Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

737 results about "OCTENYLSUCCINIC ACID" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Linseed oil microcapsule powder and its prepn

InactiveCN101019838AImprove stabilityKeep aliveOrganic active ingredientsPharmaceutical non-active ingredientsFreeze-dryingHigh pressure

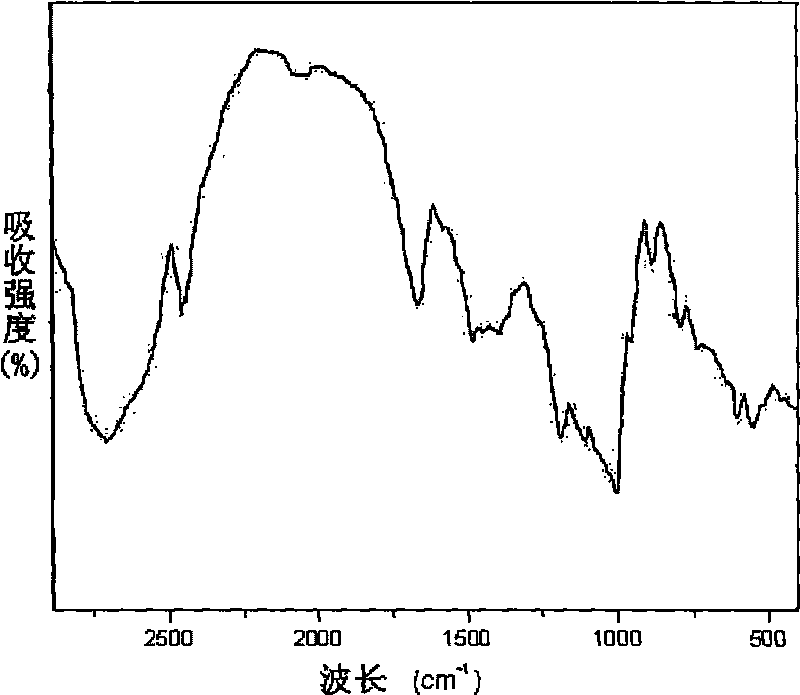

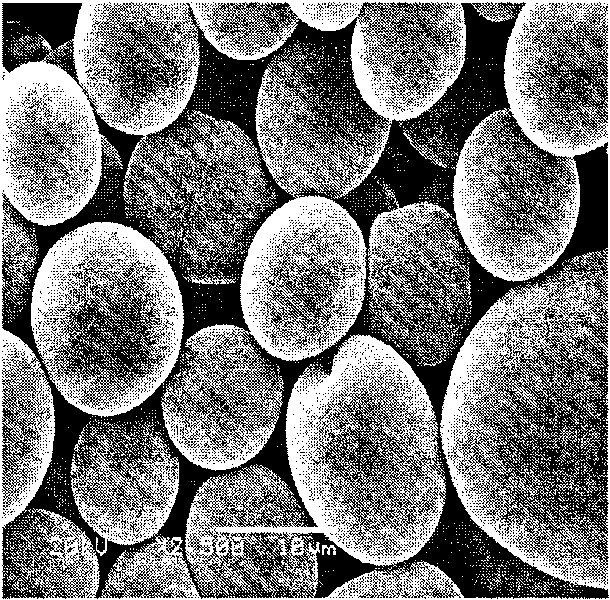

The present invention is linseed oil microcapsule powder and its preparation, and features that modified polysaccharide, sodium octyl alkenyl succinate starch, is used as capsule wall material for forming microcapsule in preparing linseed oil microcapsule powder. The preparation process includes adding linseed oil into the solution of sodium octyl alkenyl succinate starch, stirring to form homogeneous emulsion, high pressure homogenizing to obtain linseed oil emulsion of granularity smaller than 1000 nm, and final spray drying or freeze drying to obtain white linseed oil microcapsule powder with high stability and high flowability. The linseed oil microcapsule powder has high linseed oil activity, high stability and high bioavailability, and may be applied in food and health product.

Owner:TSINGHUA UNIV +1

Vitamin powder and preparation method thereof

ActiveCN102716087AHigh mechanical strengthGood dispersionPowder deliveryHydroxy compound active ingredientsEmbedding rateAntioxidant

The invention mainly discloses vitamin powder and a preparation method of the vitamin powder. The vitamin comprises the following components in mass percentage: 5-60% of fat soluble vitamin, 30-70% of wall material, 5-30% of assistant wall material, 0.5-2% of emulsifier, 0.1-2% of antioxidant and 0.1-3% of cross linking agent. The invention further relates to a preparation method of the vitamin powder. By using a microencapsulation technique, the fat soluble vitamin oil (e.g. vitamin A, vitamin D3, vitamin E and vitamin K) is embedded to a micro-capsule, the wall material used in the embeeding process is starch sodium octenylsuccinate, the vitamin oil is embeeded in the wall and then the micro-capsule is subjected to cross linkage, mist spraying and drying are carried out to form the vitamin powder, and the embedding rate of the vitamin is more than 95.3%. According to the invention, the process is simple, the cost is low, the obtained vitamin powder is not soluble in water, high in oil loading amount and good in flowability, and can be used in the fields such as foods, daily-used industrial chemicals and medicines.

Owner:ZHEJIANG ZHONGTONG TECH

Instant powdery grease treating starch sodium octenylsuccinate as wall material, and its preparation method

The invention relates to an instant powdery grease treating starch sodium octenylsuccinate as a wall material. The instant powdery grease comprises 30-70% by mass of the wall material, 5-60% by mass of grease, 5-60% by mass of an auxiliary wall material, 0.5-3% by mass of an emulsifier, 0.1-2% by mass of an antioxidant and 0.1-0.5% by mass of a cosolvent. The invention also relates to a preparation method of the powdery grease. The preparation method is characterized in that a microencapsulation technology is adopted to embed fat-soluble grease in order to prepare a microcapsule, the wall material used for embedding is starch sodium octenylsuccinate, the addition of the emulsifier and the addition of the auxiliary wall material improve the emulsification shear speed, improve the homogenization pressure and increase the homogenization frequency, grease is embedded in the wall material and undergoes spray drying, and the addition of the cosolvent forms the instant powdery grease. The preparation method has the advantages of simplicity and low cost, and the prepared powdery grease has the advantages of good water solubility, fast dissolving, high oil carrying amount, and good fluidity and can be applied to the food field, the daily-use chemical engineering field, the medicine field and the like.

Owner:ZHEJIANG ZHONGTONG TECH

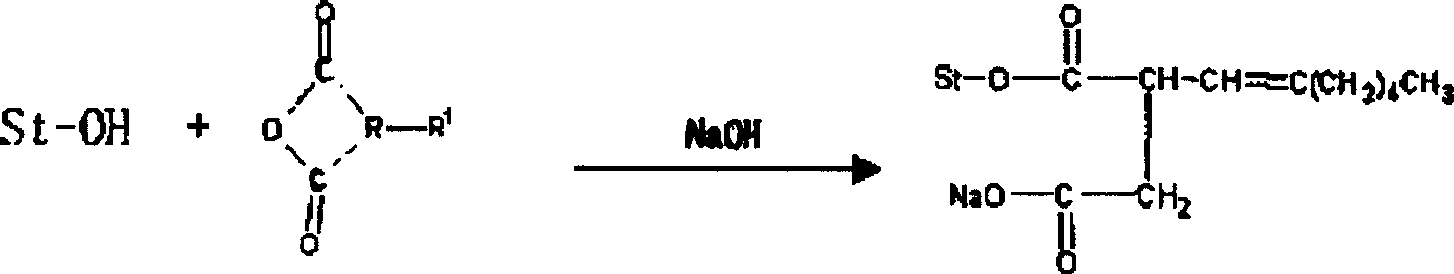

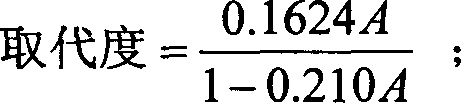

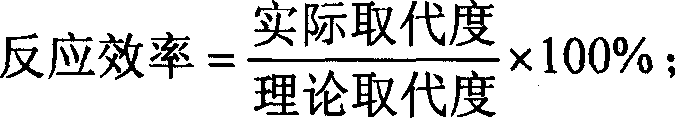

Process for producing starch octenylsucciniate

The invention discloses a manufacturing method of octal-olefin succinic starch ester, which comprises the following steps: 1) blending potato starch and water in the thermostatic magnetic stirrer into emulsion; 2) adopting 3% sodium hydroxide to adjust the pH value of emulsion to 7.5-8.0; 3) adopting anhydrous alcohol to dilute octal-olefin succinic anhydride; 4) blending the diluted octal-olefin succinic anhydride and emulsion phase in the step 2) to form reacting system; adding 3% NaOH solution to maintain the pH value of reacting system; reacting 2-4h; 5) using 2mol / L alcaine to adjust the pH value to 6.4-6.6; washing through water and 70% alcohol separately; drying; grinding.

Owner:ZHEJIANG UNIV

Method to Prepare a Stable High-Load Paprika Extract in Powder Form

The invention relates to a preparation for foodstuffs. It is proposed in this case that the preparation comprise at least a fat soluble dye, dispersed in a lipid-based carrier medium; polyglycerol esters of edible fatty acids; citric acid esters of monoglycerides and / or diglycerides of edible fatty acids; or mixtures of these esters; and starch sodium octenyl succinate.

Owner:SENSIENT FOOD COLORS GERMANY

Acid-resistant non-dairy creamer and preparation method thereof

ActiveCN101919454ARaw materials are simpleSolve the problem of acid intoleranceEdible oils/fatsMonoglycerideVegetable oil

The invention discloses acid-resistant non-dairy creamer and a preparation method thereof, and the acid-resistant non-dairy creamer comprises the following components by weight percent: 20-35% of partially hydrogenated vegetable oil, 5-15% of starch sodium octenylsuccinate, 0.3-0.7% of monoglyceride, 0.3-0.7% of sodium stearoyl lactylate, 0.2-0.4% of silicon dioxide and the balance of glucose syrup. A product can solve the difficult problem that the non-dairy creamer in the prior art has no acid resistance, simplify the application method of the non-dairy creamer in the prior art, reduce the uncertainty of the process, reduce auxiliary supplementary materials required during applications and expand the range of the applications.

Owner:JIAHE FOODS IND CO LTD

Preparation process of peony seed oil micro-capsule powder

ActiveCN104206561AGood instant solubilityImprove stabilityFood shapingEdible oils/fatsSodium CaseinateWarm water

The invention discloses a preparation process of peony seed oil micro-capsule powder. The preparation process is characterized by sequentially comprising the following steps: (1) dissolving a wall material and an emulsifying agent by using warm water; (2) adding peony seed oil into the dissolved wall material and emulsifying agent, and uniformly mixing and stirring to obtain a mixed solution; (3) homogenizing the mixed solution obtained in the step (2) under high pressure to obtain a solution in a good emulsification state; and (4) spray-drying the solution obtained in the step (3) to obtain the peony seed oil micro-capsule powder, wherein the wall material is one or a mixture of more of sodium caseinate, starch sodium octenylsuccinate, gelatin, arabic gum and malt syrup, and the emulsifying agent is one or a mixture of more of mono-and diglycerides of fatty acids, sodium stearyl lactate and diacetyl monostearin tartrate. The peony seed oil micro-capsule powder prepared by virtue of the process is high in peony seed oil embedding rate and high in grease content; the process flow is simple and efficient, and facilitates large-scale production and application.

Owner:BEIJING ALCHEMIST TECH

Method for preparing octenylsuccinate potato starch ester

The invention relates to a method for preparing octenylsuccinate potato starch ester, which comprises the following steps: (1) mixing potato starch and water into a starch emulsion of which the temperature is between 30 and 40 DEG C and the emulsion concentration is 35 to 45 percent, and adjusting the pH value to between 7.5 and 8.0; (2) diluting octenyl succinic anhydride into solution with the concentration of 3 to 5 percent by using tween mixed solution; (3) mixing the starch emulsion with the diluted alkenyl succinic anhydride in the step (2), and using NaOH solution to keep the pH value between 7.5 and 8.0 until the reaction is finished so as to obtain an octenylsuccinate potato starch ester emulsion; and (4) using hydrochloric acid solution to adjust the pH value of the octenylsuccinate potato starch ester emulsion to between 6.5 and 7.0, standing the mixture, removing the supernatant, washing, drying and crushing the mixture, and screening the powder by a sieve of 80 meshes. The method has a simple production process and simple operations, is easy to grasp and has a low cost and small pollutions, and the octenylsuccinate potato starch ester produced by the method has high effective material content and stable product performance.

Owner:GANSU AGRI UNIV

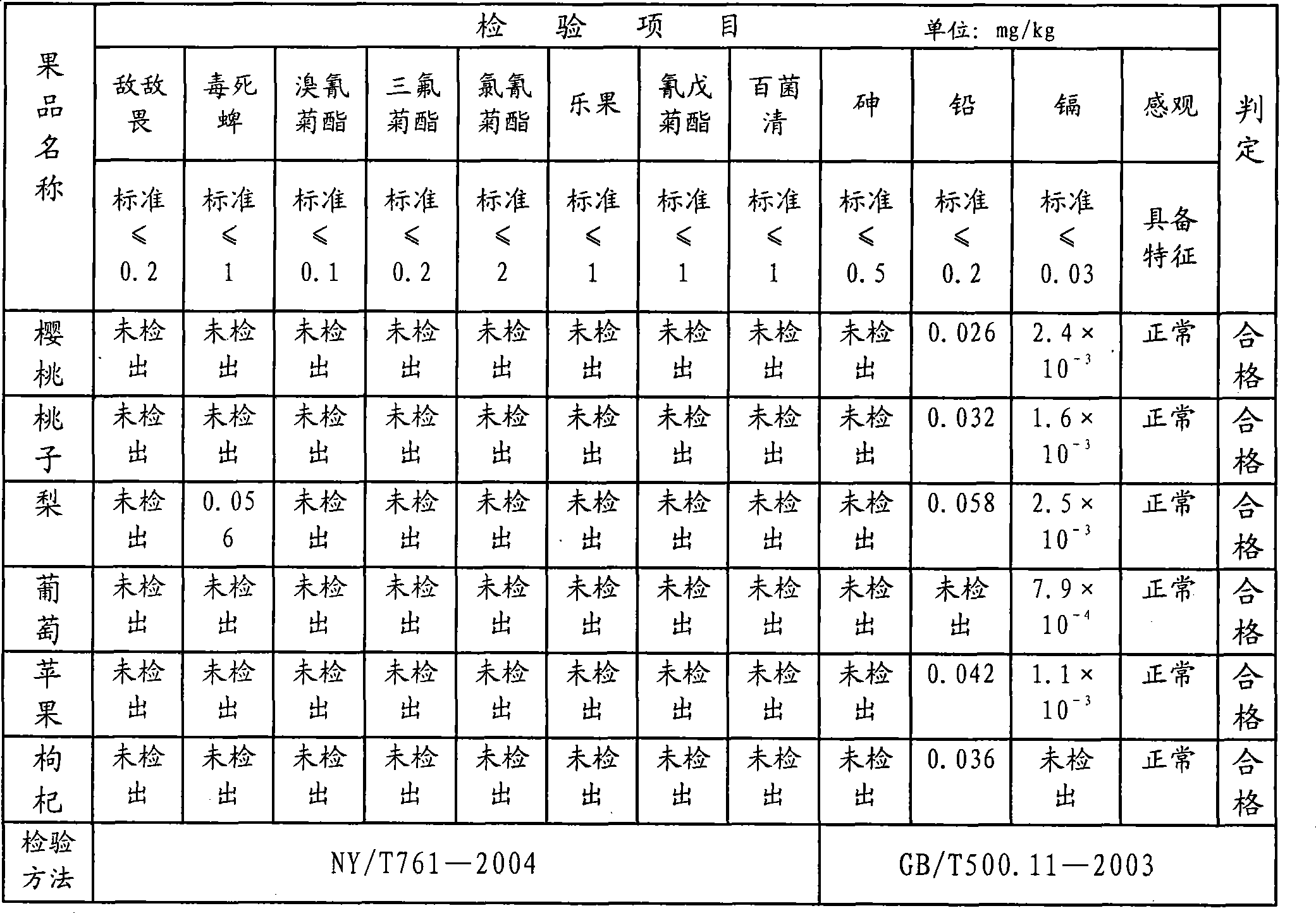

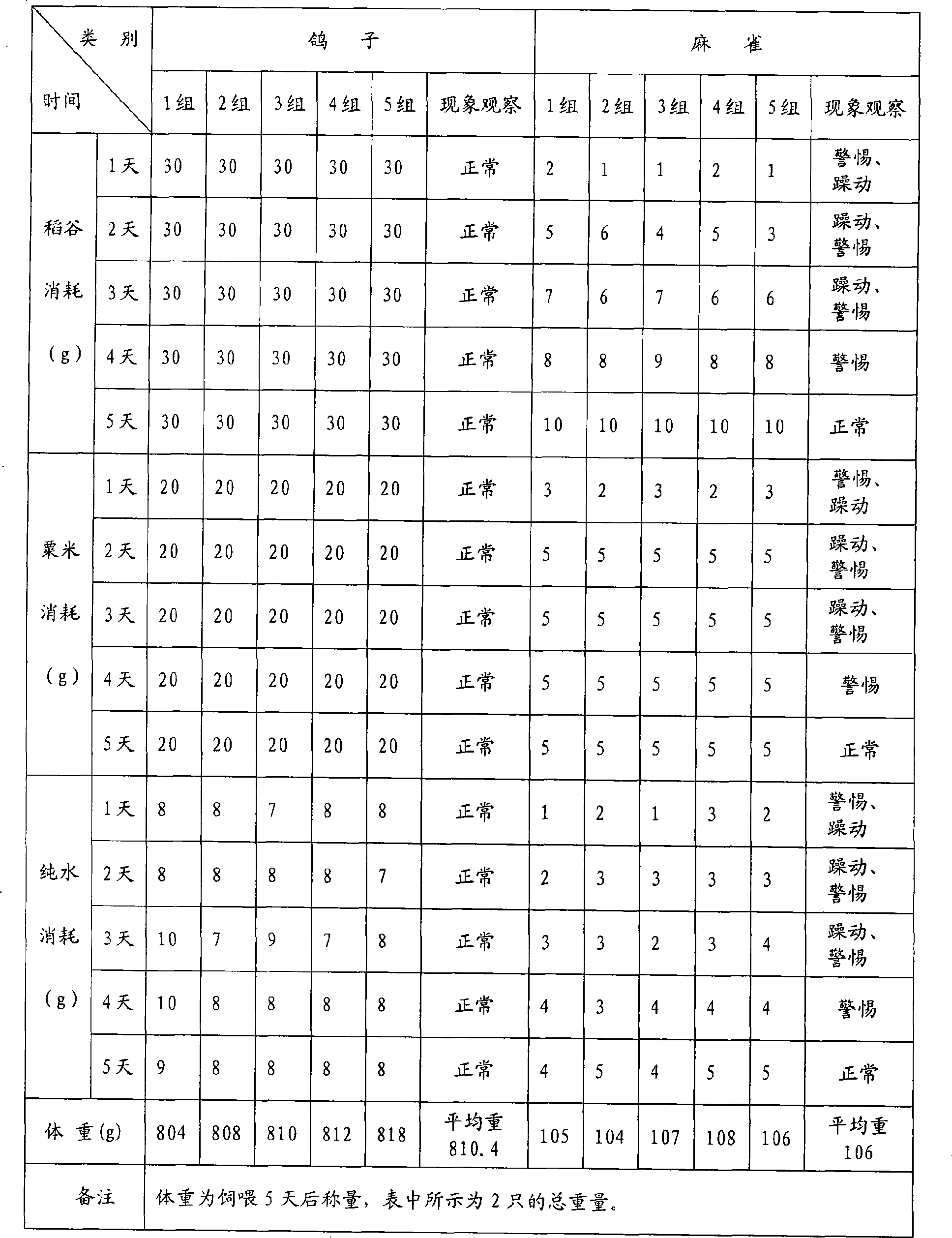

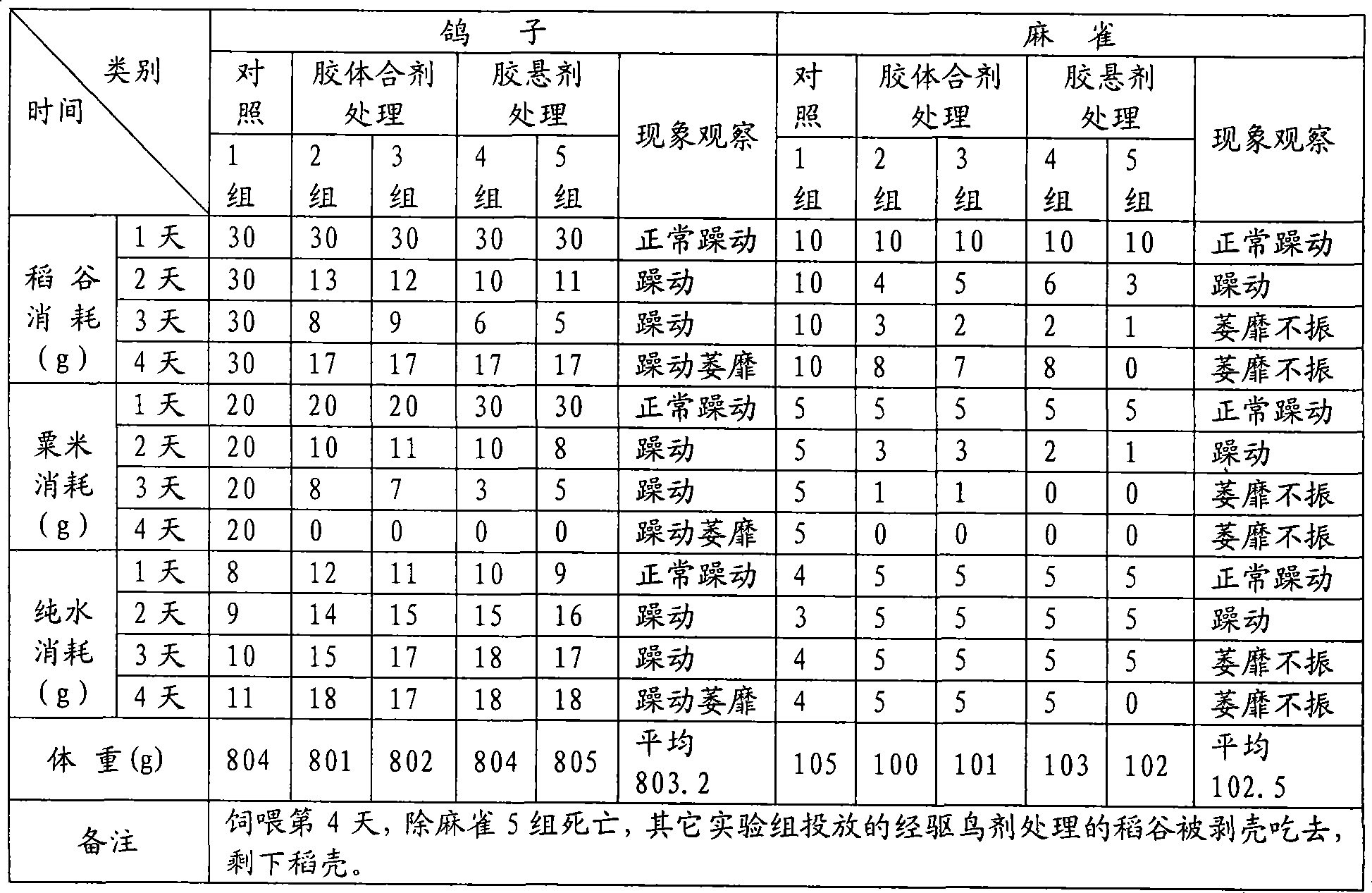

Bird driving composition and colloid mixture thereof, suspending agent and preparation method thereof

A driving-bird composite contains the following materials by different weight percentage: the driving-bird spice is selected from: 1 to 50 percent of methyl ortho-aminobenzoate, one or two of the 0.1-5 percent of heartleaf houttuynia herb essential oil or 10-21 percent of muskiness T; an antioxidant is selected from one or two of the 0.02-0.5 percent of 2, 6-BHT and sodium ascorbate, and the rest is control-released carriers. The driving-bird colloid mixture is made of the driving-bird composite, and the control-released carrier contains organic base or inorganic base, unsaturated fatty acid, antiseptic, emulsification, stabilizing agent, anti-freeze agent and the like. The driving-bird SC is made of the driving-bird composite, and the control-released carrier contains michael essien alkenyl succinic acid ester of starch sodium or Beta-cyclodextrin, antiseptic, emulsification, stabilizing agent, anti-freeze agent and the like. The invention utilizes the odor of the driving-bird spice for leading the bird-trigeminal to generate anaphylactic reaction and the bird-physiology to generate anorexia after pecking by means of diluting the sprayer, the driving-bird composite has the advantages of convenient usage and good effect of driving, and is harmless to the birds and the plant, thus belonging to the environment friendly biological agent products.

Owner:HUANGSHAN SHUANGBAO TECH APPLIED

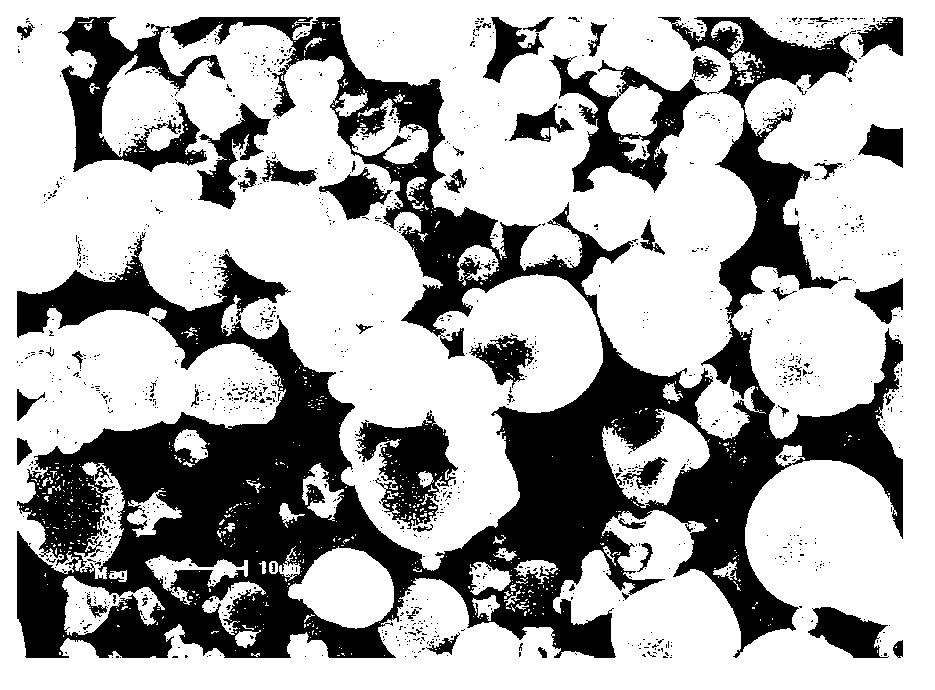

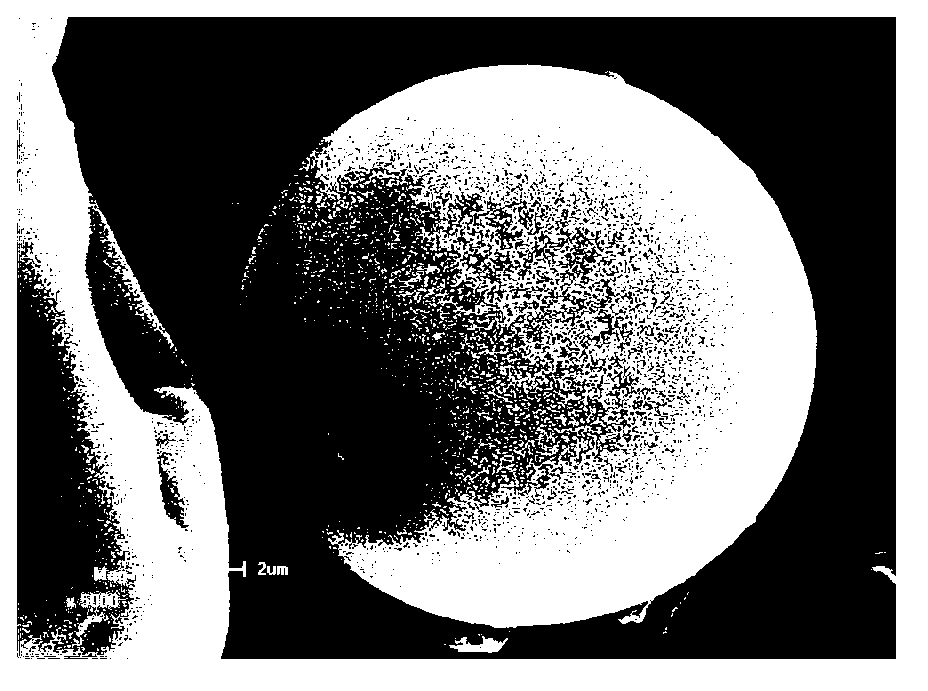

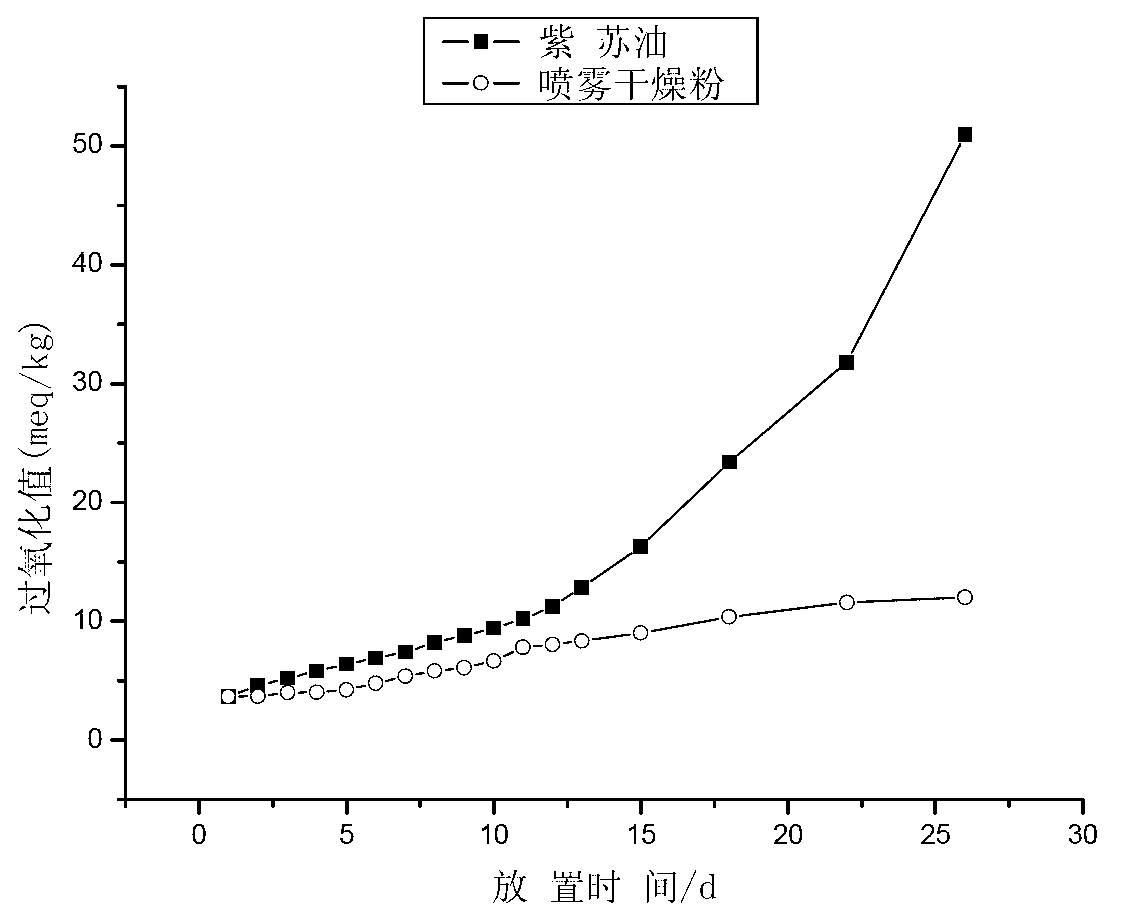

Method for preparing perilla oil powder through microencapsulation

InactiveCN103054030AGood emulsifying effectGood film formingFood shapingFood preparationDispersitySolubility

The invention discloses a method for preparing perilla oil powder through microencapsulation, and provides a method for preparing perilla oil powder with simple technology and good water solubility. The method comprises the following steps of: heating to gelatinize starch octenylsuccinate at 90-100 DEG C, and cooling to room temperature; preparing the gelatinized starch octenylsuccinate into an aqueous solution of starch octenylsuccinate with mass concentration of 30-40%; adding perilla oil into the aqueous solution of starch octenylsuccinate, and stirring for emulsification at high temperature to obtain an emulsion; and homogenizing the emulsion, and spray-drying to obtain perilla oil powder. The preparation method disclosed by the invention adopts starch octenylsuccinate as a wall material, does not need addition of an emulsifier and realizes high embedding rate; the operation technology is simple; and the perilla oil powder has good water solubility, good dispersity and good stability. Moreover, the starch octenylsuccinate has low price, the product cost can be lowered, and the product popularization is facilitated.

Owner:TIANJIN UNIV OF COMMERCE

Starch esters and method of preparation

A lipophilic starch is provided along with methods of making the same. The starch is prepared by modifying the starch with an organic acid anhydride reagent, such as octenyl succinic anhydride, drying the modified starch to a moisture content of less than 15% by weight, and then heat treating the dried starch at a temperature of at least 100° C. for at least one minute.

Owner:KANSAS STATE UNIV RES FOUND

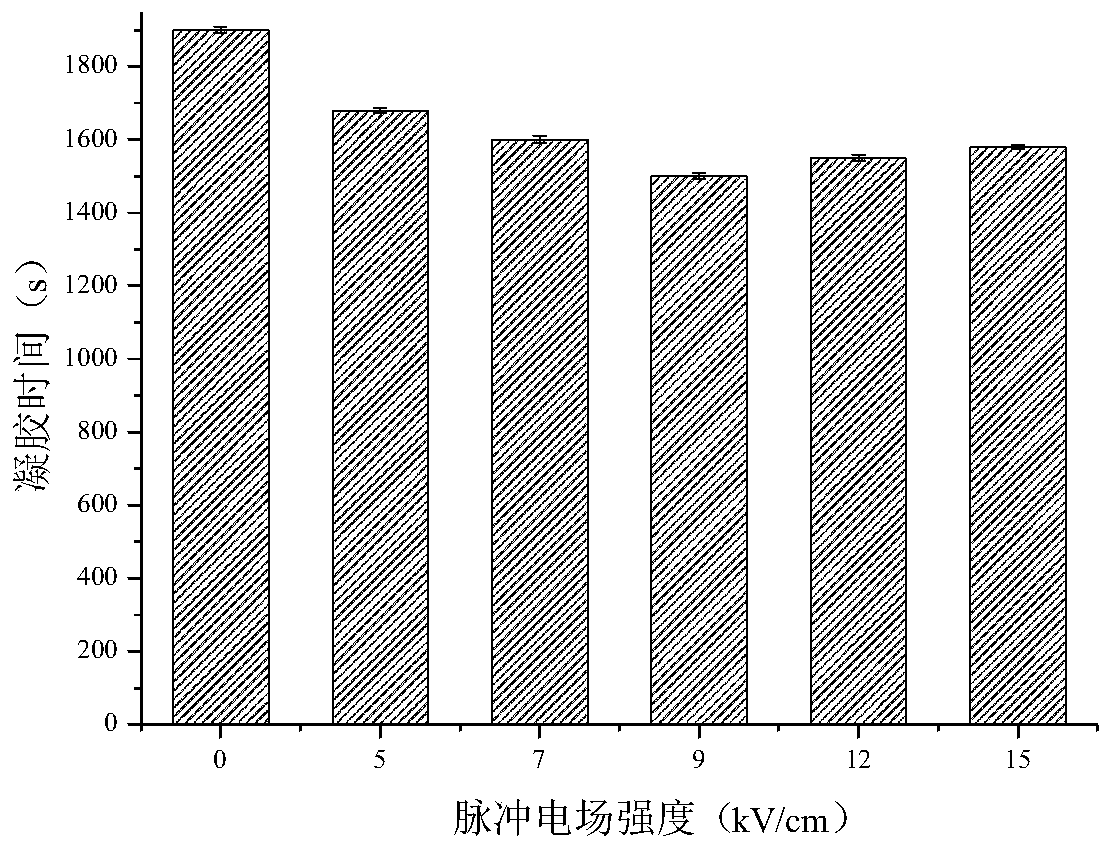

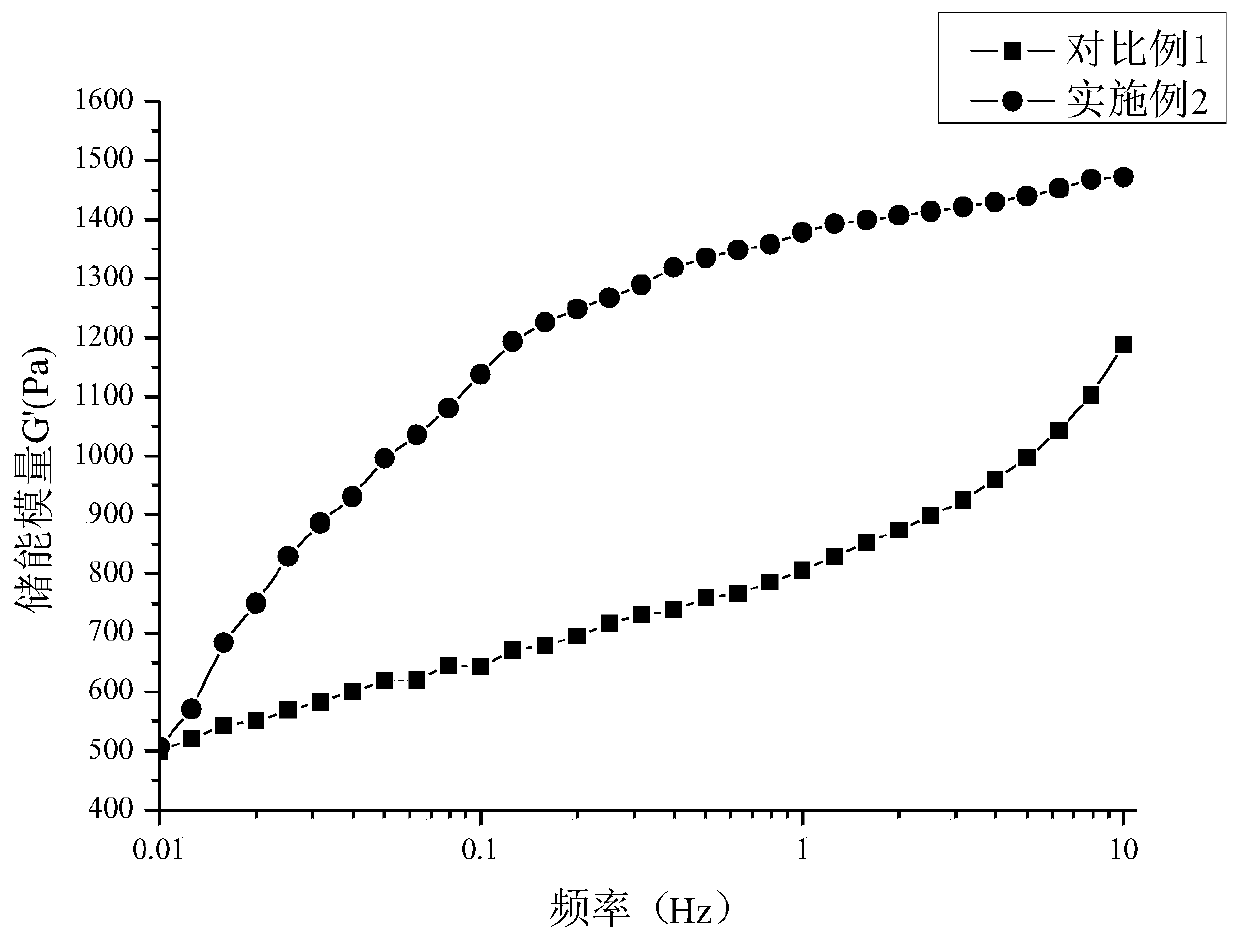

Emulsion gel embedding fat-soluble vitamins and production method based on pulsed electric field

InactiveCN110693003ASimple preparation processReaction is easy to controlFood scienceCelluloseMethyl cellulose

The invention discloses an emulsion gel in which fat-soluble vitamins are embedded and a production method based on a pulse electric field. The production method includes the following steps: dissolving octenyl succinic acid modified starch in water, heating in a water bath, stirring until the material is completely gelatinized and dissolved, and cooling to room temperature; adding edible oil in which fat-soluble vitamins are dissolved to obtain a mixed solution; using a high-speed shearing machine and a high-pressure homogenizer to shear and homogenize the obtained mixed solution so as to a coarse emulsion; adding starch into the coarse emulsion, and uniformly stirring to obtain an emulsion; adding a methylcellulose solution to the emulsion, uniformly mixing and performing pulse electricfield treatment, heating in a water bath, degassing, and cooling to obtain an emulsion gel. The pulsed electric field of the invention promotes the interaction between methylcellulose and starch molecules, has a higher elastic modulus, and is easier to form a network structure that is more favorable for embedding fat-soluble vitamins. Thereby, fat-soluble vitamins are effectively embedded, and thepurpose of slowly releasing fat-soluble vitamins is achieved.

Owner:SOUTH CHINA UNIV OF TECH

Starch film and method for manufacturing starch foam

A biodegradable starch film is provided. The biodegradable starch film includes a starch which is cross-linked by means of a cross-linking agent. The cross-linking agent comprises glycidyl methacrylate 2,3-epoxypropyl methacrylate (GMA), octenyl succinyl anhydride (OSA), or dodecyl succinic anhydride (DDSA) or combinations thereof. The cross-linking agent is 1 to 10 weight parts based on the starch of 100 weight parts. Furthermore, a method for manufacturing starch foam is also provided.

Owner:IND TECH RES INST

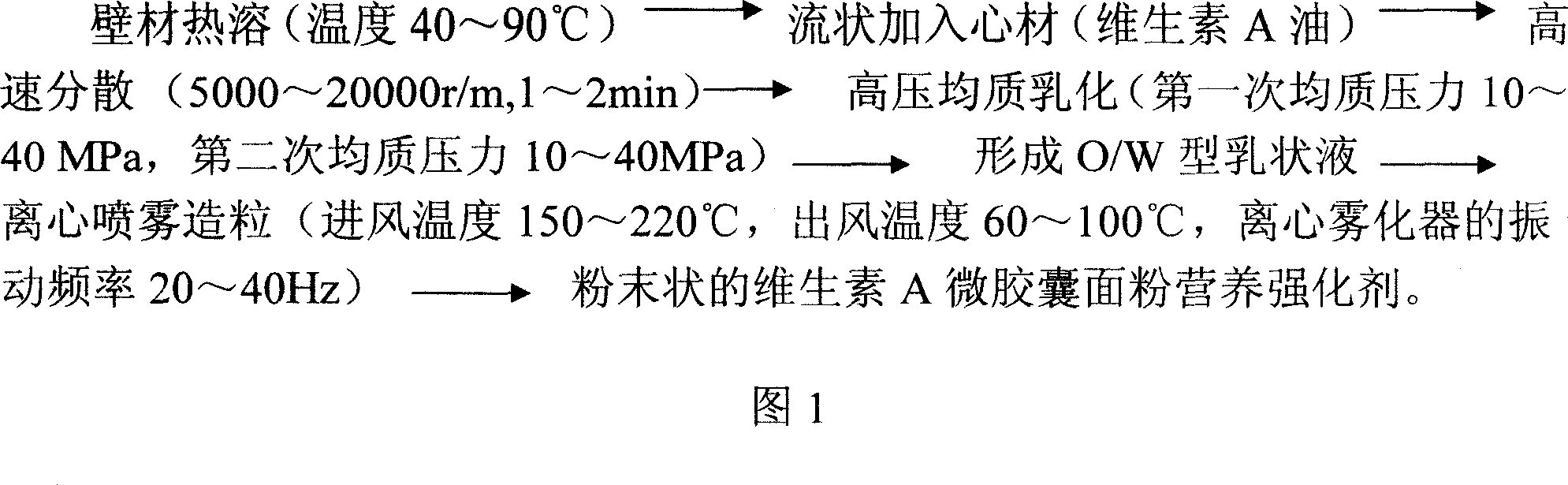

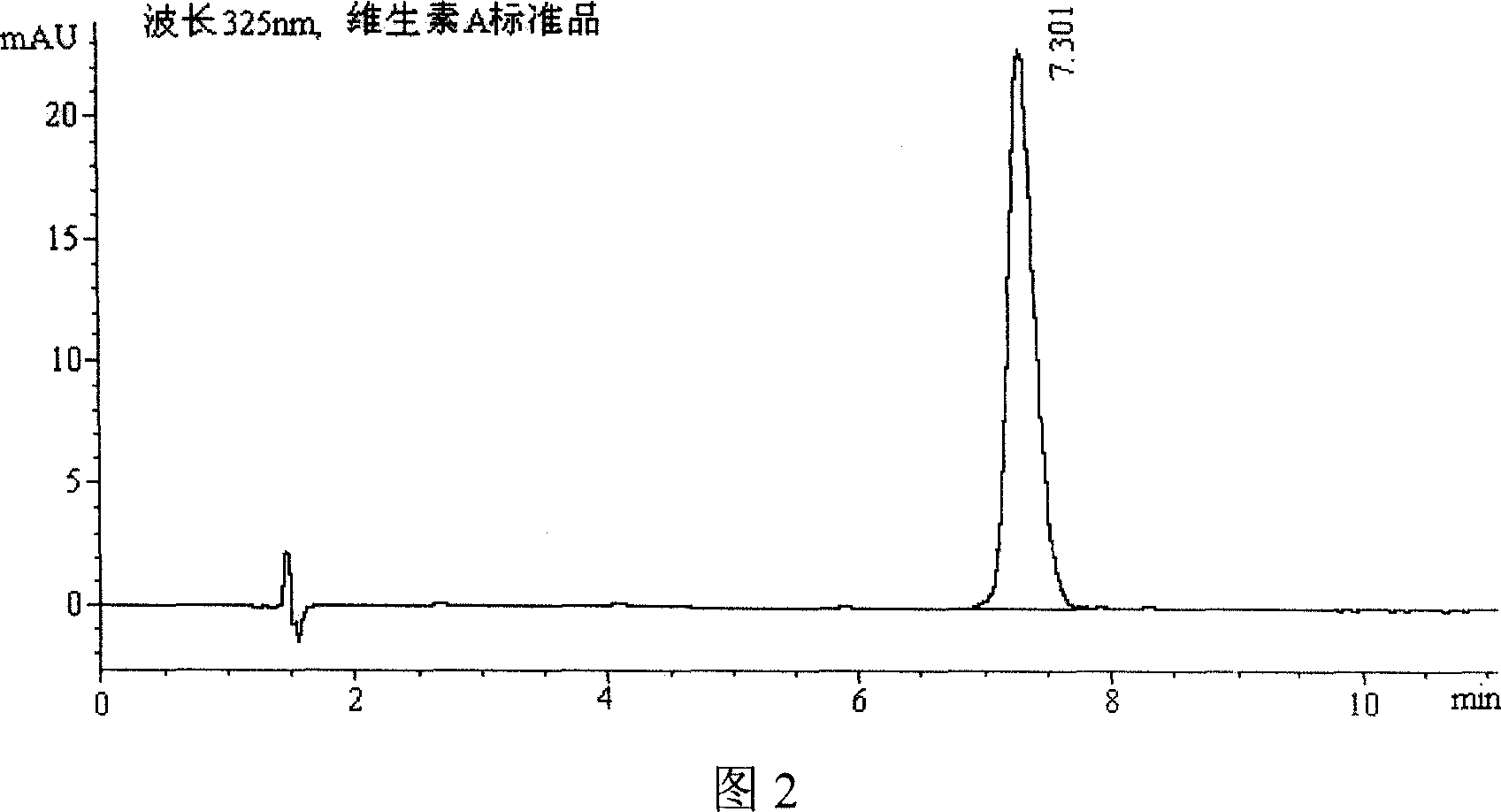

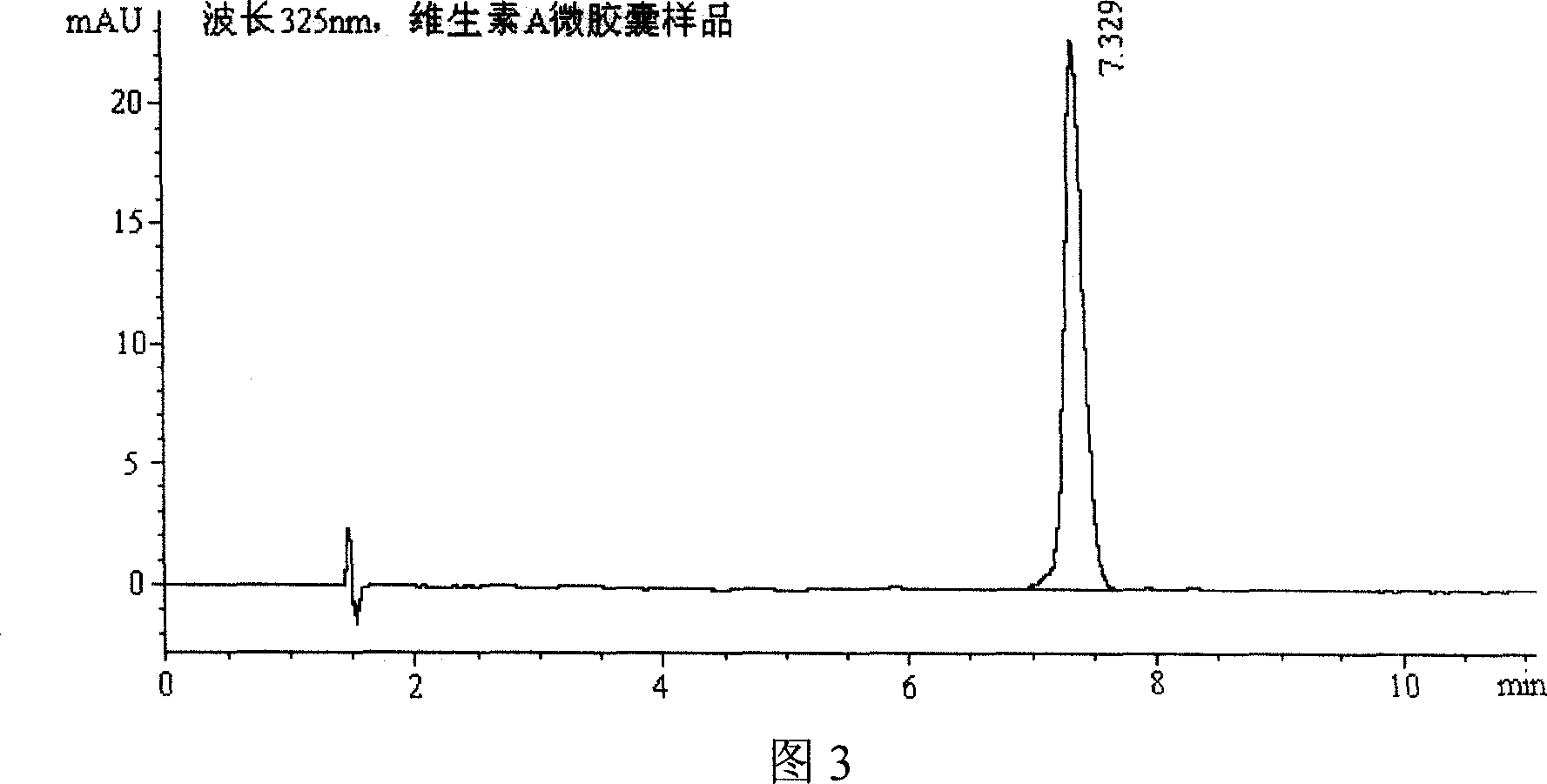

Method for preparing flour nutrition intensifying Vitamin A microcapsule

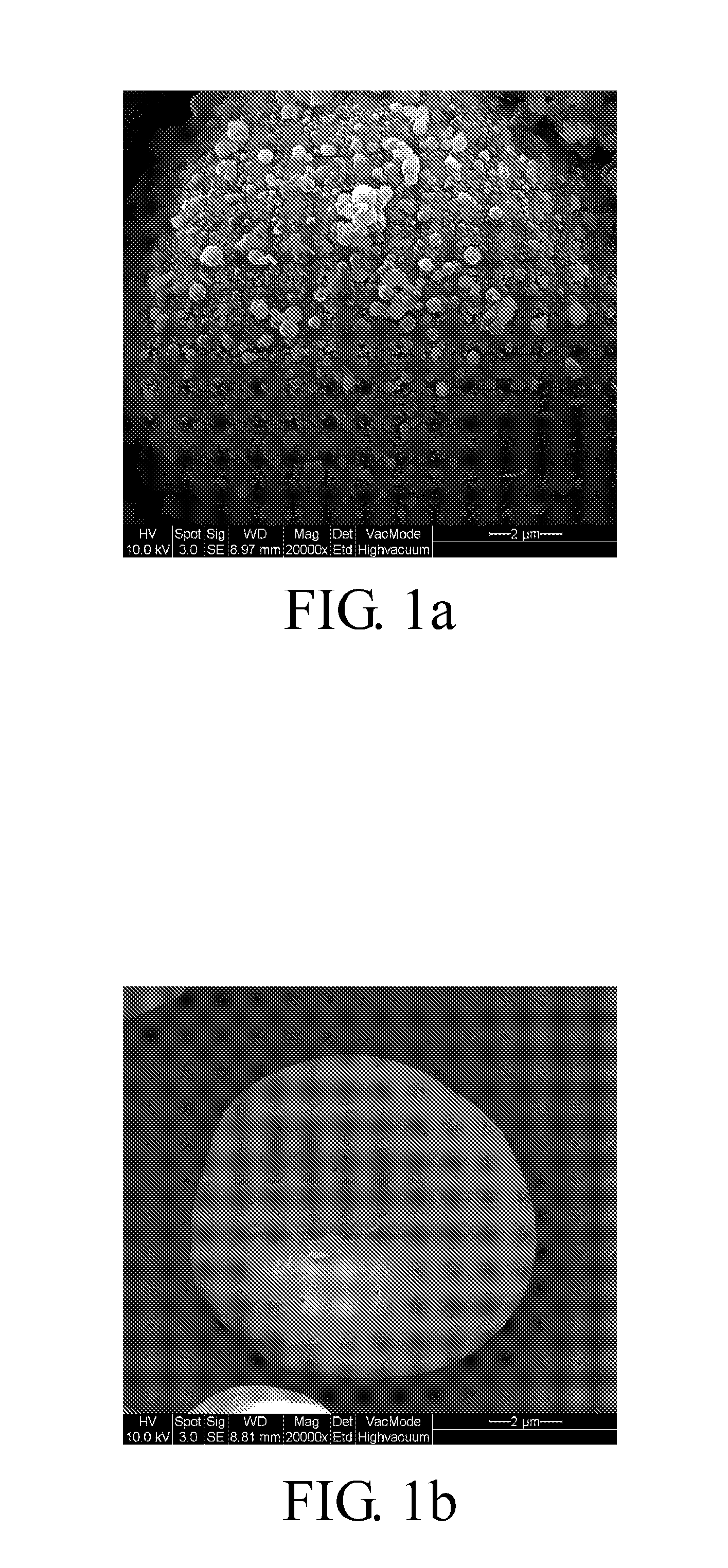

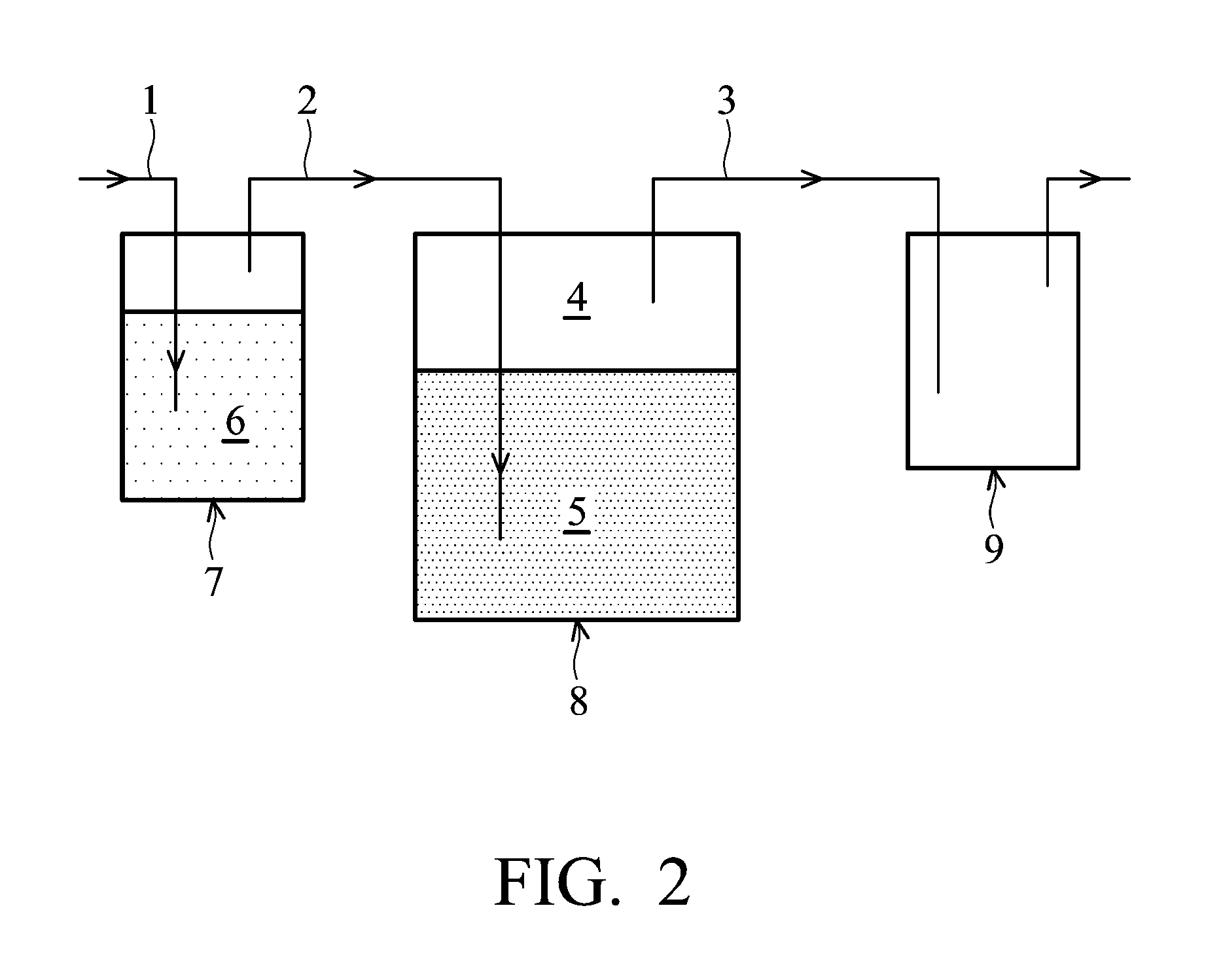

InactiveCN1965657AWell mixedEase of mass productionDough treatmentHydroxy compound active ingredientsFood additiveVitamin A Alcohol

The invention relates to a method for preparing vitamin A microcapsule flour nourishment reinforcer, wherein it uses vitamin A oil as corn, uses HI-CAP100 as wall material, uses O / W high-pressure to emulsify and eccentric atomization technique, to prepare the microcapsule with stable property and flow property. The efficiency of said microcapsule is 99.06%, the yield is 97.81%; with high-pressure liquid test, the vitamin A content is higher than 3.5*105IU / g, the average particle diameter is 85.6 mum; and its bulk specific gravity is not significant different from the bulk specific gravity of flour (P>0.05, stop angle (phi)<=30degree).

Owner:JIANGNAN UNIV +1

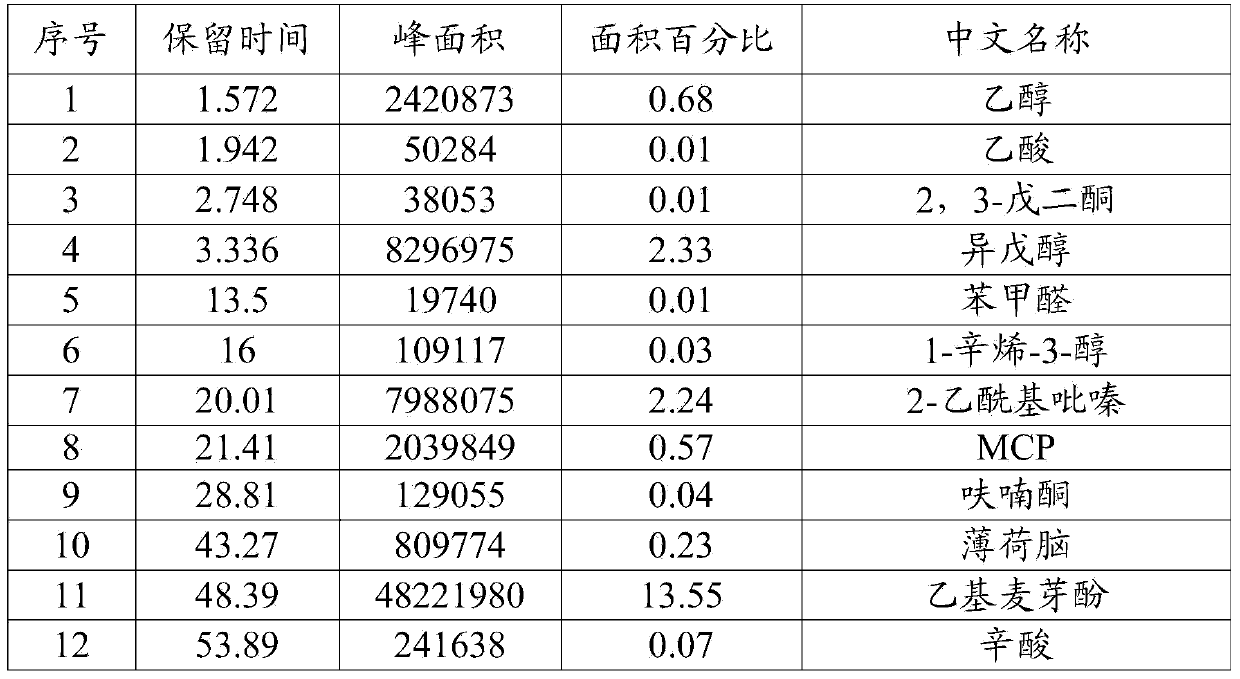

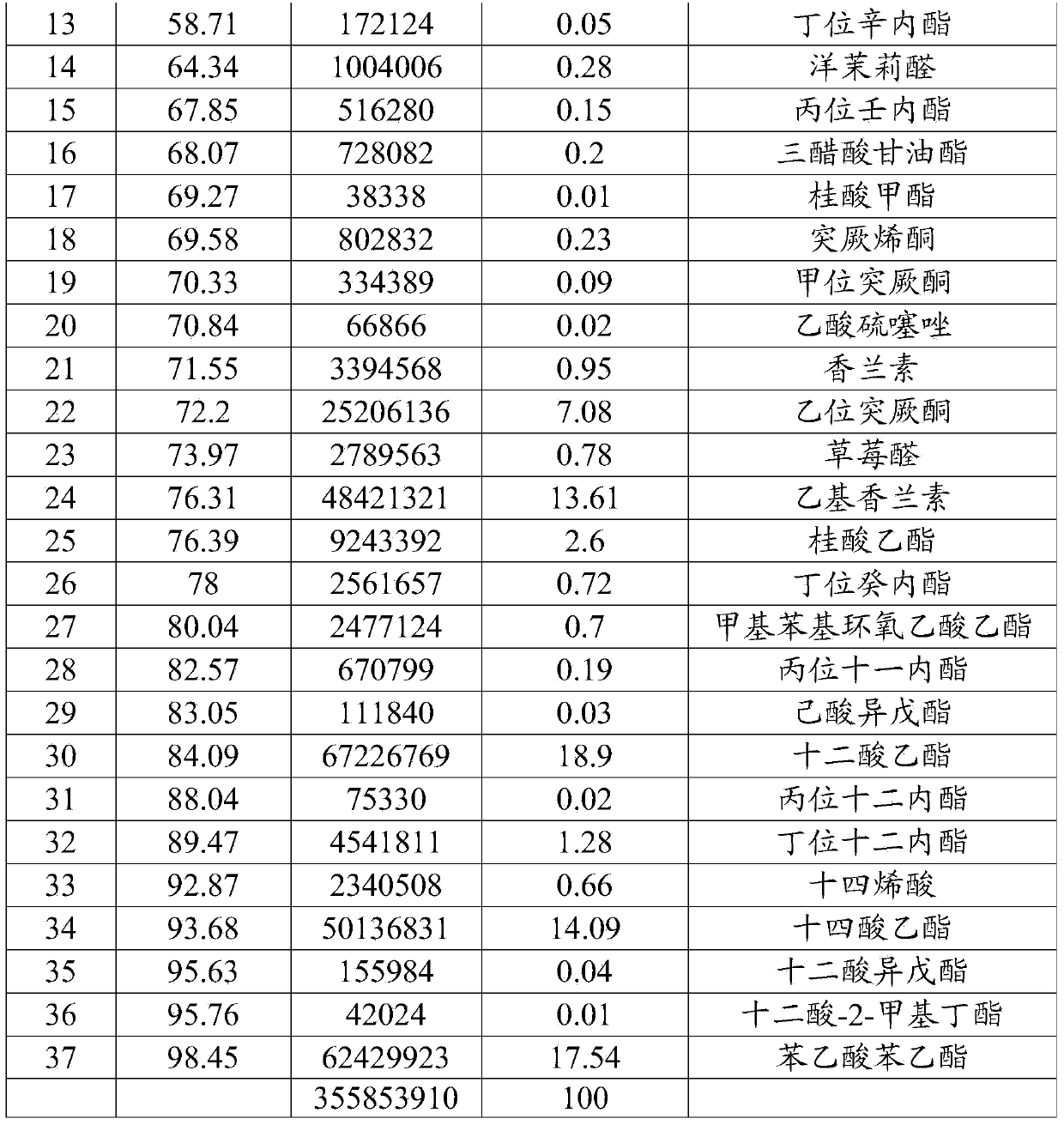

Red jujube flavor and preparation method thereof

InactiveCN103695177AImprove the effect of fragranceAdd lessEssential-oils/perfumesFood preparationFlavorOctenyl succinate

The invention discloses red jujube flavor and a preparation method thereof. The red jujube flavor is mainly prepared by the following materials by weight: 95-105 parts of red jujube enzymes, 1-3 parts of red jujube bases, 12-18 parts of maltodextrin and 2.5-3.5 parts of sodium starch octenyl succinate. The preparation method of the red jujube enzymes comprises the following steps: pretreatment: mixing red jujube with water according to the weight ratio of 1 : (2 to 5), and processing by a colloid grinder to prepare red jujube paste; enzymolysis: mixing the red jujube paste with plant enzyme hydrolysis (the Danish Novozymes) according to the weight ratio of 10 : (0.02 to 0.05) and enzymolysis, wherein, the temperature of the enzymolysis is from 50 DEG C to 60 DEG C, and the time is from 1 to 5 hours; deactivating the enzymes. The red jujube flavor has the advantages of good flavor enhancing effect, little additive amount in the practical application and high added-value. The preparation method is simple and easy to operate.

Owner:广东江大和风香精香料有限公司

Coenzyme Q10- Containing Composition

ActiveUS20080248013A1Excellent stability and bioavailabilitySuperior coenzymeOrganic active ingredientsCosmetic preparationsOrganic acidMonoglyceride

There is provided a coenzyme Q10-containing composition having a high coenzyme Q10 content and excellent stability and bioavailability of coenzyme Q10, without using synthetic emulsifiers such as glycerin fatty acid esters, polyglycerin fatty acid esters, organic acid monoglycerides or sucrose fatty acid esters.The coenzyme Q10-containing liquid composition is obtained by dispersing and emulsifying coenzyme Q10 in an aqueous liquid containing a water-soluble substance consisting of octenylsuccinate starch and dextrin, and glycerin. The liquid composition may be dried to prepare a coenzyme Q10-containing solid composition.

Owner:NISSHIN PHARMA INC

Method for preparing starch ester by recycling octenyl succinic anhydride

The invention discloses a method for utilizing octenyl succinic anhydride to produce starch ester in circulation. The method comprises steps that: water is added to 100 parts of dry basis starch; the starch is homogenized and emulsified; the pH value of the starch is regulated to 8 to 10; the starch is added to an octenyl succinic anhydride solution containing 3 parts of octenyl succinic anhydride, and is subject to a reaction; when the reaction is finished, the pH value of a reaction liquid is regulated to 5.5 to 6.5; the reaction liquid is filtered, and is processed from processes of washing, drying, crushing and sieving three times, such that white starch sodium octenyl succinate is obtained; a residual from the filtering process is mixed with the filtered washing solution, such that an octenyl succinic anhydride mixed solution is obtained; the solution is distilled, octenyl succinic anhydride is supplemented, and a solvent is added for dissolving, such that an octenyl succinic anhydride solution is obtained; water and ethanol obtained from distillation are fractionated, ethanol concentration is adjusted, and the materials can be repeatedly used. The method provided by the invention is advantaged in that: the technology is simple and is easy to control; recycling of octenyl succinic anhydride and recycling of the solvent can both be realized.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

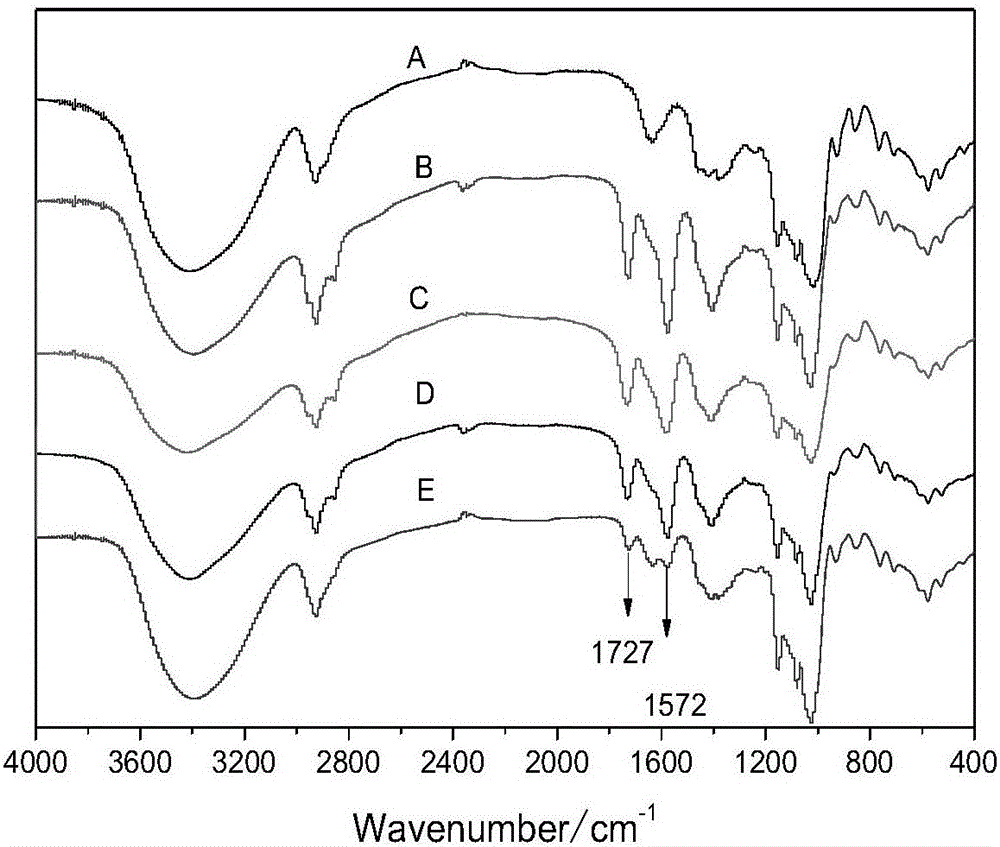

Preparation method of low-viscosity octenyl succinic anhydride modified starch

InactiveCN102532329ARaise the temperature of esterificationShort reaction timeDistilled waterSuccinic acid

The invention relates to a preparation method of low-viscosity octenyl succinic anhydride modified starch. The method comprises the following steps of: (1) adjusting the pH value of a starch emulsion to 8.0-8.5, adding an H2O2 solution, adding a hydrochloric acid solution for neutralizing the starch emulsion till the pH value is 6.5-7.0, washing and drying to obtain low-viscosity oxidized starch; and (2) mixing the low-viscosity oxidized starch with distilled water to obtain a starch emulsion, continually stirring in a constant-temperature water bath, adjusting the pH value to 8.0-8.5, adding 2 mol / L of an MgSO4 solution which accounts for 1 percent of the weight of the starch emulsion, slowly adding octenyl succinic anhydride which accounts for 2-3 percent of the total mass of the low-viscosity oxidized starch obtained in the step (2), adjusting the pH value to 5.5-6.5, washing with water and ethanol respectively twice, and drying to obtain a white finished product. The product has the advantages of stable performance, simple and environmentally-friendly process steps, reduction in preparation time, no residue of oxidant and increase in production efficiency.

Owner:天津市轻工业化学研究所有限公司 +1

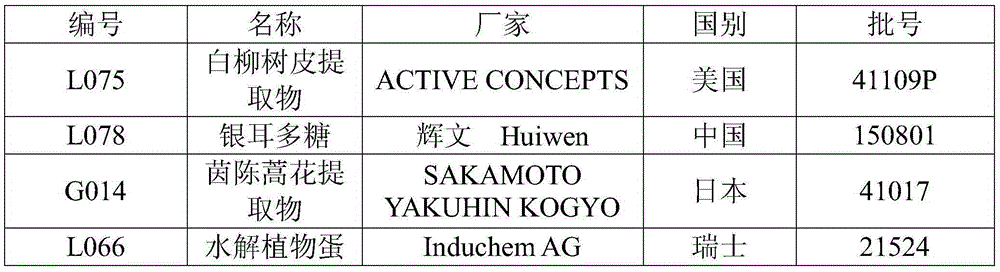

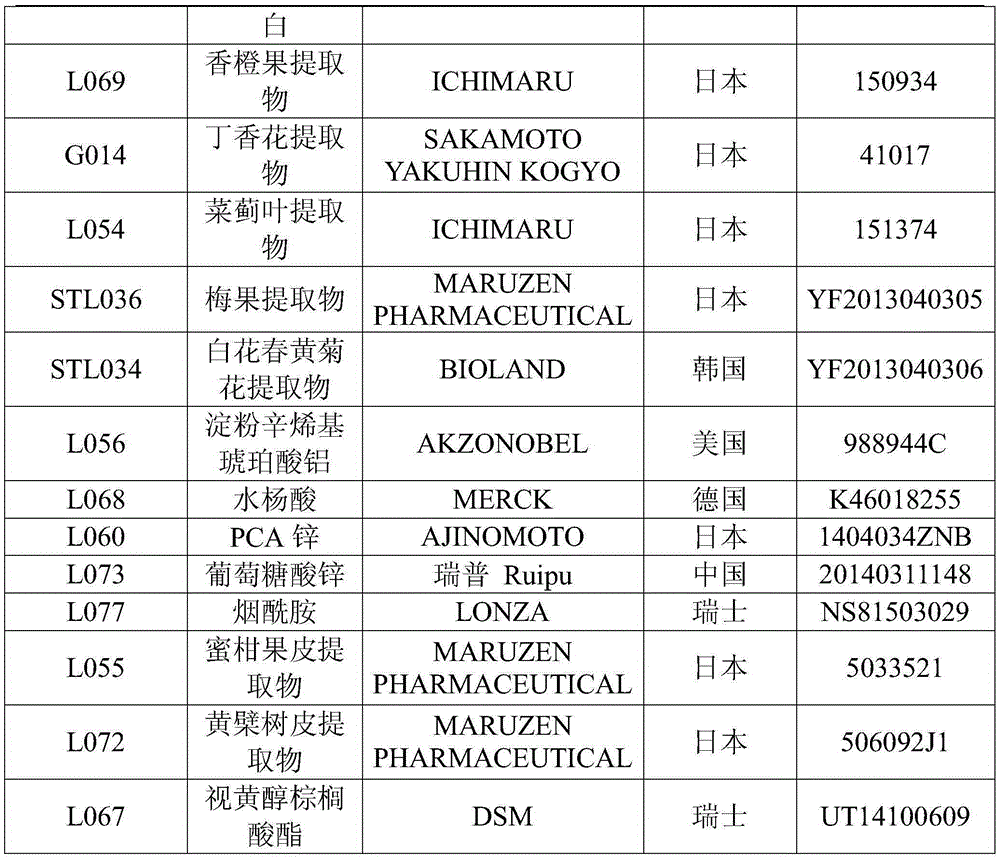

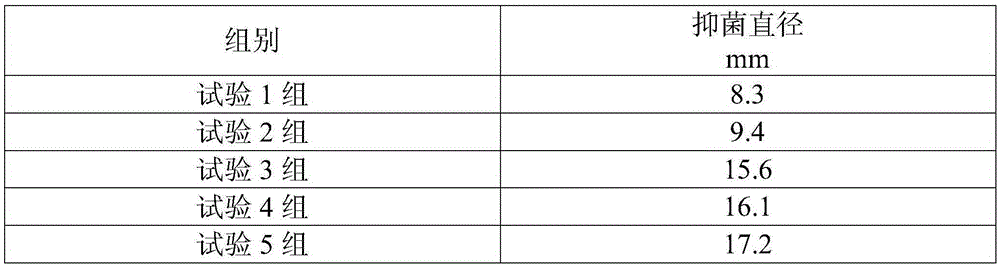

Acne treatment essence cream and preparing method thereof

The invention belongs to the technical field of cosmetics, and particularly relates to acne treatment essence cream and a preparing method thereof. The essence cream contains aluminum starch octenylsuccinate, salicylic acid, PCA zinc, zinc gluconate, nicotinamide, tangerine orange pericarp extract, amur corktree bark extract and retinyl palmitate. The acne treatment constituents in the essence cream are obtained through screening. The new acne treatment constituents in the essence cream can effectively restrain propionibacterium acnes. Experimental studies prove that a good acne treatment effect can be realized by adding the acne treatment constituents to the essence cream. Stability studies show that the essence cream has higher stability.

Owner:HUAANTANG BIOTECH GRP CO LTD

Alum-free starch noodles and sheet jelly as well as a preparation method thereof

ActiveCN102669605ANo loss of edible performanceSafe edible performanceFood preparationHydrogenPhospholipid

The invention discloses alum-free starch noodles and sheet jelly as well as a preparation method thereof. The product is prepared from starch, modified phospholipid and certain ancillary materials, wherein the ancillary materials comprise propylene glycol alginate, sticky corn starch, hydrogen potassium sorbate, esterified modified starch, sodium glycerophosphate and octenyl succinic starch ester. Compared with the original starch noodles containing alum, the alum-free starch noodles have the benefits that the prepared product is free from alum and safer, and the edible performance does not decrease obviously.

Owner:HEILONGJIANG GANGJIN FOOD TECH DEV

New technique for producing starch of octane succinate

InactiveCN1563096APromote safe productionProduct quality is easy to controlOctenyl succinateOCTENYLSUCCINIC ACID

The invention provides a new production process of octoalkenyl succinate starch, and adopts a method of thermal dextrinization to implement industrialization production of octoalkenyl succinate starch. Its step includes two processes of esterization raw material starch into starch milk, adding dilute alkali to regulate pH value to 8.0-9.0, then adding octoalkenyl succinyl oxide to make heating reaction, after the reaction is completed, adding dilute acid to regulate pH value to about 5.0, then washing and centrifugally-drying; and the dextrinization process includes the following steps: placing the above-mentioned esterized octoalkenyl succinate starch semifinished product in mixer, and adding dilute acid to regulate pH value to 2.4-2.5, predrying, feeding the above-mentioned material into double-cone reactor to make high-temp. vacuum reaction, then discharging material, cooling and packaging finished product.

Owner:BAISHIDA STARCH GUANGXI

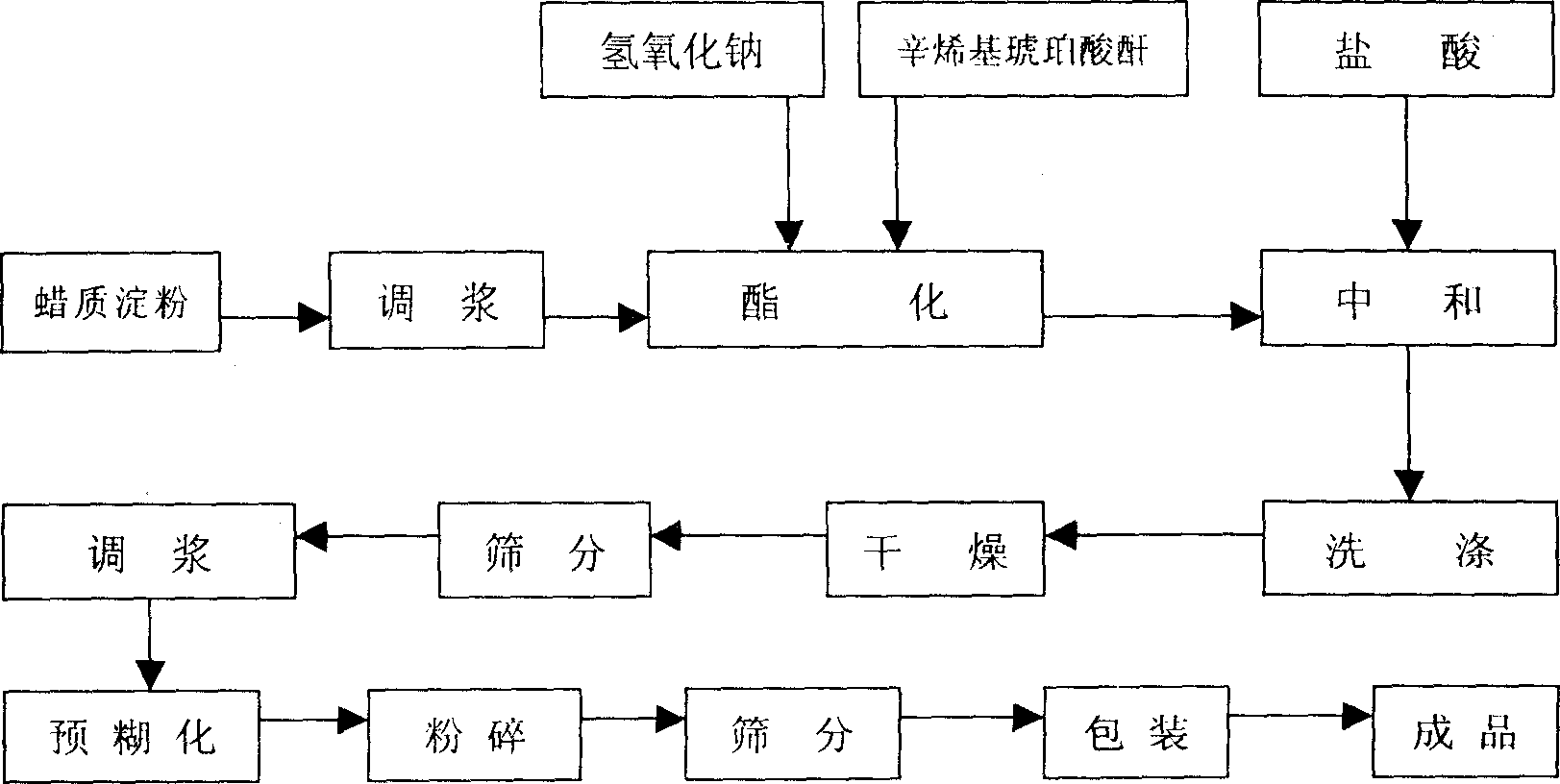

Predextrinization octeneyl succinate starch and its preparation method

InactiveCN1903883AWide variety of sourcesThe process flow is simple and applicableSolubilityOctenyl succinate

The present invention discloses a kind of pregelatinized octalkenyl succinate starch and its preparation method. It is made up by using waxy starch, octalkenyl succinic anhydride, hydrochloric acid and sodium hydroxide as raw material and making said raw materials undergo the processes of mixing paste, esterification, neutralization, washing, drying, screening, mixing paste, pregelatinizing, pulverizing, screening and packaging. Besides, said invention also provides its concrete application range.

Owner:四平帝达变性淀粉有限公司

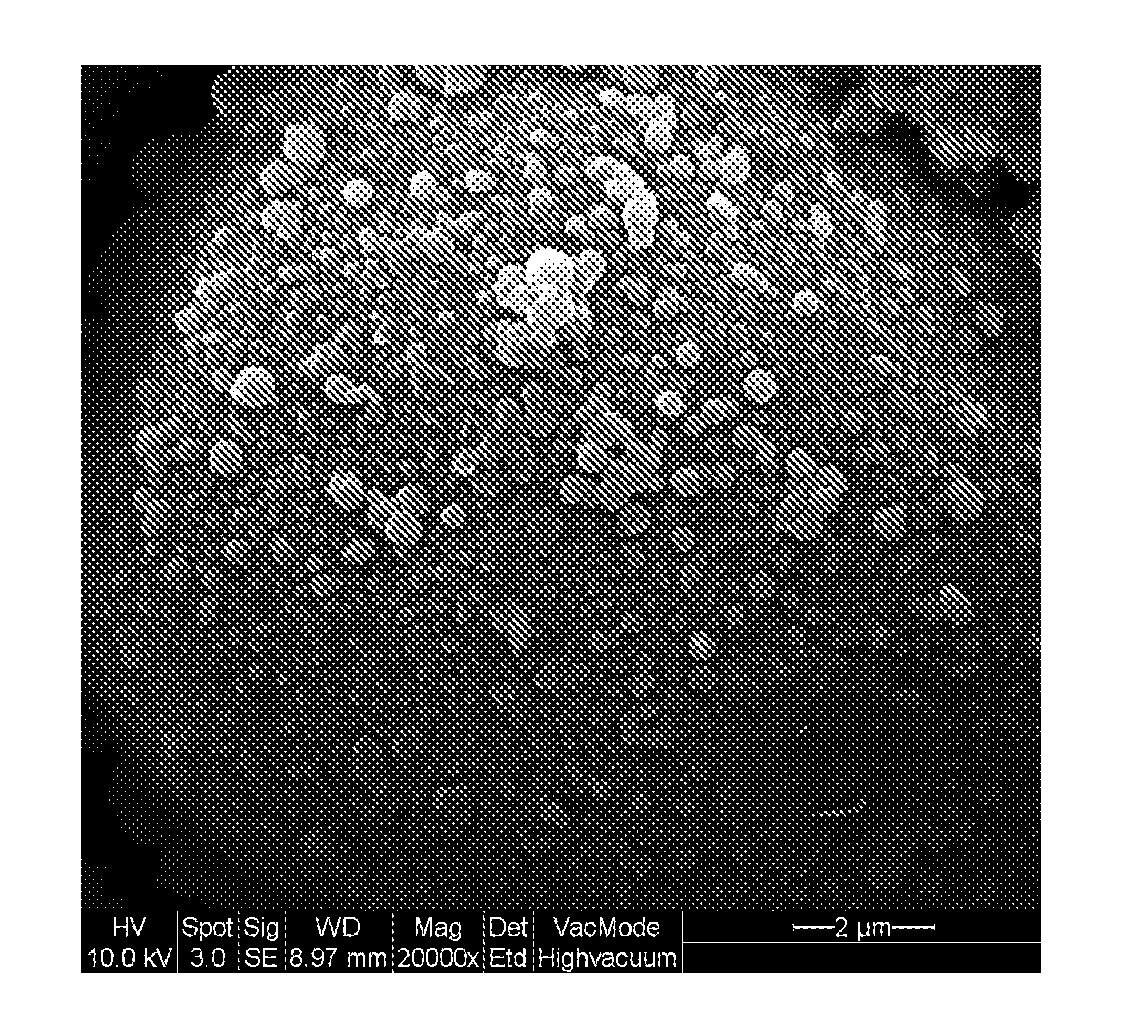

Amphipathic octenyl succinic short-straight chain starch nano-particles and preparation method thereof

ActiveCN106580879AReduce lossesEfficient deliveryHydroxy compound active ingredientsPharmaceutical non-active ingredientsSide effectPullulanase

The invention relates to preparation process of amphipathic octenyl succinic short-straight chain starch nano-particles. The preparation process comprises the following steps: (1) performing enzymolysis on gelatinized starch by using pullulanase, and obtaining short straight chain starch; (2) preparing a short straight chain starch solution, performing gelatinization, adding an octenyl succinic anhydride solution which accounts for 25-100% of the weight of dry powder of short straight chain starch, and continuously stirring for 6-10 hours, so as to obtain a modified octenyl succinic short straight chain starch solution; preparing a 1-10mg / mL solution of the octenyl succinic short-straight chain starch, stirring for 6-10 hours at 37-40 DEG C, and cooling to the room temperature, thereby obtaining a amphipathic octenyl succinic short-straight chain starch nano-particle solution. The particle size of the nano-particles is within 5-100nm, the nano-particles are good in tissue adhesion property, are capable of wrapping hydrophobic active substances, are high in loading rate and low in cost, the conveying efficiency of lyophobic active components by gastrointestinal tracts can be improved, and the bioavailability of the nano-particles can be improved. The lyophobic active components can be protected, the stability of the lyophobic active components can be improved, and the release of adverse flavor can be shielded; in addition, the addition amount and the toxic and side effects of bioactive components can be effectively reduced.

Owner:QINGDAO AGRI UNIV

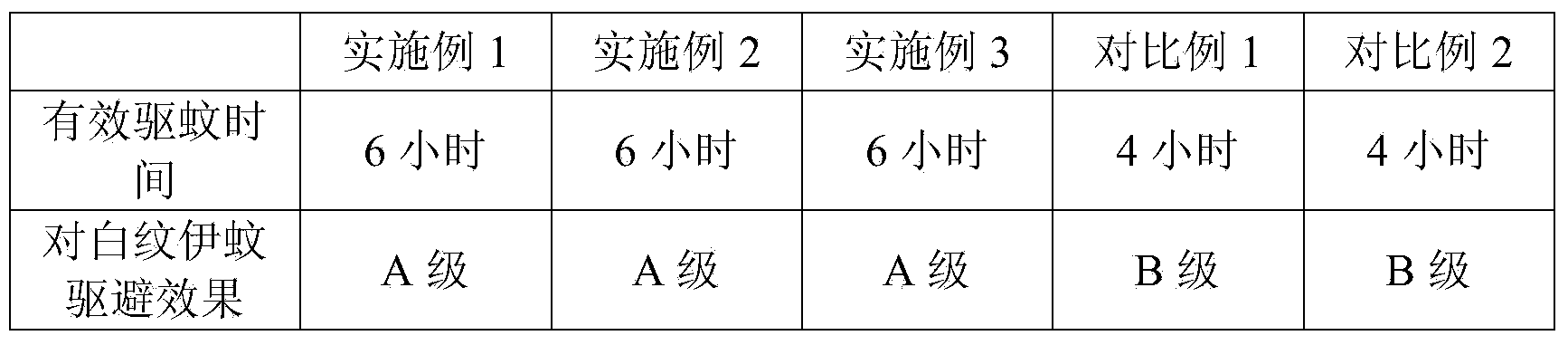

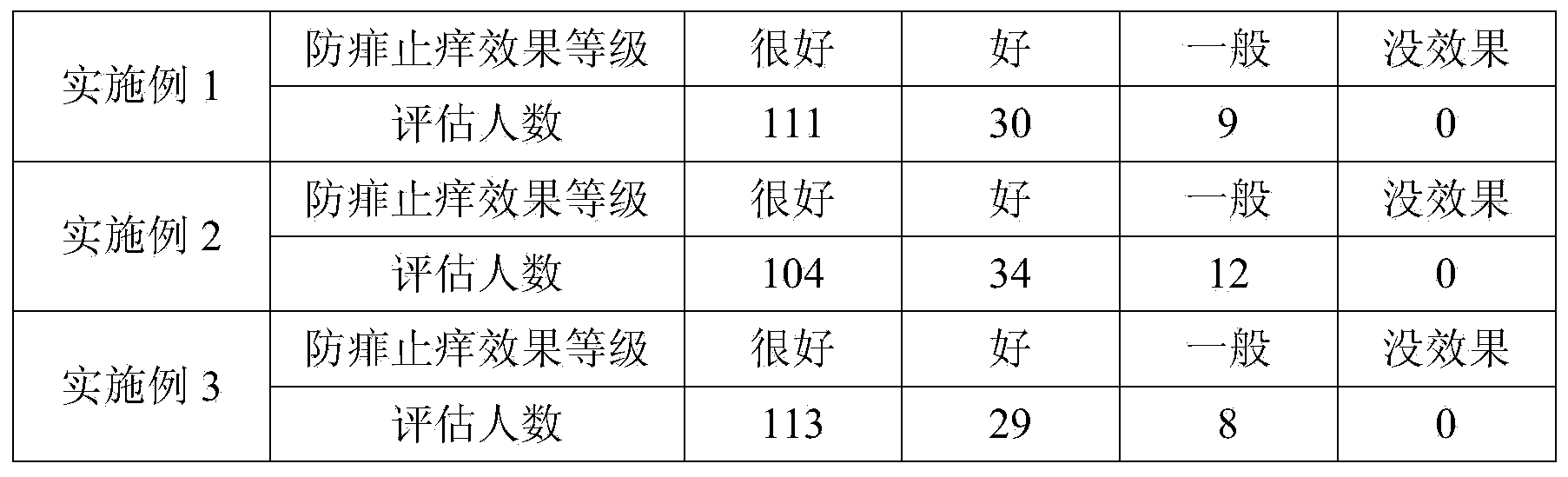

Mosquito-repellent composition microcapsule and preparation method and application of composition microcapsule

ActiveCN103520005AQuality improvementBoth anti-prickly heatCosmetic preparationsToilet preparationsJojoba oilBeta-Cyclodextrins

The invention provides a mosquito-repellent composition microcapsule and a preparation method and application of the composition microcapsule. The microcapsule is prepared by the following steps: mixing a plant extract with a mosquito-repellent effect with starch aluminum octenyl succinate, maltodextrin, beta-cyclodextrin, gelatin, chitosan, sodium alginate, soya bean lecithin, jojoba oil and water; and performing spray drying to obtain powder which is the mosquito-repellent composition microcapsule. The mosquito-repellent composition microcapsule provided by the invention can directly act on a human body or can be used for producing cosmetics to act on the human body to realize a long-time mosquito-repellent effect; moreover, the mosquito-repellent composition microcapsule also has a miliaria preventing and itching relieving effect.

Owner:TIANJIN YU MEI JING GRP

Fresh and cool sun-resistant composition with grease controlling function

InactiveCN105534737AUniform textureGood application effectCosmetic preparationsToilet preparationsSunscreen agentsHydroxystearic Acid

The invention belongs to the technical field of cosmetics, and relates to a fresh and cool sun-resistant composition with a grease controlling function. The sun-resistant composition contains starch aluminum octenylsuccinate and polyhydroxystearic acid. Starch aluminum octenylsuccinate is used for improving greasy feeling when people use the sun-resistant cosmetic, controlling and absorbing grease and relieving the shiny skin problem; polyhydroxystearic acid is used for improving a whitening phenomenon in the using process of the sun-resistant cosmetic. When starch aluminum octenylsuccinate and polyhydroxystearic acid are added into the cosmetic by an appropriate ratio, even if the content of an grease soluble sun-resistant agent and an inorganic sun-resistant agent in the sun-resistant cosmetic is high, a user feels fresh and cool without a greasy feeling, the sun-resistant composition has grease absorbing and controlling effects, and the whitening phenomenon after the sun-resistant composition is smeared is avoided.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +2

Modified starch and manufacturing method and application of modified starch

ActiveCN102634049AReduce crystallinityImprove chemical reactivityOrganic solventOCTENYLSUCCINIC ACID

The invention discloses modified starch and a manufacturing method and application of the modified starch. The manufacturing method of the modified starch provided by the invention comprises the following steps: dispersing starch by an organic solvent, adding water and uniformly mixing to prepare a starch suspension, and performing the microwave or the ultrasonic treatment to obtain the modified starch. According to the invention, crystalline regions in modified starch granules are greatly reduced, and the crystallinity of the modified starch granules is decreased from 15-45% to 8-30%. After the crystallinity is decreased, cassava starch is used for manufacturing dialdehyde starch, hydroxypropyl starch and octenyl succinic anhydride starch ester and has obviously improved reactivity.

Owner:GUANGXI UNIV FOR NATITIES

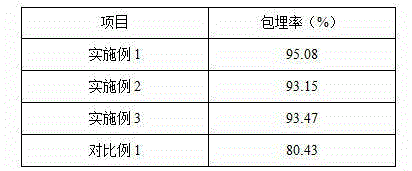

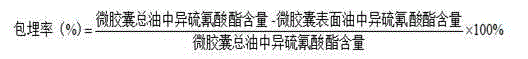

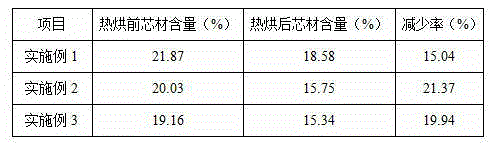

Microcapsule mustard essence and preparation method thereof

InactiveCN104921047APackage completelyReasonable ratioFood ingredient as thickening agentFood ingredient as encapsulating agentPolymer scienceAllyl thiocyanate

The present invention discloses a microcapsule mustard essence which consists of wall materials and core materials; the wall materials are prepared by using the following components in parts by weight: starch sodium octenylsuccinate 5.0-25 parts, soybean protein isolate 1.0-5.0 parts, sodium caseinate 0.1-3.0 parts, maltodextrin 20-60 parts and thickening agents 0.2-6.5 parts; and the core materials comprise the following raw materials in parts by weight: natural mustard oil 1.0-20 parts and / or allyl isothiocyanate 1.0-20 parts, and fragrance enhancing and coordinating agents 0.4-1.5 parts. The microcapsule mustard essences have high embedding rate and good heat resistance, can improve the stability of the mustard oil, overcome the shortcomings of highly volatility and strong irritation of liquid essences used in the past, and not easily being preserved in products, and better exert the fragrance of the mustard oil; and at the same time, the wall materials of the microcapsule mustard essences are widely accessible, have low production cost, and can be widely promoted and applied.

Owner:ZENGCHENG HANDYWARE SEASONING

Preparation method and application of chemically-modified arabic gum

InactiveCN104961840AImprove emulsifying propertiesImprove embedding propertiesMicroballoon preparationMicrocapsule preparationPolymer scienceOCTENYLSUCCINIC ACID

The invention relates to a preparation method and application of chemically-modified arabic gum. The preparation method comprises the following steps: dissolving arabic gum in a 60-80-DEG C water bath to form an arabic gum solution of which the concentration is not lower than 10% (w / w) and not higher than 40% (w / w) and the pH value is 7.5-8.0, and slowly adding octenyl succinic anhydride into the arabic gum solution which is kept at 38-63 DEG C to perform esterification reaction, wherein in the reaction process, the pH value of the arabic gum solution is kept at 7.5-9.0, and the reaction is performed for 1-2.5 hours; and after the reaction finishes, regulating the pH value of the reaction solution to 6, and finally, drying to prepare the colorless odorless chemically-modified arabic gum with excellent emulsifying capacity and embedding property. The chemically-modified arabic gum is applicable to the aspects of emulsions, beverages, microcapsules, essences and the like.

Owner:NANCHANG UNIV

Water-soluble sea buckthron oil microcapsules with high oil carrying capacity and preparation method thereof

InactiveCN106343577AEasy to prepareEasy to operateFood shapingFood ingredient functionsWater dispersibleOperability

The invention provides water-soluble sea buckthron oil microcapsules with high oil carrying capacity and a preparation method thereof. The microcapsules mainly take starch sodium octenylsuccinate as a wall material. A specific process comprises the following steps: dissolving the wall material by using a suitable amount of water and performing pasteurizing; then, cooling to 50 to 60 DEG C and performing high-speed shearing; adding pretreated sea buckthron oil to prepare a macro emulsion with the soluble solid content of 40 percent or higher; performing spray-drying after high-pressure homogenizing to obtain the sea buckthron oil microcapsule powder. The oil carrying capacity of the microcapsules reaches 48 percent, and the embedding rate of the microcapsules exceeds 97 percent. The product prepared by the preparation does not use an emulsifying agent, is high in water dispersibility, simple in process flow, high in operability, high in repeatability and suitable for industrialized continuous production, and has the shelf life of 18 months.

Owner:BEIJING POWDERY FOOD

Microcapsule production technology

InactiveCN104324675APrevent volatilizationInhibitory activityCapsule deliveryMicroballoon preparationCarrageenanEmbedding rate

The invention discloses a microcapsule production technology including five steps of preparation of a wall material solution, emulsification mixing of a core material and a wall material, ultrasonic embedding, homogeneous dispersion and micro capsule spray drying. The preparation technology has the advantages of simple operation, selection of the reasonable wall materials such as octenyl succinic starch ester, seaweed gum, carrageenan and the like, easily obtained raw materials, wide scope of application, safe and reliable use, capability of well preventing the volatilization, oxidation or inactivation of instable raw materials, and effectively preventing the release of the core material, by selection of a suitable emulsifier and stirring speed, the micro capsule embedding rate is improved; microcapsule is prepared by spray drying method, and the microcapsule production technology is high in production capacity, simple in technology, and suitable for continuous industrial and automatic production.

Owner:ZHEJIANG CHUNBAO CAPSULES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com