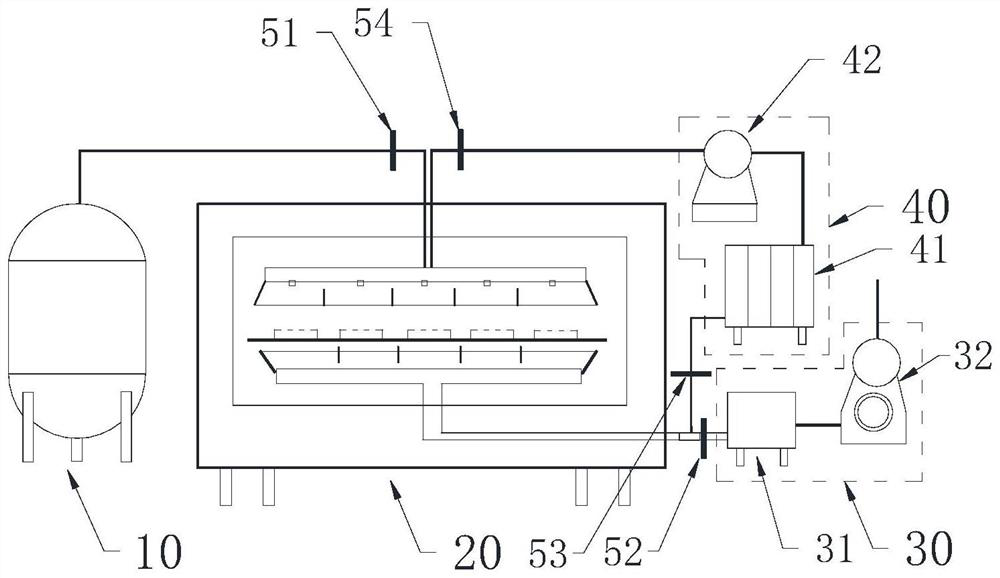

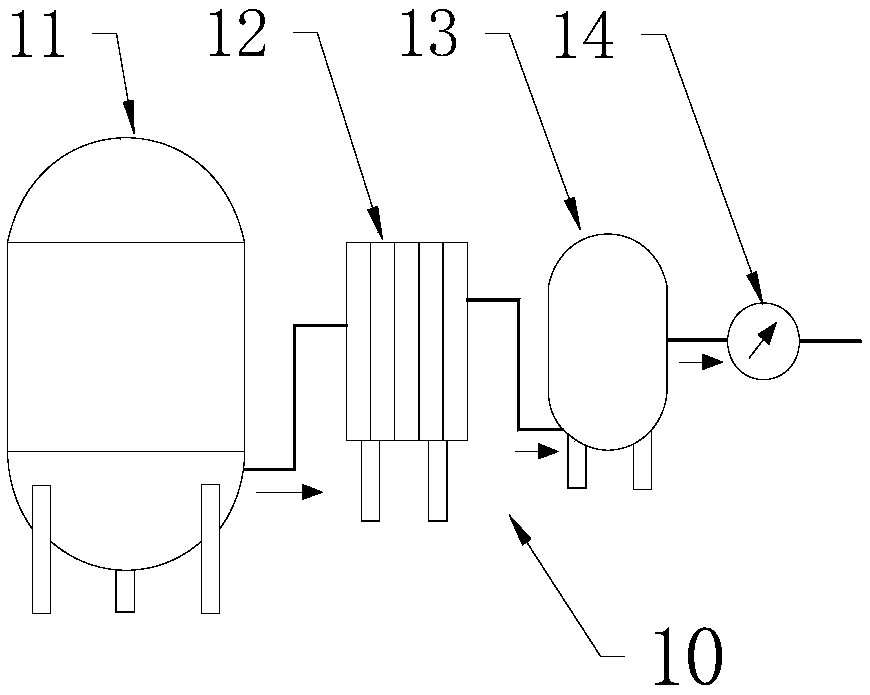

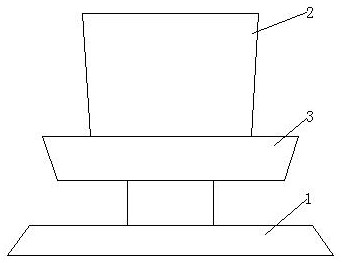

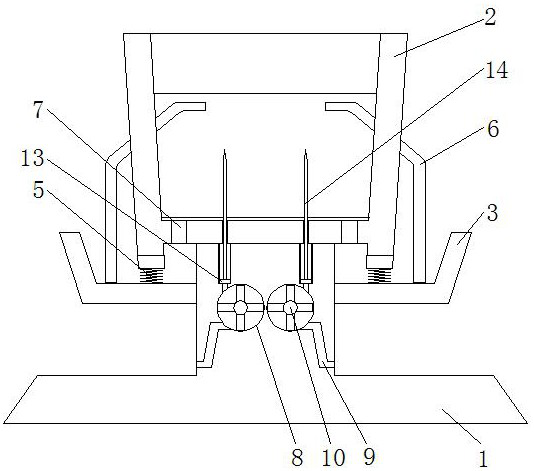

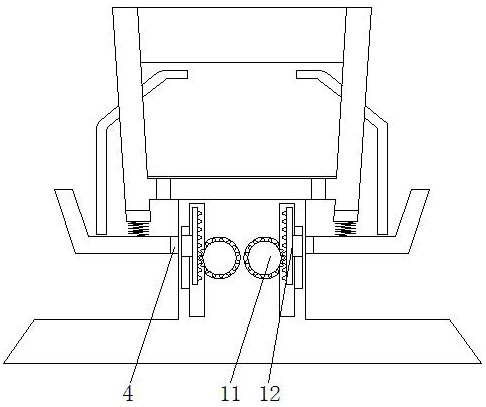

Intelligent baking device and baking method beneficial to prolonging food shelf-life

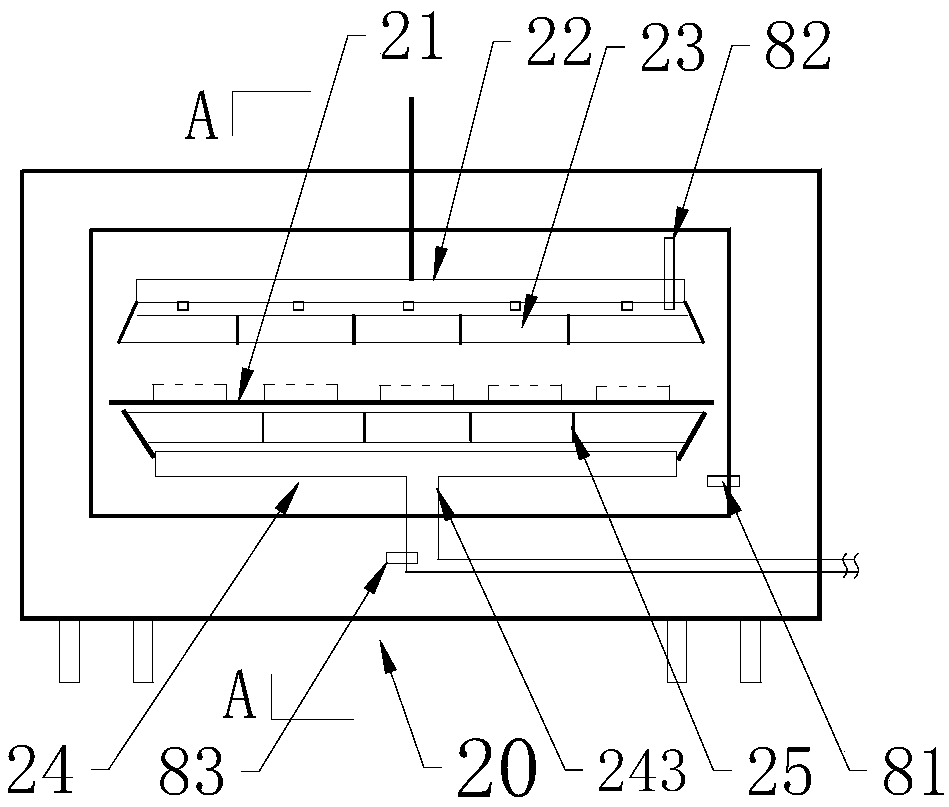

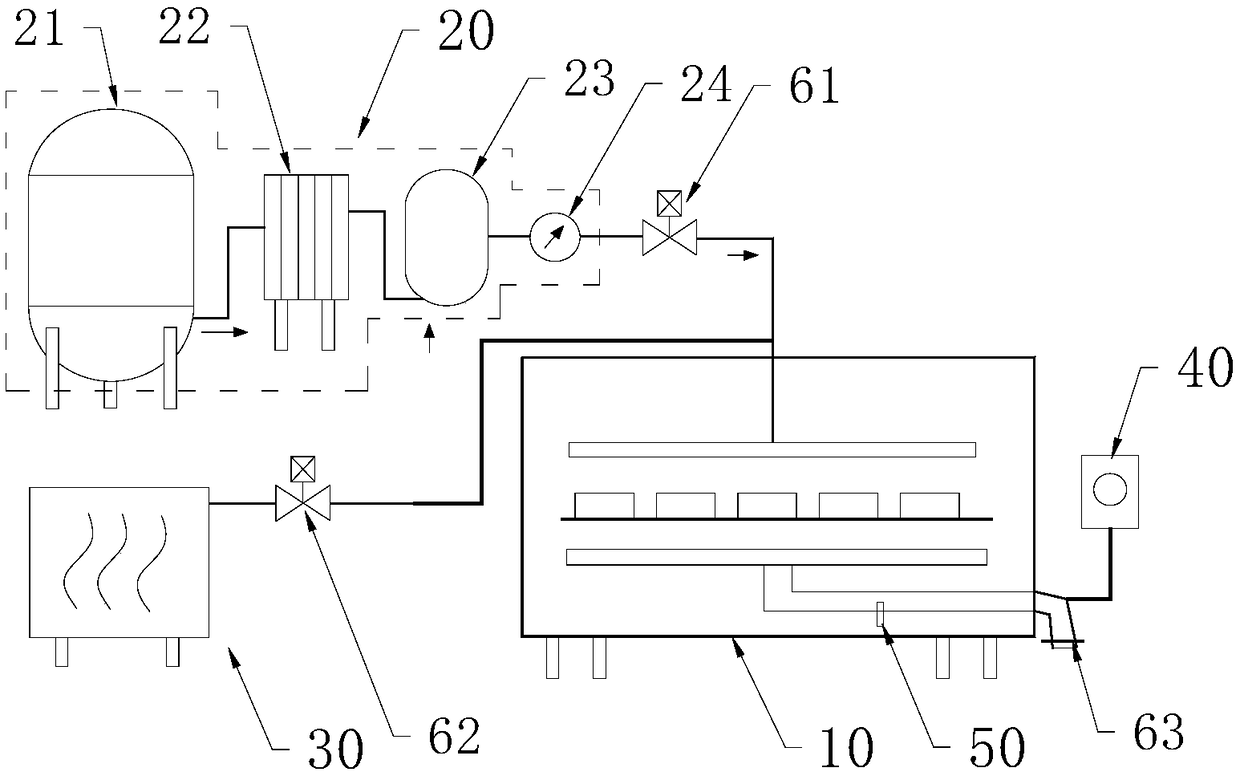

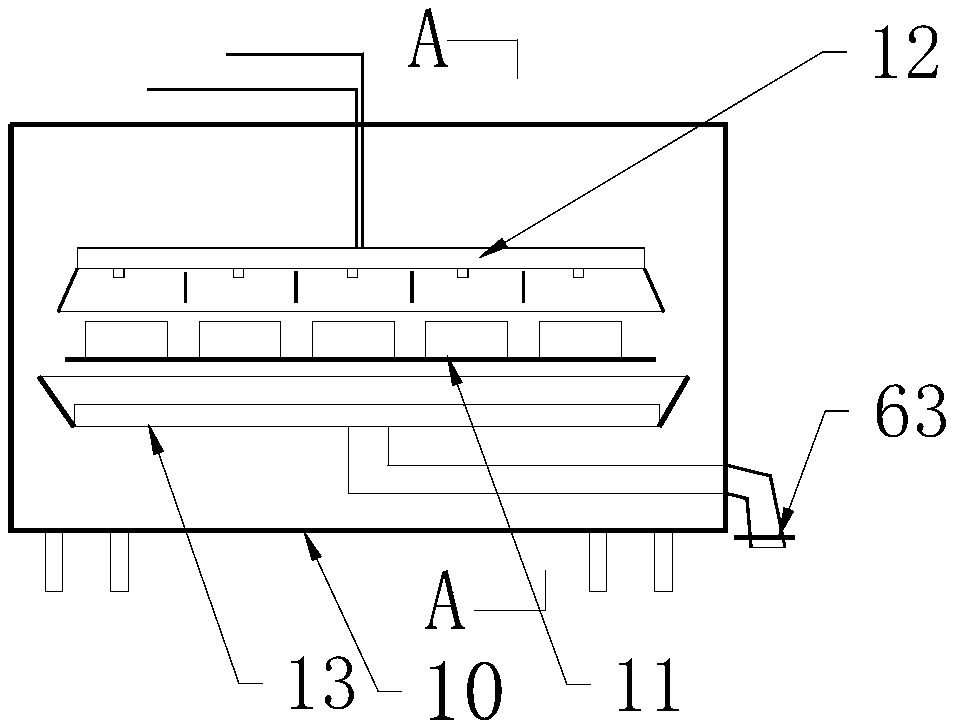

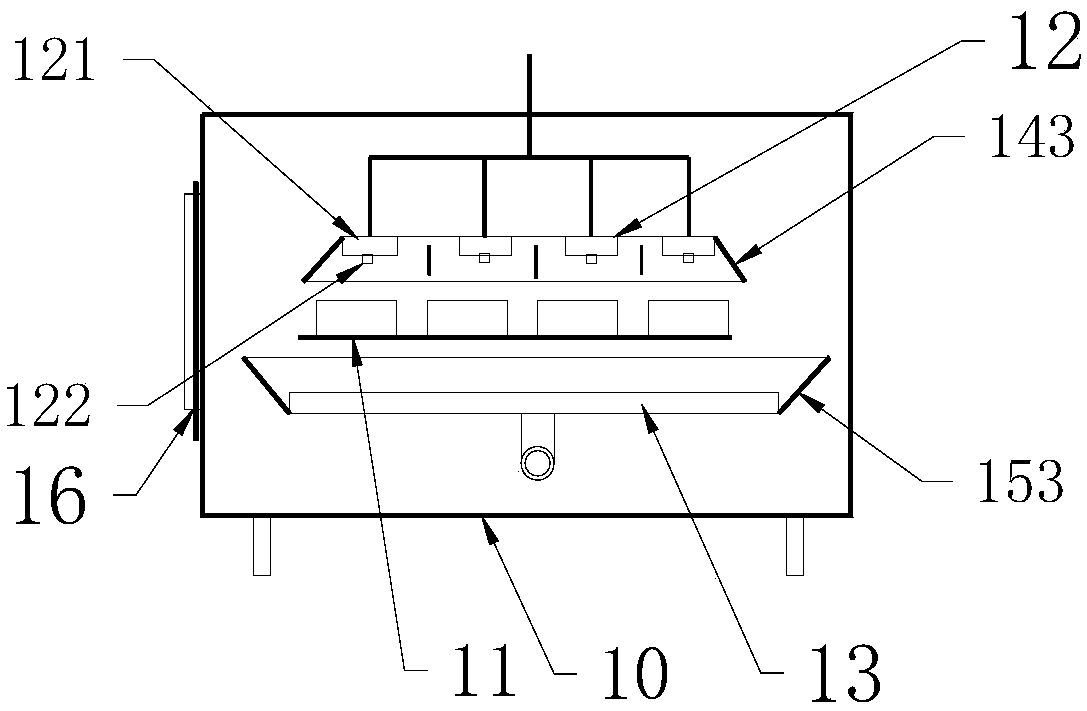

The invention discloses an intelligent baking device and a baking method beneficial to prolonging food shelf-life. The intelligent baking device comprises a control device suitable for process control, a baking device internally provided with a baking chamber, an air supply device, an exhaust fan and an oxygen sensor, wherein a jet head, a baking tray and an air capturing head are sequentially arranged in the baking chamber; an air output port of the air supply device and an air input port of the jet head are communicated; an exhaust port of the air capturing head and an exhaust pipeline are communicated; the oxygen sensor is assembled into the exhaust pipeline, and is suitable for judging whether air in the baking chamber is discharged fully or not; a gate is arranged at an access port suitable for moving in and out food on one side of the baking device in a sealing way so as to be suitable isolating the baking chamber and air; the control device controls the baking device to bake andcool food in the protecting gas environment. The food and the air are isolated through the protection gas, so that a grease in the food during the baking and cooling period is hard to oxidize, the remain quantity of oil oxidation deterioration substances and oxygen in the food is less, the oxygen inhalation capacity is low, the food is easy to preserve, and the shelf life can be improved by 0.5 to 1 time.

Owner:李明守

Slurry covering flame-retardant slurry for fire extinguishing of gangue dump and application thereof

InactiveCN113559453AIncrease the amount of participationReduce manufacturing costFire rescueBoring toolsSlagCarbide

The invention provides slurry covering flame-retardant slurry for fire extinguishing of a gangue dump and application thereof. The flame-retardant slurry is prepared from the following raw materials in parts by mass: 60 to 80 parts of fly ash, 20 to 40 parts of desulfurized gypsum, 25 to 45 parts of lime powder, 20 to 30 parts of carbide slag, 10 to 15 parts of a flame retardant and 110 to 270 parts of water. The flame-retardant slurry has a good fire extinguishing effect and can achieve the purpose of rapidly extinguishing fire and cooling a gangue dump, and a cured layer formed after the flame-retardant slurry is cured has good strength and good water resistance.

Owner:国家能源集团煤焦化有限责任公司 +2

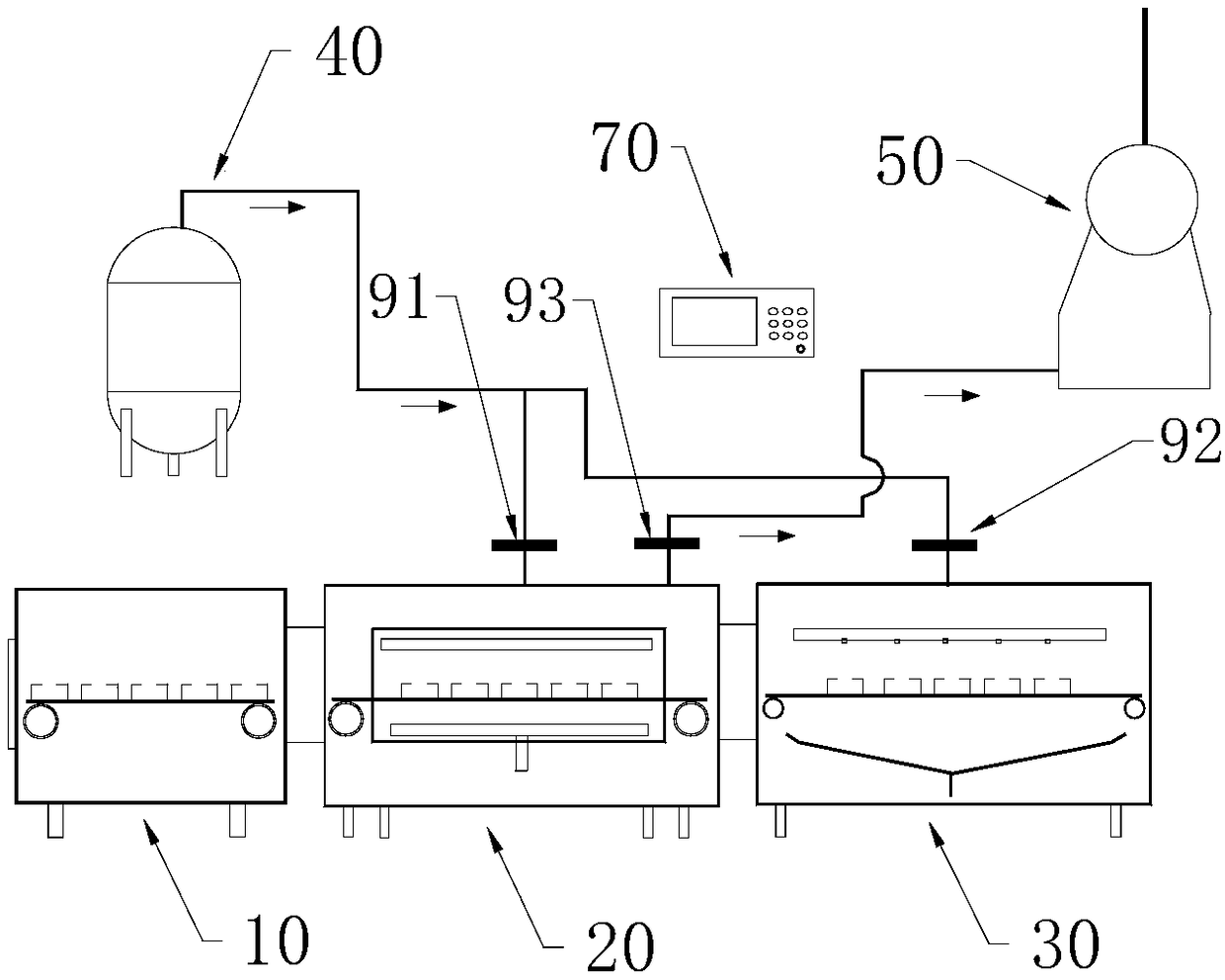

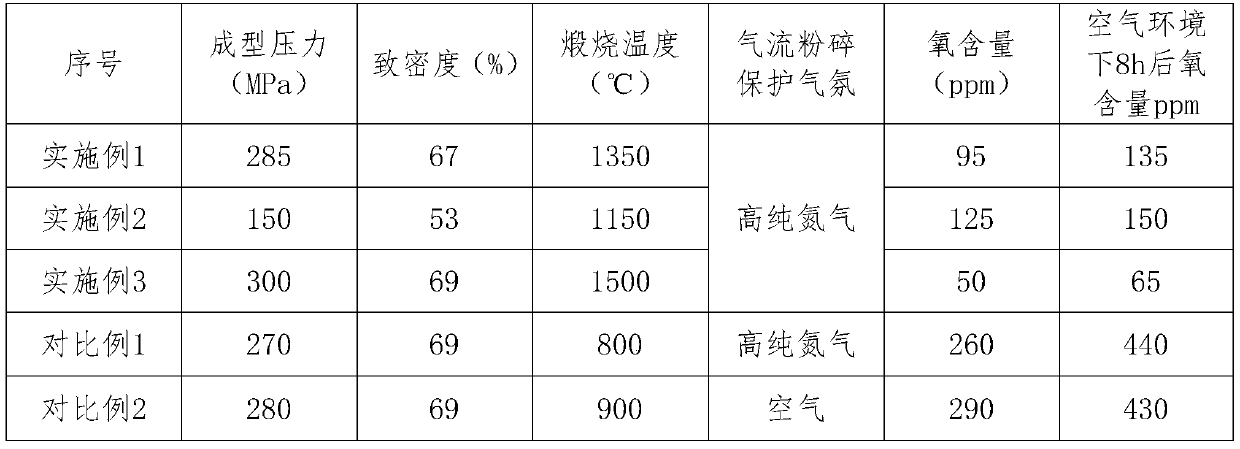

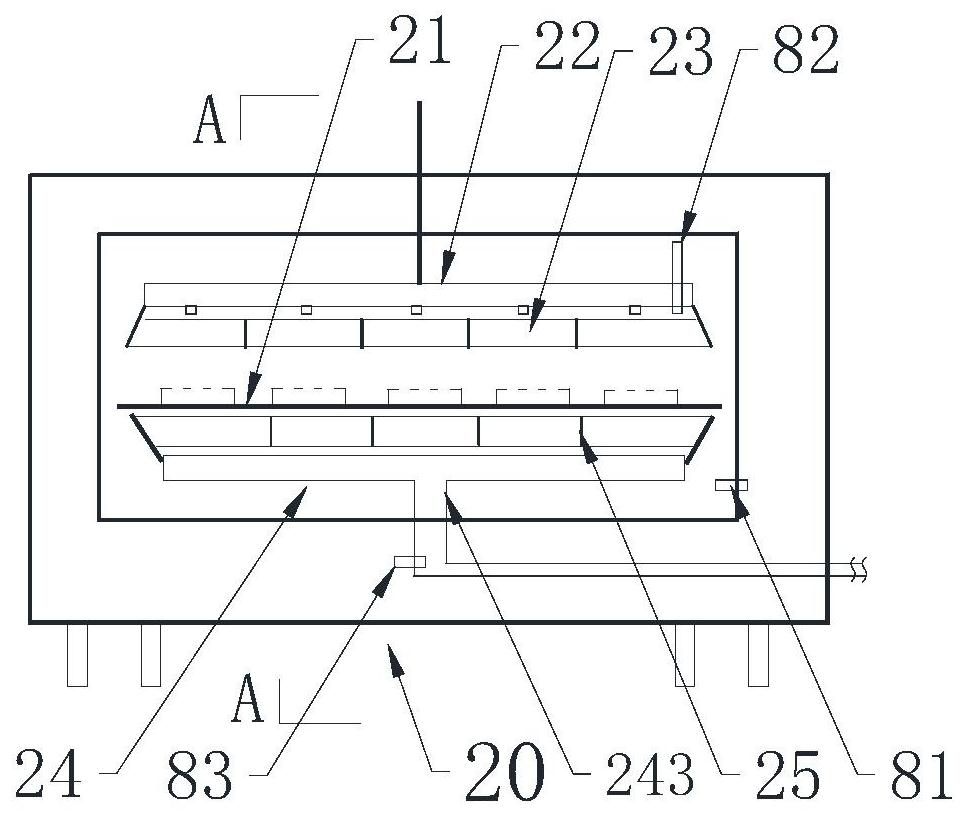

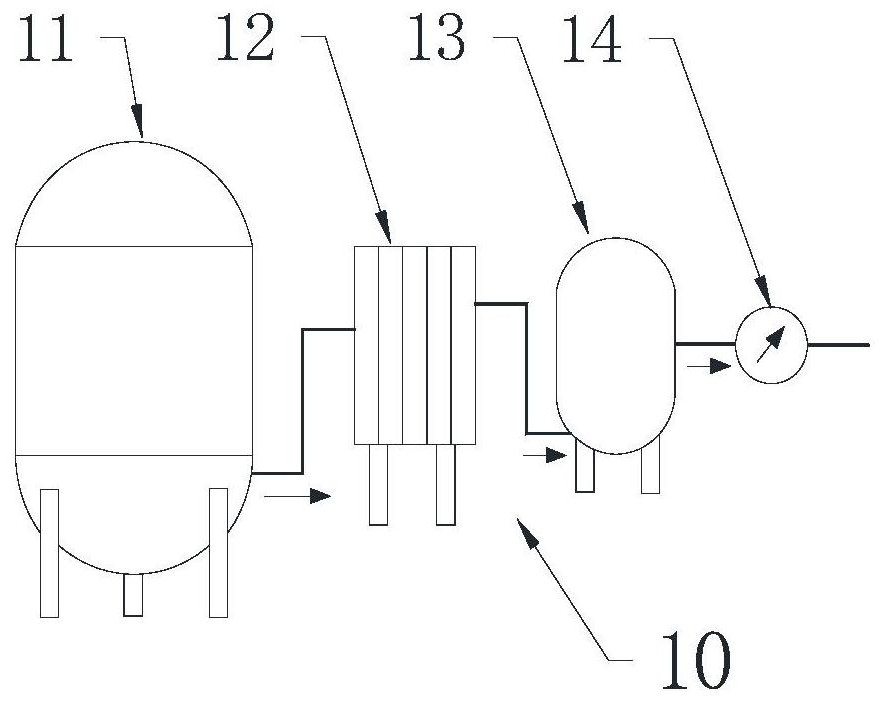

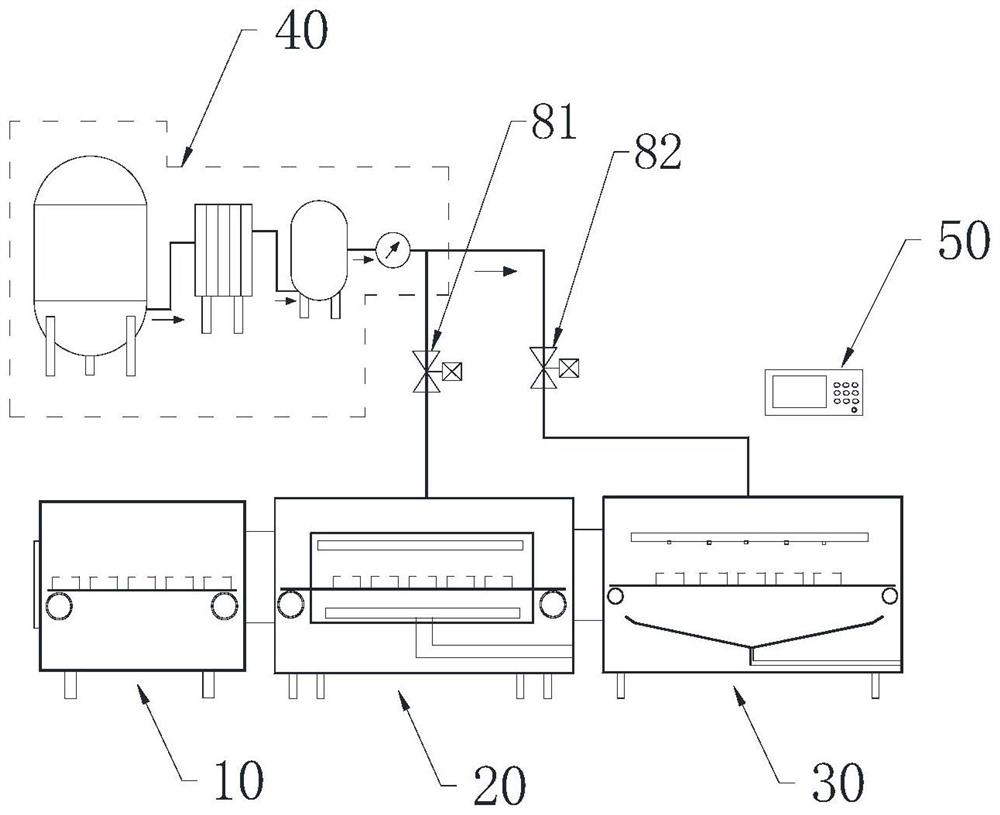

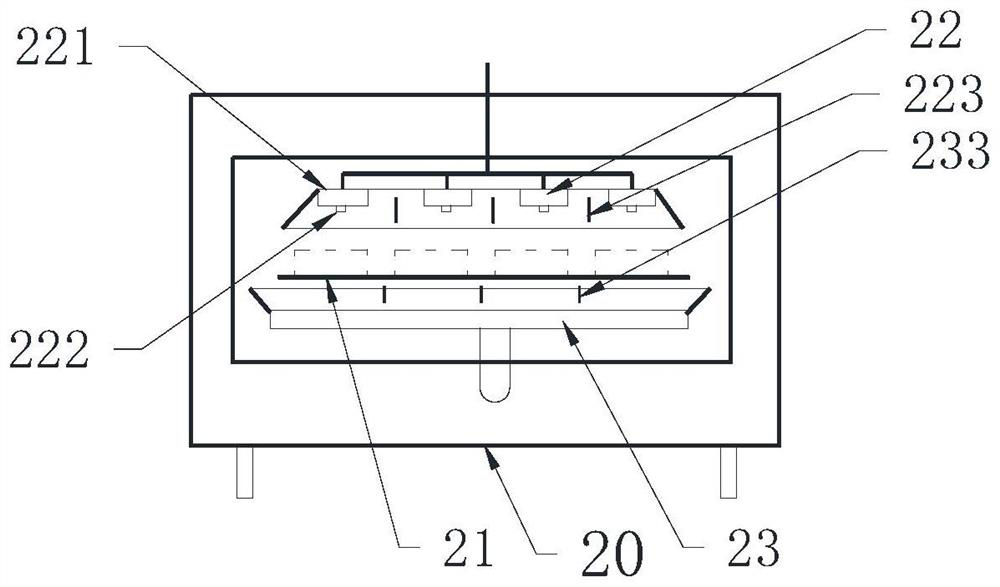

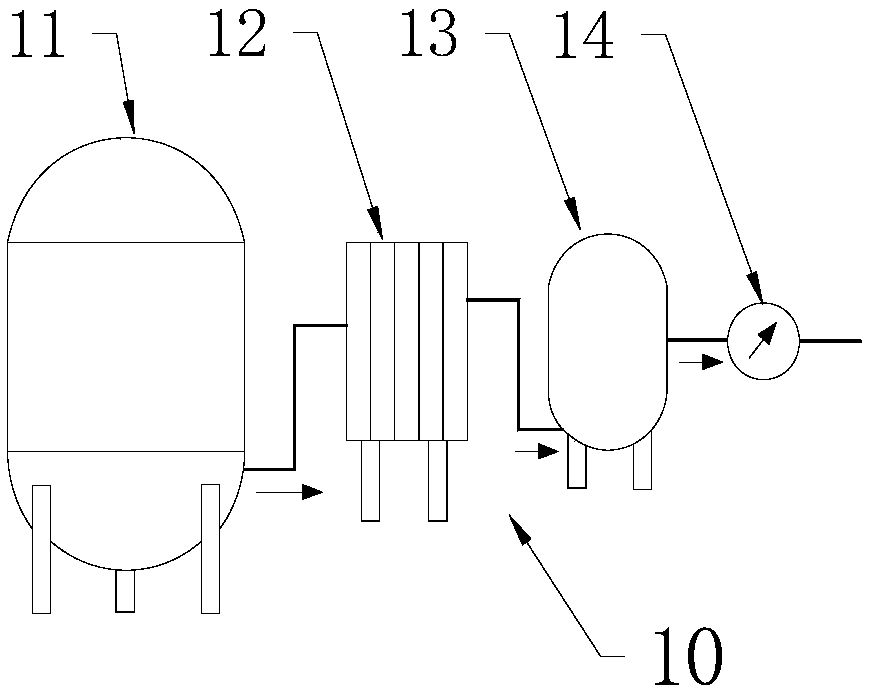

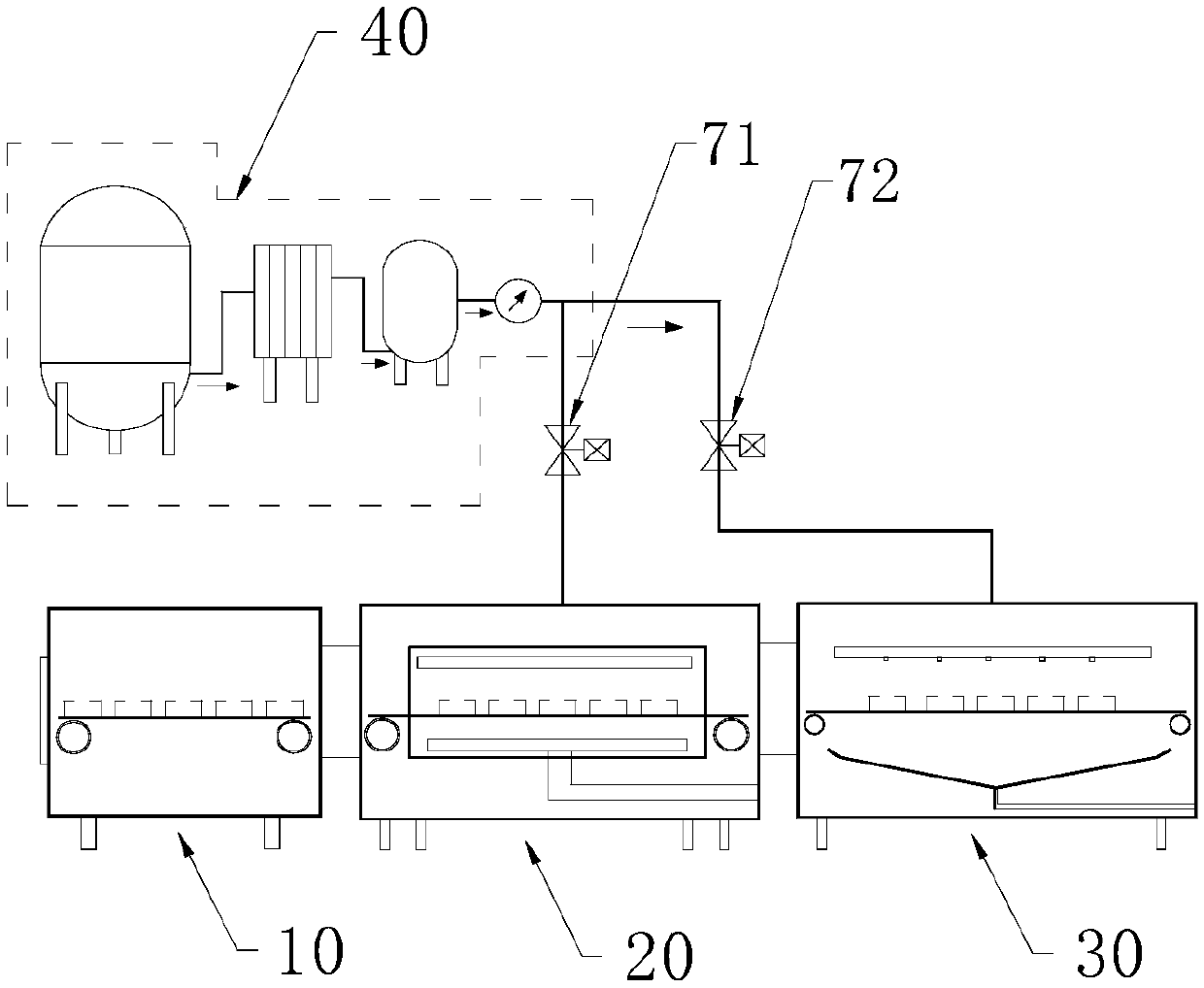

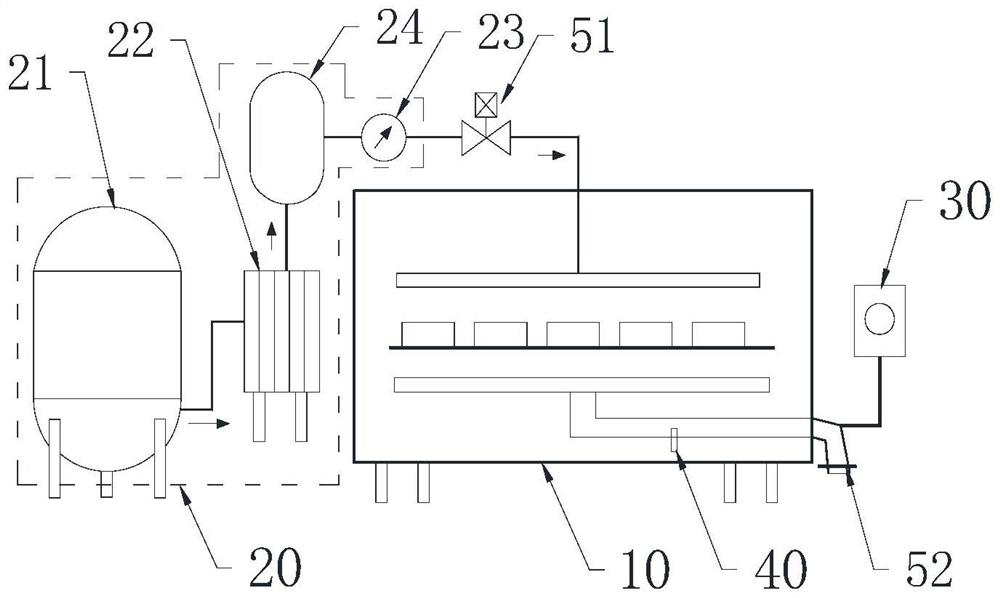

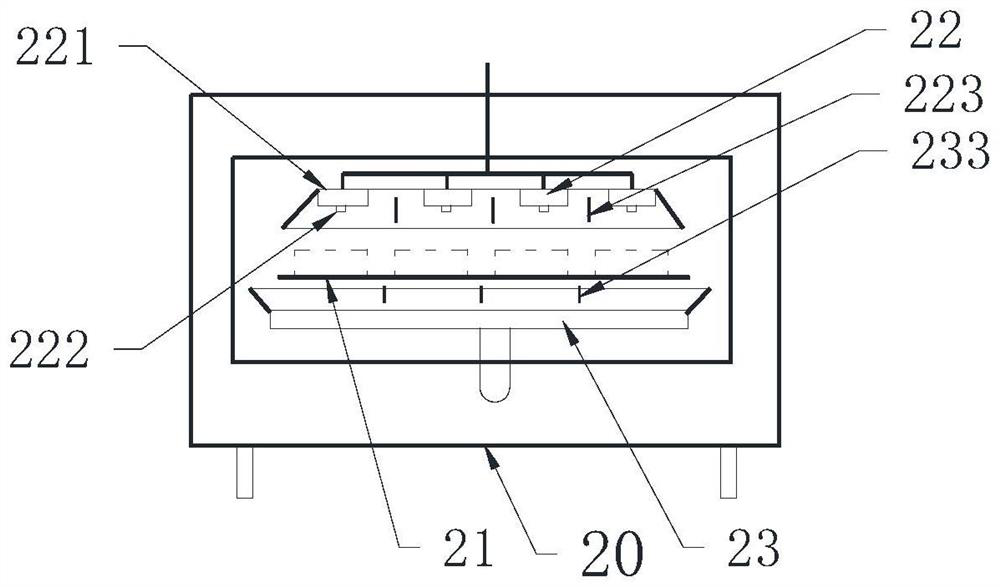

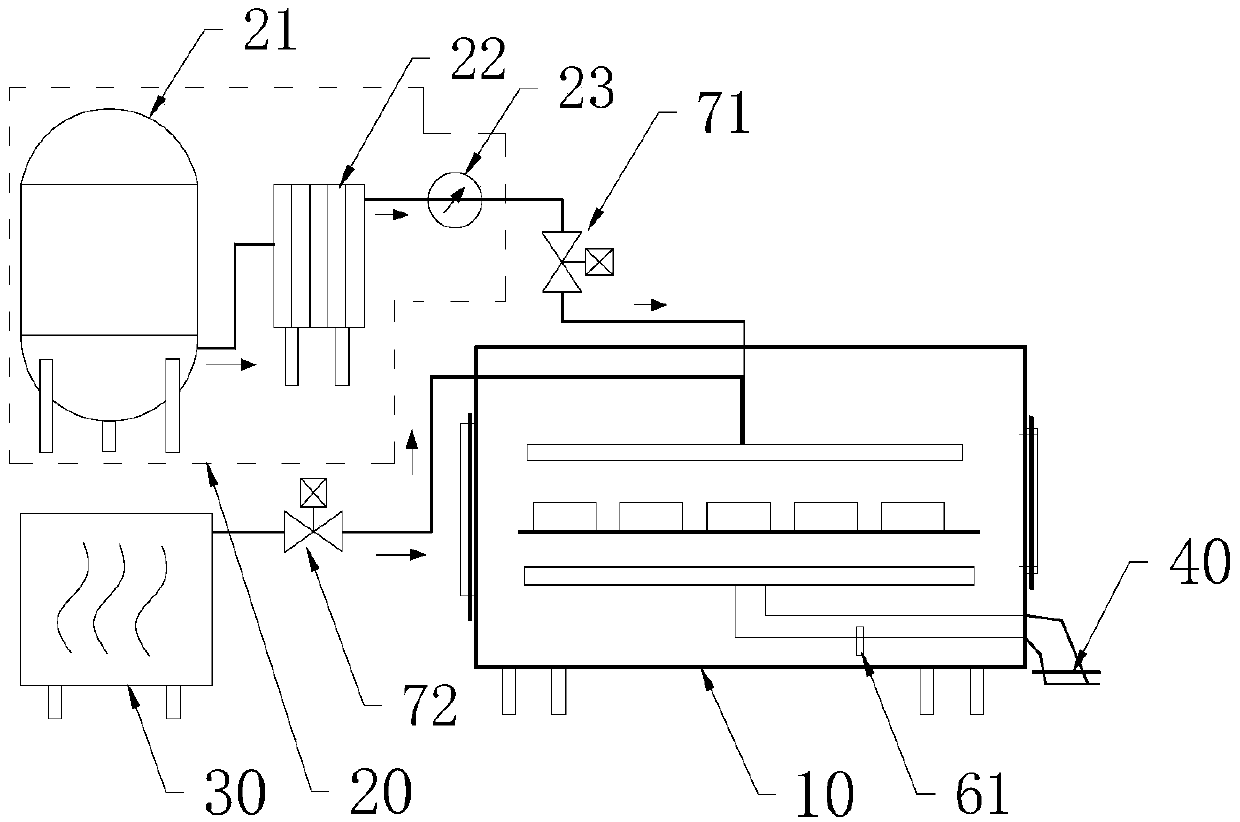

Intelligent food vacuum baking system suitable for improving crispy taste

ActiveCN109105411AImprove crispnessImprove uniformityOven air-treatment devicesCooking & bakingCooling chamber

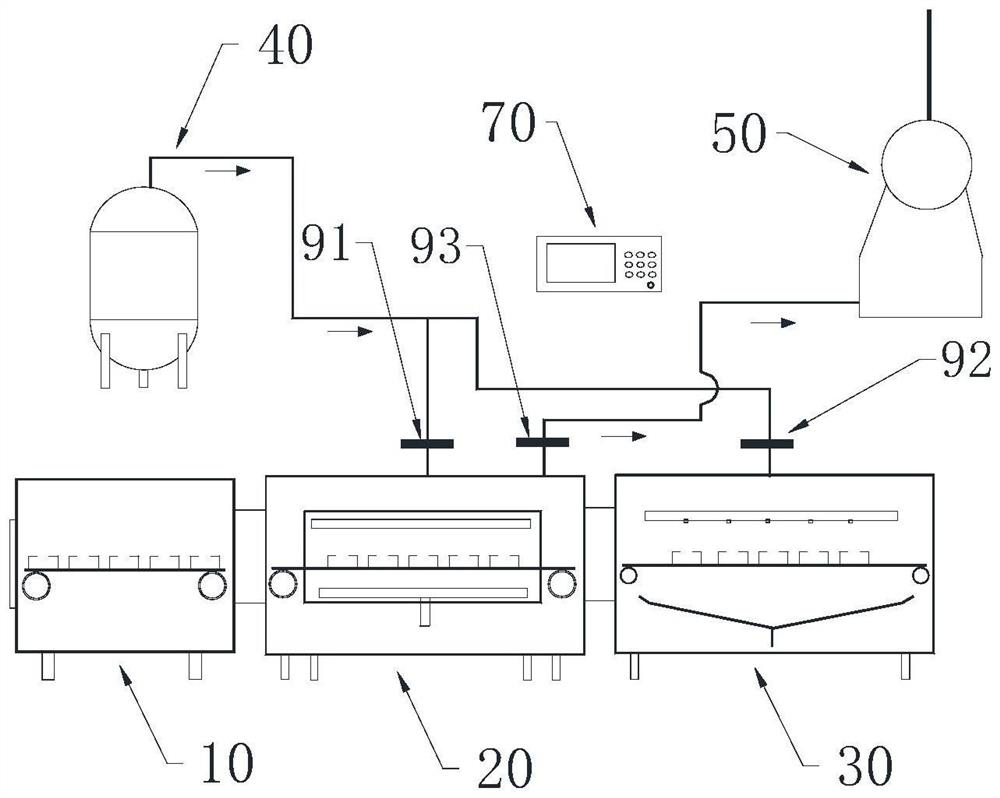

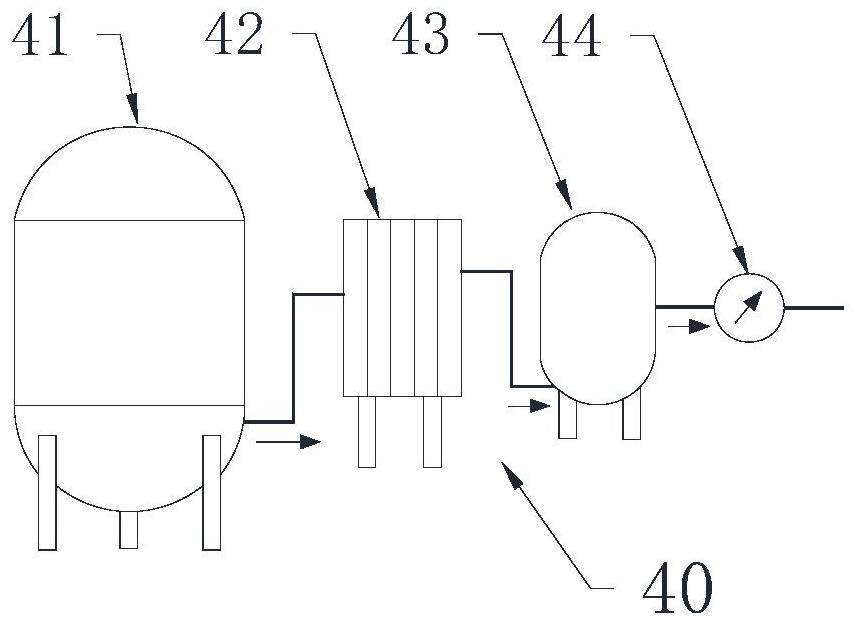

The invention belongs to the food equipment field and especially discloses an intelligent food vacuum baking system suitable for improving a crispy taste. The system comprises a baking device with a built-in baking chamber, a cooling device with a built-in cooling chamber, a gas supply device suitable for conveying a carrier gas to the baking chamber and the cooling chamber, a vacuum device, a circulating device and a control device. The baking device and the cooling device are sealed and connected, and a gate is arranged through a sealing mode so that the baking chamber is separated from thecooling chamber. The food input port of the baking device and the food output port of the cooling device are provided with the gates through the sealing mode. Based on a built-in baking technology, the control device makes the vacuum device vacuumize the baking chamber so that the food is baked in a vacuum environment having the carrier gas, and makes the circulating device drive the carrier gas in the cooling chamber to circularly flow so as to cool the food. The food is baked in the vacuum environment having the carrier gas and is cooled in the circulating carrier gas, the crispy taste of the food is improved, oxidative deterioration objects and oxygen residues in the food are less, and the quality guarantee period of the food can be increased by 0.5-1 times.

Owner:揭阳市港荣食品发展有限公司

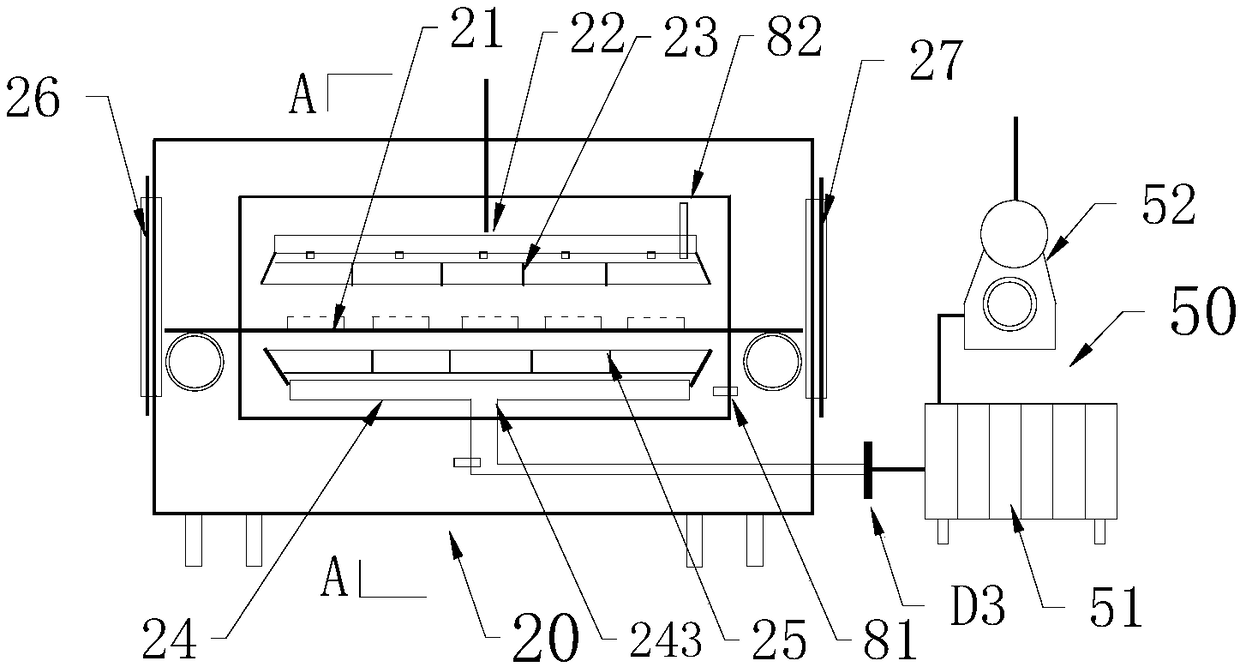

Vacuum food baking equipment suitable for improving crispness of food

ActiveCN109380455AReduce air pressureNot easy to hardenOven air-treatment devicesCooking & bakingProcess engineering

The invention belongs to the field of food equipment and particularly discloses vacuum food baking equipment suitable for improving crispness of food. The equipment comprises a baking device with a built-in baking chamber, a gas supply device suitable for conveying carrier gas into the baking chamber, a vacuum device suitable for providing a vacuum environment for the baking chamber and a circulating device suitable for cyclic flowing of the carrier gas in the baking chamber in order to cool the food. A gate is arranged at an access port in a sealing mode, wherein the access port is suitable for food input and output and is formed in one side of the baking device; gas spraying heads and gas collecting heads which are suitable for uniform distribution of the carrier gas are arranged in thebaking chamber. The vacuum device is operated to vacuum the baking chamber, the baking device is operated to bake the food in the vacuum environment with the carrier gas, and the circulating device isoperated to make the carrier gas in the baking chamber cyclically flow to cool the food. By baking the food in the vacuum environment, the crispness and crispness uniformity of the food are obviouslyimproved, the carrier gas is discharged with baked volatile matters and leaking air, deteriorated fat-oxidative matter and oxygen residues in the food are further reduced, the preservation of the food is facilitated, and the shelf life can be prolonged by 0.5-1 time.

Owner:龙海优麦嘉食品有限公司

Composite ion-injection surface modification method for copper and its alloy

InactiveCN101070592BGuaranteed antimicrobial propertiesImprove surface strengthVacuum evaporation coatingSputtering coatingHigh energyOxidation resistant

The invention relates to a surface modified method for composite ion infusion of copper and its alloy in the area of material technology. Firstly, the copper or the copper alloy surface is grinded, and is polished to 1200#-1500#. Then the deionized water and organic liquid are used to ablution the surface of sample, after drying spare. Composite ion infusion technology is adopted to infuse copperand its alloy into the equipment of ion implantation compound coating, which can realize simultaneously infusion the nonmetallic element and the metallic element to the surface of copper and its alloy. For high energy ion infusion into copper and its alloy surface at very high speed, causes its surface to have many point defects and line defects are yielded in the surface of copper and its alloy.These defects can strengthen the surface of material surface, enhance its degree of hardness, and improve its wear-resisting performance. It also can remarkably reduce adsorptive capacity of oxygen inthe surface of copper and its alloy, or form a slice of compact oxidized protective film in its surface, and thus enhance the anti-oxygenic properties and the corrosion-resisting properties of copperand its alloy.

Owner:SHANGHAI JIAOTONG UNIV

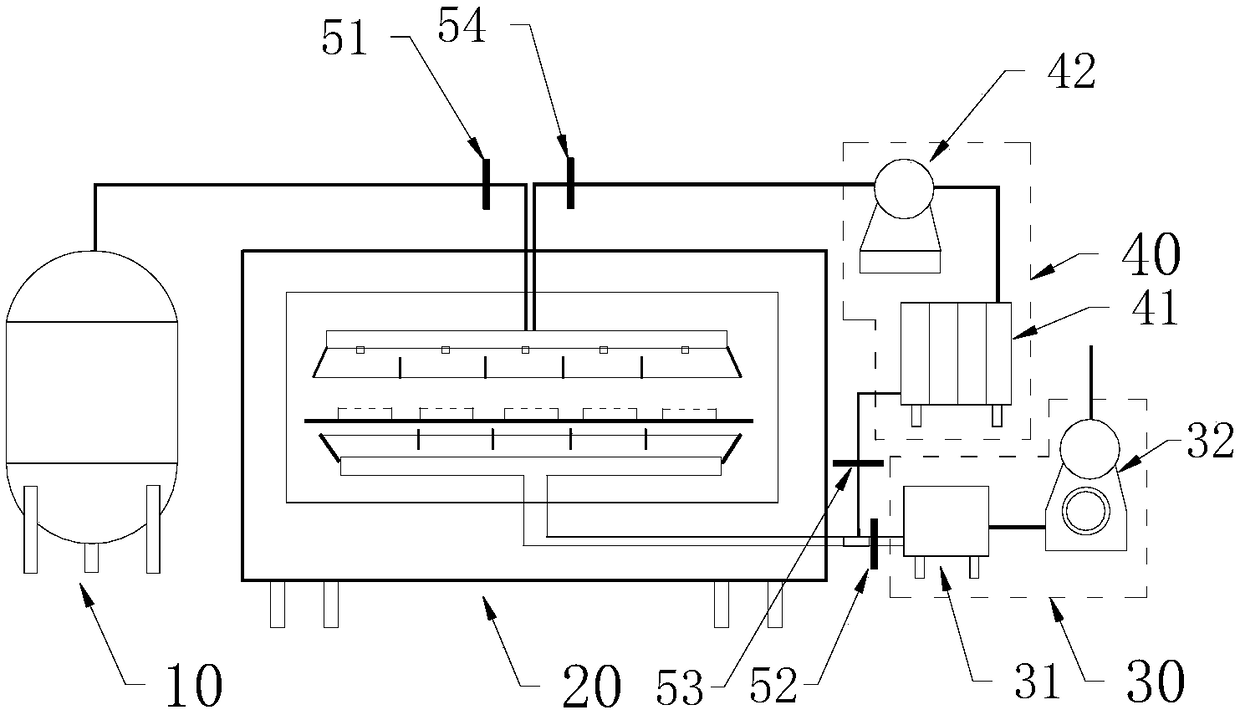

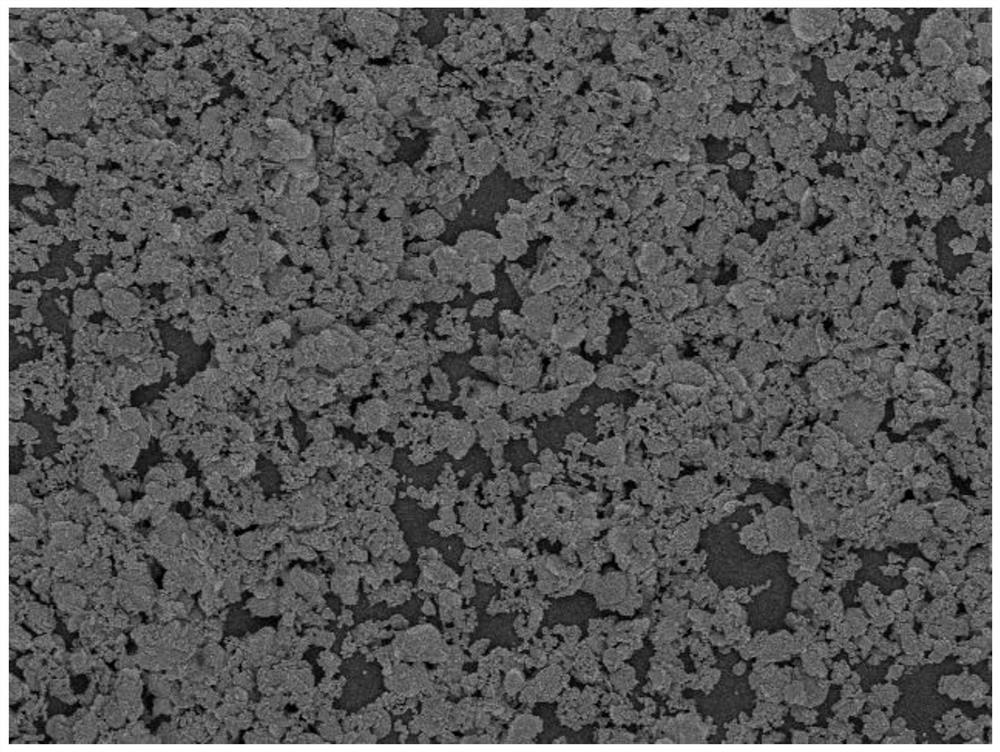

Preparation method of low-oxygen-content molybdenum powder

ActiveCN110576180AStable oxygen contentReduced oxygen uptakeTransportation and packagingMetal-working apparatusMicrometerGranularity

The invention relates to a preparation method of low-oxygen-content molybdenum powder. The method comprises the following steps that 2-10-micrometer molybdenum powder is adopted as a raw material andmolded by a cold isostatic press under the pressure of 150-300 MPa, then, a millstone machine is adopted for breaking the powder into 100-200 meshes, the powder is screened through a 100-mesh screen,the powder is subjected to hydrogenation treatment under the temperature of 1,000-1,500 DEG C, heat preservation is performed for 1-5 h, the powder is cooled to the room temperature and smashed through nitrogen atmosphere airflow and screened by a 100-mesh screen, and the molybdenum powder with the uniform granularity being 100 meshes and the oxygen content being 50-150 ppm is obtained. The technology is simple, the technology is extended directly on the traditional preparation technology, only a small amount of investment is needed, and the capacity is not limited; more importantly, the oxygen content is quite low, and the oxygen content of the molybdenum powder which is ordinarily 500-700 ppm is lowered to 50-150 ppm. The preparation method has the beneficial effect that the remarkable competitive advantages and profit space are shown in the aspects of the manufacturing cost, the product performance, large-scale production, environmental friendliness and the like.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

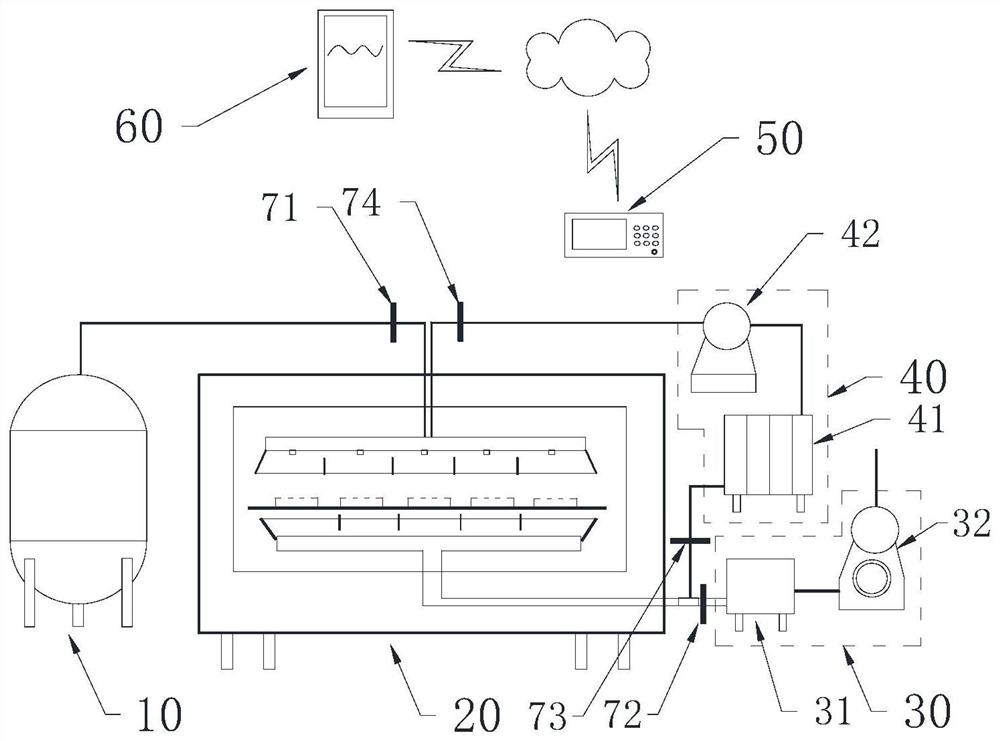

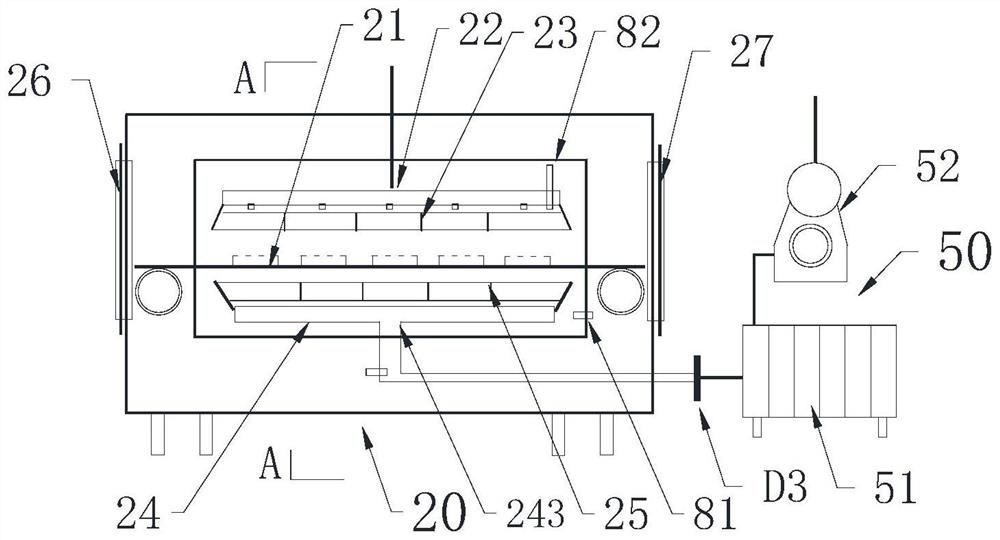

Intelligent baking equipment based on control of internet of things, and baking method

InactiveCN110870489AReduced oxygen uptakeLow residual oxygenBaking ovenOxygen sensorProcess engineering

The invention discloses intelligent baking equipment based on control of internet of things, and a baking method. The intelligent baking equipment comprise a control terminal and a control device which are in communication connection, a baking device internally provided with a baking chamber, an air supply device and an oxygen sensor; air jet heads, a baking tray, and an air collecting head are arranged in the baking chamber in sequence; an air outlet of the air collecting head communicates with an exhaust pipeline; the oxygen sensor is assembled in the exhaust pipeline and is suitable for judging whether air in the baking chamber is completely exhausted; and a gate suitable for moving food in and out is arranged at an opening on one side of the baking device in a sealing manner to isolatethe baking chamber from air. The control terminal is used for operating the control device to set a baking process through internet of things, and the control device is used for operating the bakingdevice to bake and cool the food in a protective gas environment based on the set baking process. Protective gas isolates the food from air, then grease hardly participates in an oxidation reaction during baking and cooling, so that oxidized and deteriorated substances in the food are few and the oxygen residual amount in the food is low, oxygen absorption capacity is low, the food is easy to store, and the shelf life can be improved by 0.5 to 1 time.

Owner:李明守

Composite gel inhibitor for preventing and controlling spontaneous combustion of coal in coal mine and preparation method thereof

InactiveCN101713296BEasy to sprayEasy to operateOther chemical processesDust removalSpontaneous combustionWater soluble

The invention relates to a composite gel inhibitor for preventing and controlling spontaneous combustion of coal in a coal mine and a preparation method thereof. The composite gel inhibitor provided by the invention comprises the following components in percentage by weight: 10 to 65.0 percent of graft copolymer, 0 to 4.00 percent of flame retardant, 20 to 60.0 percent of water glass, and the balance of water. The graft copolymer containing a -COOH functional group is obtained by adopting a water soluble polymer and unsaturated carboxylic acid monomers to perform graft copolymerization, and the composite gel inhibitor for preventing and controlling the spontaneous combustion of the coal in the coal mine is obtained by adding the flame retardant and the water glass into the graft copolymer. The flame retardant provided by the invention has the advantages of excellent retarding effect, environmental friendliness and the like.

Owner:府谷能源投资集团五一矿业有限公司

Intelligent food baking equipment suitable for extending shelf life

ActiveCN109122743AReduced oxygen uptakeLow residual oxygenOven air-treatment devicesBaked articles handlingCooking & bakingAbsorption capacity

The invention belongs to the food equipment field and especially relates to intelligent food baking equipment suitable for extending a shelf life. The equipment comprises an air supply device, a baking device, a cooling deice, an oxygen sensor group used for determining whether air is discharged completely and a control device. A baking technology including a protection gas parameter and a bakingtemperature is arranged in the control device. The air supply device conveys a protection gas to the baking device and the cooling device. The baking device and the cooling device are sealed and connected so that food can be transferred into the cooling device from the baking device. The food inlet of the baking device and the food outlet of the cooling device are provided with gates in a sealingmode so that the food is separated from the air. The control device makes the baking device bake and cool the food in a protection gas environment based on the baking technology. The food is separatedfrom the air by the protection gas, a grease in the food is difficult to initiate an oxidation reaction, an oil-oxidation deteriorated substance and oxygen residues in the food are extremely less, anoxygen absorption capacity is poor, the food is easy to preserve, and the shelf life can be increased by 0.5-1 times.

Owner:好运来(福建)食品有限公司

A kind of vacuum baking equipment suitable for improving the crispness of food

ActiveCN109380455BReduce air pressureNot easy to hardenOven air-treatment devicesThermodynamicsEngineering

The invention belongs to the field of food equipment and particularly discloses vacuum food baking equipment suitable for improving crispness of food. The equipment comprises a baking device with a built-in baking chamber, a gas supply device suitable for conveying carrier gas into the baking chamber, a vacuum device suitable for providing a vacuum environment for the baking chamber and a circulating device suitable for cyclic flowing of the carrier gas in the baking chamber in order to cool the food. A gate is arranged at an access port in a sealing mode, wherein the access port is suitable for food input and output and is formed in one side of the baking device; gas spraying heads and gas collecting heads which are suitable for uniform distribution of the carrier gas are arranged in thebaking chamber. The vacuum device is operated to vacuum the baking chamber, the baking device is operated to bake the food in the vacuum environment with the carrier gas, and the circulating device isoperated to make the carrier gas in the baking chamber cyclically flow to cool the food. By baking the food in the vacuum environment, the crispness and crispness uniformity of the food are obviouslyimproved, the carrier gas is discharged with baked volatile matters and leaking air, deteriorated fat-oxidative matter and oxygen residues in the food are further reduced, the preservation of the food is facilitated, and the shelf life can be prolonged by 0.5-1 time.

Owner:龙海优麦嘉食品有限公司

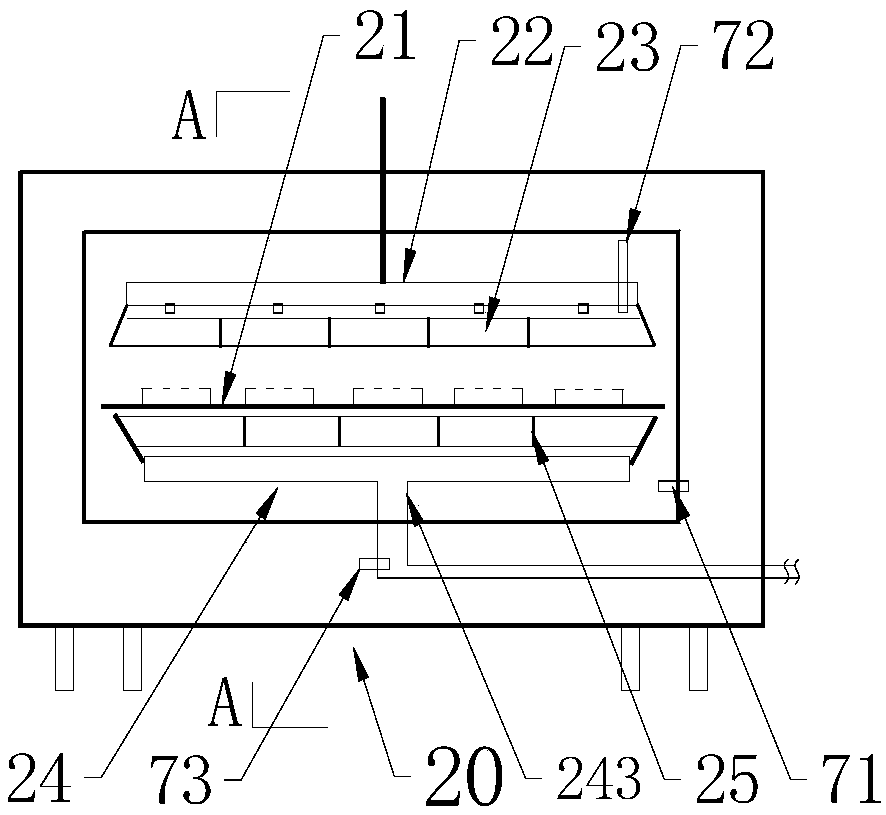

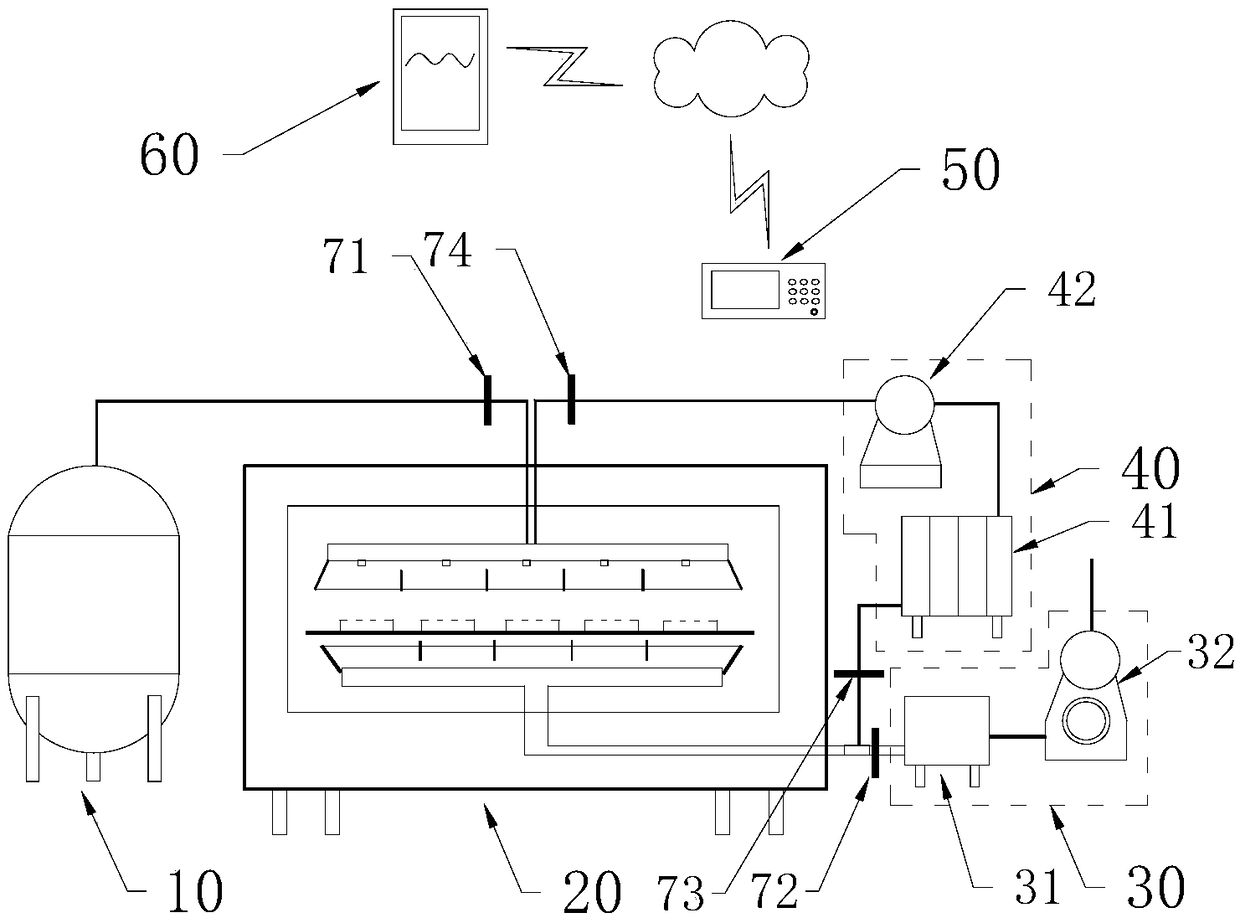

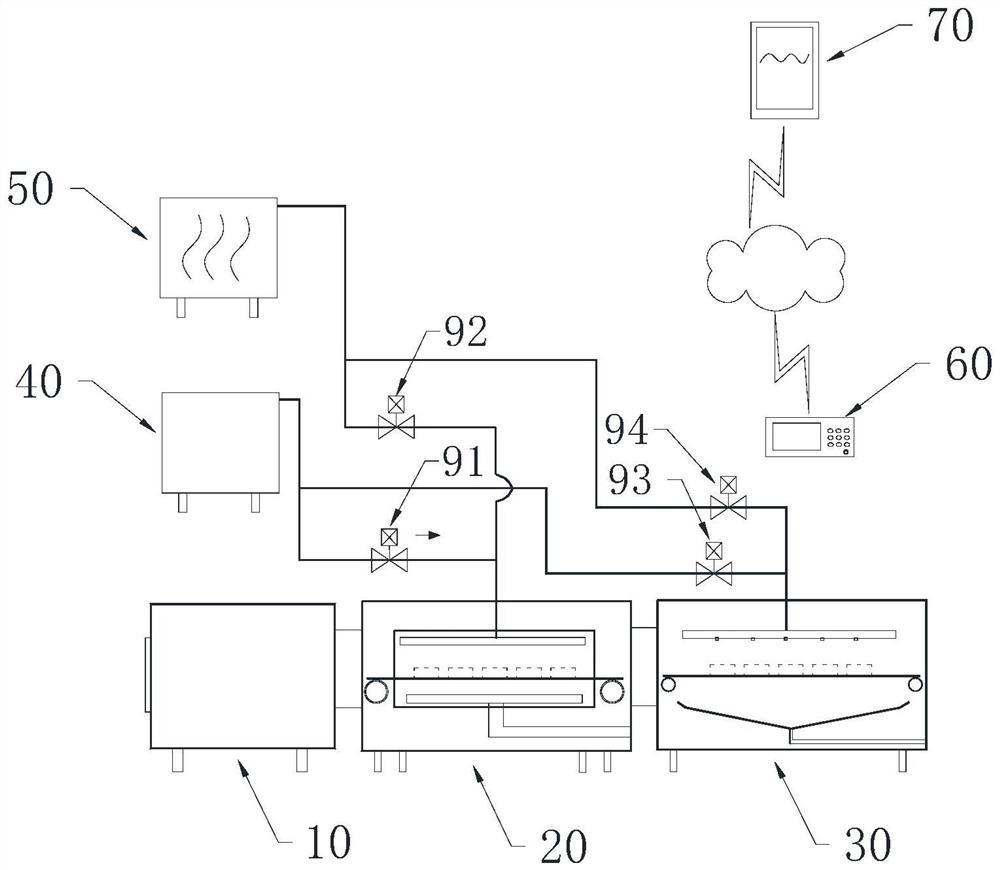

A food intelligent vacuum baking equipment based on Internet of Things control

ActiveCN109287689BEasy to debugEasy to operateOven air-treatment devicesThe InternetProcess engineering

Owner:威海三昌食品有限公司

Intelligent baking equipment beneficial to improving crispness of food

InactiveCN110881486AImprove crispnessImprove uniformityOven air-treatment devicesProcess engineeringPumping vacuum

The invention belongs to the field of food equipment, in particular to intelligent baking equipment beneficial to improving crispness of food. The baking equipment comprises a baking device with a built-in baking chamber, a gas supply device suitable for conveying carrier gas into the baking chamber, a vacuum device suitable for generating a vacuum environment in the baking chamber, a circulatingdevice suitable for the carrier gas in the baking chamber to circularly flow so as to cool food, and a control device is internally provided with a baking process corresponding to to-be-baked food; agate is arranged at an inlet / outlet suitable for food input and output on one side of the baking device in a sealing manner; the control device controls the vacuum device to vacuumize the baking chamber, controls the baking device to bake the food in a vacuum environment with carrier gas, and controls the circulating device to drive the carrier gas in the baking chamber to circularly flow to coolthe food. The food is baked in a vacuum environment, the crispness and crispness uniformity of the food are remarkably improved, a baking volatile matter is discharged in time through the carrier gas,the residual quantity of grease oxidative metamorphic substances and oxygen in the food is smaller, food preservation is facilitated, and the quality guarantee period can be prolonged by 0.5-1 time.

Owner:李明守

A food intelligent baking equipment suitable for extending the shelf life

ActiveCN109122743BReduced oxygen uptakeLow residual oxygenOven air-treatment devicesBaked articles handlingOxygen sensorProcess engineering

The invention belongs to the field of food equipment, and specifically discloses an intelligent food baking equipment suitable for extending the shelf life, including an air supply device, a baking device, a cooling device, an oxygen sensor group and a control device suitable for judging whether the air has been fully discharged The control device is built with a baking process including protective gas parameters and baking temperature; the air supply device sends protective gas to the baking device and the cooling device respectively, and the baking device and the cooling device are sealed and connected, which is suitable for food from the baking device to the cooling device. transfer in the cooling device; the food input port of the baking device and the food output port of the cooling device are respectively provided with gates in a sealed manner to isolate the food from the air; the control device manipulates the baking equipment to process the food in a protective gas environment based on the baking process Baking and cooling, the protective gas isolates the food from the air, the oil in the food is difficult to gas and oxidize, the oxidative deterioration of the oil in the food and the residual oxygen are very small, the oxygen absorption capacity is poor, the food is easy to store, and the shelf life can be increased by 0.5 -1 times.

Owner:好运来(福建)食品有限公司

A preparation method of light rare earth complex modified sintered samarium cobalt magnet

ActiveCN106024234BReduced oxygen uptakeImprove magnetismInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementHigh energy

The invention discloses a preparation method of a light rare earth complex modified sintered samarium-cobalt magnet. The method includes the following steps of melting an Sm-Co-Fe-Cu-Zr master alloy cast ingot, smashing the cast ingot into powder through rough breaking and jet milling, injecting an antioxidant, adding mixed liquid of light rare earth complex and methyl acetate to a samarium-cobalt powder material, conducting high-energy ball-milling, crushing and even mixing, pressing the mixed material into a blank magnet according to magnetic alignment, putting the blank magnet into a vacuum sintering furnace to be subjected to sintering and solution treatment, then conducting ageing treatment, and conducting natural cooling to the room temperature to obtain the samarium-cobalt magnet. By adding light rare earth complex to the mixed material and combining the high-energy ball-milling technology, sintered light rare earth elements are mainly distributed on cell walls, cellular structures are greatly refined, and therefore the coercivity and magnetic energy product of the sintered samarium-cobalt magnet are improved. The method is simple in process, easy to operate and suitable for mass production.

Owner:东阳富仕特磁业有限公司

Food intelligent baking equipment beneficial to improving soft and moist mouthfeel

InactiveCN110870488AKeep moist and softGood softness and uniformityOven air-treatment devicesOven doors/gatesOxygen sensorProcess engineering

The invention discloses food intelligent baking equipment beneficial to improving the soft and moist mouthfeel. The equipment includes a gas supply device, a steam device, a baking device in which a baking chamber is arranged, an exhaust fan, an oxygen sensor and a control device; a gas spray head, a baking tray and a gas capture head are sequentially arranged in the baking chamber, the gas supplydevice and the steam device respectively deliver gas into the gas spray head, the oxygen sensor is arranged in a gas discharge pipeline communicating with the gas capture head, and the oxygen sensoris suitable for judging whether the air in the baking chamber is completely discharged; an inlet-outlet through which food moves in and out located in one side of the baking device is provided with agate in a sealed manner, and the gate is suitable for isolating the baking chamber from the air; and the control device controls the baking device to bake the food in the protective gas environment containing water vapor, moisture of the food is uniformly volatilized, and the food is moister and softer. The protective gas isolates the food from the air, an oxidation reaction of grease in the foodis difficult to realize, grease oxidation deteriorated substances and oxygen residues in the food are extremely small, the oxygen absorption capacity is poor, the food is easy to preserve, and the shelf life can be prolonged by 0.5 to 1 time.

Owner:李明守

Food intelligent vacuum baking equipment based on control of Internet of Things

ActiveCN109287689AEasy to debugEasy to operateOven air-treatment devicesThe InternetProcess engineering

The invention belongs to the field of food equipment, and particularly discloses food intelligent vacuum baking equipment based on control of Internet of Things. The food intelligent vacuum baking equipment comprises a baking device in which a roasting chamber is arranged, a gas supply device suitable for transporting carrier gas to the roasting chamber, a vacuum device suitable for producing vacuum environment in the roasting chamber, a circulating device suitable for enabling the carrier gas in the roasting chamber to circulate, a control device and an operation and control terminal, whereina gate is arranged at an entrance and exit suitable for foods to input and output, in one side of the baking device, in a sealing manner; the operation and control terminal is used for manipulating the control device through the Internet of Things in a long-distance manner and setting a corresponding roasting technology; and the control device is used for manipulating the vacuum device to vacuumize the roasting chamber, roasting foods in the vacuum environment with carrier gas and manipulating the circulating device to drive the carrier gas to cool the foods. The foods are roasted in the vacuum environment, so that the crispness of the foods and the uniformity of the crispness are notably improved; the carrier gas is exhausted in time for baking volatile matter; and the quantity of oil oxidative deterioration substances and oxygen residual quantity in the foods are lower, the preservation of the foods is facilitated, and the quality guarantee period can be prolonged by 0.5-1 time.

Owner:威海三昌食品有限公司

A kind of preparation method of molybdenum powder with low oxygen content

ActiveCN110576180BStable oxygen contentReduced oxygen uptakeTransportation and packagingMetal-working apparatusDisc millNitrogen atmosphere

The invention relates to a method for preparing molybdenum powder with low oxygen content, comprising the following steps: using 2-10 micron molybdenum powder as a raw material, forming it through a cold isostatic pressing machine at 150-300 MPa, and then crushing it to 100-200 mesh with a disc grinder and Pass through a 100-mesh sieve, hydrogenate the powder at 1000-1500°C, keep it warm for 1-5 hours, cool the powder to room temperature, and then crush it in a nitrogen atmosphere and pass through a 100-mesh sieve to obtain a powder with an average particle size of 100 mesh and an oxygen content of 50-150ppm Molybdenum powder. The process of the present invention is simple, directly extends the process on the traditional preparation technology, only requires a small amount of investment, and the production capacity is not limited; more importantly, the oxygen content is extremely low, and the oxygen content of the molybdenum powder can be reduced from the general 500-700ppm to 50- 150ppm. The effect and benefit of the present invention are that it exhibits significant competitive advantages and profit margins in terms of manufacturing cost, product performance, large-scale production, environmental friendliness and the like.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

Food baking equipment suitable for suppressing oxidation of grease during baking

InactiveCN110870493AReduced oxygen uptakeLow residual oxygenOven air-treatment devicesPreservation by coolingOil and greaseOxygen sensor

The invention belongs to the field of food equipment, and specifically discloses food baking equipment suitable for suppressing oxidation of grease during baking. The equipment includes a gas supply device, a baking device, a cooling device, an oxygen sensor group suitable for judging whether the air is completely discharged, and a valve group; the gas supply device conveys a protective gas to thebaking device and the cooling device respectively, a food conveying outlet of the baking device is in sealed communication with a food conveying inlet of the cooling device, an isolation gate is arranged, and the isolation gate is suitable for transferring the food between the baking device and the cooling device; and a food conveying inlet of the baking device and a food conveying outlet of thecooling device are respectively provided with gates in a sealed manner to isolate the food from the air. The baking equipment is operated to bake and cool the food in the protective gas environment, the protective gas isolates the food from the air, an oxidation reaction of the grease in the food is difficult to realize, grease oxidation deteriorated substances and oxygen residues in the food areextremely small, the oxygen absorption capacity is poor, the food is easy to preserve, and the shelf life can be prolonged by 0.5 to 1 time.

Owner:李明守

Baking equipment applicable to wetting type food baking

InactiveCN108850038AImprove uniformityGreat tasteOven air-treatment devicesOil and greaseCooking & baking

The invention belongs to the field of food equipment, and concretely discloses baking equipment applicable to wetting type food baking. The equipment comprises a gas supply device, a steam device, abaking device, an exhaust machine and an oxygen sensor, wherein a gas spraying head, a support baking tray and a gas capture head are built in a baking chamber of the baking device; an output openingof the gas supply device and an output opening of the steam device are respectively communicated with an input opening of the gas spraying head; an oxygen sensor is assembled in an exhaust pipeline communicated with an exhaust opening of the gas capturing head and is suitable for being used for judging whether air in the baking chamber is completely exhausted or not; a gate is arranged in a sealedway in an inlet and outlet opening, suitable for being used for moving in or moving out food, at one side of the baking device and is suitable for being used for isolating the baking chamber away from the air; the baking device performs baking and cooling on the food in the water vapor-comprising protection gas environment; the food is looser, softer and more delicious; the protection gas isolates the food from the air; grease in the food is difficult to generate oxidization reaction; grease oxidization deterioration materials and oxygen residues in the food are very few; the oxygen absorption capability is poor; the food can be easily stored; the shelf life can be prolonged by 0.5 to 1 time.

Owner:李明守

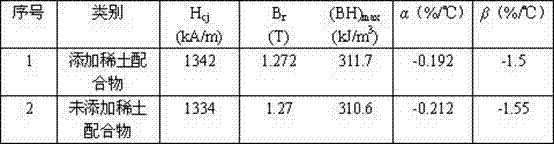

A preparation method for enhancing the coercive force of sintered NdFeB by organic heavy rare earth complexes

ActiveCN105427995BAvoid contactReduced oxygen uptakeTransportation and packagingMetal-working apparatusAlloyDiethyl ether

The invention discloses a preparation method for enhancing the coercive force of sintered NdFeB by organic heavy rare earth complexes. The mixed liquid of organic heavy rare earth complex and ether is injected into the NdFeB alloy powder; the mixed material is magnetically oriented, pressed into a rough magnet, and sintered. The invention adds the mixture of rare earth complexes and ether in a spraying manner, which can effectively prevent particles from contacting with oxygen, reduce the oxygen content of magnetic particles, and improve the distribution uniformity of organic heavy rare earth complexes between grain boundaries of sintered magnets. The addition of organic heavy rare earth complexes decomposes with the increase of sintering temperature, and the residual heavy rare earth ions will be evenly distributed on the surface of NdFeB magnetic particles, and penetrate into the interior of NdFeB particles under the action of high temperature, thereby improving the magnetic crystal of the main magnetic phase. Anisotropy and coercivity. The process is simple and easy to operate, and is suitable for mass production.

Owner:浙江凯文磁业有限公司

Flowerpot capable of improving air permeability of soil

InactiveCN112772216AWon't clogSmooth entrySelf-acting watering devicesSoil-working equipmentsWater storageEnvironmental engineering

The invention relates to the technical field of green plant cultivation equipment, and discloses a flowerpot capable of improving air permeability of soil. The flowerpot comprises a base, a pot body is fixedly mounted at the top end of the base, a water storage disc is slidably mounted on the side surface of the base, and a magnetic part is fixedly mounted at the sliding joint of the water storage disc and the base; and the lower end of the pot body is fixedly connected with one end of a tension spring, the other end of the tension spring is fixedly connected with the water storage disc, a water absorption cotton core is fixedly installed on the side face of the pot body, the lower end of the water absorption cotton core is placed in the water storage disc, a drainage hole is formed in the bottom face of the pot body, and an air exhaust cavity is formed in the base. According to the flowerpot, through the arrangement of the water storage disc and the tension spring, in the process that water in the pot body leaks to the water storage disc, the water storage disc moves downwards due to the weight of the water, the water in the water storage disc cannot block the drainage hole, air in the external environment can smoothly enter the pot body, and therefore the problem that plants die due to oxygen deficiency of the roots of the plants is avoided.

Owner:古嘉明

Preparation method of rare earth complex crystal boundary modification sintered neodymium-iron-boron magnetic body

ActiveCN102184776BAvoid contactReduced oxygen uptakeInductances/transformers/magnets manufactureMetallurgyOxidizing agent

The invention discloses a preparation method of a rare earth complex crystal boundary modification sintered neodymium-iron-boron magnetic body. The preparation method comprises the following steps of: preparing neodymium-iron-boron alloy particles, smashing the neodymium-iron-boron alloy particles into powder and injecting an antioxidant; ejecting mixed liquid of a rare earth complex and petroleum into neodymium-iron-boron powder in a spraying manner and mixing uniformly; and pressing the mixture into a blank magnetic body in magnetic aligning and sintering. In the preparation method, the mixture of the rare earth complex and the petroleum is added in the spraying manner, so that contact of the particles with oxygen can be effectively prevented, the oxygen absorption in the magnetic body preparing process is lowered, and the magnetic performance of the sintered magnetic body is enhanced. The rare earth complex is added and a rare earth product left by the decomposition of the sinteredrare earth complex is mainly positioned at a crystal boundary, so that the prepared sintered neodymium-iron-boron magnetic body has a higher coercive force value and a lower temperature coefficient compared with the conventional sintered neodymium-iron-boron magnetic body. Moreover, the preparation method has a simple process, is easy to operate, and is suitable for batch production.

Owner:浙江凯文磁业有限公司

An intelligent food vacuum baking system suitable for improving the crispy taste

ActiveCN109105411BImprove crispnessImprove uniformityOven air-treatment devicesCooling chamberProcess engineering

The invention belongs to the field of food equipment, and specifically discloses an intelligent food vacuum baking system suitable for improving the crispy taste, including a baking device with a built-in baking chamber, a cooling device with a built-in cooling chamber, Gas supply, vacuum, circulation and control for delivery of carrier gas. The roasting device is connected with the cooling device in a sealed manner, and a gate is provided in a sealed manner, which is suitable for isolating the roasting chamber from the cooling chamber. Gates are respectively provided in a sealed manner at the food input port of the roasting device and the food output port of the cooling device. Based on the built-in baking process, the control device operates the vacuum device to evacuate the baking chamber, bakes food in a vacuum environment with carrier gas, and operates the circulation device to drive the carrier gas to circulate in the cooling chamber to cool the food. The food is baked in a vacuum with a carrier gas and cooled in a circulating carrier gas, the crispness of the food is improved, the oxidative deterioration of the oil in the food and the amount of oxygen residue are less, and the shelf life of the food can be increased by 0.5-1 times.

Owner:揭阳市港荣食品发展有限公司

Baking equipment and baking process capable of prolonging food shelf life

ActiveCN108991052BReduced oxygen uptakeLow residual oxygenOven air-treatment devicesOxygen sensorProcess engineering

The invention belongs to the field of food equipment, and specifically discloses a baking device and a baking process capable of prolonging a food warranty period. The device comprises an air supply device, a roast device, an exhaust fan, and an oxygen sensor. A roast cavity of the roast device is provided with a jet head, a roast tray, and an air capture head in sequence from up to bottom. An airoutlet of the air supply device is communicated with an air inlet of the jet head. An exhaust port of the air capture head is communicated with an exhaust air duct. The oxygen sensor is assembled inthe exhaust air duct, and determines whether all air in the roast cavity is discharged. One side of the roast device is provided with an entrance for moving food in and out. The entrance is provided with a gate in a sealing manner, and the gate isolates the roast cavity from air. The roast device bakes and cools food in a shielding gas environment. The shielding gas isolates food from air. Duringbaking and cooling periods, grease in food is difficult to take oxidation reaction, grease oxidative deterioration substances and oxygen residual quantity in the food are very little, oxygen uptake capacity is low, so that the food is easy to store, and warranty period can improve by 0.5-1 time.

Owner:龙海市安得马富机械有限公司

A food intelligent baking system based on Internet of things control

ActiveCN109197927BGood for healthGood moist softnessOven air-treatment devicesBaked articles handlingThermodynamicsThe Internet

The invention discloses a food intelligent baking system based on control of Internet of Things. The food intelligent baking system comprises a control terminal, a control device, a gas supply device,a steam device, a baking device and a cooling device, wherein the control terminal is in communication connection with the control device; the gas supply device is used for transporting shielding gasto the baking device and the cooling device; the steam device is used for transporting steam to the baking device and the cooling device; the baking device is in sealing communication with the cooling device, and is suitable for enabling foods to transfer from the baking device to the cooling device; gates are respectively arranged at a food input opening of the baking device and a food output opening of the cooling device in a sealing manner, so that foods are isolated from air; and the control terminal is used for manipulating the control device and setting a baking technology through the Internet of Things; and the control device manipulates the baking system to bake and cool foods in the shielding gas environment containing vapor, moisture in foods is uniformly volatilized, and foodsare damper and softer. Through the adoption of the food intelligent baking system disclosed by the invention, the foods are isolated from the air, the quantity of fat oxidative deterioration substances and the quantity of residual oxygen in the foods are low, the oxygen sucking capacity is poor, the foods are easy to store, and the quality guarantee period can be prolonged by 0.5-1 time.

Owner:DONGGUAN HUAMEI FOOD

Baking method for moon cakes and baking equipment

InactiveCN110870492AReduced oxygen uptakeLow residual oxygen contentOven air-treatment devicesBaking processesEngineeringOrganic chemistry

The invention belongs to the field of food processing, and specifically discloses a baking method for moon cakes. The method comprises the following steps: baking moon cakes to be baked in an isolatedgas environment composed of a preset gas, and cooling the baked moon cakes in the isolated gas environment. The moon cakes are baked and cooled in the isolated gas environment, the moon cakes are isolated from the air, baking is performed in the oxygen-free environment, so that an oxidation reaction of grease in the moon cakes can be effectively inhibited from generating oxidation deteriorated substances harmful to health; and the moon cakes are baked in the environment isolated from the air, the content of oxygen residues and the oxidation deteriorated substances in the moon cakes is extremely small, the oxygen absorption capacity of the moon cakes is reduced, and the shelf life of the moon cakes is increased by 0.5 time or more. The invention also discloses baking equipment. The bakingequipment includes a baking device and a gas supply device, the gas supply device supplies the preset gas to the baking device to form the isolated gas environment composed of the preset gas in the baking device, the isolated gas environment is isolated from the air, the moon cakes are baked and cooled in the isolated gas environment, the content of the oxidation deteriorated substances and the oxygen residues in the moon cakes is small, and the moon cakes are easier to store.

Owner:李明守

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com