Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

190results about "Preservation by cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

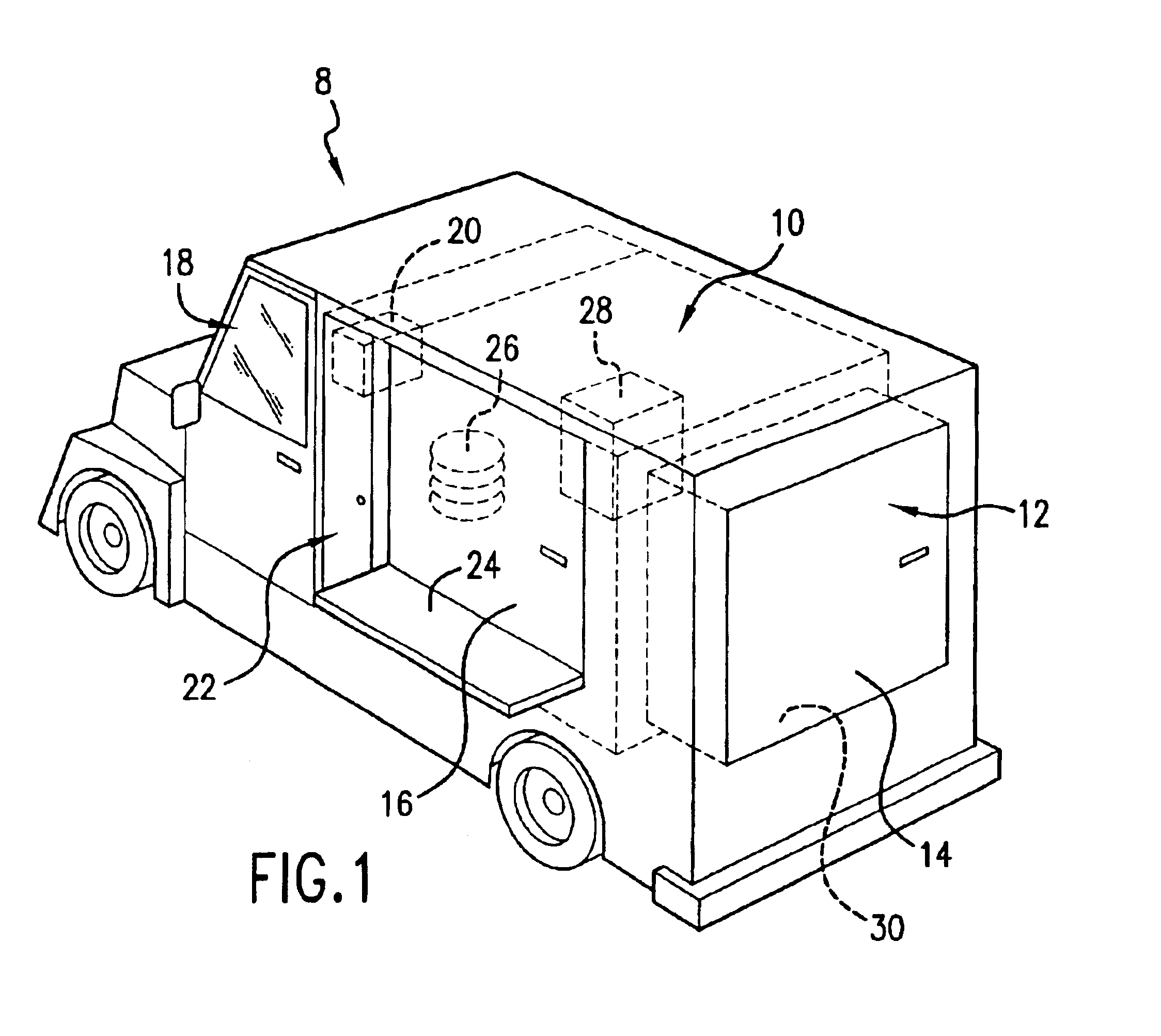

Frozen crustless sliced sandwich and method and apparatus for making same

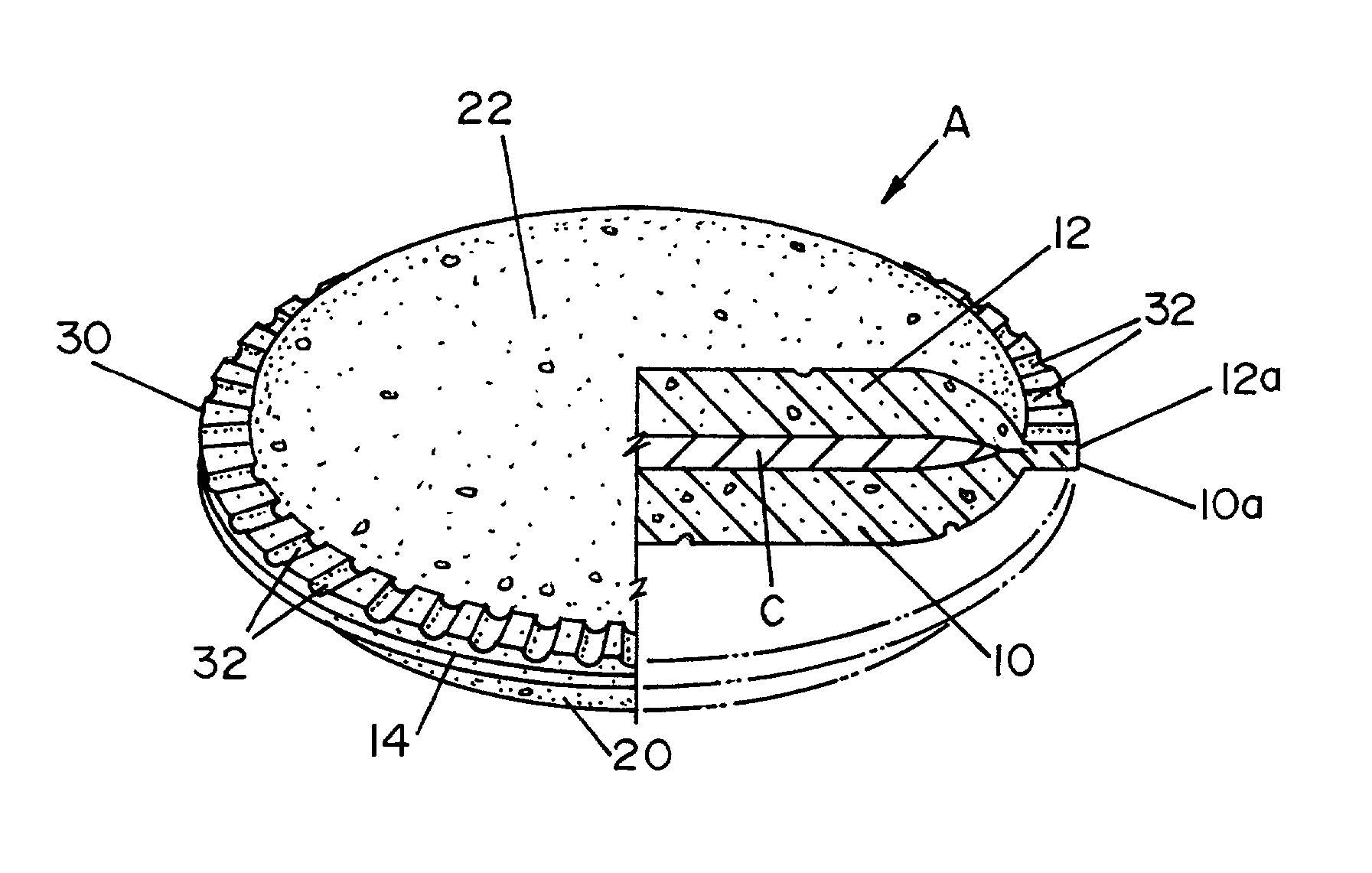

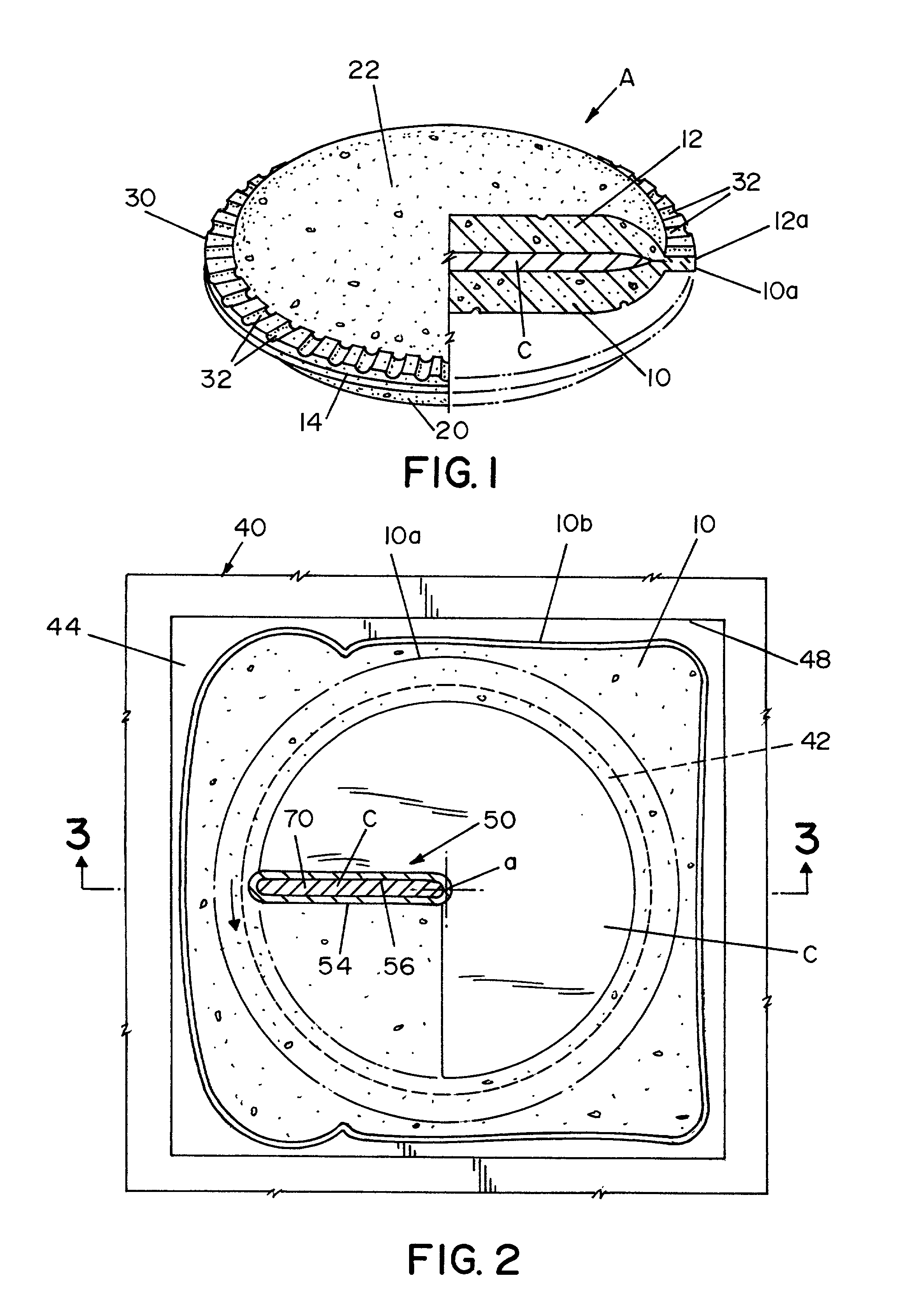

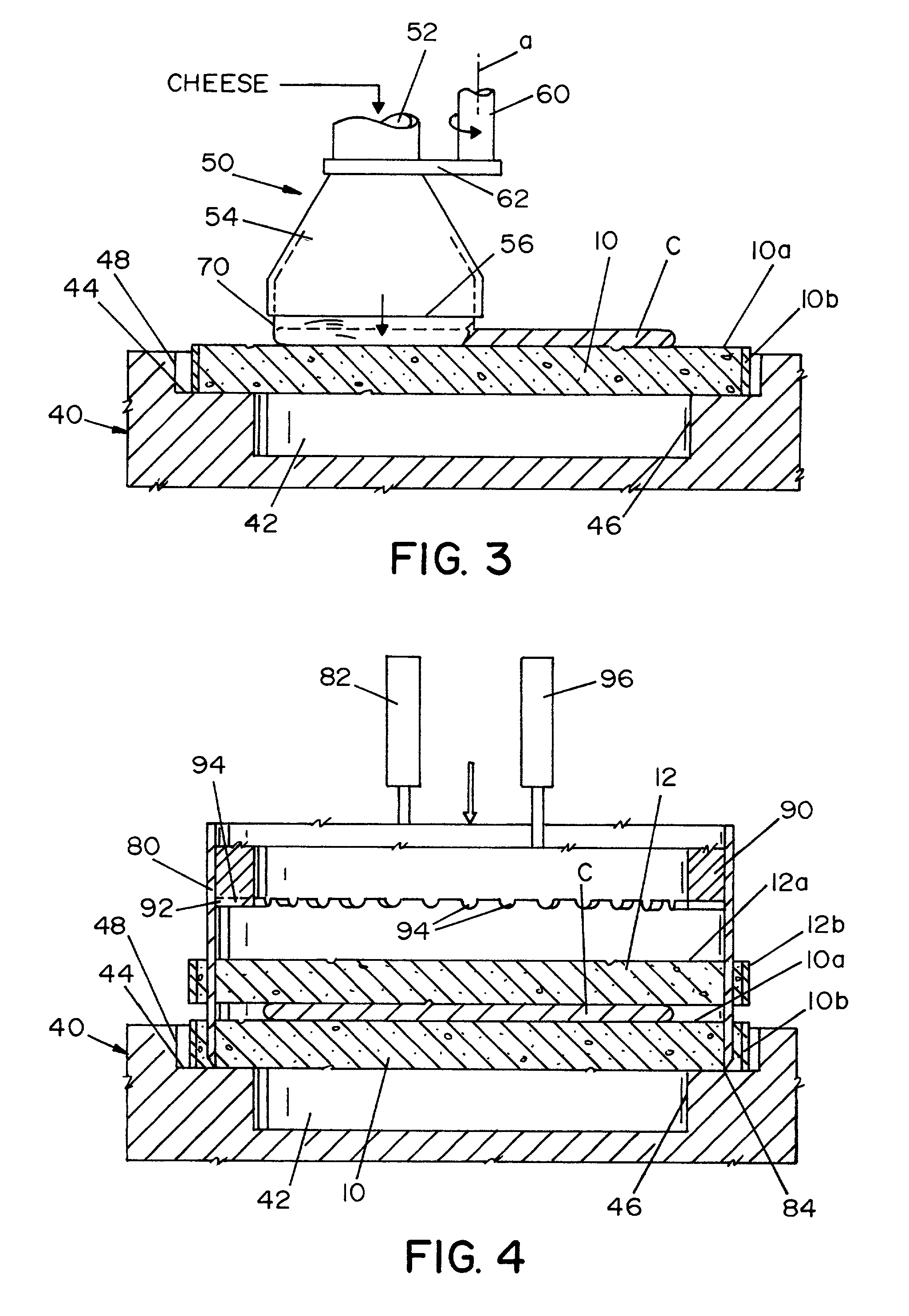

A frozen sandwich for commercial sales comprising a first portion of bread cut from a first slice of crusted bread and having an outer surface, a given periphery and a center area surrounded by a marginal area. A layer of masticated, plasticized cheese deposited on the center area of the first slice and spaced inwardly from the marginal area. A second portion of bread cut from a second slice of crusted bread and overlying the first portion and the center layer of cheese. The second portion also having an outer surface, a periphery generally matching the periphery of the first portion and a marginal area generally matching and coextensive with the marginal area of the first portion where the marginal areas are compressed together to form a seal generally matching the peripheries of the bread portions and the outer surfaces of the bread portions are heat scorched to transform a thin skin of the cut bread portions into a toasted bread condition.

Owner:THE J M SMUCKER CO

Filled pastry

InactiveUS20060073239A1Increase moisture contentSuitable for toastingDough treatmentPreservation by coolingGraham crackerFood flavor

A filled pastry having a cooked dough shell and a filling. The cooked dough shell is made from raw dough that includes whole-wheat flour, wheat bran, sweetener, shortening, and water and can have an appearance and flavor that is similar to graham crackers. The filling is prepared from a material that is distinct from the dough shell. The filling is substantially retained within the dough shell. An interface between the dough shell and the filling minimizes moisture migration.

Owner:GENERAL MILLS INC

Freeze-dried foods and process for producing the same

InactiveUS6361813B1Excellent in smooth melting in mouthPorous structureMilk preparationFrozen sweetsEmulsionFreeze-drying

There are described freeze-dried food products which have porous structure with fine texture than those obtained by conventional processes to give smooth melting in mouth and a process for preparing the freeze-dried food products. According to the process, raw materials for the food are made into a form of aqueous solution or paste, emulsified, made into semi-frozen state by cooling the emulsion, freeze-dried by further cooling in a mold, and then subjected to freeze-drying treatment.

Owner:MEIJI SEIKA KAISHA LTD

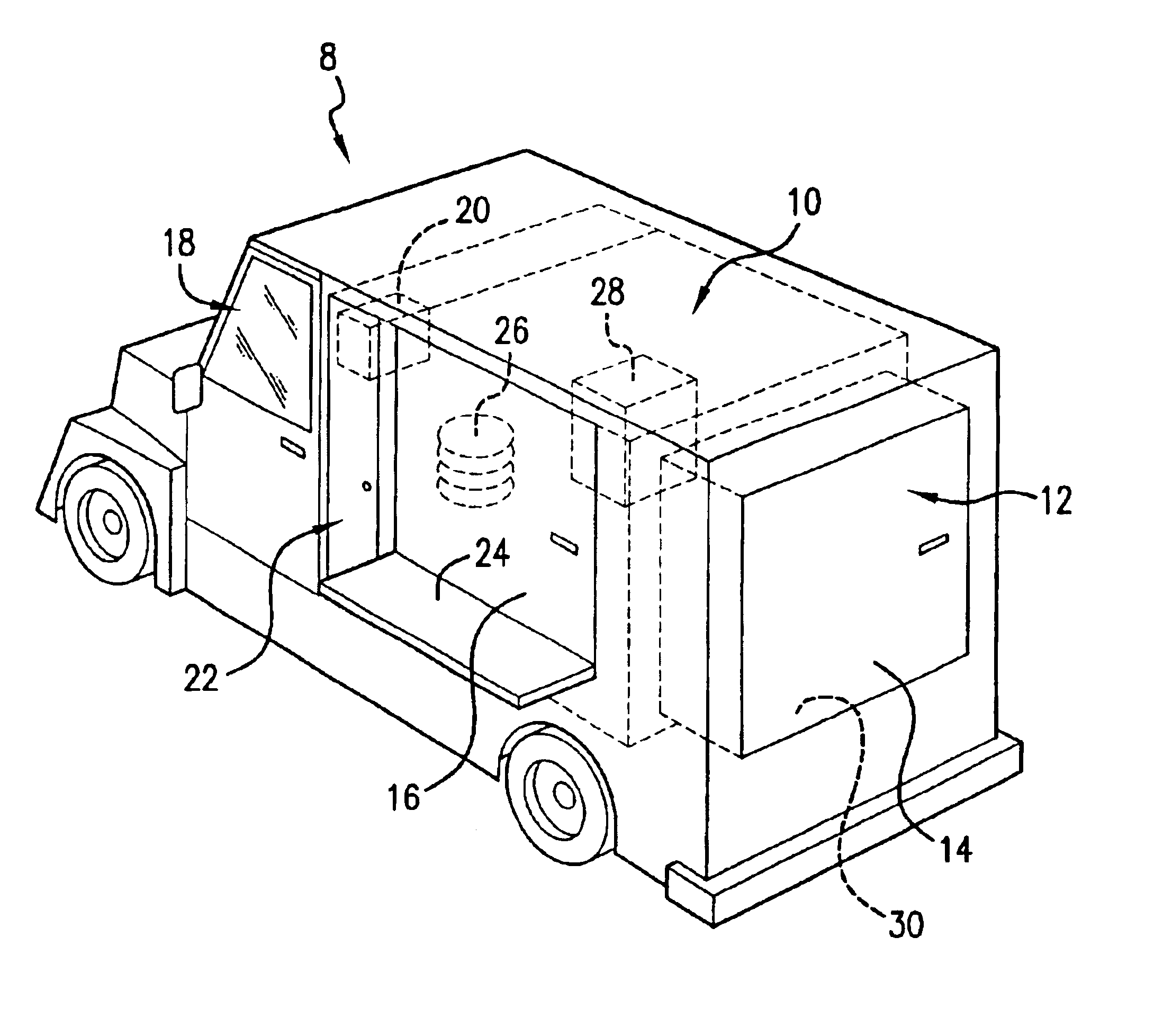

Pizza preparation and delivery method and unit

The present invention relates to pizzas and pizza-type products preparation and delivery method. The present invention deals with a method for providing to consumer a freshly baked pizza-type food product using individually frozen ingredients, combining them and baking them in less than 5 minutes; the individually frozen ingredients and the pizza-type food product being respectively stored and baked in a mobile, compact and energetically autonomous baking-selling unit.

Owner:NESTEC SA

Heat-treated food which has been wrapped in a pastry of wheat flour dough for cooking in a microwave oven

According to the present invention, there may be provided a heat-treated food which has been wrapped in a pastry of wheat flour dough for cooking in a microwave oven and which is capable of reproducing the so-called crispy feeling as well as favorable flavor and taste just cooked, said heat-treated food tending to migrate water to the heat-treated surface from the inside ingredients during its distribution and storage terms. The present invention relates to a heat-treated food wherein the inside ingredients have been wrapped in a pastry of wheat flour dough for cooking in a microwave oven and whose heat-treated surface is in contact with a microwave heat susceptor.

Owner:AJINOMOTO CO INC

Rice cake and manufacturing method thereof

InactiveCN102919319AOvercome RetrogradeOvercome the disadvantage of poor tasteDough treatmentPreservation by coolingCooking & bakingCorn flour

The invention relates to a rice cake and a manufacturing method thereof. The rice cake is prepared from the following main raw materials in percentage by mass: 15 to 30% of glutinous rice flour, 15 to 30% of millet flour or corn flour and 18 to 35% of eggs; and the rice cake is manufactured by mixing, fermenting and steaming the main raw materials. According to the rice cake, the rice flour is matched with natural food components such as eggs, honey and the like, the raw materials are widely available, and the formula of the raw materials is healthy and reasonable; a steaming method is adopted, the processing technique is simple, nutrient loss caused by high-temperature baking is avoided, and a lot of unsafe factors are also avoided; the texture of a product can be improved through yeast fermentation, so that the defects of easy rawness returning and poor mouthfeel of the rice flour are overcome; and through a freezing fresh-keeping technology, the problems of surface skin cracking, collapsing in shape, tooth adhesion and the like which appear easily when the conventional rice cakes are steamed again are solved.

Owner:JIANGNAN UNIV

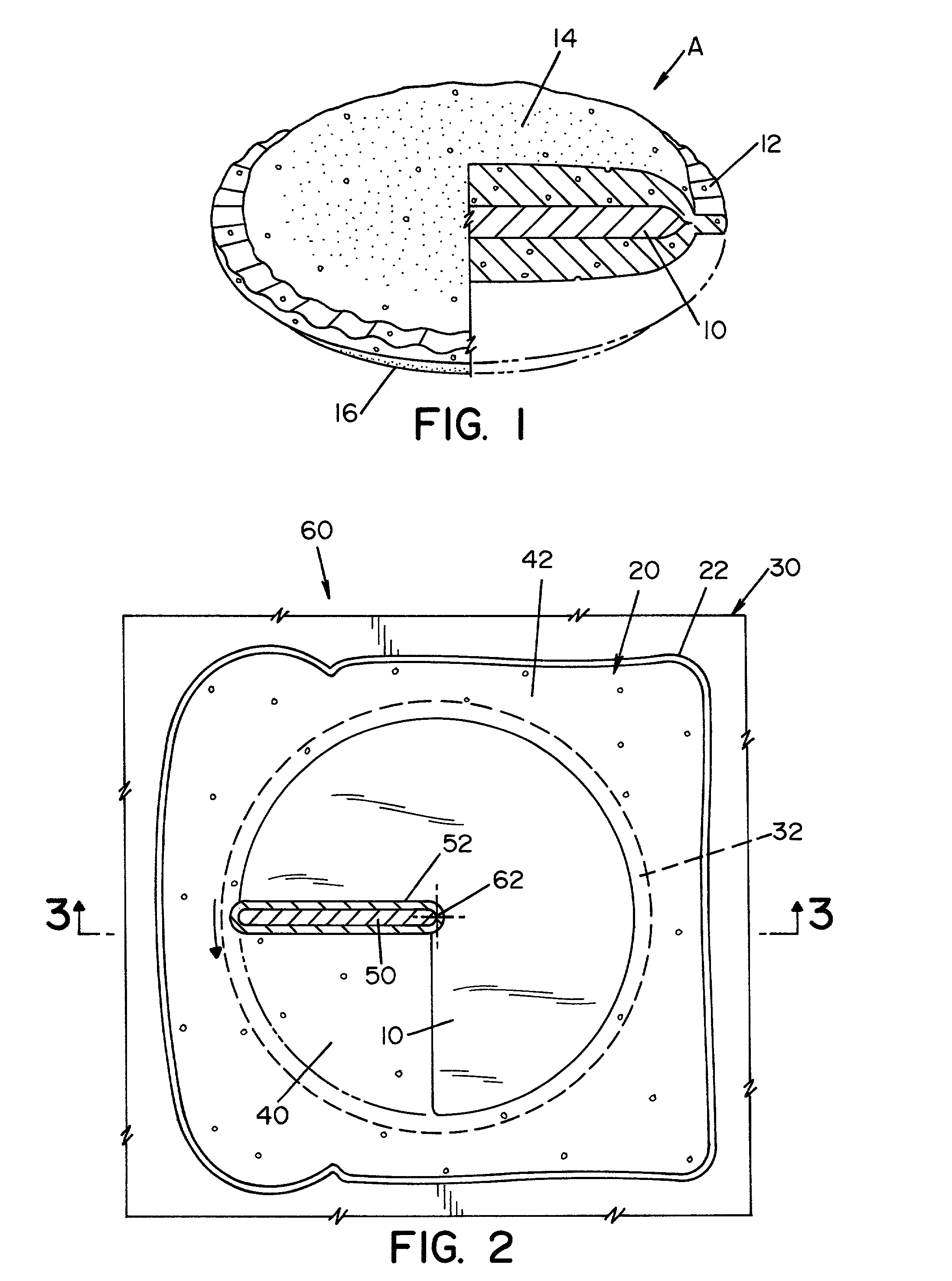

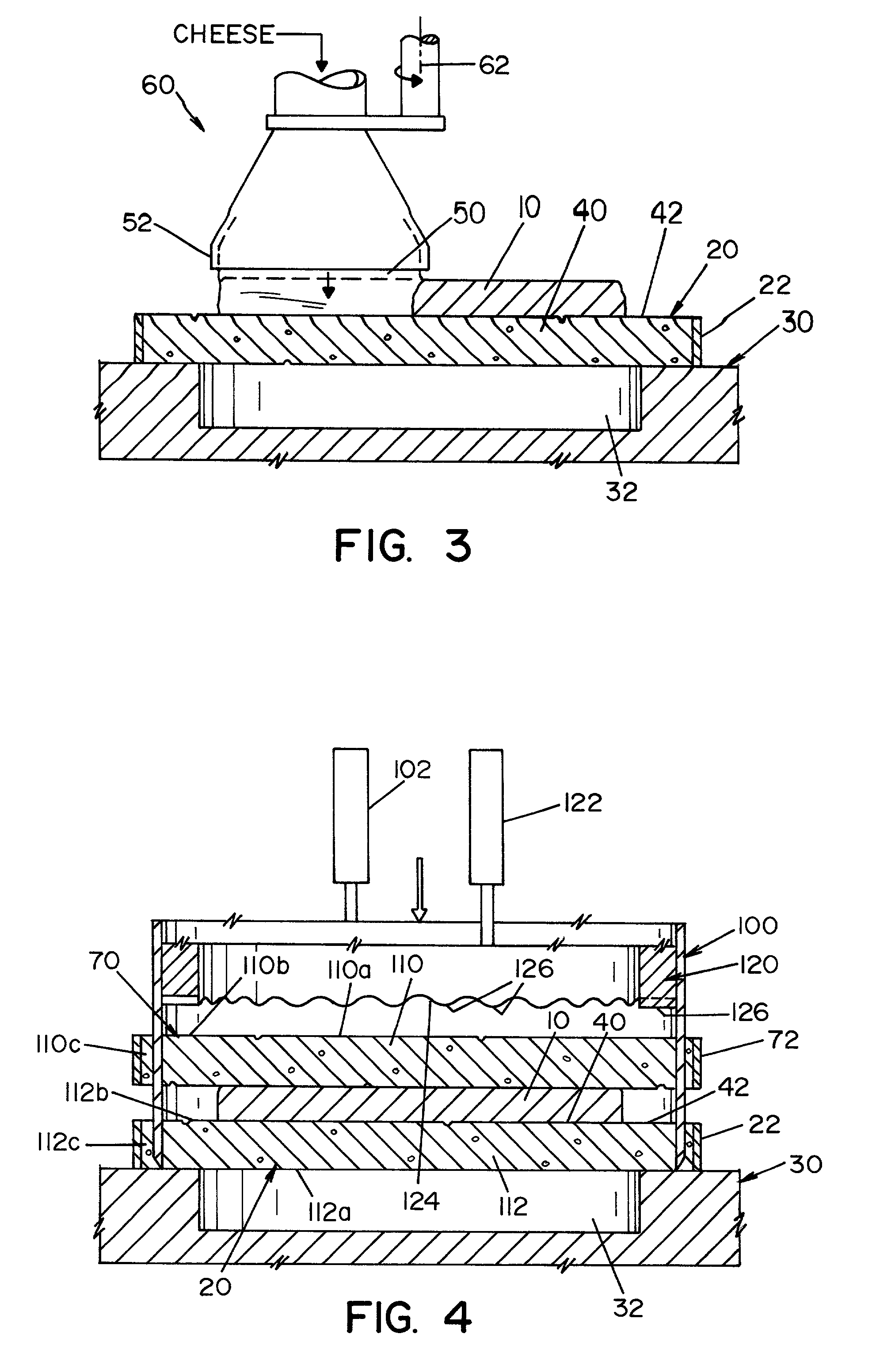

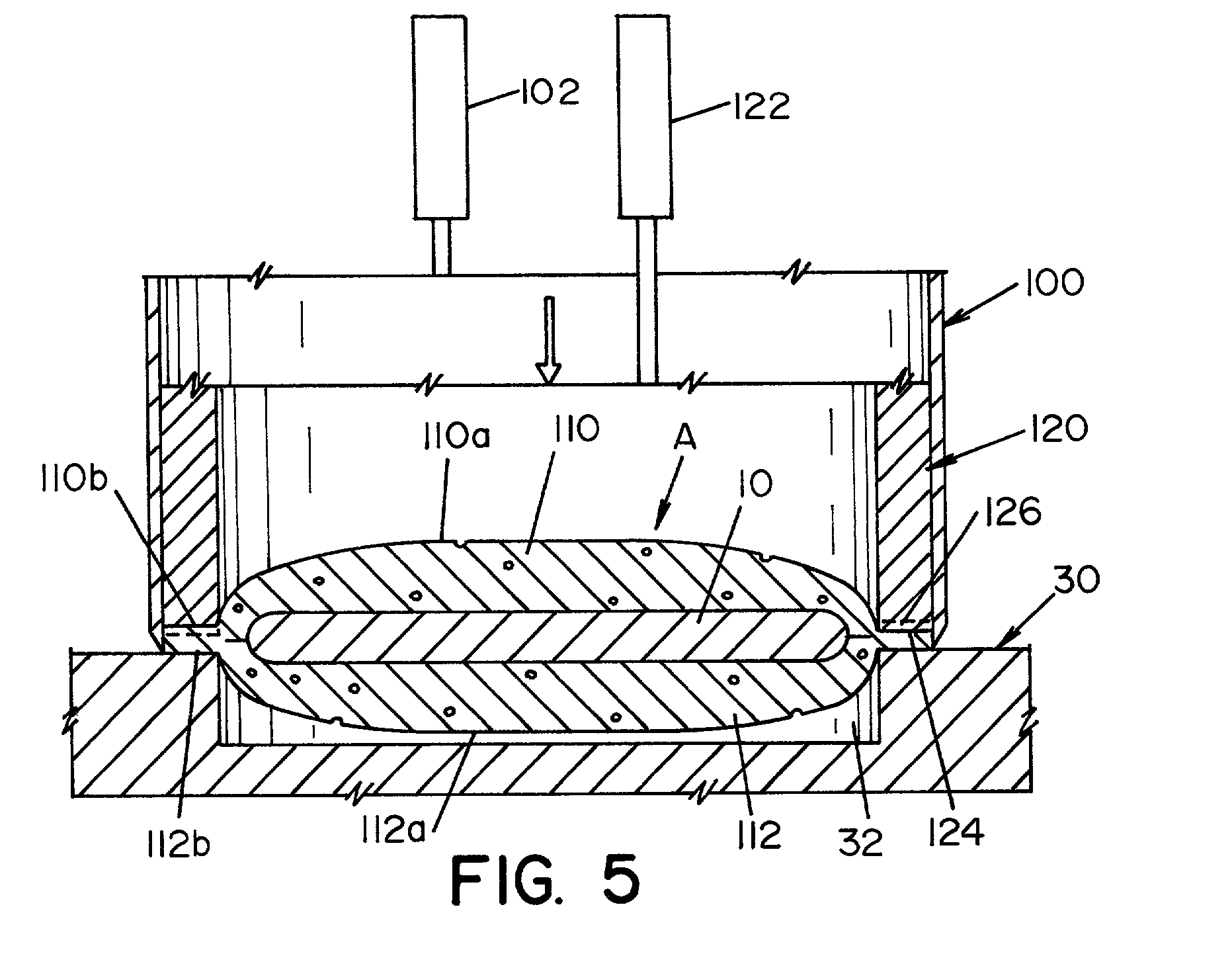

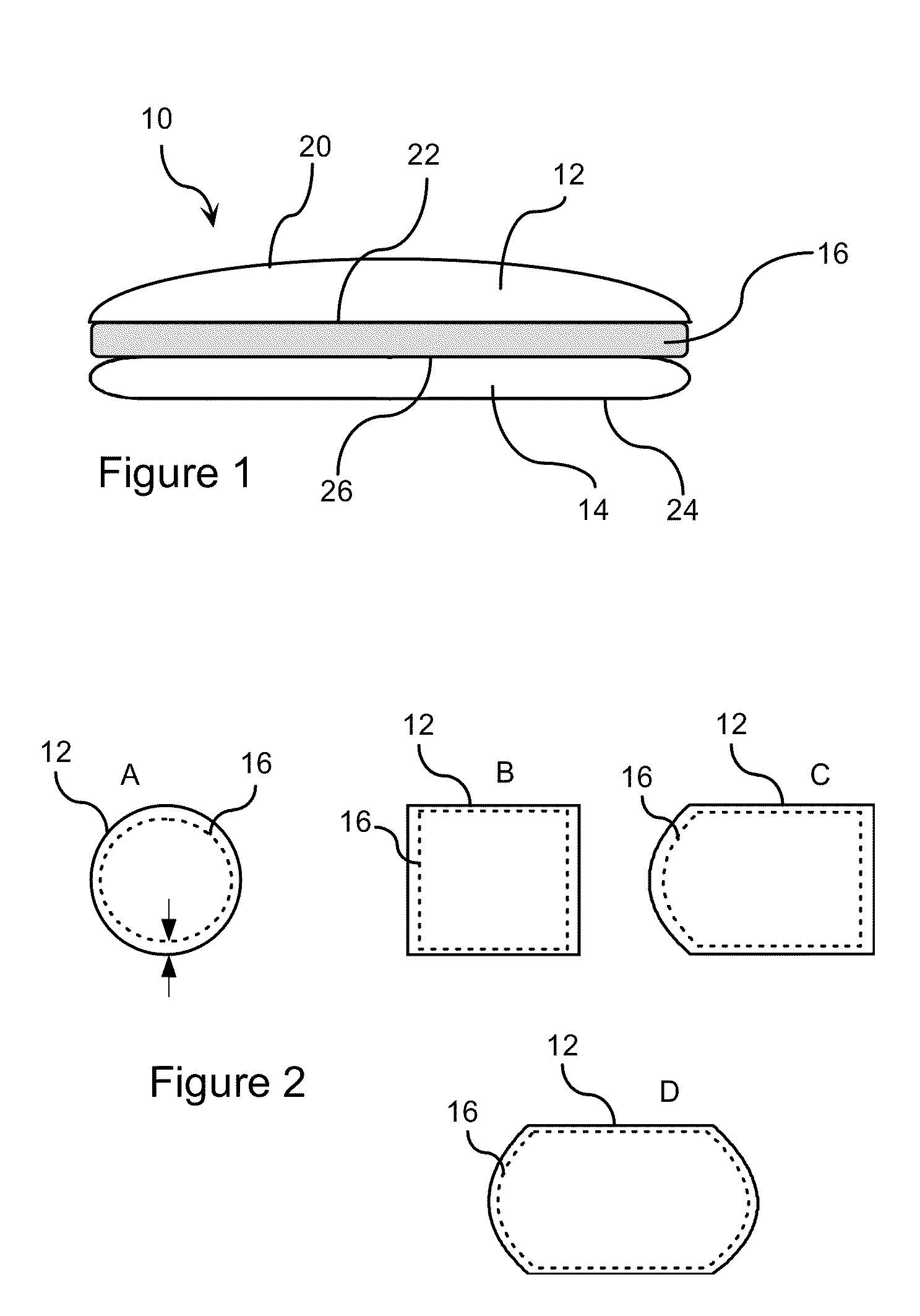

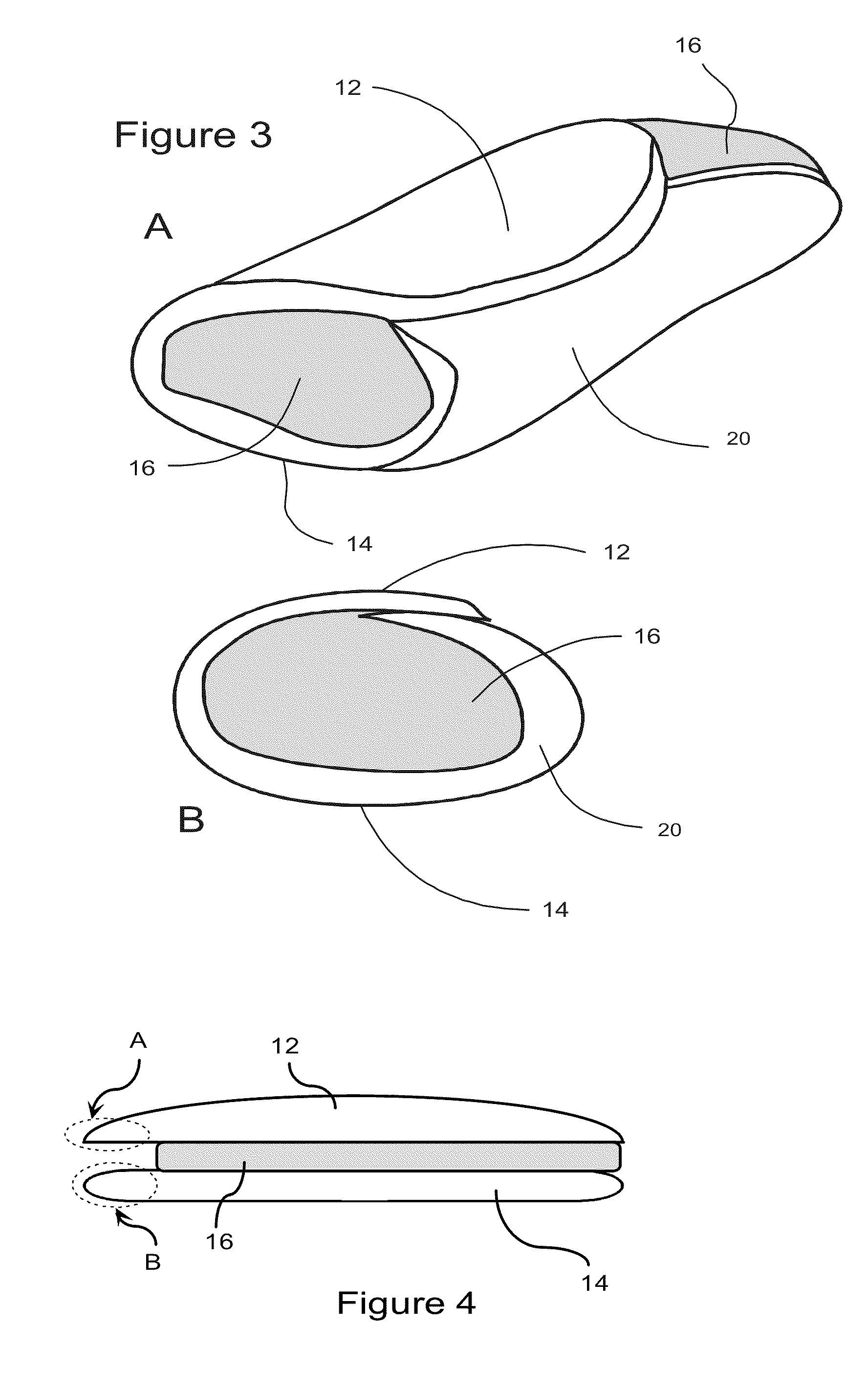

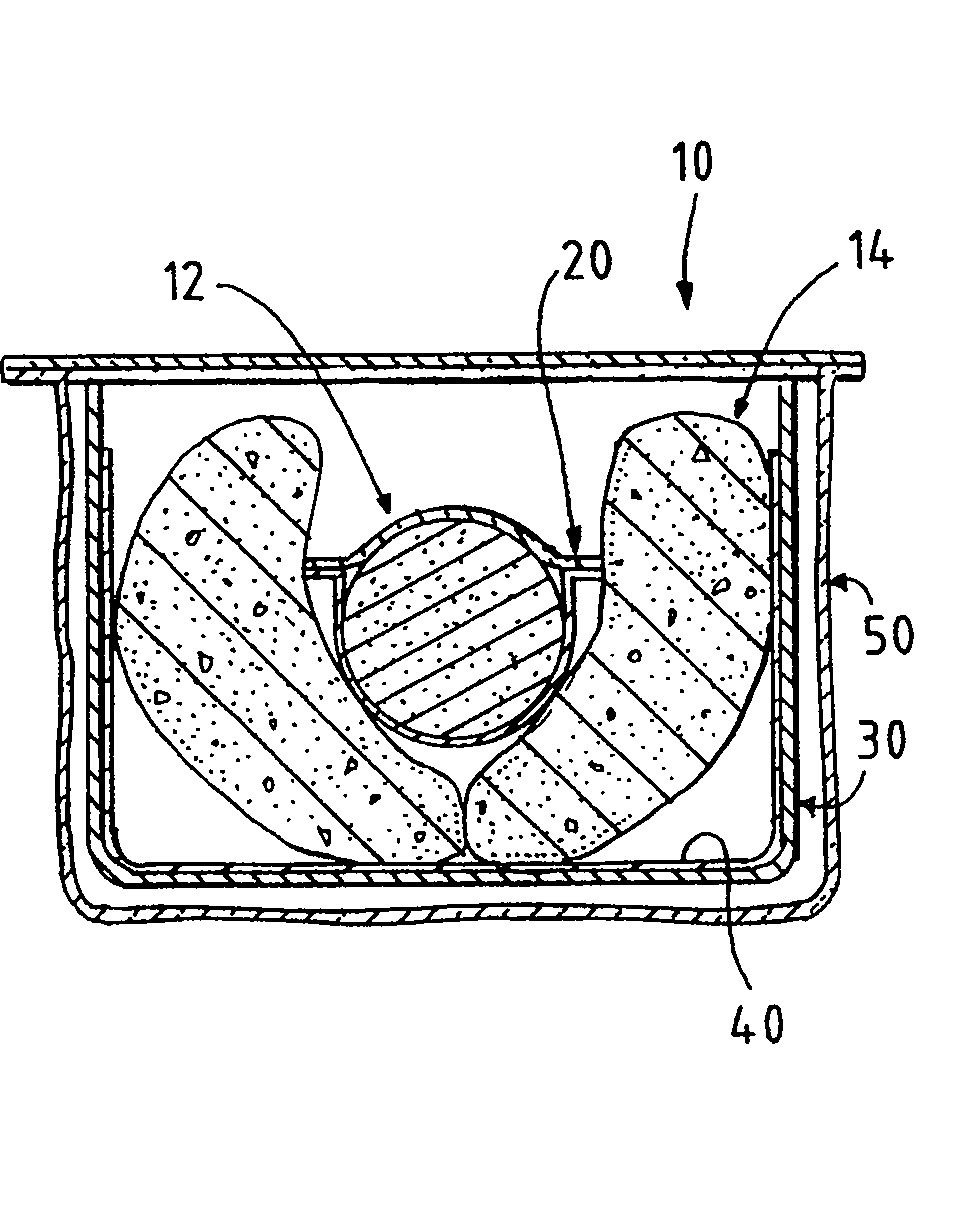

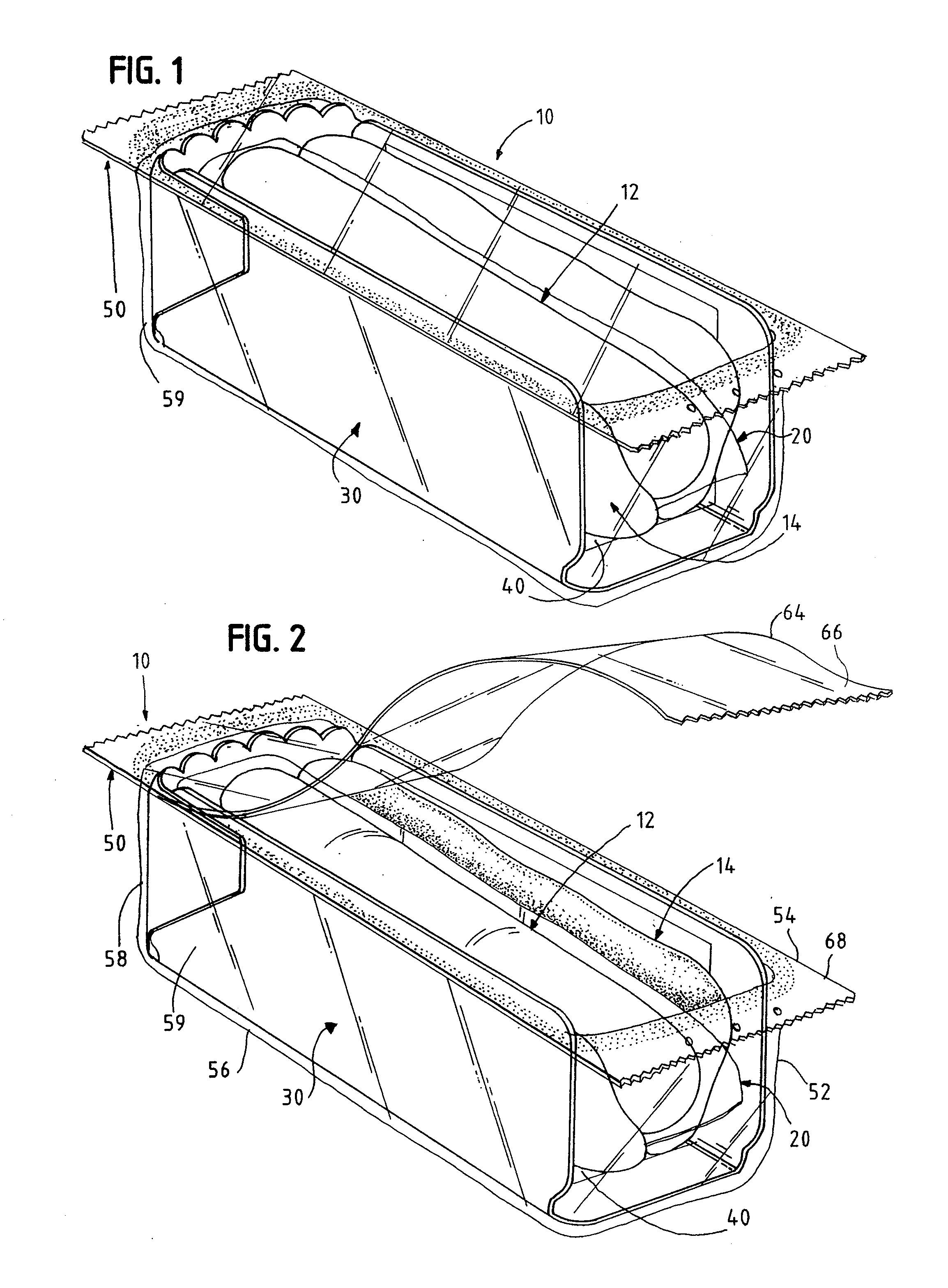

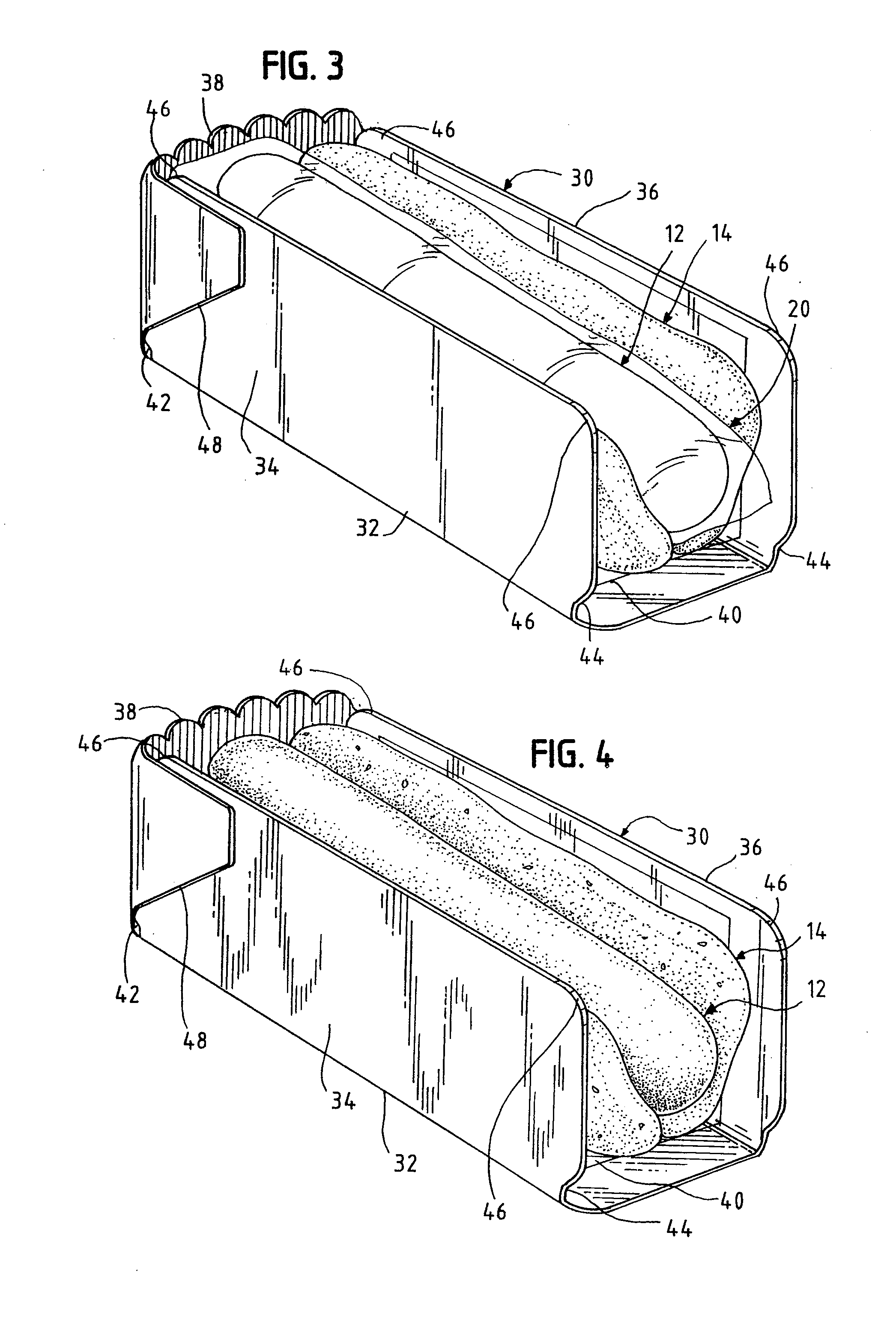

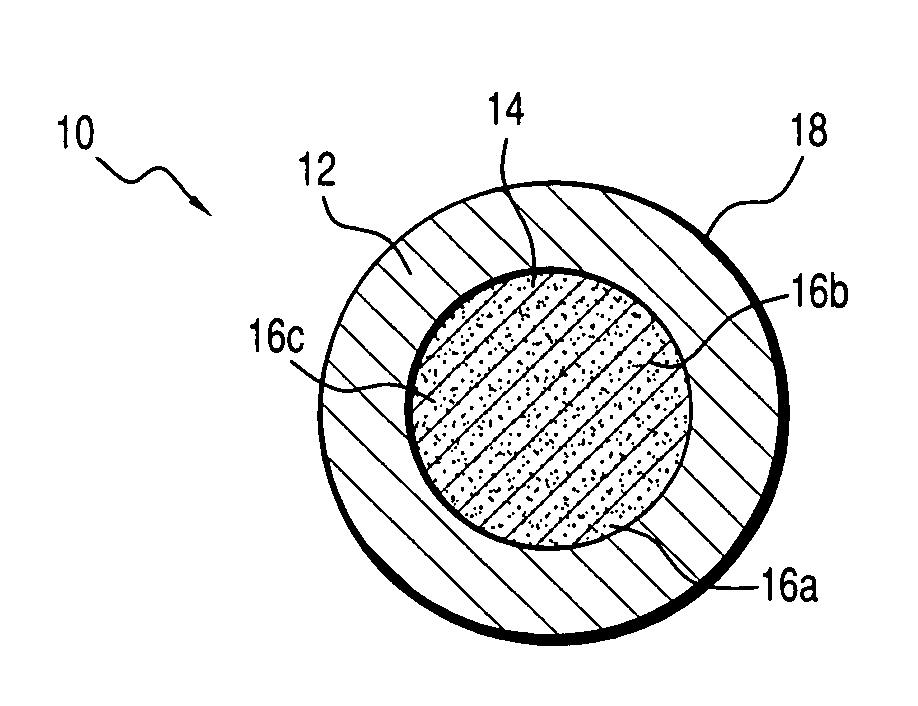

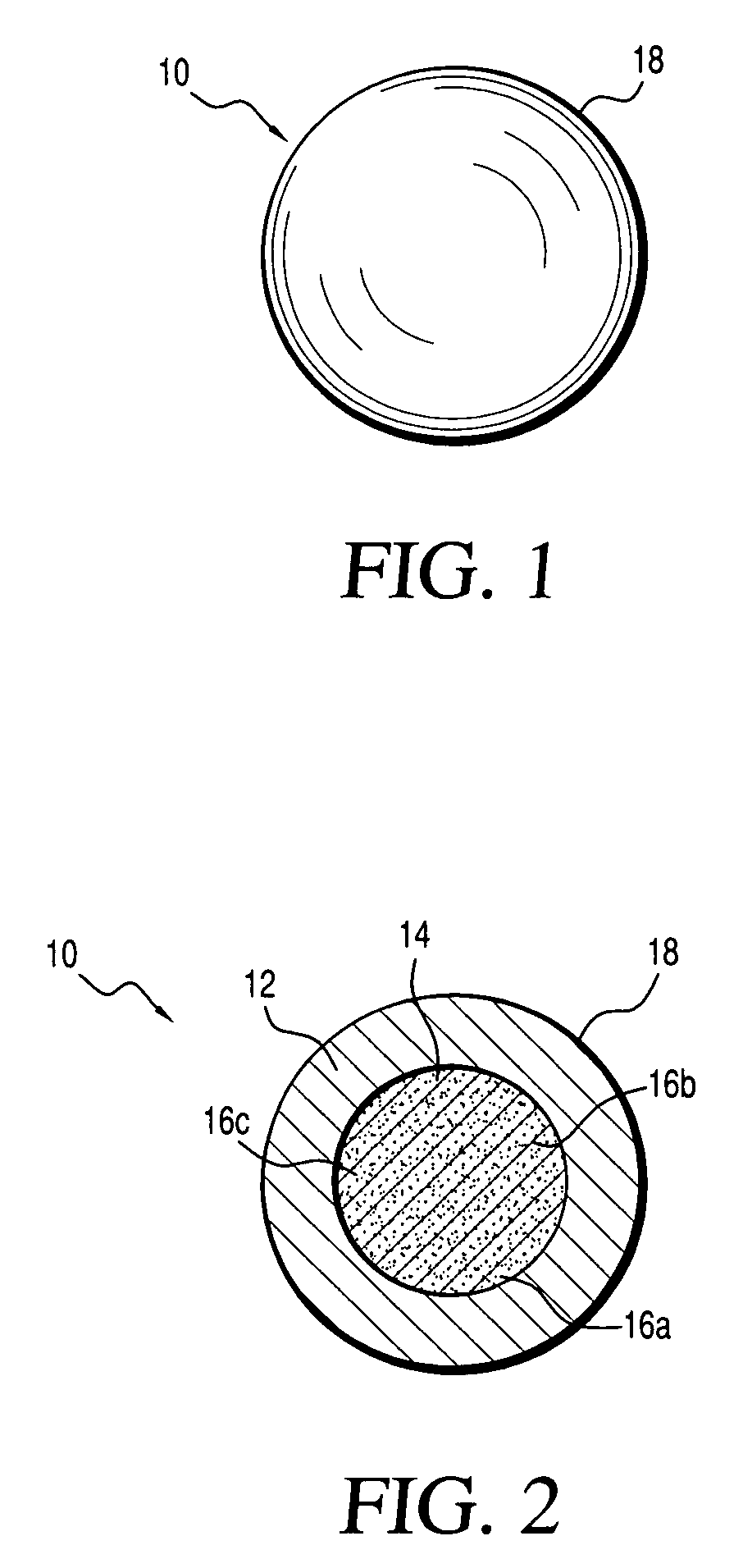

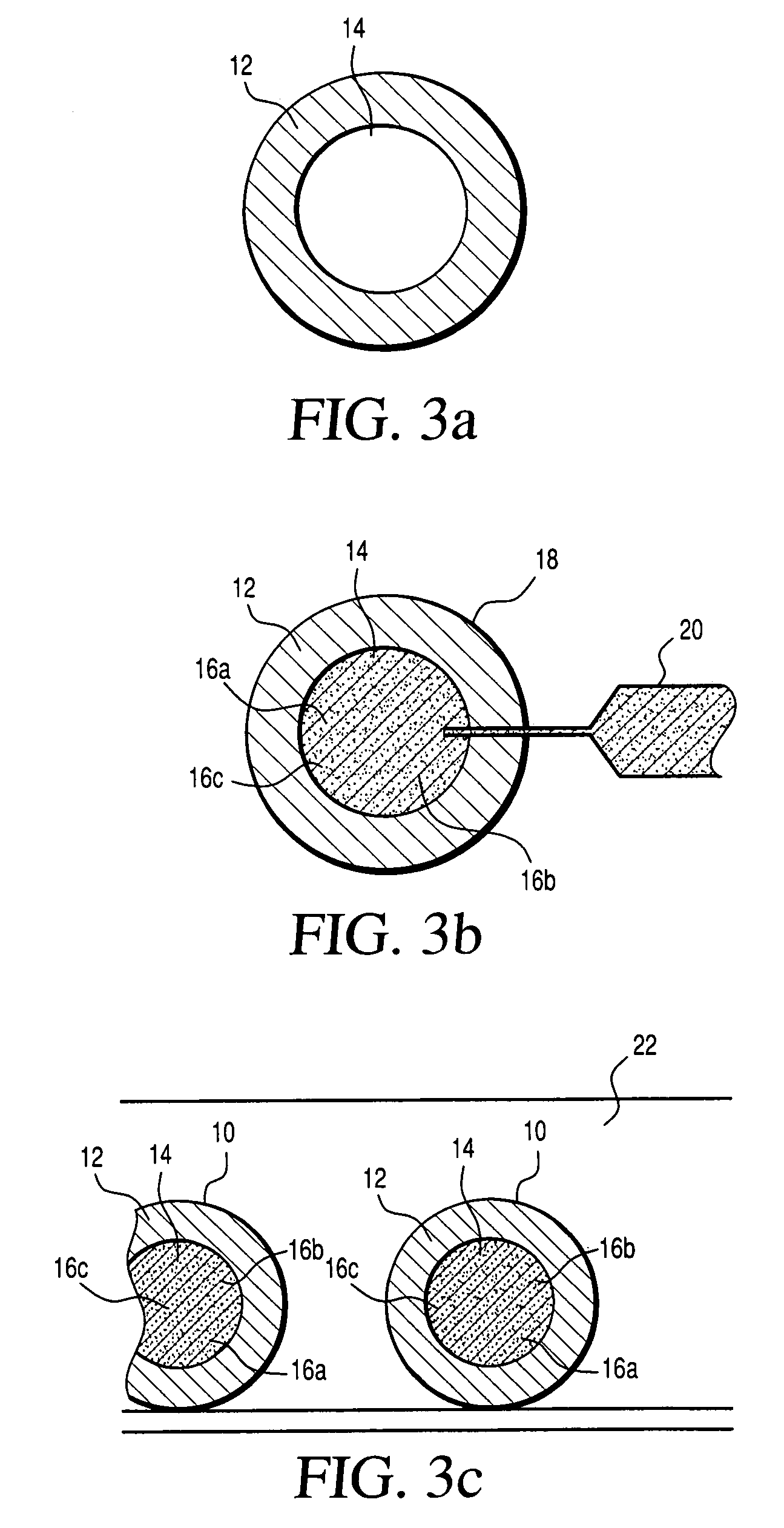

Frozen sandwich and method of making same

InactiveUS20030008037A1Affect resultPositively lockingConfectioneryPreservation by coolingBiomedical engineeringEdge region

A frozen sandwich for commercial sales comprising a first portion of bread cut from a first slice of crusted bread. This first portion has an outer surface, a given periphery and a center area surrounded by a marginal area. A layer of unmelted solid cheese is deposited on the center area and is spaced inwardly from the marginal area. A second portion of bread cut from a second slice of crusted bread and overlying the first portion and the layer of cheese has an outer surface, a periphery generally matching the periphery of the first portion and a marginal area generally matching and coextensive with the marginal area of the first portion. The marginal areas are smashed together sufficiently to form a seal generally matching the peripheries of the bread portions. The surfaces of the bread portions are heat scorched to transform a thin skin of the portions into toasted bread.

Owner:THE J M SMUCKER CO

Dough-enrobed foodstuff

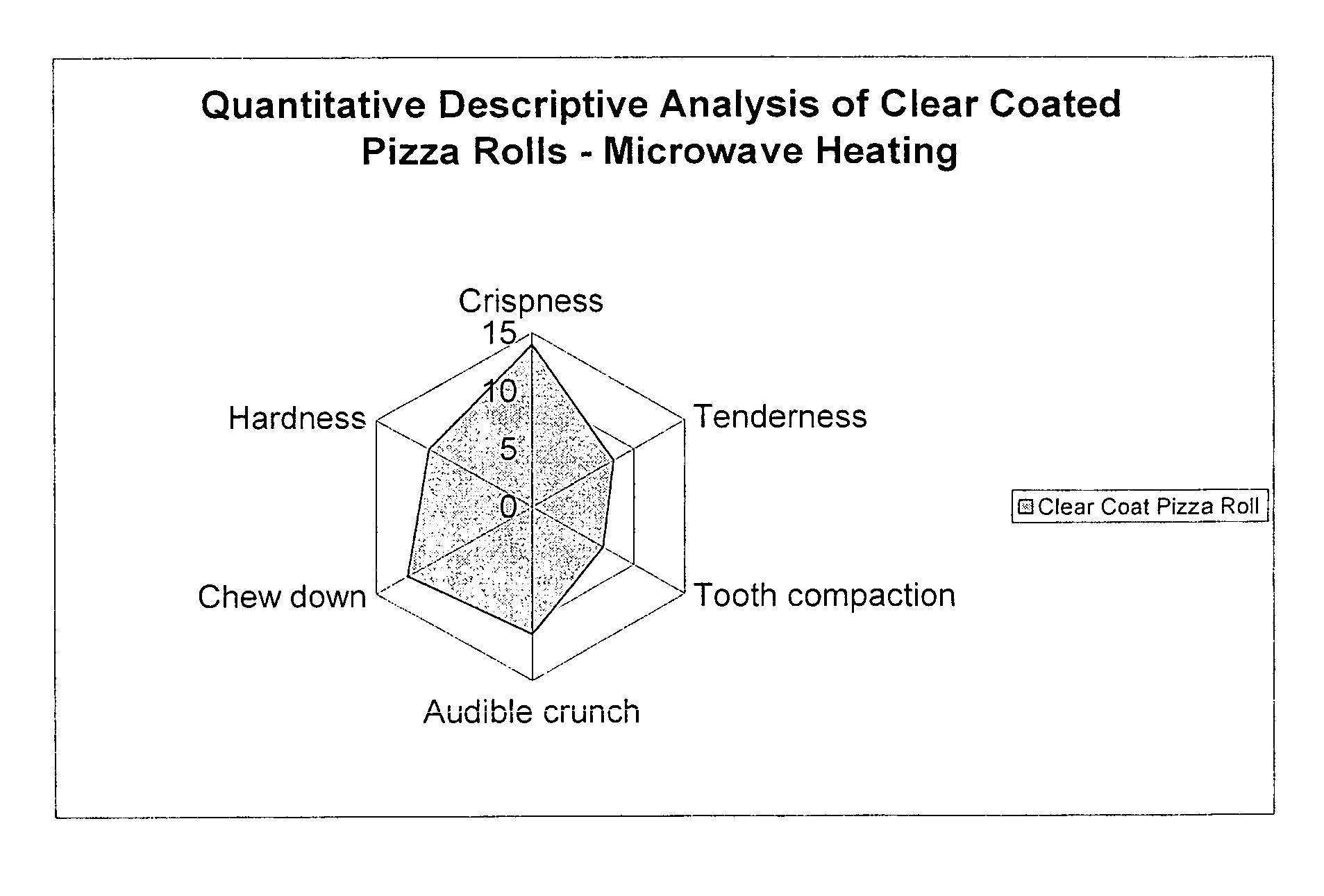

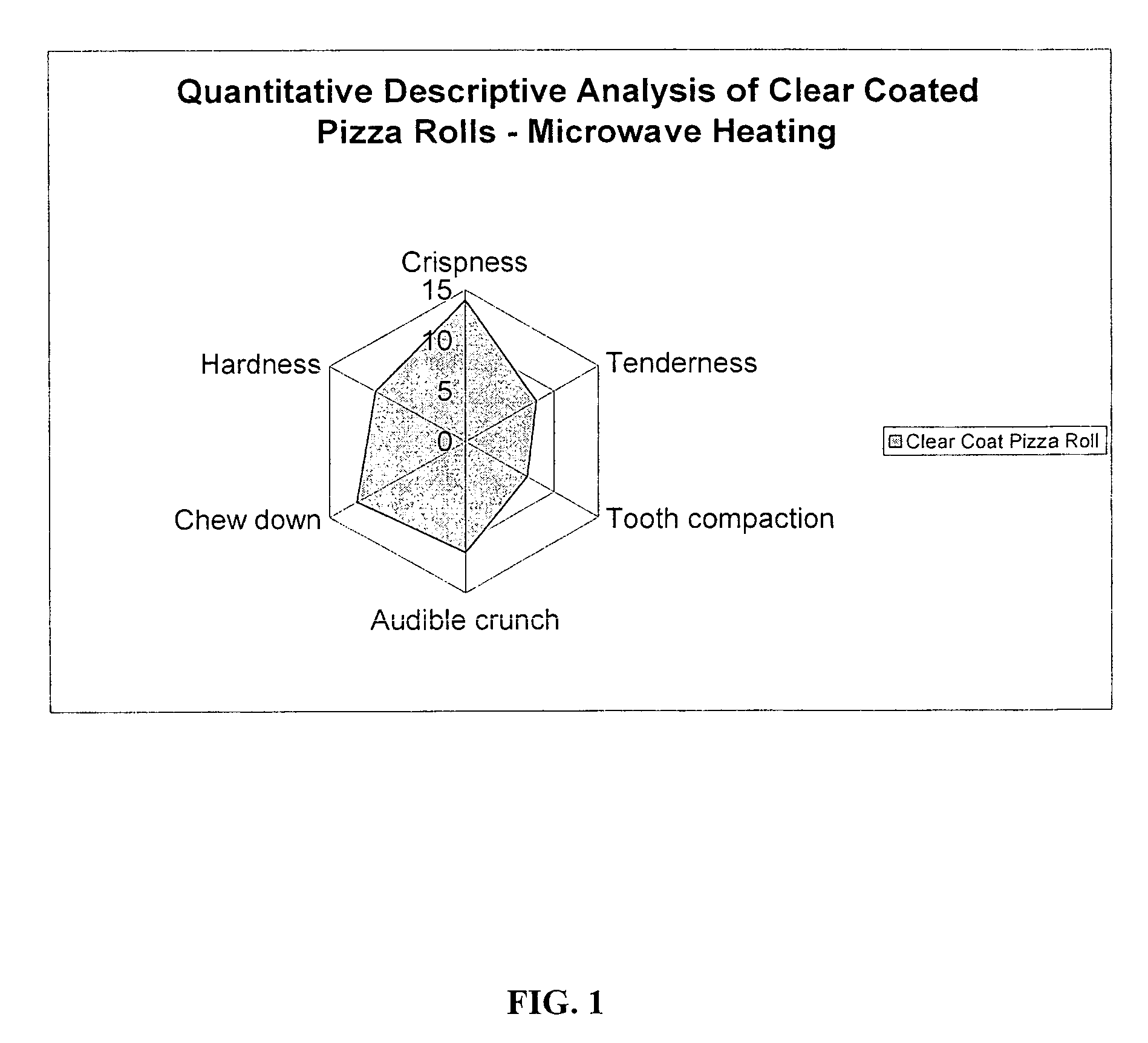

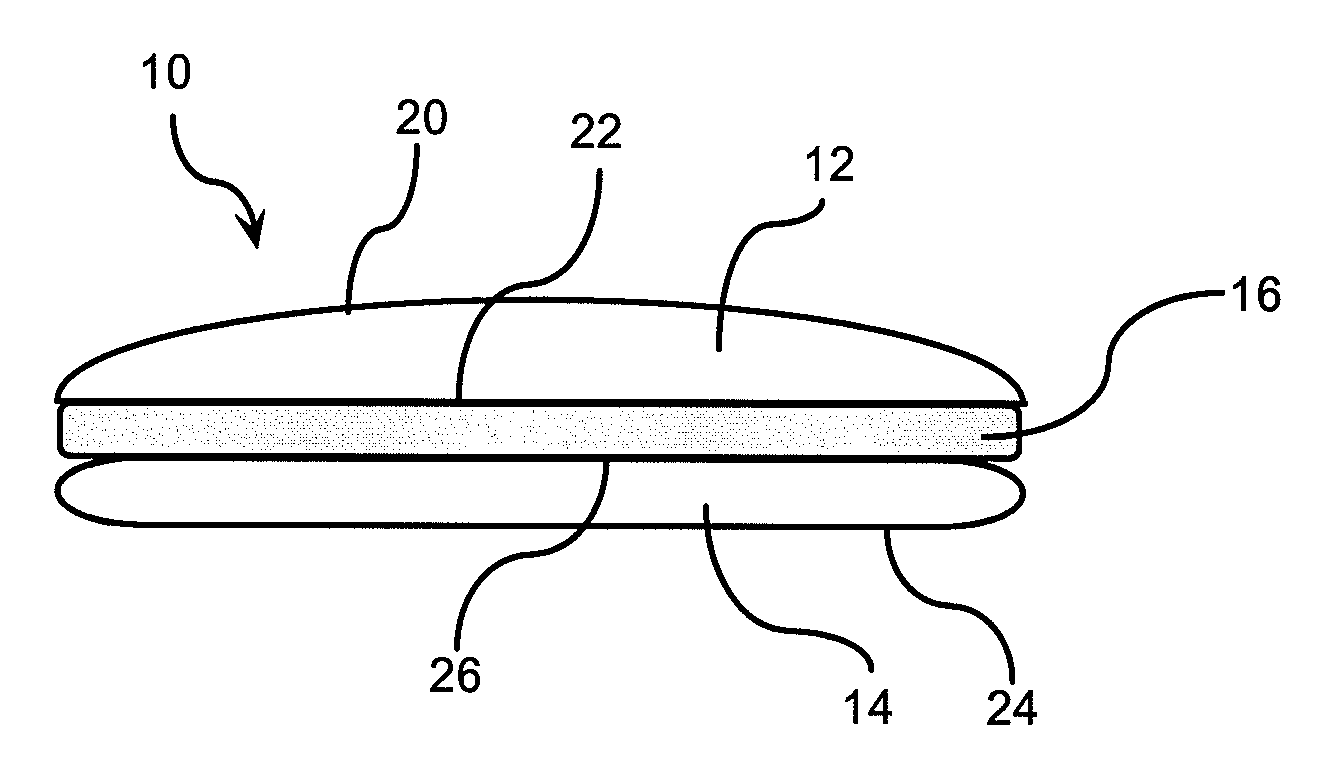

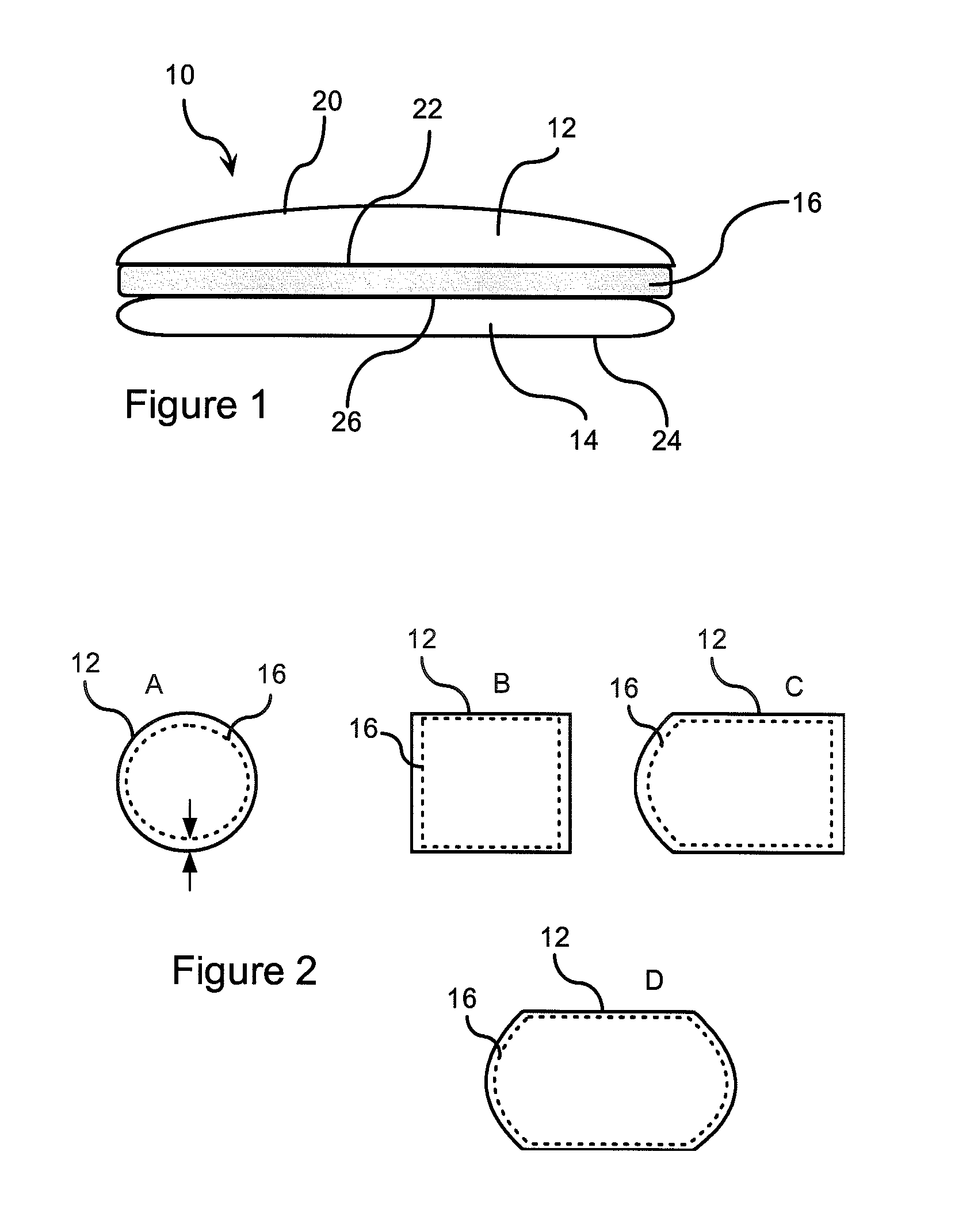

InactiveUS7998512B1Clear appearanceImprove crispnessConfectioneryPreservation by coolingFood itemFOOD STARCH

A dough-enrobed foodstuff is provided that contains a filling and is coated with a coating composition that includes a dextrin where less than 50% of the dextrin is soluble in about 25° C. (77° F.) water and modified food starch having an amylose content of less than 50% based on the weight of the modified food starch. The coated foodstuff is thermally processed such that the coating becomes substantially clear. The coated thermally processed foodstuff is then frozen. On reheating, the coated foodstuff is crispier than an uncoated, frozen foodstuff after reheating and substantially prevents the filling from breaking the dough-enrobed foodstuff upon reconstitution by subsequent thermal processing.

Owner:ADVANCED FOOD TECH

Baked Microwavable Frozen Bread and Bakery Products

InactiveUS20080063755A1Satisfactory textureSatisfactory chewability characteristicBakery product refreshing by heating/thawingDough treatmentMicrowave ovenFood products

A fully assembled frozen food product is provided which comprises a bread portion having a top portion and a bottom portion and having a filling between, and co-extensive with, the top and bottom portions, wherein the fully assembled frozen food product can be heated in a microwave oven to provide a heated food product which is then ready to be eaten, wherein the bread portion of the heated food product is not dried out and wherein the filling in the heated food product has an essentially uniform temperature.

Owner:KRAFT FOODS GRP BRANDS LLC

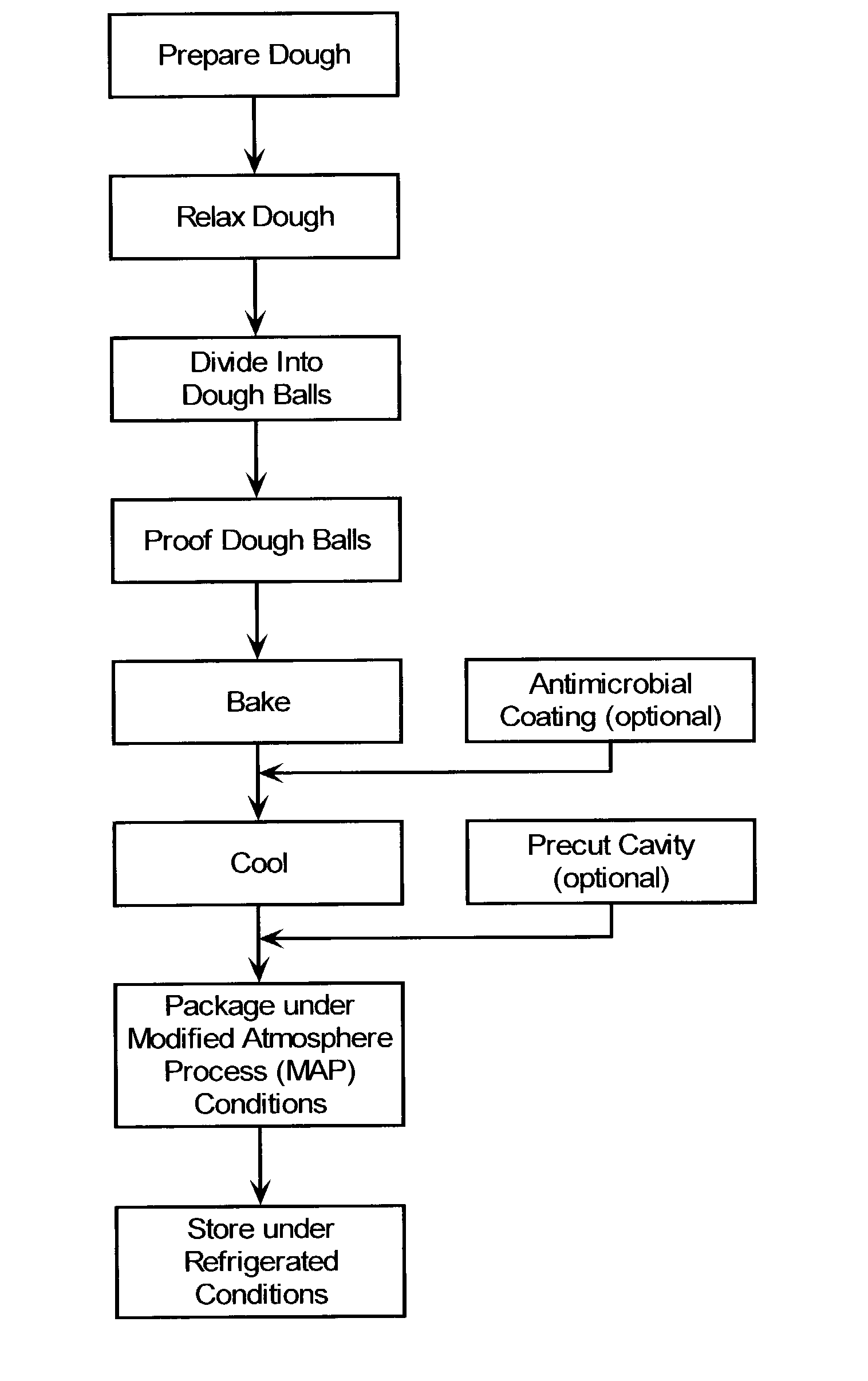

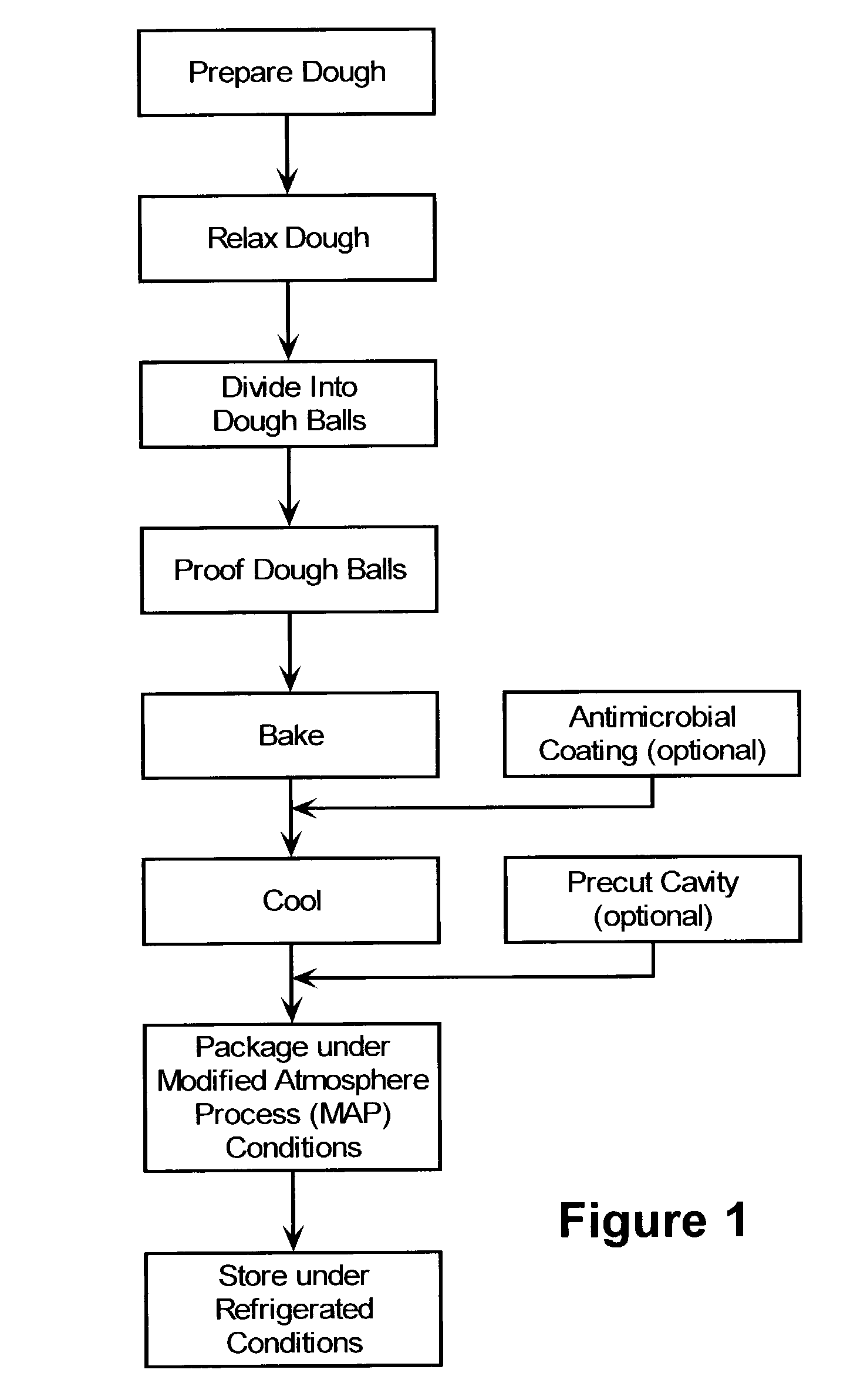

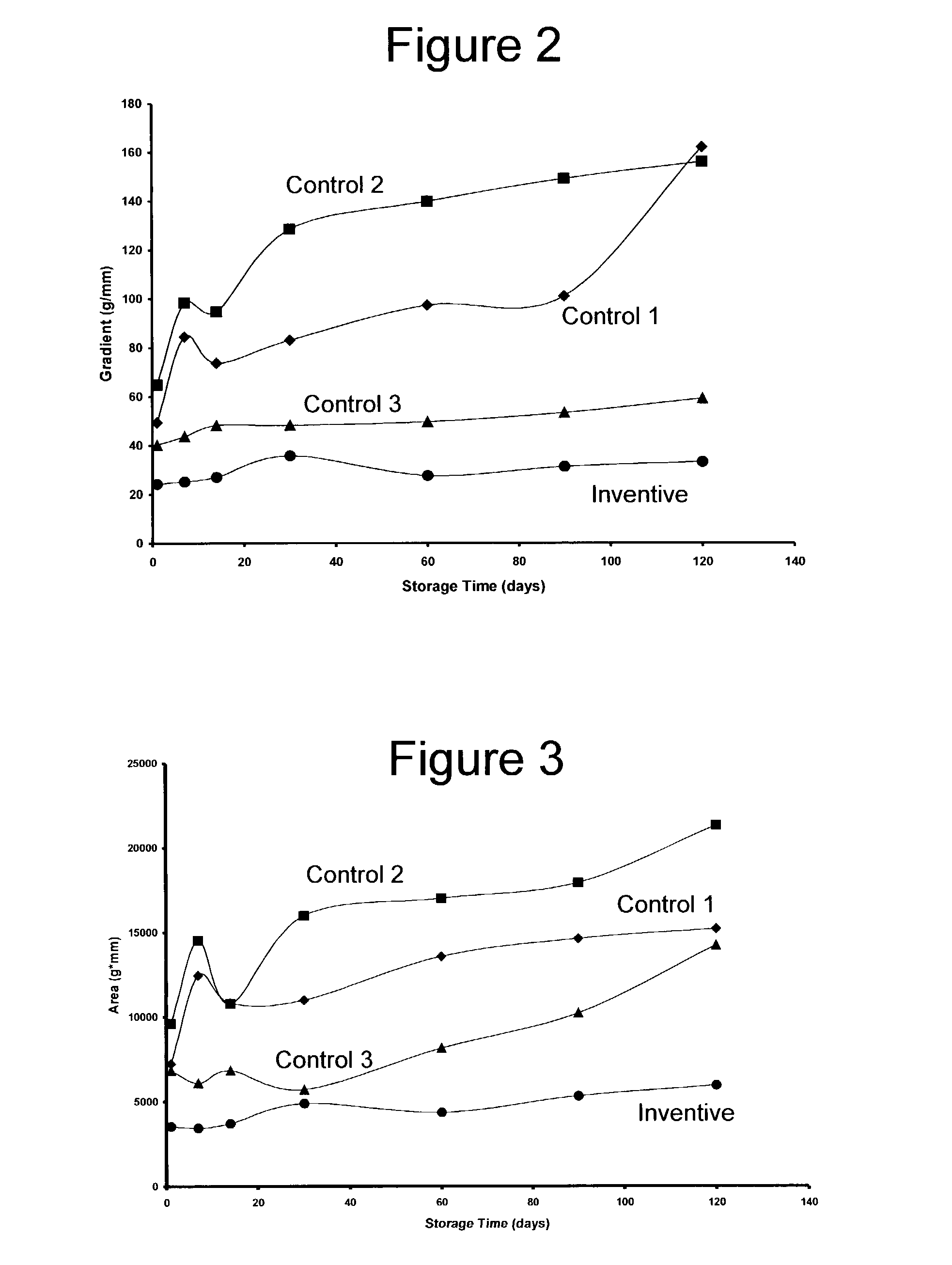

Refrigerated extended shelf-life bread products

InactiveUS7014878B2Satisfactory soft textureSatisfactory chewability characteristicReady-for-oven doughsMilk preparationTO-18High-fructose corn syrup

A fully baked bread product is provided which can be stored for extended periods of time and which retains its desirable soft texture for the shelf life (e.g., at least about 3 months) of the product if maintained under a modified atmosphere (i.e., low oxygen and preferably inert gas) at refrigerated conditions (i.e., about 35 to about 45° F.). The fully baked bread is prepared from dough comprising, in baker's percentages, about 100 pounds flour, about 0.75 to about 3.5 pounds salt, about 0.2 to about 1 pounds microbial inhibitor, about 0 to about 3 pounds gluten, about 1 to about 5 pounds leavening agent, about 0.1 to about 1 pound enzyme, about 9 to 18 pounds high fructose corn syrup, about 3 to about 10 pounds shortening, about 0.1 to about 3 pounds mono- and diglycerides, and about 45 to about 60 pounds of water.

Owner:KRAFT FOODS GRP BRANDS LLC

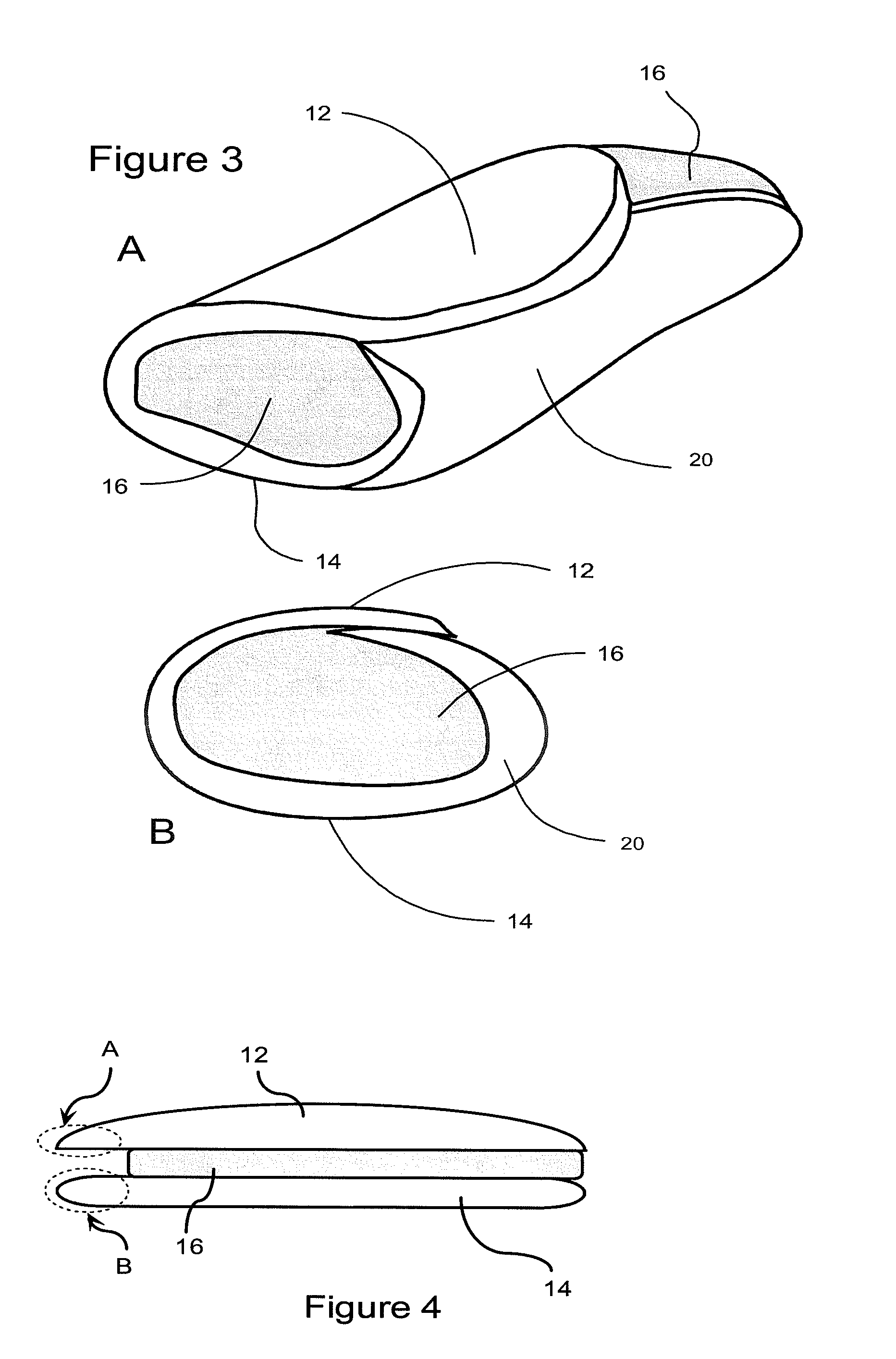

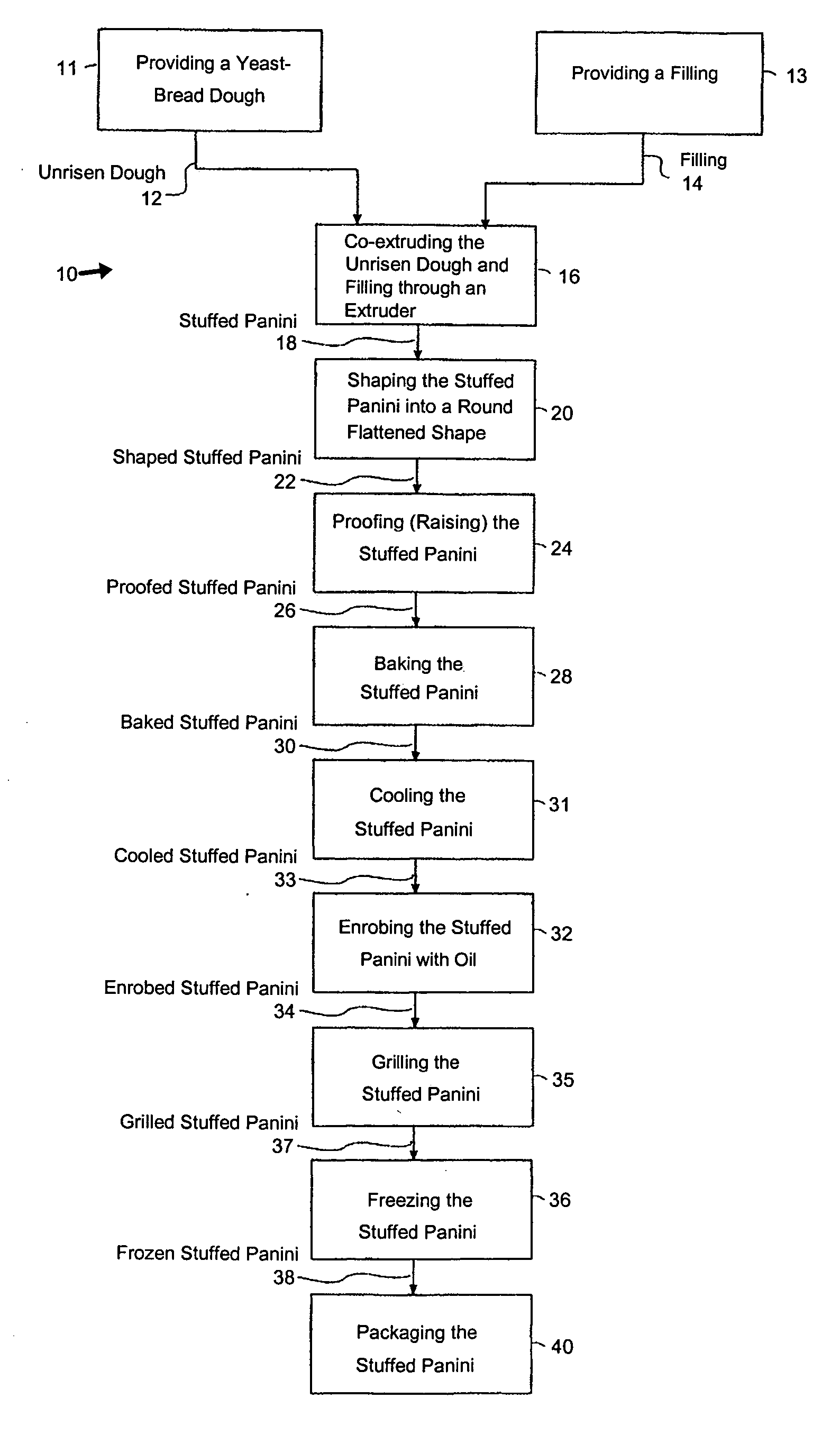

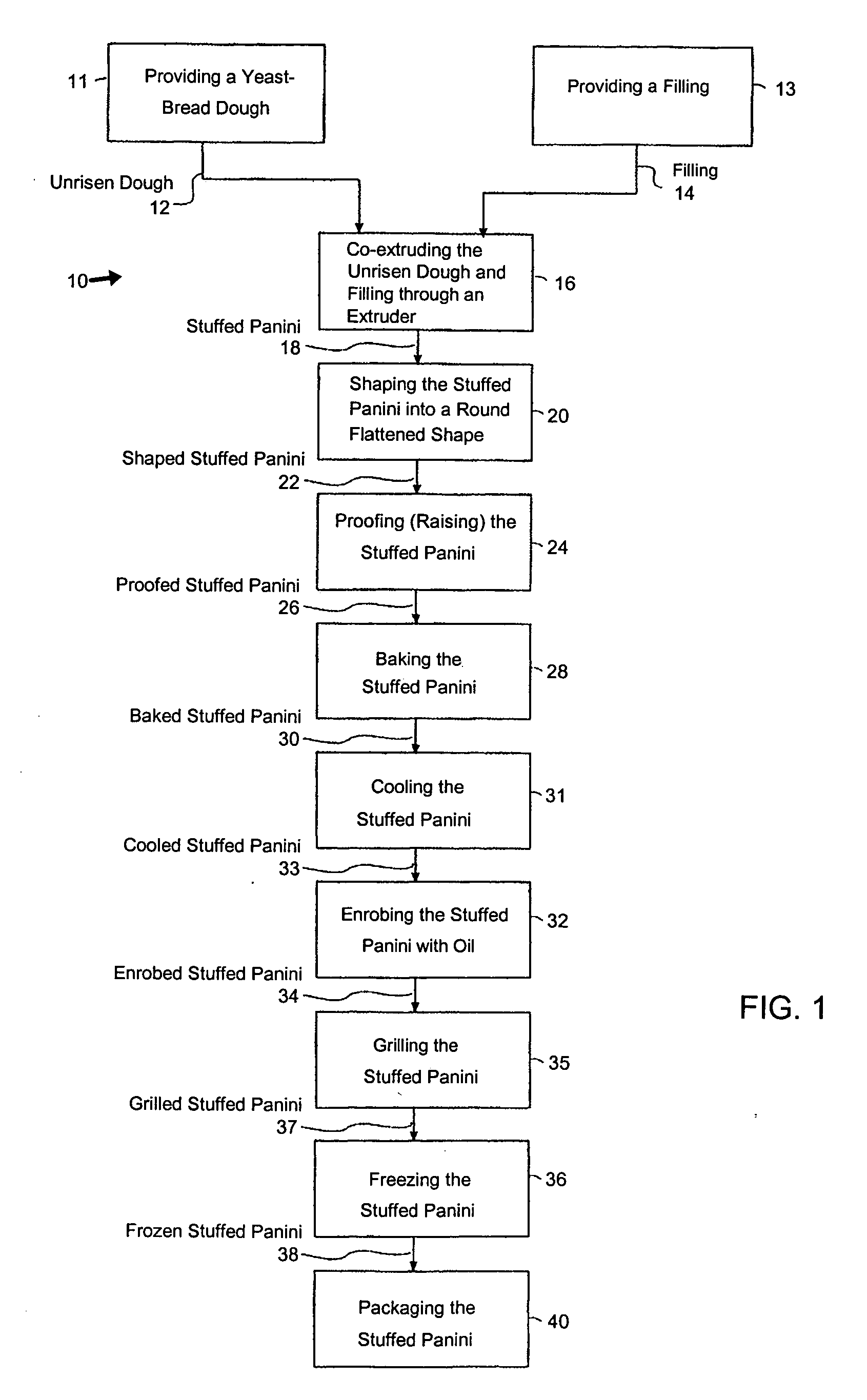

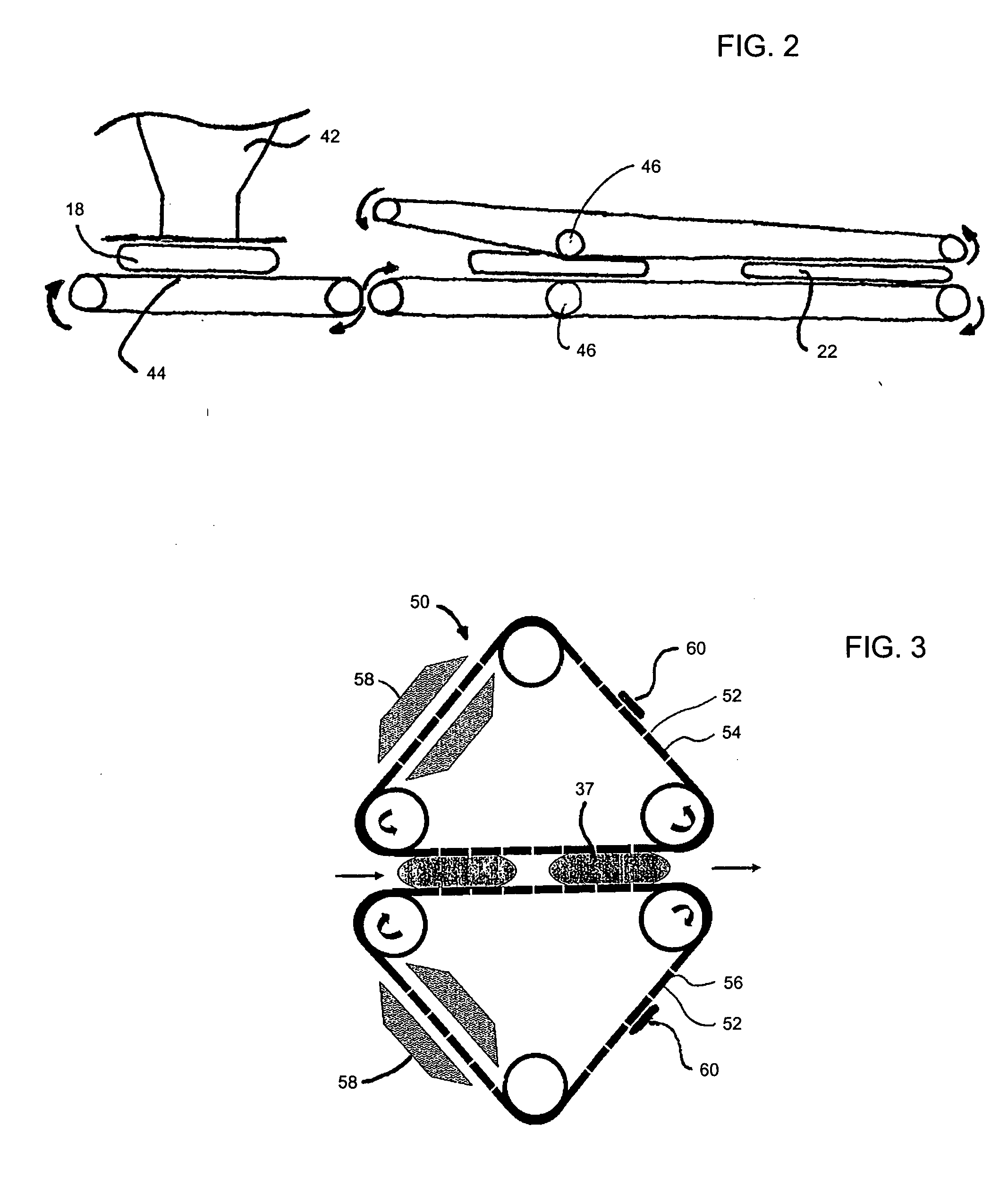

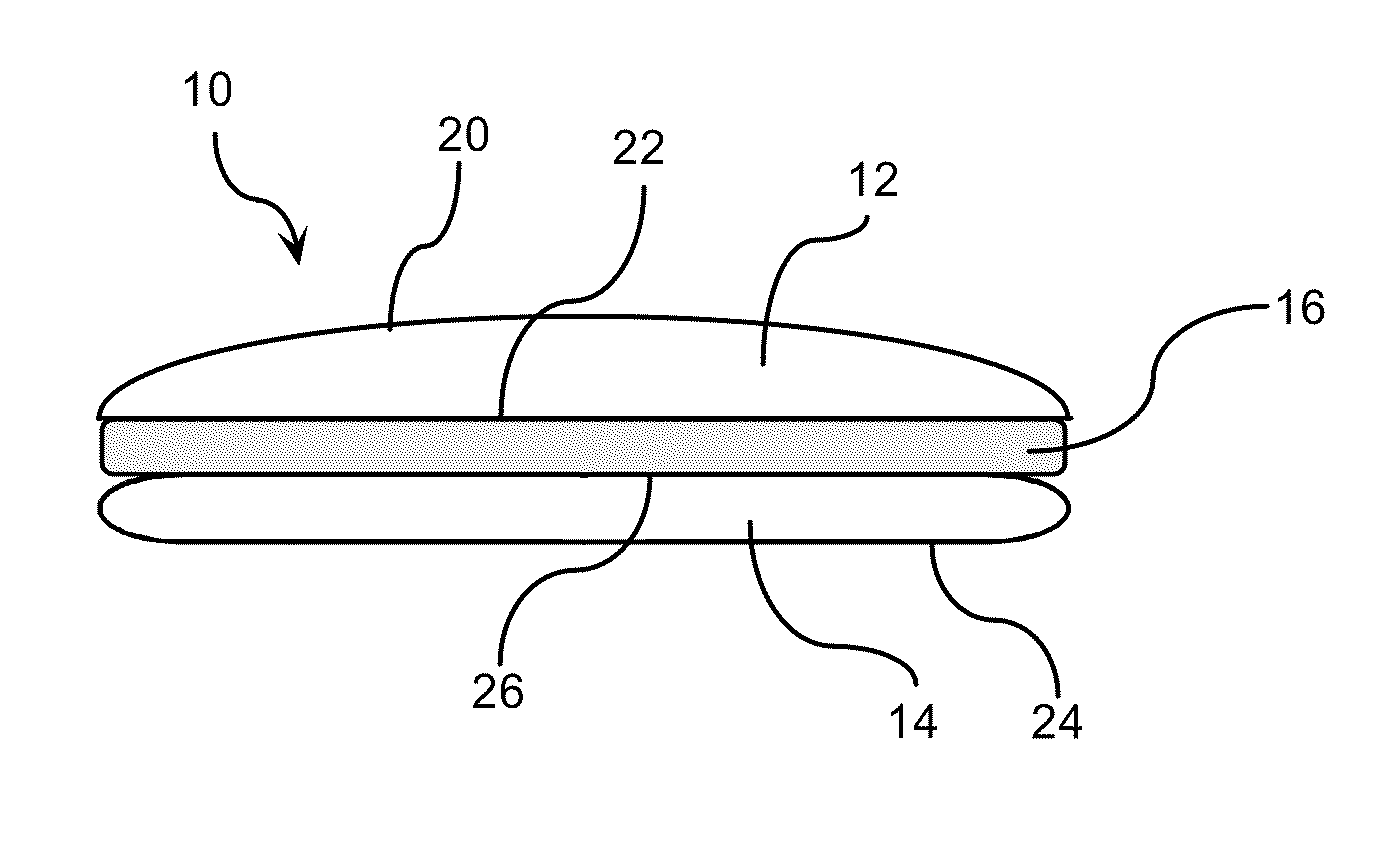

Frozen filled yeast-leavened bread product and a method for making the product

ActiveUS20070059413A1Eliminate leaksEliminate all of fillingPreservation by coolingBaking processesCooking & bakingFood science

A frozen, filled, yeast-bread product and a method for producing the same, the method including coextruding an unrisen yeast-bread dough and a filling through an extruder that is capable of at least encasing the filling with the unrisen yeast-bread dough to form a filled, unrisen yeast-bread dough; shaping the filled, unrisen yeast-bread dough into a consistent flattened shape; proofing, baking, cooling, enrobing, grilling and freezing the filled, unrisen yeast-bread dough to form a frozen, filled, yeast-leavened bread product that experiences substantially no leaking of filling from out of the bread product.

Owner:PAULUCCI JENO F

Baked products containing soybean protein and process for producing soybean protein

InactiveUS20040151817A1Low efficacyGood colorDough treatmentLeguminous plant bakery productsSolid componentAlcohol

The invention provides a process for producing a baked food of wheat flour by using a soybean protein in which NSI shows a low denature value of 40 or more, the content of solid component extracted with a solvent mixture of chloroform and methanol (2:1) is 2.0 wt % or less, and the crude protein content is 63% or more. When wheat flour in dough is replaced with the soybean protein at a small ratio, baked foods of wheat flour which are resistant to freezing and show good texture even after thawing in a microwave oven can be obtained. Moreover, a process for making a baked food mainly comprising soybean proteins, which has a good taste and texture and is appropriately taken by human, can be provided by replacing most part or all of wheat flour with a soybean protein. In addition, the invention provides a process for producing a low denatured soybean protein having a good color and taste which comprises treating low denatured defatted soybeans as proteinous materials used in baked foods with an alcohol while regulating a decrease in NSI.

Owner:FUJI OIL CO LTD

Baked Microwavable Frozen Bread and Bakery Products

InactiveUS20090155426A1Satisfactory textureSatisfactory chewability characteristicReady-for-oven doughsBakery product refreshing by heating/thawingMicrowave ovenFood products

A fully assembled frozen food product is provided which comprises a bread portion having a top portion and a bottom portion and having a filling between, and co-extensive with, the top and bottom portions, wherein the fully assembled frozen food product can be heated in a microwave oven to provide a heated food product which is then ready to be eaten, wherein the bread portion of the heated food product is not dried out and wherein the filling in the heated food product has an essentially uniform temperature.

Owner:KRAFT FOODS GRP BRANDS LLC

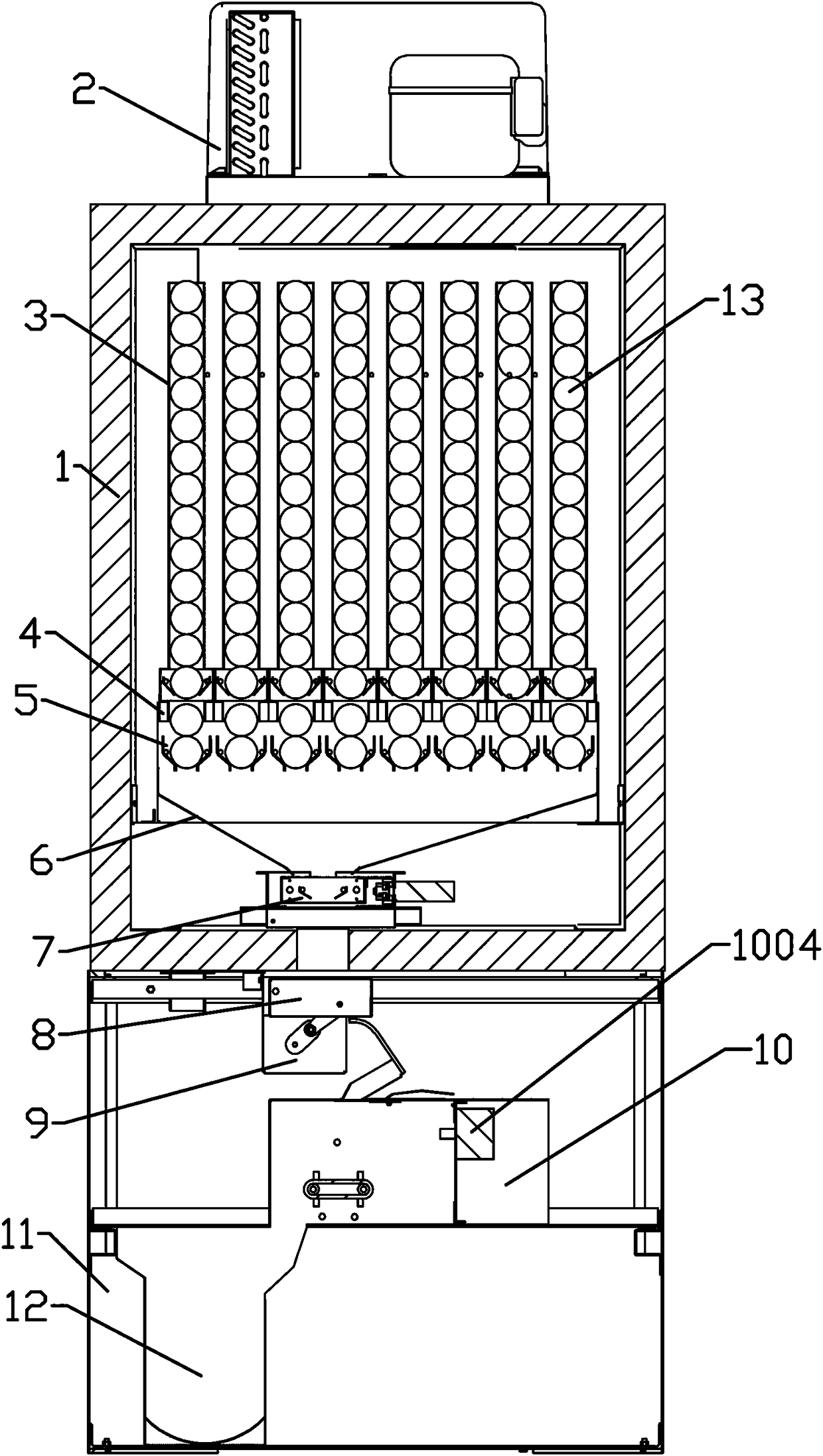

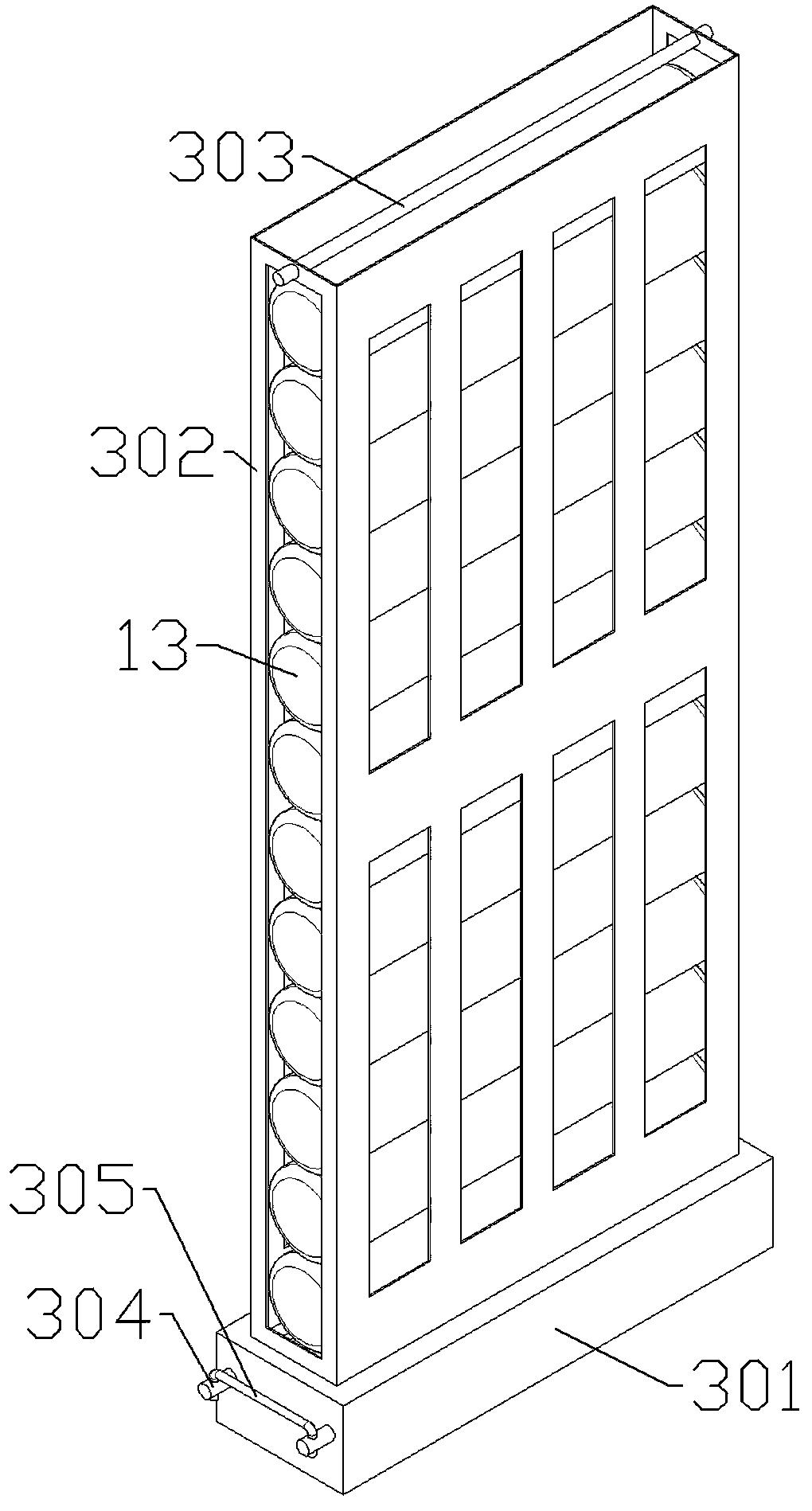

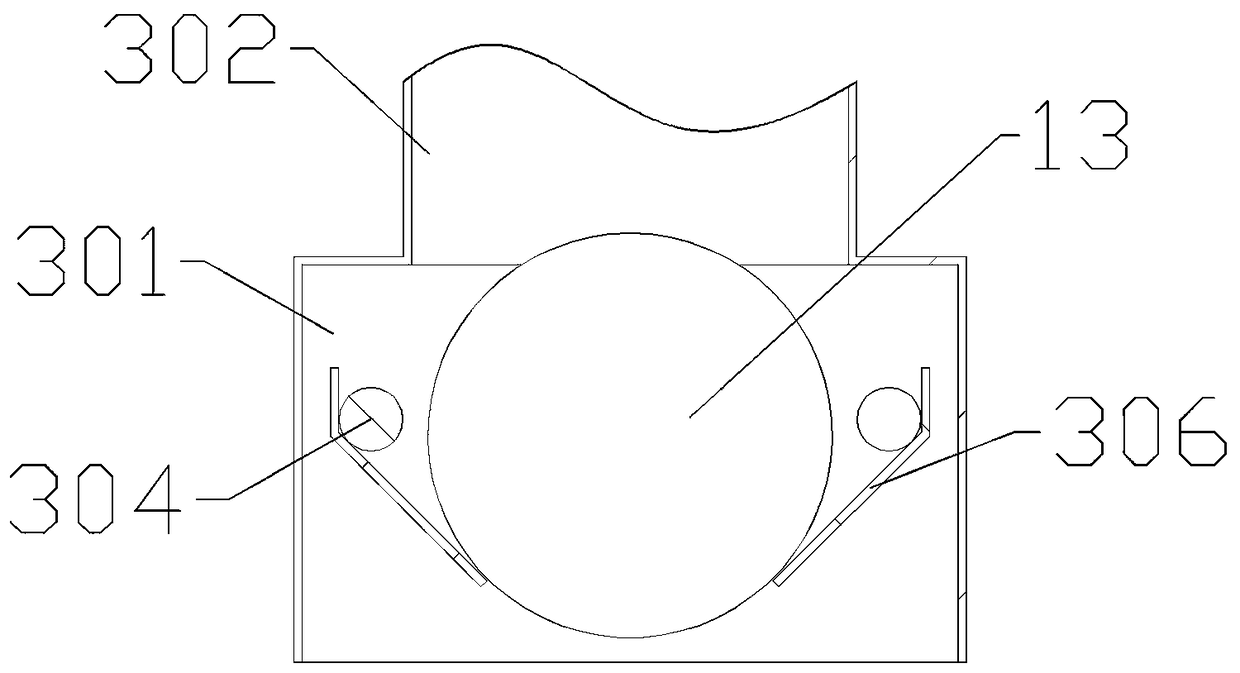

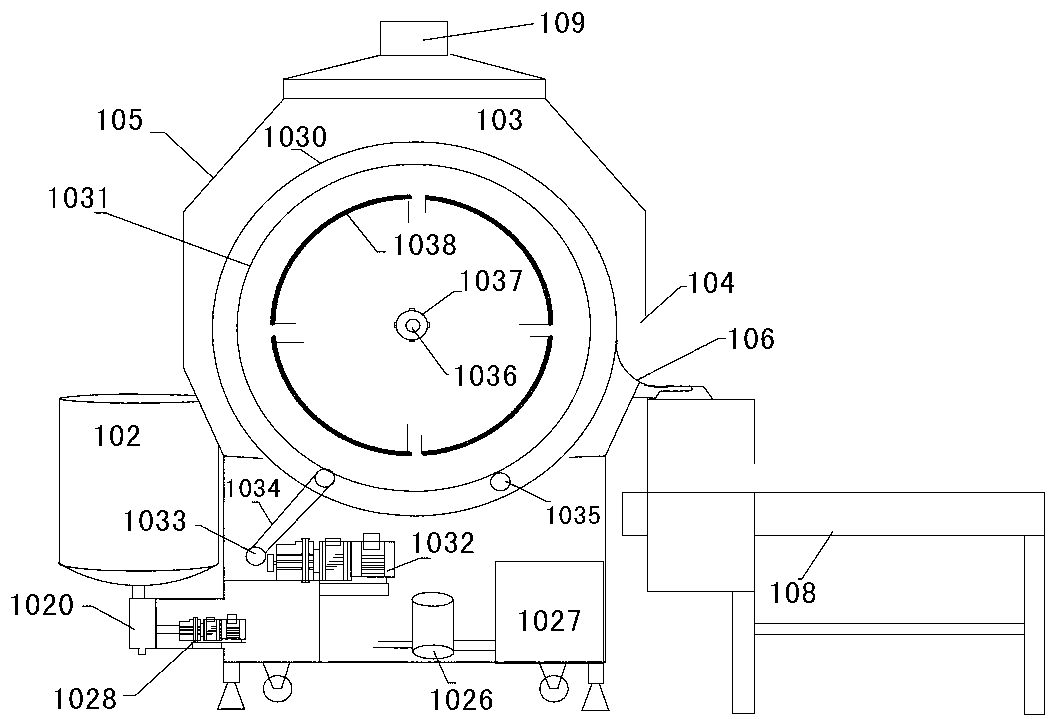

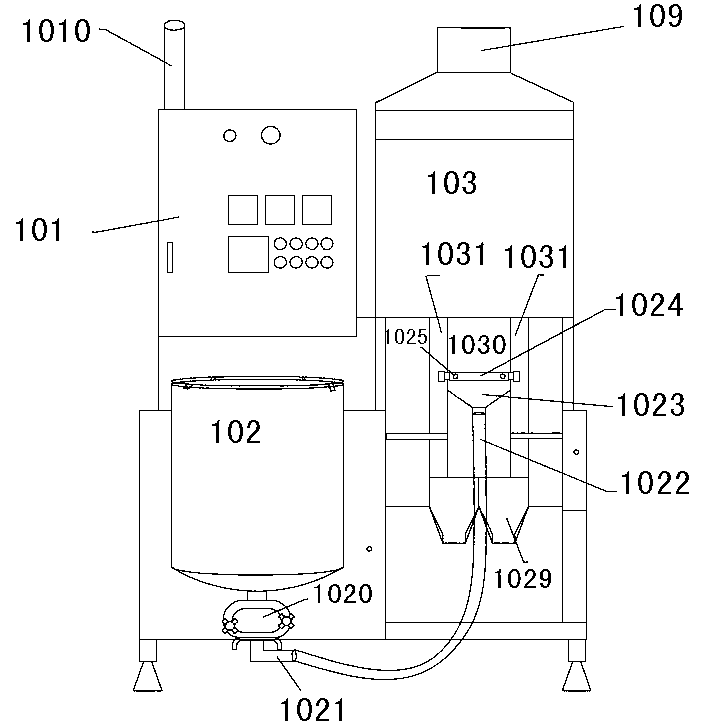

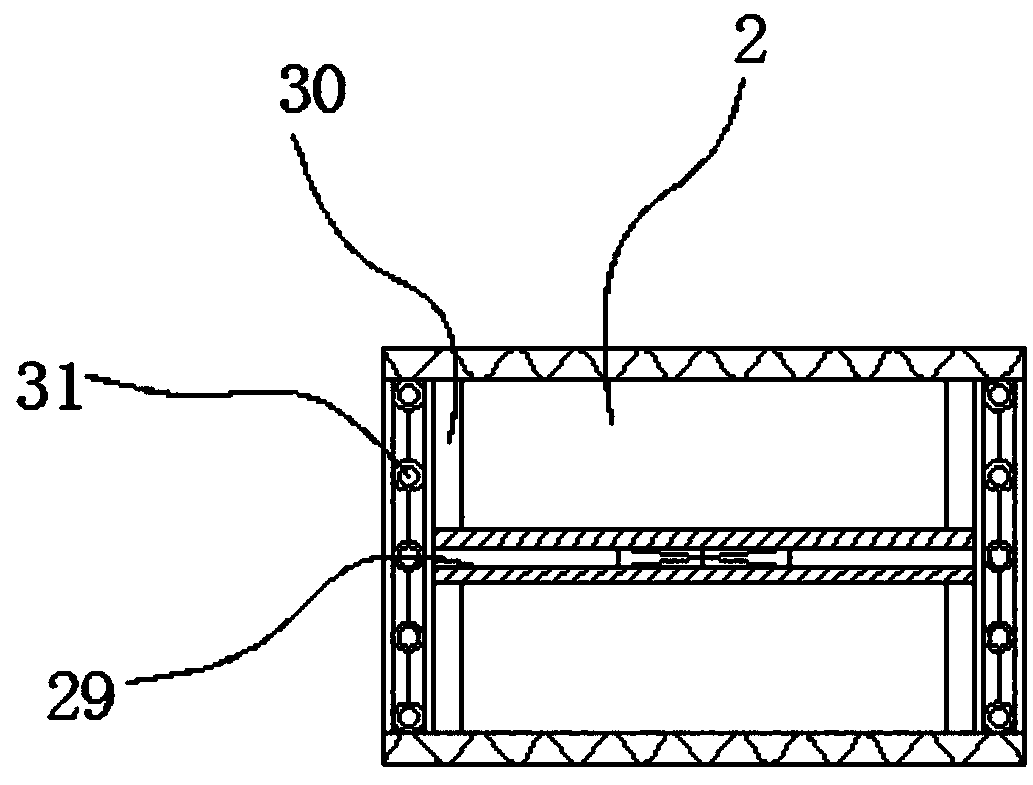

Columnar quick-frozen food baking heating unmanned vending machine

PendingCN109300254AAvoid destructionEasy to transportDough treatmentPreservation by coolingCooking & bakingPulp and paper industry

The invention relates to the field of vending machines, in particular to a columnar quick-frozen food baking heating unmanned vending machine. The machine comprises a frozen material cabin; a lower box body is arranged at the lower end of the frozen material cabin; an oven is arranged in the lower box body; a discharging bracket is arranged on the lower side of the oven; and a material getting hole is formed in a side wall of the lower box body at the discharging bracket. The structure is compact, the occupied space is small, the processing is convenient, and the energy utilization rate is high.

Owner:郑州哆味哆客智能科技有限公司

Quick-frozen rice pizza product and preparation method thereof

ActiveCN104222211ASimple methodReasonable workmanshipPreservation by coolingBakery productsProcess engineeringRice grain

The invention provides a quick-frozen rice pizza product and a preparation method thereof and belongs to the field of processing of quick-frozen rice flour products. Rice serves as a cake raw material, a cake is made, tomato sauce, beef paste and stuffing are spread over the baked cake uniformly, and a rice pizza with the beef flavor and with cheese covering the surface is prepared. The preparation method comprises the steps of rice selecting, soaking, stewing, forming, baking and quick-freezing. The preparation method is simple, reasonable in process, easy to operate and convenient to implement. The prepared product can be eaten directly after being heated through microwaves, and is clear in rice grains, tasty, refreshing, sticky, moderate in softness, rich in feature and convenient to eat. Therefore, the quick-frozen rice pizza product serves as novel quick-frozen rice flour processed food suitable for people of all ages.

Owner:福州市食品工业研究所

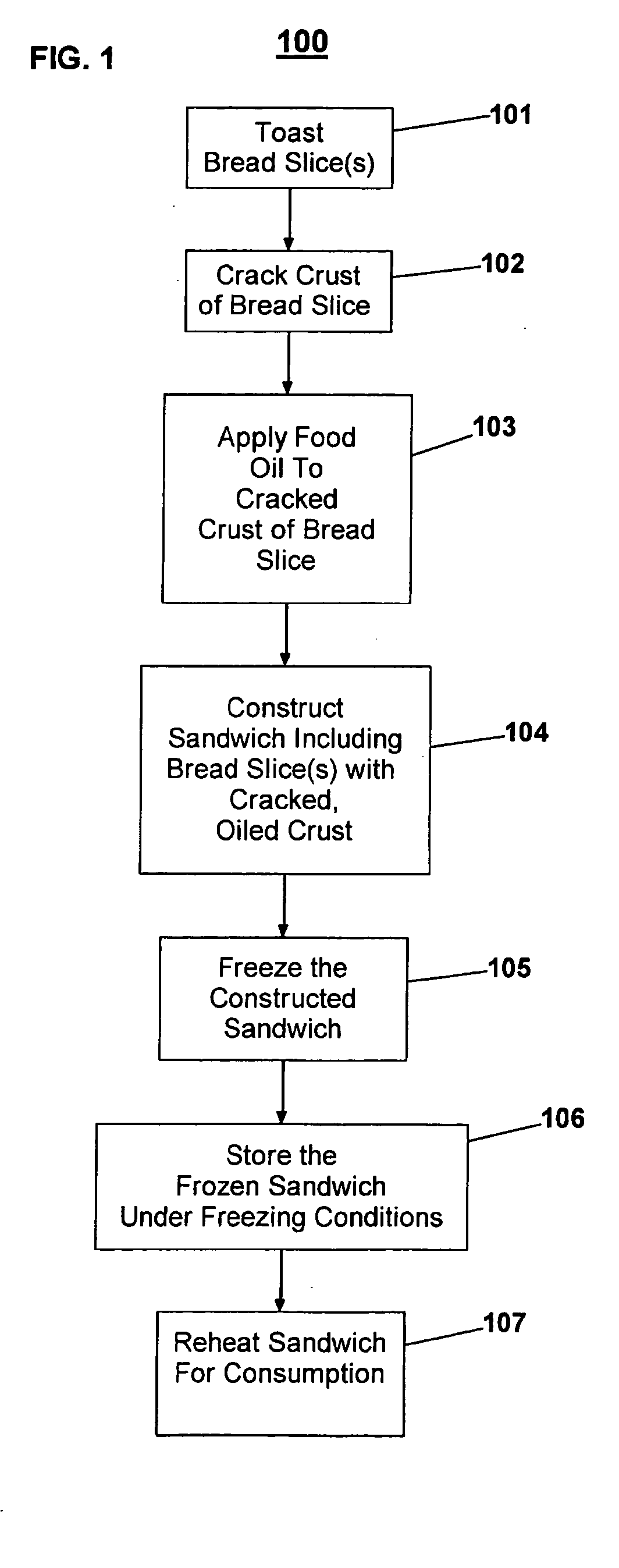

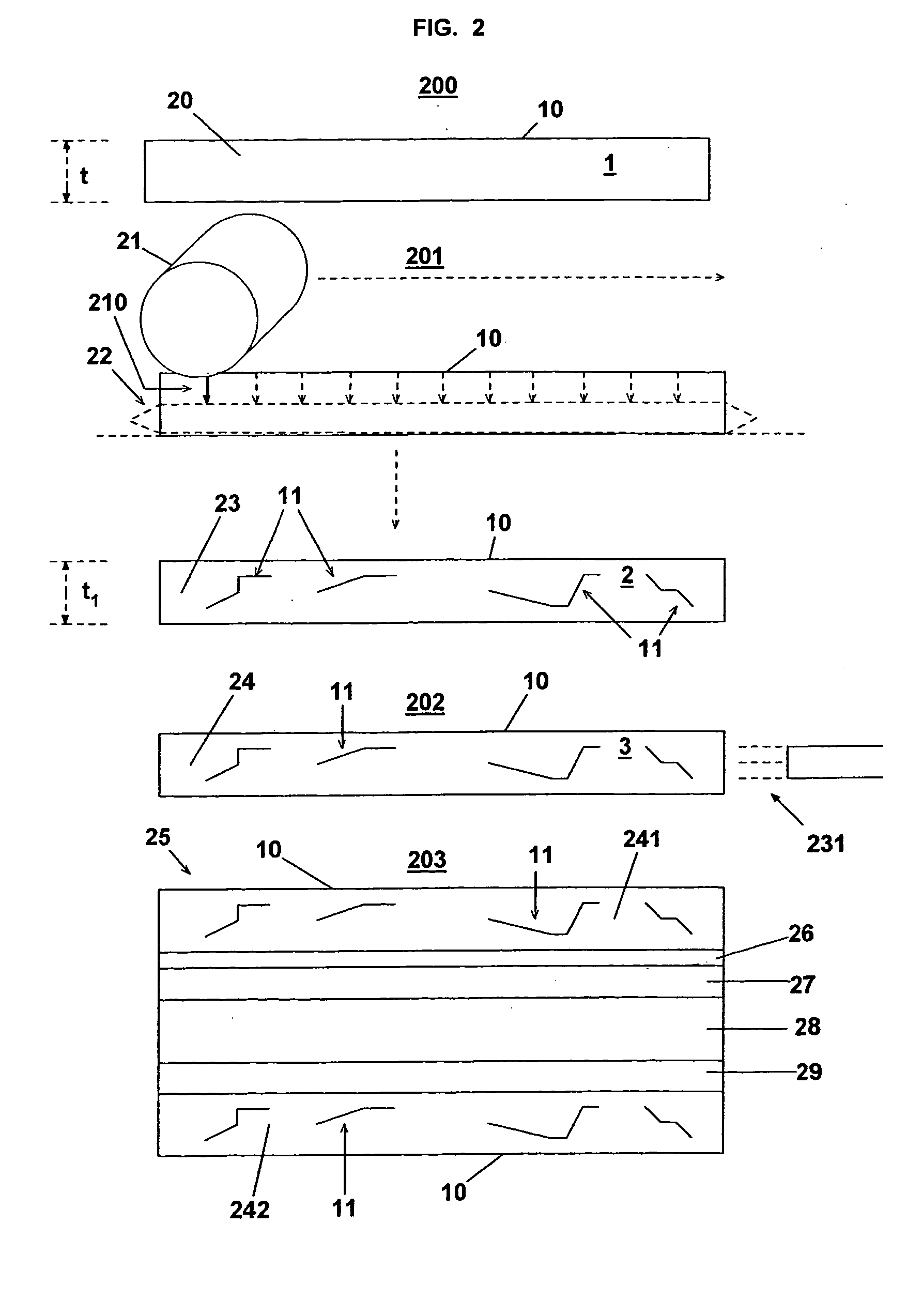

Freezer-stable toasted bread slices

InactiveUS20050175738A1Improve textureReduce consumptionConfectioneryPreservation by coolingFood science

Toasted sandwich bread slices are provided having crusts that remain chewable and crunchy in texture even after the sandwiches are frozen and reheated. This improved crust texture is achieved by a process of physically tenderizing the crusts of toasted bread slices before they are frozen. The bread crusts are cracked by application of compressive force to the bread slices without permanently substantially flattening the bread slices. The cracked toasted bread are highly useful in constructing a sandwich that is frozen for stable storage, and later reheated for consumption without the crusts becoming overly hard, dry and difficult to chew.

Owner:KRAFT FOODS INC

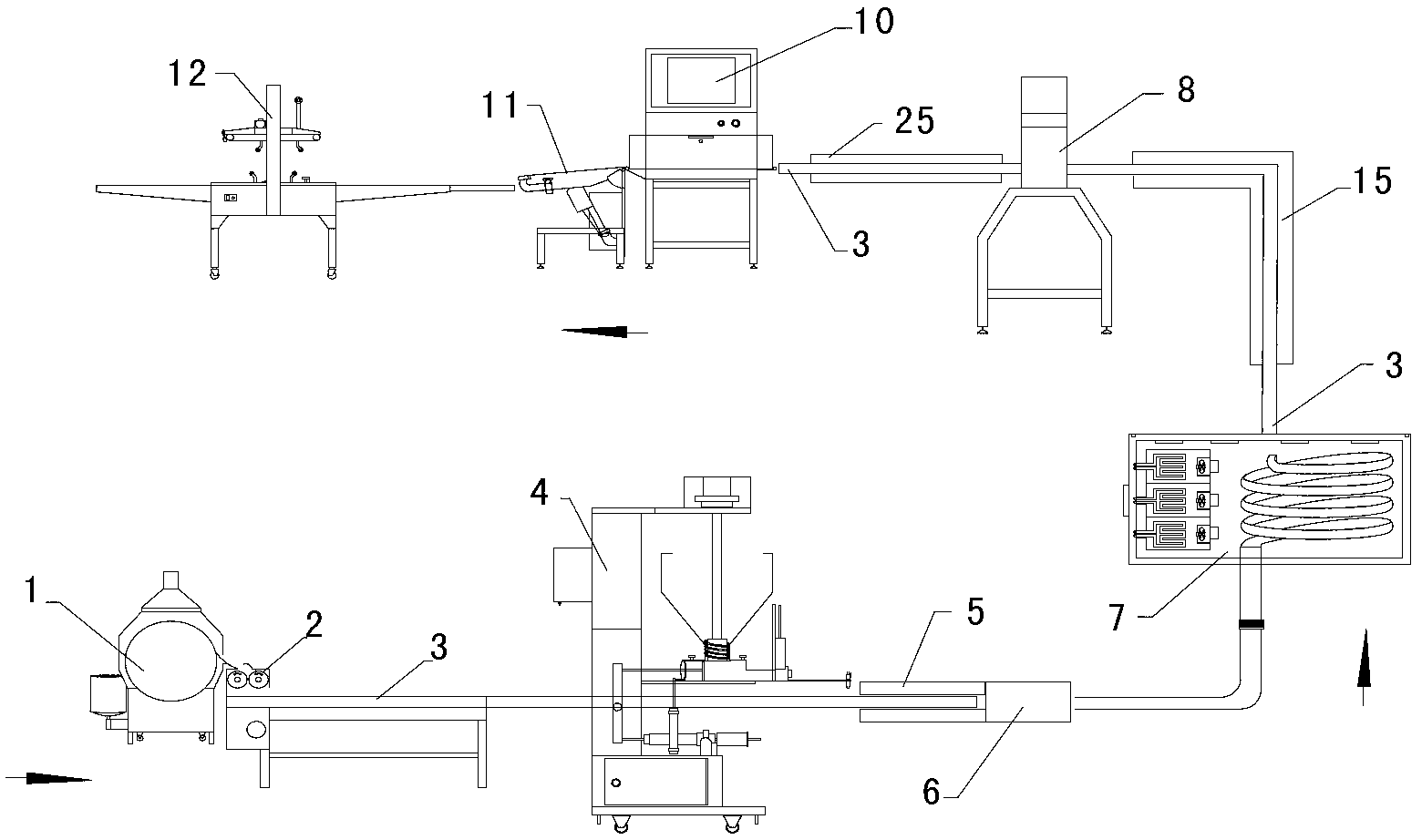

System of spring roll production flow

ActiveCN103250750AReduce labor intensitySame sizePreservation by coolingOil/fat bakingX-rayEngineering

The invention discloses a system of a spring roll production flow and relates to food machinery. The system of the spring roll production flow is provided with a skin producing machine, a skin cutting machine, a conveying belt, a filling discharging machine, a spring roll making operating platform, a first metering platform, an instant freezer, a metal detector, an X-ray machine, a conveying belt lifting platform, an adhesive tap sealing machine, a film covering operating platform and a second metering platform. An outlet of a baking roller box of the skin producing machine is connected with the skin cutting machine, the skin cutting machine is connected with the filling discharging machine through the conveying belt, an outlet of a propelling cavity of the filling discharging machine is connected with the spring roll making operating platform through the conveying belt, one end of the first metering platform is connected with the spring roll making operating platform, the other end of the first metering platform is connected with the instant freezer through the conveying belt, a conveying belt outlet of the instant freezer is connected with the conveying belt, the film covering operating platform is arranged between the instant freezer and the metal detector, the second metering platform is connected with the metal detector, one end of the X-ray machine is connected with the second metering platform through the conveying belt, the other end of the X-ray machine is connected with the conveying belt lifting platform, and the conveying belt lifting platform is connected with the adhesive tap sealing machine.

Owner:漳州市孚美实业有限公司

Preparation method of low AGEs wafer biscuits

InactiveCN107125286AImprove food safetyIncrease nutritionDough treatmentPreservation by coolingSodium bicarbonateVegetable oil

The present invention relates to a preparation method of low AGEs wafer biscuits. Flour, starch, ammonium bicarbonate, sodium bicarbonate, water and catechins are taken to be mixed evenly, the mixture is beat into slurry at a water temperature of 14 DEG C, and the slurry is filtered to remove insoluble substances; the slurry is poured into an aperture disk type wafer baking mold to be baked and qualified wafer biscuit slices are picked; white granulated sugar, vegetable oil, sesame seed paste, peanut butter, whole milk powder, edible salt, edible spices and catechins are mixed evenly to prepare stuffing; a slice stacking machine is used to add the stuffing into the picked biscuit slices to obtain wafer biscuit blocks; the wafer biscuit blocks are sent into a slice pressing machine to be treated, the treated wafer biscuit blocks are frozen, and the frozen wafer biscuit blocks are stored in a low temperature freezer; and the wafer biscuits are cut according to design weights. The catechins are added in the manufacture process of the wafer biscuits and a natural antioxidant, and can reduce production of advanced glycation end products and enhance edible safety and nutrition of the wafer biscuits. The wafer biscuits are fresh in flavor and enable users to feel at ease and assured.

Owner:HUBEI UNIV OF TECH

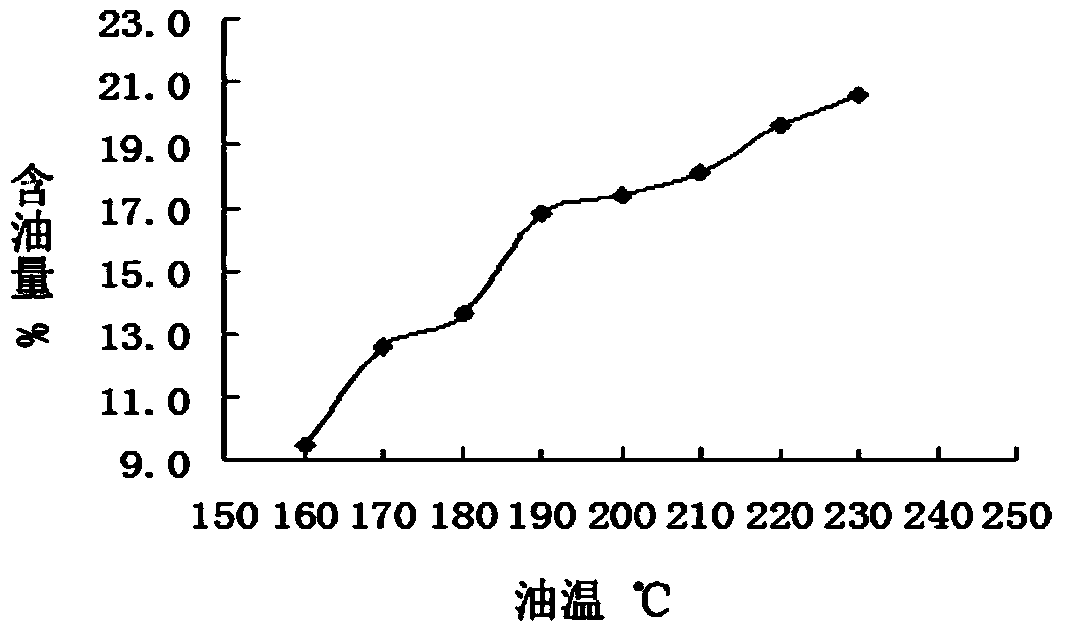

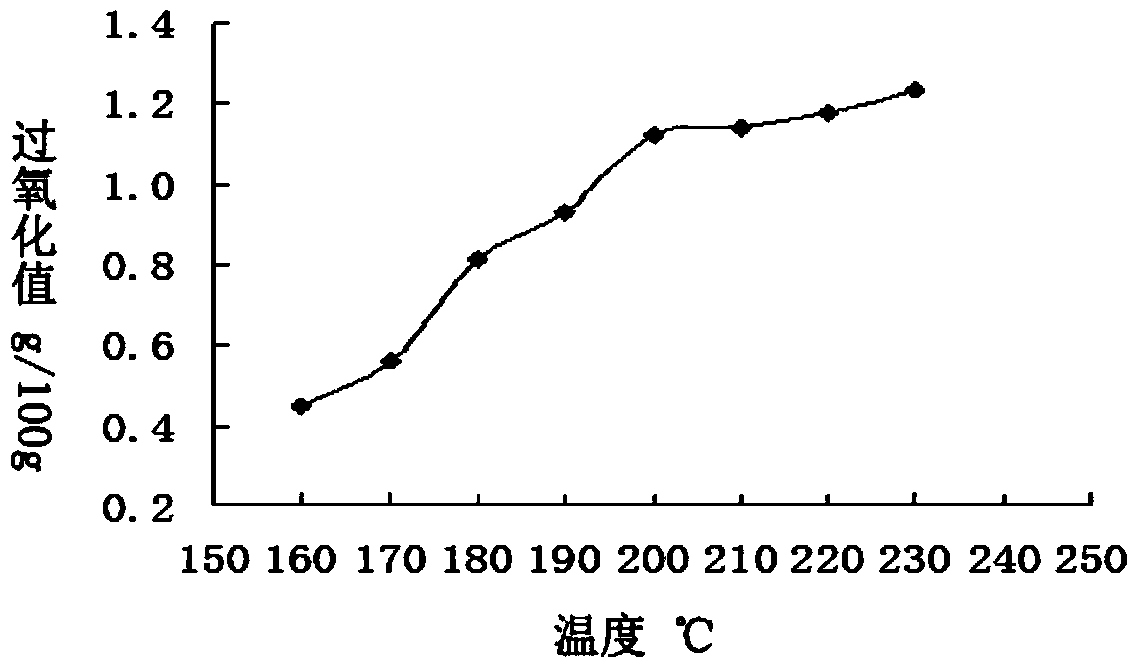

Quick-frozen fresh-keeping deep-fried dough stick and making method thereof

ActiveCN103875755AFull of nutritionPromote expansionDough treatmentPre-baking dough treatmentFrost crackQuick Freeze

The invention discloses a quick-frozen fresh-keeping deep-fried dough stick and a making method thereof and belongs to the technical field of food processing. The quick-frozen fresh-keeping deep-fried dough stick is mainly composed of, by weight, 110-120 parts of flour special for making deep-fried dough sticks, 8-10 parts of acetylated wheat modified starch, 10-15 parts of white glutinous rice flour, 60-70 parts of water, 2-3 parts of leavening agents, 0.1-0.2 part of yeast, 3-5 parts of soybean oil, 5-10 parts of edible salt, 5-10 parts of eggs and 7-12 parts of white sugar. The flour special for making the deep-fried dough sticks, the acetylated wheat modified starch and the white glutinous rice flour are adopted, so that forming of a gluten network can be promoted, strength and gluten tenacity of the deep-fried dough stick are improved, and frost crack rate of skin of the deep-fried dough stick after quick freezing can be lowered; a low-temperature quick deep-fry method and a quick freezing method are adopted to make the deep-fried dough stick, so that water content, oil content, acid value and peroxide value of the deep-fried dough stick can be lowered, and original freshness and nutrition facts of the deep-fried dough stick can be maintained furthest.

Owner:云鹤食品有限公司

Microwavable Food Products

ActiveUS20090155419A1Shorten heating timeExtend heating timeBakery product refreshing by heating/thawingDough treatmentMicrowaveEngineering

Owner:KRAFT FOODS GRP BRANDS LLC

Low glycemic impact breads for the nutrition of diabetics, obese and metabolic syndrome diets

InactiveUS8815319B2Reduce loadReduce impactDough treatmentPreservation by coolingLow glucoseGlycemic

A method for producing low Glycemic Index bread and baked products for diabetic dieting and Metabolic Syndrome patients using a selection of ancient cereals, pseudo cereals and grain varieties with high content of complex carbohydrate molecules, low speed and low adiabatic temperature milling, encapsulation of carbon dioxide bubbles created during leavening of dough in a slowly digested denaturalized protein matrix, inclusion of partially milled chunks of cereal and grain into the dough, baking at low temperatures and short time periods, rapid chilling of the bread and freezing for storage.

Owner:ZAPP GLAUSER JORGE LUIS

Method for increasing shelf life of baked goods

InactiveUS20050191387A1Delay water lossReduce Shrinkage ProblemsDough treatmentMilk preservationBaked goodsGranular starch

The invention provides a method of reducing moisture loss and a method of reducing shrinkage in a frozen baked good. Each method comprises preparing a baked good comprising a pre-gelatinized modified granular starch and freezing the baked good, the starch being present in said baked good in an amount effective to reduce moisture loss or shrinkage upon freezing relative to the absence of the starch.

Owner:GRAIN PROCESSING CORP

Pulverluent mixture that is palatable to the taste even though some of its ingredients may otherwise taste bitter if tasted separately

InactiveUS20090317516A1Great tasteRelieve stomach gasDough/pre-mixesPreservation by coolingNutrition supplementationAdditive ingredient

An edible item, which may be a food or nutritional supplement, that is palatable to the taste with a palatably pleasant aftertaste and is a mixture of pre-processed components in a granular or heterogeneous mixture. When added with a liquid such as water or milk, the heterogeneous mixture forms a batter that may be cooked into a shape indicative of a pancake. At least one of the pre-processed components segregates from the remainder of the cooked batter. It does not dissolve as a result of the addition of the liquid.

Owner:NEWSTEDER ROBERT

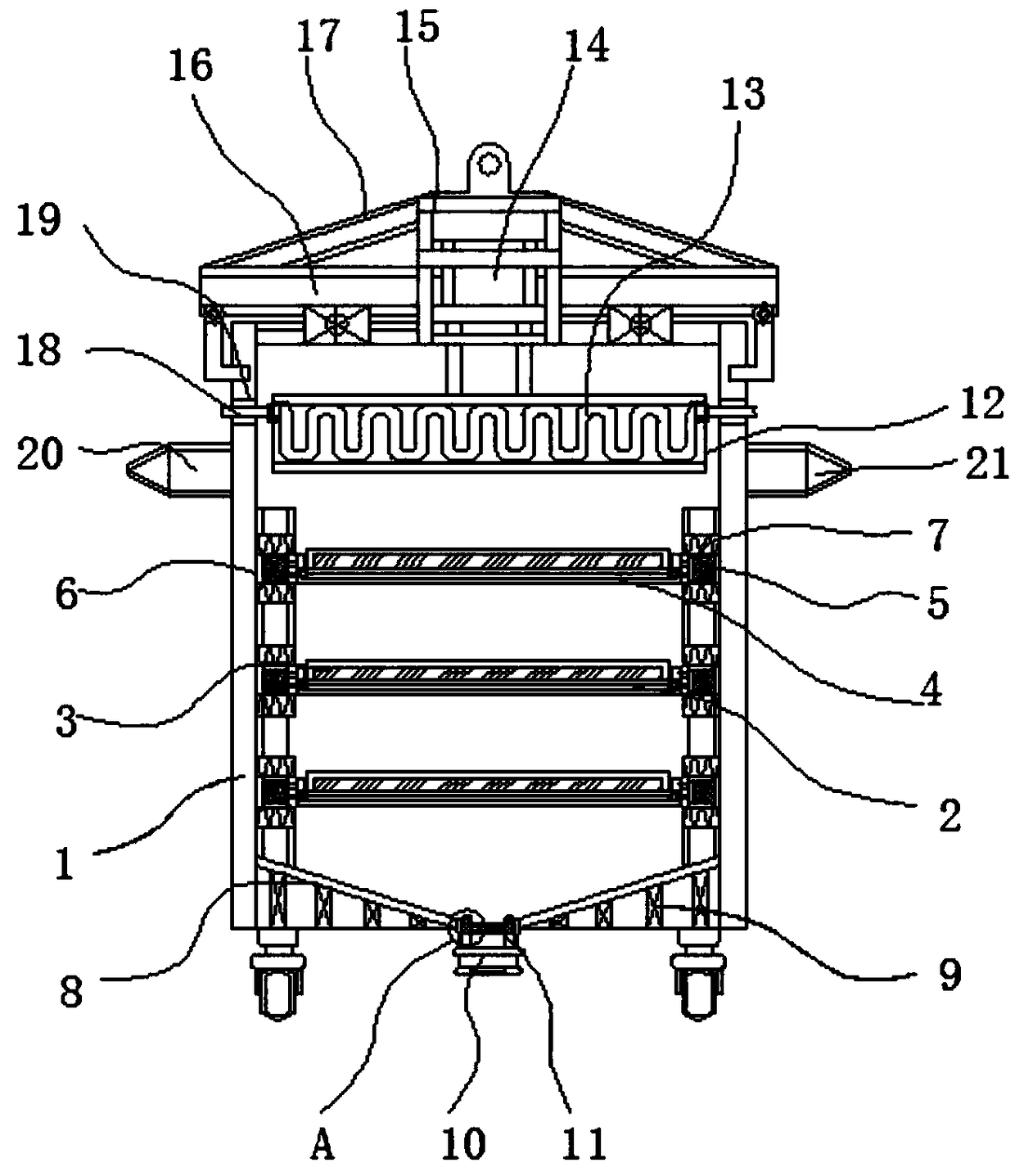

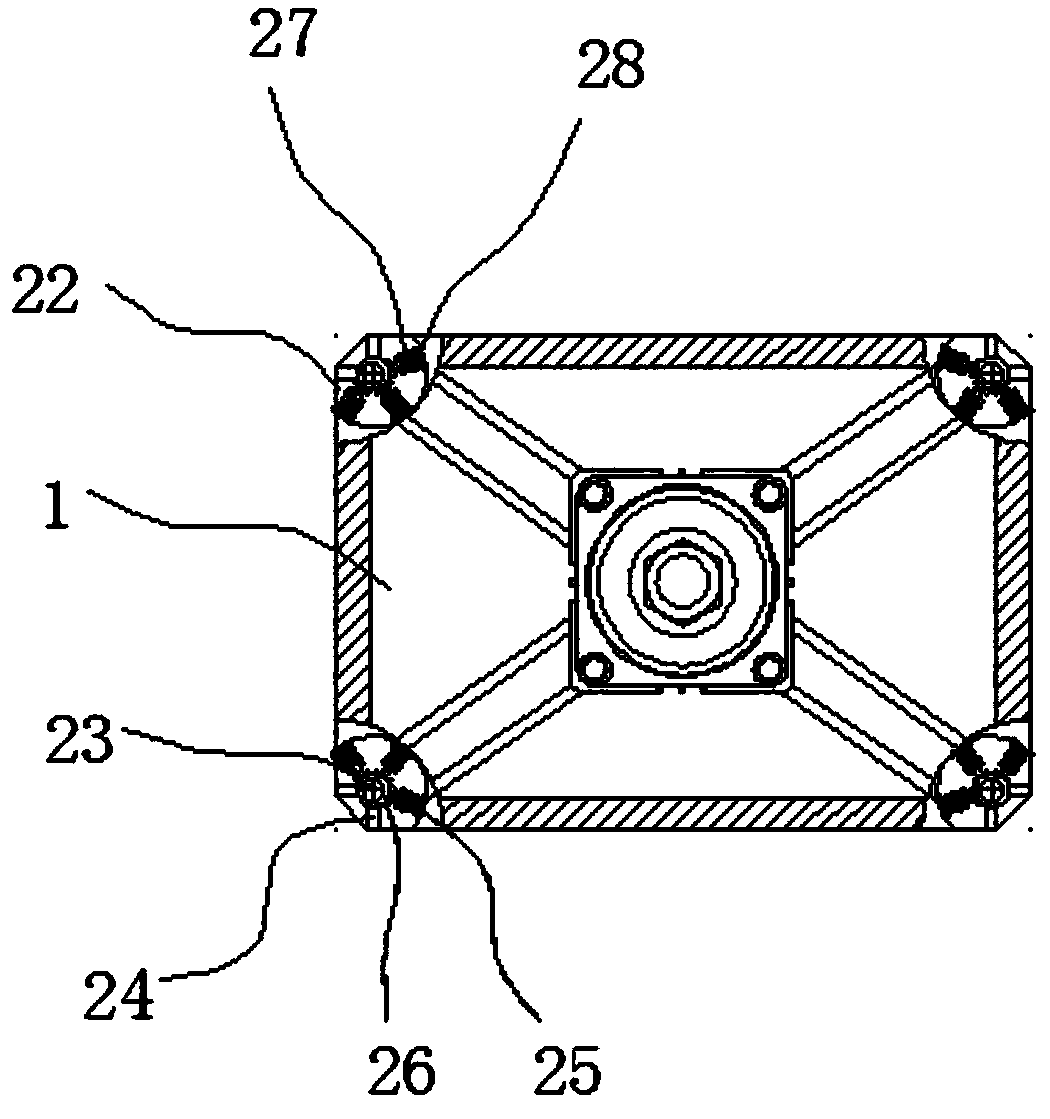

Baked food cooling box for food processing

InactiveCN109221345AAvoid damageIntegrity guaranteedPreservation by coolingCooking & bakingBaked goods

The invention discloses a baked food cooling box for food processing, and relates to the technical field of food processing. The baked food cooling box comprises a cooling box body and a cooling framework, baking trays are installed inside the cooling box body, the cooling framework is arranged over the baking trays, and the baking trays are connected with the cooling box body through grooves; guide slide wheels are installed at the left and right ends of each baking tray, a partition board is movably connected to the front of each baking tray, a cooling pipeline is installed inside the cooling framework, and the top of the cooling framework is in threaded connection with a hydraulic air cylinder. The baked food cooling box for food processing has the advantages that through the arrangement of the cooling box body, a turnover cover plate and the cooling framework, when the turnover cover plate covers the top of the cooling box body, the cover plate and the cooling box body are combinedto form a relative sealed shell. Through the cooperation of the cooling framework, food inside the cooling box body can be hermetically cooled.

Owner:FOSHAN UNIVERSITY

Method for combining infrared and microwave to conduct repeated heating to promote brittleness of freezing cooked fried dumpling after repeated heating

InactiveCN106900812AGood water retentionImprove water retentionDough treatmentPreservation by coolingMicrowavePhosphate

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

Freeze-dried foods and process for producing same

There are described freeze-dried food products which have porous structure with fine texture than those obtained by conventional processes to give smooth melting in mouth and a process for preparing the freeze-dried food products. According to the process, raw materials for the food are made into a form of aqueous solution or paste, emulsified, made into semi-frozen state by cooling the emulsion, freeze-dried by further cooling in a mold, and then subjected to freeze-drying treatment.

Owner:MEIJI SEIKA KAISHA LTD

Churros and method for making same

InactiveUS20050112261A1Less oilPre-baking dough treatmentPreservation by coolingMarkedly elevated IgEAdditive ingredient

Owner:1010684 ONTARIO

Baking method for additive-free cake

ActiveCN104824098AExtended shelf lifeImprove freshnessPreservation by coolingBaking processesCooking & bakingWater activity

The invention discloses a baking method for additive-free cake, and relates to the baking method of cake. The baking method comprises the steps of material mixing; material beating; air inflation; slip casting; baking; cooling and sterilizing; nitrogen-filled packing; in the step of baking, the cake in the slip casting enters a tunnel baking oven for being baked, the running speed of a conveyor belt is 0.1-2m / min, the baking time of a first temperature zone is 10 min-30 min, the temperature of hot air in an upper cavity is 220 DEG C+ / -10DEG C, and the temperature of hot air in a lower cavity is 180 DEG C+ / -10 DEG C; the baking time of a second temperature zone is 10 min-30 min, the temperature of the lower cavity is 200 DEG C+ / -10 DEG C, and the temperature of the upper cavity is 160 DEG C+ / -10 DEG C; the baking time of a third temperature zone is 10 min-30 min, the temperature of the lower cavity is 180DEG C+ / -10 DEG C, the temperature of the upper cavity is 150 DEG C+ / -10 DEG C, and the water activity of baked cake is below 78; in the step of cooling and sterilizing, the baked cake enters a cooling and sterilizing box for being cooled and sterilized, and the cooling and sterilizing box adopts a 360-degree all-dimensional stiffing and sterilizing box.

Owner:FUZHOU JIAOTIANXIA BIOTECH CO LTD

Frozen dumplings

A frozen dumpling is obtained by applying to a dumpling, a first layer of a batter, and a second layer of water or a seasoning solution, wherein the first layer is present in an amount of 5 to 30% by weight relative to the dumpling, and the second layer is present in an amount of 20 to 100% by weight relative to the dumpling, and then freezing the dumpling. Tray-packed frozen dumplings are obtained by placing the dumplings on a tray, and contacing the dumplings with a first layer of batter, and a second layer of water or a seasoning solution, and freezing the dumplings, wherein the first layer is present in an amount of 5 to 30% by weight relative to the dumpling, and the second layer is present in an amount of 20 to 100% by weight relative to the dumpling.

Owner:AJINOMOTO WINDSOR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com