Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

476results about "Dough/pre-mixes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat resistant probiotic compositions and healthy food comprising them

Owner:DEGAMA PROBIOTICS +1

High fiber and high protein baked goods production

InactiveUS20100303991A1Pleasant tastePotential healthDough/pre-mixesConfectioneryStarch gelatinizationHigh protein food

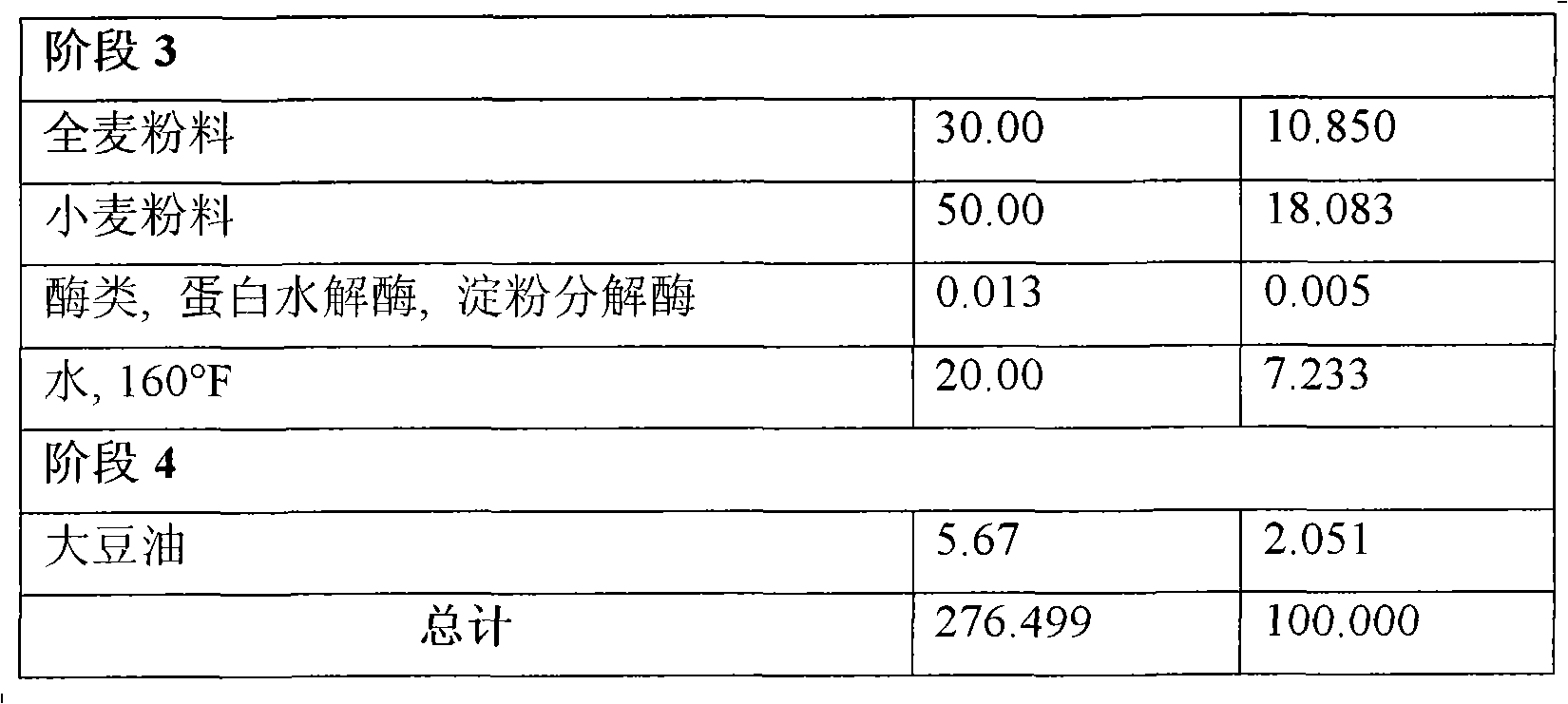

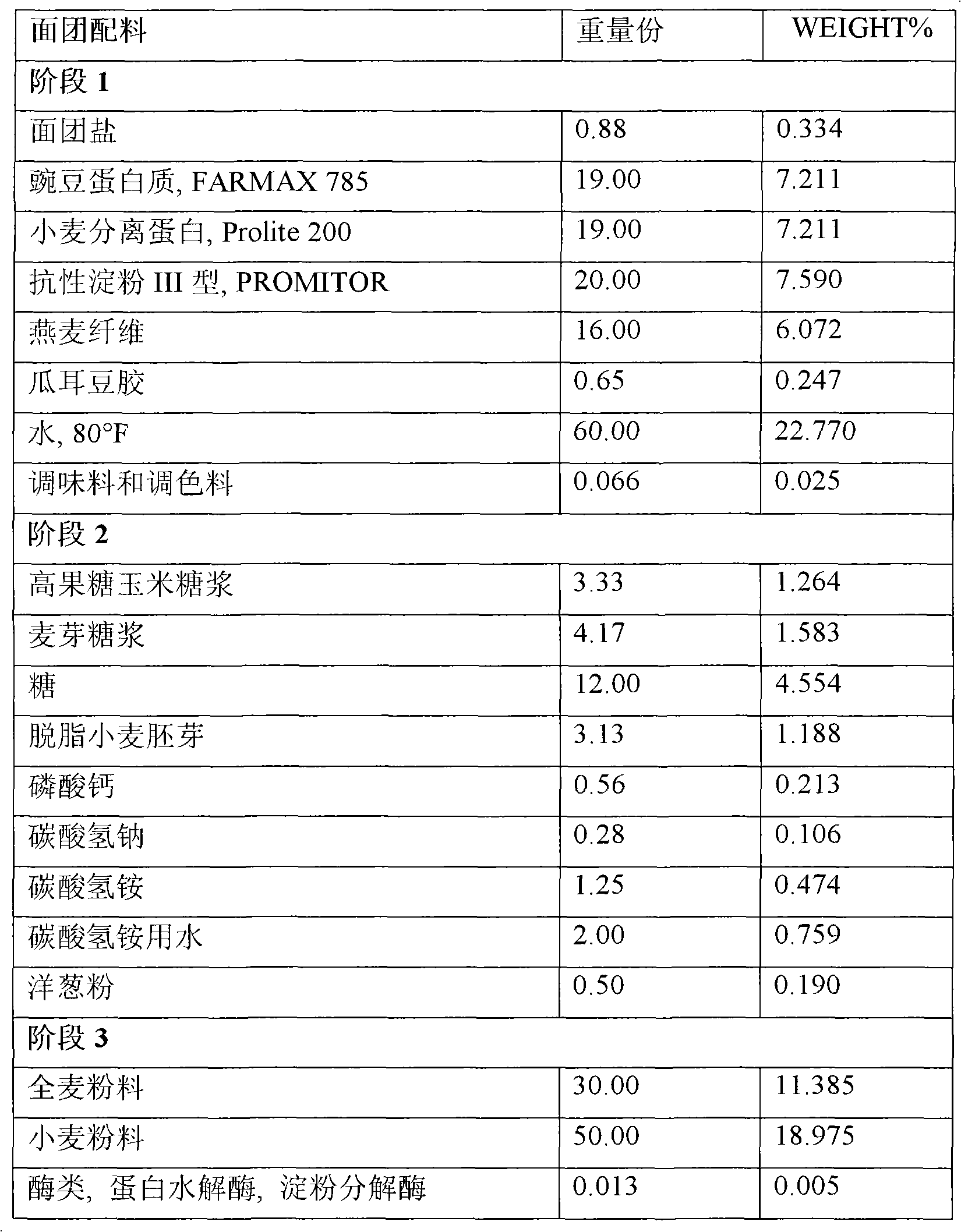

Substantially uniform hydration and dispersion of high amounts of protein and fiber are achieved while avoiding lump formation, hard textures, and off-tastes in the continuous, mass production of high protein and high fiber content sheetable doughs, and baked goods such as crackers, snacks, and cookies made from the sheeted doughs, by hydrating the protein and fiber with water at a temperature below the denaturization temperature of the proteins, and steaming the hydrated mixture without substantial gelatinization of starch during dough production. The steamed, hydrated mass may be admixed with ingredients comprising at least one flour comprising starch to obtain a dough while avoiding substantial gelatinization of starch of the at least one flour during mixing. The baked goods may have a protein content of at least about 4 g, a fiber content of at least about 4 g, and a whole grain flour content of at least about 4 g per 30 g serving.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

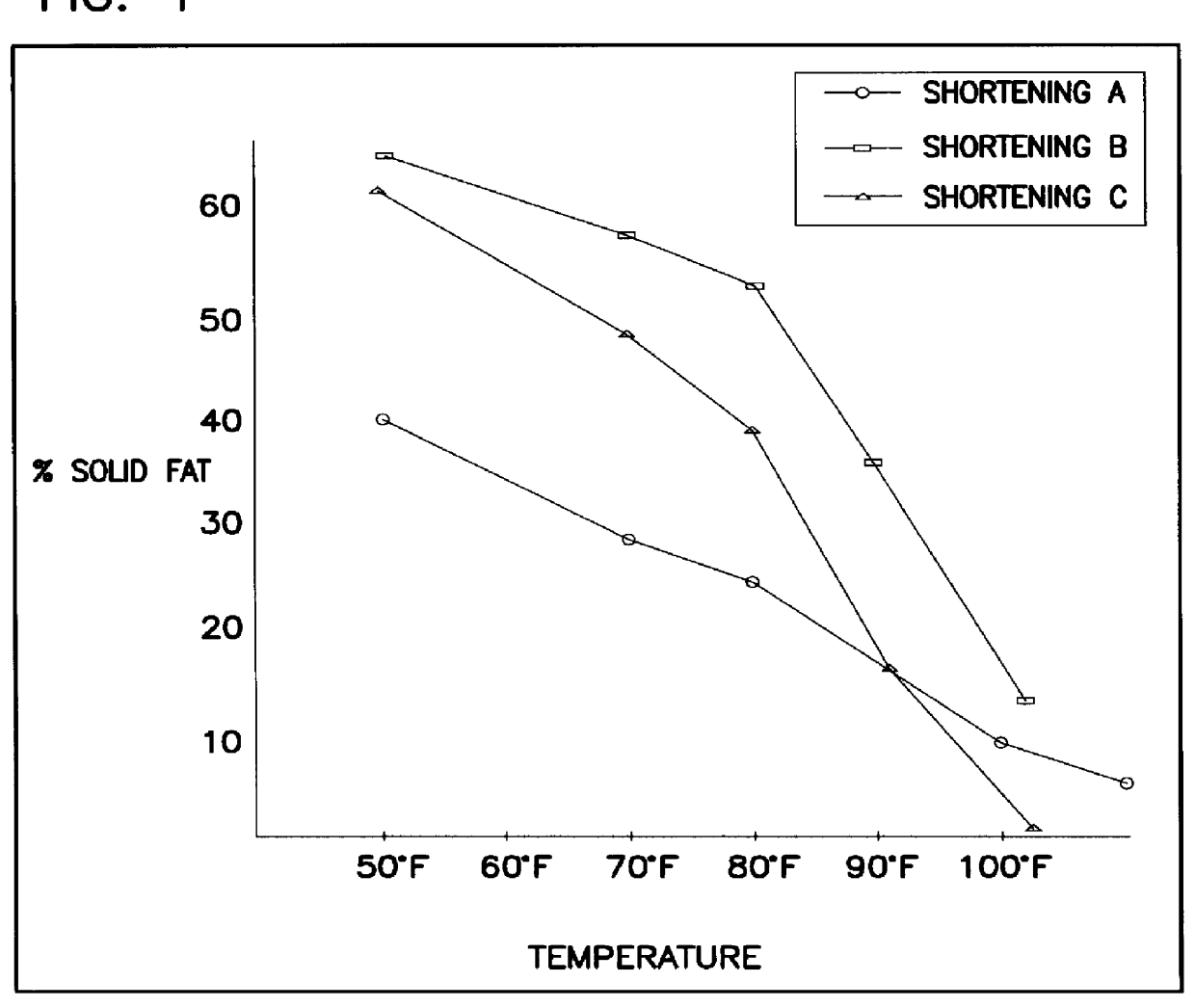

High fat biscuit mix and products resulting therefrom

The invention is a high fat biscuit mix as well as dough and biscuit products resulting therefrom. The mix comprises flour, a leavening agent, and emulsifier along with a protein supplement and shortening. The shortening has a high initial solids content at low temperatures (50 DEG F.) and a melting point of 104 DEG F. or less resulting in a biscuit product having an improved moistness, flakiness and uniform height. The protein supplement and emulsifier generally provide a product having an improved outer crust layer, improved height and shape, and an interior which is tender without being doughy. The mix and resulting dough comprise a high concentration of fat and further a high concentration of fat contributed by shortening chips within the dough.

Owner:U S BANK NAT ASSOC +1

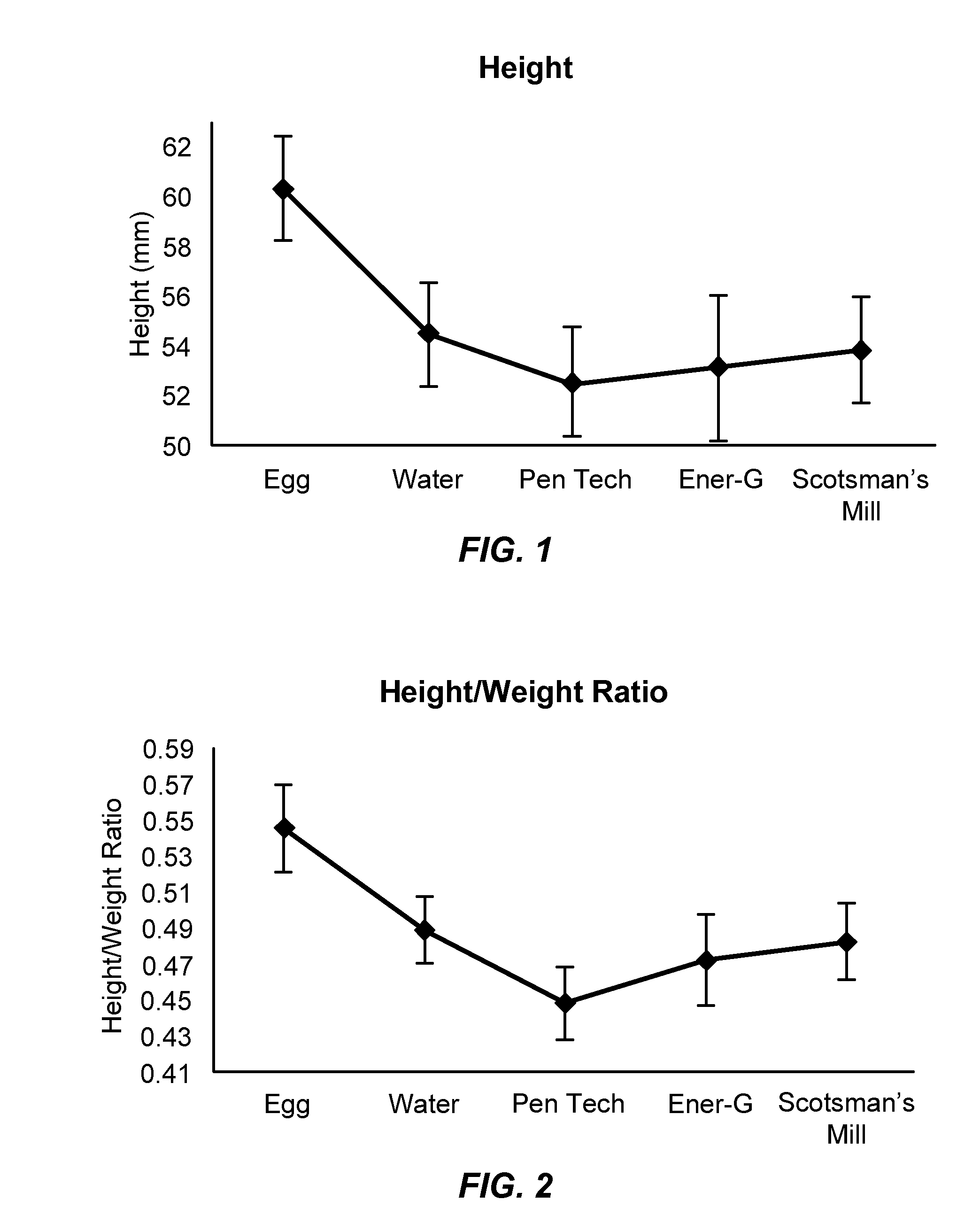

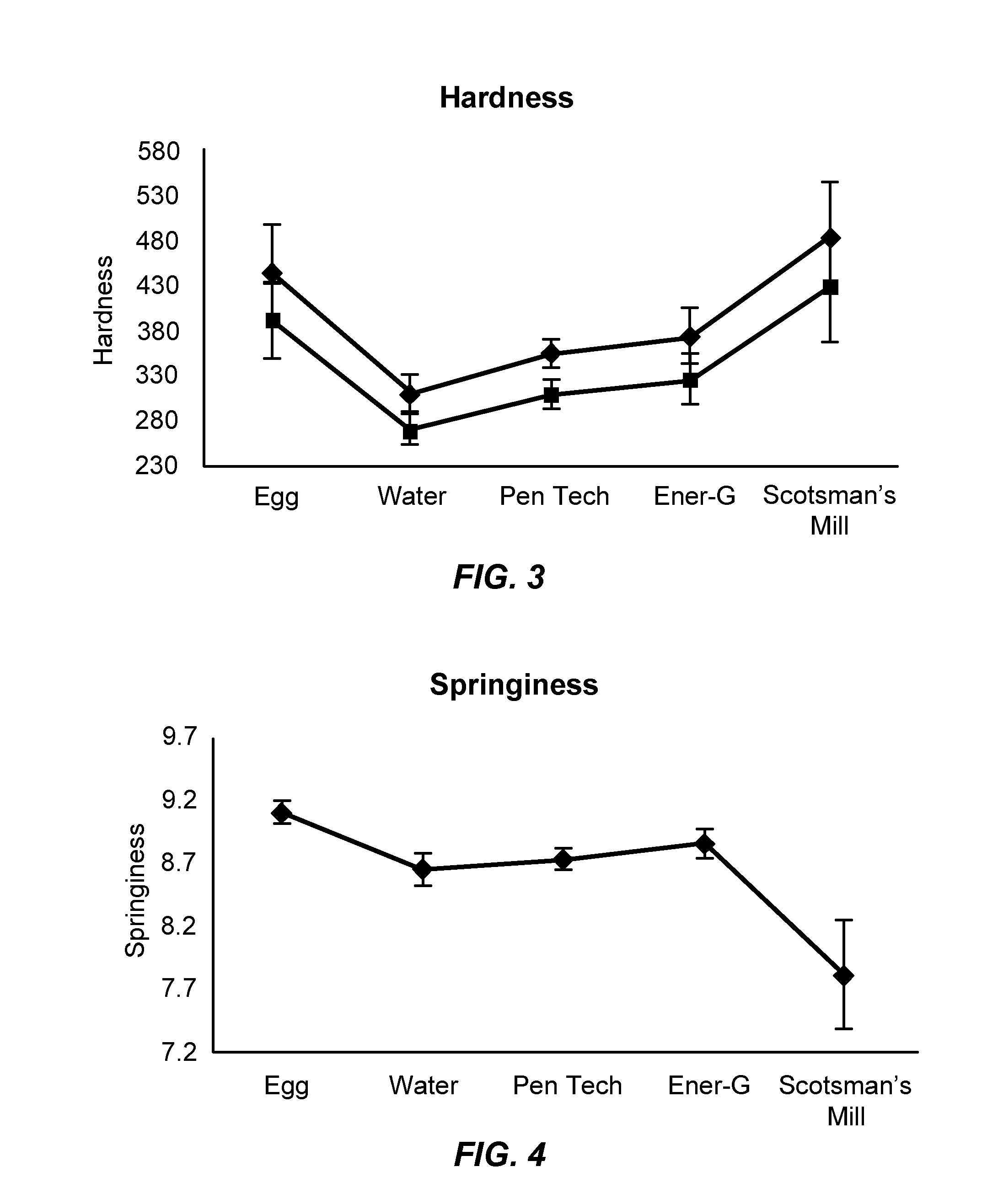

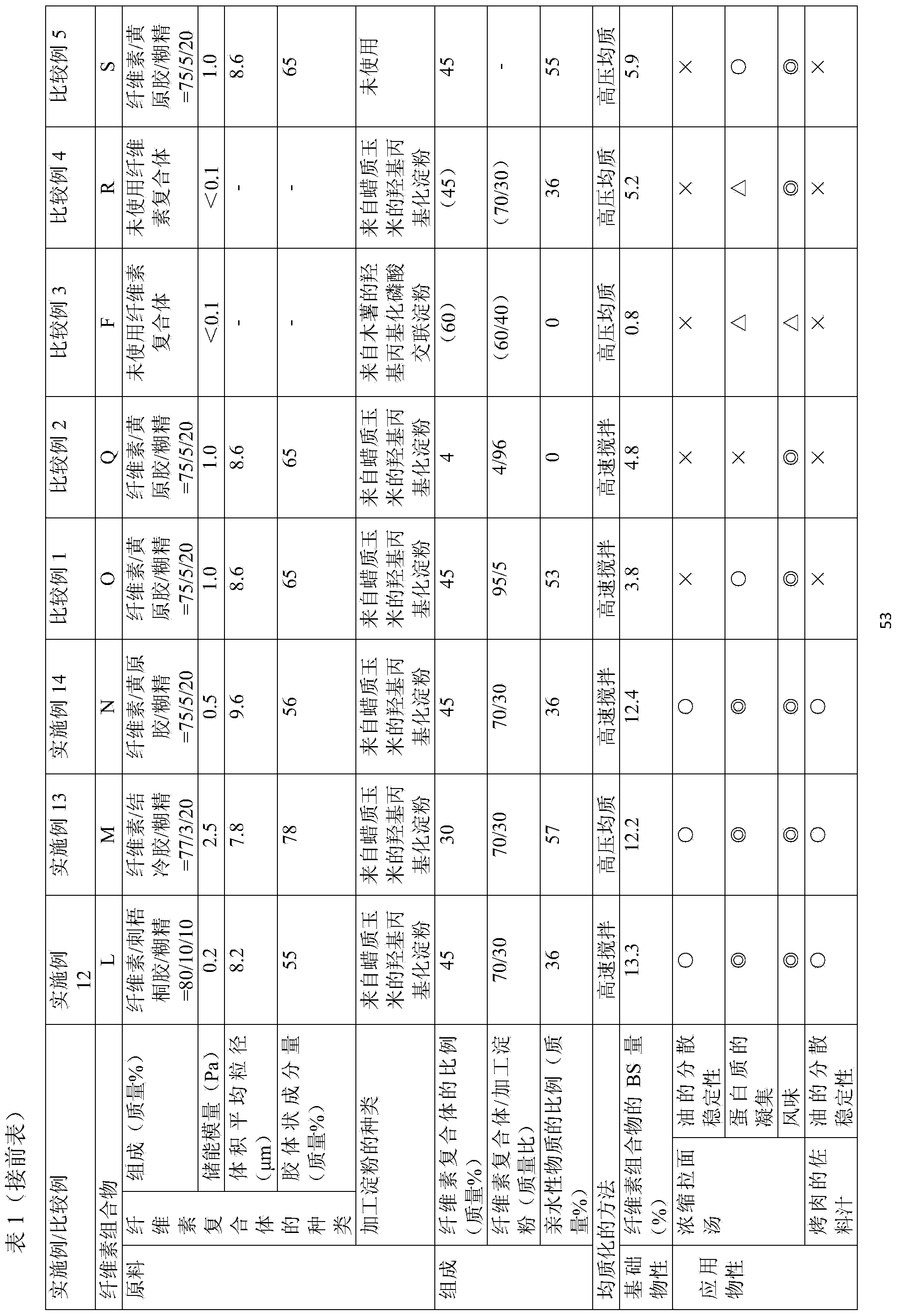

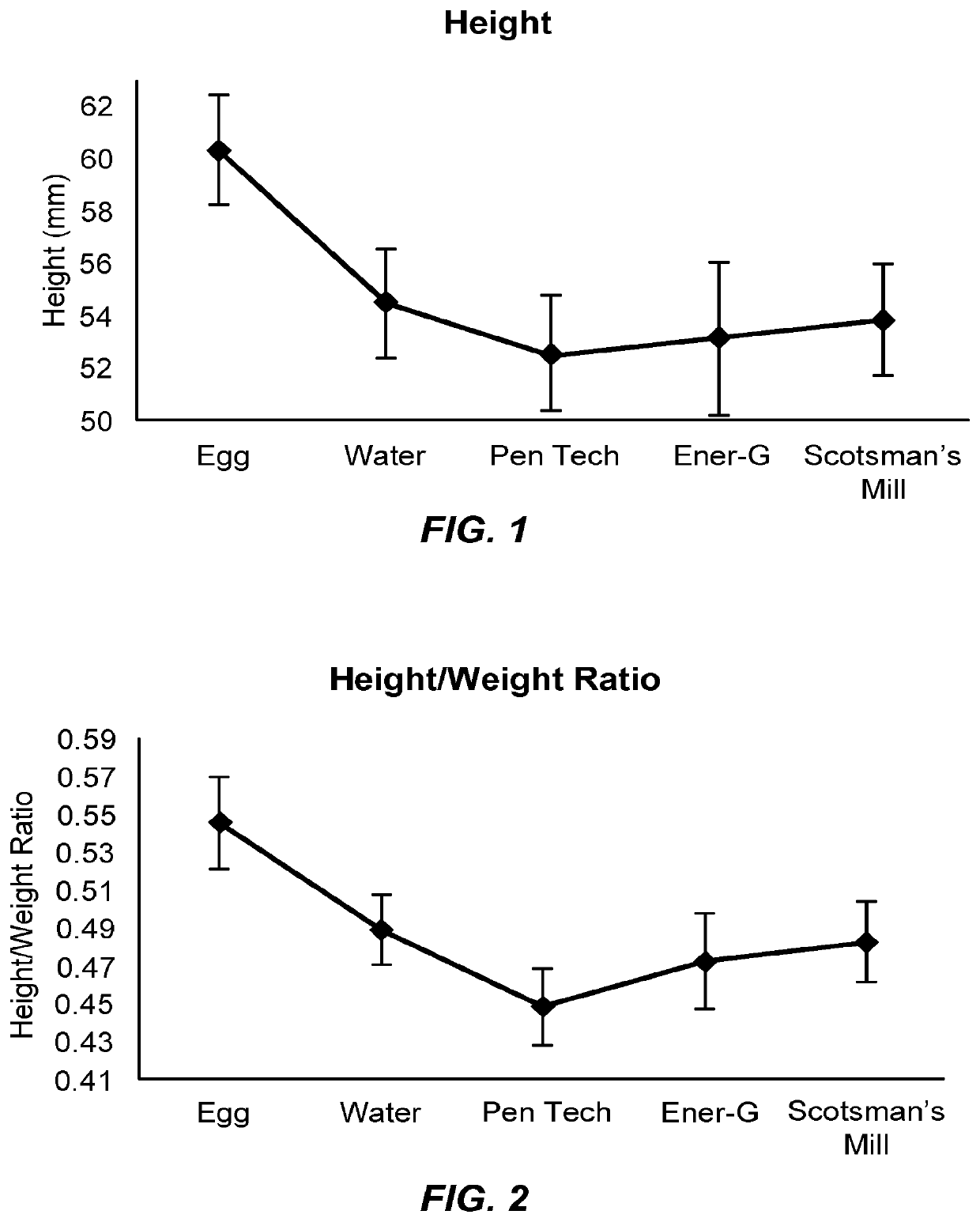

Plant-based egg substitute and method of manufacture

Disclosed herein are non-egg compositions that can be used as egg substitutes. The disclosure is directed to egg substitutes and methods of manufacturing the same, and compositions comprising the egg substitutes, including edible compositions such as baked goods and edible emulsions.

Owner:HAMPTON CREEK INC

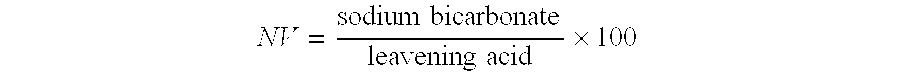

Process and formulation for a chemically leavened dough or bakery product

InactiveUS6149960AElimination of fermentationShorten proofing timeDough treatmentDough/pre-mixesChemistryCarbon dioxide

Chemically leavened bakery product(s) are disclosed which have characteristics similar to bakery product(s) that have been yeast leavened. A process is provided to make such a bakery product without utilizing yeast as the source of carbon dioxide for leavening. Chemically leavened dough is disclosed which may be heated as a fresh dough, or refrigerated or frozen and thereafter heated to prepare a bakery product. Multi-part dry mixes or compositions for preparing such chemically leavened bakery products are disclosed.

Owner:ICL SPECIALTY PROD INC

Dry mix compositions and method for making and utilizing the same having an enhanced anti-microbial shelf life

A food composition comprising a dry mix for production of a bakery product having an extended yeast-free and mold-free shelf life of at least 21 days. The dry mix comprising about 0.01% to about 1.0% of an encapsulated acid such as citric, fumaric, lactic, malic, phosphoric, sodium acid sulfate and mixtures thereof. A method of preparing bakery products having a shelf life enhancing composition are also described.

Owner:GENERAL MILLS INC

High fiber and high protein baked goods production

ActiveCN101897353APleasant tasteNo smellDough/pre-mixesConfectioneryHigh protein foodAdditive ingredient

Substantially uniform hydration and dispersion of high amounts of protein and fiber are achieved while avoiding lump formation, hard textures, and off-tastes in the continuous, mass production of high protein and high fiber content sheetable doughs, and baked goods such as crackers, snacks, and cookies made from the sheeted doughs, by hydrating the protein and fiber with water at a temperature below the denaturization temperature of the proteins, and steaming the hydrated mixture without substantial gelatinization of starch during dough production. The steamed, hydrated mass may be admixed with ingredients comprising at least one flour comprising starch to obtain a dough while avoiding substantial gelatinization of starch of the at least one flour during mixing. The baked goods may have a protein content of at least about 4 g, a fiber content of at least about 4 g, and a whole grain flour content of at least about 4 g per 30 g serving.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Dry mixes comprising glycerine

Dry mixes for forming dough and batters are provided comprising homogenous dispersions of glycerine on one or more ingredients in particulate form. The dry mixes are rendered more resistant to microbial growth due to the presence of glycerine. Food products prepared from the dry mixes exhibit several benefits including improved moisture retention and / or increased shelf-life.

Owner:LESAFFRE YEAST CORP

Food ingredient containing wheat gluten, soy grits and soy flour

InactiveUS6733815B2Efficient preparationHeavy in textureReady-for-oven doughsDough treatmentAdditive ingredientSoy product

The present invention includes a food ingredient comprising soy grits and gluten. The food ingredient is effective to make a food product having a structure substantially the same as a corresponding soy-free product made with wheat flour.

Owner:CARGILL INC

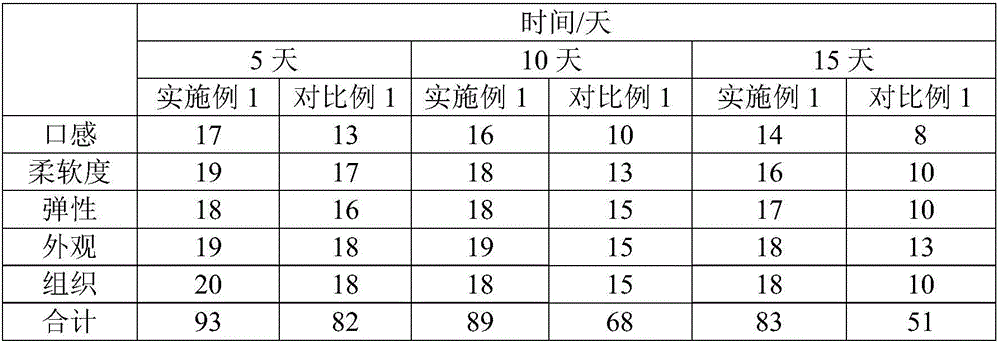

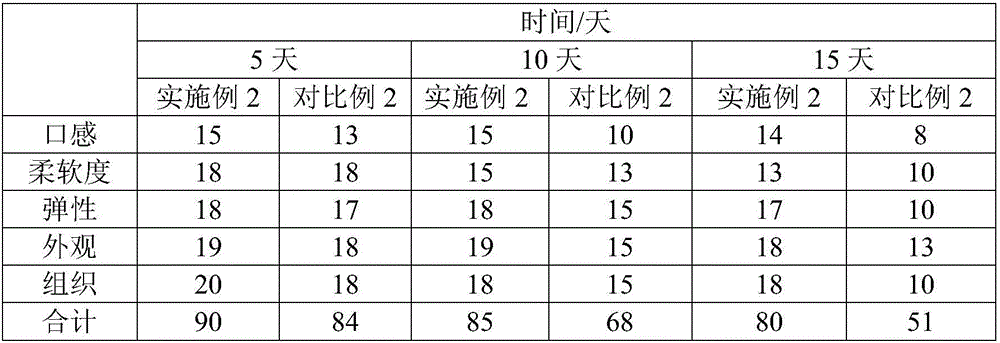

Anti-ageing composition for cakes, cakes and preparation method of cakes

InactiveCN106259601AHigh degree of anti-agingExtended shelf lifeDough treatmentDough/pre-mixesSucroseAnti ageing

The invention discloses an anti-ageing composition for cakes. The anti-ageing composition is prepared from the following components in percentage by weight: 70 percent to 90 percent of hydroxypropyl distarch phosphate, 1 percent to 5 percent of a thickener, 5 percent to 10 percent of sucrose fatty acid ester, 5 percent to 15 percent of an emulsifier, 0.3 percent to 1.5 percent of sodium polyacrylate and 0.1 percent to 1 percent of maltogenic amylase, wherein the sum of the total weight percent of the components is 100 percent. Furthermore, the invention also discloses the cakes containing the anti-ageing composition and a preparation method of the cakes, wherein the use amount of the anti-ageing composition is 10 percent to 20 percent of the use amount of flour. After the anti-ageing composition provided by the invention is added into the cakes, the cakes can have the effects of not dropping dreg, not becoming dry and not becoming hard; the cakes are convenient to use and high in safety.

Owner:东莞市欣荣天丽科技实业有限公司

Process for preparing bakeable probiotic food

InactiveUS20100303962A1Improve stabilityMilk preparationDough/pre-mixesIntestinal microorganismsProbiotic bacteria

Heat-processed health food is provided, as well as a process for making it, the food being particularly probiotic pastry which comprises a probiotic component capable of resisting baking heat, and so it beneficially affects the consumer's intestinal microbial balance.

Owner:DEGAMA PROBIOTICS

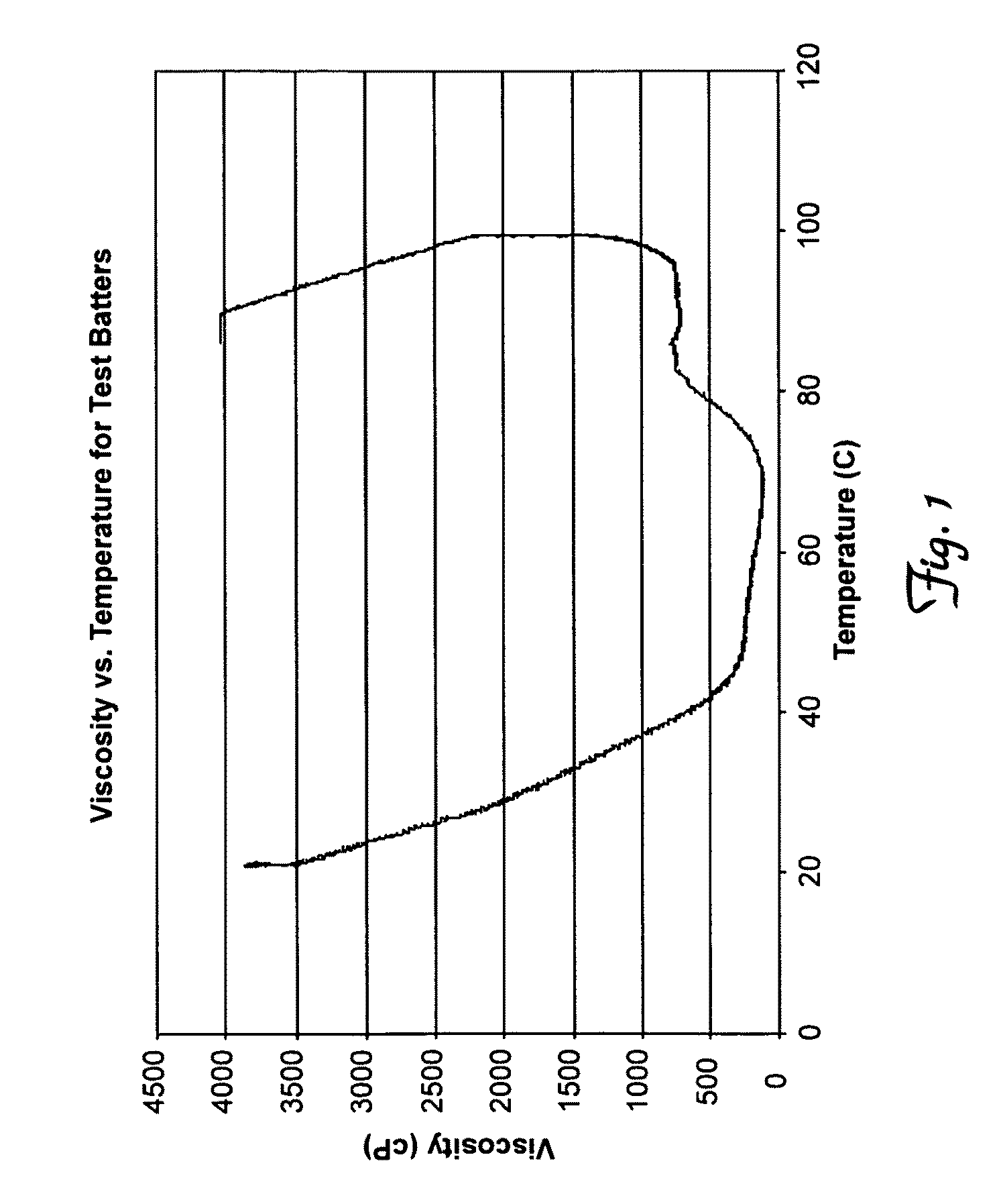

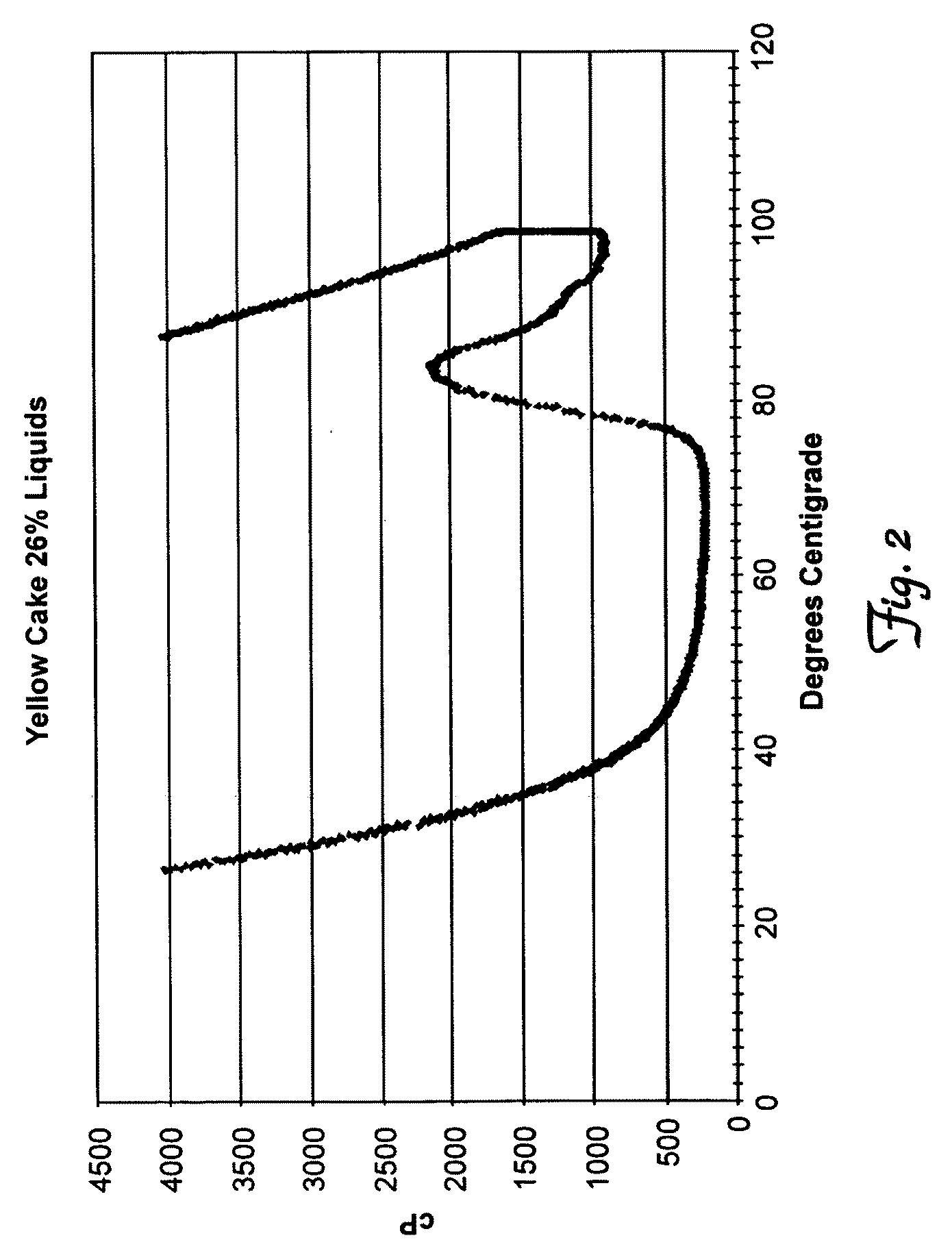

Batter-like compositions containing setting agent and methods of preparing and using same

InactiveUS20070065554A1Easy to handleMaintain structural integrityDough treatmentDough/pre-mixesCooking & bakingAdditive ingredient

The invention provides batter-like compositions including flour or a flour replacement ingredient, sweetener, a fat source, a chemical leavening system, and a setting agent. The resulting batter-like compositions are capable of being formed into discrete product pieces (such as pucks), and maintaining the puck form throughout storage and handling of the batter-like composition prior to baking. The invention further provides methods of preparing batter-like compositions having a discrete form, and methods of using such batter-like compositions to provide baked goods.

Owner:GENERAL MILLS MARKETING INC

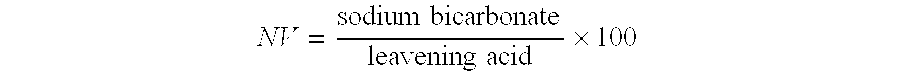

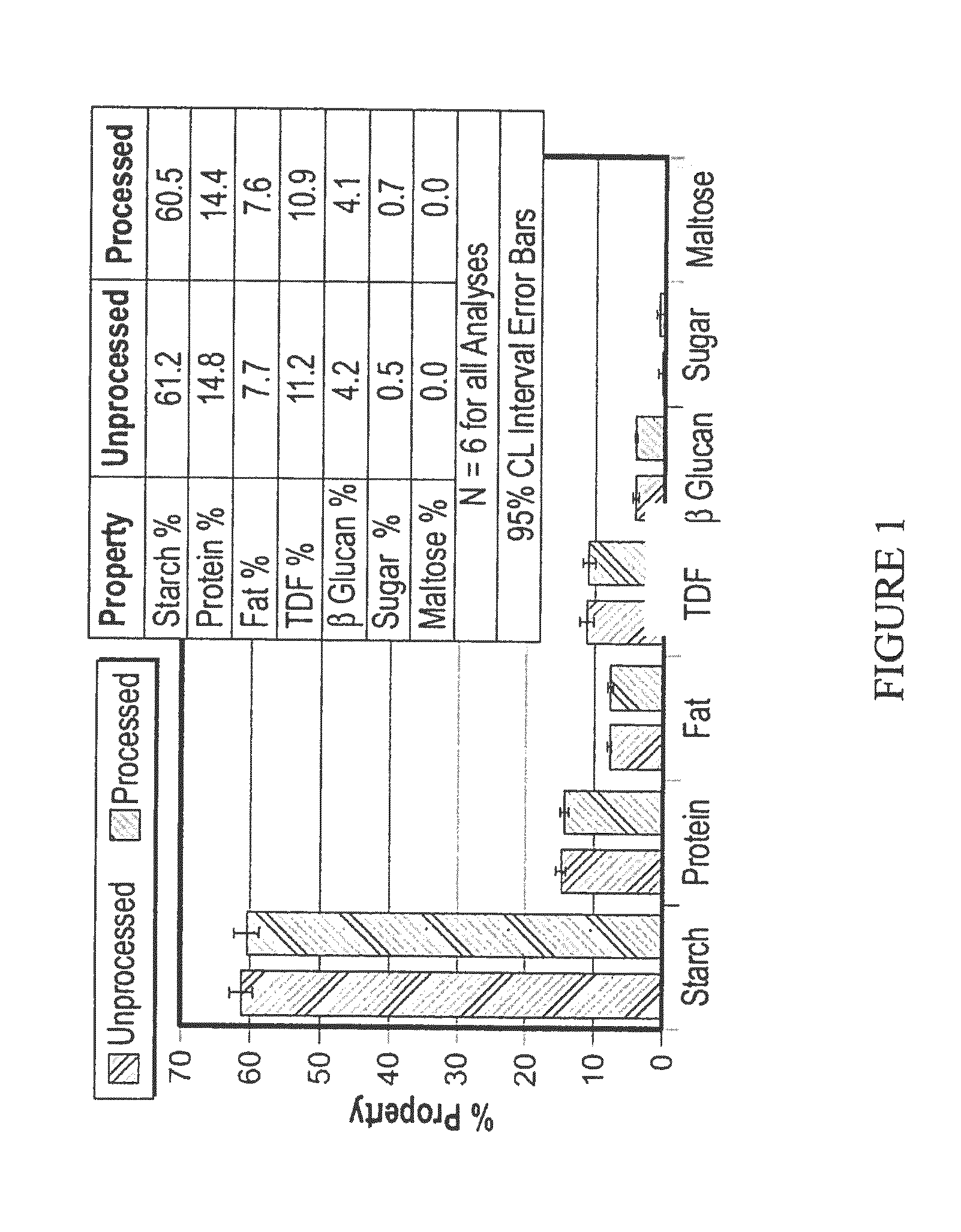

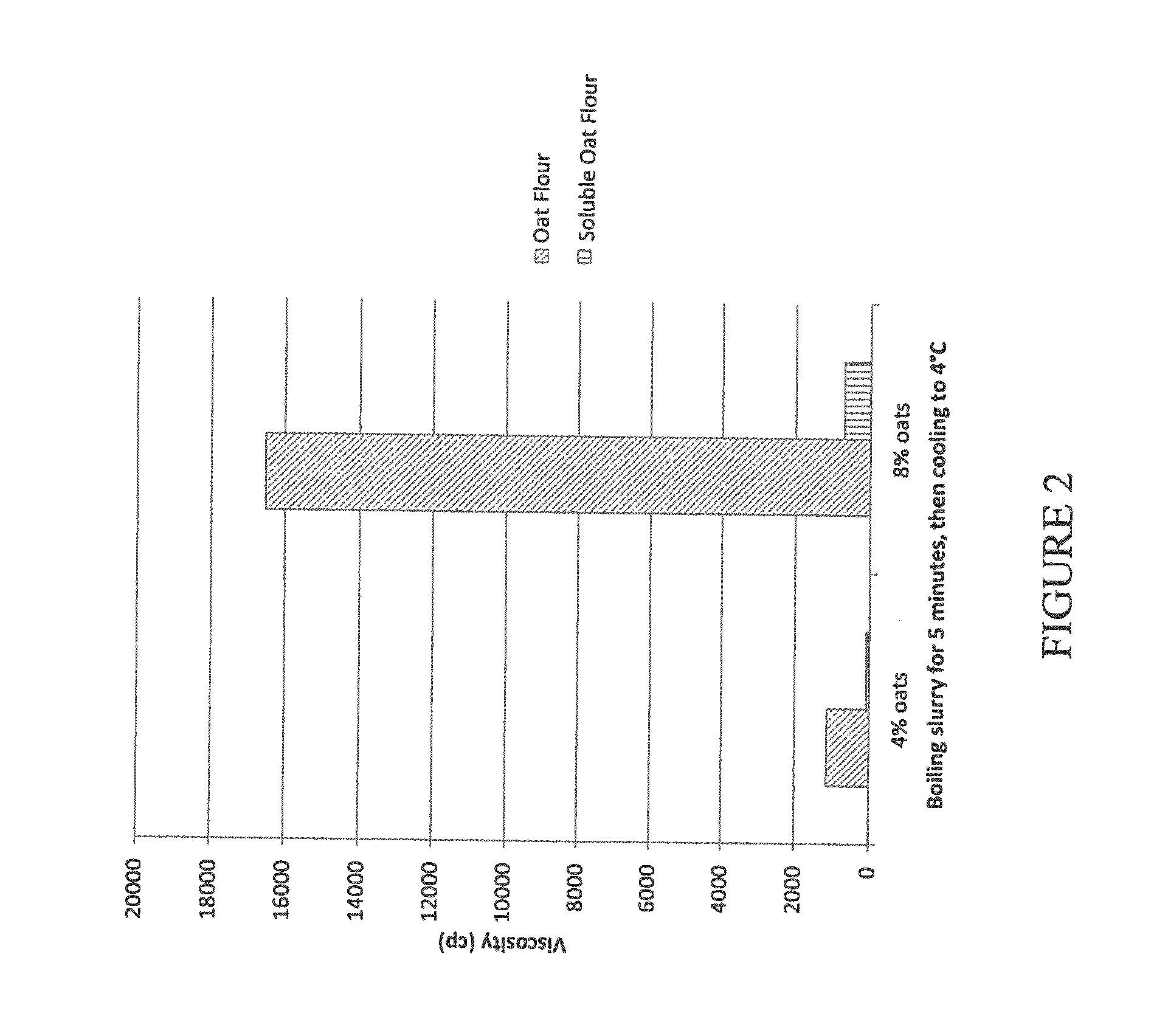

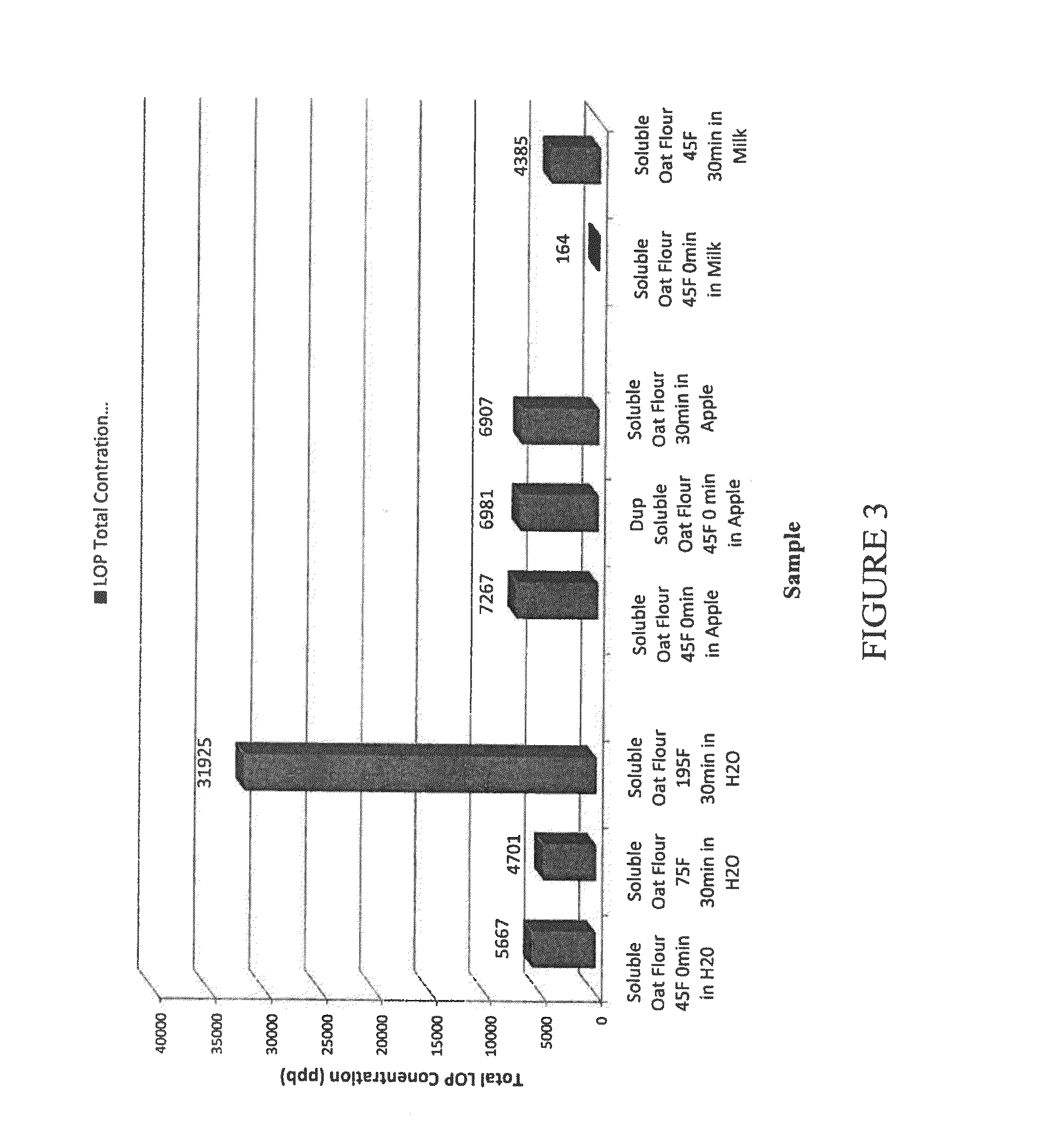

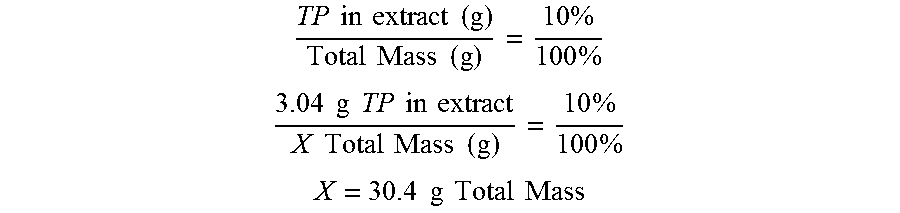

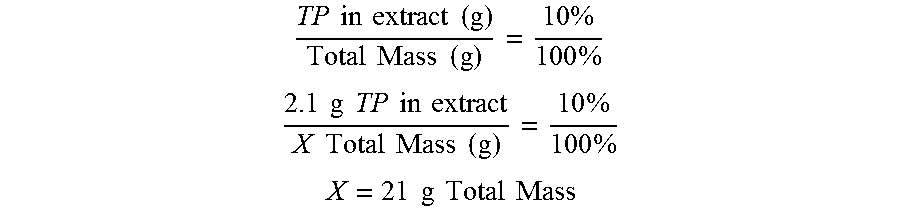

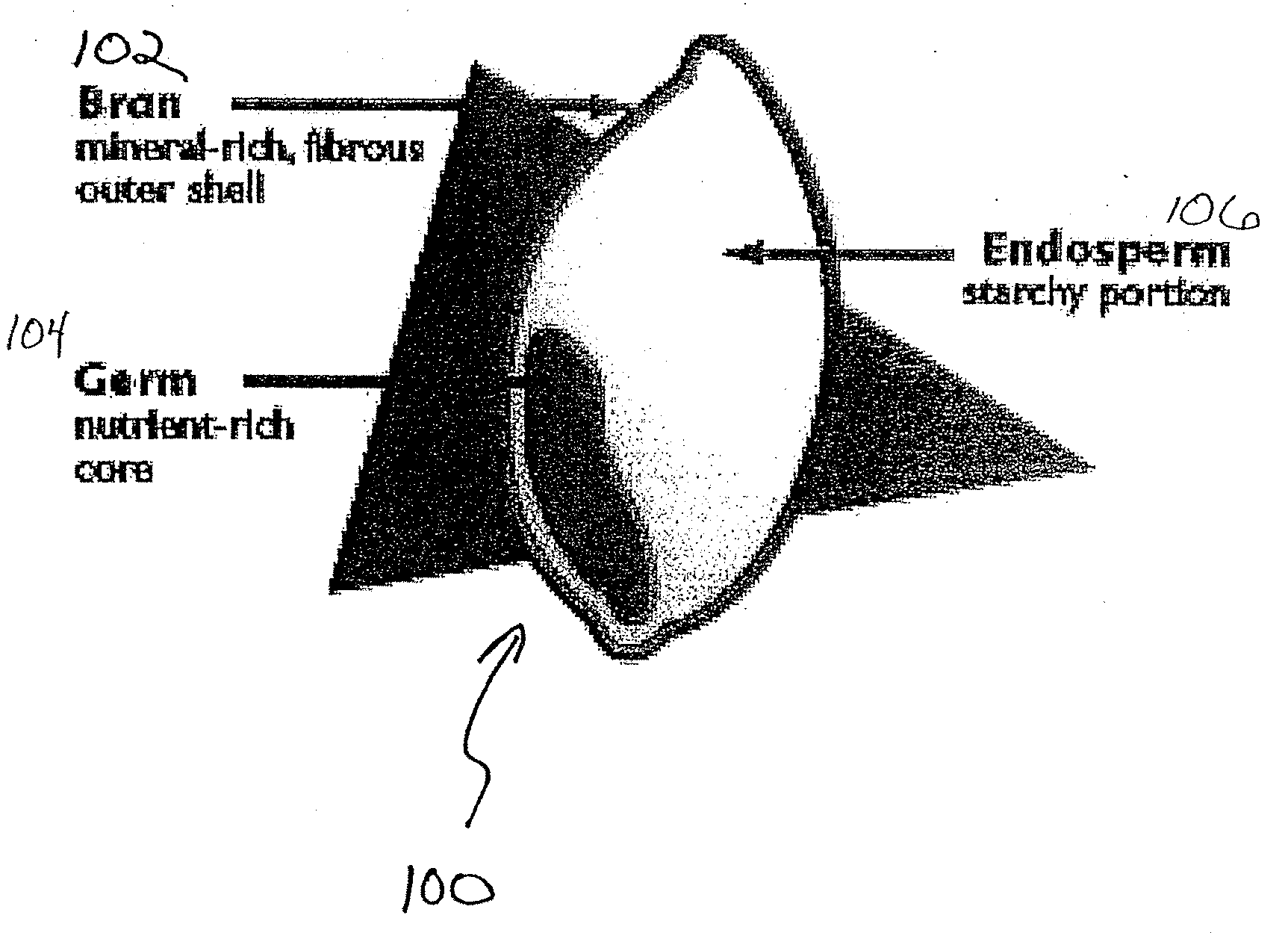

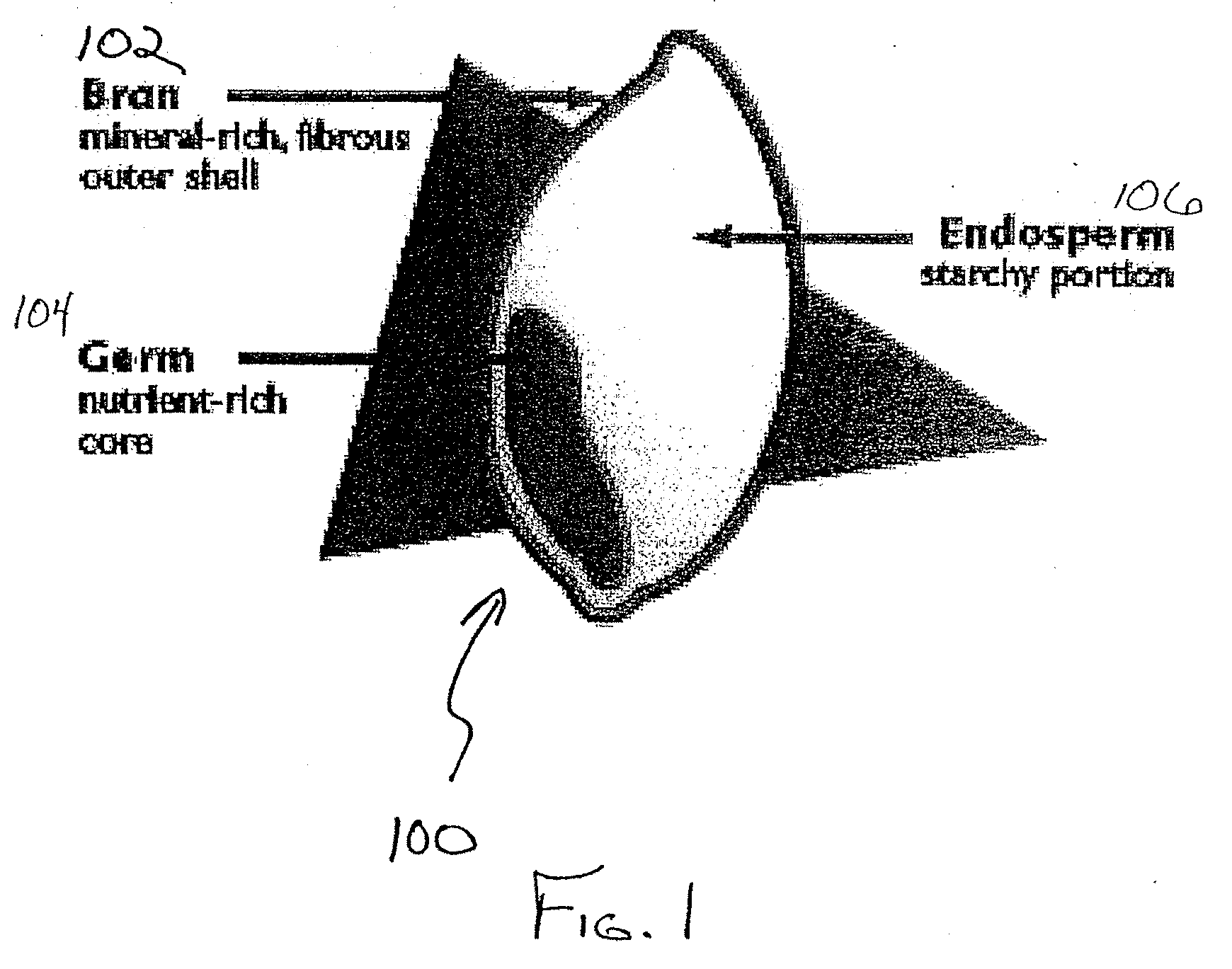

Whole Grain Composition Comprising Hydrolyzed Starch

A composition comprising a whole grain with hydrolyzed starch. Although the starch can shift from relatively higher molecular weight moieties to relatively lower molecular weight moieties during hydrolysis, the relative proportions of the principal anatomical components of the caryopses of the grain—the starchy endosperm, germ and bran—remain approximately the same as evinced, for example, by the weight percentages and relative mass ratios of starch, fat, protein, dietary fiber, beta-glucan, and sugar in the composition. Additionally, the whole grain composition can be a powder, for example, a flour, and the whole grain composition can be granulated to a desired size to provide a powder that is highly dispersible in liquid. When gelatinized, hydrated and dispersed in a liquid, the whole grain with hydrolyzed starch can have a lower viscosity, grittiness, and graininess compared to the same variety of whole grain with unhydrolyzed starch.

Owner:THE QUAKER OATS CO

Baking mixes and processes for making the same

InactiveUS20120263824A1Eliminate and mitigate amountReduce the amount of solutionDough treatmentDough/pre-mixesGlucose polymersD-Glucose

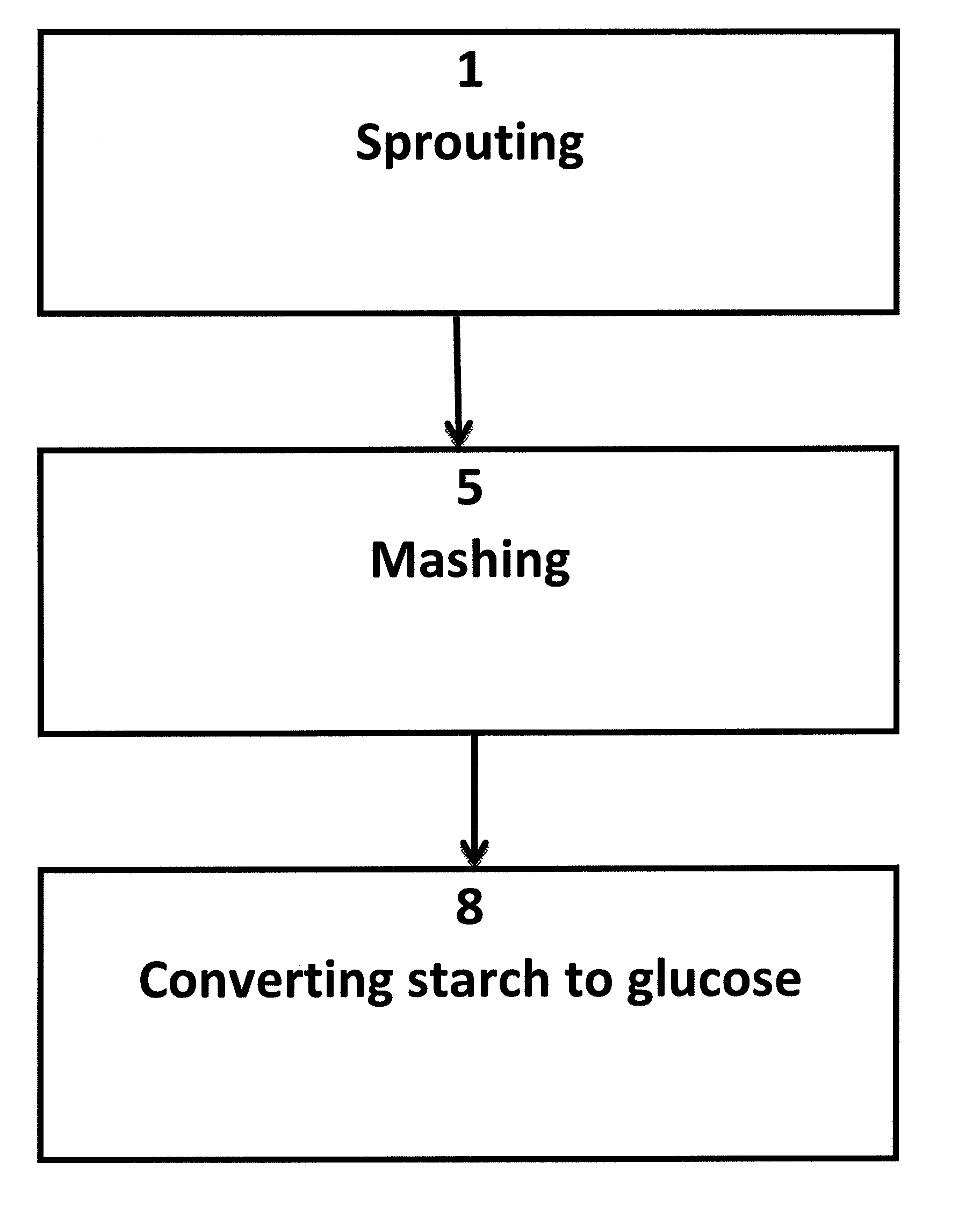

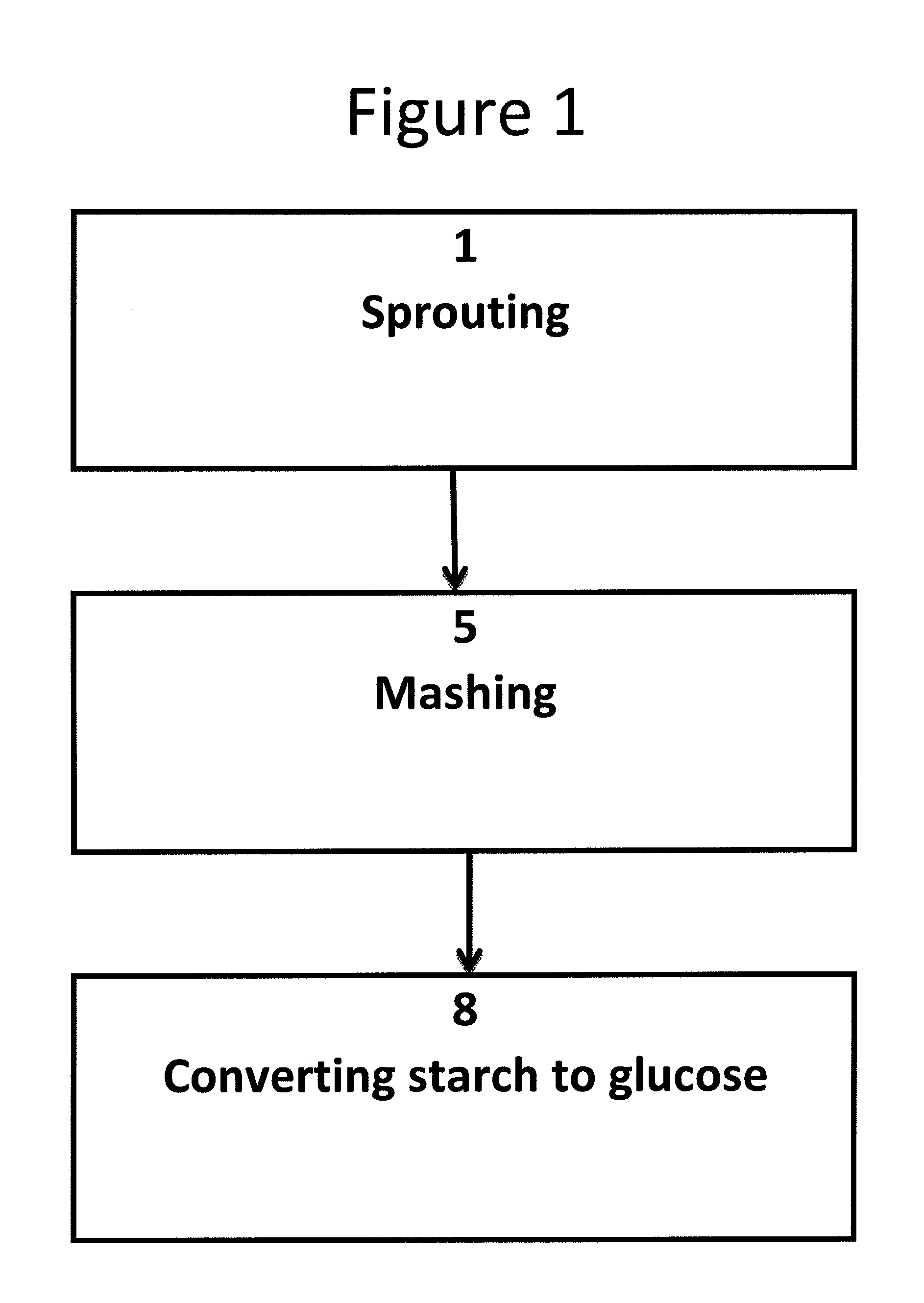

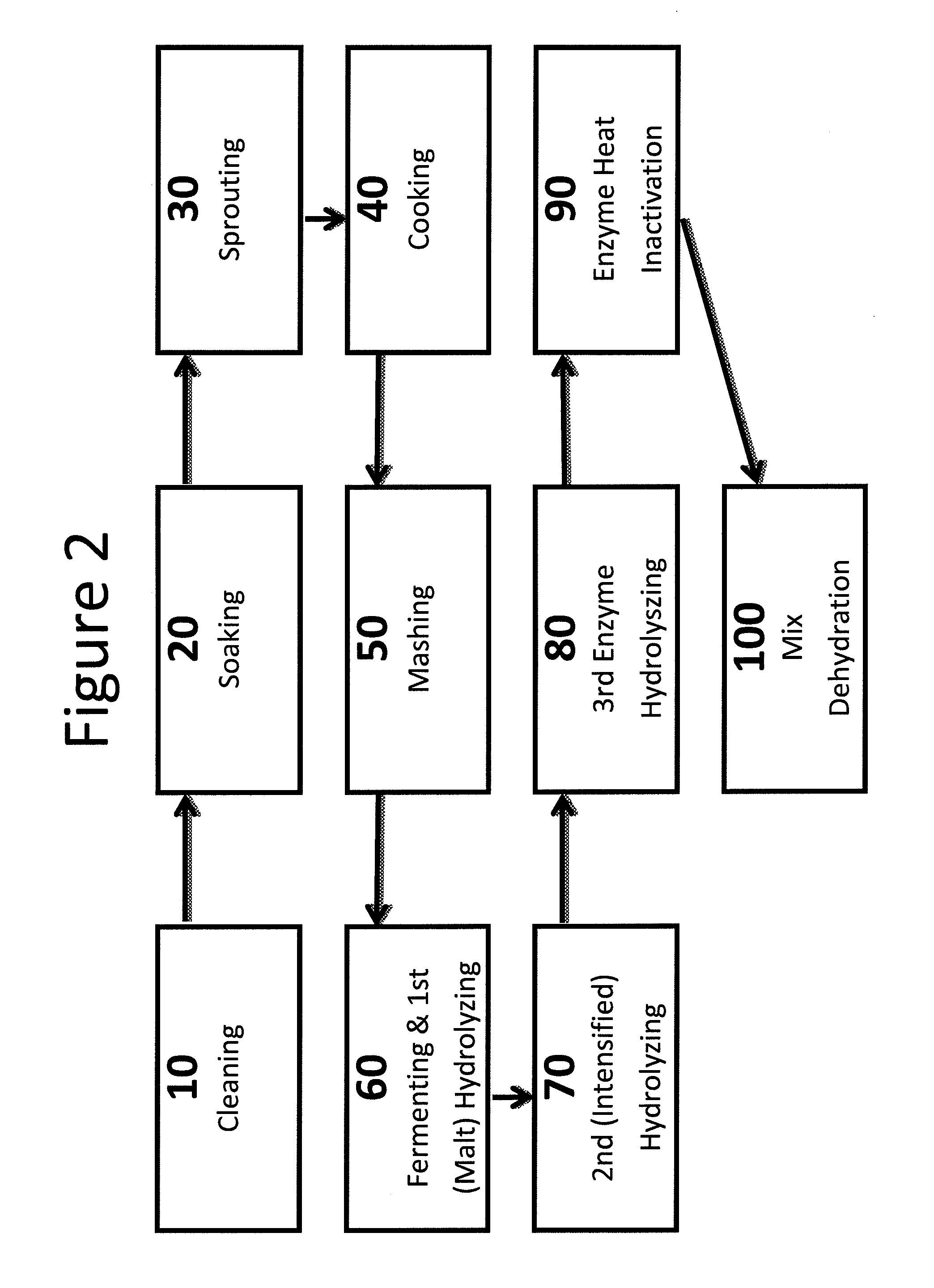

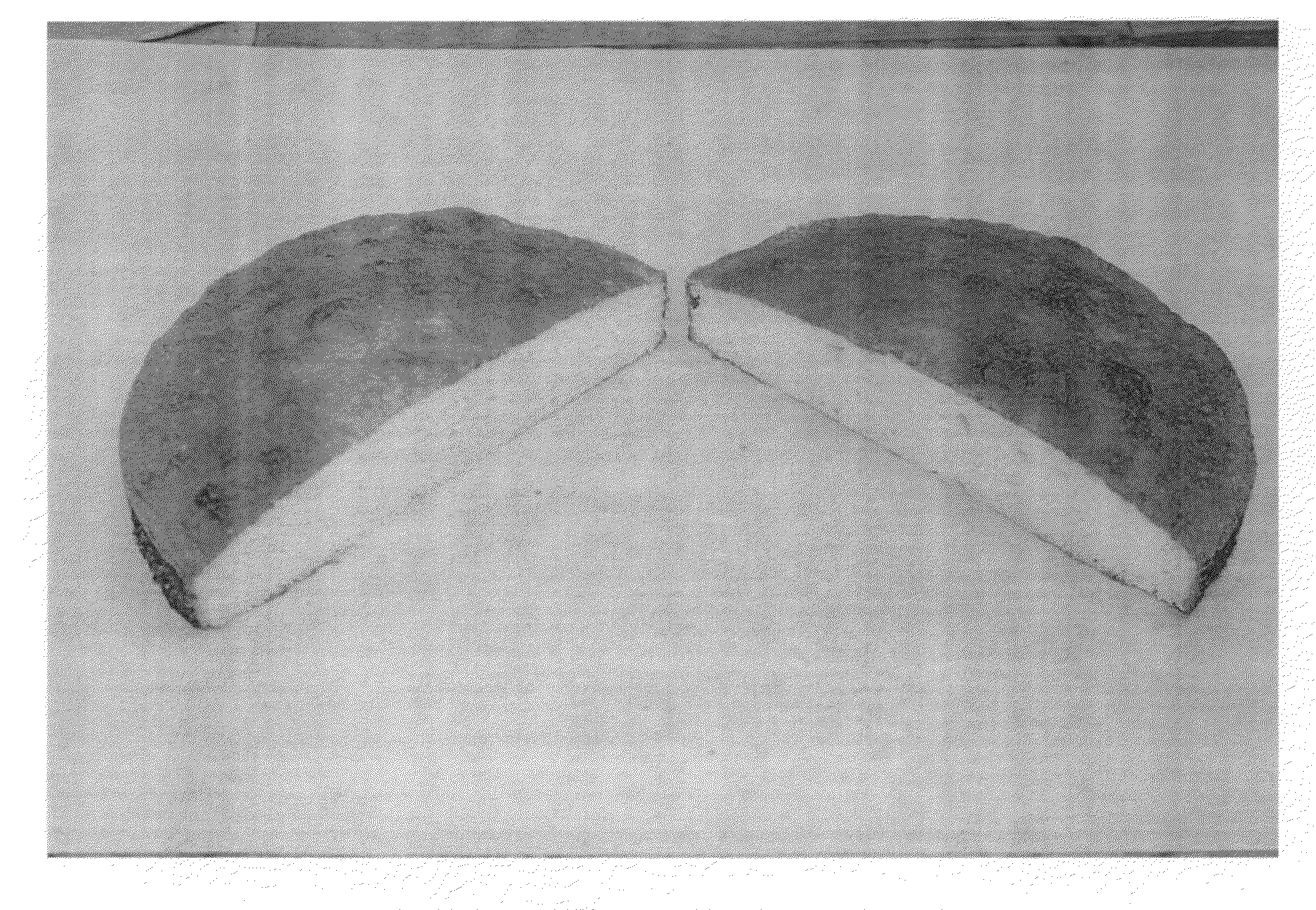

The present invention is related to processes for producing baking mixes in which a whole grain is sprouted and at least a portion of the sprouted whole grain's starch content is enzymatically converted into glucose to provide a sprouted whole grain mix.

Owner:ROMAN MEAL

Dry Mixtures for Making Dough for Bread and Methods for Production Thereof

InactiveUS20070275121A1High acceptabilityQuality improvementDough treatmentDough/pre-mixesGluten-free breadFood science

Dry mixture compositions and methods for preparation of bread are provided. The dry mixture compositions and methods are particularly useful in easy, rapid and inexpensive preparation of wholesome and nourishing gluten-free bread.

Owner:MALBY JYTTE

Gluten-free baked products and methods of preparation of same

InactiveUS20090092716A1Level of optimizationReduce probabilityDough/pre-mixesLeguminous plant bakery productsAdditive ingredientDelivery system

The present invention provides an ingredient delivery system and methods of producing a gluten-free bakery product using an oven to produce quality gluten-free bakery products made by this method.

Owner:CARGILL INC

Full-Fat Soybean Flour-Containing Composition, and Egg Substitute Composition

InactiveUS20110008522A1Add flavorImprove textureDough treatmentDough/pre-mixesAdditive ingredientEgg substitute

A full-fat soybean flour-containing composition which is capable of improving flavor and texture of foods by using as a substitute for a part or the entirety of a basic ingredient of a food, or by additionally using as a novel basic ingredient, and a food prepared using the same are provided. In addition, an egg substitute composition which can be used in a food as an egg substitute and which contains a full-fat soybean flour as a principal component, and a food prepared using the same are provided. The full-fat soybean flour-containing composition of the present invention contains a full-fat soybean flour, a plant protein, an emulsifying agent, and a masking agent. Moreover, the egg substitute composition of the present invention contains a full-fat soybean flour, a plant protein, an emulsifying agent, and a masking agent, and can be used in a food as an egg substitute.

Owner:THE NISSHIN OILLIO GRP LTD

Nutritional bread premixing flour containing tartary buckwheat germ flour, processing method and application

The invention discloses nutritional bread premixing flour containing tartary buckwheat germ flour, a processing method and application. The nutritional bread premixing flour containing the tartary buckwheat germ flour consists of the following materials in part by weight: 12-14 parts of tartary buckwheat flour, 4-5 parts of tartary buckwheat germ flour, 50-55 parts of high gluten wheat flour, 0.5-1.5 parts of refined salt, 6-8 parts of powdered oil, 12-14 parts of compound sugar, 3-4 parts of compound bread improvers, 4-5 parts of vital gluten and 0.1-0.5 part of baking powder. Nutritional bread which is processed by the nutritional bread premixing flour containing the tartary buckwheat germ flour has characteristics of low oil content, low sugar content, low glycemic indexes, high flavonoid content and the like, has a function of balancing nutrition of food, and meets demands of current people on nutrition of the food.

Owner:SHANGHAI INST OF TECH

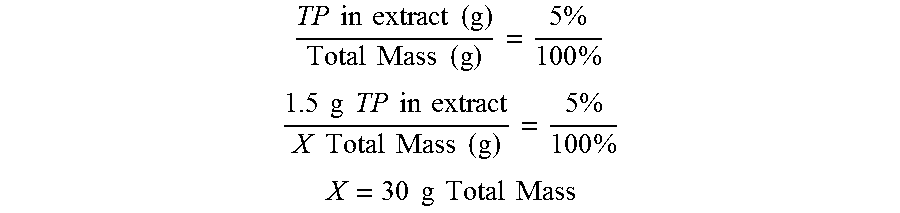

Production of enriched products

ActiveUS20150245645A1Fruit and vegetables preservationDough treatmentDietary supplementDietary product

The present disclosure provides methods for the production of enriched substances that can be used in the preparation of enriched food products, dietary supplements, medical foods, cosmetic products or pharmaceutical agents.

Owner:BOARD OF TRUSTEES RUTGERS THE STATE UNIV OF NEW JERSEY

Composition and method of manufacture

InactiveUS20140093611A1Large scaleReduce contentReady-for-oven doughsMilk preparationAnti nutrientsCow milk

There is provided a gluten-free composition for use in making a gluten-free leavened breadstuff or the like. The composition comprises from 4% by weight to about 27% by weight pulse flour. The composition also comprises starch flour, other flour, a leavening agent and a fermentation agent. There is also described a method of preparing a gluten-free leavened breadstuff or the like. The method comprises the steps of: (a) reducing the anti-nutrient content of a pulse flour; (b) combining the reduced anti-nutrient pulse flour with starch flour, other flour, a leavening agent and a fermentation agent to provide a gluten-free composition; and (c) baking the composition to provide a gluten-free breadstuff or the like. The breadstuffs can be made without the use of any gluten, egg or milk or derivatives or components thereof, and thus can be consumed by those who are allergic or intolerant to such substances.

Owner:PULSETTA

Whole grain products made with whole grain durum wheat

Whole grain baked products and mixes comprising milled whole grain durum wheat are provided. Whole grain durum baked products and mixes utilize milled whole grain durum flour having a generally white-like color wherein durum particulate matter is visually indistinguishable from durum fines by the unassisted eye. Through the use of milled whole grain durum flour, white-like whole grain durum products including white-like whole grain durum breads can be prepared that satisfy generally accepted color and baking performance characteristics for traditional white breads yet contain the bran and germ constituents to provide the nutritional advantages of whole grain products.

Owner:GENERAL MILLS INC

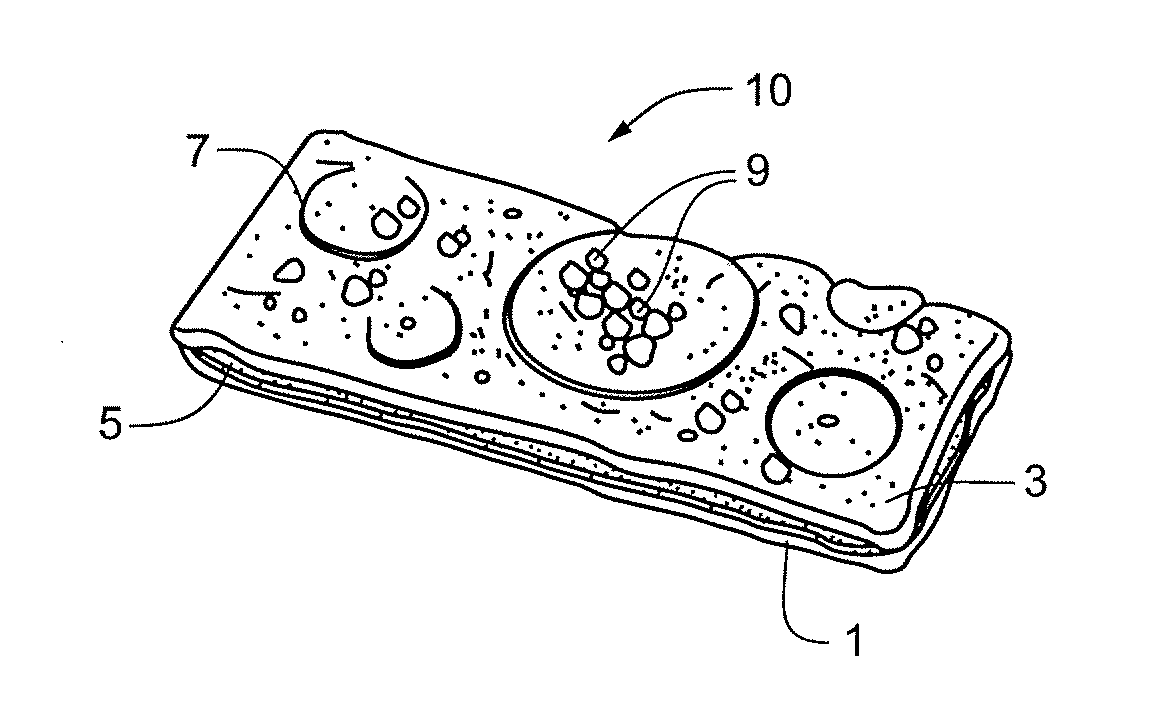

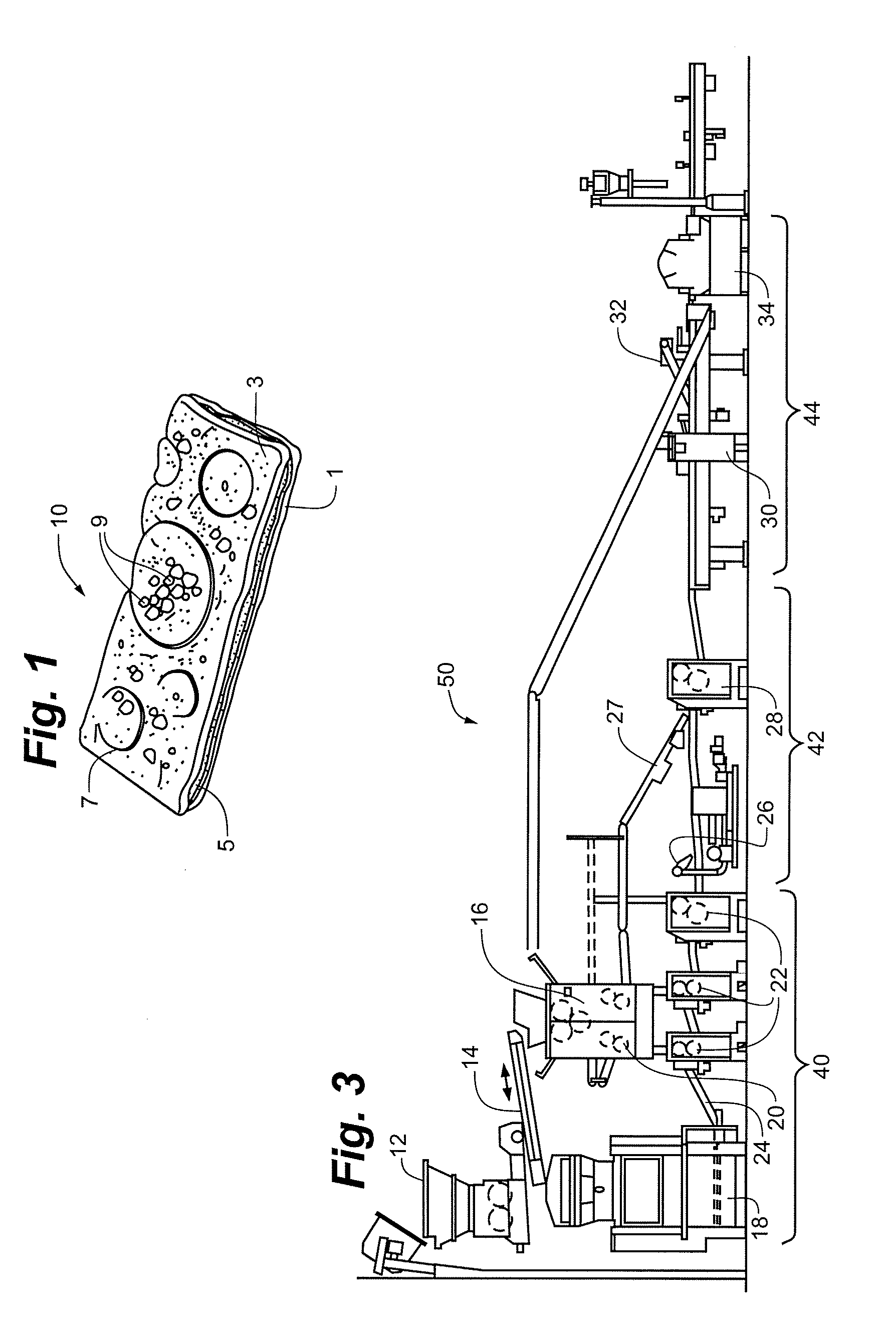

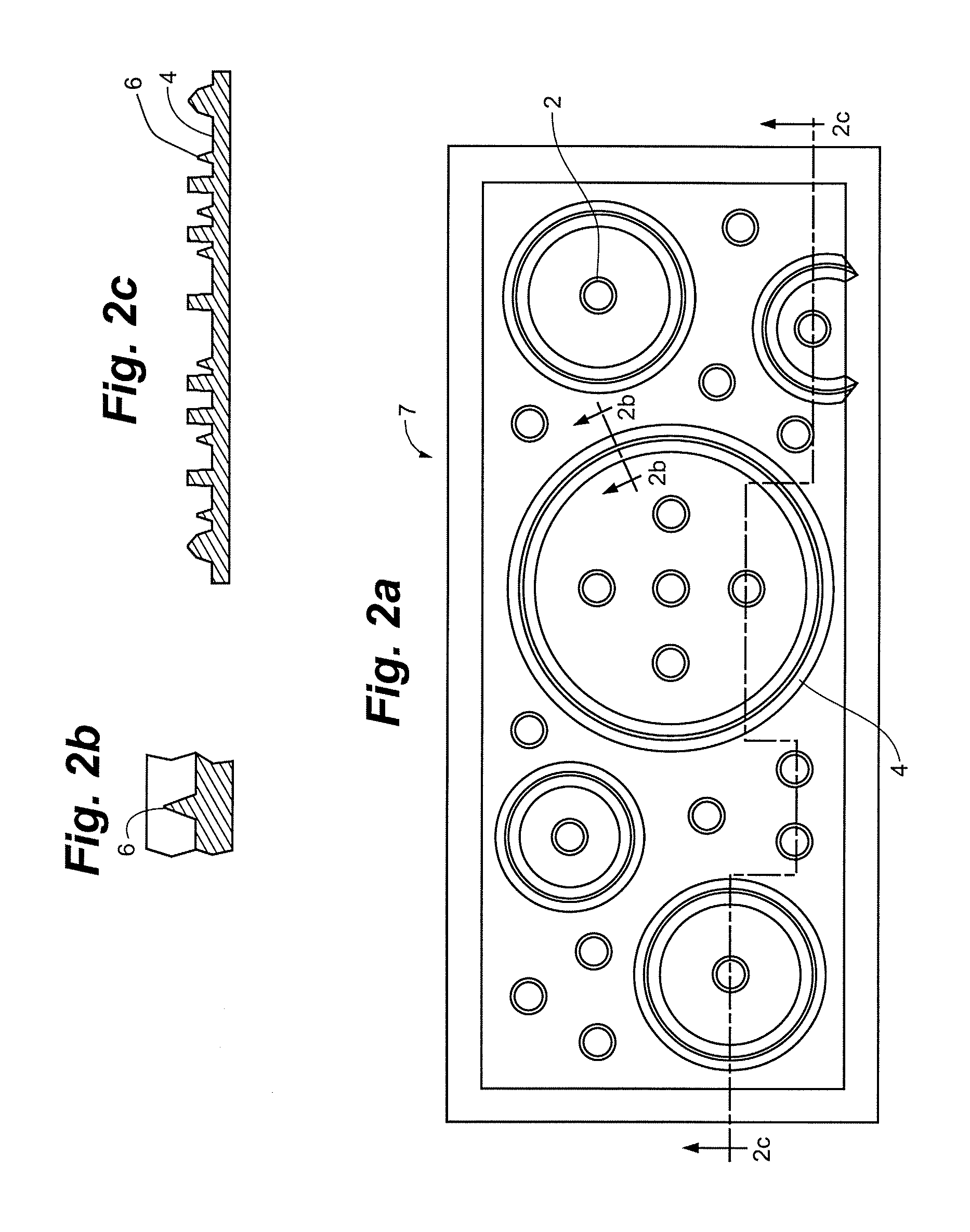

Laminated baked snack bar

ActiveUS20090110780A1High solid contentStay softDough treatmentDough/pre-mixesThin layerThermal stability

A laminated baked snack bar includes a layer of low moisture filling laminated between two thin layers of dough. The dough layers of the snack bar have a crunchy, cracker-like texture while the filling layer remains soft. The total thickness of the baked snack bar is preferably less than 7 millimeters. The snack bar is prepared by calibrating dough sheets to a thickness of less than 1 millimeter each, followed by depositing a filling composition having a high heat resistant stability on one of the calibrated dough sheets and placing a second calibrated dough sheet on top of the filling to form a laminate. The laminate is then calibrated, cut into bars and baked, using a mild baking profile. The snack bar may have a design molded on the top surface and / or a topping composition, preferably including oats, deposited on the laminate.

Owner:CORPORATIVO INT MEXICANO S DE R L DE

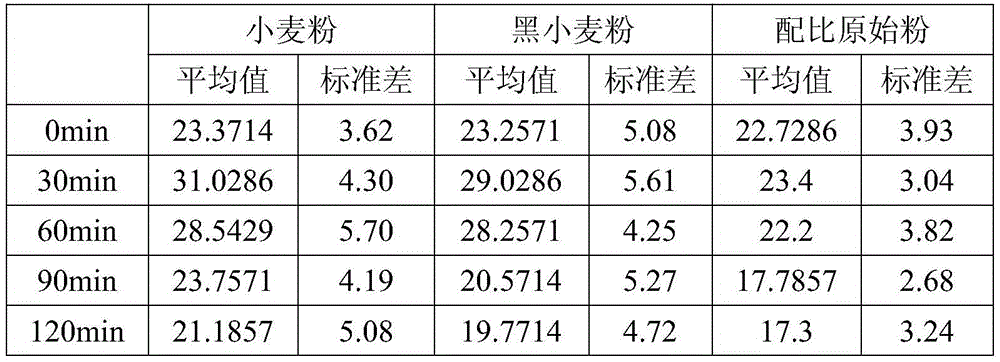

Method for preparing series food by means of triticale mixed flour

InactiveCN105558786AImprove processing qualityStrong blood sugar raising effectDough treatmentDough/pre-mixesBlood glucose increasedGluten

The invention discloses a method for preparing series food by means of triticale mixed flour. The method comprises the steps of mixing triticale flour with green bean flour according to a certain proportion to form original flour; adding a proper amount of vital gluten and / or konjaku flour to the original flour, conducting even mixing to obtain the triticale mixed flour, and making the triticale mixed flour into triticale and green bean blood glucose reduction steamed buns, triticale and green bean blood glucose reduction noodles, triticale and green bean blood glucose reduction cookies or triticale and green bean blood glucose reduction paste. Guantao triticale is taken as the main material, and the original flour obtained after triticale flour and green bean flour are mixed according to a certain proportion has a better blood glucose increase control effect compared with purer triticale flour. Meanwhile, by adding vital gluten and / or konjaku flour to the original flour, the processing quality of triticale flour is improved effectively, and products with good taste are obtained.

Owner:馆陶县科学技术局

Refined bread flour

InactiveCN101204168AIncrease in sizeGuarantee product qualityDough treatmentDough/pre-mixesVitamin CAlpha-amylase

The invention relates to a refining bread flour, belonging to a technical field of processing the flour by adding organic substances before baking, which includes: raw material flour, an additive, an emulsifier. The bread flour is characterized in that the material flour is domestic wheat flour and no potassium bromate exists in the additive; The additive adopts vitamin C, glucose oxidase, Alpha-amylase, pentosan enzyme, hemicellulase and ADA. Refined bread four produced in the invention is completely suitable for making bread and the bread products do not shrink and collapse; through adjustment of the additive, dough made by the flour presents good expansion and upright-standing after put into an oven so as meet the requirement of the consumers.

Owner:QINGDAO WHITE ORIENTAL CHERRY INDAL

Batter-like compositions containing setting agent and methods of preparing and using same

ActiveUS20070048426A1Easy to handleMaintain structural integrityDough treatmentDough/pre-mixesCooking & bakingAdditive ingredient

The invention provides batter-like compositions including flour or flour replacement ingredient, sweetener, a fat source, a chemical leavening system, and a setting agent. The resulting batter-like compositions are capable of being formed into discrete product pieces (such as pucks), and maintaining the discrete product form throughout storage and handling of the batter-like composition prior to baking. The invention further provides methods of preparing batter-like compositions having a discrete form, and methods of using such batter-like compositions to provide baked goods.

Owner:GENERAL MILLS INC

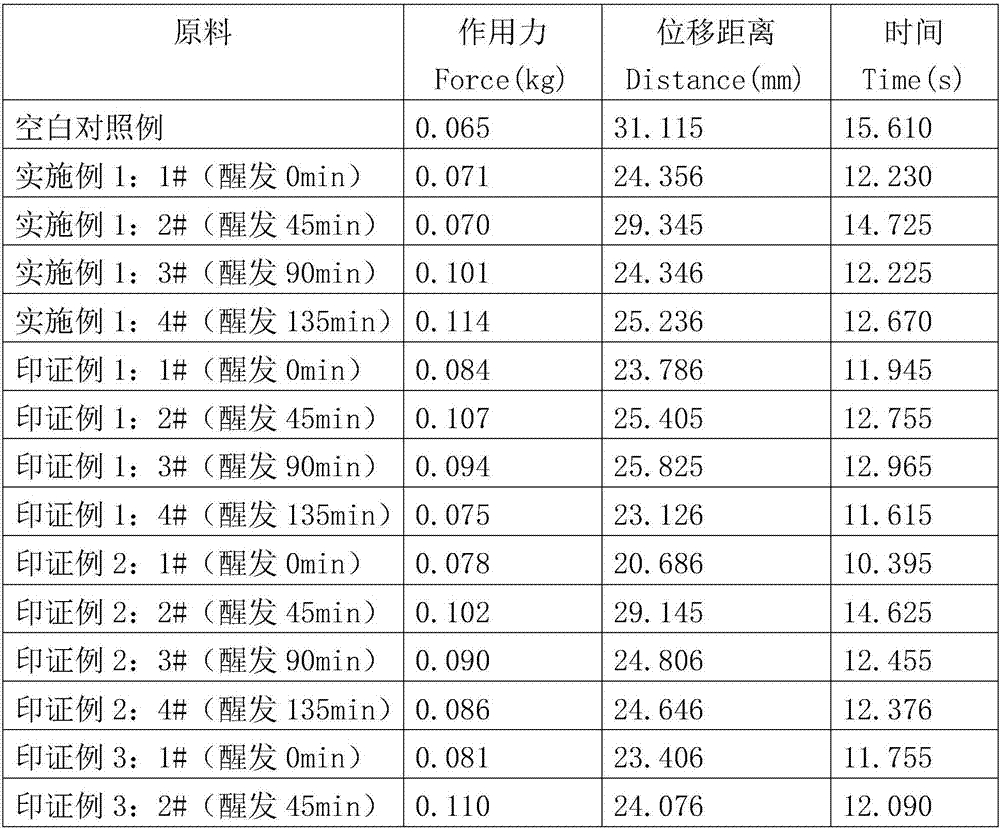

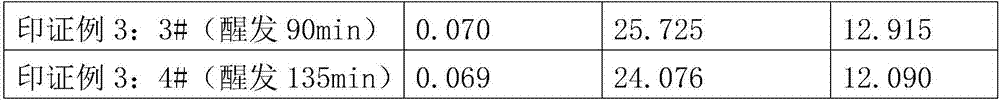

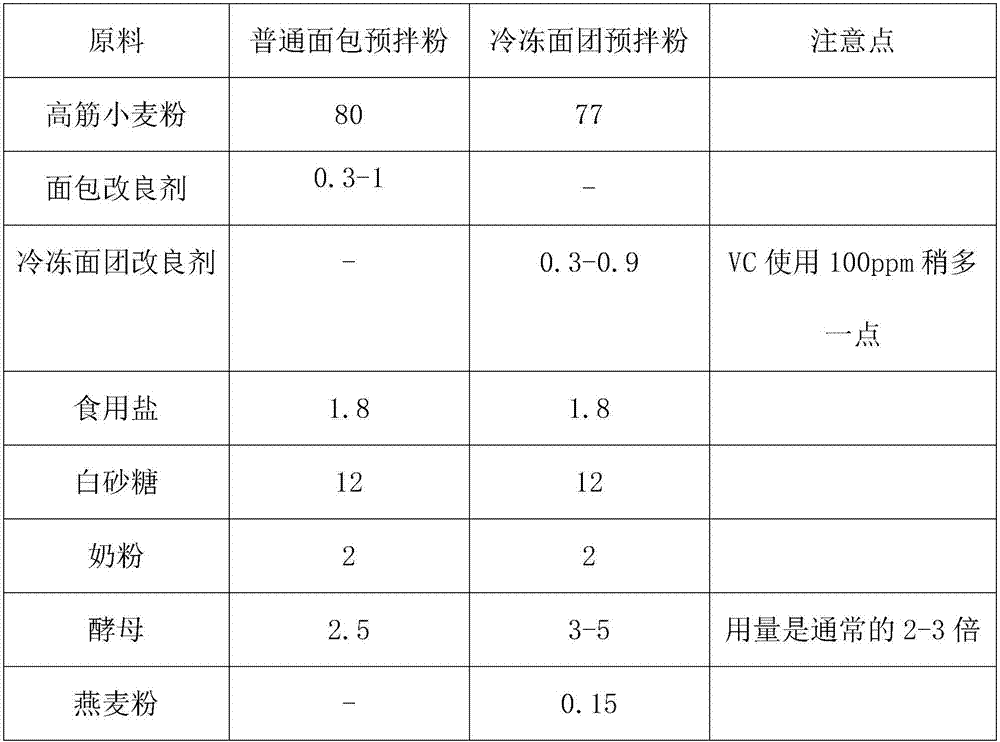

Frozen-dough bread premixing powder and preparation method thereof

InactiveCN107006556APrevent spoilageImprove qualityDough treatmentDough/pre-mixesMonoglyceridePhosphate

The invention provides a frozen-dough bread premixing powder and a preparation method thereof. The frozen-dough bread premixing powder includes a frozen dough improver, a high-gluten wheat flour, oat flour, edible salt, white granulated sugar, milk powder and yeast. The frozen dough improver refers to one or a mixture of glucose oxidase, xylanase, alpha-amylase, fatty acid monoglyceride, fatty acid diglyceride, calcium sulfate, calcium dihydrogen phosphate, tricalcium phosphate, ascorbic acid, trehalose, wheat gluten powder, sodium polyacrylate and corn starch. By means of an emulsifier, oil and water are fully combined and mixed in dough, the dough, oil and water can be fully kneaded together, a more excellent water water-retaining property is obtained, and products thus have more advantages in softness, preservation duration and shelf life. The frozen-dough bread premixing powder using the frozen dough improver can avoid the deterioration of the dough at low temperature, the shelf life is prolonged, and the quality of the frozen dough is improved.

Owner:JIANGXI AGRICULTURAL UNIVERSITY +1

Dry mix compositions including corn syrup and methods of preparing baked goods such as cookies and brownies therefrom

InactiveUS20070110869A1Easy illustrationReduced sweetening agent-to-flourDough treatmentDough/pre-mixesBaked goodsCorn syrup

The invention provides shelf stable dry mix compositions for use in preparing a baked good, the dry mix compositions including flour, sweetening agent, wherein a portion of the sweetening agent is corn syrup, and fat source. Optionally, the dry mix compositions include leavening systems. Methods of making shelf stable dry mixes are also described.

Owner:GENERAL MILLS INC

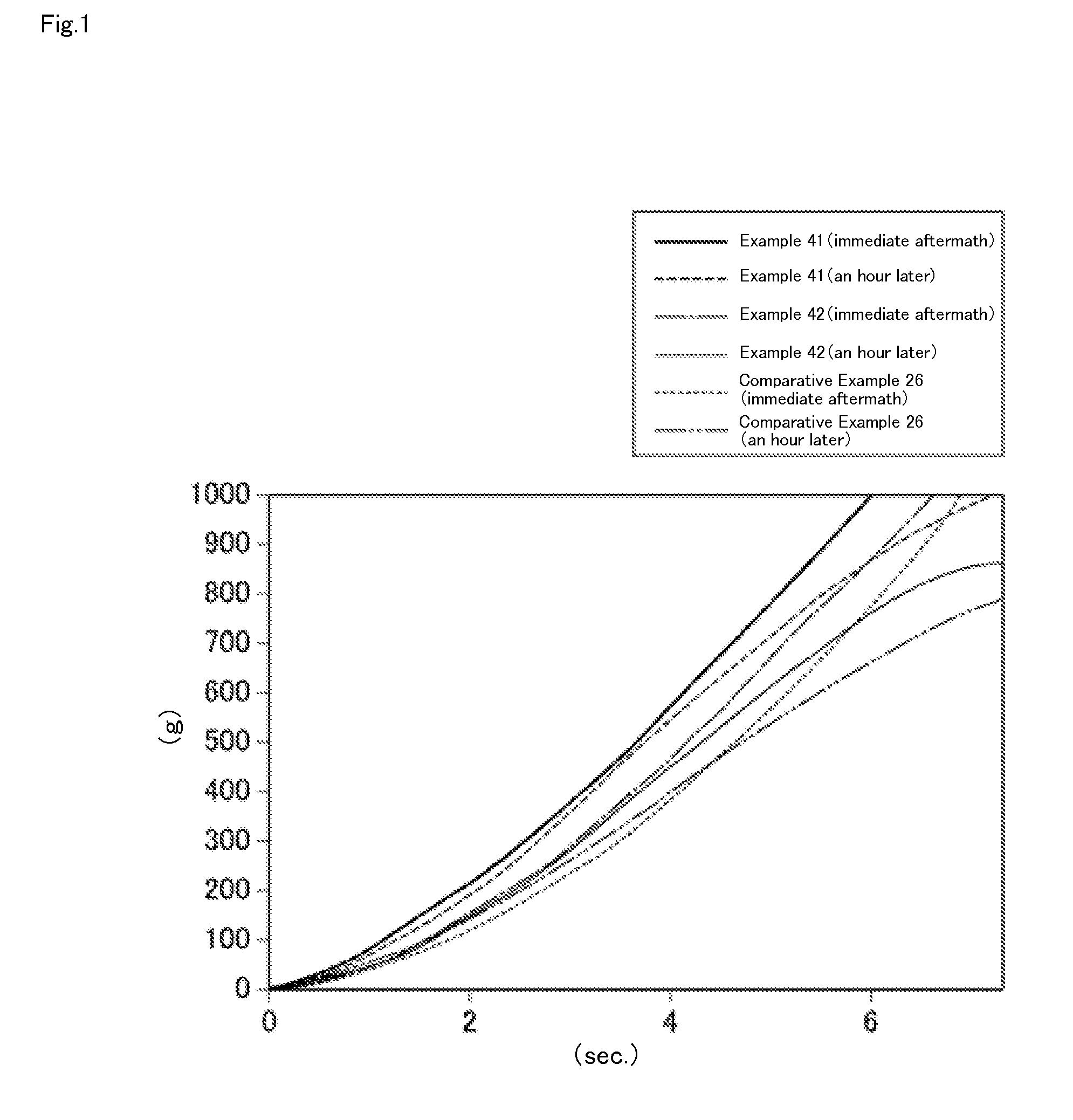

Rice flour composition for producing breads/cakes, rice flour breads and cakes and process for producing the same

A rice flour composition is provided, which includes a rice flour produced by a conventional flour milling method without any special apparatus or treatment and which can produce breads or confectionery excellent in appearance, internal phase, taste, and keeping quality, through a process similar to a conventional process of making breads or confectionery. Also provided are a dough product and a food product each produced with such a composition, and a method of producing such a food product. Such a rice flour composition for use in breads or confectionery comprises: 100 parts by weight of grain flour including 80 to 85 parts by weight of rice flour and 15 to 20 parts by weight of gluten; and 1 to 30 parts by weight of maltose, wherein the rice flour is a product of stamp milling, roll milling, stone milling, jet stream milling, or high speed rotation impact milling. A dough product and a food product are each produced with such a composition. A method of producing such a food product is also provided.

Owner:SHITOGI JAPAN

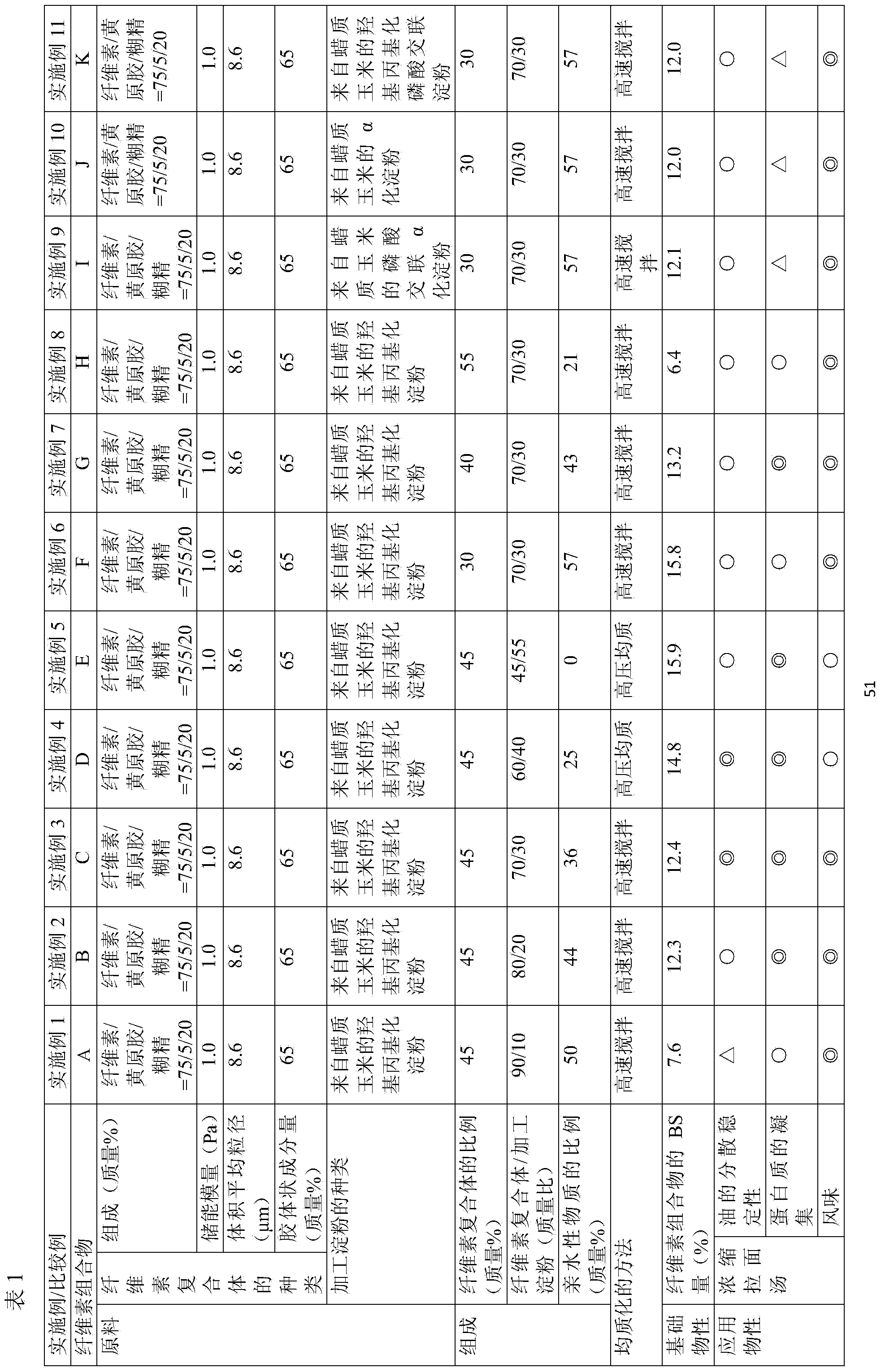

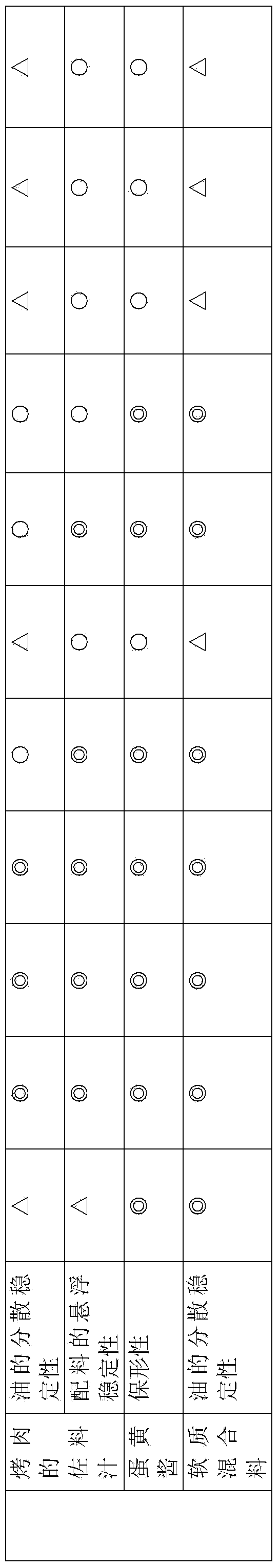

Cellulose composition

InactiveCN104114037AGood dispersionImprove dispersion stabilityDough treatmentDough/pre-mixesCelluloseWater soluble polysaccharides

[Problem] To provide a cellulose composition which can be easily dispersed in an aqueous medium having a high salt concentration, and which, particularly when used in a food or drink having a high oil content, has a high dispersion stabilizing effect for unemulsified oils, as well as a suspension stabilizing effect and a shape retaining effect. Also, to improve the quality and production suitability of low-density confectionery having a delicate texture, and improve the texture of bakery products using said cellulose composition. [Solution] A cellulose composition including cellulose, a water-soluble polysaccharide, and a modified starch, said cellulose composition having, when dispersed in an aqueous solution of 5 mass% sodium chloride such that the concentration of said cellulose composition therein is 0.01 mass% and subjected to sonication for two minutes, a particle size distribution of 6% or greater of 1-mum or smaller components in an area frequency histogram obtained by measuring using a laser diffraction / scattering particle size distribution analyzer at a refractive index of 1.04.

Owner:ASAHI KASEI KK

Plant-based egg substitute and method of manufacture

Disclosed herein are non-egg compositions that can be used as egg substitutes. The disclosure is directed to egg substitutes and methods of manufacturing the same, and compositions comprising the egg substitutes, including edible compositions such as baked goods and edible emulsions.

Owner:JUST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com