Microcapsule mustard essence and preparation method thereof

A mustard flavor and microcapsule technology, which is used in food preparation, food ingredients as thickeners, food science, etc., can solve the problems of strong volatility and unsuitable retention, and achieves high encapsulation rate, less loss of effective ingredients, and retention. Effect of characteristic aroma components of mustard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

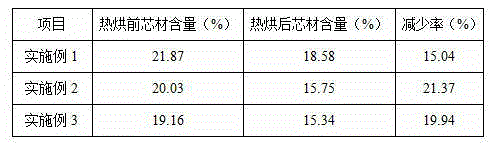

Embodiment 1

[0028] Embodiment 1, microcapsule mustard essence of the present invention and preparation thereof

[0029] formula:

[0030] (1) Wall material: 180g sodium starch octenyl succinate, 30g soybean protein isolate, 20g sodium caseinate, 500g maltodextrin and 40g thickener, the thickener includes gum arabic, xanthan gum and seaweed The weight ratio of sodium nitrate and carboxymethyl cellulose is 3: 0.2: 0.2: 0.4;

[0031] (2) Core material: 120g of natural mustard oil, 100g of allyl isothiocyanate and 10g of 3-butenyl isothiocyanate.

[0032] preparation:

[0033] (1) Take the formula amount of sodium starch octenyl succinate, soybean protein isolate, sodium caseinate and maltodextrin and mix them into water at a temperature of 60°C. The amount of water used is 1.5% of the total weight of the wall material and the core material. Double the weight, stir at a slow speed of 20 rpm for 20 min, then increase the stirring speed to 80 rpm, and stir until a homogeneous emulsion is obt...

Embodiment 2

[0038] Embodiment 2, microcapsule mustard essence of the present invention and preparation thereof

[0039] formula:

[0040] (1) Wall material: 200g sodium starch octenyl succinate, 50g soybean protein isolate, 30g sodium caseinate, 440g maltodextrin and 65g thickener, the thickener includes gum arabic, xanthan gum, seaweed The weight ratio of sodium nitrate and carboxymethyl cellulose is 1:0.4:0.4:0.1;

[0041] (2) Core material: 200g of natural mustard oil, 15g of isopropyl isothiocyanate.

[0042] preparation:

[0043] (1) Take the formula amount of sodium starch octenyl succinate, soybean protein isolate, sodium caseinate and maltodextrin and mix them into water at a temperature of 65°C. The amount of water used is 1.2% of the total weight of the wall material and core material. Double the weight, stir at a slow speed of 30 rpm for 10 min, then increase the stirring speed to 100 rpm, and stir until a homogeneous emulsion is obtained;

[0044] (2) Take the thickener o...

Embodiment 3

[0048] Embodiment 3, microcapsule mustard essence of the present invention and preparation thereof

[0049] formula:

[0050] (1) Wall material: 140g sodium starch octenyl succinate, 20g soybean protein isolate, 10g sodium caseinate, 600g maltodextrin and 25g thickener, the thickener includes gum arabic, xanthan gum and seaweed The weight ratio of sodium nitrate and carboxymethyl cellulose is 5:0.1:0.1:0.6;

[0051] (2) Core material: 200g of allyl isothiocyanate, 5g of isobutyl isothiocyanate.

[0052] preparation:

[0053] (1) Take the formula amount of sodium starch octenyl succinate, soybean protein isolate, sodium caseinate and maltodextrin and mix them into water at a temperature of 50°C. The amount of water used is 1.2% of the total weight of the wall material and the core material. Double the weight, stir at a slow speed of 5 rpm for 30 min, then increase the stirring speed to 60 rpm, and stir until a uniform emulsion is obtained;

[0054] (2) Take the thickener of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com