Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

855 results about "Sodium Caseinate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

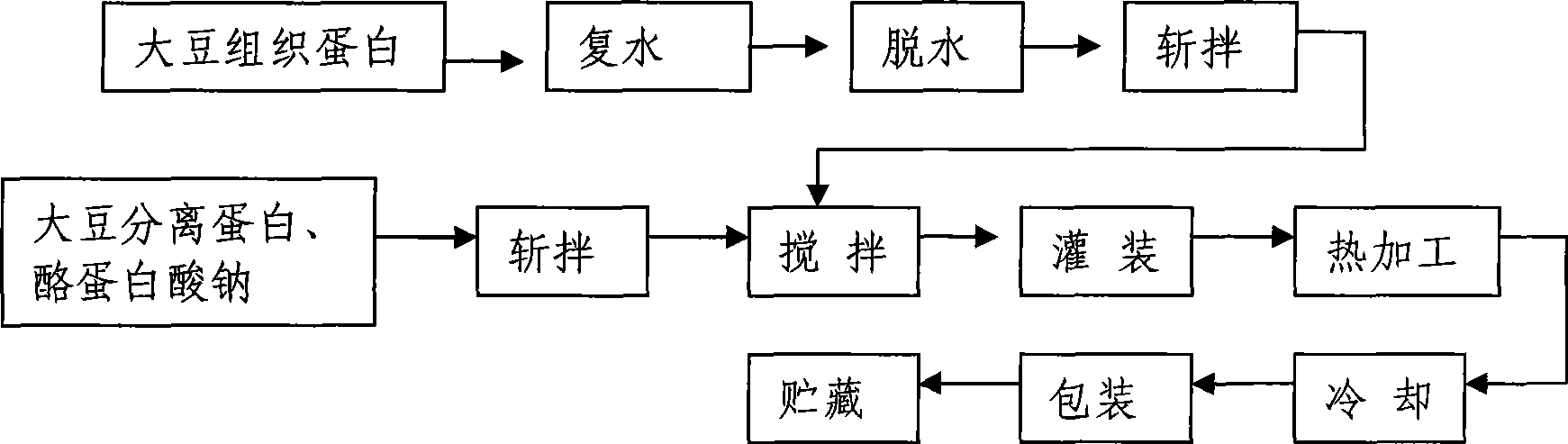

Artificial vegetarian sausage and preparation method thereof

ActiveCN101496566AGreat tasteSlicing works wellCheese manufactureFood preparationVegetable oilSodium Caseinate

The invention provides artificial prosages and a method for preparing the same. The artificial prosages are prepared from the raw materials including soy protein isolate, textured soybean protein, sodium caseinate, vegetable oil and starch with species through the steps of chopping, stirring, bulking, hot processing, cooking packaging, and cold storage or refrigeration. The artificial prosages made by the method comprise artificial vegetarian pork and green bean sausages, artificial vegetarian beef and carrot sausages, artificial vegetarian chicken sausages, artificial vegetarian fish and green pepper sausages and the like. The prosages have the same appearance and almost the same taste and flavor as artificial sausages and are processed by the same devices and equipment as the artificial sausages. The major part of the proteins in the artificial prosages is vegetable soybean protein and the protein content is high; the fat of the artificial prosages is vegetable oil and the fat content is high; and the artificial prosages do not have cholesterin. The artificial prosages are applicable to both vegetarians and common people and can improve the health of people.

Owner:CHINA MEAT RES CENT

Zero-trans fatty acid non-dairy creamer and preparation method thereof

The invention relates to a zero-trans fatty acid non-dairy creamer and a preparation method thereof, and belongs to the technical field of non-dairy creamers. The zero-trans fatty acid non-dairy creamer consists of the following components in percentage by weight: 22 to 32 percent of vegetable oil and fat, 2.2 to 3.5 percent of sodium caseinate, 0.8 to 1.5 percent of mono-and diglycerides, 0.5 to 1 percent of stearoyl sodium lactate, 1.2 to 1.5 percent of dipotassium phosphate, 0.25 to 0.5 percent of silicon dioxide and the balance of glucose syrup. The preparation method comprises the following steps of: heating, dissolving, mixing, shearing at high temperature, homogenizing, spray-drying and packaging to obtain the zero-trans fatty acid non-dairy creamer. The preparation process is simple and easy to operate; and the obtained non-dairy creamer is high in nutritional performance, good in mouthfeel, fragrant and smooth, does not contain trans fatty acid, meets the consumption demand of health and nutrition at present, and is particularly suitable to be drunk by old people, overweight people, patients who suffer from diabetes and consumers. The zero-trans fatty acid non-dairy creamer can be used as coffee creamers to be mixed with coffee, fruit juice, tea and the like respectively for drinking and also can be used as instant drinks independently for drinking.

Owner:杭州博多工贸有限公司

Method for preparing fish oil ethyl ester microcapsule from fish pomace

ActiveCN101940240AHigh purityImprove qualityEdible oils/fatsFood preparationForeign matterNeutral protease

The invention relates to a method for preparing a fish oil ethyl ester microcapsule from fish pomace, which mainly comprises the extraction of fish oil, the preparation of fish fatty acid ethyl ester, the purification of fish oil ethyl ester and the preparation of a fish oil ethyl ester microcapsule, wherein the extraction of fish oil comprising the following steps: eliminating foreign matters from fish viscus, cleaning, mashing, adding pepsin and neutral protease for enzymolysis, then adding anhydrous alcohol, standing to stratify, and centrifuging to obtain the fish oil; the preparation of fish fatty acid ethyl ester comprising the following steps: mixing the fish oil with ethanol, making the mixture to be subject to an esterification reaction under the catalysis of sodium ethylate, vaporizing the ethanol, washing with water, and then centrifuging to obtain the fish oil ethyl ester; in the purification process, supercritical CO2 extraction is adopted, the purified fish oil ethyl ester is a golden yellow transparent liquid, and EPA ethyl ester and DHA ethyl ester contents thereof are more than 50%; and the preparation of a fish oil ethyl ester microcapsule comprises the following steps: mixing sodium alginate, maltodextrin and sodium caseinate, dissolving in water, adding the purified fish oil ethyl ester, and adopting a spray drying method to obtain the powdered fish oil ethyl ester microcapsule which can hide the fishy smell of the fish oil ethyl ester, improve the mouth feel and be beneficial to packaging and storage.

Owner:DALIAN POLYTECHNIC UNIVERSITY

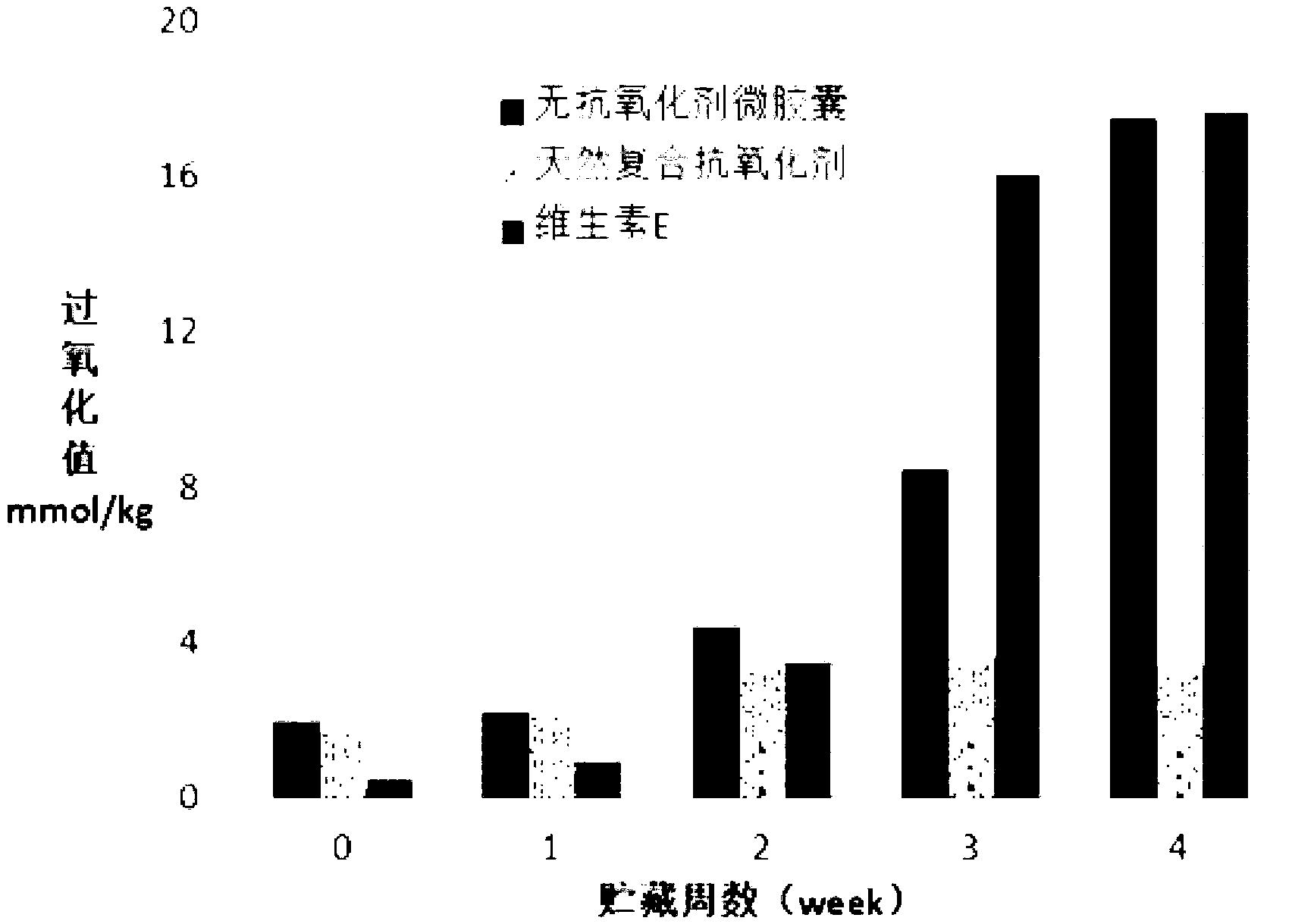

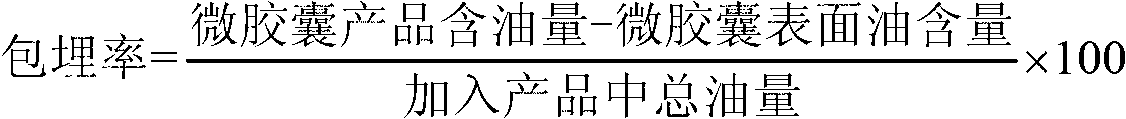

Flaxseed oil microcapsule and production method thereof

ActiveCN102934703AFit for consumptionImprove stabilityFood shapingEdible oils/fatsSodium CaseinateOil phase

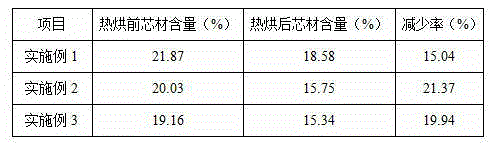

The invention discloses a flaxseed oil microcapsule and a production method thereof. The core material of the flaxseed oil microcapsule is flaxseed oil, and the wall material is made of modified starch, maltodextrin and sodium caseinate. The production method comprises steps of adding the modified starch, the maltodextrin and the sodium caseinate to hot water with high-speed stirring until the the modified starch, the maltodextrin and the sodium caseinate are dissolved completely and forming a water phase; weighing and taking the flaxseed oil, adding vitamin E, rosemary and tea polyphenol step by step, stirring the mixture until the mixture is dissolved completely and forming an oil phase; conducting high-speed cutting for the obtained water phase by using a cutting machine, adding the obtained oil phase slowly and obtaining an emulsion; homogenizing the emulsion by using a high-pressure homogenizer; sterilizing the emulsion which is homogenized by using an ultra high-temperature sterilizing machine; and spraying and drying the sterilized and obtaining the flaxseed oil microcapsule. The embedding rate of the flaxseed oil microcapsule is more than 90%, the capacity of the flaxseed oil can reach 45%, the process is simple, the taste is special, the scent is obvious and the shelf life is long.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD +3

Krill oil microcapsual powder and its preparation method

The invention discloses a krill oil microcapsual powder and its preparation method. The preparation method comprises steps of: preparation of an oil phase solution and an aqueous phase solution, mixing and emulsification of the two solutions, homogenizing, drying and the like. The krill oil microcapsual powder is prepared from the following raw materials of: by weight, 0.001-90% of krill oil, 0.5-90% of sodium caseinate and 0-99% of a filler. In addition, 0.001-10 wt% of an oil phase antioxidant, 0.001-5 wt% of an aqueous phase antioxidant, 0.001-5 wt% of an aqueous stabilizer and 0.001-5 wt% of an anti-caking agent can also be added. The krill oil microcapsual powder has high content of the encapsuled krill oil and has good stability and fluidity. After rehydration, krill oil can be dispersed into water completely in the form of particles (nm); and krill oil is stable if stored for a long time, and has no phenomenon such as floating oil, precipitation, adhesion to bottles and the like. therefore, the application range of krill oil is broadened, and krill oil is applied to fields such as dry mixing, drinks, dairy products, bakery, tablets and the like.

Owner:辽渔集团有限公司

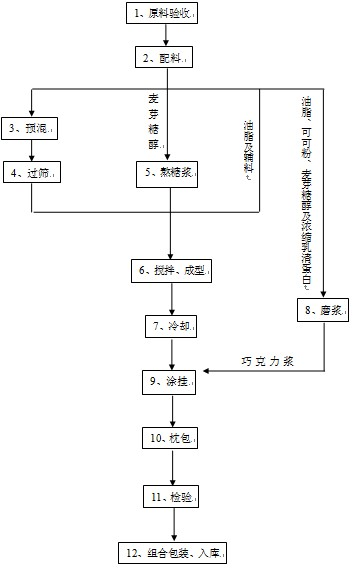

Weight-losing nutrition bar and preparation method thereof

The invention provides a weight-losing food with balanced nutrition, containing the following components of: soybean isolate protein expanded grains, maltitol liquid, water-soluble dietary fiber, concentrated lactalbumin, glycerol, fish collagen protein, phytosterol, quick-freezing blueberry grains, Arabic gum, sodium caseinate and compound vitamin. The weight-losing bar has the advantages of good taste and high protein content; the weight-losing food bar can enhance the satiety and also can supplement the protein; and meanwhile, functional food raw materials including the fish collagen protein, the phytosterol and the like, the compound vitamin and the like are added, so as to achieve the aim of healthily losing the weight of a consumer.

Owner:浙江诺特健康科技股份有限公司

Chitosan-galangal essence microcapsule as well as preparation method and application of microcapsule

InactiveCN104587921AReduce volatilityProlong the action timeBiocideFibre treatmentSodium CaseinateHeat stability

The invention discloses a chitosan-galangal essence microcapsule which comprises a core material and a wall material, wherein galangal essence is taken as the core material, and the wall material is formed through complex coacervation of chitosan, polylysine and sodium caseinate; and the core material is covered inside the wall material. The invention further discloses a preparation method of the chitosan-galangal essence microcapsule and application of the microcapsule in a mosquito repellent and a textile antibiotic finishing agent. The chitosan-galangal essence microcapsule disclosed by the invention can be used for improving the light and heat stability of the galangal essence, and has the advantages of high intensity, good heat stability, long and lasting mosquito repelling and antibiotic effects, and the like.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Whipped cream powder, preparation method and application

ActiveCN103039631AHigh foaming rateImprove plasticityEdible oils/fats production/working-upSodium CaseinateAnticaking agent

The invention relates to a preparation method of whipped cream powder. The method comprises the following steps that (1) vegetable fat and an emulsifying agent are mixed uniformly to form mixed liquid 5; white granulated sugar, sodium caseinate, whey protein and milk powder are mixed with water to form mixed liquid 1; the mixed liquid 1 is mixed with glucose syrup to form mixed liquid 3; a water retention stabilizer and a thickener are mixed with the water to form mixed liquid 2; the mixed liquid 2 is mixed with the mixed liquid 3 to form mixed liquid 4; the mixed liquid 5 is mixed with the mixed liquid 4 to form oil-water mixed pulp; the oil-water mixed pulp is stirred, sheared and emulsified to form uniform light-milk yellow pulp; (2) the pulps obtained in Step (1) are homogenized to form homogenized pulp; and (3) the homogenized pulp is pasteurized and subjected to spray drying; an anticaking agent is added to powder obtained through the spray drying, and mixed uniformly to form the whipped cream powder. The whipped cream powder can serve as a principal raw material of preparation of decorative cakes, mousse cakes and puffs.

Owner:无锡超科食品有限公司

Compound microcapsule wall material and application thereof in essence microcapsules for cigarettes

InactiveCN103396886AImprove solubilityGood emulsifying effectEssential-oils/perfumesSucroseSodium Caseinate

The invention provides a compound microcapsule wall material and an application thereof in essence microcapsules for cigarettes. The compound microcapsule wall material is mixed by the following components in percentage by weight: 30.0-50.0% of starch octenylsuccinate, 15.0-30.0% of maltodextrin, 10.0-30.0% of sodium carboxymethyl starch, 10.0-30.0% of soy isolate protein, 1.0-5.0% of Arabic gum, 1.0-5.0% of sodium caseinate, 1.0-5.0% of saccharose, 0.1-0.5% of sodium alginate, 0.1-0.5% of xanthan gum and 0.1-0.5% of pullulan. The compound microcapsule wall material provided by the invention is good in solubleness, good in emulsibility, good in film-forming property, low in solution viscosity, and economical and practical benefits. Higher embedding rate can be obtained by using the wall material to prepare the essence microcapsules for cigarettes, and the product is good in sensory performance, smooth and uniform in particle, compact in capsule wall, lower in moisture content, good in dispersibility and stronger in practicality.

Owner:HUBEI CHINA TOBACCO IND +1

Preparation process of peony seed oil micro-capsule powder

ActiveCN104206561AGood instant solubilityImprove stabilityFood shapingEdible oils/fatsSodium CaseinateWarm water

The invention discloses a preparation process of peony seed oil micro-capsule powder. The preparation process is characterized by sequentially comprising the following steps: (1) dissolving a wall material and an emulsifying agent by using warm water; (2) adding peony seed oil into the dissolved wall material and emulsifying agent, and uniformly mixing and stirring to obtain a mixed solution; (3) homogenizing the mixed solution obtained in the step (2) under high pressure to obtain a solution in a good emulsification state; and (4) spray-drying the solution obtained in the step (3) to obtain the peony seed oil micro-capsule powder, wherein the wall material is one or a mixture of more of sodium caseinate, starch sodium octenylsuccinate, gelatin, arabic gum and malt syrup, and the emulsifying agent is one or a mixture of more of mono-and diglycerides of fatty acids, sodium stearyl lactate and diacetyl monostearin tartrate. The peony seed oil micro-capsule powder prepared by virtue of the process is high in peony seed oil embedding rate and high in grease content; the process flow is simple and efficient, and facilitates large-scale production and application.

Owner:BEIJING ALCHEMIST TECH

Plant lipid cream and production method thereof

InactiveCN101647496AFine foamImprove the decorative effectEdible oils/fats production/working-upDispersitySucrose

The invention discloses a plant lipid cream and production method thereof. The plant lipid cream is prepared by the steps that proteolytic enzyme is utilized to restrict hydrolyzed soy separation, soas to obtain soy proteolysis solution; the soy proteolysis solution is mixed with partially hydrogenated plant oil, sucrose, starch syrup, sodium alginate tech grade, carrageenan, microcrystalline cellulose, phosphate, edible emulsifier; and then filtering, aqueous phase material preparation, oil phase material preparation, mixing, blending, secondary homogeneity, aging, filling and packing are carried out sequentially. The invention modifies enzymolysis of isolated soy protein, dissolubility, dispersity and emulsibility are obviously improved, and the functional characteristic is close to casein, thus substituting application of nutrose in plant lipid cream; plant raw materials are adopted, raw material cost is reduced, thus having positive significance on nutrition and health care function; the product has favourable mouthfeel and flavour; and the production method of the invention is based on plant lipid cream similarity processing technology, utilizes biological enzyme technology and has wide applicability.

Owner:GUANGDONG IND TECHN COLLEGE

Comprehensive nutritional and semi-digested formulated food for special medical use, and preparation method thereof

ActiveCN104082739AImprove immunityBlood sugar controlSugar food ingredientsFood ingredient functionsDiseaseVegetable oil

The invention provides a comprehensive nutritional and semi-digested formulated food for special medical use, and a preparation method thereof. Every 100 g of the comprehensive nutritional and semi-digested formulated food for special medical use comprises 5-15 g of hydrolyzed whey protein, 3-8 g of egg white protein, 1-4 g of soy isolate protein, 1-4 g of concentrated whey protein, 0.5-2 g of sodium caseinate, 37-60 g of carbohydrate with a low GI value, 1-4 g of fructose oligosaccharide, 0.005-0.05 g of carboxymethyl pachymaran, 15-22 g of vegetable oil powder, 4-10 g of a medium-chain fatty acid, 3-8 g of a mineral premix and 0.2-1.4 g of a vitamin premix. A finished product is prepared by mixing the above components uniformly. With a synergistic effect of the above components, partial digestion functions of a patient after operation can be taken fully used to keep, maintain and promote comprehensive restoration of the digestion functions of the patient; an immune function can be regulated; and body disease-resistant ability can be enhanced, thereby influencing development and conversion of the disease.

Owner:广州纽健生物科技有限公司

Cold cut type non-dairy creamer and preparation method thereof

ActiveCN101919455AReduce manufacturing costSolve the characteristicsEdible oils/fatsGlucose-Fructose SyrupVegetable oil

The invention discloses a cold cut type non-dairy creamer and a preparation method thereof. The cold cut type non-dairy creamer comprises the following components by weight percent: 20-35% of low melting point vegetable oil and fat, 2.0-4.0% of sodium caseinate, 0.5-2.0% of Datem, 1.0-1.99% of dipotassium phosphate, 0.2-0.4% of silica and the balance of glucose syrup. The invention solves the problem that the non-dairy creamer is difficult to dissolve in cooling water, and expands the application filed in the low-temperature environment.

Owner:JIAHE FOODS IND CO LTD

Medium carbon chain fatty acid powder grease and preparation method thereof

ActiveCN101919453AImprove stabilityAvoid the risk of ingestionEdible oils/fatsDipotassium hydrogen phosphateGlucose-Fructose Syrup

The invention discloses medium carbon chain fatty acid powder grease and a preparation method thereof. The medium carbon chain fatty acid powder grease comprises the following components in percentage by weight: 40%-60% of MCT (Medium Chain Fatty Acid) grease, 4%-6% of sodium caseinate, 0.5%-2.0% of monoglyceride, 0.3%-0.7% of sodium stearoyl lactylate, 1%-2% of dipotassium hydrogen phosphate, 0.2%-0.4% of silicon dioxide and the balance of glucose syrup. The invention greatly enhances the stability of the MCT grease, extends the application of the MCT grease in the field of foods, prevents the risk of excessive grease intake and also reduces the potential hazards of excessive antioxidant intake.

Owner:JIAHE FOODS IND CO LTD

Non-dairy cream of mixed milk fat and preparation method thereof

The invention designs non-dairy cream of mixed milk fat. The non-dairy cream is characterized by comprising the components in percentage by weight: 8-18% of vegetable fat, 0.05-0.5% of anhydrosorbitan monostearate, 0.02-0.5% of lecithin, 0.02-1% of lactic monoglycerate, 0.02-0.5% of sodium stearyl lactate, 0.05-1% of monoglycerin fatty acid ester and diglycerin fatty acid ester, 0.05-0.8% of sucrose fatty acid ester, 0.02-0.5% of polyglycerol ester, 0.01-1.5% of carrageenan, 0.05-0.8% of microcrystalline cellulose, 0.05-1% of modified cellulose, 0.1-1.5% of sodium caseinate, 0.02-0.2% of potassium dihydrogen phosphate, 2-6% of sugar, 2-12% of corn syrup, 8-18% of milk fat dairy products and 20-60% of water. The non-dairy cream provided by the invention has the advantages that the non-dairy cream is convenient to operate without cream and non-dairy cream which are mixed and whipped topped; the non-dairy cream is more convenient to condition and is not affected by original flavor of the non-dairy cream; the whipped topping rate of the product reaches over 3.6 which is greater than that of existing similar products. The non-dairy cream is more economic and applicable for client.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

Yoghourt ice cream power and ice cream preparation method using same

InactiveCN1919031AWith health functionRich Fermented Yogurt FlavorMilk preparationFrozen sweetsSodium CaseinateWhole milk

The invention discloses a yoghourt and ice cream power comprising the following constituents (by weight portions): refined granulated sugar 30-50 parts, yoghourt powder 10-40 parts, whole milk powder 5-20 parts, plant grease powder 5-20 parts, guar gum 0.4-1.2 parts, xanthan gum 0.1-0.6 part, propylene glycol alyinate 0.2-1.2 parts, sodium caseinate 0.2-1.2 parts, milk essence 0.05-0.6 part, ethyl maltol 0.001-0.006 part. The invention also discloses the process for preparing ice-cream by utilizing the powder.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD

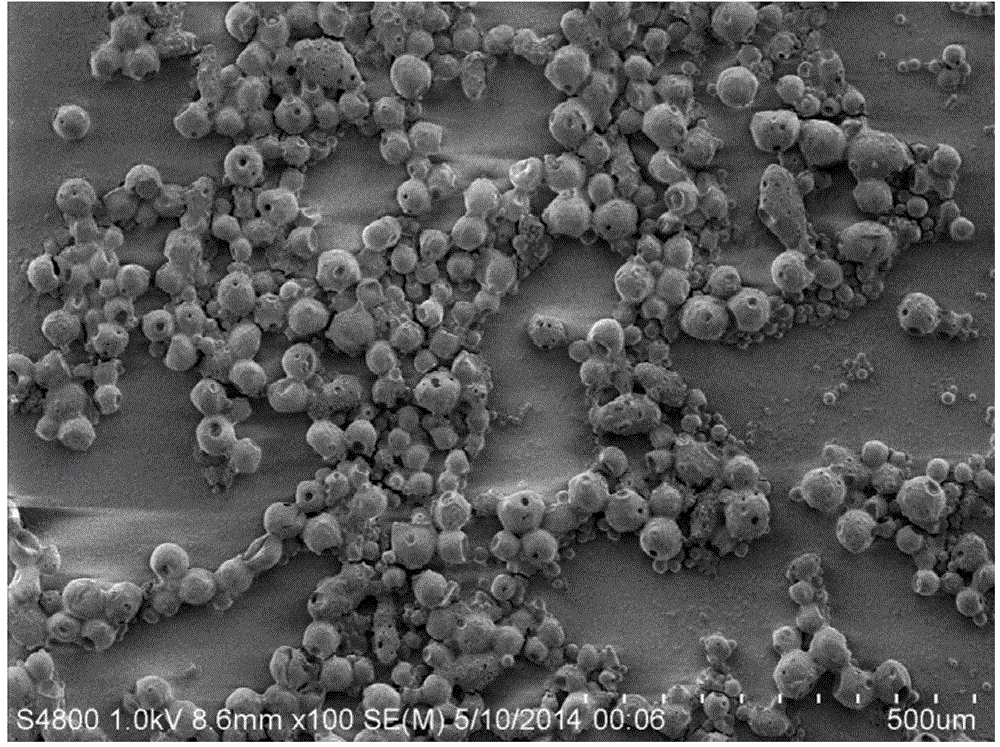

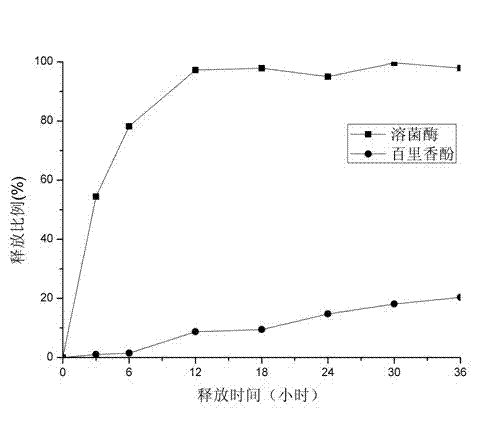

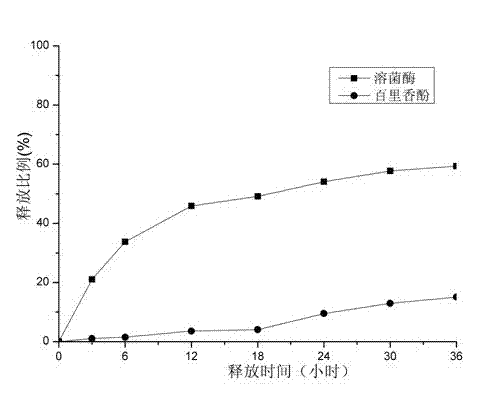

Preparation method of controlled release antibacterial film

The invention discloses a preparation method of a controlled release antibacterial film. The method includes the following steps of: (1) dissolving zein and a hydrophobic antibacterial agent into an alcoholic solution; (2) preparing a sodium caseinate aqueous solution; (3) adding the sodium caseinate aqueous solution into the solution obtained in step (1) under stirring; (4) subjecting the solution obtained in step (3) to rotary evaporation and centrifugation, then freeze drying the supernatant, thus obtaining nanoparticle powder; (5) dissolving a film-forming matrix in water, adding the nanoparticle powder and lysozyme to form a mixed solution; and (6) adding glycerin, and conducting film pouring, thus obtaining the film product. The method provided in the invention can simultaneously reduce initial microbial activity and inhibit microbial growth for a long term, and has the advantages of low instrument requirement, and controllable bacterium inhibiting intensity, thus having broad application prospects in food and medical products.

Owner:SOUTH CHINA UNIV OF TECH

Polyphyly fat mixture for feeding animals and microcapsule applying mixture

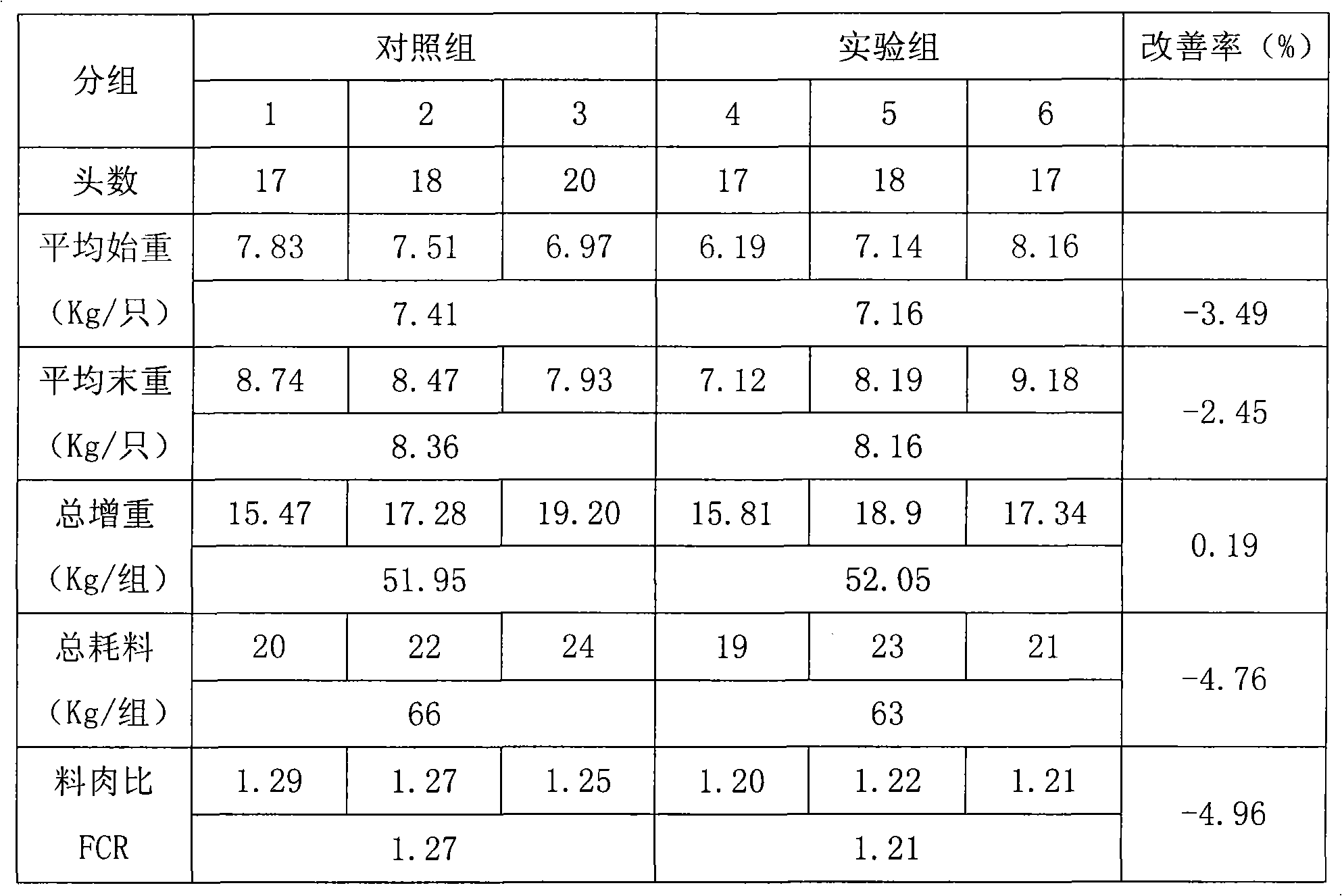

InactiveCN101647512ACompatible with growth performanceProductive full expressionAnimal feeding stuffAccessory food factorsLong chain fatty acidSodium Caseinate

The invention discloses a polyphyly fat mixture for feeding animals, which is formed by mixing more than two greases. The mixture comprises long chain fatty acid and medium chain fatty acid, and the weight ratio of the long chain fatty acid to the medium chain fatty acid is 30-90:60-10. A microcapsule applying the polyphyly fat mixture for feeding animals comprises the following raw materials in percentage by weight: 25-80 percent of olyphyly fat mixture, 0.8-4 percent of complex emulsifying agent F, 0.8-4 percent of sodium stearoyl-2-lactylate, 0.3-5 percent of sodium caseinate and 10-70 percent of encrusting substance. The polyphyly fat mixture accords with the growth performance of animals and ensures that the production performance of the animals can be fully expressed. Experiments prove that after feeding the polyphyly fat mixture, the fresh of piggies is improved by 3.96 compared with piggies fed with single derived fat feed. By adopting the fatty acid mode and fat products, after feeding nursing sows, the weight of weaning litter of the piggies is improved by 3.96 percent. After feeding the polyphyly fat mixture, the fresh of broiler chickens is improved by 3.96 percent compared with broiler chickens fed by single derived fat.

Owner:SINGAO

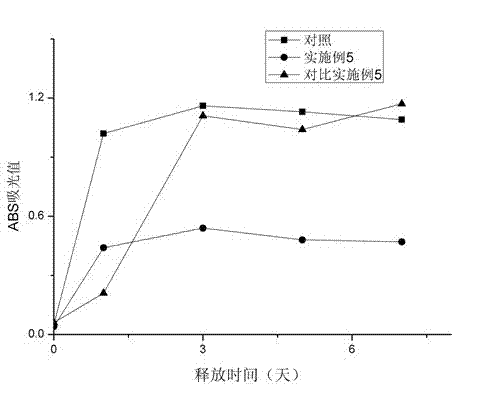

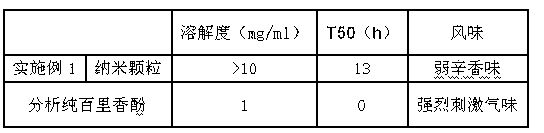

Preparation method of edible antibacterial nanometer particles

InactiveCN102783693AEffective embeddingImprove solubilityFruit and vegetables preservationMeat/fish preservation using chemicalsSodium CaseinateAnti bacterial

The invention discloses a preparation method of edible antibacterial nanometer particles. The preparation method comprises the following steps: 1, dissolving zein and an antiseptic in an aqueous solution of ethanol; 2, preparing an aqueous solution of sodium caseinate; 3, adding the aqueous solution of sodium caseinate to the ethanol solution obtained in step 1 under stirring; and 4, carrying out rotary evaporation of the solution obtained in step 3, centrifuging, and lyophilizing the resultant supernatant to obtain the edible antibacterial nanometer particles. The antibacterial nanometer particles obtained through the method disclosed in the invention have particle sizes of 160-260nm and a good monodispersion, and are easy to redissolve. The preparation method has the advantages of low requirements on an apparatus, simplicity and easy operation, and the prepared antibacterial nanometer particles have the sustained release antioxidation and antibiosis effects, so the method disclosed in the invention can be widely applied to foods and medical products.

Owner:SOUTH CHINA UNIV OF TECH

Soybean-honey acidophilus milk and preparation method thereof

InactiveCN102422882AUnique flavorIncrease the way of deep processingMilk preparationSodium CaseinateAnimal protein

The invention discloses a soybean-honey acidophilus milk and a preparation method thereof, wherein the soybean-honey acidophilus milk consists of the following materials: pure soybean milk, fresh milk or reconstituted milk, honey, cane sugar, fructooligosaccharide or xylooligosaccharide, sodium caseinate, pectin, calcium citrate and tamed lactobacillus fermentation broth. The soybean-honey acidophilus milk is integrated with the advantages of vegetable protein and animal protein, has the fresh aroma of the honey, and is rich in nutrition and aroma, the health-care functional value of the acidophilus milk is increased, and the variety of acidophilus milk is enriched.

Owner:HEFEI UNIV OF TECH

Litsea coreana yoghourt and preparation method and application thereof

The invention discloses Litsea coreana yoghourt, a preparation method and application thereof. The Litsea coreana yoghourt is prepared from the following raw materials: fresh milk or reconstituted milk, isomaltose hypgather, fructooligosaccharide, soybean oligosaccharide, sodium caseinate, Litsea coreana, Lactobacillus delbrueckii and Streptococcus thermophilus. The preparation method for the Litsea coreana yoghourt comprises the following steps of: adding the Litsea coreana serving as a functional factor into the fresh milk or the reconstituted milk, and inoculating lactic acid bacteria for fermentation. The Litsea coreana yoghourt can reduce blood sugar and improve immunity, improves the healthcare function value of yoghourt, and enriches the variety of the yoghourt.

Owner:HEFEI UNIV OF TECH

Folium isatidis cellulose fiber having antiviral, antibacterial and skin-care functions and preparation method thereof

InactiveCN105603556AEasy to takeGood textile processabilityArtificial filaments from viscoseWet spinning methodsSodium CaseinateEngineering

The invention discloses a folium isatidis cellulose fiber having antiviral, antibacterial and skin-care functions and a preparation method thereof. The folium isatidis cellulose fiber contains, by weight, 2.0-8.0 parts of folium isatidis extract, 2.0-8.0 parts of sodium caseinate, 2-30 parts of porous starch and 2-50 parts of protein. The preparation method includes the following steps that 1, preparation of folium isatidis extract-sodium caseinate compound microcapsules, 2 preparation of a blended spinning stock solution and 3 spinning and post-processing. Compared with conventional viscose fibers, the influenza A virus inactivation rate of the fiber is 82.0% or above, the herpes virus inactivation rate is 84.0% or above, a bacteriostatic activity value is greater than or equal to 2.0, a bactericidal activity value is greater than or equal to 0.2, a variety of amino acids and trace elements are contained in the fiber, the fiber has good skin-care and health-care functions, the physical index of the product can meet the requirements of GB / T14463-2008 viscose staple fiber first-grade products, and the fiber has good wearability and textile processing performance.

Owner:单大伟

Water-soluble protein-phytosterin nanometer particles as well as preparation and application

ActiveCN105410934AHigh nutritional valueImprove functional propertiesFood scienceProtein solutionSolubility

The invention belongs to the technical field of processing of functional foods, and discloses water-soluble protein-phytosterin nanometer particles as well as preparation and application. The preparation method comprises the following steps of dispersing and dissolving sodium caseinate, soy protein isolate or whey protein concentrate in deionized water so as to obtain a solution; then placing the solution at the temperature of 0-10 DEG C for hydration for 6-12 hours so as to obtain a protein solution; dispersing and dissolving phytosterin in N-hexane so as to obtain a phytosterin solution; then adding the phytosterin solution to the protein solution, and performing homogenizing treatment and micro jet treatment so as to obtain mixed emulsion; and finally performing steaming so as to remove the N-hexane in the mixed emulsion, and performing freeze drying so as to obtain the water-soluble protein-phytosterin nanometer particles. The preparation method disclosed by the invention is simple, low in cost, safe and environment-friendly; the obtained water-soluble protein-phytosterin nanometer particles are small in particle diameters, good in water solubility and high in embedding rate, and can be used as functional factors to be used for the production of functional foods or medicines.

Owner:SOUTH CHINA UNIV OF TECH

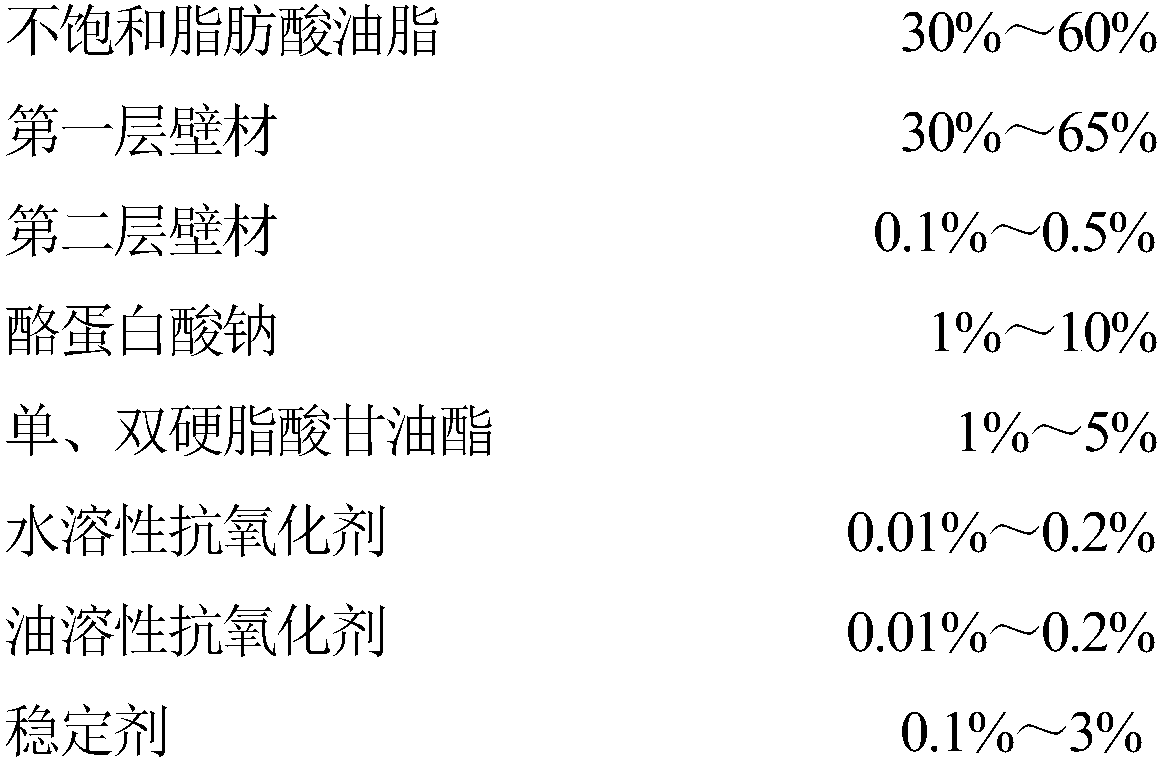

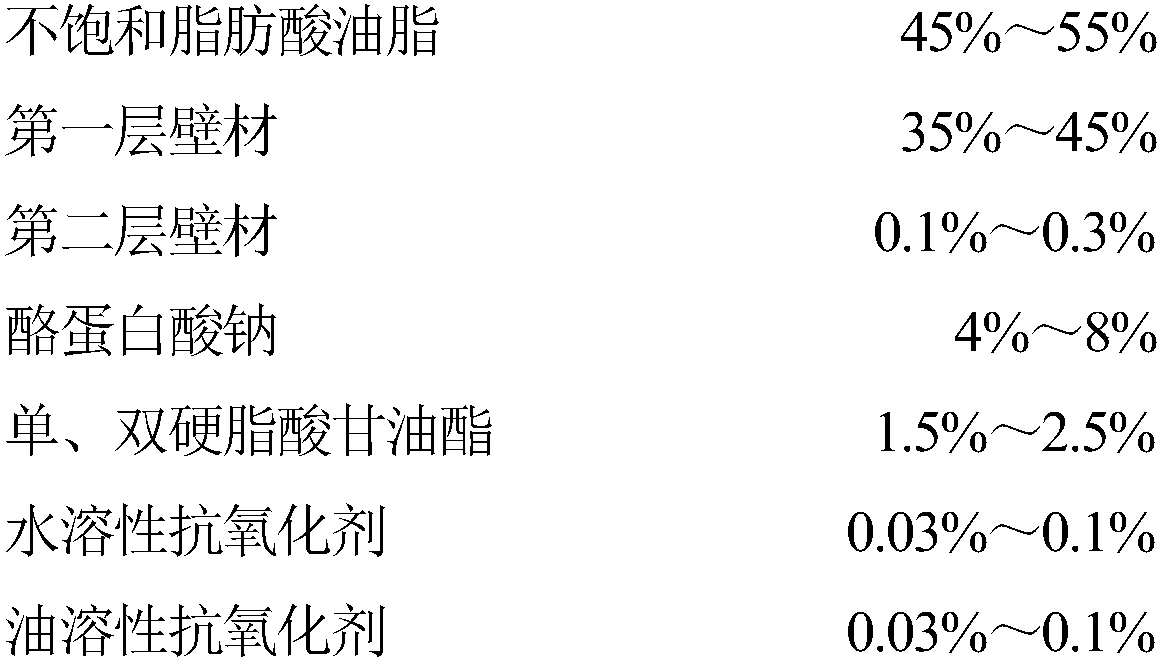

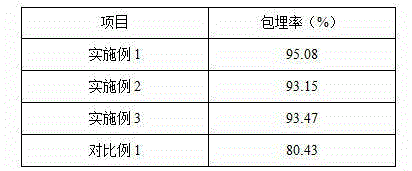

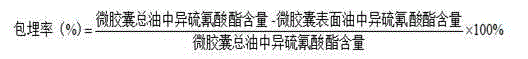

High-temperature-resistant unsaturated fatty acid fat microcapsule powder and preparation method thereof

InactiveCN108338360AGood embedding effectIsolated contactFood ingredient as antioxidantClimate change adaptationAntioxidantSodium Caseinate

The invention discloses high-temperature-resistant unsaturated fatty acid fat microcapsule powder and a preparation method thereof. The preparation method comprises the following steps of adding a first-layer wall material, sodium caseinate, a water-soluble antioxidant and a stabilizing agent to water to obtain a water phase; adding glyceryl monostearate, glycerol distearates and an oil-soluble antioxidant to unsaturated fatty acid fat to obtain an oil phase; and adding the oil phase to the water phase, performing shearing and homogenizing, adding a second-layer wall material to form final emulsion, then performing spray drying, and performing screening so as to obtain the high-temperature-resistant unsaturated fatty acid fat microcapsule powder. According to the high-temperature-resistantunsaturated fatty acid fat microcapsule powder and the preparation method thereof disclosed by the invention, a dual-embedding technique is adopted, the second-layer wall material is made from high-temperature-resistant macromolecule materials, and a layer of high-temperature-resistant films is formed on the surface of a product, so that the air permeability is low, and oxygen, nitrogen, carbon dioxide and the like can hardly pass through the film; and in addition, water and oil diphase antioxidants synergistically strengthen the oxidation resistance of the microcapsule powder, the oxidationof outside high temperature environment and the oxygen on the unsaturated fatty acid fat is effectively prevented, the shelf life of the product is prolonged, the stability of the product is improved,and the preparation process is environmental-friendly.

Owner:SHAANXI HEALTHFUL BIOLOGICAL ENG

Formulation of water soluble micro-capsule fat powder feed and manufacturing process thereof

InactiveCN1883294AImprove digestion and absorption utilizationEasy to stir and mixAnimal feeding stuffAccessory food factorsSodium CaseinateSodium stearyl

The invention discloses a water-soluble microcapsule fat powder preparation for animals and process for production, wherein the preparation comprises (by weight percent) sodium caseinate 0.3-5%, composite emulsifying agent F 0.8-4%, sodium stearyl lactate 0.8-4%, oil 30-70%, sodium citrate 0.2-1.2%, disodium hydrogen phosphate 0.2-1.2%, coating articles 70-30% and water 80-150% of the total raw material amount.

Owner:SINGAO

Composite nutritional isolated soybean protein bean curd and making method thereof

The invention discloses a composite nutritional isolated soybean protein bean curd. The composite nutritional isolated soybean protein bean curd comprises, by mass, 10-13% of isolated soybean protein, 1-2% of a soybean dietary fiber, 0.5-1% of sodium caseinate, 10-26% of plant oil, 3-7% of starch, 1-2% of a seasoning, and 50-68% of ice water. The composite nutritional isolated soybean protein bean curd fully utilizes the high gel property of the isolated soybean protein, is not added with a coagulant, has the characteristics of good chewiness, smooth and tender mouthfeel and high nutritional values, can supplement dietary fibers required by human bodies, and is suitable for eating methods comprising decocting, stir-frying, cooking, frying, cold-mixing and the like.

Owner:山东禹王生物技术有限公司

Microcapsule mustard essence and preparation method thereof

InactiveCN104921047APackage completelyReasonable ratioFood ingredient as thickening agentFood ingredient as encapsulating agentPolymer scienceAllyl thiocyanate

The present invention discloses a microcapsule mustard essence which consists of wall materials and core materials; the wall materials are prepared by using the following components in parts by weight: starch sodium octenylsuccinate 5.0-25 parts, soybean protein isolate 1.0-5.0 parts, sodium caseinate 0.1-3.0 parts, maltodextrin 20-60 parts and thickening agents 0.2-6.5 parts; and the core materials comprise the following raw materials in parts by weight: natural mustard oil 1.0-20 parts and / or allyl isothiocyanate 1.0-20 parts, and fragrance enhancing and coordinating agents 0.4-1.5 parts. The microcapsule mustard essences have high embedding rate and good heat resistance, can improve the stability of the mustard oil, overcome the shortcomings of highly volatility and strong irritation of liquid essences used in the past, and not easily being preserved in products, and better exert the fragrance of the mustard oil; and at the same time, the wall materials of the microcapsule mustard essences are widely accessible, have low production cost, and can be widely promoted and applied.

Owner:ZENGCHENG HANDYWARE SEASONING

Solid state cartridge for electronic cigarettes and preparation method thereof

InactiveCN104382224ARich flue gas compositionPrevent volatilizationTobacco treatmentBiotechnologyCarrageenan

The invention relates to a solid state cartridge for electronic cigarettes. The solid state cartridge mainly includes the following ingredients according to percentage by weight: 0.1 to 20 percent of tobacco extract, 1 to 10 percent of food gum, 10 to 50 percent of humectant, 0.001 to 1 percent of preservative, 0.1 to 10 percent of heat-conducting filler, 0.1 to 10 percent of tobacco essence and flavor and 10 to 30 percent of water; the tobacco extract is one or combination of tobacco essential oil and tobacco extract; the food gum is one or combination of more than one of glutin, sodium caseinate, Arabic gum, sodium alginate, carrageenan, pectin, xanthan gum, Beta-cyclodextrine, sodium starch phosphate, sodium carboxymethyl starch, hydroxypropyl starch and propylene glycol alginate; the heat-conducting filler is one or combination of more than one of calcium carbonate, titanium dioxide, silicon carbide and carbon powder. The taste of the solid state cartridge is improved, the stability of the product is enhanced, and potential safety hazards caused by the leakage of electronic cigarette liquid are further prevented.

Owner:CHINA TOBACCO ZHEJIANG IND

Sterilizing flavouring sour milk and preparation method thereof

The invention relates to yoghurt and its preparation method, in particular to sterilized flavored yoghurt and its preparation method. It belongs to the field of dairy products. A sterilized flavored yoghurt, comprising 820-900kg of milk, 50-120kg of white sugar, 1-10kg of sodium caseinate, 5-15kg of concentrated whey protein, 10-30kg of cream and 1-13kg of stabilizer. The production state of the method of the invention is stable, and the product can be stored for 100-180 days at normal temperature.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Water-retaining agent for frozen shrimp meat, and preparation method and application thereof

InactiveCN105076350AGuaranteed qualityComponents are easily availableMeat/fish preservation using chemicalsFlavorShrimp

The present invention discloses a water-retaining agent for frozen shrimp meat. The water-retaining agent comprises the following components by weight: 2-4% of alginate oligosaccharide, 1-3% of sucrose ester, 0.3-0.5% of sodium carbonate, 0.5-1% of sorbitol, 0.5-1% of sodium caseinate, 0.3-0.5% of xanthan gum and the balance of water. The water-retaining agent for frozen shrimp meat uses readily available and low-cost ingredients, which are environment-friendly and safe and mutually cooperate. The water-retaining agent has excellent water retention properties, and can better maintain the fresh flavor and flexibility of shrimp, so as to reduce loss of shrimp juice and guarantee the quality of frozen shrimp meat. The present invention also discloses a preparation method of the frozen shrimp meat; the method has simple steps, less investment in equipment, and strong operability, and is applicable to industrial production.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com