Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

127results about How to "Stay soft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

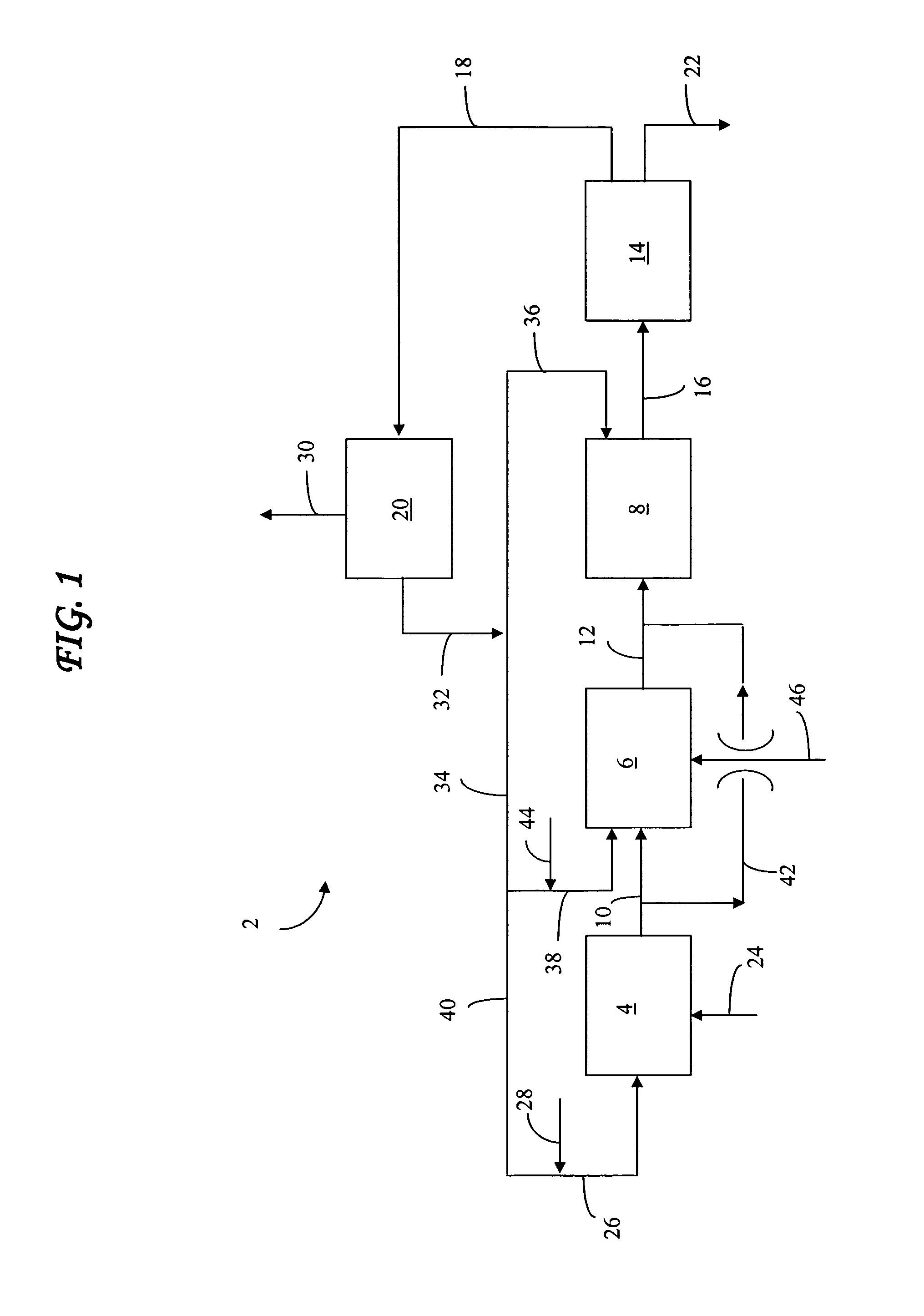

Polymer blends and pellets and methods of producing same

Blends of at least two polymers incorporating propylene-derived units and processes for producing such blends are provided. The first polymer of the blend is a low crystallinity polymer including propylene-derived units. The second polymer is a high crystallinity polymer including propylene-derived units. The polymer blends exhibit the beneficial performance characteristics of low crystallinity propylene polymers while minimizing certain processing and handling problems associated with low crystallinity propylene polymers. Low crystallinity propylene polymer pellets often exhibit a tendency to agglomerate because of the softness of such particles. Agglomeration of the pellets creates problems in handling and processing the particles. The polymer blends disclosed reduce the tendency of polymer pellets to agglomerate while maintaining the desirable physical properties, such as elastomeric properties, exhibited by low crystallinity propylene polymers. Various processes for producing the polymer blends are also provided.

Owner:EXXONMOBIL CHEM PAT INC

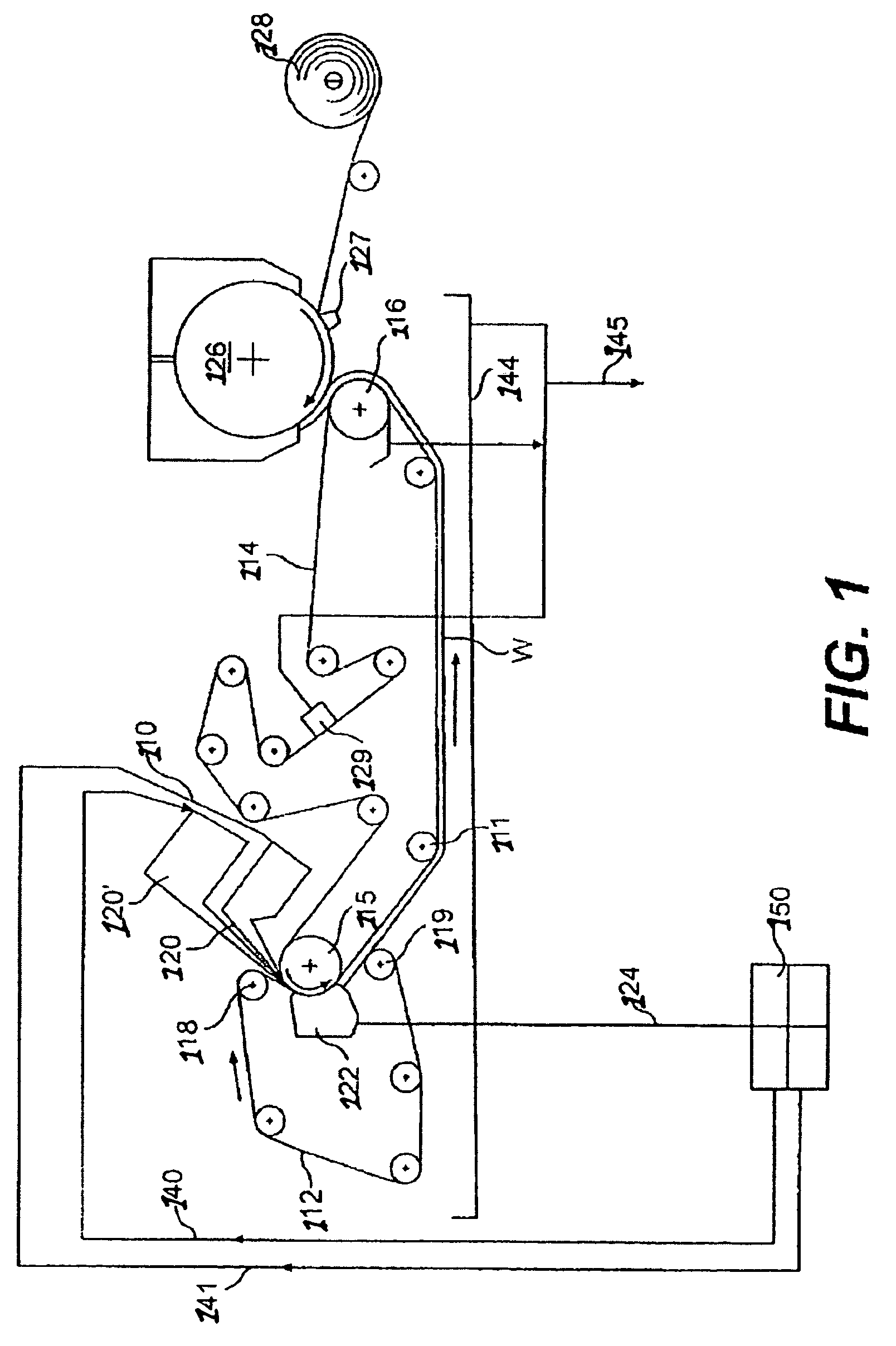

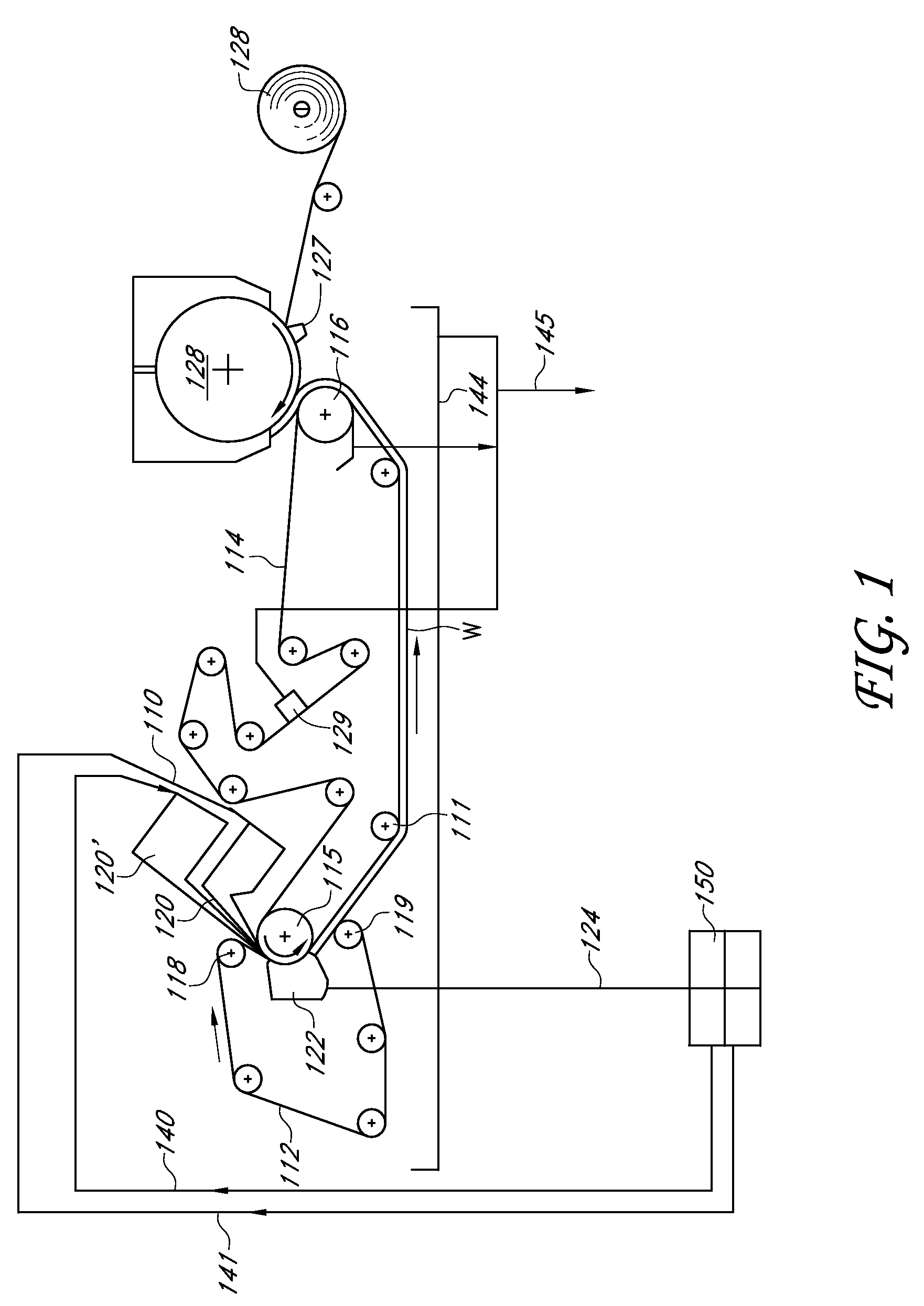

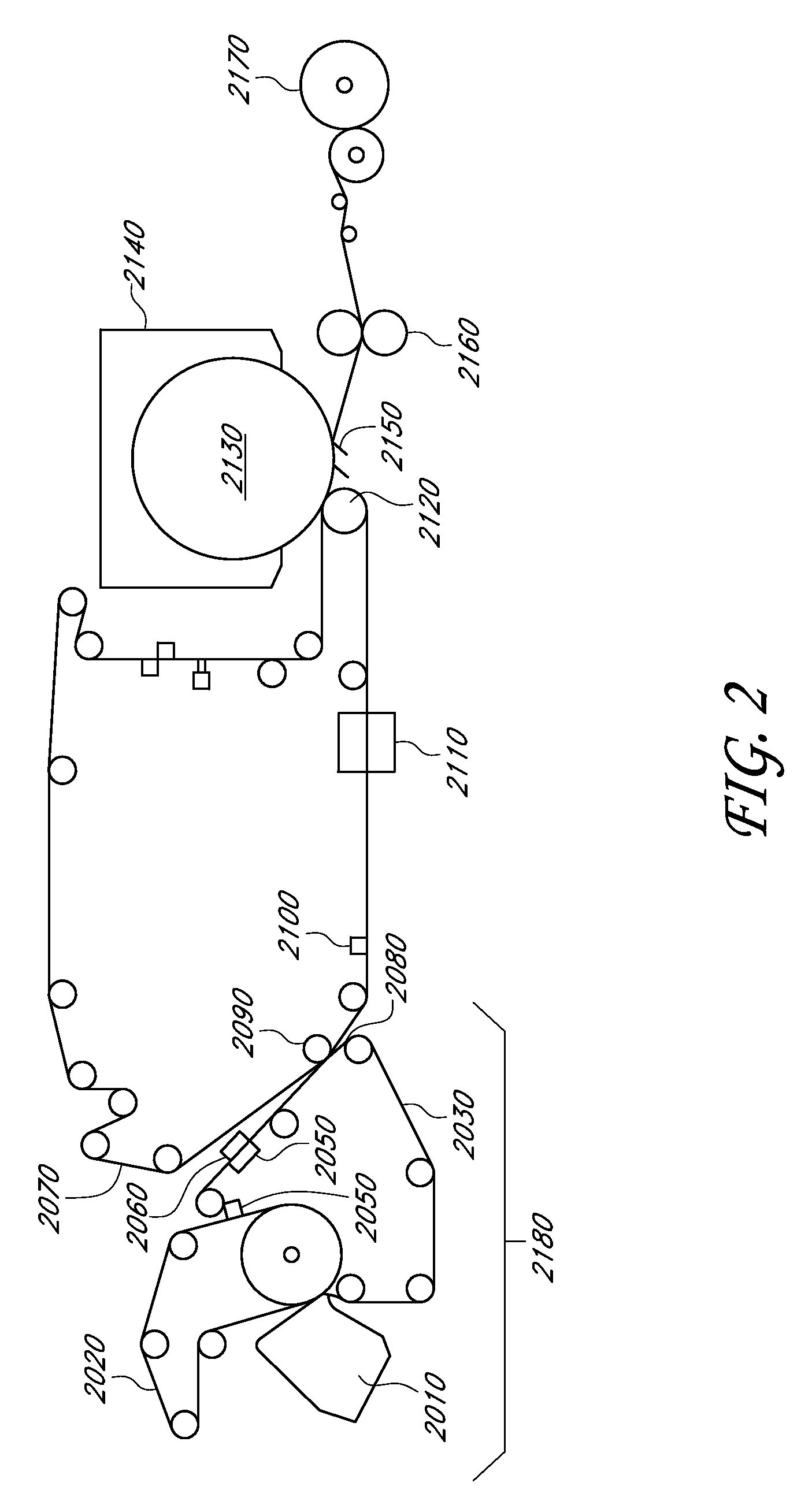

Methods for creping paper

ActiveUS7744722B1Reduce accumulationPrevent adhesive build-upNatural cellulose pulp/paperMechanical working/deformationAdhesiveCrêpe paper

A creping aid system for use on a creping cylinder, for example, a Yankee dryer, comprises a creping adhesive and a creping modifier, the combination comprising polyethylene.

Owner:SOLENIS TECH CAYMAN

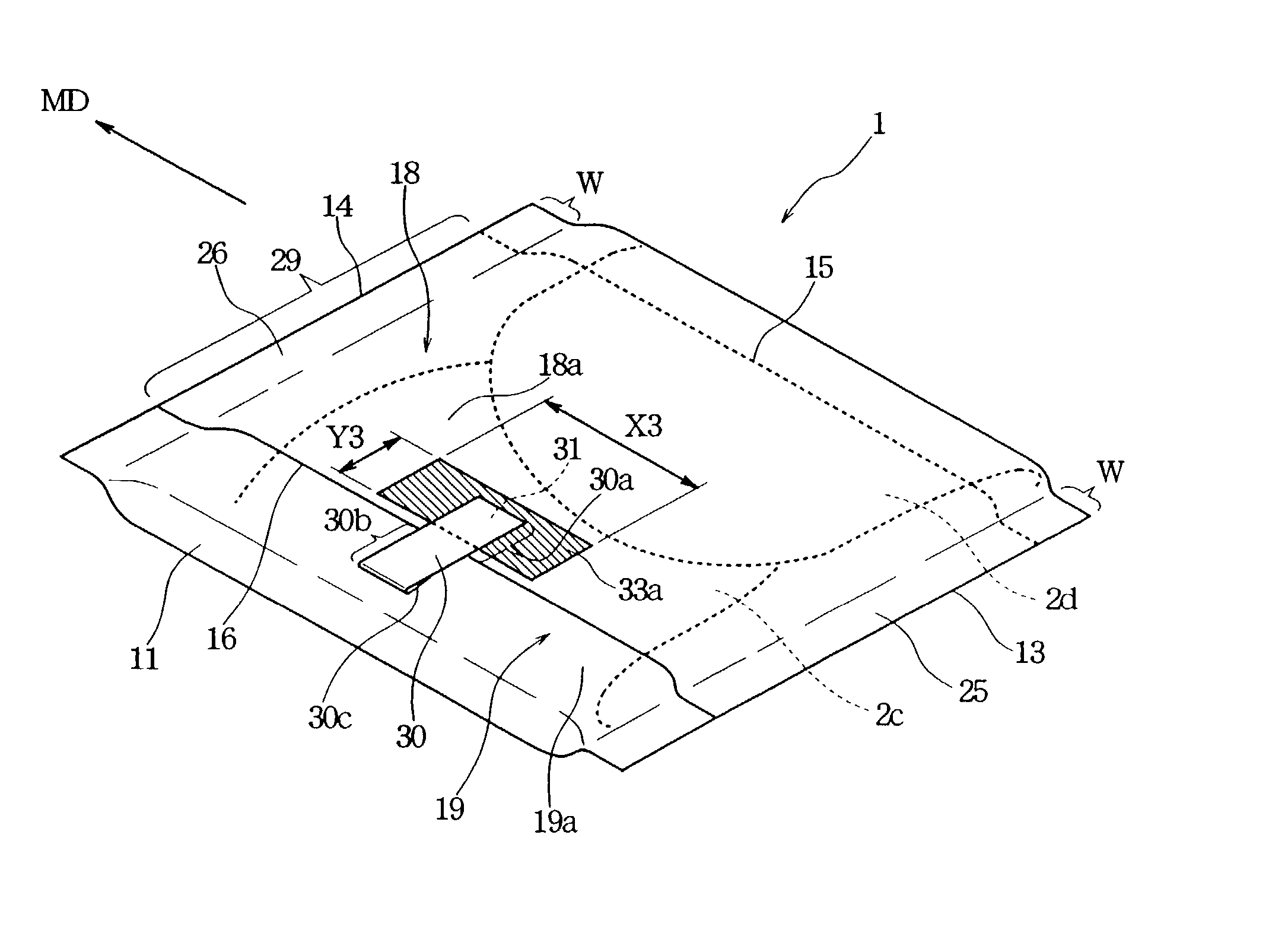

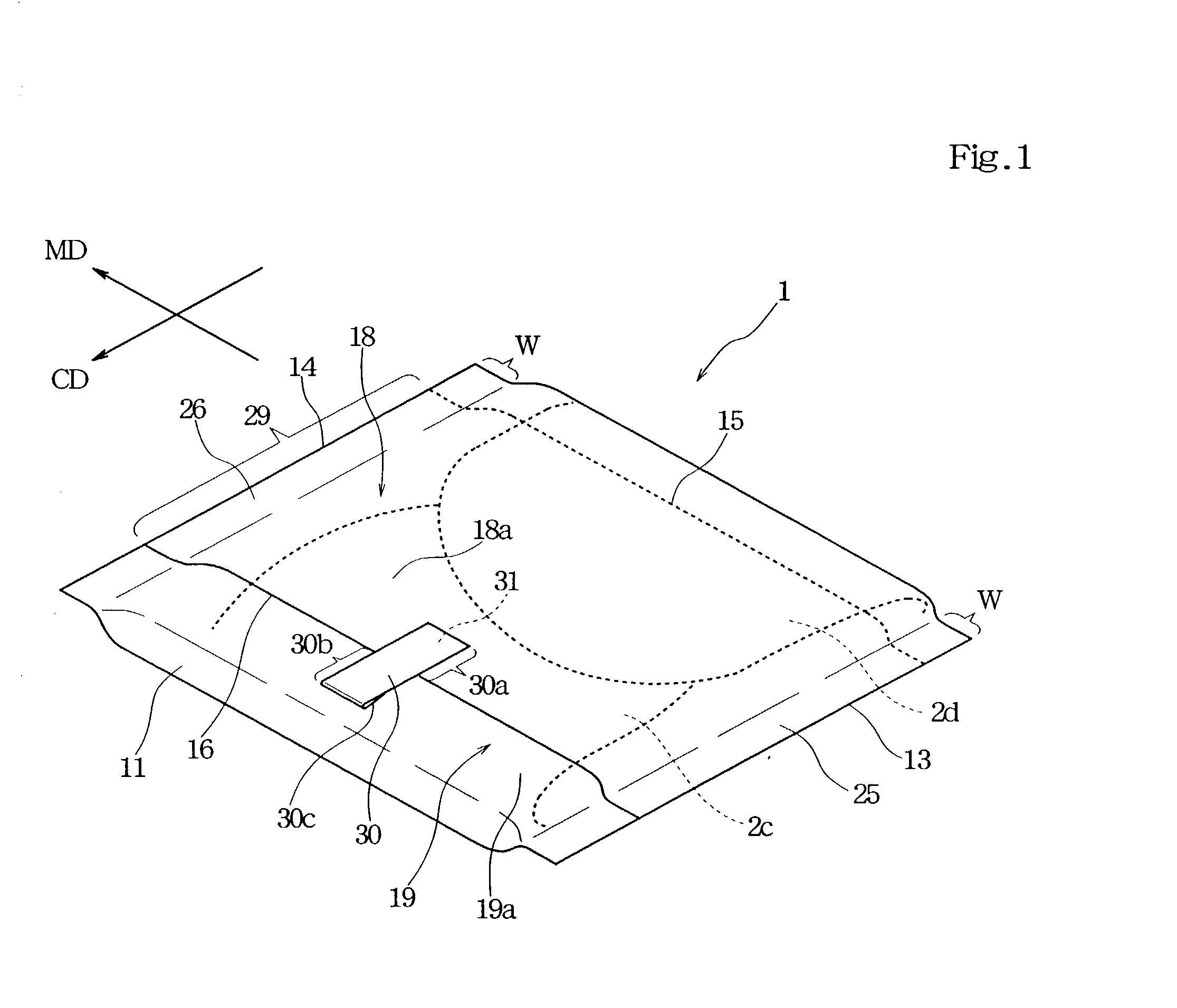

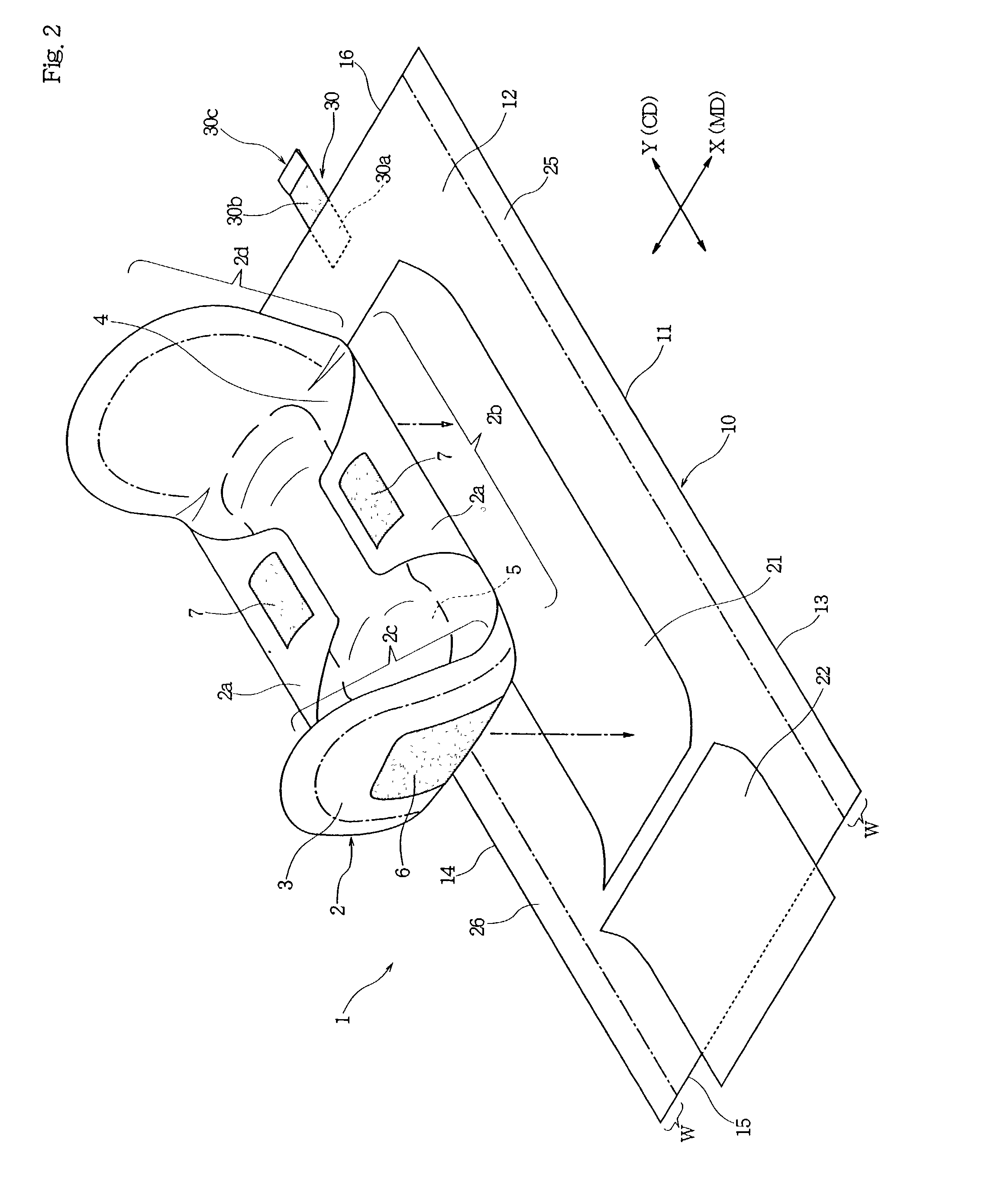

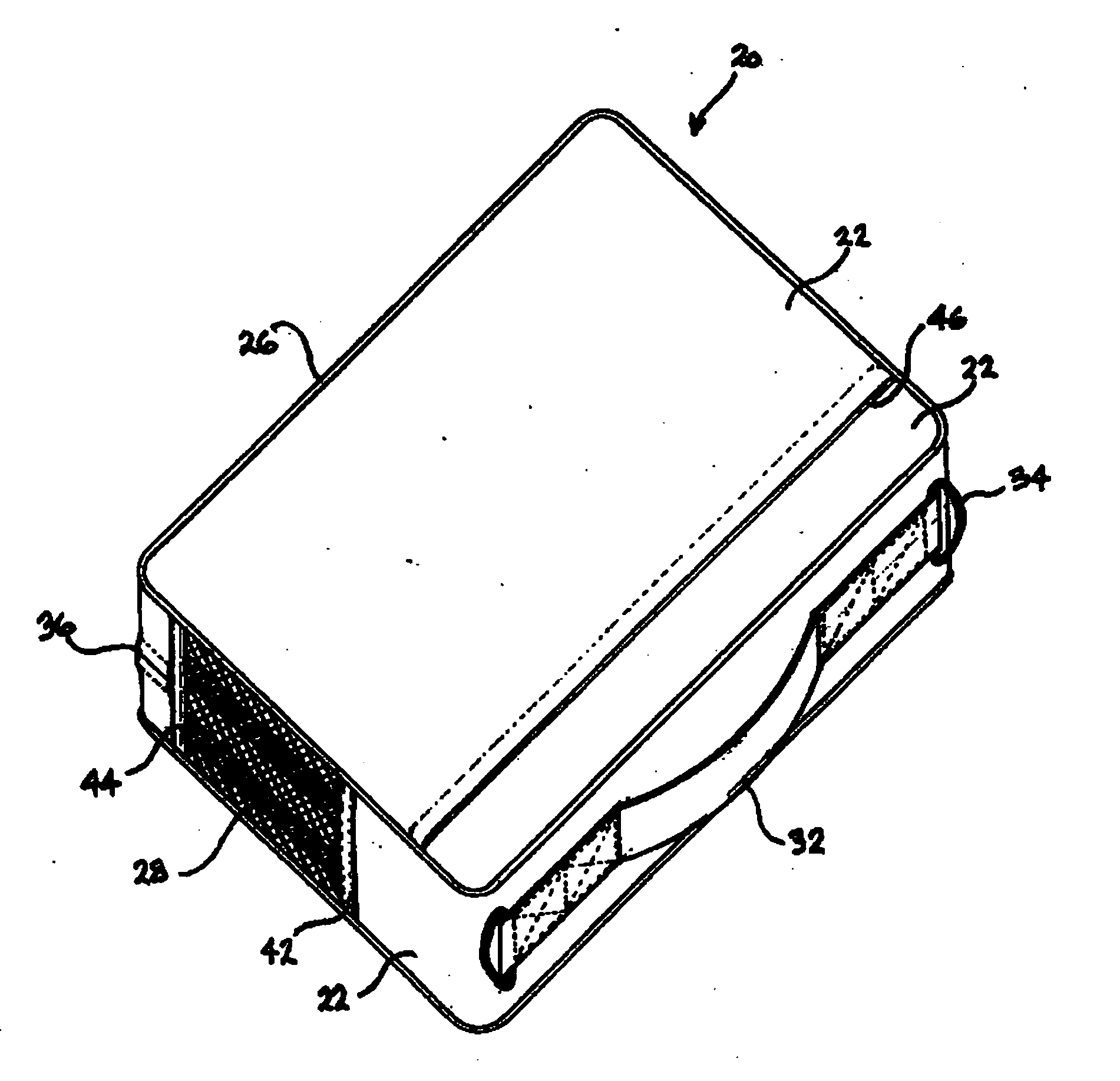

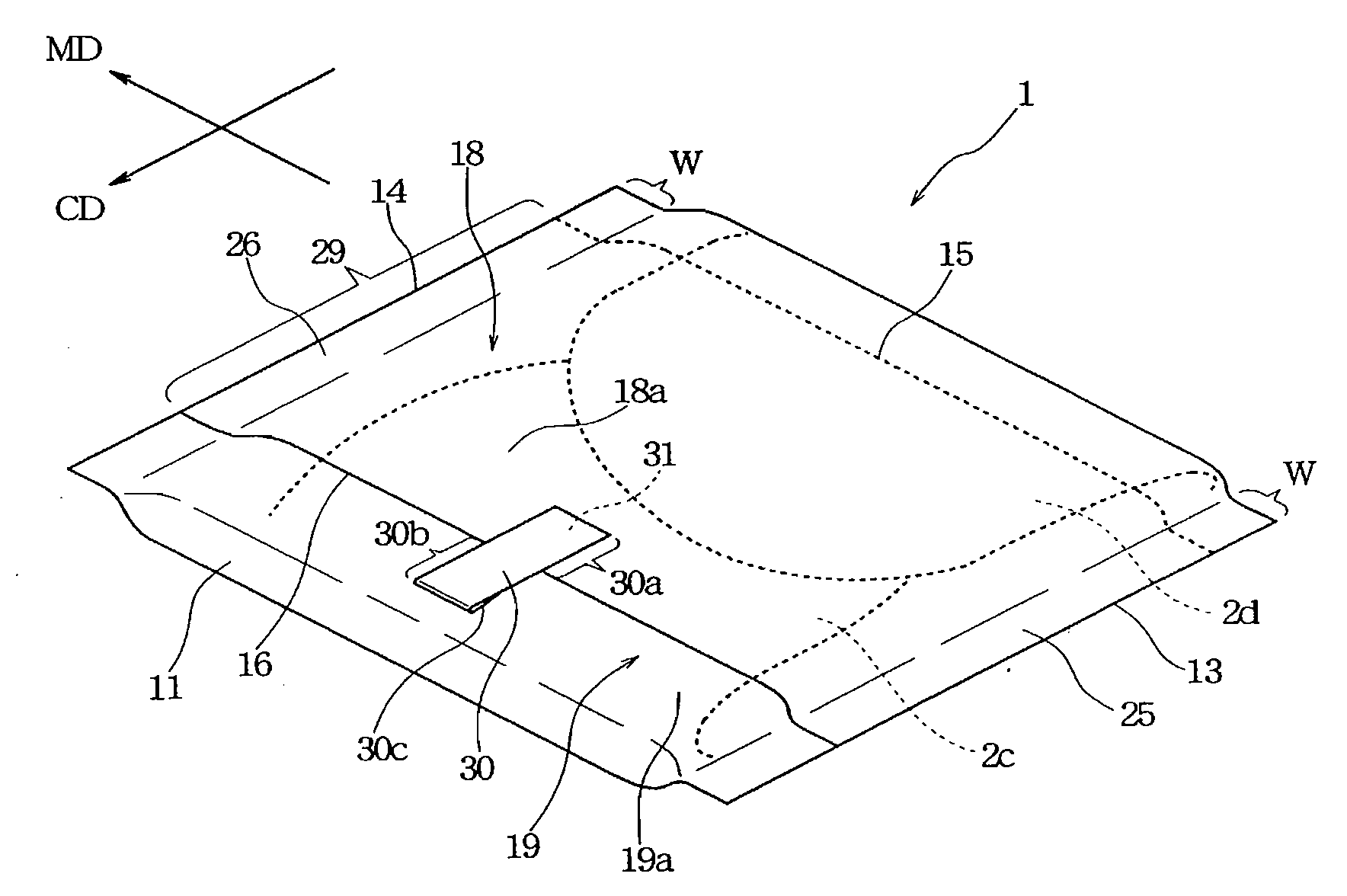

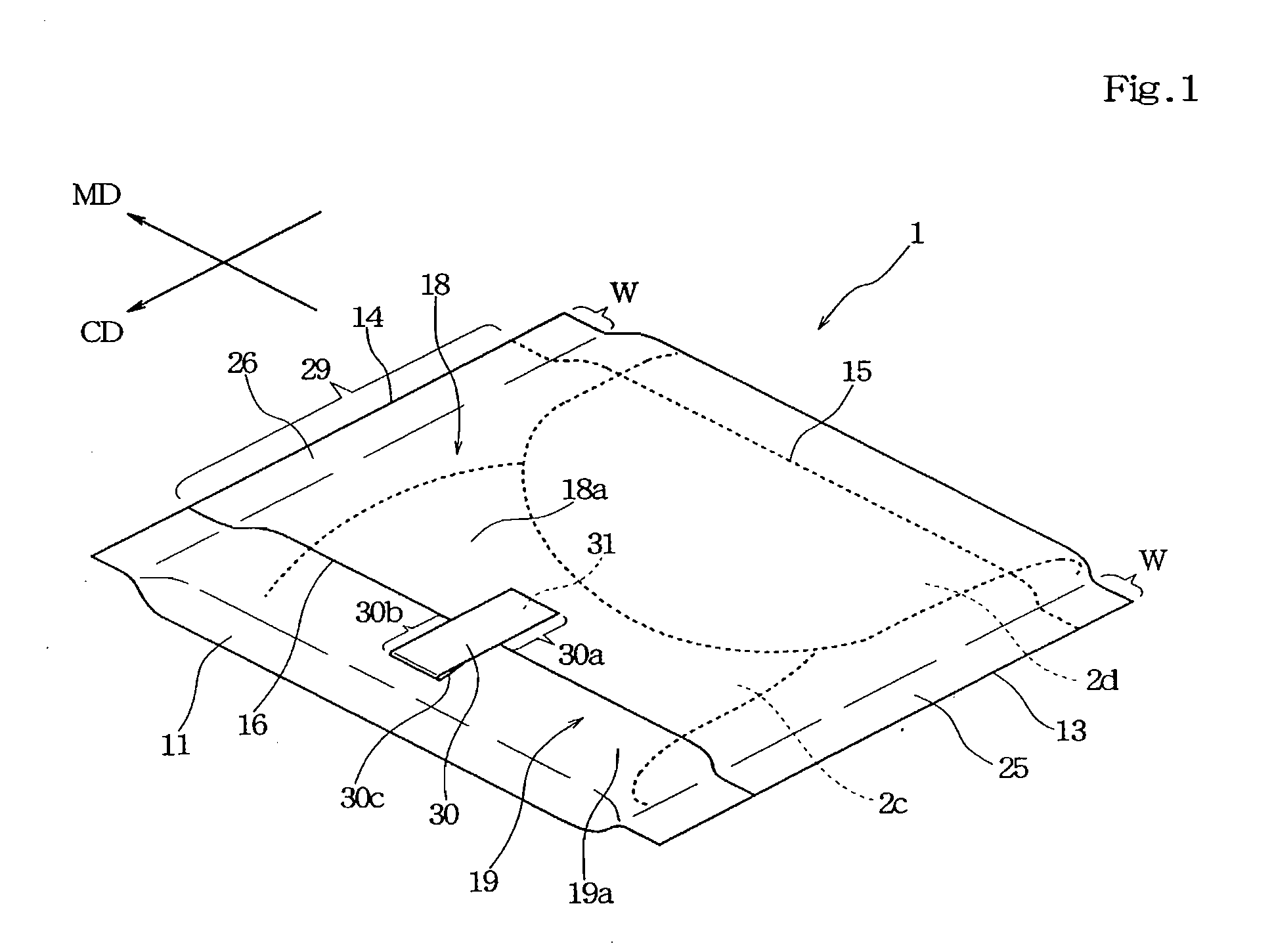

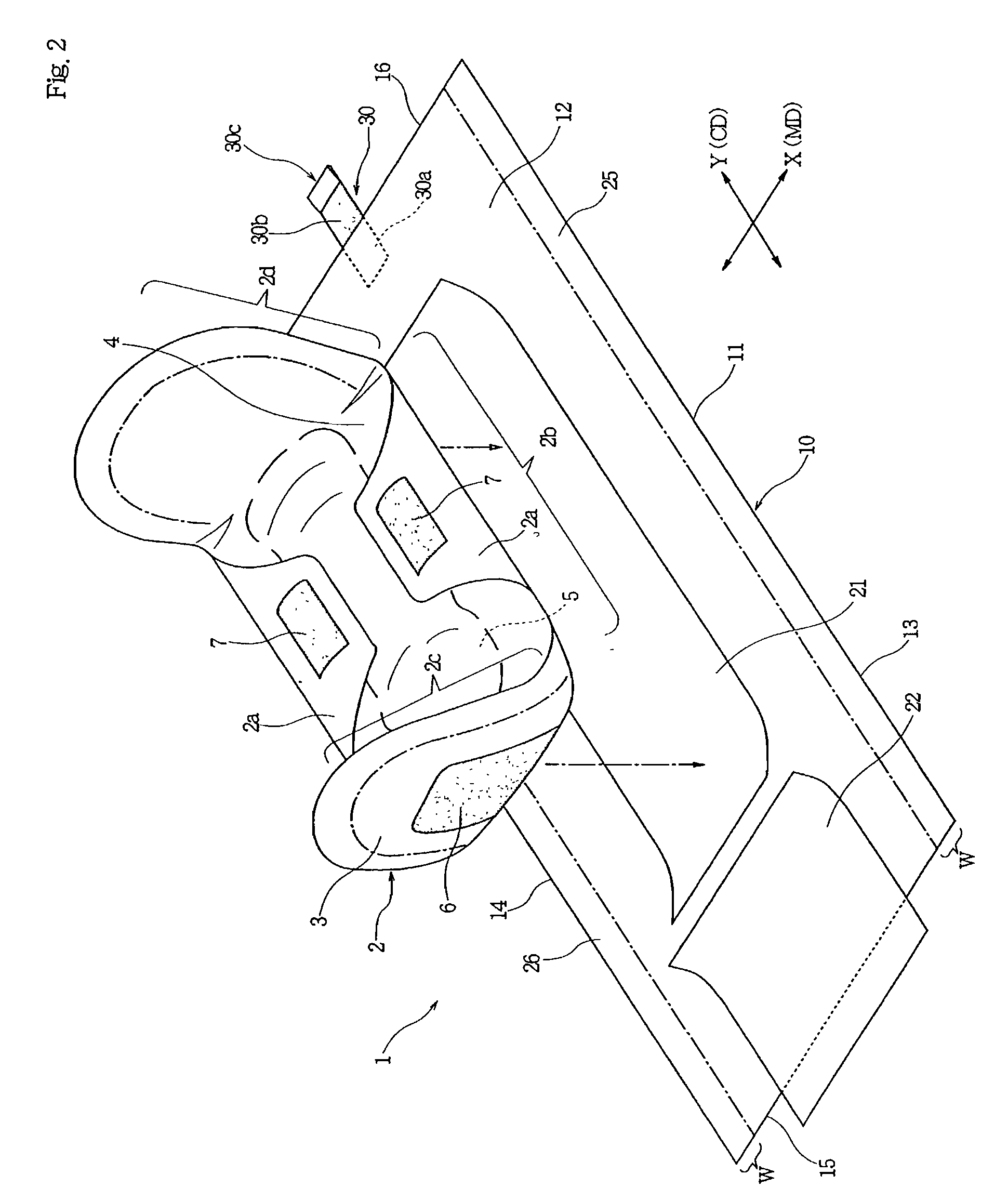

Individual package of absorbent article

InactiveUS20030065302A1Stay softMaintain forceContainers for flexible articlesCatheterEngineeringUltimate tensile strength

An individual package of an absorbent article permits a base end of a tape to be bonded with sufficiently large bonding strength without complicating packaging process and increasing manufacturing cost. The absorbent article is wrapped by a package sheet having side edge portions and end edges, and one end edge is overlapped over the other end edge. The package sheet is sealed along the side edge portions, a base end of a tape is fixed on the surface of the package sheet located outside in an overlapping portion, and a free end of the tape extends across one end edge and is releasably adhered on the outer surface of the package sheet adjacent one end edge. The package sheet has a surface, on which the base end of the tape is fixed, the surface being smoothed by a smoothing process.

Owner:UNI CHARM CORP

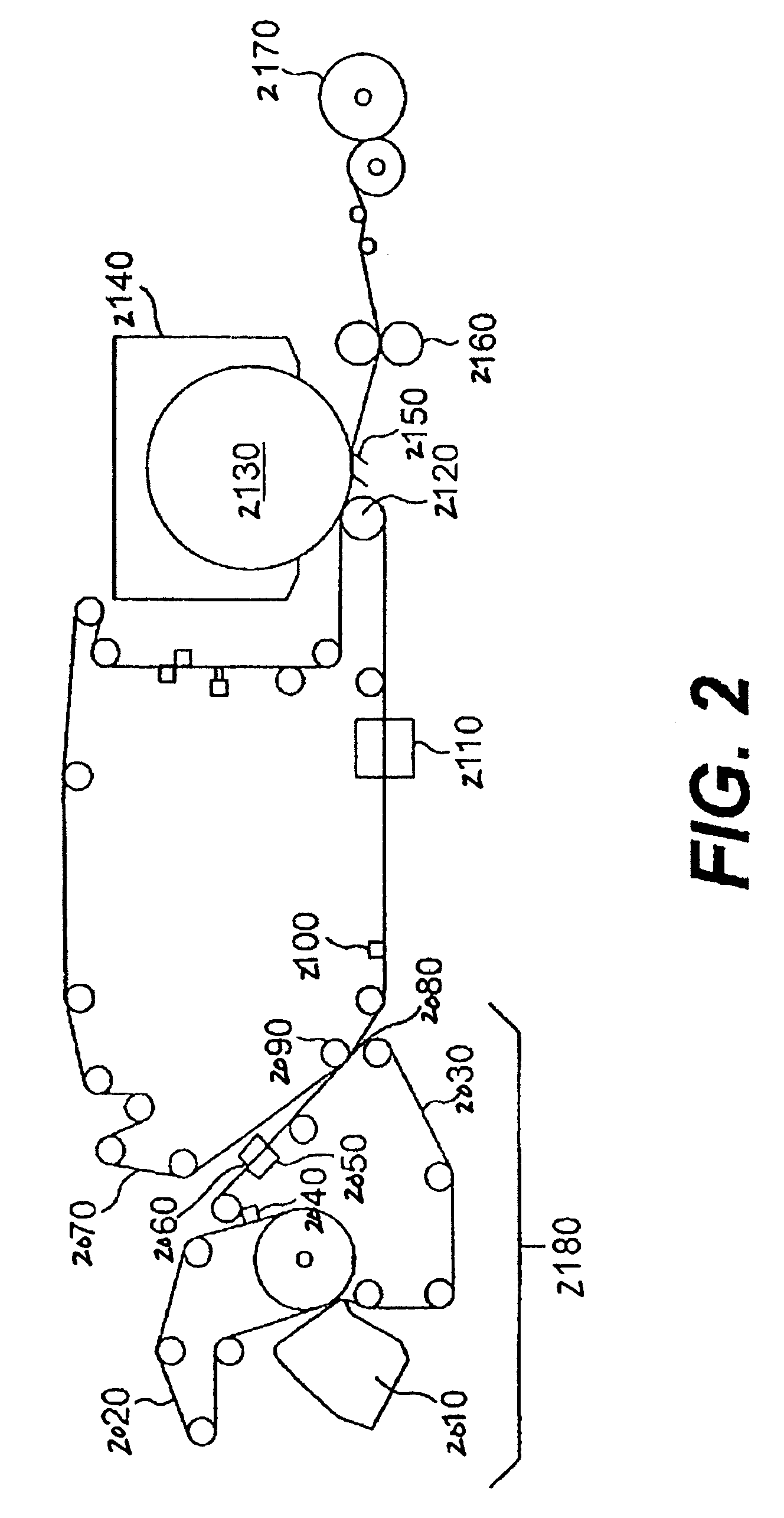

Creping adhesive modifier and methods for producing paper products

ActiveUS8147649B1Prevent adhesive build-upSpeed up the processNatural cellulose pulp/paperMechanical working/deformationAdhesivePaper production

A creping aid system for use on a creping cylinder, for example, a Yankee dryer, comprises a creping adhesive and a creping modifier, the combination comprising polyethylene.

Owner:SOLENIS TECH CAYMAN

Pre-mixed flour of mochi bread with prolonged shelf life, mochi bread and preparation method thereof

ActiveCN101971868AElasticity adjustableIncrease elasticityDough treatmentModified nutritive productsAlcohol sugarsFermentation

The invention discloses pre-mixed flour of mochi bread with prolonged shelf life, mochi bread and a preparation method thereof. The pre-mixed flour of mochi bread comprises the following components: 30 to 50% of modified starch, 5 to 10% of water-milled glutinous rice flour, 7 to 13% of non reducing sugar, 6 to 10% of sugar alcohol, 1.8 to 3.8% of edible colloid, 2 to 3% of edible emulsifier, 1 to 3% of salt, 1 to 3% of full-cream milk powder and 20 to 30% of self-raising flour. To produce the mochi bread from the pre-mixed flour of the mochi bread, the pre-mixed flour of the mochi bread is uniformly mixed with whole eggs, water, syrup and soybean oil to obtain the required properties, and then the mixture is baked to obtain the mochi bread without fermentation. The preparation method of the mochi bread is simple, and the prepared mochi bread has honeycomb internal phase and is softer than the common bread and not sticky; moreover, the shelf life of the mochi bread is obviously prolonged that the mochi bread can be stored for a month at normal temperature.

Owner:广州合诚实业有限公司

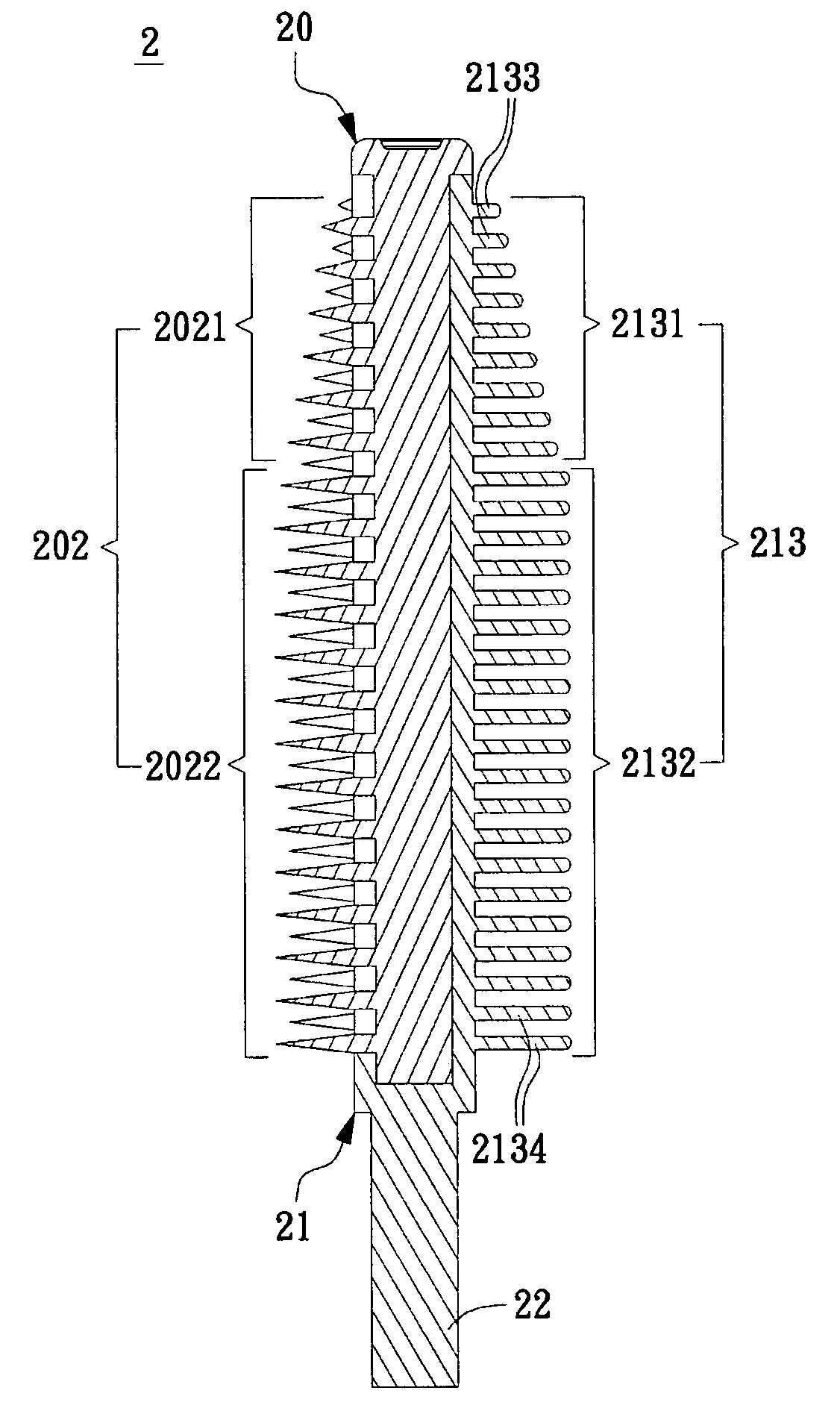

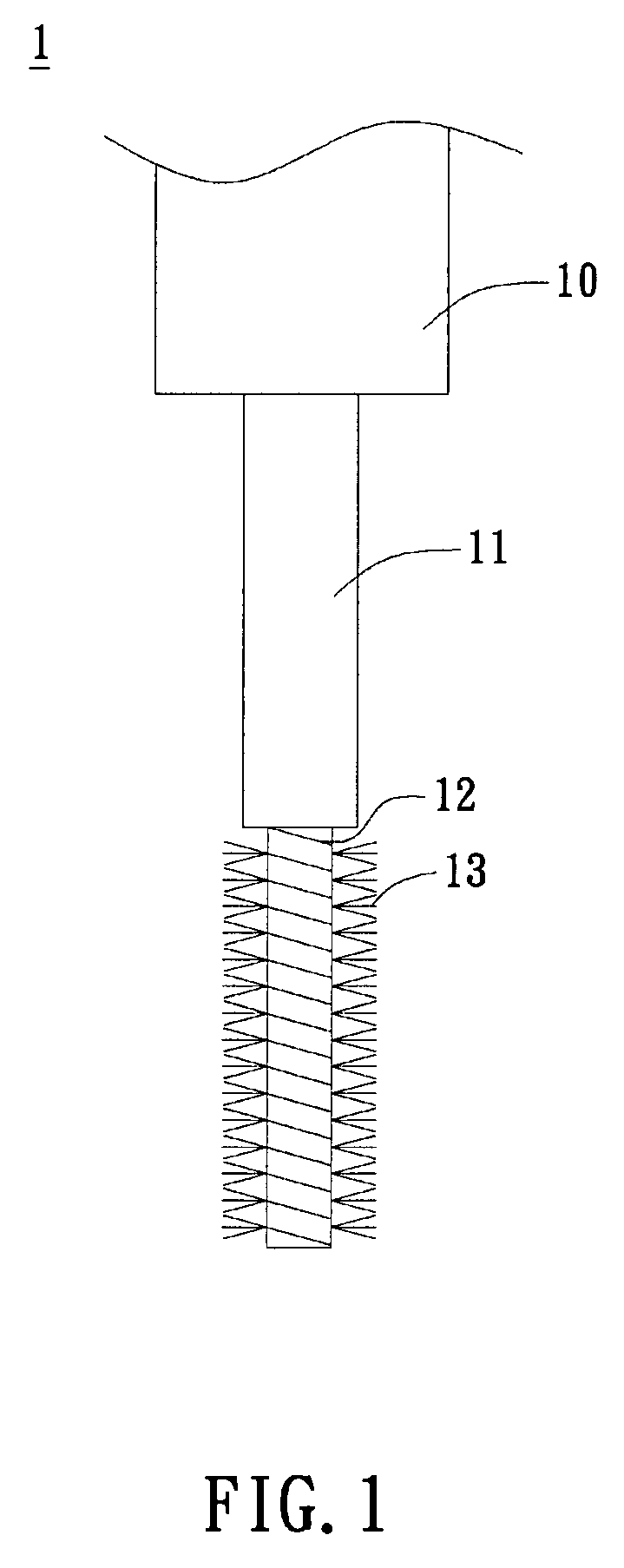

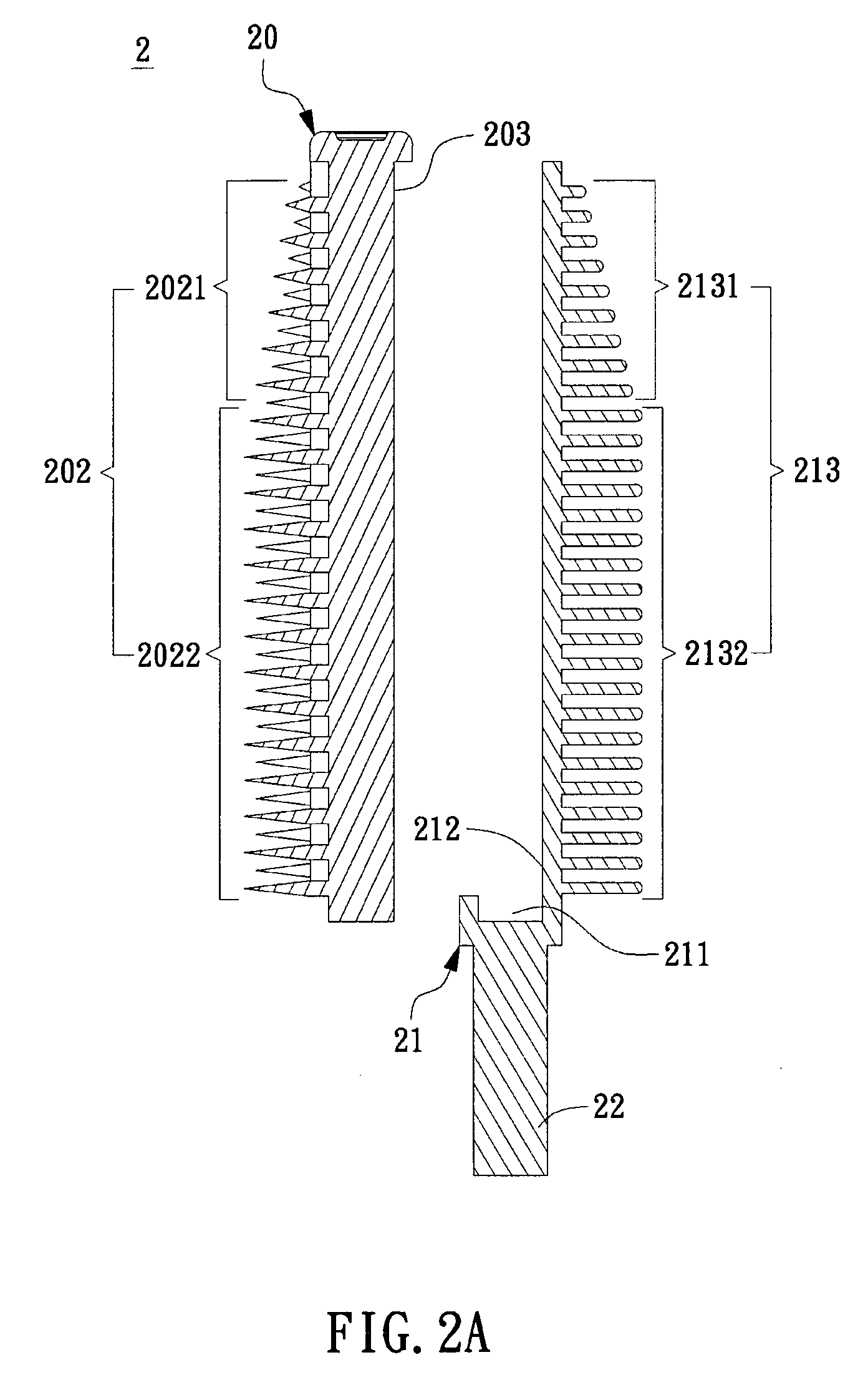

Eyelash brush

The present invention provides an eyelash brush including a flexible body and a rigid body. The flexible body has a plurality of rows of soft brushes, and the rigid body is installed on a lateral side of the flexible body, and the rigid body has at least one row of hard combs.

Owner:KUNSHAN YIH TAI GLASS IND CO LTD

Multi-resistant nutrient for plant growth and preparation method thereof

The invention provides a multi-resistant nutrient for plant growth and a preparation method of the multi-resistant nutrient for plant growth. The multi-resistant nutrient comprises the components in parts by weight as follows: 6-10 parts of compound amino acids, 0.5-1.5 parts of mushroom protein polysaccharide, 0.5-1.5 parts of water soluble chitosan, 2-4 parts of zinc sulfate, 1-3 parts of boric acid and 90-180 parts of water. The preparation method comprises the steps of: heating part of water and dissolving zinc sulfate and boric acid; then heating the residual water and dissolving compound amino acids, mushroom protein polysaccharide and water soluble chitosan; then heating while agitating, and uniformly mixing with zinc sulfate and boric acid; and cooling after insulating so as to obtain the multi-resistant nutrient for plant. The multi-resistant nutrient for plant is rich in various amino acid trace elements which prompt growth of the plant, has remarkable effects of enhancing the immunologic function of the plant and preventing diseases and insect pests, has various biological adjusting functions, and is stress resistant, cold resistant, draught resistance and prevents diseases and insect pests.

Owner:YONGREN YUANNAN AGRI COMPREHENSIVE DEV CO LTD

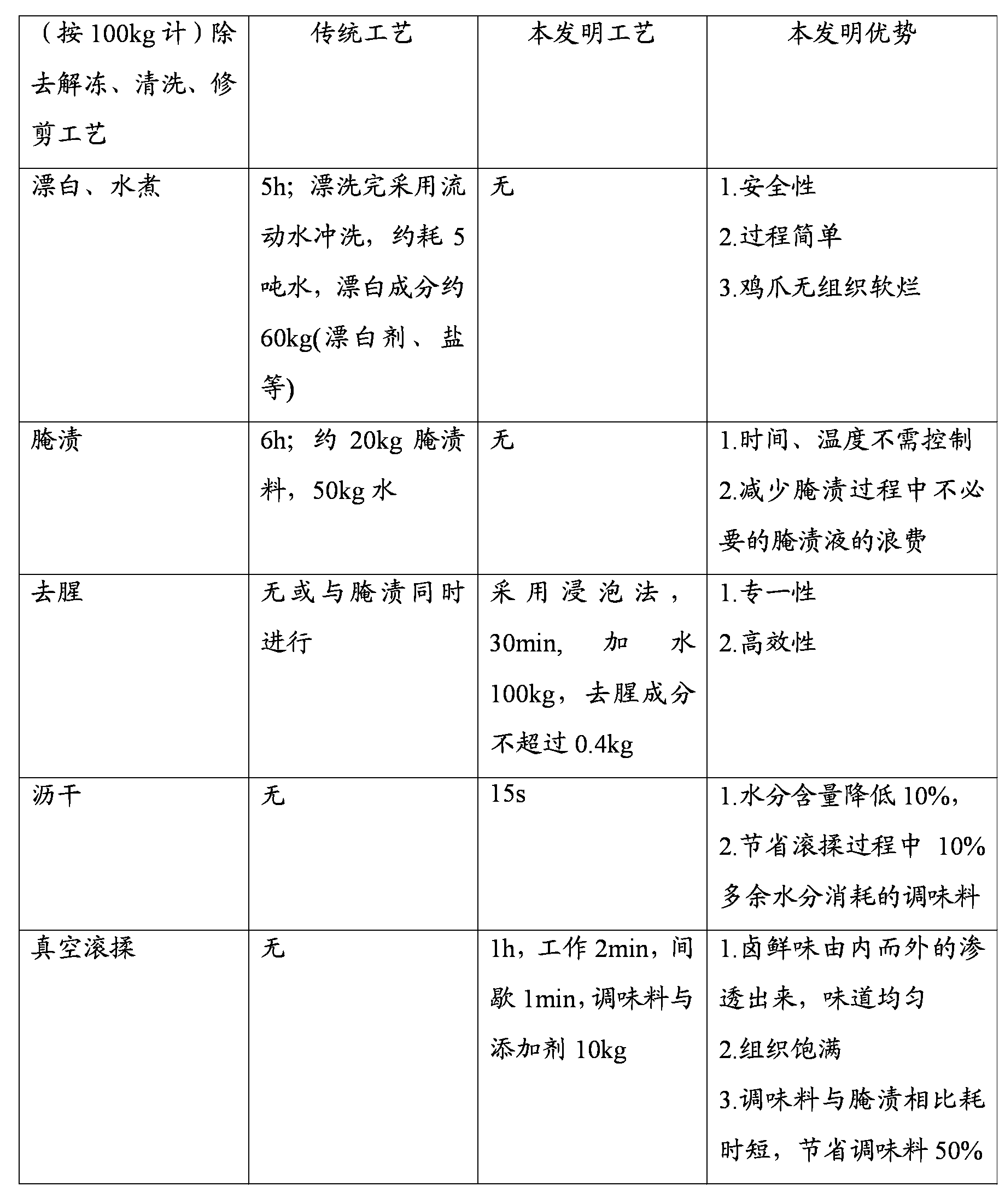

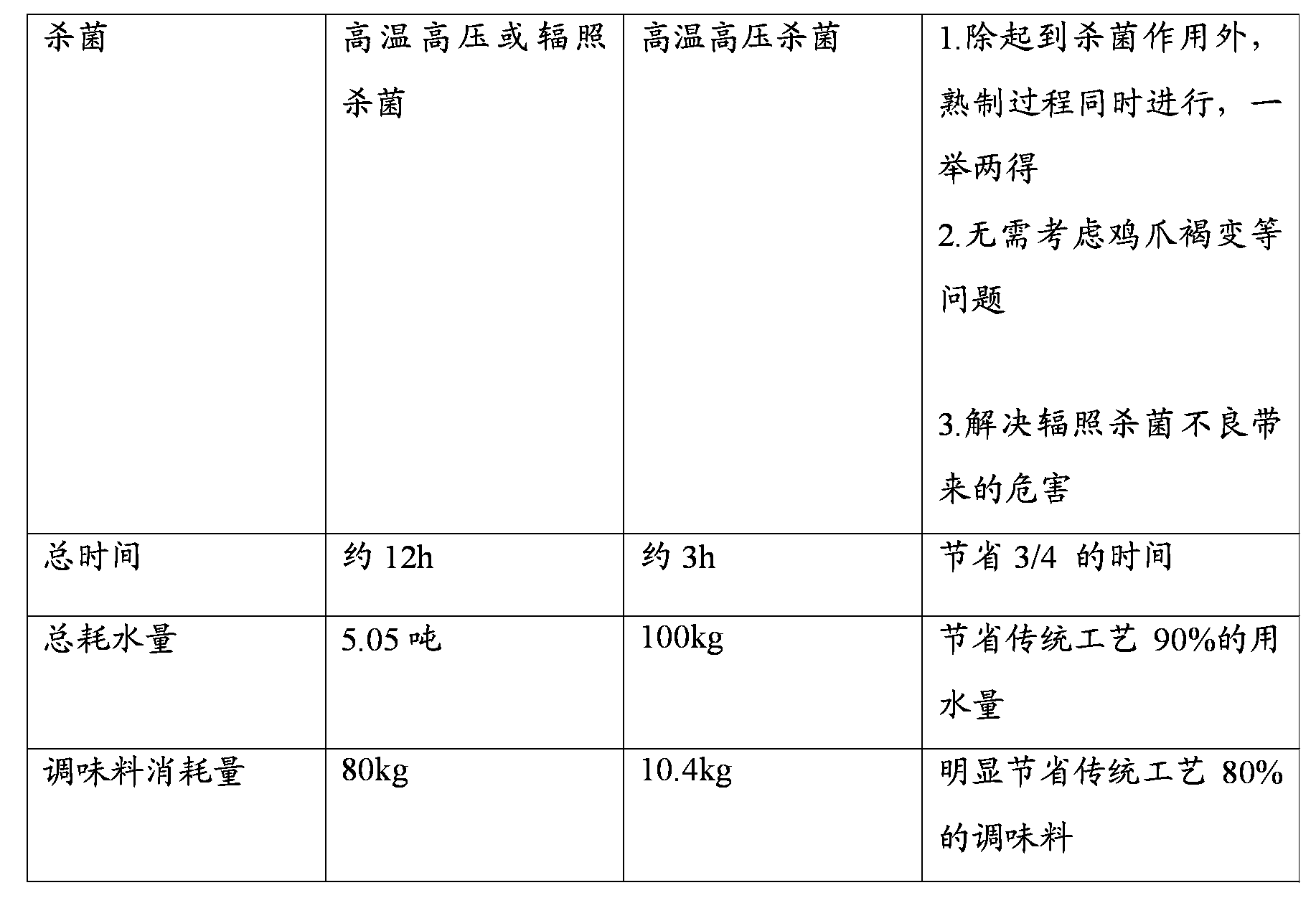

Processing method for fragrant marinated chicken claw

InactiveCN103054062AEffectively remove fishy smellImprove satisfactionFood preparationChicken-clawsHigh pressure

The invention provides a processing method for a fragrant marinated chicken claw. The processing method comprises the following steps: thawing of a raw material; cleaning and trimming; soaking for removal of meaty smell; draining; rolling and kneading under vacuum; high temperature high pressure sterilization; cooling and air drying; and storage. The invention has the following main beneficial effects: 1, reduction of time and enhancement of efficiency; 2, conservation of flavoring; and 3, improvement of product quality. The preparation method provided by the invention is simple and easily practicable; the produced fragrant marinated chicken claw is convenient for eating; and the method improves a processing utilization rate of chicken claws, increases an added value of the fragrant marinated chicken claw and enables flavor and varieties of leisure food to be enriched.

Owner:ZHEJIANG SHANSHUILANG FOOD

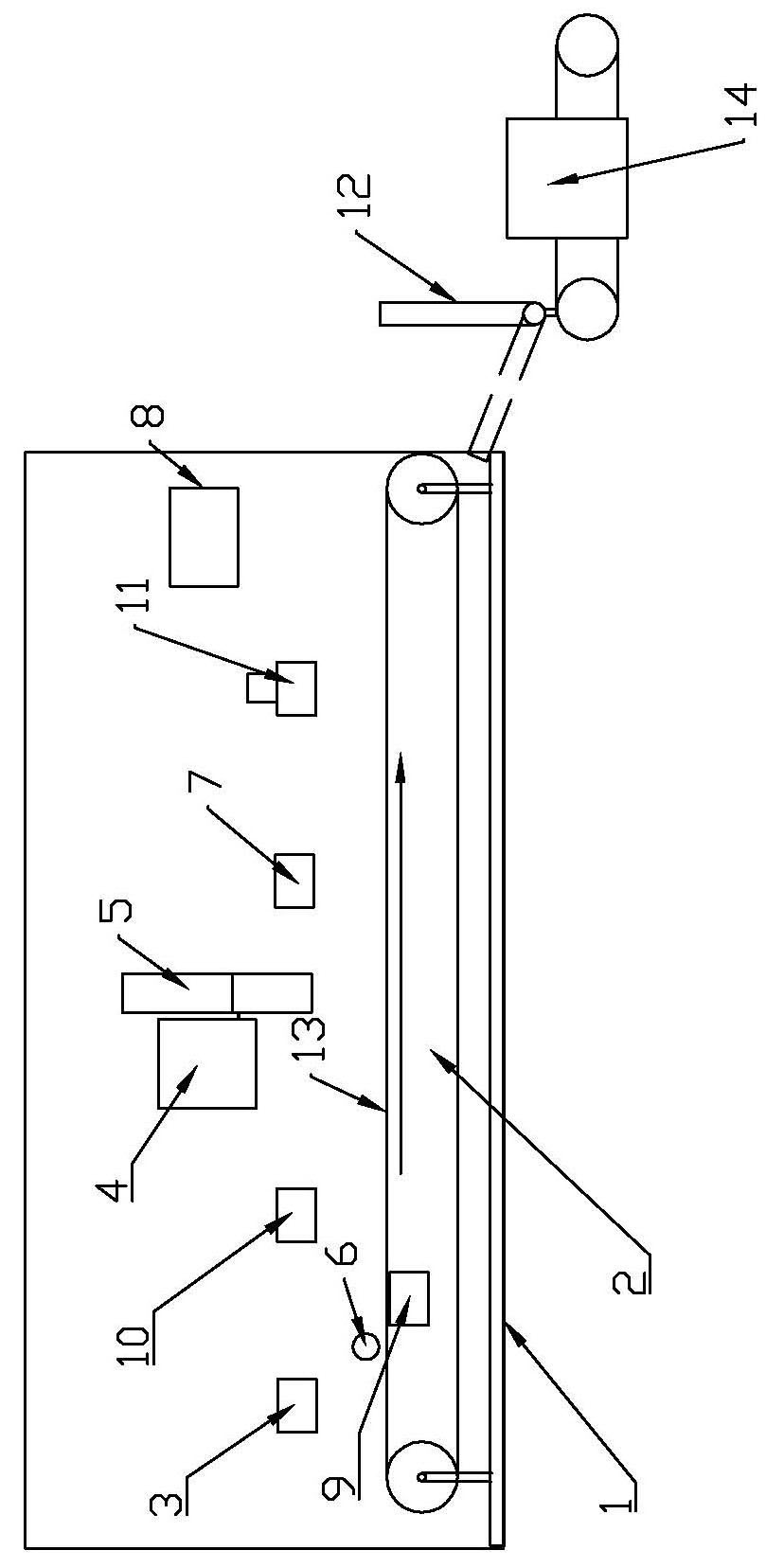

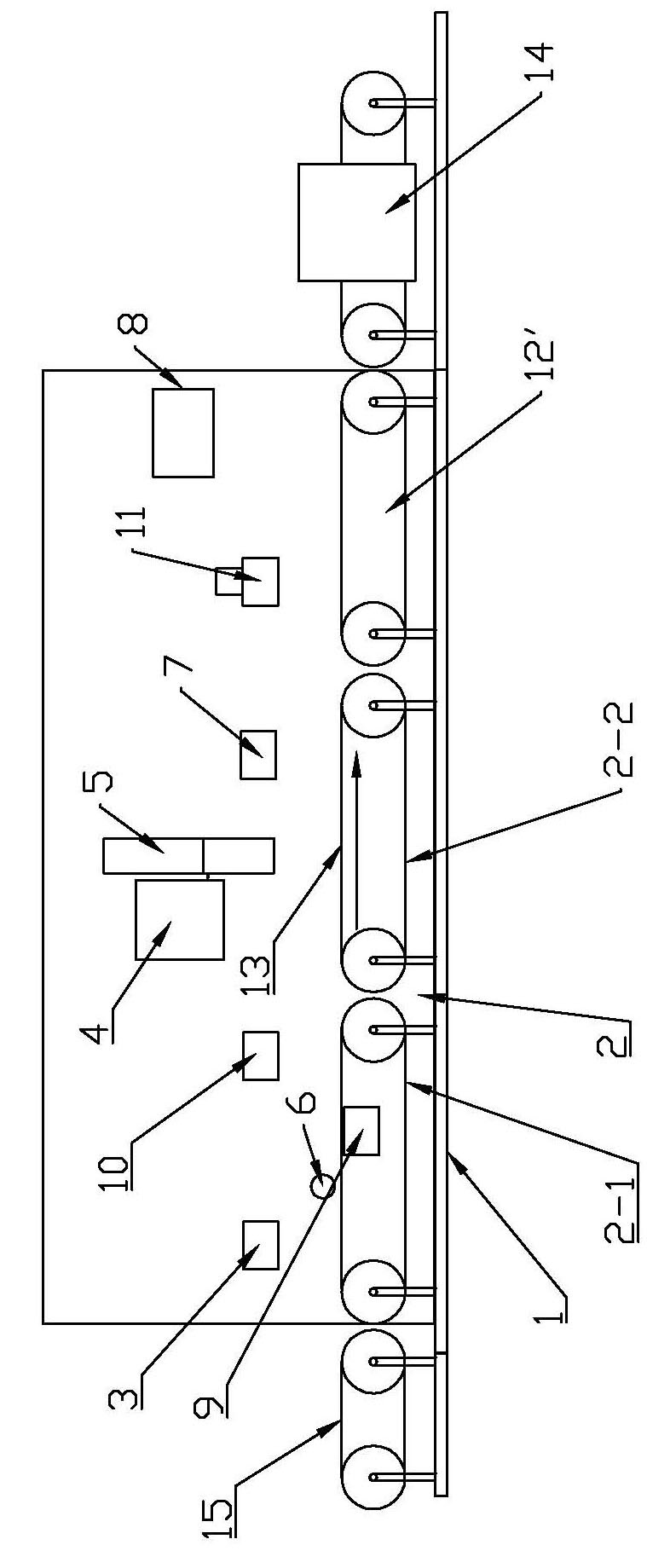

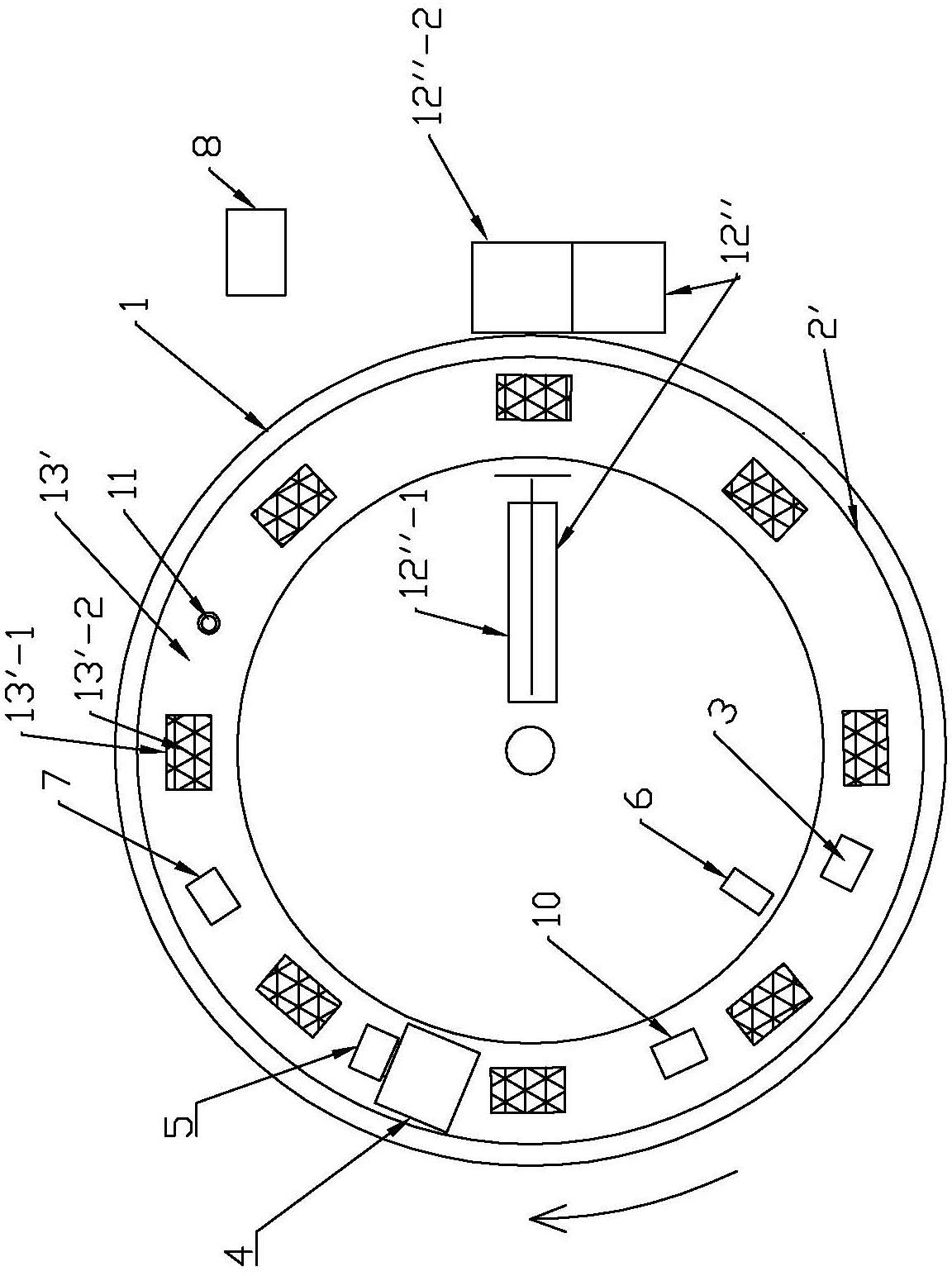

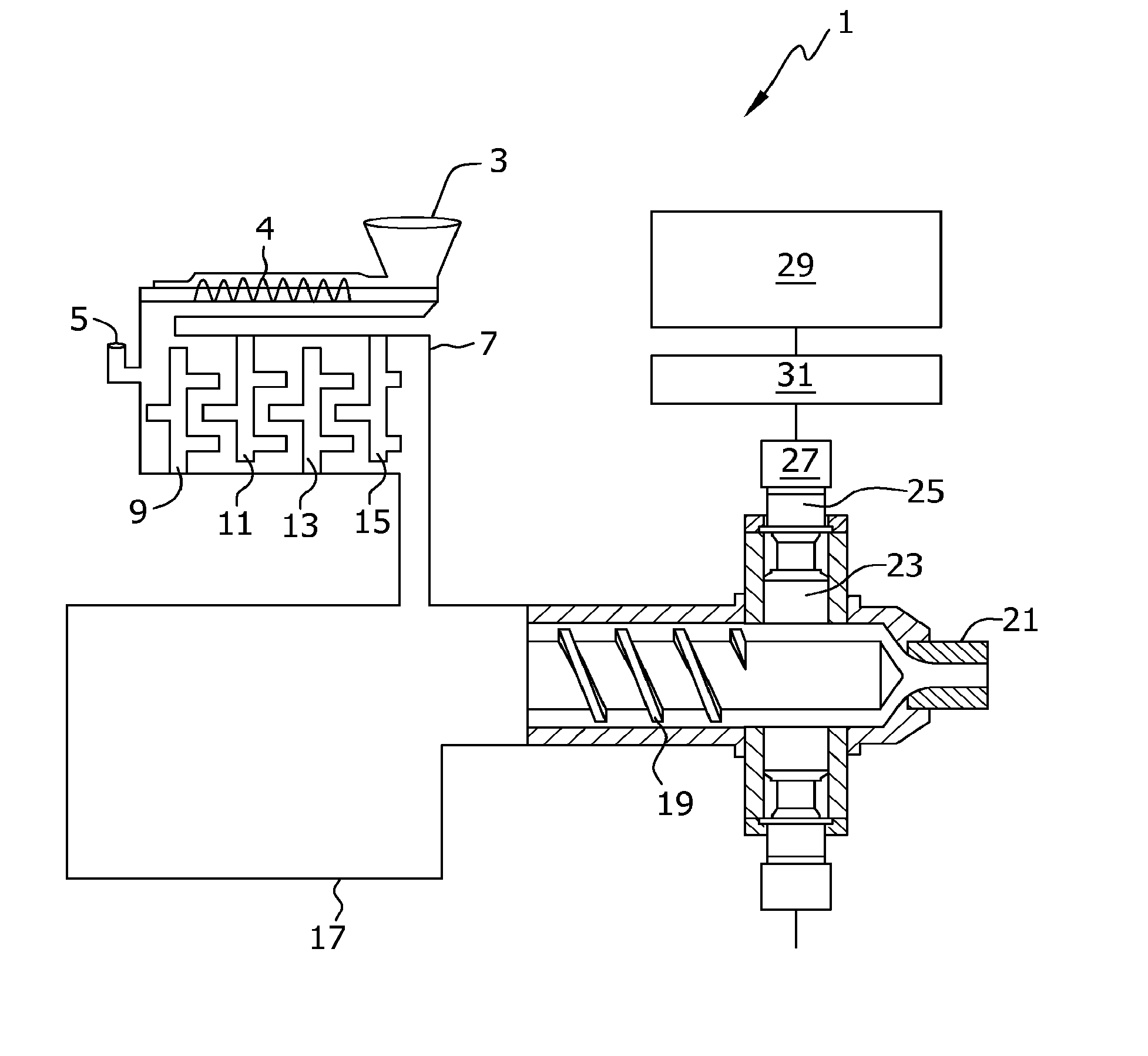

Intelligent processing system for blood components

ActiveCN101948019AGood technical effectStay softPackaging automatic controlIndividual articlesBlood componentIdentification device

The invention discloses an intelligent processing system for blood components, which comprises a frame, a blood bag conveying mechanism, a high-precision scanner, a label printing device with a stripping film, a label adhering device with a label absorber, a blood bag sensor, a checking device and a computer, and is characterized by also comprising a weighing sensing device, a color identification device and a sorting device, wherein the blood bag conveying mechanism is arranged on the frame; and the high-precision scanner, the blood bag sensor, the weighing sensing device, the color identification device, the label printing device with the stripping film, the label adhering device with the label absorber, the checking device and the sorting device, which are communicated with the computer, are arranged on the frame in turn along with the moving direction of a blood bag conveying surface of the blood bag conveying mechanism. Compared with the prior art, the intelligent processing system for the blood components has remarkable advantages; and the technical scheme of the invention can comprehensively and intelligently process the blood components, completely replace the manual operation process and save time and labor.

Owner:SHENZHEN PONTED BIO MED

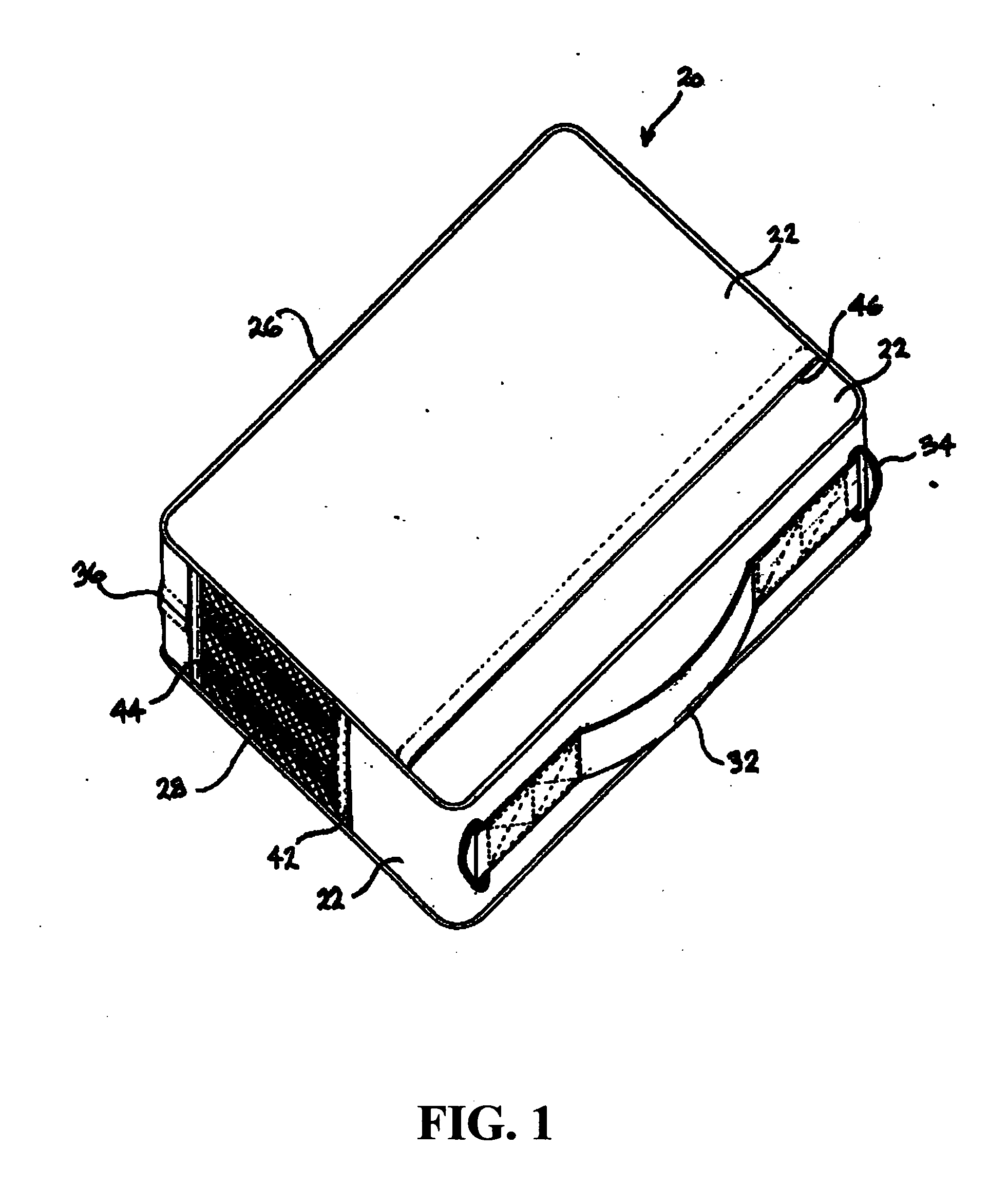

Stadium seat

InactiveUS20060059628A1Improve comfortCreates comfortStuffed mattressesDismountable chairsHuman bodyEngineering

A weight distribution and suspension system is disclosed. This system provides comfort for the human body in a seated position by using a plurality of foam layers of alternating densities and elasticities to form a seat cushion. In one embodiment, the system is comprised of a plurality of foam layers of alternating densities and elasticities, a vinyl cushion cover, a second layer of vinyl, covering the top surface and creating a pocket, a fabric cushion backing, a mesh pocket for holding small items, a nylon zipper, and one or more elastic bands for holding small items. In this embodiment the system is intended to provide user comfort in stadium seating.

Owner:HAMILTON LAWRENCE S +1

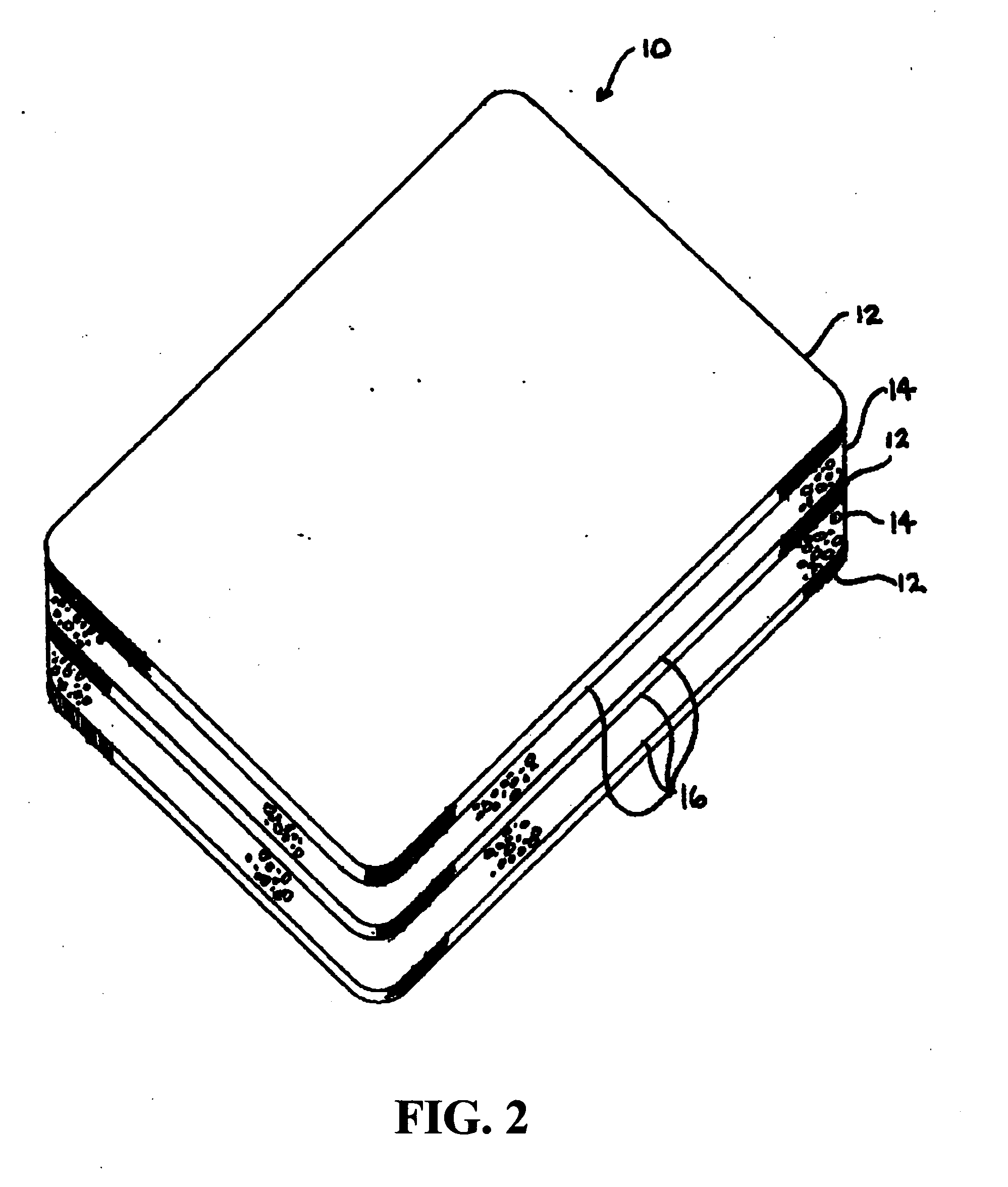

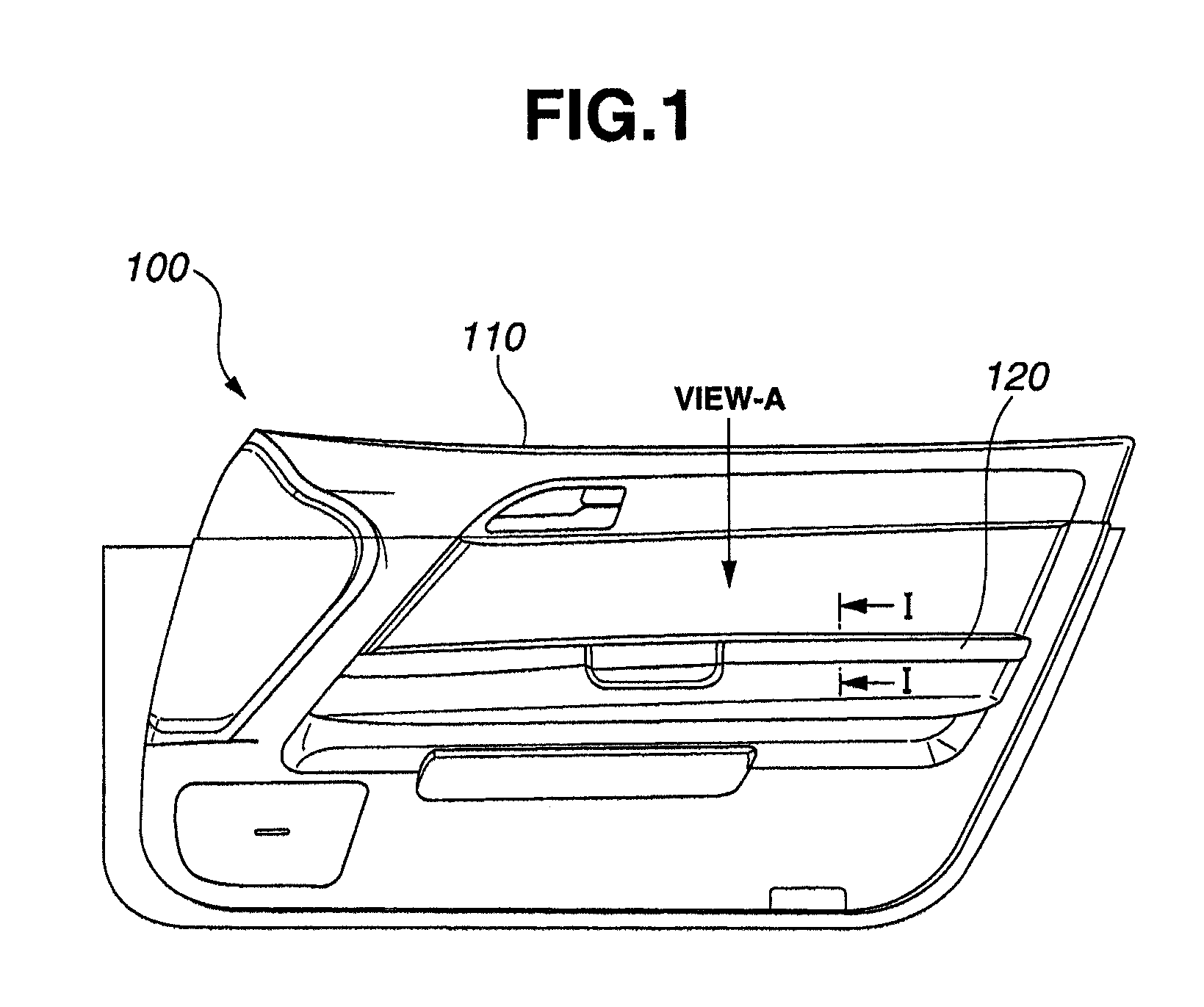

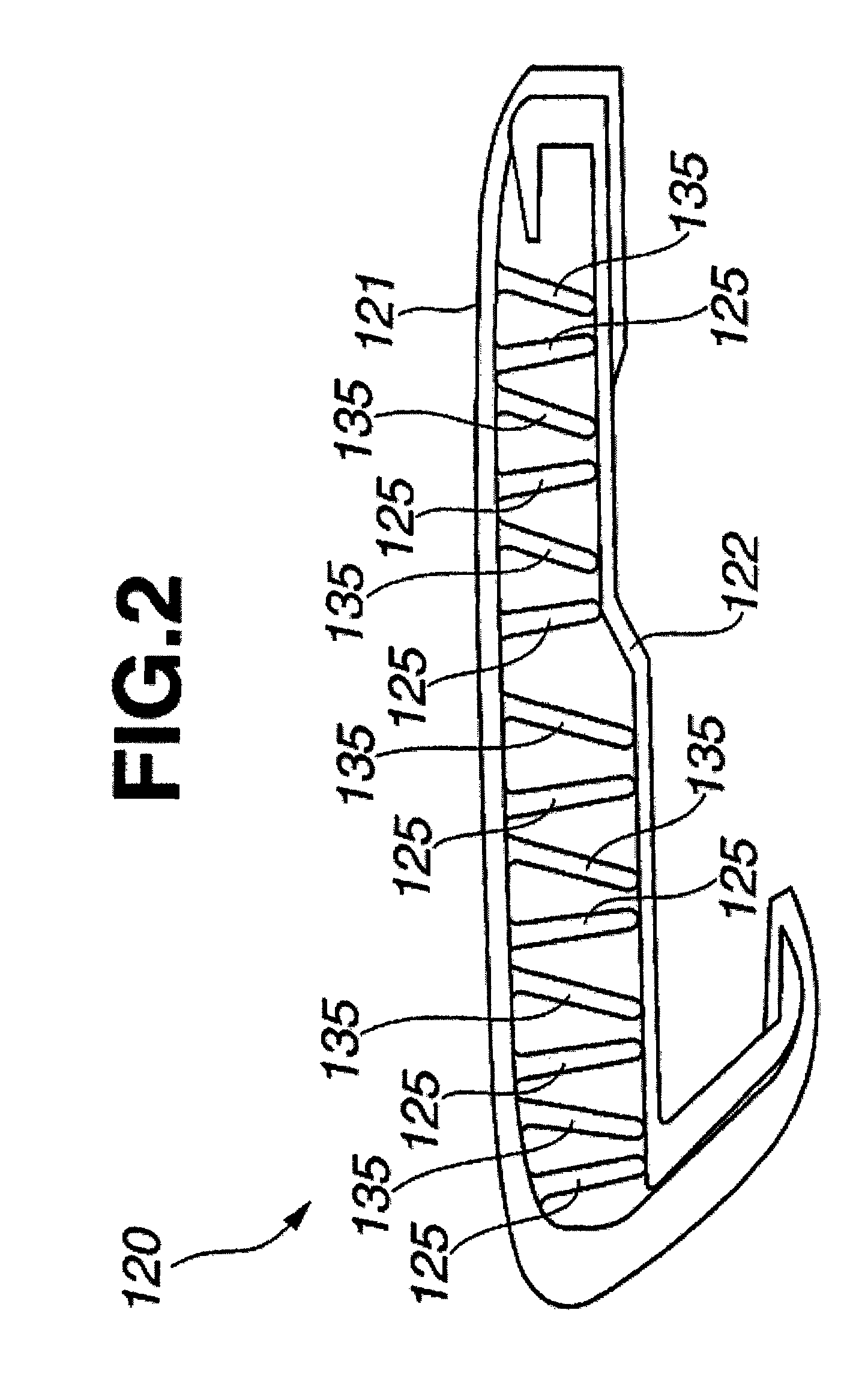

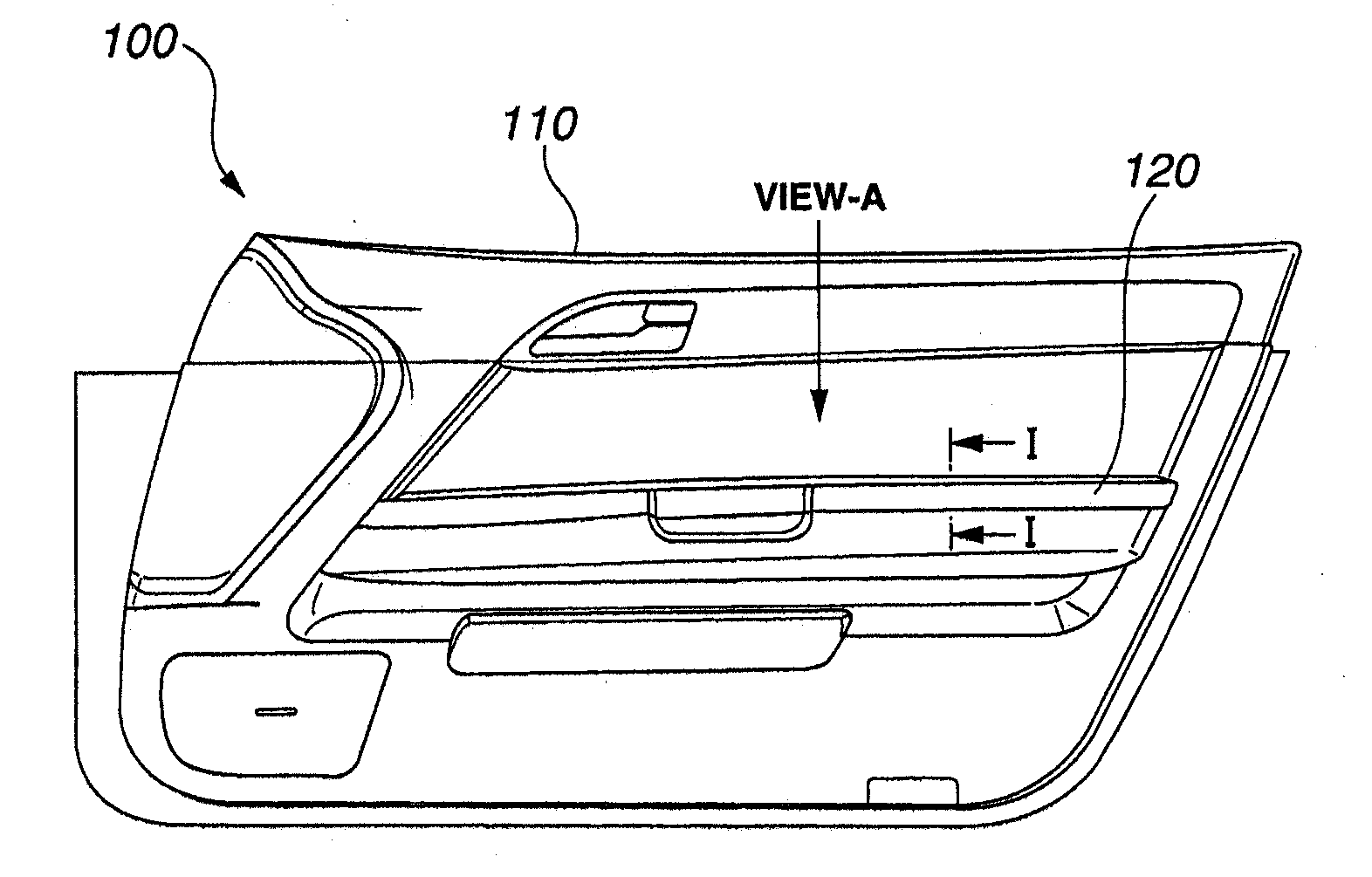

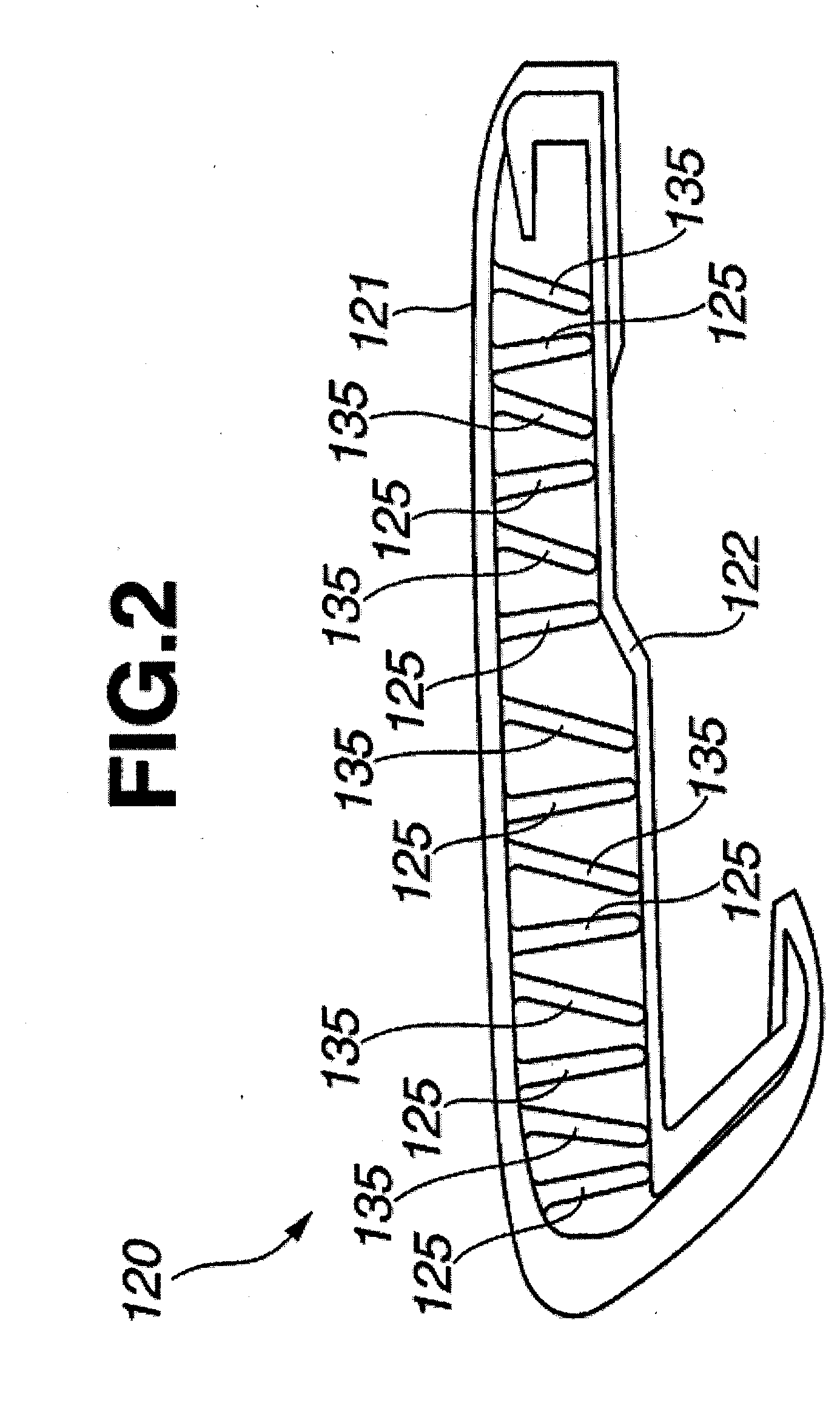

Support structure

InactiveUS8157309B2Stay softReduce impactLayered productsPedestrian/occupant safety arrangementBiomedical engineering

Owner:NISSAN MOTOR CO LTD

Support structure

InactiveUS20100264680A1Stay softReduce impactLayered productsFurniture partsEngineeringBiomedical engineering

Owner:NISSAN MOTOR CO LTD

Individual package of absorbent article

InactiveUS20080276570A1High bonding strengthStay softContainers for flexible articlesWrapper folding/bending apparatusEngineeringUltimate tensile strength

An individual package of an absorbent article permits a base end of a tape to be bonded with sufficiently large bonding strength without complicating packaging process and increasing manufacturing cost. The absorbent article is wrapped by a package sheet having side edge portions and end edges, and one end edge is overlapped over the other end edge. The package sheet is sealed along the side edge portions, a base end of a tape is fixed on the surface of the package sheet located outside in an overlapping portion, and a free end of the tape extends across one end edge and is releasably adhered on the outer surface of the package sheet adjacent one end edge. The package sheet has a surface, on which the base end of the tape is fixed, the surface being smoothed by a smoothing process.

Owner:UNI CHARM CORP

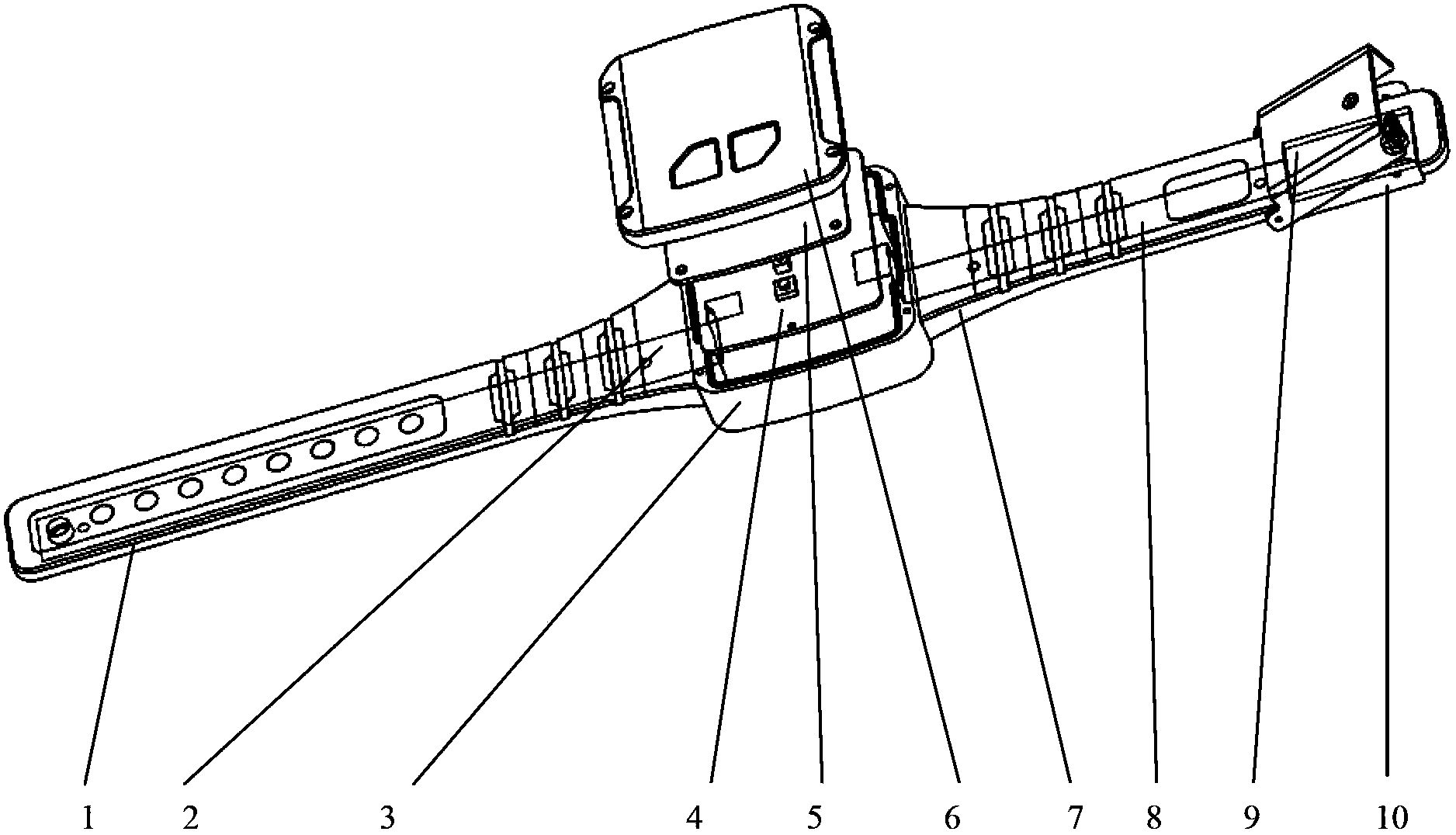

Wearing-type anti-dismantling alarm apparatus

ActiveCN103794022AWon't breakApplicableAlarmsRecord carriers used with machinesFlexible circuitsEngineering

The invention discloses a wearing-type anti-dismantling alarm apparatus. The wearing-type anti-dismantling alarm apparatus comprises a gauge head 3, a top cover 6 (provided with a top cover PCB 5), an electronic label 4, a gauge band including a long gauge band 1 and a short gauge band 7, a long flexible circuit board 2, a short flexible circuit board 8, and a gauge buckle including an upper gauge buckle 9 and a lower gauge buckle 10. When an active alarm device is started, an alarm signal is generated; when the long gauge band is destroyed, an anti-dismantling alarm circuit is disconnected, and an alarm signal is generated; when the short gauge band is destroyed, a sensing type anti-dismantling alarm circuit is disconnected, and an alarm signal is generated; and when the upper gauge buckle, the lower gauge buckle or the top cover are opened in unauthorized cases, the sensing type anti-dismantling alarm circuit generates the alarm signal. The wearing-type anti-dismantling alarm apparatus is provided with waterproof and super-low power consumption functions and the like, therefore, the service life is longer, and the adaptability is higher. At the same time, the wearing-type anti-dismantling alarm apparatus also has the advantages of dismantling alarm, wrong alarm prevention and the like.

Owner:BEIJING INST OF COMP TECH & APPL

Cake modifying agent

ActiveCN107156220AStay softSoft tasteDough treatmentLeguminous plant bakery productsPhosphateSodium Caseinate

The invention relates to a cake modifying agent. The cake modifying agent comprises, by weight, 3-20% of emulsifying agent, 2-15% of thickening agent, 65-94.9% of food raw materials, and 0.1-2% of enzyme preparation, wherein the emulsifying agent is one or more of single / double-glycerin fatty acid ester, sucrose fatty acid ester, sodium caseinate, and polyglycerin fatty acid ester; the thickening agent is one or more of hydroxypropyl di-starch phosphate and xanthan gum; the enzyme preparation is one or more of maltogenic amylase and alpha-amylase. The cake modifying agent is suitable for being applied to black rice cake manufacturing, the water-prevention and moisture-retaining performance of the black rice cake can be intensified, the ageing problem like product spalling and scaling are postponed, and thus soft, delicate and wet mouthfeel of the cake is maintained.

Owner:GUANGZHOU WELBON BIOLOGICAL TECH

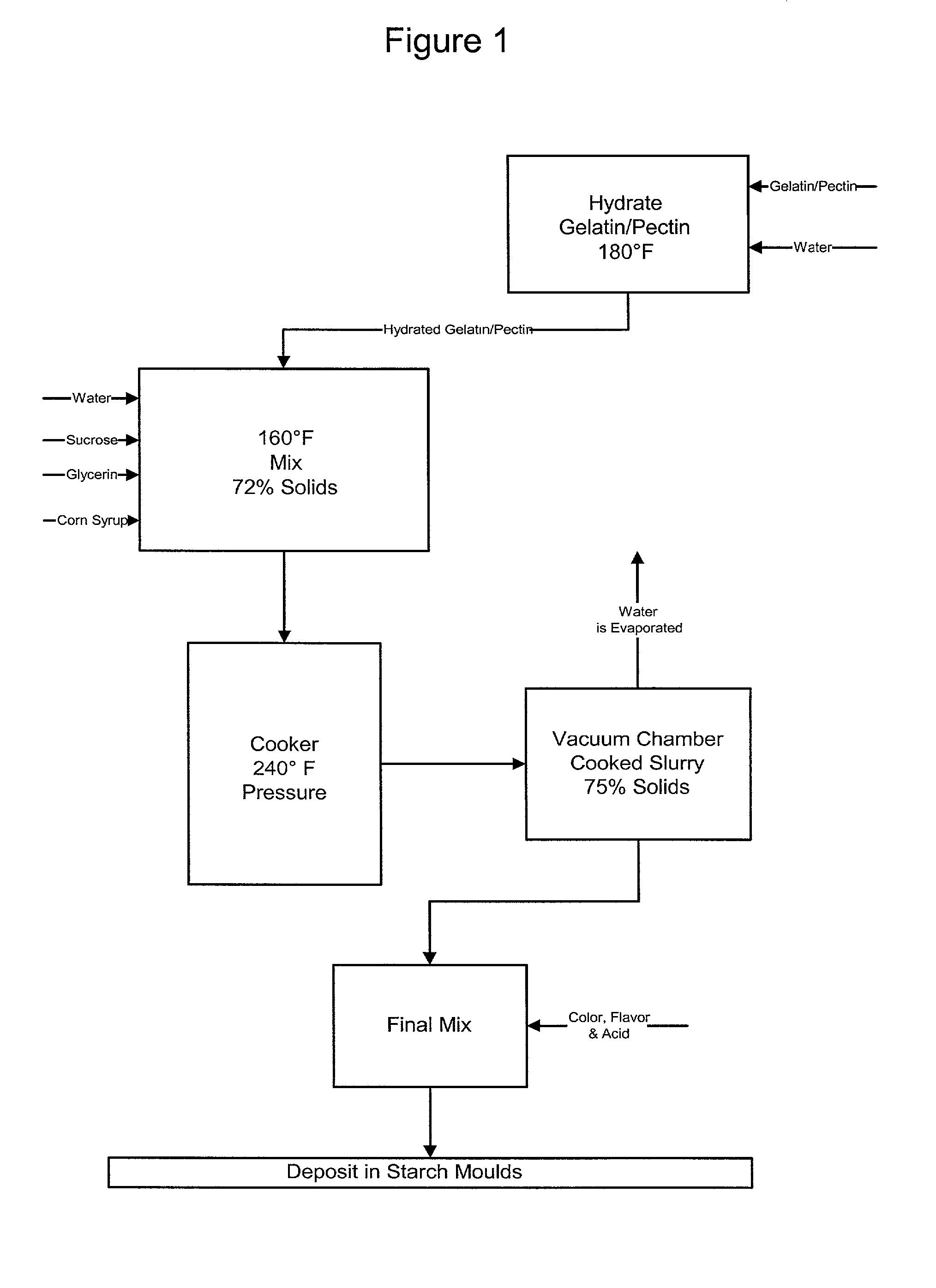

Soft candies for ice cream and method of making

A process is provided for preparing soft, gummy candies that retain their physical shapes well and have a pleasant bite and chew when employed in ice cream. The process entails preparing a first premix of sucrose, glycerin, corn syrup and water and blending it with a hydrated gelatin / pectin solution. The resulting combined solution is then cooked at elevated temperature and pressure to form a candy melt. The resulting candy melt is reduced in moisture content and mixed with color, flavor and acid prior to forming the candy melt into discrete, soft candy pieces, e.g., by depositing in starch moulds. The candies are mixed with ice cream to form a soft candy and ice cream confection.

Owner:WM WRIGLEY JR CO

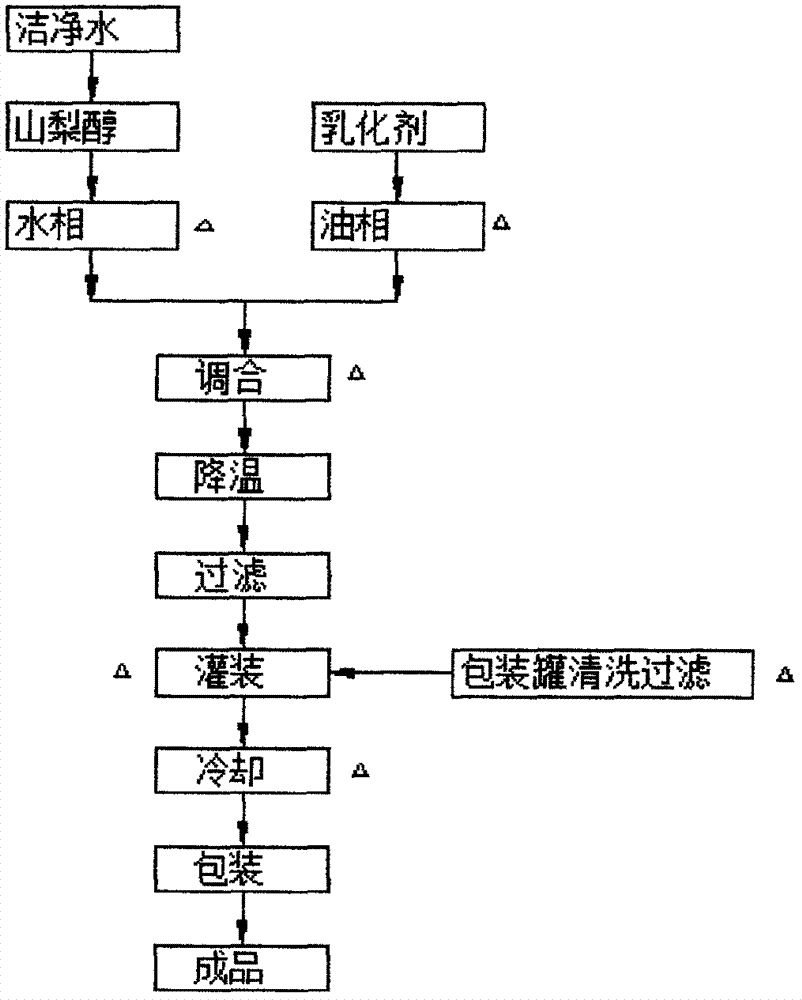

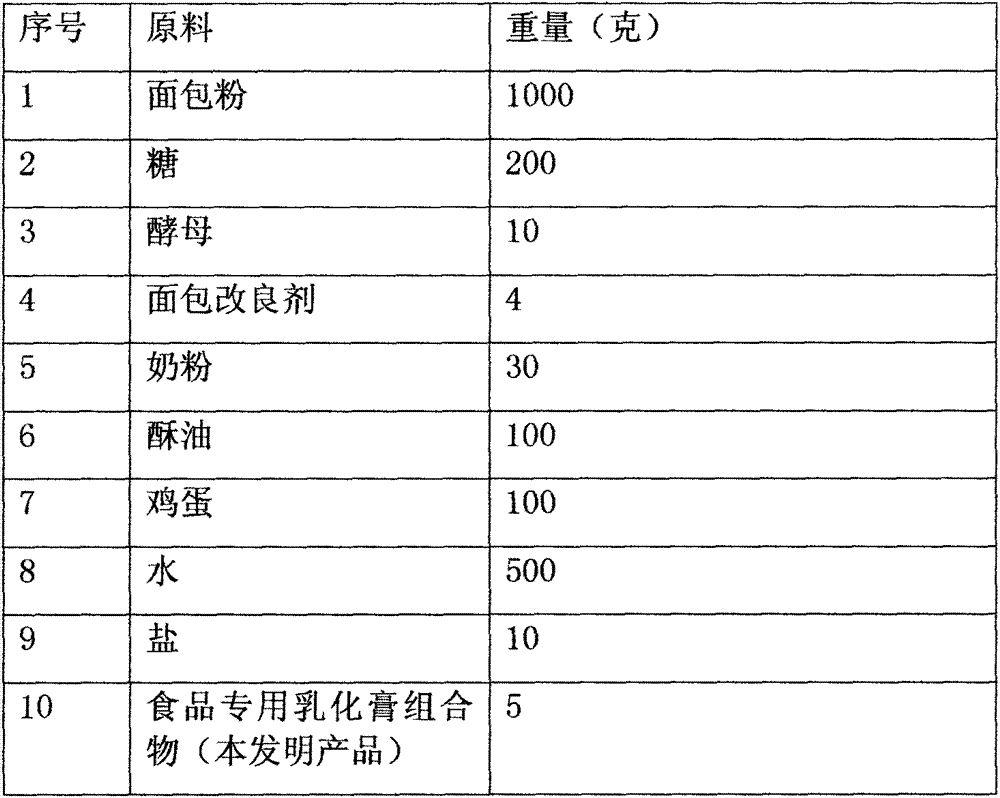

Emulsifying paste composition special for foods and production technology of emulsifying paste

InactiveCN107136149AHighlight substantive featuresSignificant progressDough treatmentSorbitan monostearateSucrose

The invention relates to an emulsifying paste composition special for foods. The emulsifying paste composition consists of 30-40% of water, 20-30% of sorbitol liquid, 6-10% of sorbitan monostearate, 10-14% of monoor / and diglyceryl stearate, 4-8% of polyglyceryl fatty ester, 6-12% of sucrose fatty acid ester and 3-8% of sodium stearoyl lactylate. The emulsifying paste composition disclosed by the invention is simple and convenient to make; and besides, a sorbitol composition and an emulsifying agent composition are processed and stirred at a special temperature, so that the application functions are effectively increased, the made emulsifying paste composition can lock moisture in bread, cakes and the like, can maintain food tissue soft, fine and smooth and increase smooth mouth feel.

Owner:广州市美日一统食品科技有限公司

Ultrasonically-treated nutritional products having extended shelf life

InactiveUS20140220198A1Extended shelf lifeIncrease powerMilk preservationDough treatmentEngineeringNutritional products

Disclosed are nutritional products and nutritional bars having increased shelf life. The nutritional product or nutritional bar is manufactured utilizing high power ultrasound in combination with an extrusion process or slabbing process. It has been found that by utilizing high power ultrasound during the manufacturing process of nutritional products and nutritional bars, that the resulting product has increased shelf life and improved texture. In some embodiments, the nutritional bars include a solid crisp matrix.

Owner:ABBOTT LAB INC

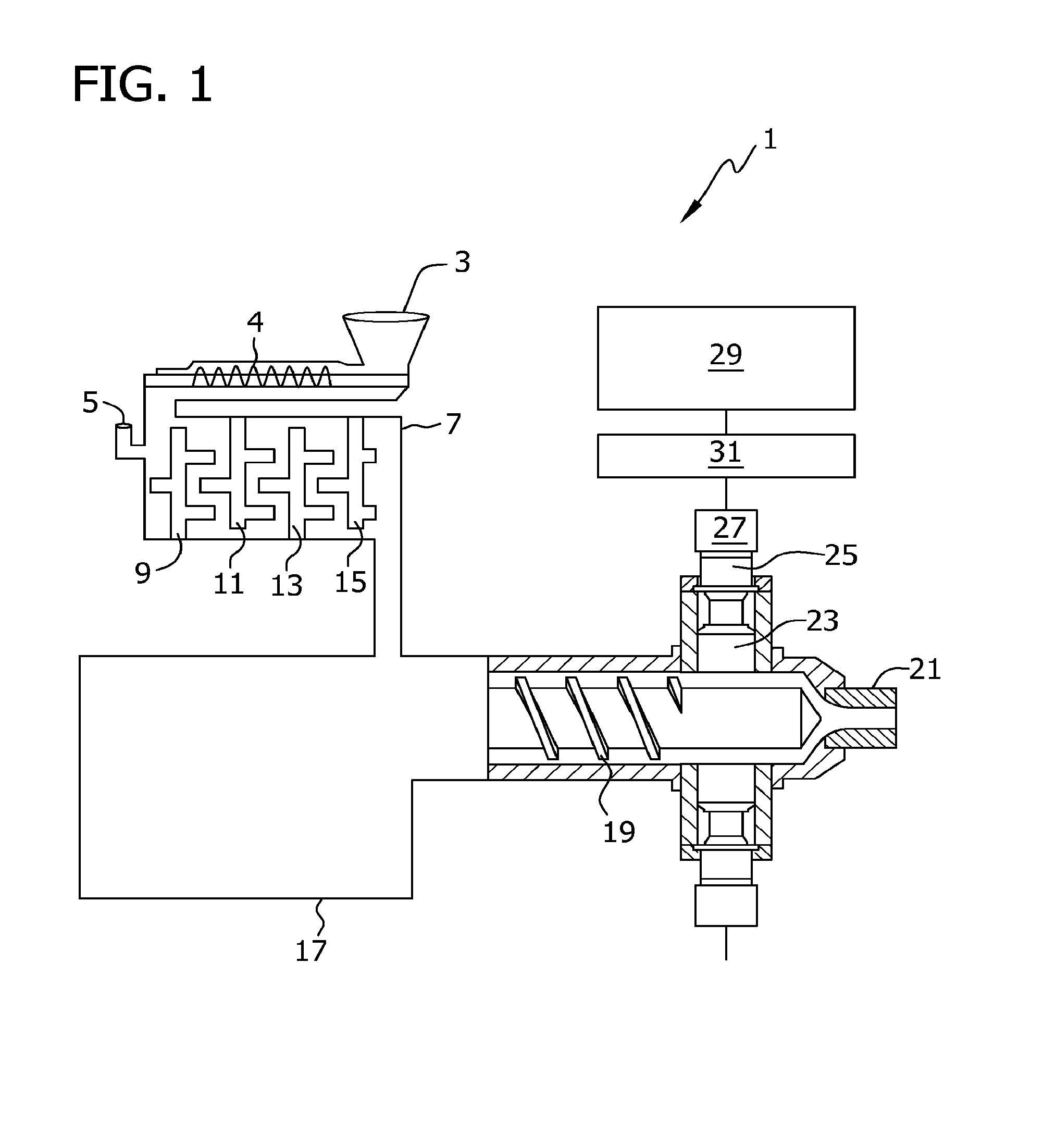

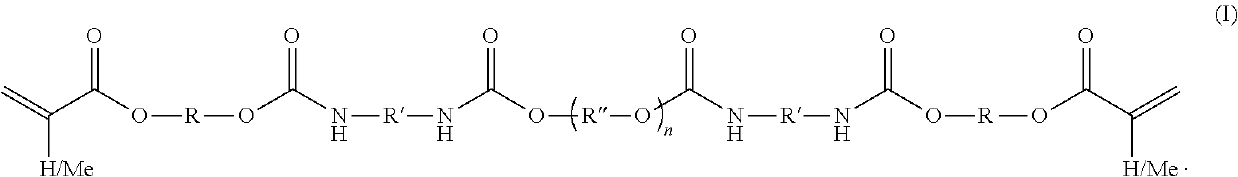

Uv-curing acrylic resin compositions for thermoformable hard coat applications

InactiveUS20190185602A1Flexibility and hardnessPoor impact resistanceCoatingsMonomer compositionMeth-

The present invention provides ultraviolet (UV) curing acrylic compositions for use in making thermoformable hard coats for curved optical displays comprising: (a) one or more multifunctional (meth)acrylate diluents chosen from (a1) an aliphatic trifunctional (meth)acrylate monomer; (a2) an aliphatic tetrafunctional (meth)acrylate monomer; or (a3) an aliphatic pentafunctional (meth)acrylate monomer; (b) from 3 to 30 wt. %, based on the total weight of monomer solids, of one or more one (meth)acrylate monomer containing an isocyanurate group; (c) from 5 to 40 wt. %, based on the total weight of monomer solids, of one or more aliphatic urethane (meth)acrylate functional oligomer having from 6 to 12 (meth)acrylate groups; (d) from 2 to 10 wt. %, based on total monomer solids, of one or more UV radical initiators; and (e) one or more organic solvents for the monomer composition. The composition has a viscosity measured by Anton Parr ASVM 3001 digital viscometer at 50 wt. % solids of from 10 to 200 centipoise (cPs).

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

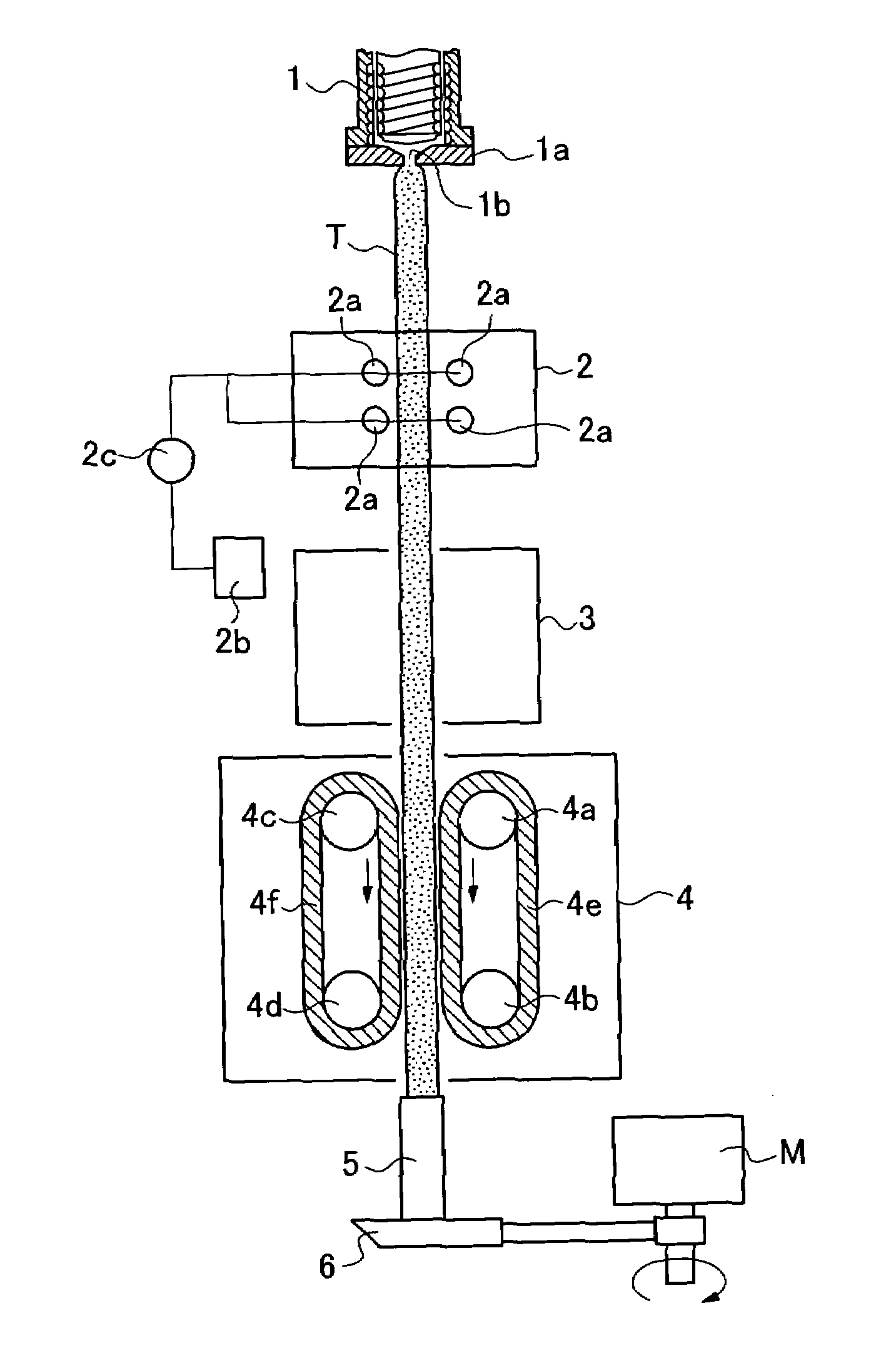

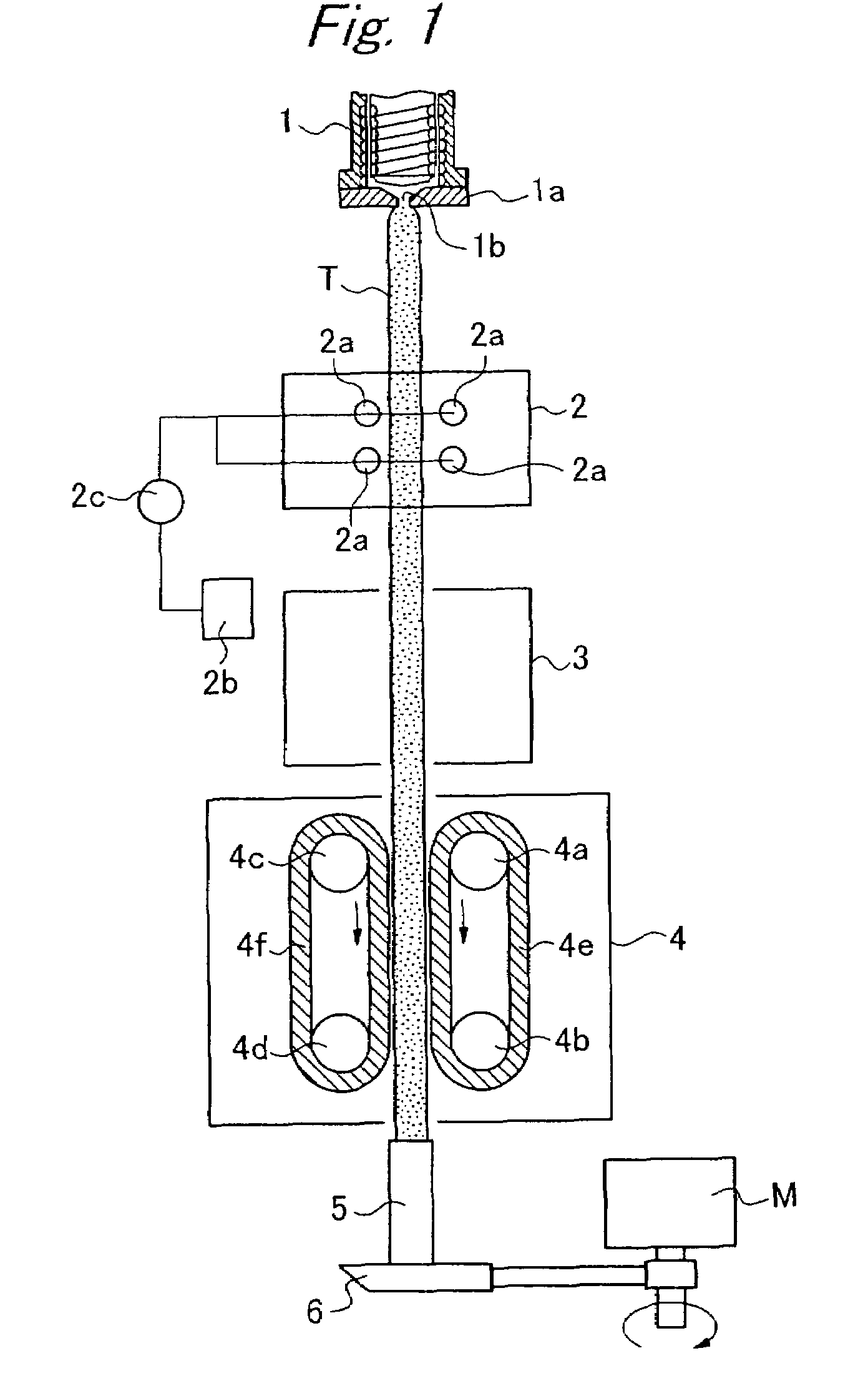

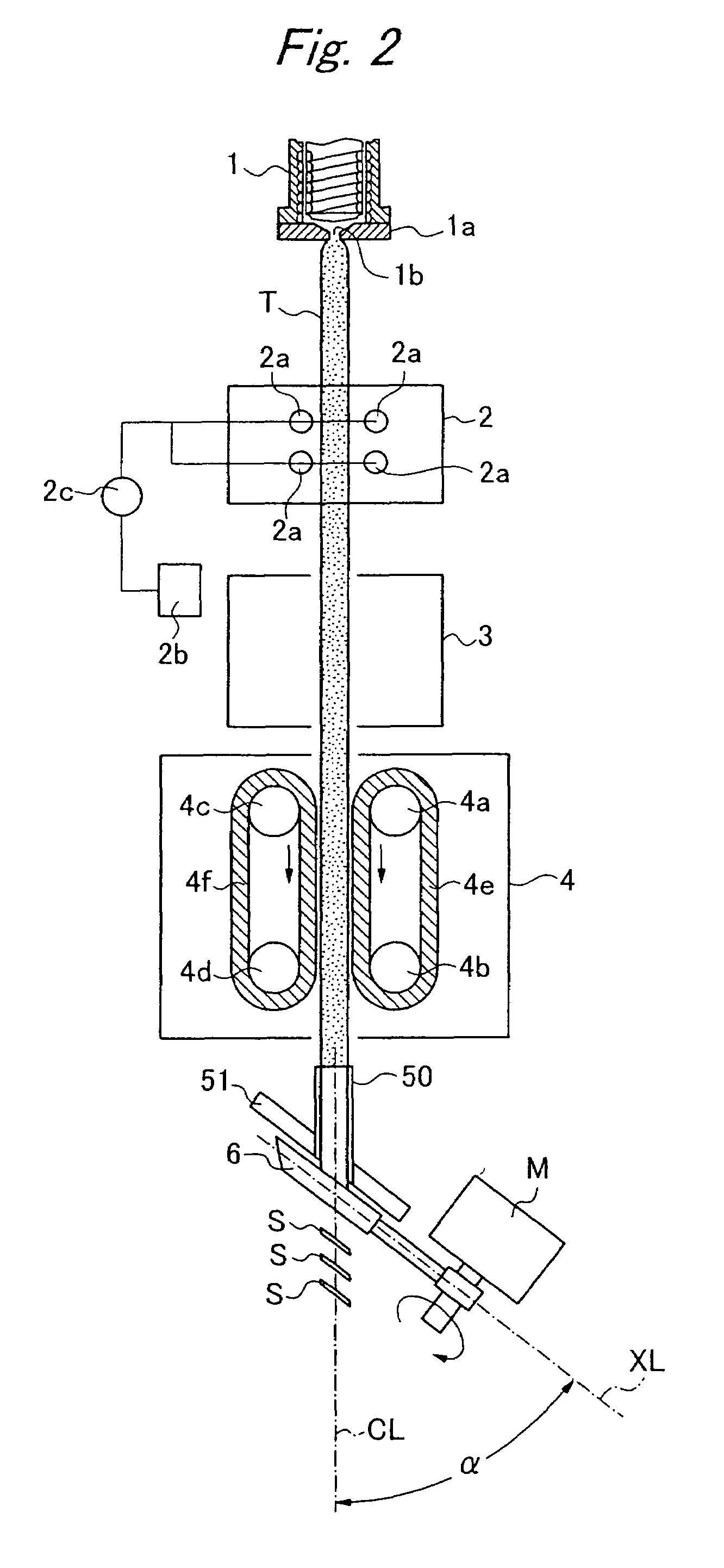

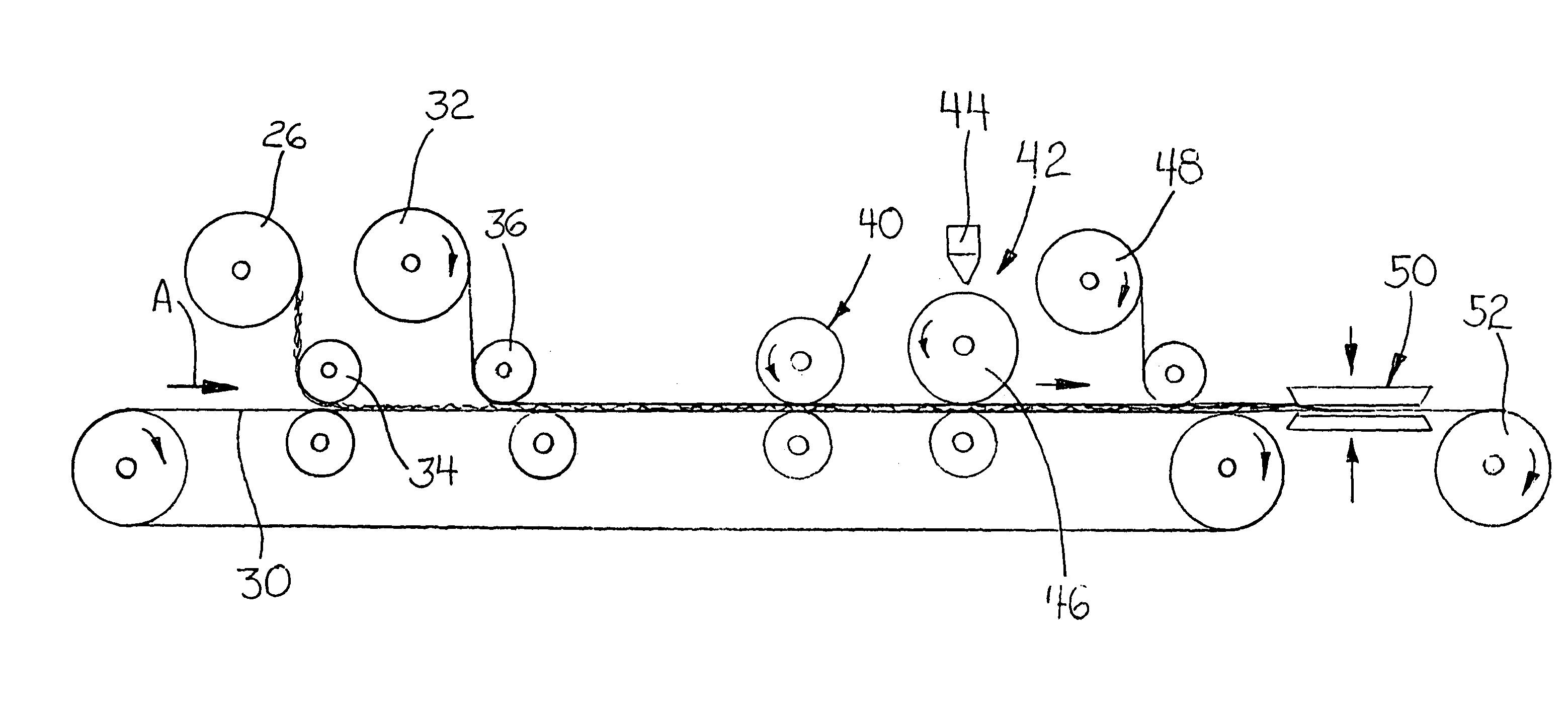

Process for producing puffed snack and production apparatus therefor

A method and apparatus for manufacturing puffed snack having a hard surface layer and soft inside, and having a good texture and a difference in color tone between the surface layer and the inside. After spraying a coating liquid or water onto the surface of a dough extruded from an extruder in the form of a rope, the extrudate is dried so that the moisture content of the sprayed extrudate becomes 5 to 12% by weight and then cut. The apparatus used for this manufacturing method comprises a spray device for uniformly spraying the surface of the dough extruded from a nozzle hole of an extruder, a drying device arranged on the downstream side of the driving device, a drawing mechanism comprising belts spanned in a tensioned state so as to clamp the extrudate, a holding cylinder for holding the extrudate and arranged adjacently on the downstream side of the drawing mechanism, and a cutting blade arranged in close proximity to the outlet side opening of the holding cylinder to cut the extrudate.

Owner:MEIJI SEIKA PHARMA CO LTD

Hair hold formulations

InactiveUS20070108418A1Excellent holdMaintain softnessCosmetic preparationsHair cosmeticsMedicineHair characteristics

Owner:BOSTON COSMETICS

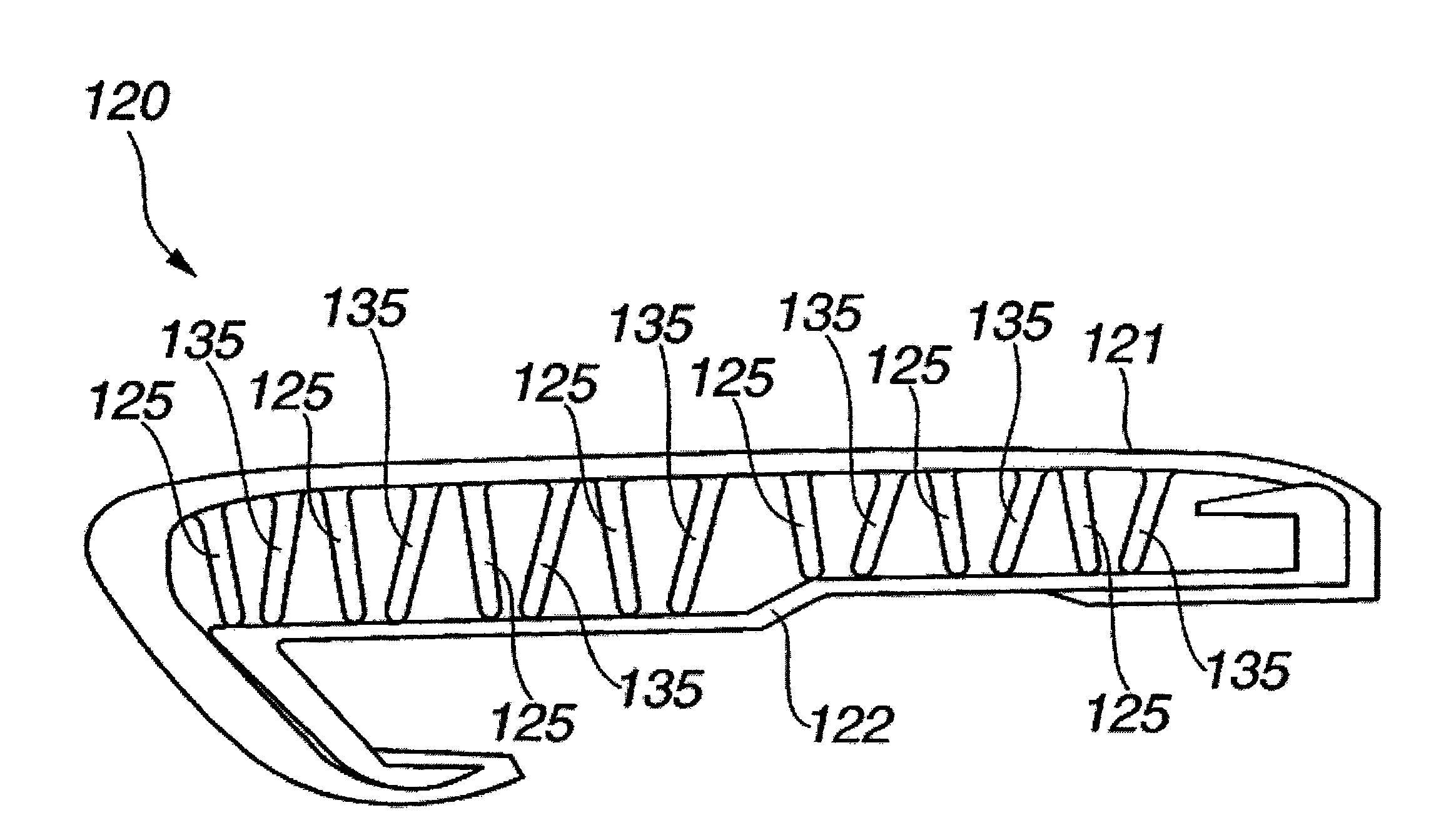

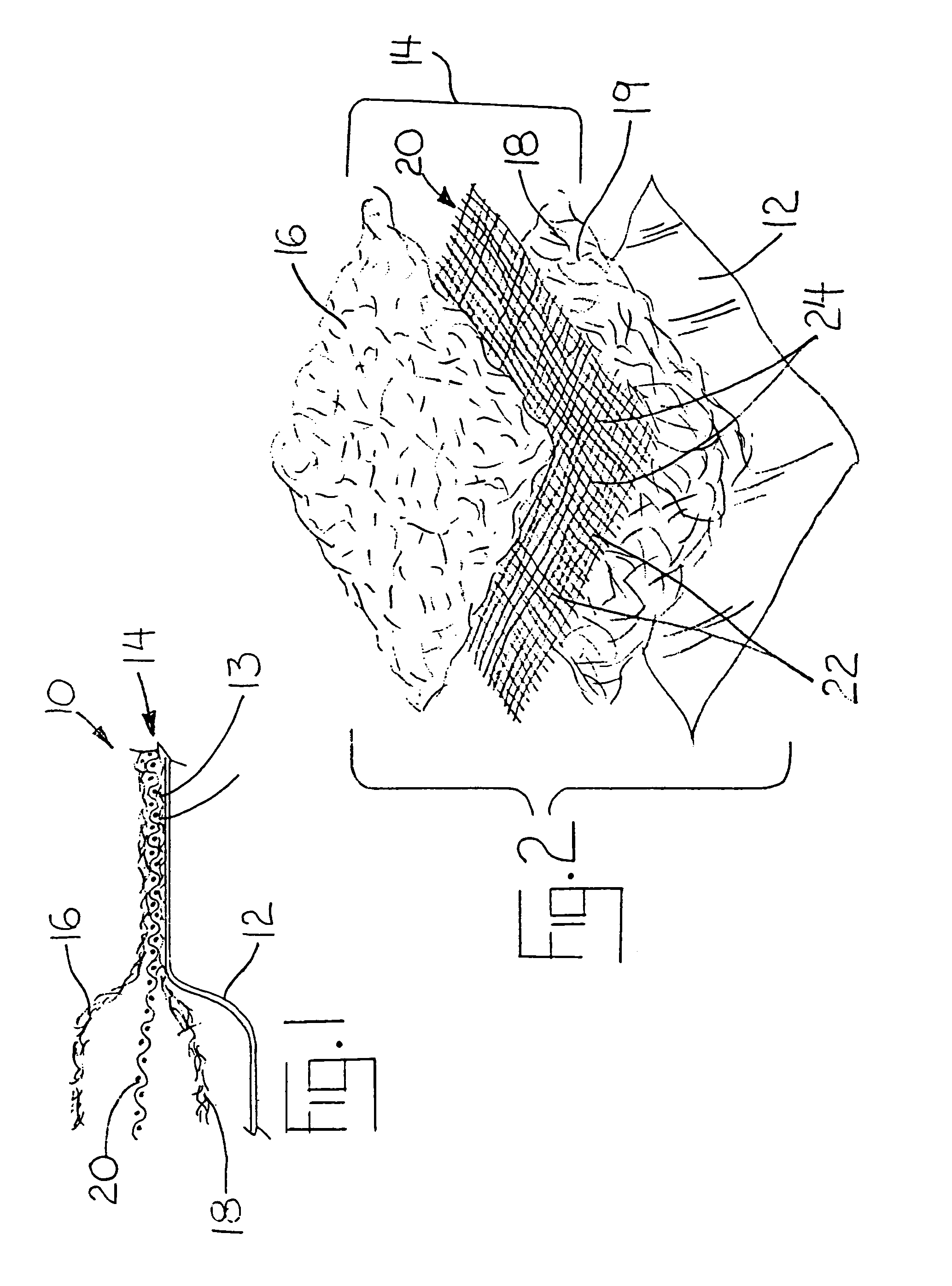

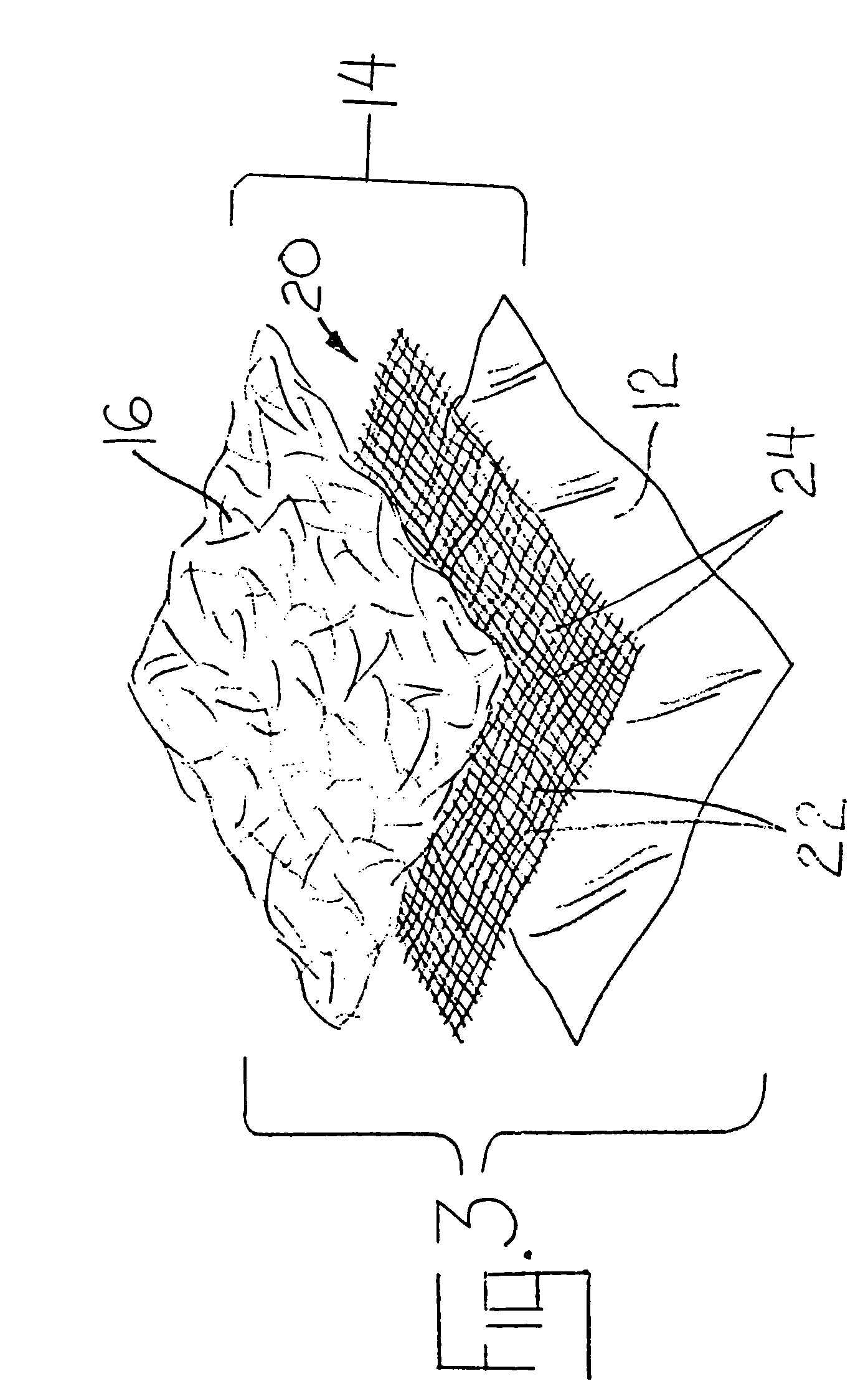

Shrink wrap material having reinforcing scrim and method for its manufacture

A shrink wrap material for protecting articles includes at least one non-woven fabric and a woven scrim defining apertures. A sufficient portion of the fibers from the non-woven fabric being forced into the apertures of the scrim such that the scrim reinforces and supports the non-woven fabric, thus increasing their strength. A shrinkable, stretchable film is intermittently bonded to at least one non-woven fabric. The material is used by placing the material around the article to be protected and then shrinking the film.

Owner:TRANSHIELD INC

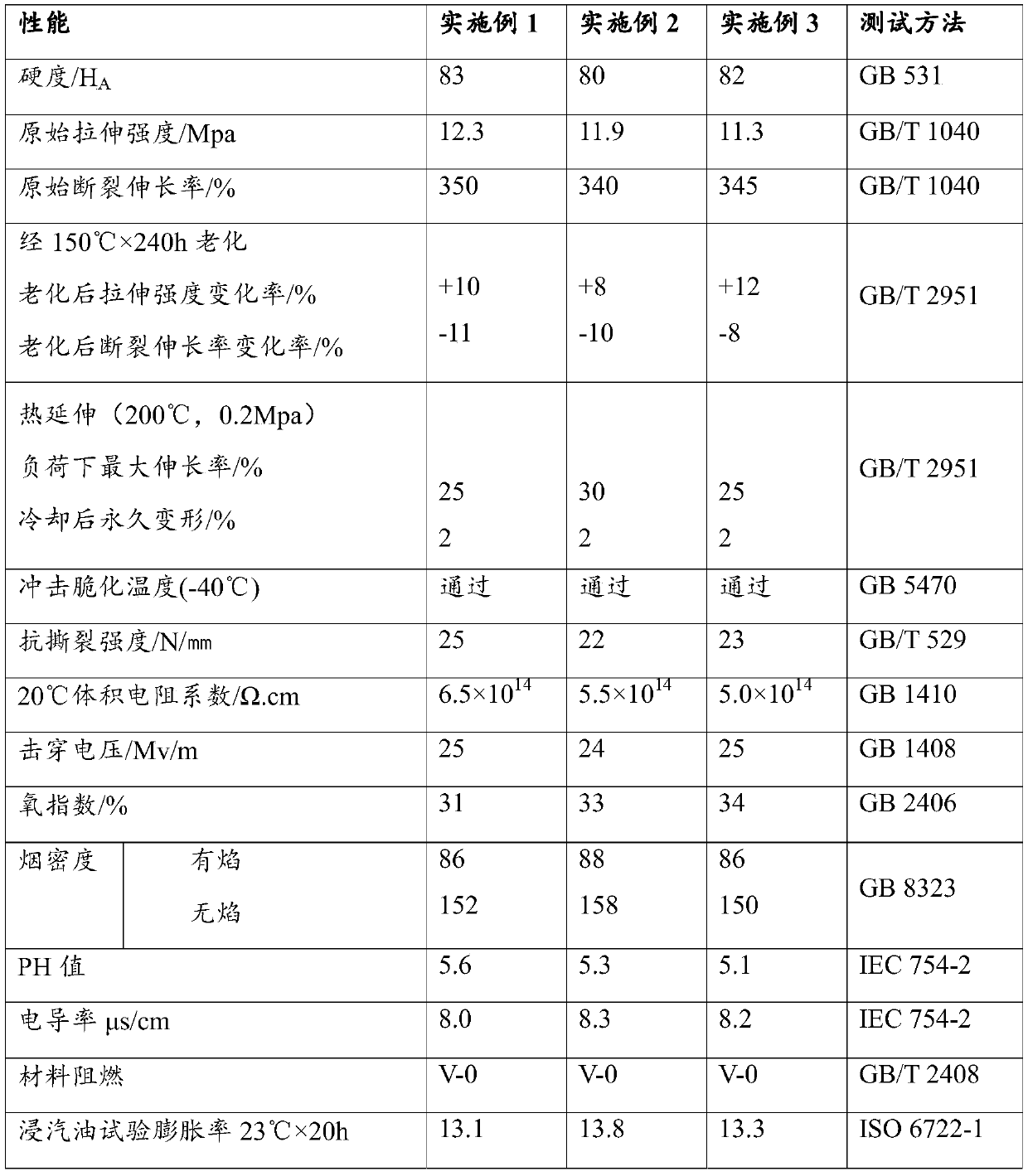

High temperature-resistant, radiation-crosslinked, low-smoke, halogen-free and flame-retardant cable material for charging pile cables, and preparation method thereof

InactiveCN110229431AGuaranteed high temperature performanceStay softRubber insulatorsPolymer scienceCrack resistance

The invention discloses a high temperature-resistant, radiation-crosslinked, low-smoke, halogen-free and flame-retardant cable material for charging pile cables, and a preparation method thereof. Thecable material comprises, by weight, 55-70 parts of ethylene-propylene-diene monomer rubber, 10-20 parts of ethylene-octene copolymer resin, 8-12 parts of maleic anhydride grafted modified resin, 8-10parts of crosslinked modified resin, 5-10 parts of polyethylene-acrylate rubber, 2-5 parts of polyphenylene ether, 60-90 parts of a flame retardant, 20-30 parts of a flame retardant synergist, 0.5-1part of polyethylene wax, 1.2-2 parts of an antioxidant, 0.9-1.2 parts of a crosslinking agent, and 0.1-0.3 part of a degradation inhibitor. The cable material of the invention can simultaneously meetthe requirements of softness, high flame retardancy, high and low temperature resistance, aging resistance, environmental crack resistance, high insulation, oil resistance, ozone resistance and ultraviolet light resistance.

Owner:WUXI JAKE PLASTIC

Method for forming multilayer coating film

ActiveUS20180281019A1Maintain softnessAvoid coatingPretreated surfacesElectrophoretic coatingsEmulsionBoiling point

The coating film formed on an automobile body has softness during a film formation even on a thermally expandable / shrinkable base, and the cured film has an excellent appearance.Provided is a method for forming a multilayer coating film, the method comprises: applying an aqueous intermediate coating composition and preheating the applied composition at 60 to 90° C. to form an uncured film;preheating to form an uncured base coating film and a clear coating film; andbaking and curing these uncured films to form a multilayer coating film,wherein the aqueous intermediate coating composition comprises (a) an acrylic resin emulsion having a specific properties, and (b) a film formation auxiliary agent that is a fatty acid diester compound having a boiling point of 280° C. to 350° C., anda cured film comprising (a) and (b) at a mass ratio of 3:1 has a rupture elongation of 1% or more.

Owner:NIPPON PAINT AUTOMOTIVE COATINGS +1

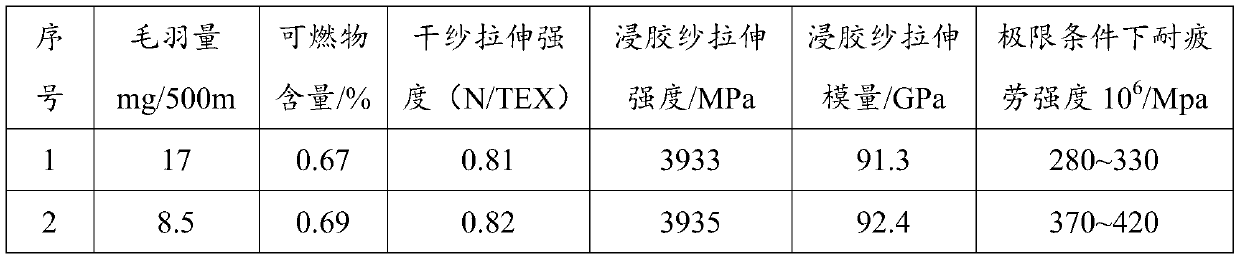

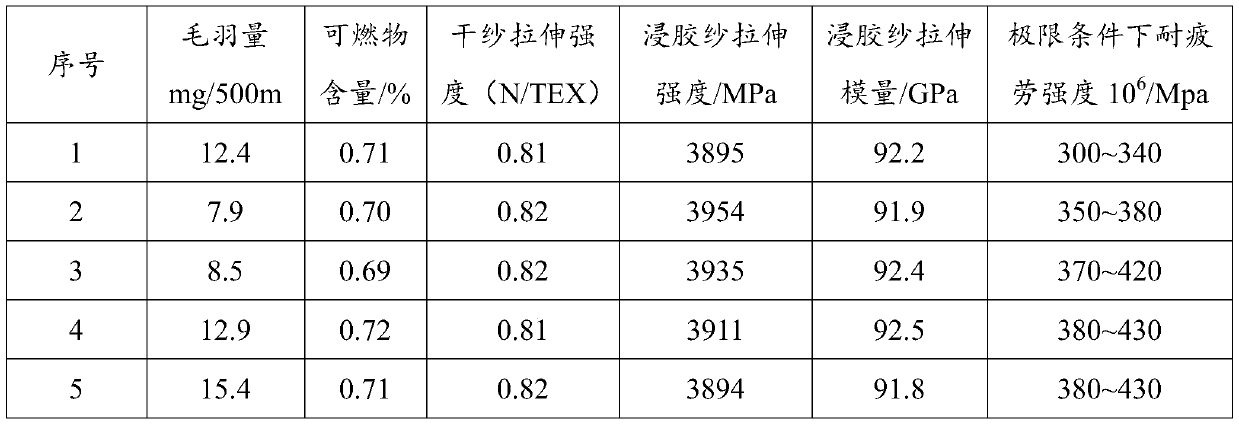

Film forming agent suitable for glass fibers, impregnating agent comprising same, and preparation method and applications of impregnating agent

The invention relates to the technical field of impregnating agents, and discloses a film forming agent suitable for glass fibers, an impregnating agent comprising the same, and a preparation method and applications of the impregnating agent. The film forming agent comprises emulsified bisphenol A type epoxy resin and polyester type polyurethane. Through the emulsification effect of a surfactant, the interfacial energy of a system is reduced, the stability of epoxy resin emulsion is improved, and thus the function of the epoxy resin emulsion can be better exerted. The polyester polyurethane film forming agent has a large molecular weight and a strong yarn-wrapping performance and easily forms a compact film on the surface of glass fibers, thus the glass fibers are isolated from the external environment, water will not enter the cracks of the glass fibers, the elasticity and wear resistant performance of yarns are improved, the anti-fatigue performance of yarns is strengthened, at the same time, the bundling force is high, and the phenomenon of yarns such as natural draping, non-uniform tension force, and the like, is effectively relieved.

Owner:SINOMA SCI & TECH

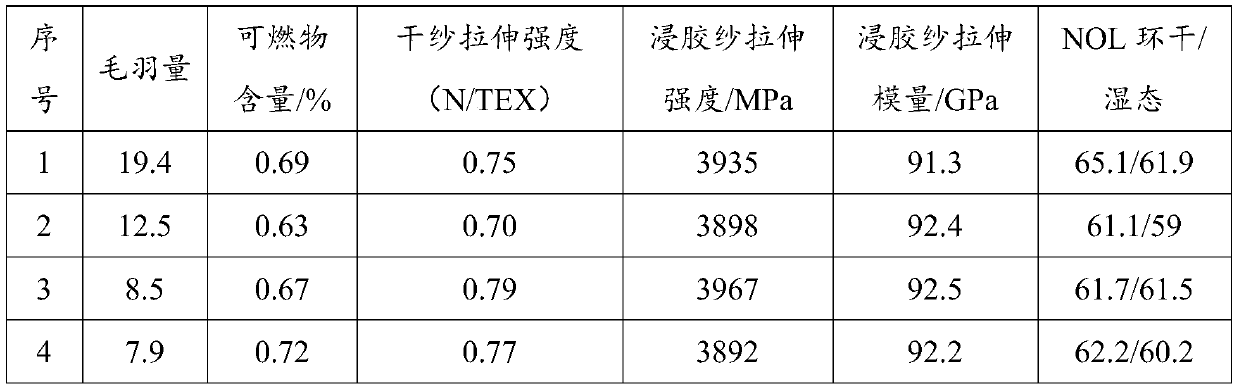

Viscose cotton yarn gluing process

ActiveCN107513831AImprove gluing effectPrevent solidificationLiquid/gas/vapor removalTextile treatment machine arrangementsYarnViscose

The invention belongs to the field of textile and particularly discloses a viscose cotton yarn gluing process. The process comprises the following steps of 1, cleaning, 2, drying before gluing, 3, cotton yarn guiding, 4, stirring and gluing, 5, frictioning, 6, drying after gluing and 7, rolling. According to the scheme, the viscose cotton yarn gluing process enhances the flowability of the viscose, so that the cotton yarn gluing is more even, the viscose is prevented from solidifying and layering when gluing is carried out, and the quality of cotton yarn gluing is improved. Besides, under the circumstance of insufficient viscose, the continuity of gluing work can still be guaranteed, the efficiency of cotton yarn gluing is improved, and the labor cost is low.

Owner:宁波隆锐机械制造有限公司

Manufacturing method for soft almond cakes

ActiveCN103947727AUnique flavorImprove textureDough treatmentBakery productsIcing sugarHigh-fructose corn syrup

The invention relates to a manufacturing method for soft almond cakes. The manufacturing method for the soft almond cakes is characterized in that the method includes the following steps: (1) premixing of powder materials: according to parts by weight, 100 parts of sprouted green bean powders, 5 to 20 parts of modified starch, 0 to 25 parts of whole egg powders, and 0.6 to 1.2 parts of a bulking agent are mixed and sieved for standby; (2) stirring: according to parts by weight, 50 to 80 parts of butter are softened at the room temperature and added with 0.2 to 0.6 part of an alpha-processed emulsifying agent, 0.4 to 1.0 part of preprocessed xanthan gum, 20 to 40 parts of powdered sugar, 25 to 40 parts of high fructose corn syrup and 0 to 10 parts of sorbitol, the mixture is stirred and beat until a bulky status is reached, the powder materials which are premixed in the step (1) for standby are then added, and the obtained mixture is stirred evenly to obtain powder balls; (3) refrigerating and standing; (4) impression forming; (5) baking; (6) cooling and sorting. The soft almond cakes manufactured through the method are different from the traditional soft almond cakes which are dry and hard, and finished products have delicate and soft textures and a unique flavor.

Owner:JUXIANGYUAN HEALTH FOOD ZHONGSHAN

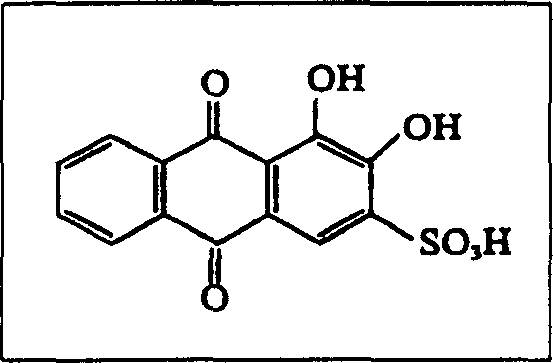

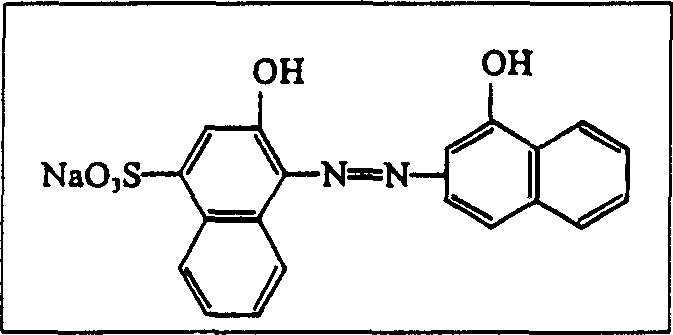

Aluminium salt bottoming acidic medium dye digitial printing ink and printing method of digital printing ink

The digital printing ink dye is refined acid medium dye and neutral dye and includes C.I. medium yellow, C.I. medium red, C.I. medium black and neutral bright blue S-GL. The ink comprises dye 0.5-5 wt%, wetter 5-50 wt%, solubilizer 0-10 wt% and preservative 0-2 wt% except water. The dye refining process includes dissolving dye in organic solvent, filtering to eliminate impurity and final removing organic solvent. The digital printing process includes the steps of: pre-mordanting fabric with aluminum salt; printing in digitally printing machine; and post-treating fabric. The present invention has the advantages of low cost, stable digital printing ink, and high color fastness of printed wool and silk.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Beef cattle breeding method

InactiveCN106070026AImprove meat performanceImprove comfortFood processingAnimal feeding stuffAnimal welfareBeef cattle

The invention discloses a beef cattle breeding method. The beef cattle breeding method comprises the steps that fine and coarse feed nutrition regulation and rail rotation feeding are carried out in month age stages according to the growth periods of beef cattle, wherein according to rail rotation feeding, one group of cattle are fed in every two adjacent small rails, five cattle are included in each group, the other rail is empty while cattle are fed in one rail, rotation of the rails is carried out once every 7.5 days according to the humidity condition of the ground padding of the rails, and the operation circulates in the whole feeding process until fattening of beef cattle is completed for slaughter finally. According to the beef cattle breeding method, the meat performance of high-grade beef cattle is improved with the methods of nutrition regulation, animal welfare improvement and the like.

Owner:GUIZHOU PROVINCE FENGGANG COUNTY WANWU AGRI TECH DEV CO LTD

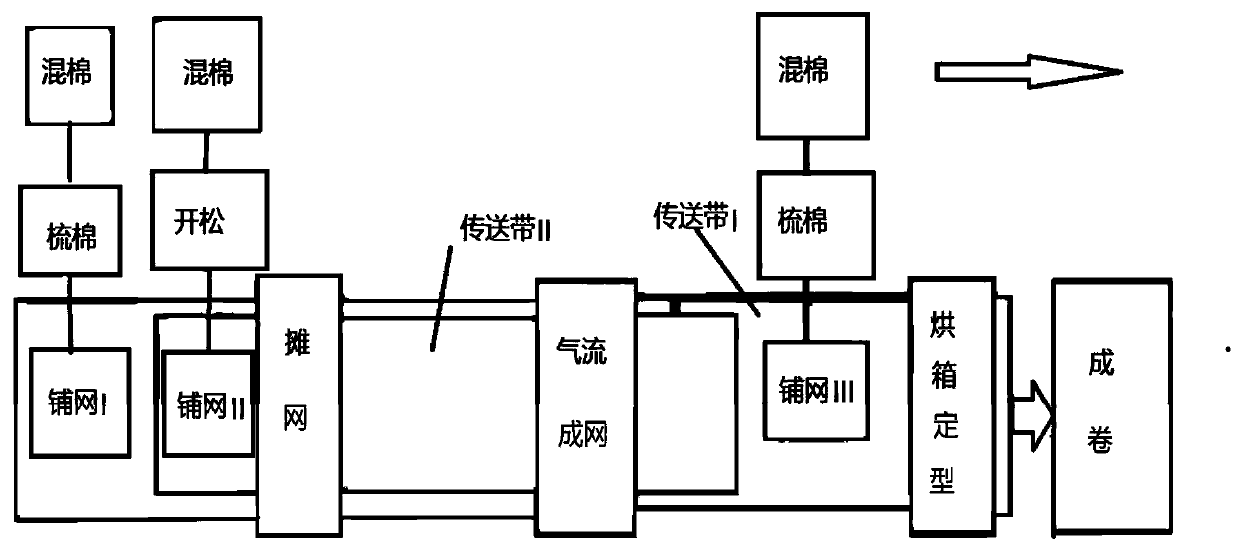

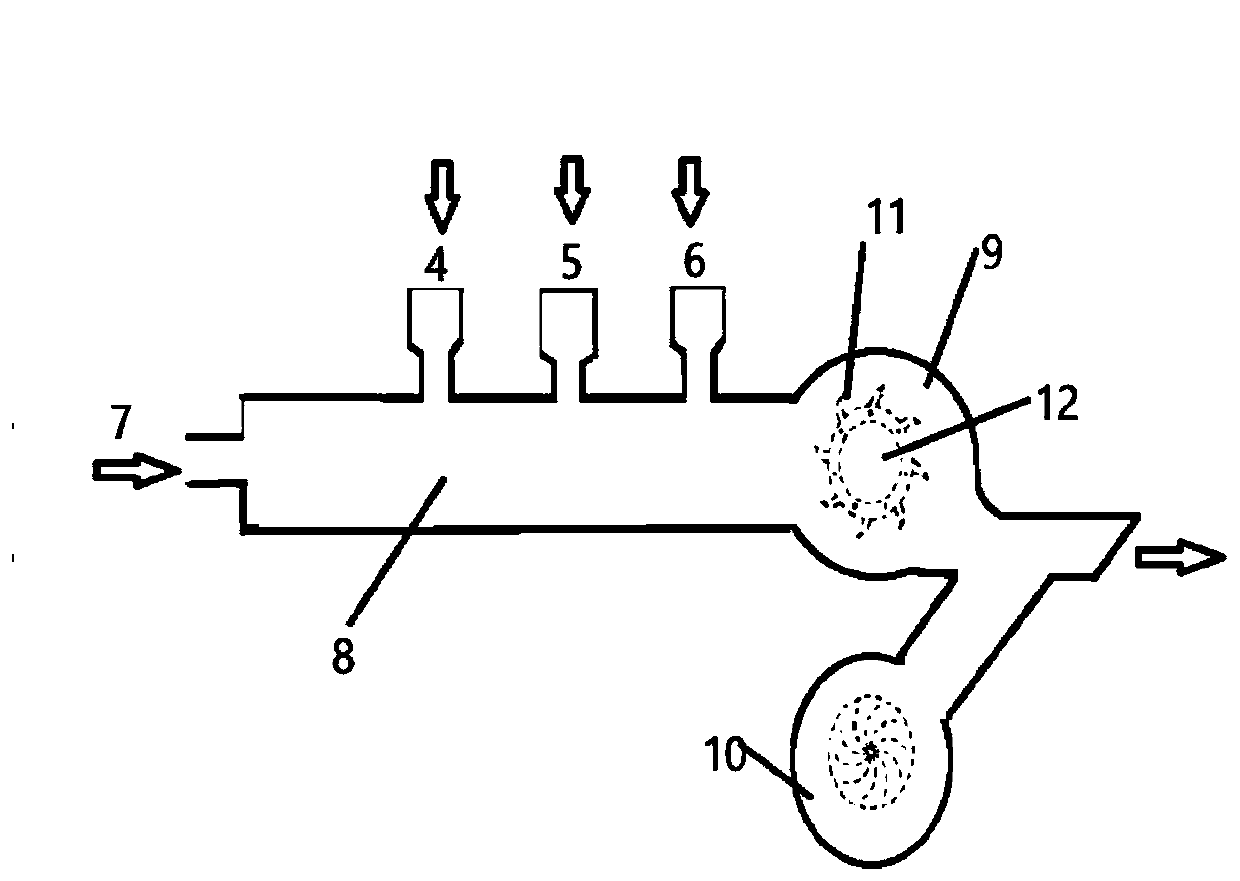

Manufacturing method of static down flake and mixed down

The invention relates to a manufacturing method of multi-layer composite static down flake and mixed down. The manufacturing method includes the steps that animal fibers and low melting point fibers are subjected to cotton blending, cotton carding and lapping, and a lower flake is manufactured; after the animal and plant fibers and the low melting point fibers are subjected to cotton blending, opening and lapping, a down fiber or other thermal insulation material, functional fiber, animal and plant fiber and low melting point fiber single product or a mixture is laid, then a middle flake is manufactured by air lay, and is laid on the lower flake; the animal fibers and low melting point fibers are subjected to cotton blending, cotton carding and lapping, and an upper flake is manufactured,and laid on the middle flake; and the lower flake, the middle flake and the upper flake are fused into one.

Owner:杭州正行纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com