Seedling planting device for agricultural machinery

A technology for agricultural machinery and planting seedlings, applied in agriculture, forestry, applications, etc., can solve the problems of poor clamping effect of tree trunks and damage of tree trunks, and achieve good clamping effects, prevent damage, and avoid the effects of trunk sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

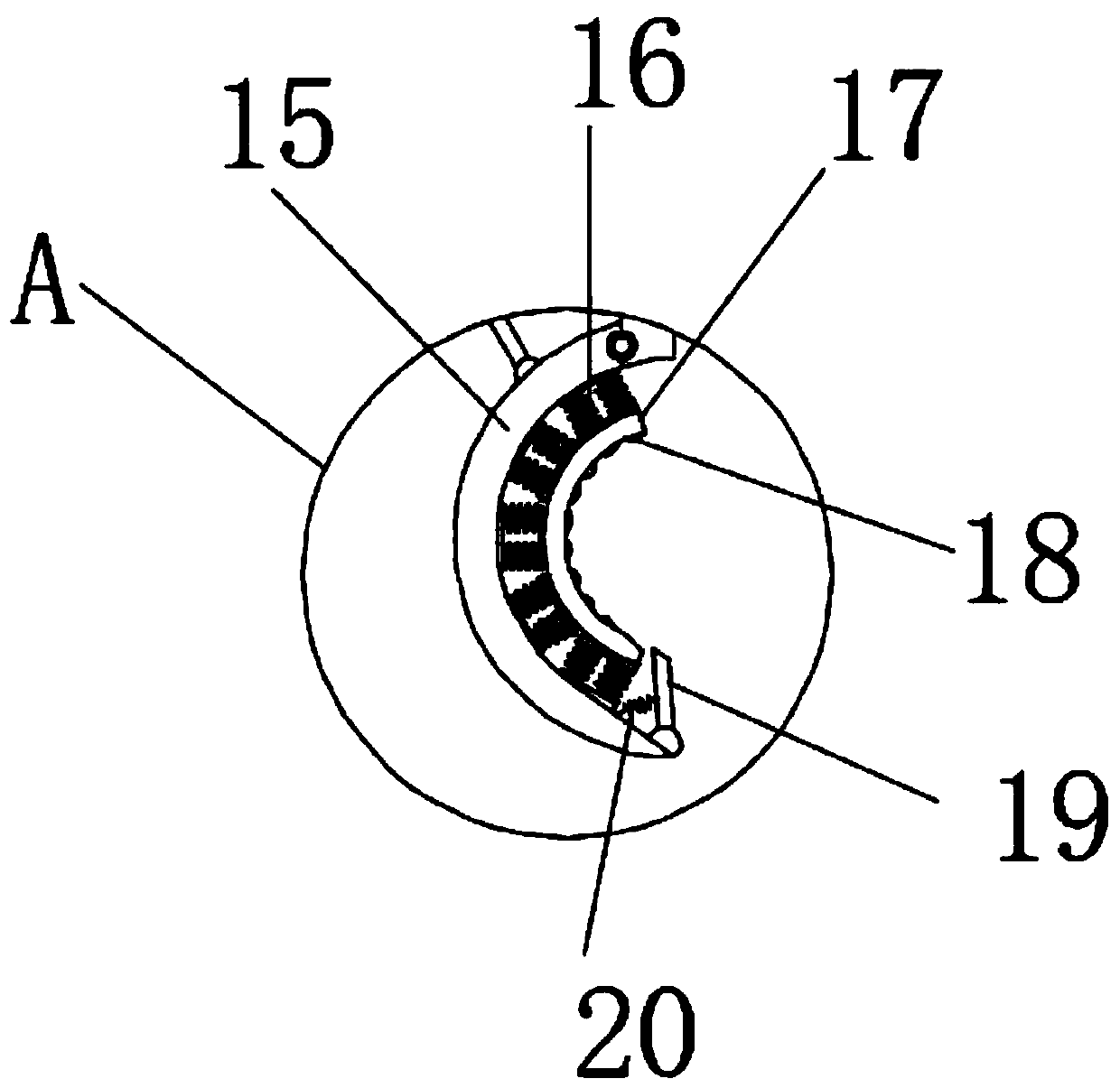

[0028] refer to Figure 1-4 , a seedling planting device for agricultural machinery, comprising a fixed block 7, the outer wall of the bottom of the fixed block 7 is provided with a groove, and the inner wall of the groove is fixed with a rotating motor 6 by screws, and the output shaft of the rotating motor 6 is connected by a coupling There is a rotating plate 13, and both sides of the outer wall at the bottom of the rotating plate 13 are fixed with a fixed plate 14 by screws, and the outer walls on the opposite side of the two fixed plates 14 are fixed with electric telescopic rods 3 by screws, and the electric telescopic rods 3 piston rods One end is fixed with a moving plate 2 by a screw, and the bottom end of the moving plate 2 is connected with a crescent-shaped splint 15 through a hinge, and the inner wall of the splint 15 is provided with a buffer spring 16, and the end of the buffer spring 16 away from the splint 15 is fixed with a clamp by a screw. ring 17, and the ...

Embodiment 2

[0038] refer to Figure 1-5, a seedling planting device for agricultural machinery, including a guide cylinder 21 fixed to the outer wall of one of the moving plates 2 by screws, and a return spring 22 is arranged on the inner wall of the guide cylinder 21, and an end of the return spring 22 far away from the guide cylinder 21 is connected with a squeeze Pressing plate 24, the outer wall of another moving plate 2 is provided with guide bar 1, and one end of guide bar 1 is provided with the extruding block 23 that section is trapezoidal structure, and extruding block 23 forms sliding fit with the inner wall of guide tube 21.

[0039] During use, during the relative movement of the two splints 15, the extruding block 23 can enter into the guide cylinder 21. Since the cross section of the extruding block 23 is an isosceles trapezoidal structure, it is very convenient to enter into the guide cylinder 21 and extrude. After the block 23 enters the guide tube 21, a connection can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com